NISSAN NAVARA 2005 Repair Workshop Manual

Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 3011 of 3171

TF-44

TROUBLE DIAGNOSIS

CAUTION:

When using a circuit tester to measure voltage for inspection, be sure not to extend forcibly any connector terminals.

CONSULT-II Function (ALL MODE AWD/4WD)EDS0031W

FUNCTION

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

CONSULT-II SETTING PROCEDURE

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

NOTE:

For details, refer to the separate “CONSULT-II Operations Manual”.

1. Turn ignition switch “OFF”.

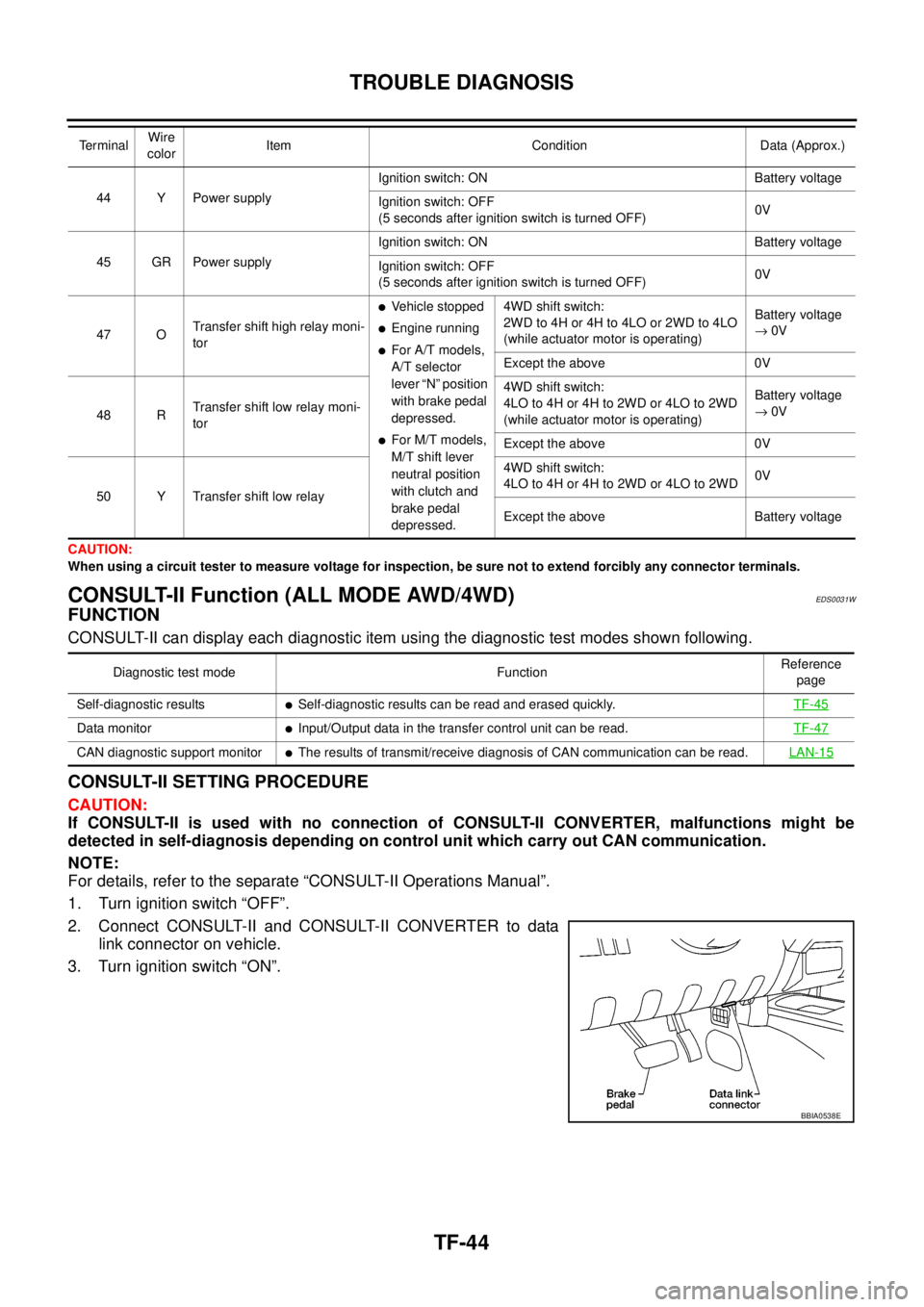

2. Connect CONSULT-II and CONSULT-II CONVERTER to data

link connector on vehicle.

3. Turn ignition switch “ON”.

44 Y Power supplyIgnition switch: ON Battery voltage

Ignition switch: OFF

(5 seconds after ignition switch is turned OFF)0V

45 GR Power supplyIgnition switch: ON Battery voltage

Ignition switch: OFF

(5 seconds after ignition switch is turned OFF)0V

47 OTransfer shift high relay moni-

tor

lVehicle stopped

lEngine running

lFor A/T models,

A/T selector

lever “N” position

with brake pedal

depressed.

lFor M/T models,

M/T shift lever

neutral position

with clutch and

brake pedal

depressed.4WD shift switch:

2WD to 4H or 4H to 4LO or 2WD to 4LO

(while actuator motor is operating)Battery voltage

®0V

Except the above 0V

48 RTransfer shift low relay moni-

tor4WD shift switch:

4LO to 4H or 4H to 2WD or 4LO to 2WD

(while actuator motor is operating)Battery voltage

®0V

Except the above 0V

50 Y Transfer shift low relay4WD shift switch:

4LO to 4H or 4H to 2WD or 4LO to 2WD0V

Except the above Battery voltage Te r m i n a lWire

colorItem Condition Data (Approx.)

Diagnostic test mode FunctionReference

page

Self-diagnostic results

lSelf-diagnostic results can be read and erased quickly.TF-45

Data monitorlInput/Output data in the transfer control unit can be read.TF-47

CAN diagnostic support monitorlThe results of transmit/receive diagnosis of CAN communication can be read.LAN-15

BBIA0538E

Page 3012 of 3171

TROUBLE DIAGNOSIS

TF-45

C

E

F

G

H

I

J

K

L

MA

B

TF

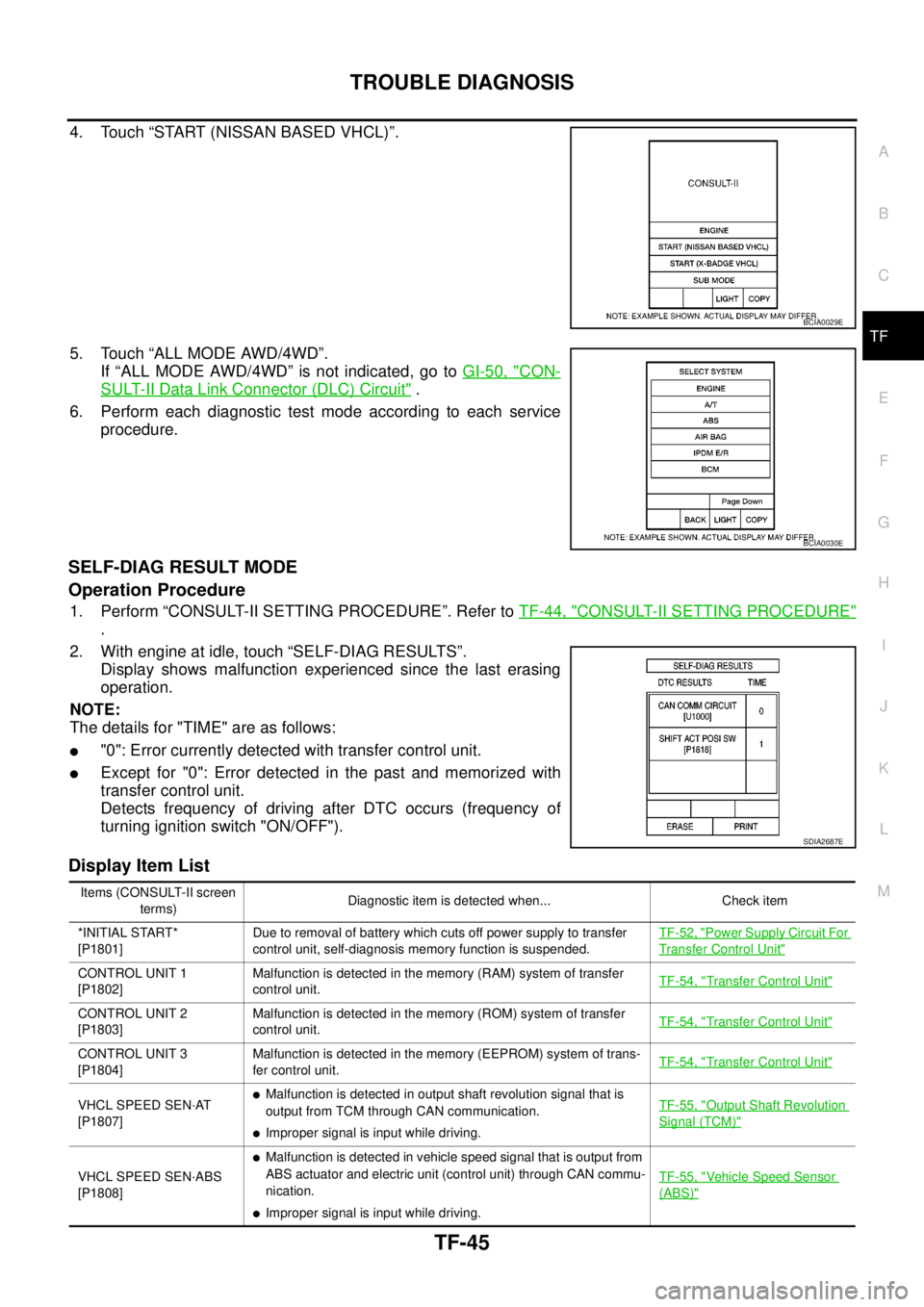

4. Touch “START (NISSAN BASED VHCL)”.

5. Touch “ALL MODE AWD/4WD”.

If “ALL MODE AWD/4WD” is not indicated, go toGI-50, "

CON-

SULT-II Data Link Connector (DLC) Circuit".

6. Perform each diagnostic test mode according to each service

procedure.

SELF-DIAG RESULT MODE

Operation Procedure

1. Perform “CONSULT-II SETTING PROCEDURE”. Refer toTF-44, "CONSULT-II SETTING PROCEDURE"

.

2. With engine at idle, touch “SELF-DIAG RESULTS”.

Display shows malfunction experienced since the last erasing

operation.

NOTE:

The details for "TIME" are as follows:

l"0": Error currently detected with transfer control unit.

lExcept for "0": Error detected in the past and memorized with

transfer control unit.

Detects frequency of driving after DTC occurs (frequency of

turning ignition switch "ON/OFF").

Display Item List

BCIA0029E

BCIA0030E

SDIA2687E

Items (CONSULT-II screen

terms)Diagnostic item is detected when... Check item

*INITIAL START*

[P1801]Due to removal of battery which cuts off power supply to transfer

control unit, self-diagnosis memory function is suspended.TF-52, "

Power Supply Circuit For

Transfer Control Unit"

CONTROL UNIT 1

[P1802]Malfunction is detected in the memory (RAM) system of transfer

control unit.TF-54, "Transfer Control Unit"

CONTROL UNIT 2

[P1803]Malfunction is detected in the memory (ROM) system of transfer

control unit.TF-54, "Transfer Control Unit"

CONTROL UNIT 3

[P1804]Malfunction is detected in the memory (EEPROM) system of trans-

fer control unit.TF-54, "Transfer Control Unit"

VHCL SPEED SEN·AT

[P1807]lMalfunction is detected in output shaft revolution signal that is

output from TCM through CAN communication.

lImproper signal is input while driving.TF-55, "

Output Shaft Revolution

Signal (TCM)"

VHCL SPEED SEN·ABS

[P1808]

lMalfunction is detected in vehicle speed signal that is output from

ABS actuator and electric unit (control unit) through CAN commu-

nication.

lImproper signal is input while driving.TF-55, "

Vehicle Speed Sensor

(ABS)"

Page 3013 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual TF-46

TROUBLE DIAGNOSIS

CAUTION:

If “CAN COMM CIRCUIT [U1000]” is displayed with other DTCs, first perform the trouble diagnosis for CAN communication

line.

NOTE:

If “SHIFT ACT POSI SW [P1818]� NISSAN NAVARA 2005 Repair Workshop Manual TF-46

TROUBLE DIAGNOSIS

CAUTION:

If “CAN COMM CIRCUIT [U1000]” is displayed with other DTCs, first perform the trouble diagnosis for CAN communication

line.

NOTE:

If “SHIFT ACT POSI SW [P1818]�](/img/5/57362/w960_57362-3012.png)

TF-46

TROUBLE DIAGNOSIS

CAUTION:

If “CAN COMM CIRCUIT [U1000]” is displayed with other DTCs, first perform the trouble diagnosis for CAN communication

line.

NOTE:

If “SHIFT ACT POSI SW [P1818]” or “SHIFT ACT CIR [P1819]” is displayed, first erase self-diagnostic results. (“SHIFT ACT POSI SW

[P1818]” or “SHIFT ACT CIR [P1819]” may be displayed after installing transfer control unit or transfer assembly.)

How to Erase Self-diagnostic Results

1. Perform applicable inspection of malfunctioning item and then repair or replace.

2. Start engine and select “SELF-DIAG RESULTS” mode for “ALL MODE AWD/4WD” with CONSULT-II.

3. Touch “ERASE” on CONSULT-II screen to erase DTC memory.

CAUTION:

If memory cannot be erased, perform applicable diagnosis.

CONTROL UNIT 4

[P1809]AD converter system of transfer control unit is malfunctioning.TF-54, "Transfer Control Unit"

4L POSI SW TF

[P1810]Improper signal from 4LO switch is input due to open or short circuit.TF-56, "4LO Switch"

BATTERY VOLTAGE

[P1811]Power supply voltage for transfer control unit is abnormally low

while driving.TF-52, "Power Supply Circuit For

Transfer Control Unit"

4WD MODE SW

[P1813]More than two switch inputs are simultaneously detected due to

short circuit of 4WD shift switch.TF-59, "4WD Shift Switch"

4WD DETECT SWITCH

[P1814]Improper signal from wait detection switch is input due to open or

short circuit.TF-63, "Wait Detection Switch"

PNP SW/CIRC

[P1816]When A/T PNP switch signal is malfunction or communication error

between the vehicles.TF-66, "PNP Switch Signal

(TCM)"

SHIFT ACTUATOR

[P1817]

lMotor does not operate properly due to open or short circuit in

actuator motor.

lMalfunction is detected in the actuator motor. (When 4WD shift

switch is operated and actuator motor is not operated)

lMalfunction is detected in transfer shift high relay and transfer

shift low relay.TF-67, "

Actuator Motor"

SHIFT ACT POSI SW

[P1818]lImproper signal from actuator position switch is input due to open

or short circuit.

lMalfunction is detected in actuator position switch.TF-75, "

Actuator Position

Switch"

SHIFT ACT CIR

[P1819]lMalfunction is detected in transfer shut off relay 1 and transfer

shut off relay 2.

lMalfunction occurs in transfer control device drive circuit.TF-52, "

Power Supply Circuit For

Transfer Control Unit",TF-78,

"Transfer Control Device"

ENGINE SPEED SIG

[P1820]lMalfunction is detected in engine speed signal that is output from

ECM through CAN communication.

lImproper signal is input while driving.TF-81, "

Engine Speed Signal

(ECM)"

CAN COMM CIRCUIT

[U1000]Malfunction has been detected from CAN communication line.TF-82, "CAN Communication

Line"

NO DTC IS DETECTED.

FURTHER TESTING MAY

BE REQUIRED.No NG item has been detected. — Items (CONSULT-II screen

terms)Diagnostic item is detected when... Check item

Page 3014 of 3171

TROUBLE DIAGNOSIS

TF-47

C

E

F

G

H

I

J

K

L

MA

B

TF

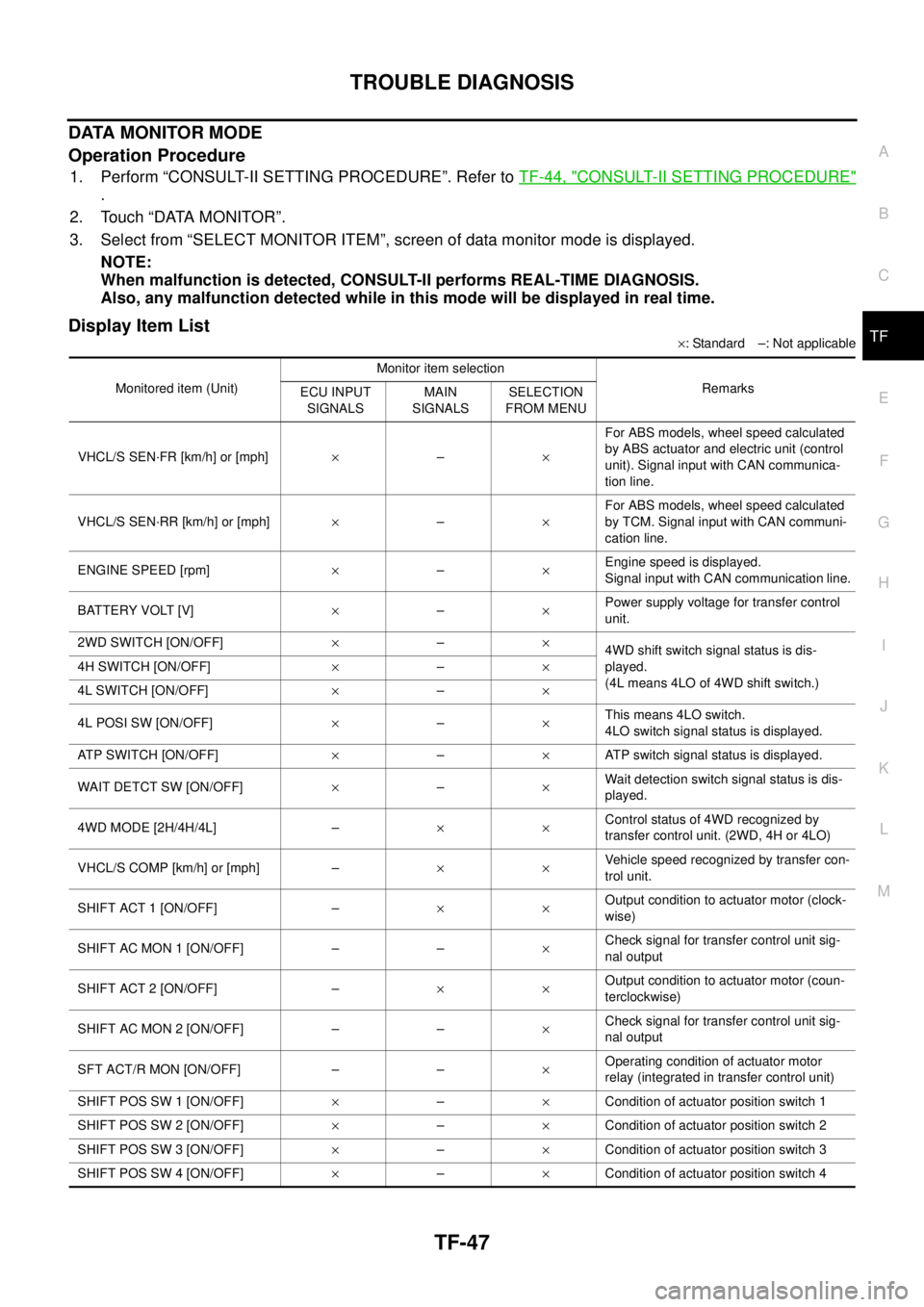

DATA MONITOR MODE

Operation Procedure

1. Perform “CONSULT-II SETTING PROCEDURE”. Refer toTF-44, "CONSULT-II SETTING PROCEDURE"

.

2. Touch “DATA MONITOR”.

3. Select from “SELECT MONITOR ITEM”, screen of data monitor mode is displayed.

NOTE:

When malfunction is detected, CONSULT-II performs REAL-TIME DIAGNOSIS.

Also, any malfunction detected while in this mode will be displayed in real time.

Display Item List

´: Standard –: Not applicable

Monitored item (Unit)Monitor item selection

Remarks

ECU INPUT

SIGNALSMAIN

SIGNALSSELECTION

FROM MENU

VHCL/S SEN·FR [km/h] or [mph]´–´For ABS models, wheel speed calculated

by ABS actuator and electric unit (control

unit). Signal input with CAN communica-

tion line.

VHCL/S SEN·RR [km/h] or [mph]´–´For ABS models, wheel speed calculated

by TCM. Signal input with CAN communi-

cation line.

ENGINE SPEED [rpm]´–´Engine speed is displayed.

Signal input with CAN communication line.

BATTERY VOLT [V]´–´Power supply voltage for transfer control

unit.

2WD SWITCH [ON/OFF]´–´

4WD shift switch signal status is dis-

played.

(4L means 4LO of 4WD shift switch.) 4H SWITCH [ON/OFF]´–´

4L SWITCH [ON/OFF]´–´

4L POSI SW [ON/OFF]´–´This means 4LO switch.

4LO switch signal status is displayed.

ATP SWITCH [ON/OFF]´–´ATP switch signal status is displayed.

WAIT DETCT SW [ON/OFF]´–´Wait detection switch signal status is dis-

played.

4WD MODE [2H/4H/4L] –´´Control status of 4WD recognized by

transfer control unit. (2WD, 4H or 4LO)

VHCL/S COMP [km/h] or [mph] –´´Vehicle speed recognized by transfer con-

trol unit.

SHIFT ACT 1 [ON/OFF] –´´Output condition to actuator motor (clock-

wise)

SHIFT AC MON 1 [ON/OFF] – –´Check signal for transfer control unit sig-

nal output

SHIFT ACT 2 [ON/OFF] –´´Output condition to actuator motor (coun-

terclockwise)

SHIFT AC MON 2 [ON/OFF] – –´Check signal for transfer control unit sig-

nal output

SFT ACT/R MON [ON/OFF] – –´Operating condition of actuator motor

relay (integrated in transfer control unit)

SHIFT POS SW 1 [ON/OFF]´–´Condition of actuator position switch 1

SHIFT POS SW 2 [ON/OFF]´–´Condition of actuator position switch 2

SHIFT POS SW 3 [ON/OFF]´–´Condition of actuator position switch 3

SHIFT POS SW 4 [ON/OFF]´–´Condition of actuator position switch 4

Page 3015 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual TF-48

TROUBLE DIAGNOSIS

4WD FAIL LAMP [ON/OFF] –´´Control status of 4WD warning lamp is dis-

played.

2WD IND [ON/OFF] – –´Control status of 4WD shift indicator lamp

(rear) is displayed.

4H IN NISSAN NAVARA 2005 Repair Workshop Manual TF-48

TROUBLE DIAGNOSIS

4WD FAIL LAMP [ON/OFF] –´´Control status of 4WD warning lamp is dis-

played.

2WD IND [ON/OFF] – –´Control status of 4WD shift indicator lamp

(rear) is displayed.

4H IN](/img/5/57362/w960_57362-3014.png)

TF-48

TROUBLE DIAGNOSIS

4WD FAIL LAMP [ON/OFF] –´´Control status of 4WD warning lamp is dis-

played.

2WD IND [ON/OFF] – –´Control status of 4WD shift indicator lamp

(rear) is displayed.

4H IND [ON/OFF] – –´Control status of 4WD shift indicator lamp

(front and center) is displayed.

4L IND [ON/OFF] – –´Control status of 4LO indicator lamp is dis-

played.

Vo l ta g e [V ] – –´The value measured by the voltage probe

is displayed.

Frequency [Hz] – –´

The value measured by the pulse probe is

displayed. DUTY-HI (high) [%] – –´

DUTY-LOW (low) [%] – –´

PLS WIDTH-HI [msec] – –´

PLS WIDTH-LOW [msec] – –´ Monitored item (Unit)Monitor item selection

Remarks

ECU INPUT

SIGNALSMAIN

SIGNALSSELECTION

FROM MENU

Page 3016 of 3171

TROUBLE DIAGNOSIS

TF-49

C

E

F

G

H

I

J

K

L

MA

B

TF

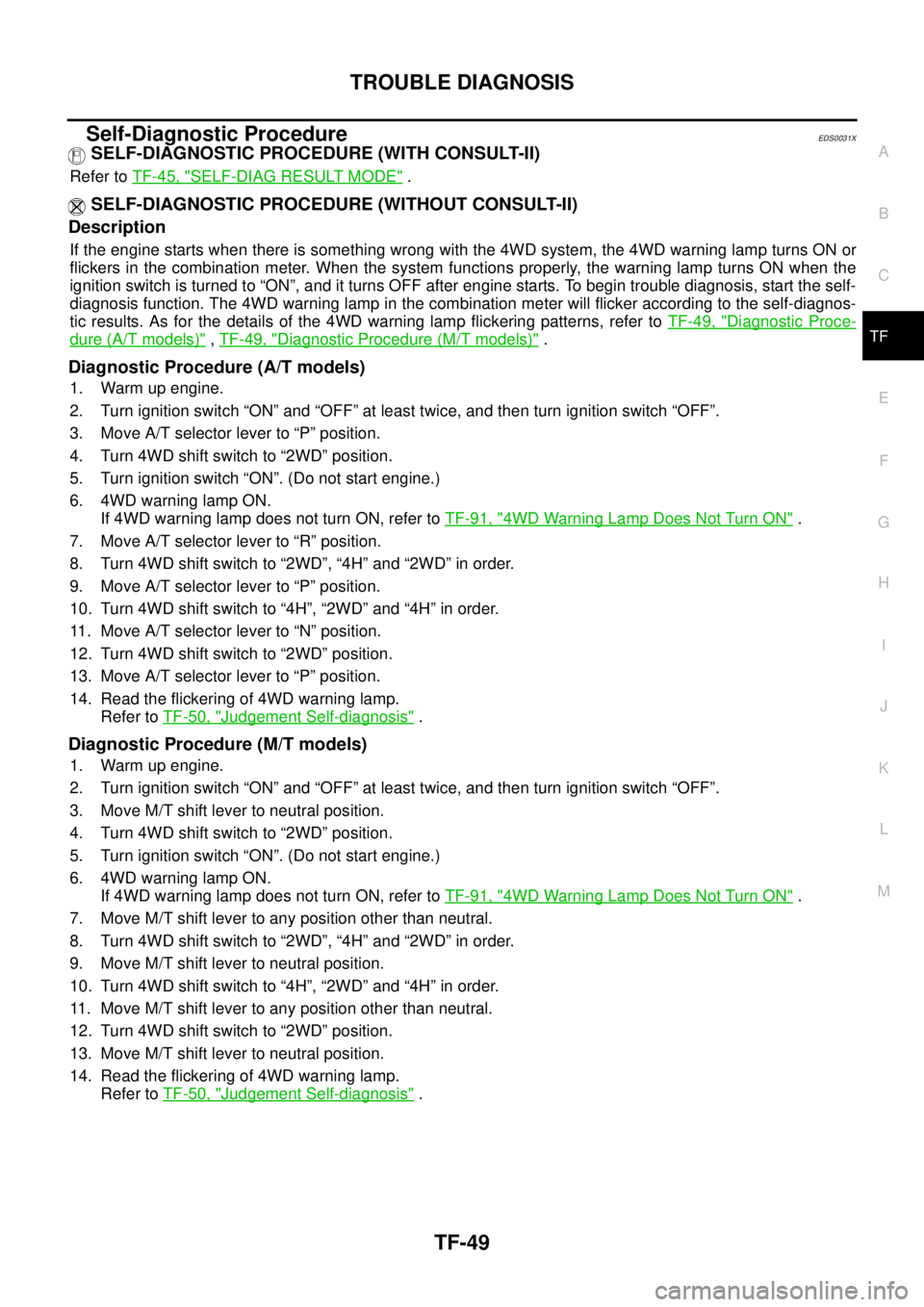

Self-Diagnostic ProcedureEDS0031X

SELF-DIAGNOSTIC PROCEDURE (WITH CONSULT-II)

Refer toTF-45, "SELF-DIAG RESULT MODE".

SELF-DIAGNOSTIC PROCEDURE (WITHOUT CONSULT-II)

Description

If the engine starts when there is something wrong with the 4WD system, the 4WD warning lamp turns ON or

flickers in the combination meter. When the system functions properly, the warning lamp turns ON when the

ignition switch is turned to “ON”, and it turns OFF after engine starts. To begin trouble diagnosis, start the self-

diagnosis function. The 4WD warning lamp in the combination meter will flicker according to the self-diagnos-

tic results. As for the details of the 4WD warning lamp flickering patterns, refer toTF-49, "

Diagnostic Proce-

dure (A/T models)",TF-49, "Diagnostic Procedure (M/T models)".

Diagnostic Procedure (A/T models)

1. Warm up engine.

2. Turn ignition switch “ON” and “OFF” at least twice, and then turn ignition switch “OFF”.

3. Move A/T selector lever to “P” position.

4. Turn 4WD shift switch to “2WD” position.

5. Turn ignition switch “ON”. (Do not start engine.)

6. 4WD warning lamp ON.

If 4WD warning lamp does not turn ON, refer toTF-91, "

4WD Warning Lamp Does Not Turn ON".

7. Move A/T selector lever to “R” position.

8. Turn 4WD shift switch to “2WD”, “4H” and “2WD” in order.

9. Move A/T selector lever to “P” position.

10. Turn 4WD shift switch to “4H”, “2WD” and “4H” in order.

11. Move A/T selector lever to “N” position.

12. Turn 4WD shift switch to “2WD” position.

13. Move A/T selector lever to “P” position.

14. Read the flickering of 4WD warning lamp.

Refer toTF-50, "

Judgement Self-diagnosis".

Diagnostic Procedure (M/T models)

1. Warm up engine.

2. Turn ignition switch “ON” and “OFF” at least twice, and then turn ignition switch “OFF”.

3. Move M/T shift lever to neutral position.

4. Turn 4WD shift switch to “2WD” position.

5. Turn ignition switch “ON”. (Do not start engine.)

6. 4WD warning lamp ON.

If 4WD warning lamp does not turn ON, refer toTF-91, "

4WD Warning Lamp Does Not Turn ON".

7. Move M/T shift lever to any position other than neutral.

8. Turn 4WD shift switch to “2WD”, “4H” and “2WD” in order.

9. Move M/T shift lever to neutral position.

10. Turn 4WD shift switch to “4H”, “2WD” and “4H” in order.

11. Move M/T shift lever to any position other than neutral.

12. Turn 4WD shift switch to “2WD” position.

13. Move M/T shift lever to neutral position.

14. Read the flickering of 4WD warning lamp.

Refer toTF-50, "

Judgement Self-diagnosis".

Page 3017 of 3171

TF-50

TROUBLE DIAGNOSIS

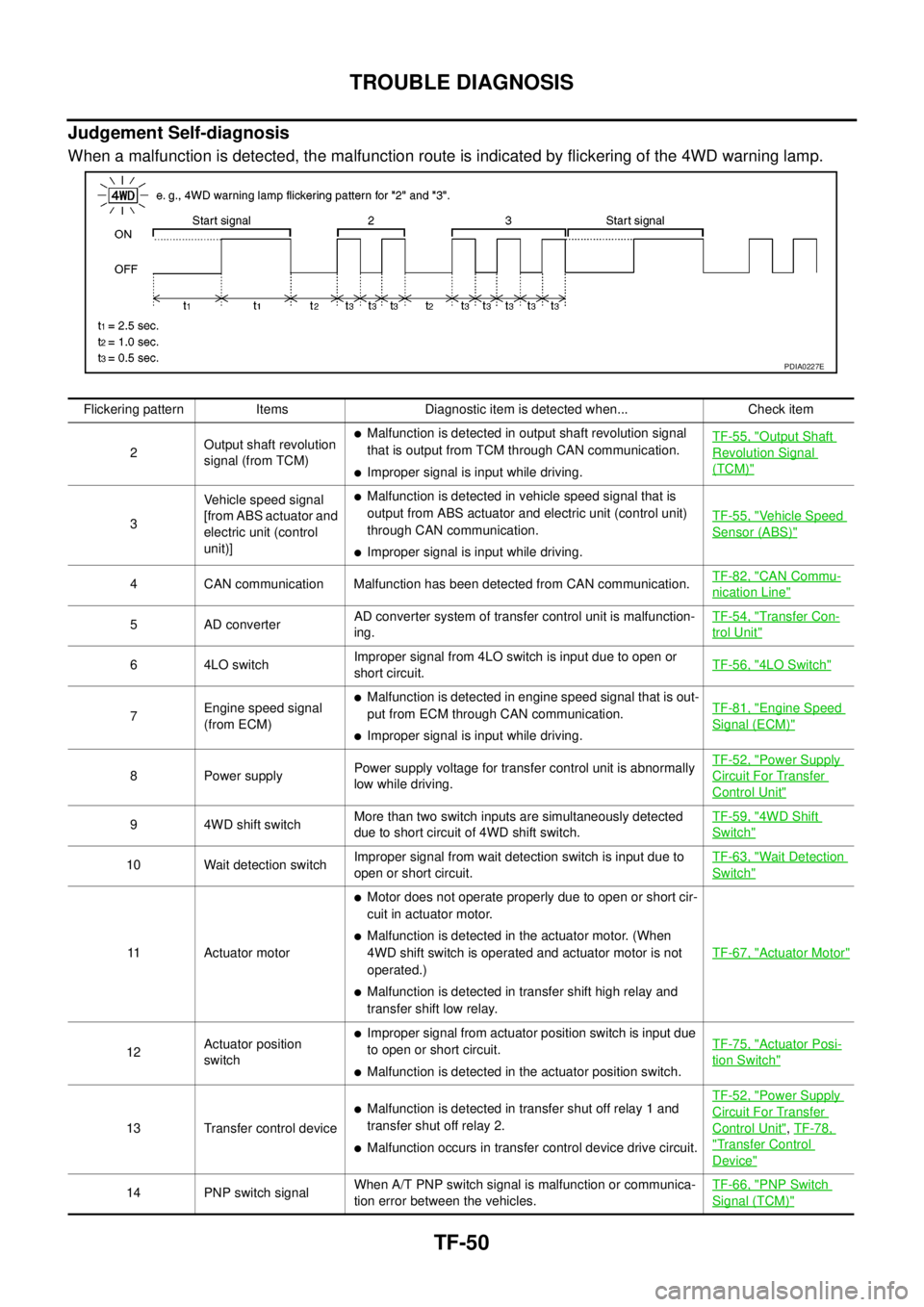

Judgement Self-diagnosis

When a malfunction is detected, the malfunction route is indicated by flickering of the 4WD warning lamp.

PDIA0227E

Flickering pattern Items Diagnostic item is detected when... Check item

2Output shaft revolution

signal (from TCM)

lMalfunction is detected in output shaft revolution signal

that is output from TCM through CAN communication.

lImproper signal is input while driving.TF-55, "

Output Shaft

Revolution Signal

(TCM)"

3Vehicle speed signal

[from ABS actuator and

electric unit (control

unit)]

lMalfunction is detected in vehicle speed signal that is

output from ABS actuator and electric unit (control unit)

through CAN communication.

lImproper signal is input while driving.TF-55, "

Vehicle Speed

Sensor (ABS)"

4 CAN communication Malfunction has been detected from CAN communication.TF-82, "CAN Commu-

nication Line"

5 AD converterAD converter system of transfer control unit is malfunction-

ing.TF-54, "Transfer Con-

trol Unit"

6 4LO switchImproper signal from 4LO switch is input due to open or

short circuit.TF-56, "4LO Switch"

7Engine speed signal

(from ECM)

lMalfunction is detected in engine speed signal that is out-

put from ECM through CAN communication.

lImproper signal is input while driving.TF-81, "

Engine Speed

Signal (ECM)"

8 Power supplyPower supply voltage for transfer control unit is abnormally

low while driving.TF-52, "

Power Supply

Circuit For Transfer

Control Unit"

9 4WD shift switchMore than two switch inputs are simultaneously detected

due to short circuit of 4WD shift switch.TF-59, "4WD Shift

Switch"

10 Wait detection switchImproper signal from wait detection switch is input due to

open or short circuit.TF-63, "Wait Detection

Switch"

11 Actuator motor

lMotor does not operate properly due to open or short cir-

cuit in actuator motor.

lMalfunction is detected in the actuator motor. (When

4WD shift switch is operated and actuator motor is not

operated.)

lMalfunction is detected in transfer shift high relay and

transfer shift low relay.TF-67, "

Actuator Motor"

12Actuator position

switch

lImproper signal from actuator position switch is input due

to open or short circuit.

lMalfunction is detected in the actuator position switch.TF-75, "

Actuator Posi-

tion Switch"

13 Transfer control device

lMalfunction is detected in transfer shut off relay 1 and

transfer shut off relay 2.

lMalfunction occurs in transfer control device drive circuit.TF-52, "

Power Supply

Circuit For Transfer

Control Unit",TF-78,

"Transfer Control

Device"

14 PNP switch signalWhen A/T PNP switch signal is malfunction or communica-

tion error between the vehicles.TF-66, "PNP Switch

Signal (TCM)"

Page 3018 of 3171

TROUBLE DIAGNOSIS

TF-51

C

E

F

G

H

I

J

K

L

MA

B

TFNOTE:

If flickering pattern 12 or 13 is displayed, first erase self-diagnostic results. Flickering pattern 12 or 13 may be displayed after installing

transfer control unit or transfer assembly.

ERASE SELF-DIAGNOSIS

lIn order to make it easier to find the cause of hard-to-duplicate malfunctions, malfunction information is

stored into the control unit as necessary during use by the user. This memory is not erased no matter how

many times the ignition switch is turned ON and OFF.

lHowever, this information is erased by turning ignition switch “OFF” after performing self-diagnostics or by

erasing the memory using the CONSULT-II.

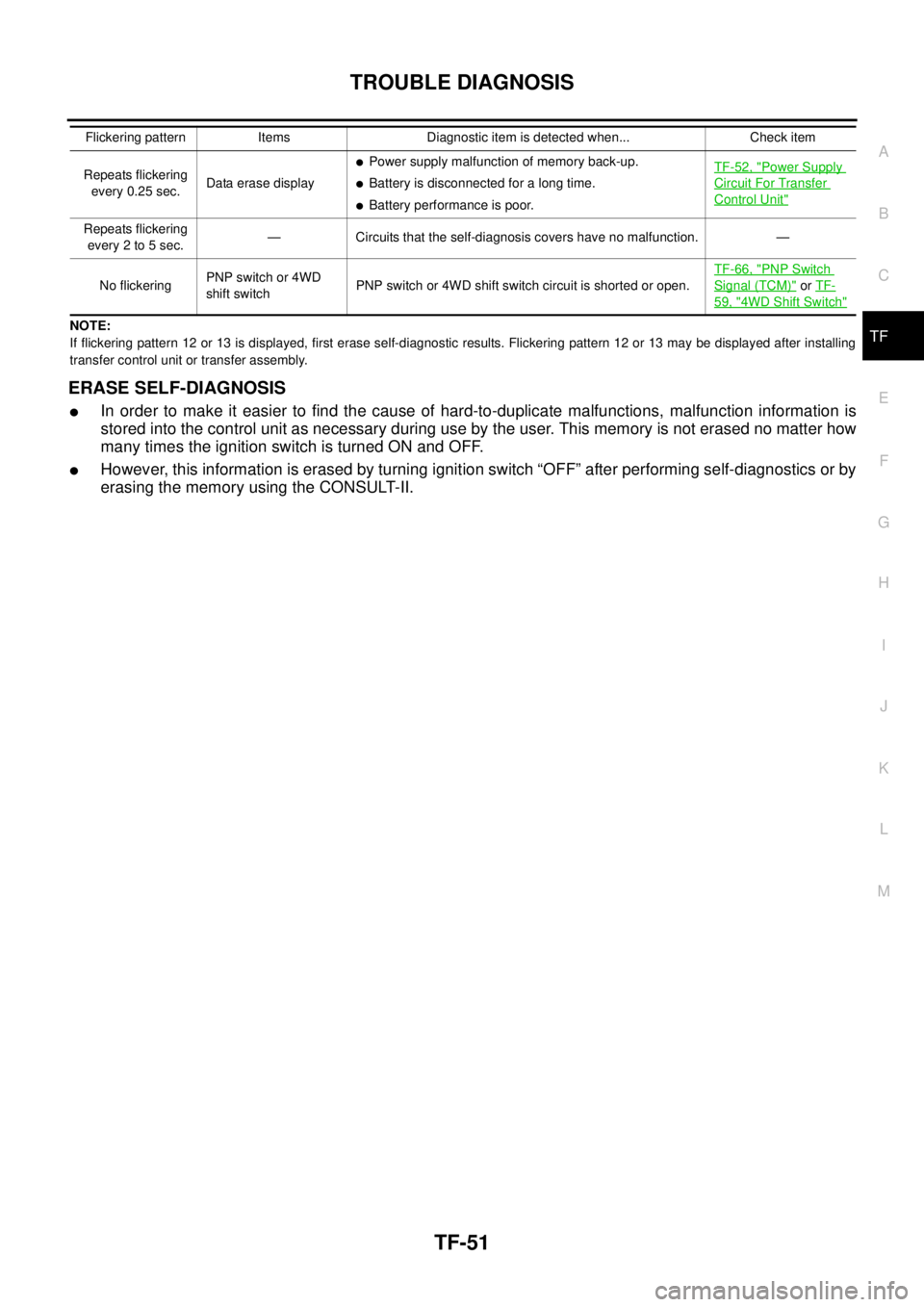

Repeats flickering

every 0.25 sec.Data erase displaylPower supply malfunction of memory back-up.

lBattery is disconnected for a long time.

lBattery performance is poor.TF-52, "

Power Supply

Circuit For Transfer

Control Unit"

Repeats flickering

every 2 to 5 sec.— Circuits that the self-diagnosis covers have no malfunction. —

No flickeringPNP switch or 4WD

shift switchPNP switch or 4WD shift switch circuit is shorted or open.TF-66, "

PNP Switch

Signal (TCM)"orTF-

59, "4WD Shift Switch"

Flickering pattern Items Diagnostic item is detected when... Check item

Page 3019 of 3171

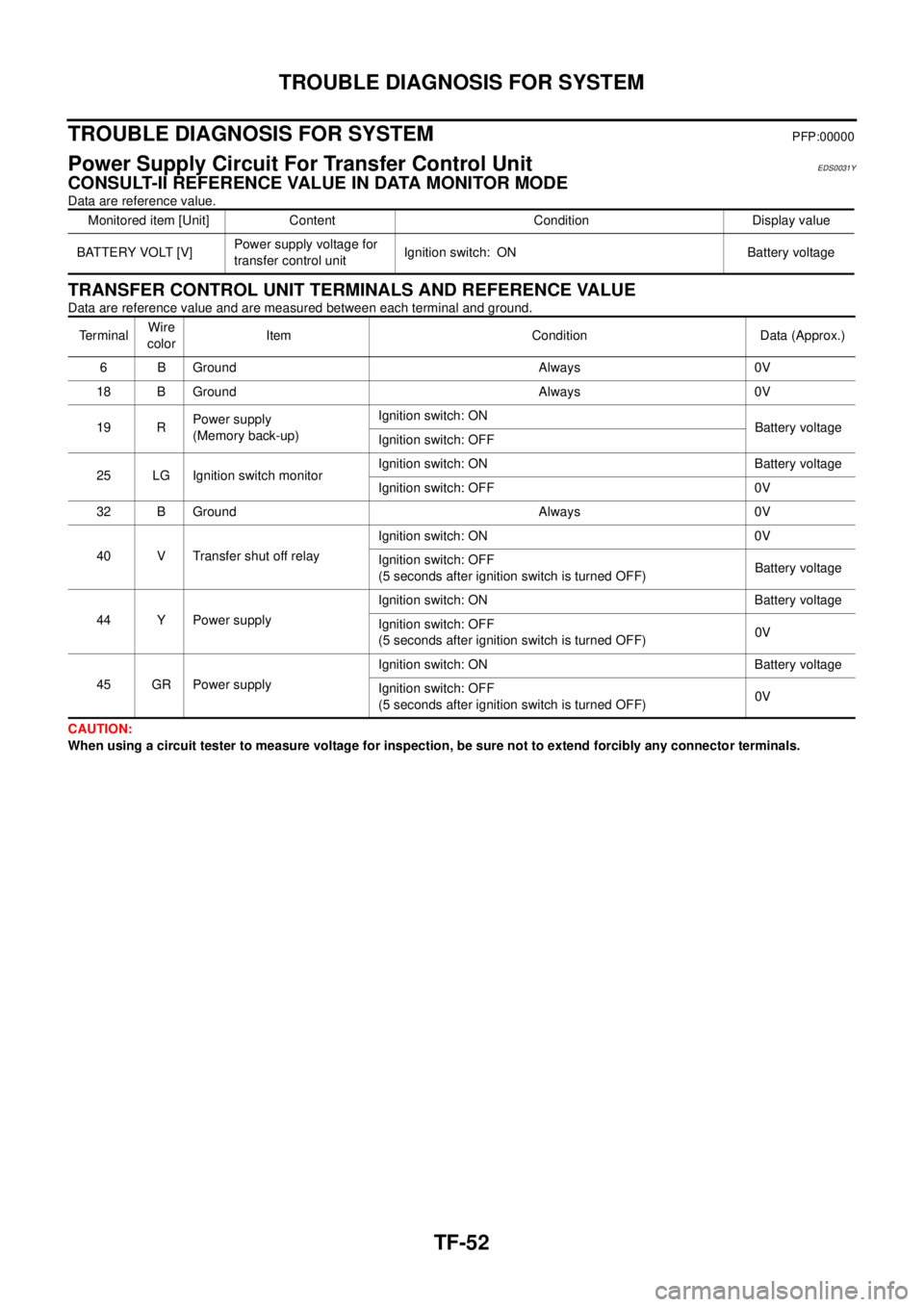

TF-52

TROUBLE DIAGNOSIS FOR SYSTEM

TROUBLE DIAGNOSIS FOR SYSTEM

PFP:00000

Power Supply Circuit For Transfer Control UnitEDS0031Y

CONSULT-II REFERENCE VALUE IN DATA MONITOR MODE

Data are reference value.

TRANSFER CONTROL UNIT TERMINALS AND REFERENCE VALUE

Data are reference value and are measured between each terminal and ground.

CAUTION:

When using a circuit tester to measure voltage for inspection, be sure not to extend forcibly any connector terminals.Monitored item [Unit] Content Condition Display value

BATTERY VOLT [V]Power supply voltage for

transfer control unitIgnition switch: ON Battery voltage

Te r m i n a lWire

colorItem Condition Data (Approx.)

6 B Ground Always 0V

18 B Ground Always 0V

19 RPower supply

(Memory back-up)Ignition switch: ON

Battery voltage

Ignition switch: OFF

25 LG Ignition switch monitorIgnition switch: ON Battery voltage

Ignition switch: OFF 0V

32 B Ground Always 0V

40 V Transfer shut off relayIgnition switch: ON 0V

Ignition switch: OFF

(5 seconds after ignition switch is turned OFF)Battery voltage

44 Y Power supplyIgnition switch: ON Battery voltage

Ignition switch: OFF

(5 seconds after ignition switch is turned OFF)0V

45 GR Power supplyIgnition switch: ON Battery voltage

Ignition switch: OFF

(5 seconds after ignition switch is turned OFF)0V

Page 3020 of 3171

TROUBLE DIAGNOSIS FOR SYSTEM

TF-53

C

E

F

G

H

I

J

K

L

MA

B

TF

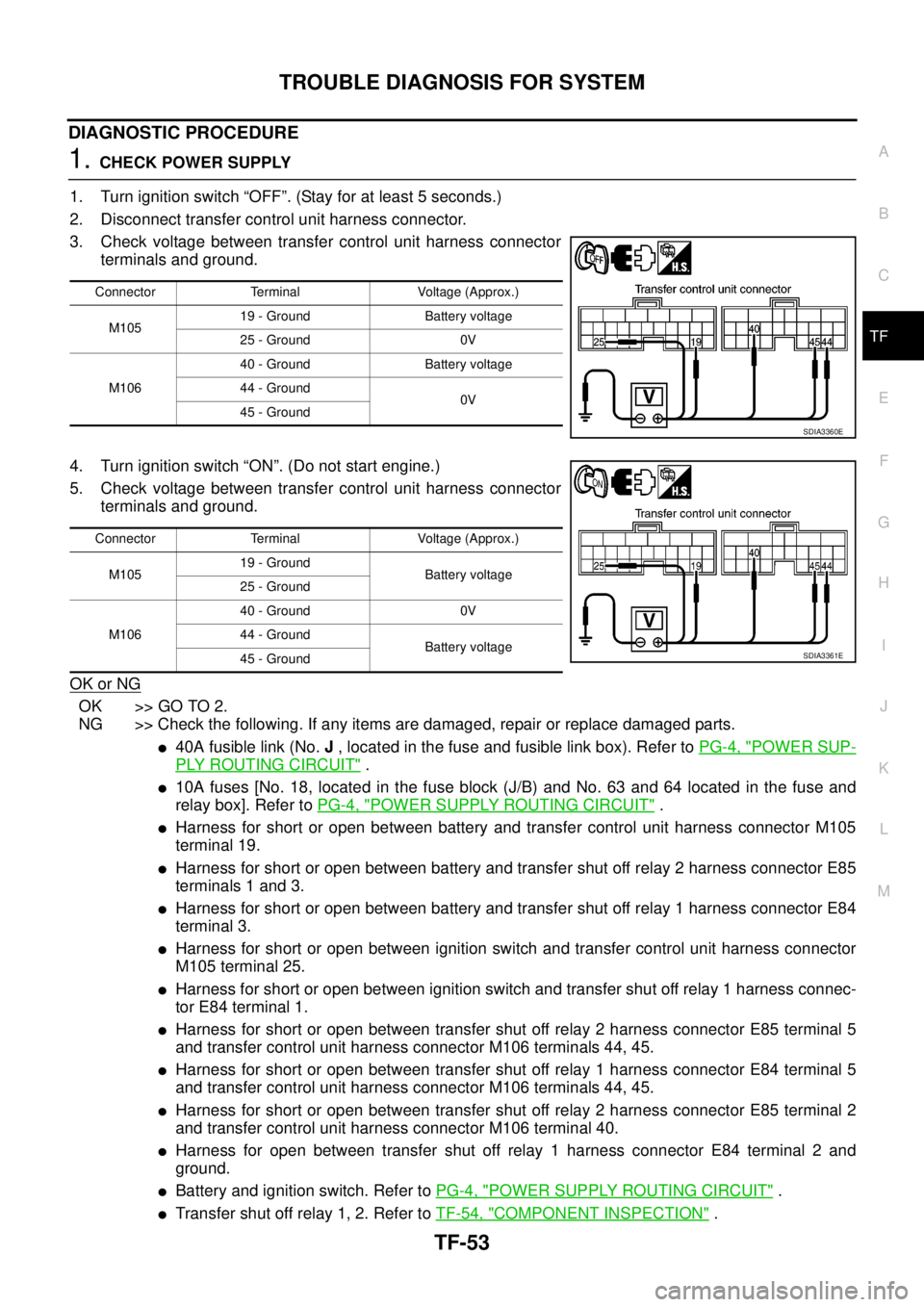

DIAGNOSTIC PROCEDURE

1.CHECK POWER SUPPLY

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Disconnect transfer control unit harness connector.

3. Check voltage between transfer control unit harness connector

terminals and ground.

4. Turn ignition switch “ON”. (Do not start engine.)

5. Check voltage between transfer control unit harness connector

terminals and ground.

OK or NG

OK >> GO TO 2.

NG >> Check the following. If any items are damaged, repair or replace damaged parts.

l40A fusible link (No.J, located in the fuse and fusible link box). Refer toPG-4, "POWER SUP-

PLY ROUTING CIRCUIT".

l10A fuses [No. 18, located in the fuse block (J/B) and No. 63 and 64 located in the fuse and

relay box]. Refer toPG-4, "

POWER SUPPLY ROUTING CIRCUIT".

lHarness for short or open between battery and transfer control unit harness connector M105

terminal 19.

lHarness for short or open between battery and transfer shut off relay 2 harness connector E85

terminals 1 and 3.

lHarness for short or open between battery and transfer shut off relay 1 harness connector E84

terminal 3.

lHarness for short or open between ignition switch and transfer control unit harness connector

M105 terminal 25.

lHarness for short or open between ignition switch and transfer shut off relay 1 harness connec-

tor E84 terminal 1.

lHarness for short or open between transfer shut off relay 2 harness connector E85 terminal 5

and transfer control unit harness connector M106 terminals 44, 45.

lHarness for short or open between transfer shut off relay 1 harness connector E84 terminal 5

and transfer control unit harness connector M106 terminals 44, 45.

lHarness for short or open between transfer shut off relay 2 harness connector E85 terminal 2

and transfer control unit harness connector M106 terminal 40.

lHarness for open between transfer shut off relay 1 harness connector E84 terminal 2 and

ground.

lBattery and ignition switch. Refer toPG-4, "POWER SUPPLY ROUTING CIRCUIT".

lTransfer shut off relay 1, 2. Refer toTF-54, "COMPONENT INSPECTION".

Connector Terminal Voltage (Approx.)

M10519 - Ground Battery voltage

25 - Ground 0V

M10640 - Ground Battery voltage

44 - Ground

0V

45 - Ground

SDIA3360E

Connector Terminal Voltage (Approx.)

M10519 - Ground

Battery voltage

25 - Ground

M10640 - Ground 0V

44 - Ground

Battery voltage

45 - Ground

SDIA3361E