4WD NISSAN NAVARA 2005 Repair Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 186 of 3171

AT-178

TROUBLE DIAGNOSIS FOR SYMPTOMS

2.CHECK CONTROL CABLE

Check control cable. Refer toAT- 2 11 , "

Checking of A/T Position".

OK or NG

OK >> GO TO 3.

NG >> Adjust control cable. Refer toAT- 2 11 , "

Adjustment of A/T Position".

3.CHECK STARTING SYSTEM

Check starting system. Refer toSC-27, "

STARTING SYSTEM".

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

In “P” Position, Vehicle Moves When PushedECS00G2D

SYMPTOM:

Even though selector lever is set in the “P” position, the parking mechanism is not actuated, allowing

the vehicle to be moved when it is pushed.

DIAGNOSTIC PROCEDURE

1.CHECK PNP SWITCH CIRCUIT

Perform self-diagnosis. Refer toAT-80, "

SELF-DIAGNOSTIC RESULT MODE",AT-89, "Diagnostic Procedure

Without CONSULT-II".

Do the self-diagnosis results indicate PNP switch?

YES >> Check malfunctioning system. Refer toAT-99, "DTC P0705 PARK/NEUTRAL POSITION

SWITCH".

NO >> GO TO 2.

2.CHECK CONTROL CABLE

Check control cable. Refer toAT- 2 11 , "

Checking of A/T Position".

OK or NG

OK >> GO TO 3.

NG >> Adjust control cable. Refer toAT- 2 11 , "

Adjustment of A/T Position".

3.CHECK PARKING COMPONENTS

Check parking components. Refer toAT- 2 3 0 , "

Parking Components (2WD Models Only)"(2WD models),AT-

263, "DISASSEMBLY"(4WD models).

OK or NG

OK >> GO TO 4.

NG >> Repair or replace damaged parts.

4.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer toAT- 2 1 8 , "

Control Valve With TCM and A/T Fluid Temperature Sensor 2".

2. Check A/T fluid condition. Refer toAT-43, "

A/T Fluid Condition Check".

OK or NG

OK >>INSPECTION END

NG >> Check malfunction items. If any items are damaged, repair or replace damaged parts. Refer toAT-

53, "Symptom Chart"(Symptom No.58)

Page 245 of 3171

ON-VEHICLE SERVICE

AT-237

D

E

F

G

H

I

J

K

L

MA

B

AT

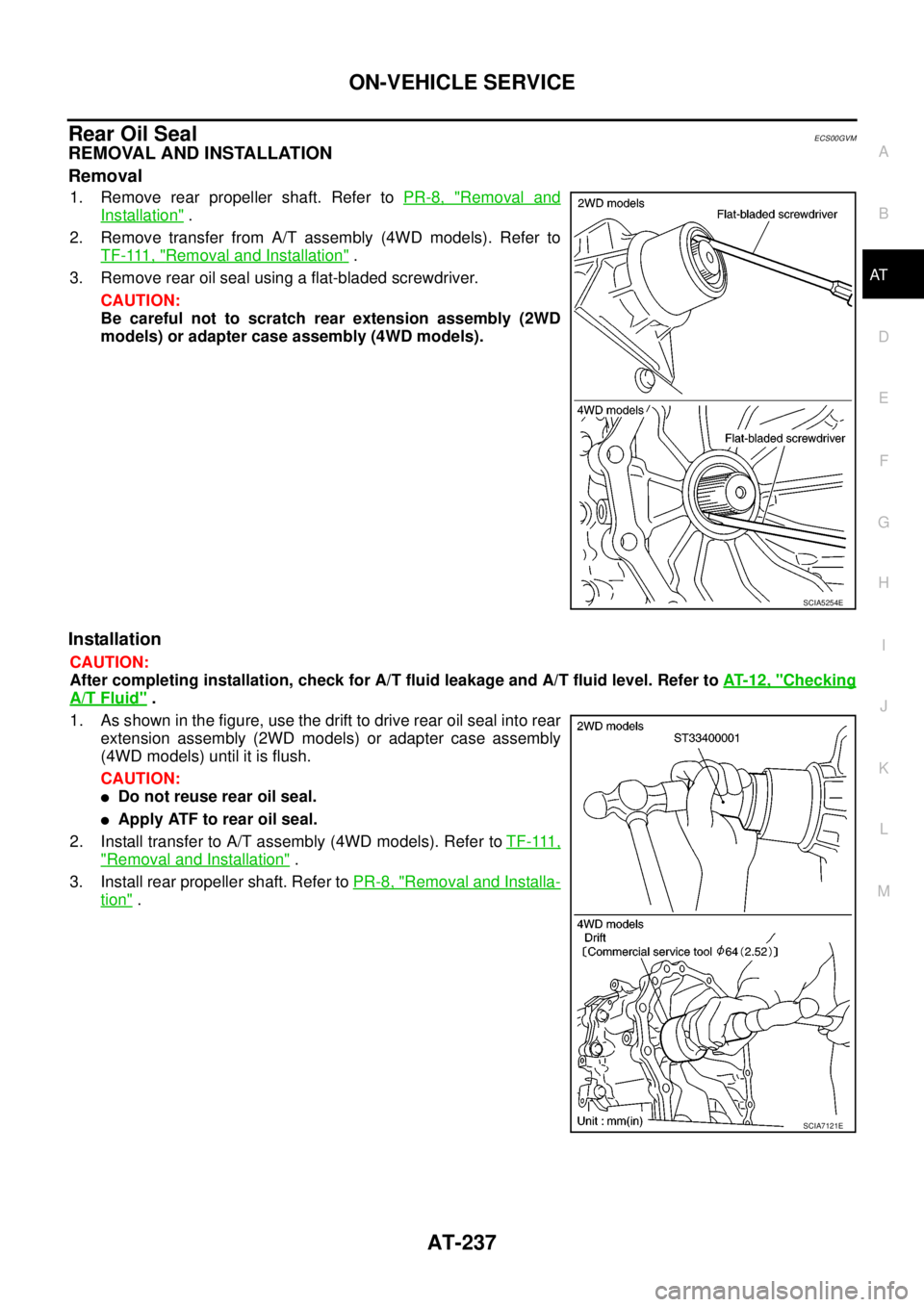

Rear Oil SealECS00GVM

REMOVAL AND INSTALLATION

Removal

1. Remove rear propeller shaft. Refer toPR-8, "Removal and

Installation".

2. Remove transfer from A/T assembly (4WD models). Refer to

T F - 111 , "

Removal and Installation".

3. Remove rear oil seal using a flat-bladed screwdriver.

CAUTION:

Be careful not to scratch rear extension assembly (2WD

models) or adapter case assembly (4WD models).

Installation

CAUTION:

After completing installation, check for A/T fluid leakage and A/T fluid level. Refer toAT- 1 2 , "

Checking

A/T Fluid".

1. As shown in the figure, use the drift to drive rear oil seal into rear

extension assembly (2WD models) or adapter case assembly

(4WD models) until it is flush.

CAUTION:

lDo not reuse rear oil seal.

lApply ATF to rear oil seal.

2. Install transfer to A/T assembly (4WD models). Refer toT F - 111 ,

"Removal and Installation".

3. Install rear propeller shaft. Refer toPR-8, "

Removal and Installa-

tion".

SCIA5254E

SCIA7121E

Page 256 of 3171

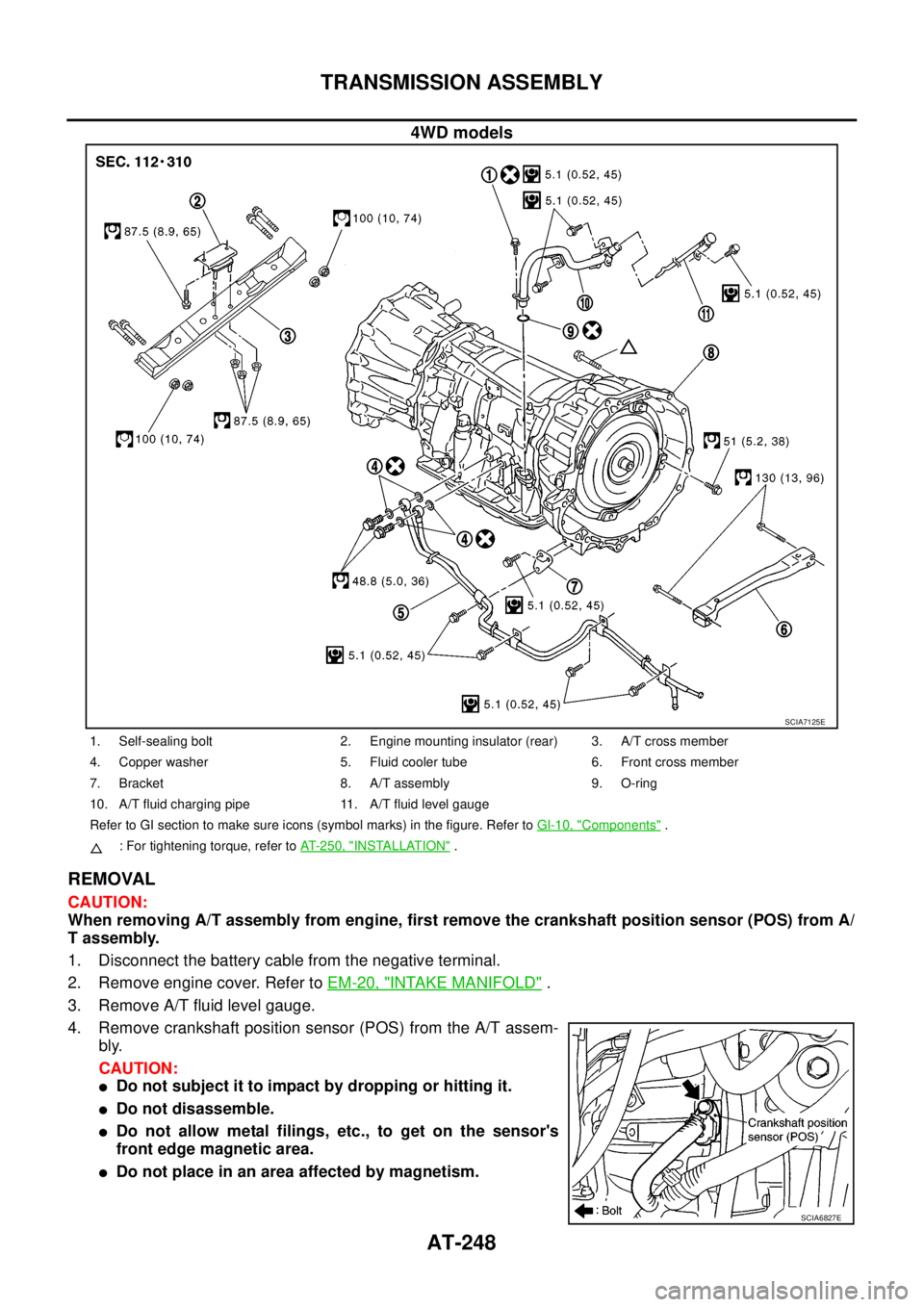

AT-248

TRANSMISSION ASSEMBLY

4WD models

REMOVAL

CAUTION:

When removing A/T assembly from engine, first remove the crankshaft position sensor (POS) from A/

T assembly.

1. Disconnect the battery cable from the negative terminal.

2. Remove engine cover. Refer toEM-20, "

INTAKE MANIFOLD".

3. Remove A/T fluid level gauge.

4. Remove crankshaft position sensor (POS) from the A/T assem-

bly.

CAUTION:

lDo not subject it to impact by dropping or hitting it.

lDo not disassemble.

lDo not allow metal filings, etc., to get on the sensor's

front edge magnetic area.

lDo not place in an area affected by magnetism.

SCIA7125E

1. Self-sealing bolt 2. Engine mounting insulator (rear) 3. A/T cross member

4. Copper washer 5. Fluid cooler tube 6. Front cross member

7. Bracket 8. A/T assembly 9. O-ring

10. A/T fluid charging pipe 11. A/T fluid level gauge

Refer to GI section to make sure icons (symbol marks) in the figure. Refer toGI-10, "

Components".

: For tightening torque, refer toAT-250, "

INSTALLATION".

SCIA6827E

Page 257 of 3171

TRANSMISSION ASSEMBLY

AT-249

D

E

F

G

H

I

J

K

L

MA

B

AT

5. Remove front valance center, engine undercover front, engine under cover middle and engine under

coverrear.RefertoEI-15, "

FRONT BUMPER".

6. Remove front cross member.

7. Remove main muffler. Refer toEX-2, "

EXHAUST SYSTEM".

8. Remove rear propeller shaft. Refer toPR-8, "

Removal and Installation".

9. Remove front propeller shaft. Refer toPR-4, "

Removal and Installation".

10. Remove starter motor. Refer toSC-31, "

Removal and Installation".

11. Remove control cable and bracket. Refer toAT- 2 1 0 , "

Control Cable Removal and Installation".

12. Disconnect fluid cooler tube.

13. Remove A/T fluid charging pipe from A/T assembly.

14. Remove O-ring from A/T fluid charging pipe.

15. Plug up openings such as A/T fluid charging pipe hole, etc.

16. Remove rear plate cover from rear plate.

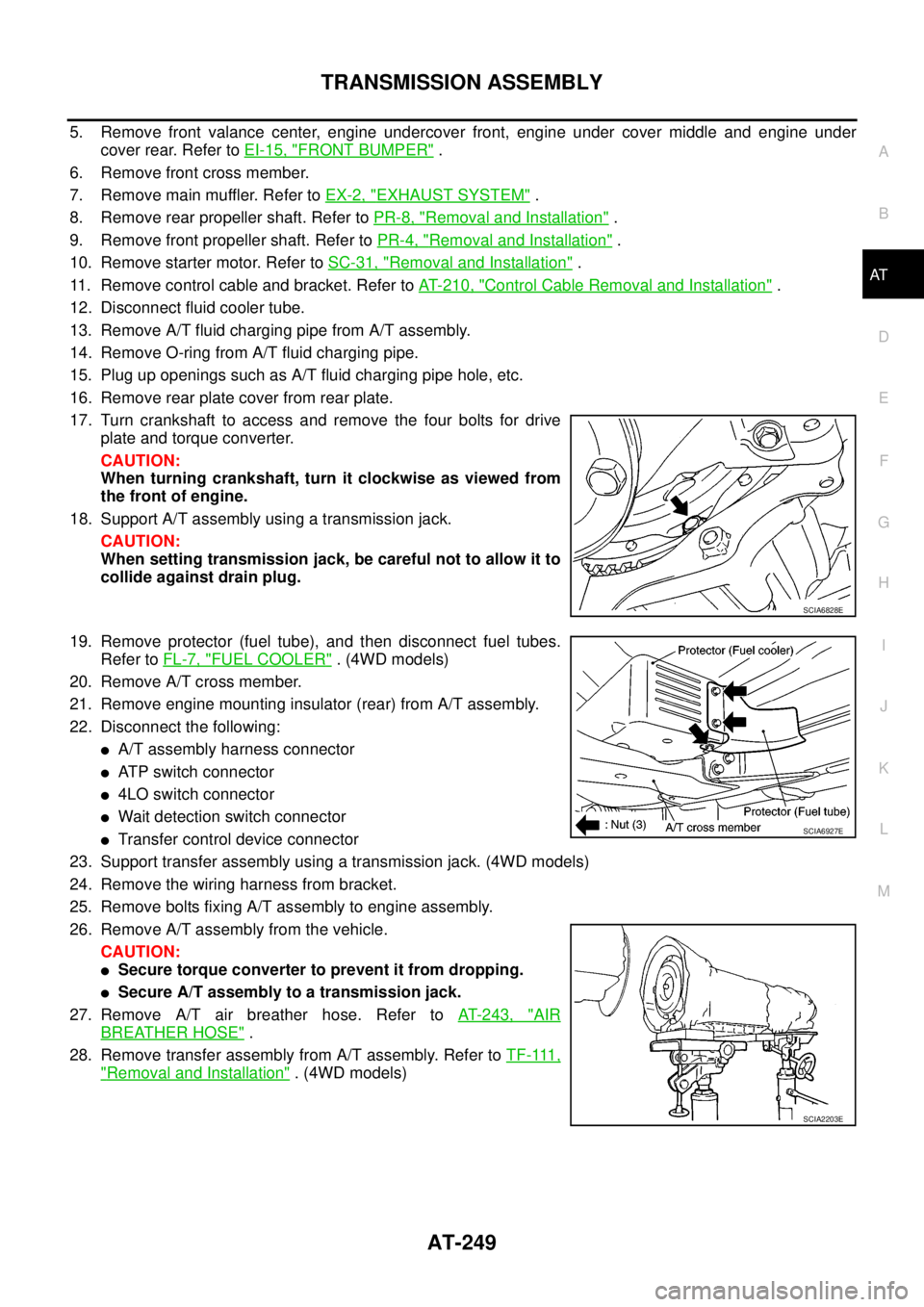

17. Turn crankshaft to access and remove the four bolts for drive

plate and torque converter.

CAUTION:

When turning crankshaft, turn it clockwise as viewed from

the front of engine.

18. Support A/T assembly using a transmission jack.

CAUTION:

When setting transmission jack, be careful not to allow it to

collide against drain plug.

19. Remove protector (fuel tube), and then disconnect fuel tubes.

Refer toFL-7, "

FUEL COOLER". (4WD models)

20. Remove A/T cross member.

21. Remove engine mounting insulator (rear) from A/T assembly.

22. Disconnect the following:

lA/T assembly harness connector

lATP switch connector

l4LO switch connector

lWait detection switch connector

lTransfer control device connector

23. Support transfer assembly using a transmission jack. (4WD models)

24. Remove the wiring harness from bracket.

25. Remove bolts fixing A/T assembly to engine assembly.

26. Remove A/T assembly from the vehicle.

CAUTION:

lSecure torque converter to prevent it from dropping.

lSecure A/T assembly to a transmission jack.

27. Remove A/T air breather hose. Refer toAT- 2 4 3 , "

AIR

BREATHER HOSE".

28. Remove transfer assembly from A/T assembly. Refer toT F - 111 ,

"Removal and Installation". (4WD models)

SCIA6828E

SCIA6927E

SCIA2203E

Page 265 of 3171

OVERHAUL

AT-257

D

E

F

G

H

I

J

K

L

MA

B

AT

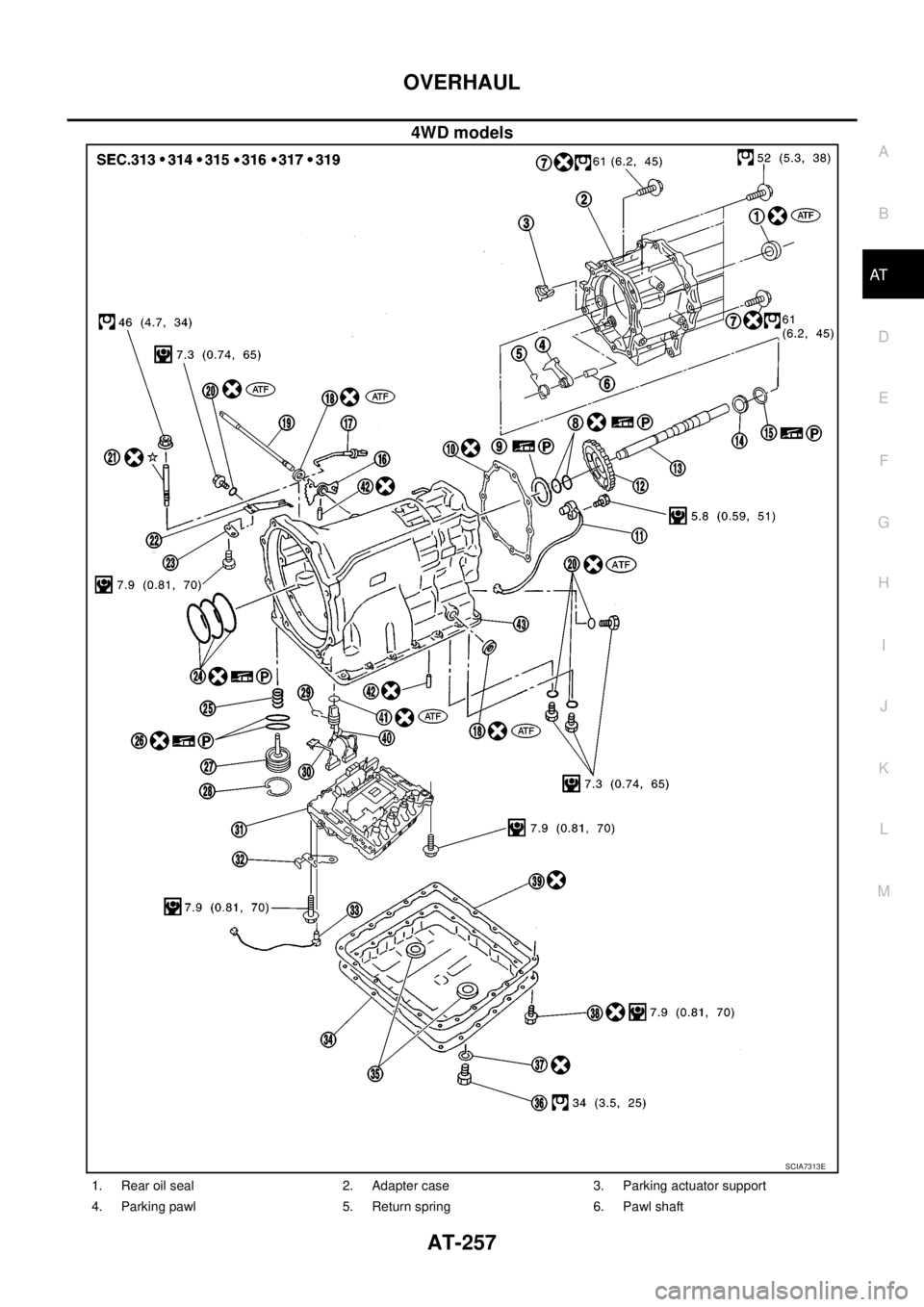

4WD models

SCIA7313E

1. Rear oil seal 2. Adapter case 3. Parking actuator support

4. Parking pawl 5. Return spring 6. Pawl shaft

Page 268 of 3171

AT-260

OVERHAUL

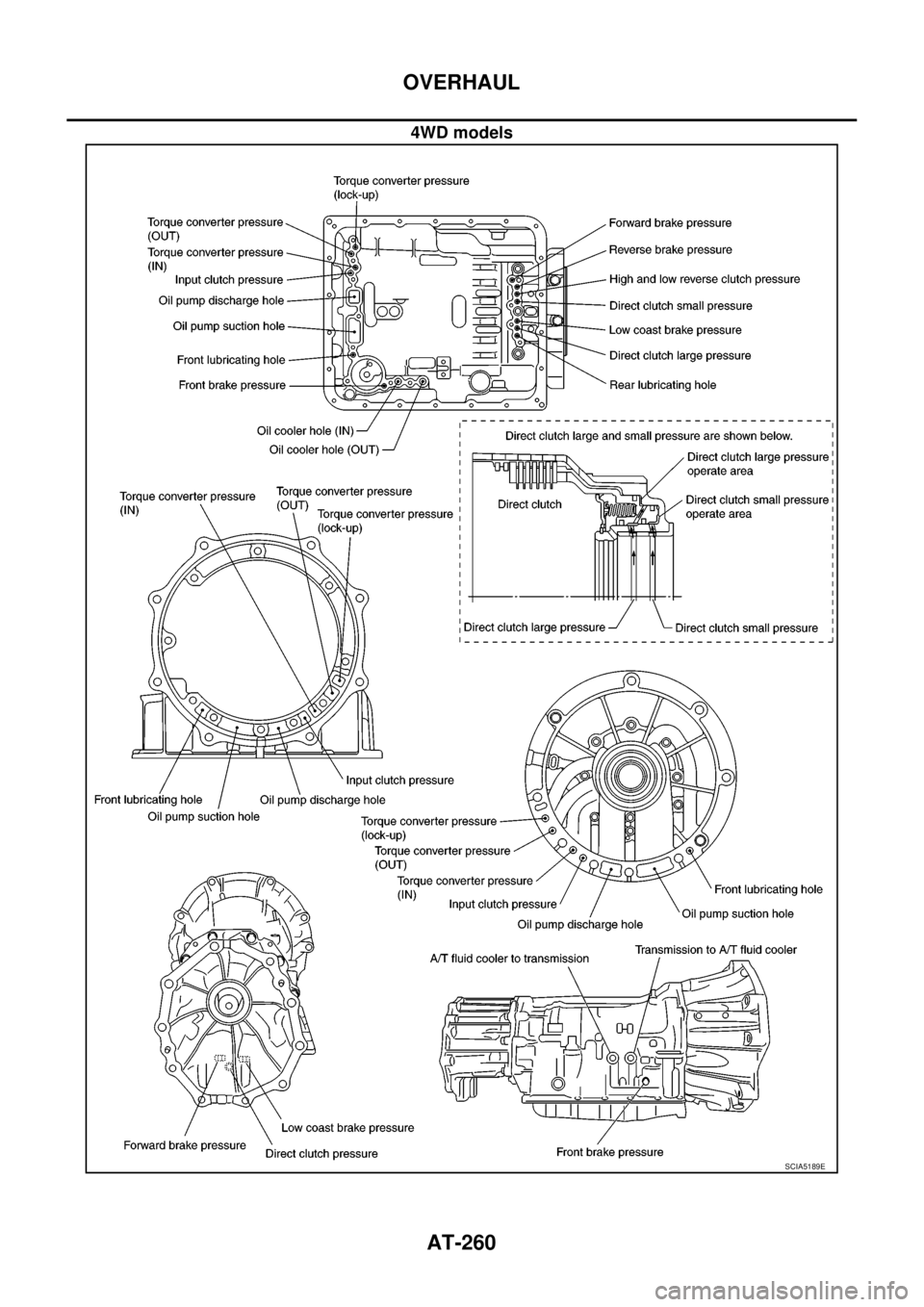

4WD models

SCIA5189E

Page 270 of 3171

AT-262

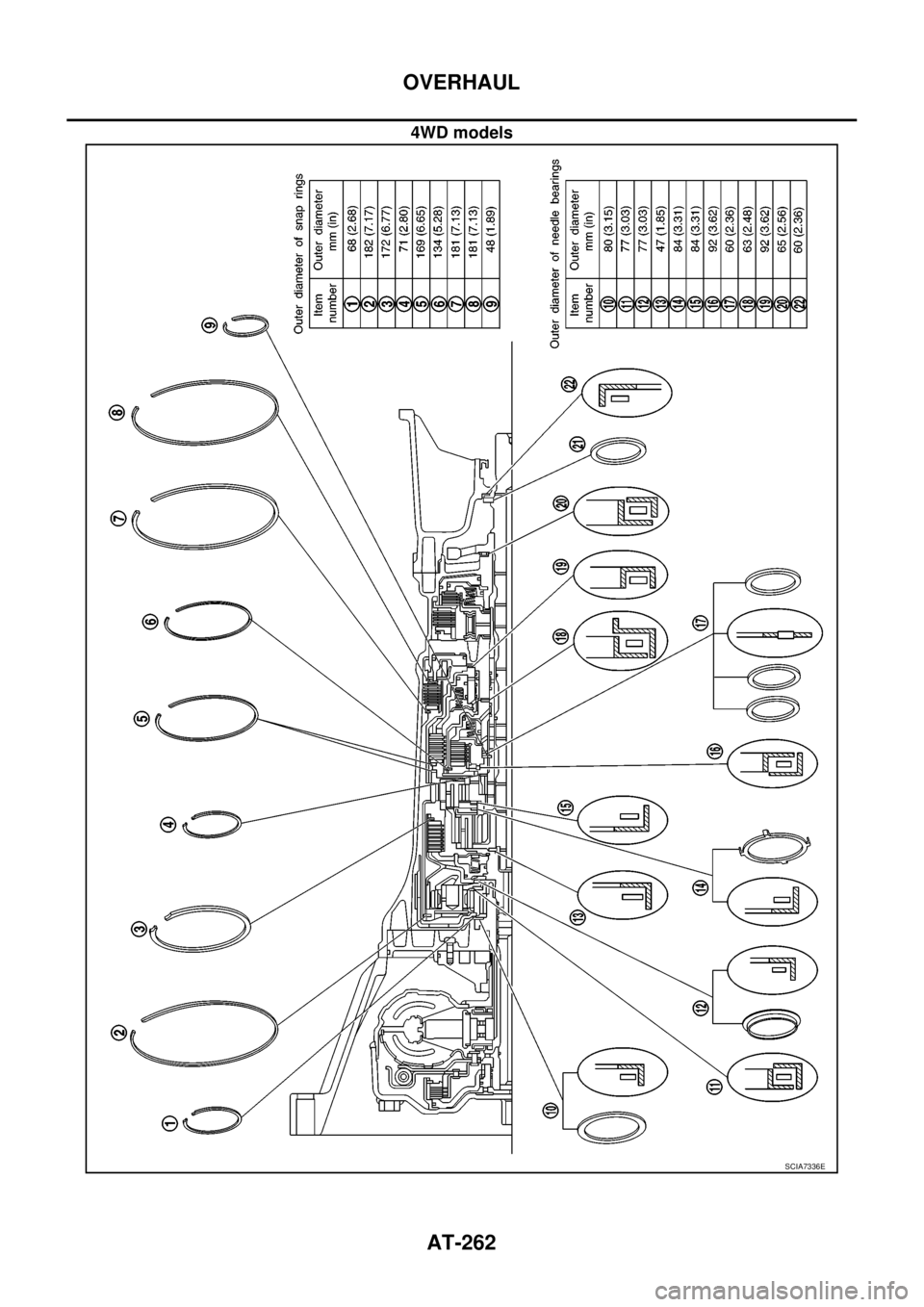

OVERHAUL

4WD models

SCIA7336E

Page 271 of 3171

DISASSEMBLY

AT-263

D

E

F

G

H

I

J

K

L

MA

B

AT

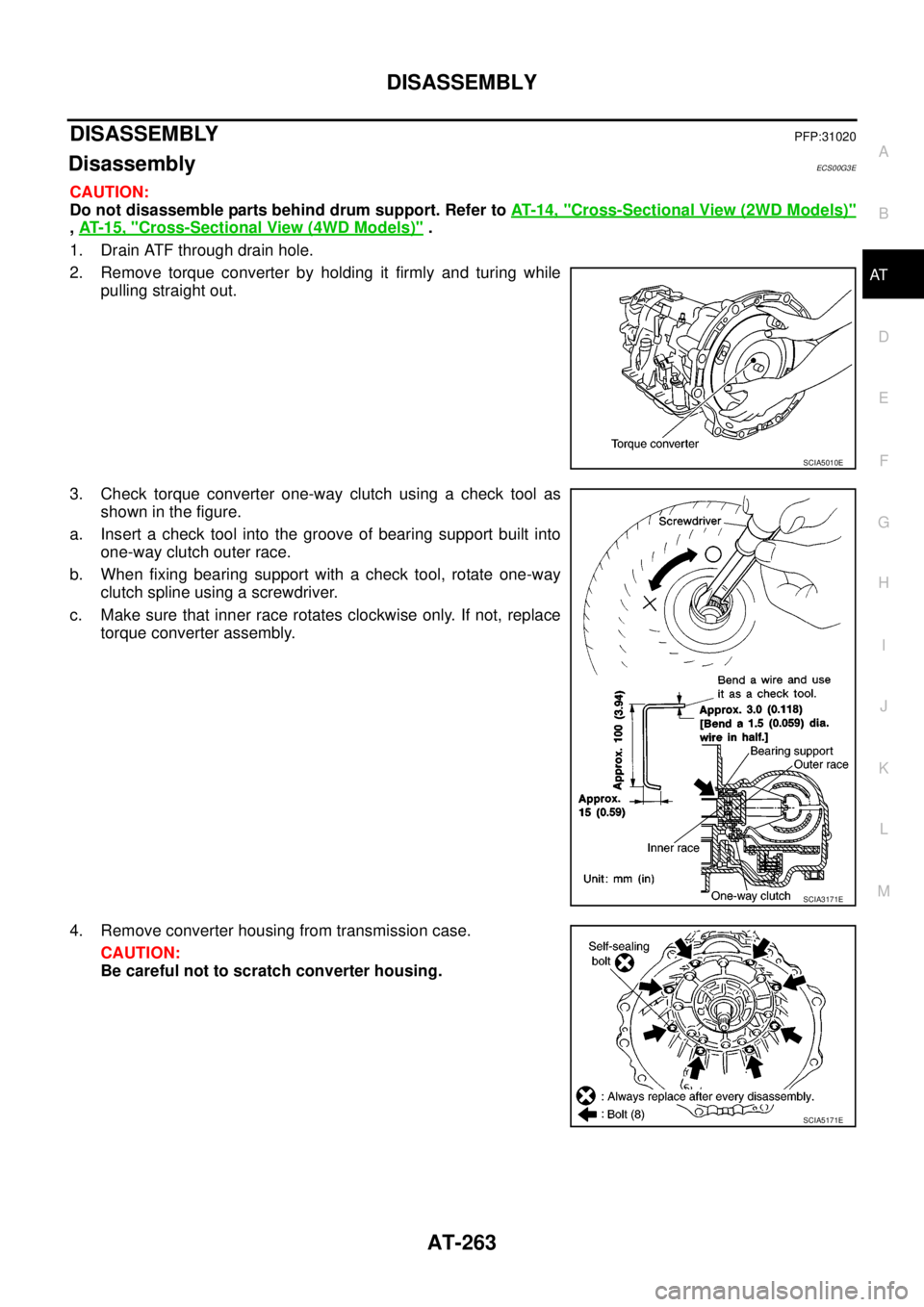

DISASSEMBLYPFP:31020

DisassemblyECS00G3E

CAUTION:

Do not disassemble parts behind drum support. Refer toAT-14, "

Cross-Sectional View (2WD Models)"

,AT-15, "Cross-Sectional View (4WD Models)".

1. Drain ATF through drain hole.

2. Remove torque converter by holding it firmly and turing while

pulling straight out.

3. Check torque converter one-way clutch using a check tool as

showninthefigure.

a. Insert a check tool into the groove of bearing support built into

one-way clutch outer race.

b. When fixing bearing support with a check tool, rotate one-way

clutch spline using a screwdriver.

c. Make sure that inner race rotates clockwise only. If not, replace

torque converter assembly.

4. Remove converter housing from transmission case.

CAUTION:

Be careful not to scratch converter housing.

SCIA5010E

SCIA3171E

SCIA5171E

Page 280 of 3171

AT-272

DISASSEMBLY

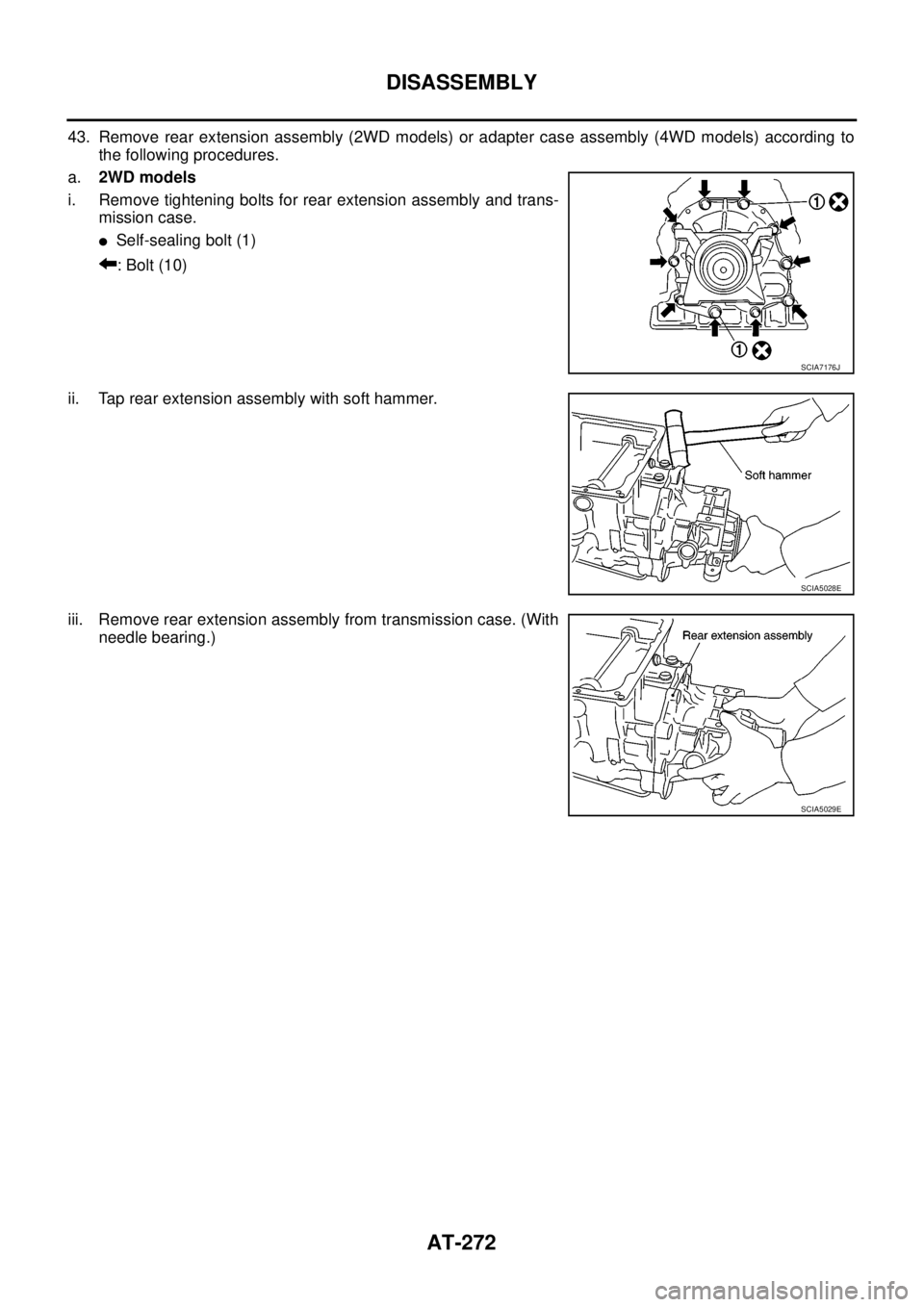

43. Remove rear extension assembly (2WD models) or adapter case assembly (4WD models) according to

the following procedures.

a.2WD models

i. Remove tightening bolts for rear extension assembly and trans-

mission case.

lSelf-sealing bolt (1)

:Bolt(10)

ii. Tap rear extension assembly with soft hammer.

iii. Remove rear extension assembly from transmission case. (With

needle bearing.)

SCIA7176J

SCIA5028E

SCIA5029E

Page 281 of 3171

DISASSEMBLY

AT-273

D

E

F

G

H

I

J

K

L

MA

B

AT

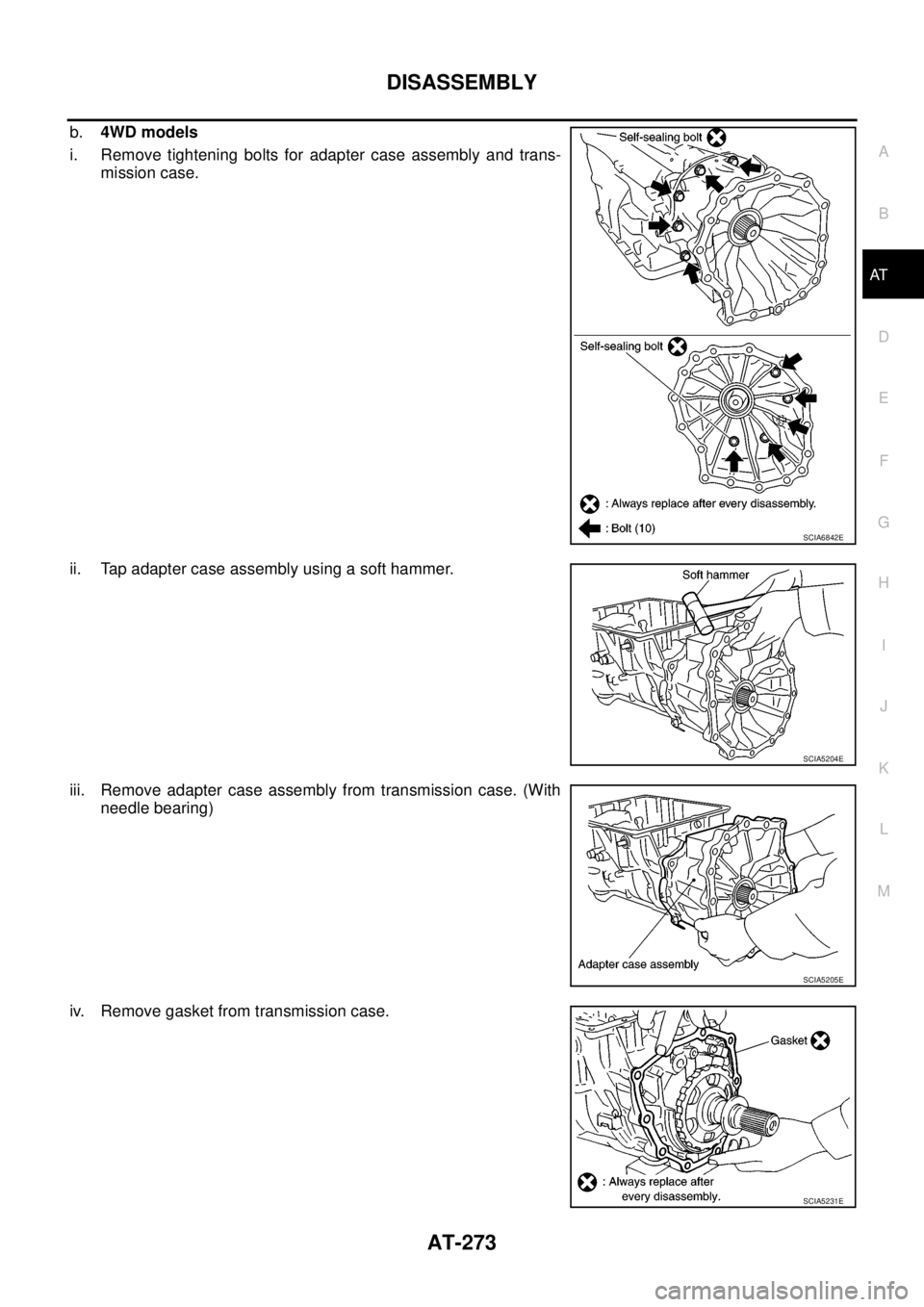

b.4WD models

i. Remove tightening bolts for adapter case assembly and trans-

mission case.

ii. Tap adapter case assembly using a soft hammer.

iii. Remove adapter case assembly from transmission case. (With

needle bearing)

iv. Remove gasket from transmission case.

SCIA6842E

SCIA5204E

SCIA5205E

SCIA5231E