4WD NISSAN NAVARA 2005 Repair Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 914 of 3171

DI-4

COMBINATION METERS

COMBINATION METERS

PFP:24814

System DescriptionEKS00L8E

UNIFIED METER CONTROL UNIT

lSpeedometer, odo/trip meter, tachometer, fuel gauge and water temperature gauge are controlled by the

unified meter control unit, which is built into the combination meter.

lWarning lamp and indicator lamp are controlled by signals drawn from each unit with CAN communication

and components connected directly to the combination meter.

lOdo/trip meter display is included in the combination meter, which displays odometer, trip-meter, vehicle

information (trip computer, engine oil maintenance information)

*and A/T position*.

*: Vehicles with each system only.

lClock display is included in the combination meter, which displays current time, ambient air temperature*

and 4WD indicator*.

*: Vehicles with each system only.

lUnified meter control unit corresponds a CONSULT-II function (self-diagnosis results and data monitor).

lThe following items can be checked during self-diagnosis mode.

–Sweep of gauges pointer

–Present gauge values

–Odo/trip meter display and clock display segments

–Condition of warning lamps/indicator lamps controlled by unified meter control unit

–Battery voltage

–Driver's seat belt buckle switch status

–CPU status of unified meter control unit

POWER SUPPLY AND GROUND CIRCUIT

Power is supplied at all times

lthrough 10A fuse [No.19, located in the fuse block (J/B)]

lto combination meter terminal 3.

With the ignition switch in the ON or START position, power is supplied

lthrough 10A fuse [No.14, located in the fuse block (J/B)]

lto combination meter terminal 16.

Ground is supplied

lto combination meter terminals 13 and 23

lthrough grounds M21, M80 and M83.

SPEEDOMETER

The speedometer indicates the vehicle speed.

lABS actuator and electric unit (control unit) converses a pulse signal from wheel sensor to vehicle speed

signal, and transmits vehicle speed signal to combination meter with CAN communication.

lCombination meter converses the vehicle speed signal to angle signal, and commands to speedometer.

TACHOMETER

The tachometer indicates engine speed in revolutions per minute (rpm).

lECM converses a signal from crank position sensor to engine speed signal, and transmits to combination

meter with CAN communication.

lCombination meter converses the engine speed signal to angle signal, and commands to tachometer.

WATER TEMPERATURE GAUGE

The water temperature gauge indicates the engine coolant temperature.

lECM converses a signal from water temperature sensor to engine coolant temperature signal, and trans-

mits to combination meter with CAN communication.

lCombination meter converses the engine coolant temperature signal to angle signal, and commands to

water temperature gauge.

Page 928 of 3171

DI-18

COMBINATION METERS

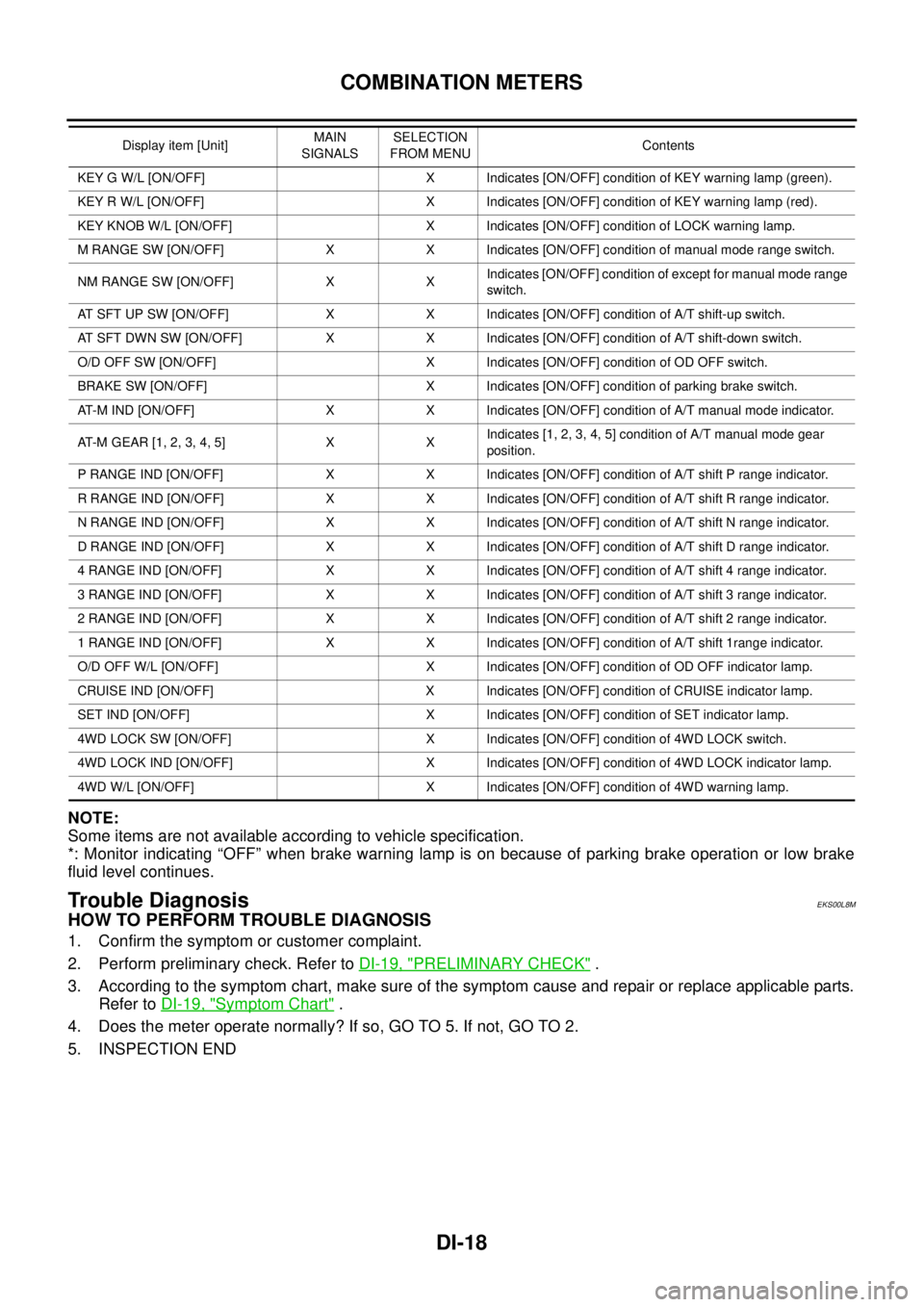

NOTE:

Some items are not available according to vehicle specification.

*: Monitor indicating “OFF” when brake warning lamp is on because of parking brake operation or low brake

fluid level continues.

Trouble DiagnosisEKS00L8M

HOW TO PERFORM TROUBLE DIAGNOSIS

1. Confirm the symptom or customer complaint.

2. Perform preliminary check. Refer toDI-19, "

PRELIMINARY CHECK".

3. According to the symptom chart, make sure of the symptom cause and repair or replace applicable parts.

Refer toDI-19, "

Symptom Chart".

4. Does the meter operate normally? If so, GO TO 5. If not, GO TO 2.

5. INSPECTION END

KEY G W/L [ON/OFF] X Indicates [ON/OFF] condition of KEY warning lamp (green).

KEY R W/L [ON/OFF] X Indicates [ON/OFF] condition of KEY warning lamp (red).

KEY KNOB W/L [ON/OFF] X Indicates [ON/OFF] condition of LOCK warning lamp.

M RANGE SW [ON/OFF] X X Indicates [ON/OFF] condition of manual mode range switch.

NM RANGE SW [ON/OFF] X XIndicates [ON/OFF] condition of except for manual mode range

switch.

AT SFT UP SW [ON/OFF] X X Indicates [ON/OFF] condition of A/T shift-up switch.

AT SFT DWN SW [ON/OFF] X X Indicates [ON/OFF] condition of A/T shift-down switch.

O/D OFF SW [ON/OFF] X Indicates [ON/OFF] condition of OD OFF switch.

BRAKE SW [ON/OFF] X Indicates [ON/OFF] condition of parking brake switch.

AT-M IND [ON/OFF] X X Indicates [ON/OFF] condition of A/T manual mode indicator.

AT-MGEAR[1,2,3,4,5] X XIndicates [1, 2, 3, 4, 5] condition of A/T manual mode gear

position.

P RANGE IND [ON/OFF] X X Indicates [ON/OFF] condition of A/T shift P range indicator.

R RANGE IND [ON/OFF] X X Indicates [ON/OFF] condition of A/T shift R range indicator.

N RANGE IND [ON/OFF] X X Indicates [ON/OFF] condition of A/T shift N range indicator.

D RANGE IND [ON/OFF] X X Indicates [ON/OFF] condition of A/T shift D range indicator.

4 RANGE IND [ON/OFF] X X Indicates [ON/OFF] condition of A/T shift 4 range indicator.

3 RANGE IND [ON/OFF] X X Indicates [ON/OFF] condition of A/T shift 3 range indicator.

2 RANGE IND [ON/OFF] X X Indicates [ON/OFF] condition of A/T shift 2 range indicator.

1 RANGE IND [ON/OFF] X X Indicates [ON/OFF] condition of A/T shift 1range indicator.

O/D OFF W/L [ON/OFF] X Indicates [ON/OFF] condition of OD OFF indicator lamp.

CRUISE IND [ON/OFF] X Indicates [ON/OFF] condition of CRUISE indicator lamp.

SET IND [ON/OFF] X Indicates [ON/OFF] condition of SET indicator lamp.

4WD LOCK SW [ON/OFF] X Indicates [ON/OFF] condition of 4WD LOCK switch.

4WD LOCK IND [ON/OFF] X Indicates [ON/OFF] condition of 4WD LOCK indicator lamp.

4WD W/L [ON/OFF] X Indicates [ON/OFF] condition of 4WD warning lamp.Display item [Unit]MAIN

SIGNALSSELECTION

FROM MENUContents

Page 1410 of 3171

EM-28

TURBO CHARGER

TURBO CHARGER

PFP:14411

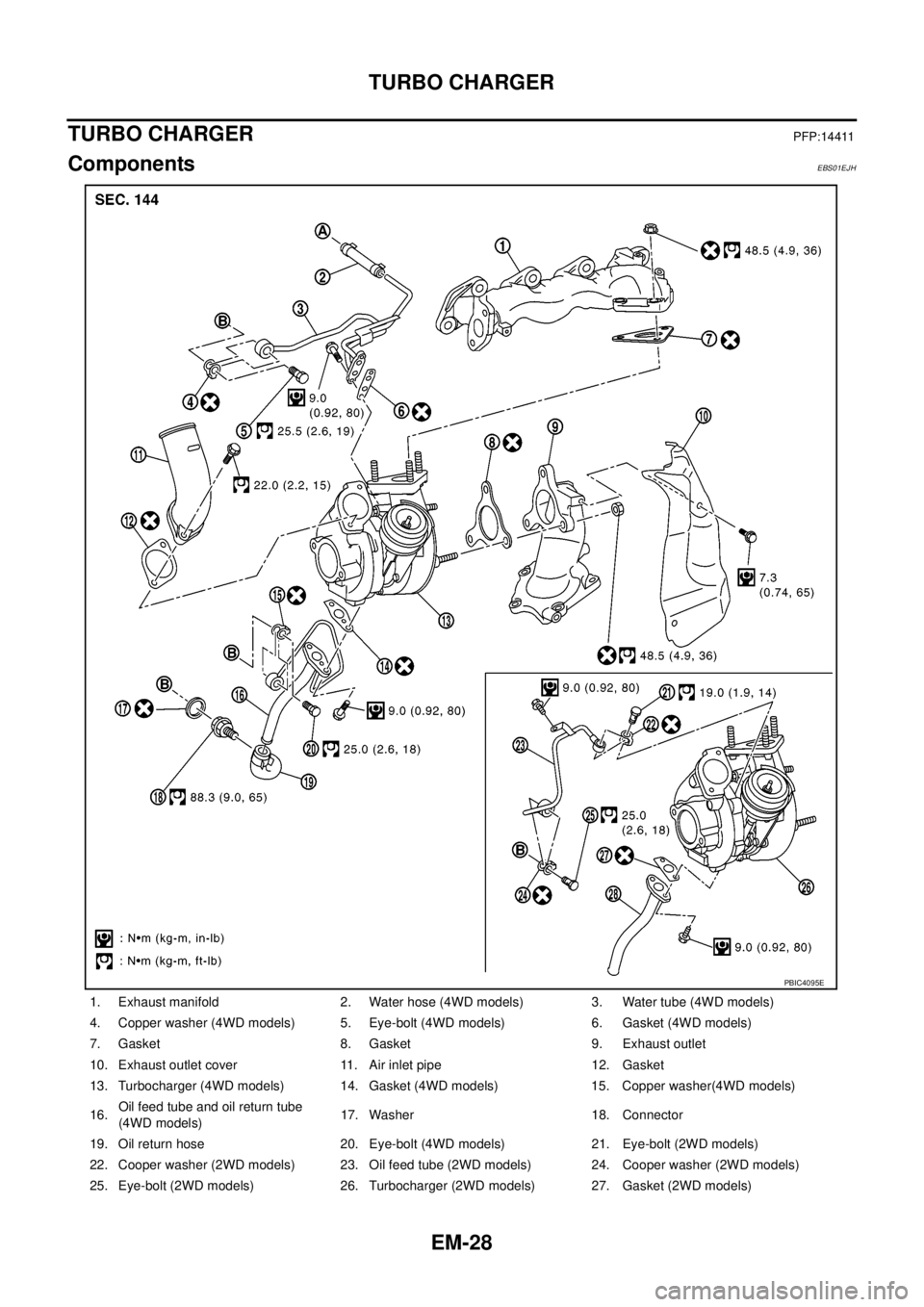

ComponentsEBS01EJH

1. Exhaust manifold 2. Water hose (4WD models) 3. Water tube (4WD models)

4. Copper washer (4WD models) 5. Eye-bolt (4WD models) 6. Gasket (4WD models)

7. Gasket 8. Gasket 9. Exhaust outlet

10. Exhaust outlet cover 11. Air inlet pipe 12. Gasket

13. Turbocharger (4WD models) 14. Gasket (4WD models) 15. Copper washer(4WD models)

16.Oil feed tube and oil return tube

(4WD models)17. Washer 18. Connector

19. Oil return hose 20. Eye-bolt (4WD models) 21. Eye-bolt (2WD models)

22. Cooper washer (2WD models) 23. Oil feed tube (2WD models) 24. Cooper washer (2WD models)

25. Eye-bolt (2WD models) 26. Turbocharger (2WD models) 27. Gasket (2WD models)

PBIC4095E

Page 1411 of 3171

TURBO CHARGER

EM-29

C

D

E

F

G

H

I

J

K

L

MA

EM

lRefer toGI-10, "Components"for symbol marks in the figure.

Removal and InstallationEBS01E5X

REMOVAL

lAfter applying penetrative lubricant to the mounting nuts, check for the penetration of the lubricant, and

then loosen the nuts to remove.

1. Drain engine coolant (4WD models). Refer toCO-7, "

Changing Engine Coolant".

2. Remove air inlet hose and air inlet pipe. Refer toEM-18, "

CHARGE AIR COOLER".

3. Remove air duct and air inlet pipes. Refer toEM-15, "

AIR CLEANER AND AIR DUCT".

4. Remove exhaust manifold cover. Refer toEM-34, "

EXHAUST MANIFOLD".

5. Remove exhaust outlet and catalyst. Refer toEM-26, "

CATALYST".

6. Remove eye bolt and water hose from water tube (4WD models).

7. Loosen and remove eye-bolts from oil feed tube.

8. Disconnect oil return hose from oil return tube.

9. Remove turbocharger with water tube (4WD models) and oil feed tube and oil return tube.

CAUTION:

Be careful not to deform water tube and oil feed tube and oil return tube.

10. Remove water tube (4WD models) and oil feed tube and oil return tube from turbocharger.

CAUTION:

lDo not disassemble or adjust the turbocharger.

lBe careful not to contact with the vehicle.

lDo not hold turbocharger boost control actuator and actuator rod.

Water Tube and Oil Tube

lClean inside of water tube (4WD models), oil feed tube and oil return tube, and check tubes for clogging.

lReplace water tube (4WD models), oil feed tube and/or oil return tube if clogging still exists after cleaning.

28. Oil return tube (2WD models)

A. To heater return pipe B. To cylinder block

Page 1412 of 3171

EM-30

TURBO CHARGER

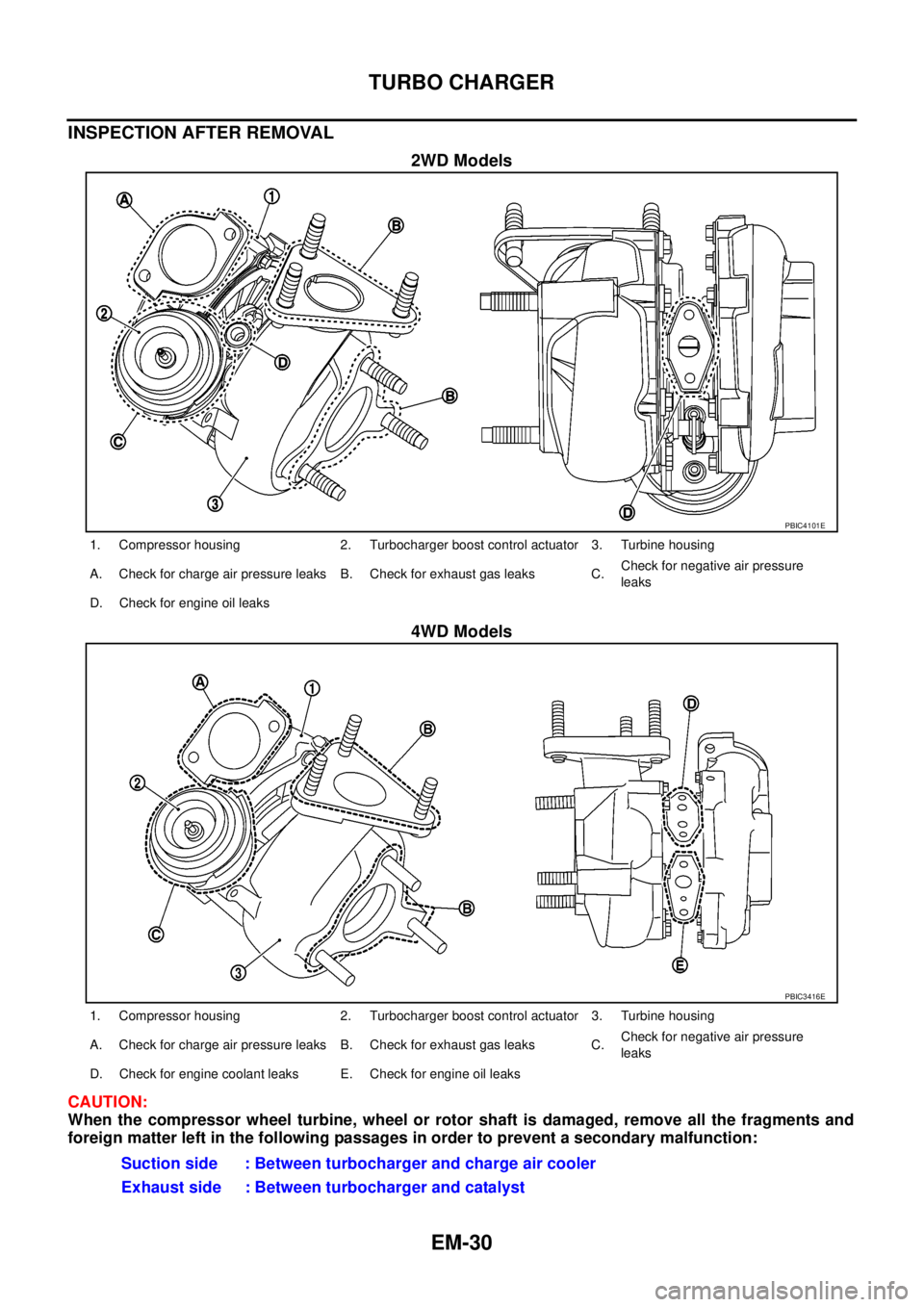

INSPECTION AFTER REMOVAL

2WD Models

4WD Models

CAUTION:

When the compressor wheel turbine, wheel or rotor shaft is damaged, remove all the fragments and

foreign matter left in the following passages in order to prevent a secondary malfunction:

PBIC4101E

1. Compressor housing 2. Turbocharger boost control actuator 3. Turbine housing

A. Check for charge air pressure leaks B. Check for exhaust gas leaks C.Check for negative air pressure

leaks

D. Check for engine oil leaks

PBIC3416E

1. Compressor housing 2. Turbocharger boost control actuator 3. Turbine housing

A. Check for charge air pressure leaks B. Check for exhaust gas leaks C.Check for negative air pressure

leaks

D. Check for engine coolant leaks E. Check for engine oil leaks

Suction side : Between turbocharger and charge air cooler

Exhaust side : Between turbocharger and catalyst

Page 1419 of 3171

OIL PAN AND OIL STRAINER

EM-37

C

D

E

F

G

H

I

J

K

L

MA

EM

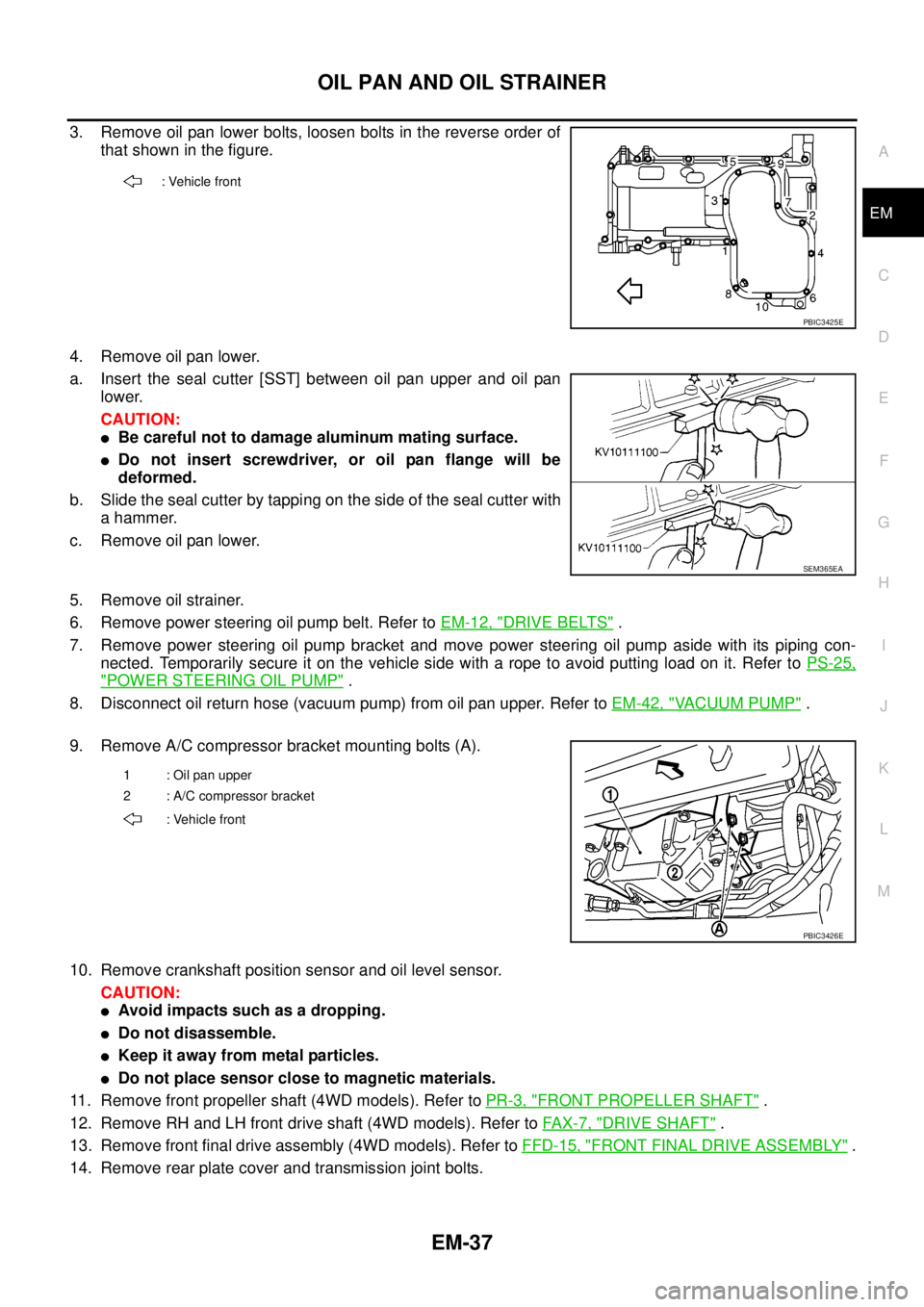

3. Remove oil pan lower bolts, loosen bolts in the reverse order of

that shown in the figure.

4. Remove oil pan lower.

a. Insert the seal cutter [SST] between oil pan upper and oil pan

lower.

CAUTION:

lBe careful not to damage aluminum mating surface.

lDo not insert screwdriver, or oil pan flange will be

deformed.

b. Slide the seal cutter by tapping on the side of the seal cutter with

a hammer.

c. Remove oil pan lower.

5. Remove oil strainer.

6. Remove power steering oil pump belt. Refer toEM-12, "

DRIVE BELTS".

7. Remove power steering oil pump bracket and move power steering oil pump aside with its piping con-

nected. Temporarily secure it on the vehicle side with a rope to avoid putting load on it. Refer toPS-25,

"POWER STEERING OIL PUMP".

8. Disconnect oil return hose (vacuum pump) from oil pan upper. Refer toEM-42, "

VACUUM PUMP".

9. Remove A/C compressor bracket mounting bolts (A).

10. Remove crankshaft position sensor and oil level sensor.

CAUTION:

lAvoid impacts such as a dropping.

lDo not disassemble.

lKeep it away from metal particles.

lDo not place sensor close to magnetic materials.

11. Remove front propeller shaft (4WD models). Refer toPR-3, "

FRONT PROPELLER SHAFT".

12. Remove RH and LH front drive shaft (4WD models). Refer toFAX-7, "

DRIVE SHAFT".

13. Remove front final drive assembly (4WD models). Refer toFFD-15, "

FRONT FINAL DRIVE ASSEMBLY".

14. Remove rear plate cover and transmission joint bolts.

: Vehicle front

PBIC3425E

SEM365EA

1 : Oil pan upper

2 : A/C compressor bracket

: Vehicle front

PBIC3426E

Page 1426 of 3171

EM-44

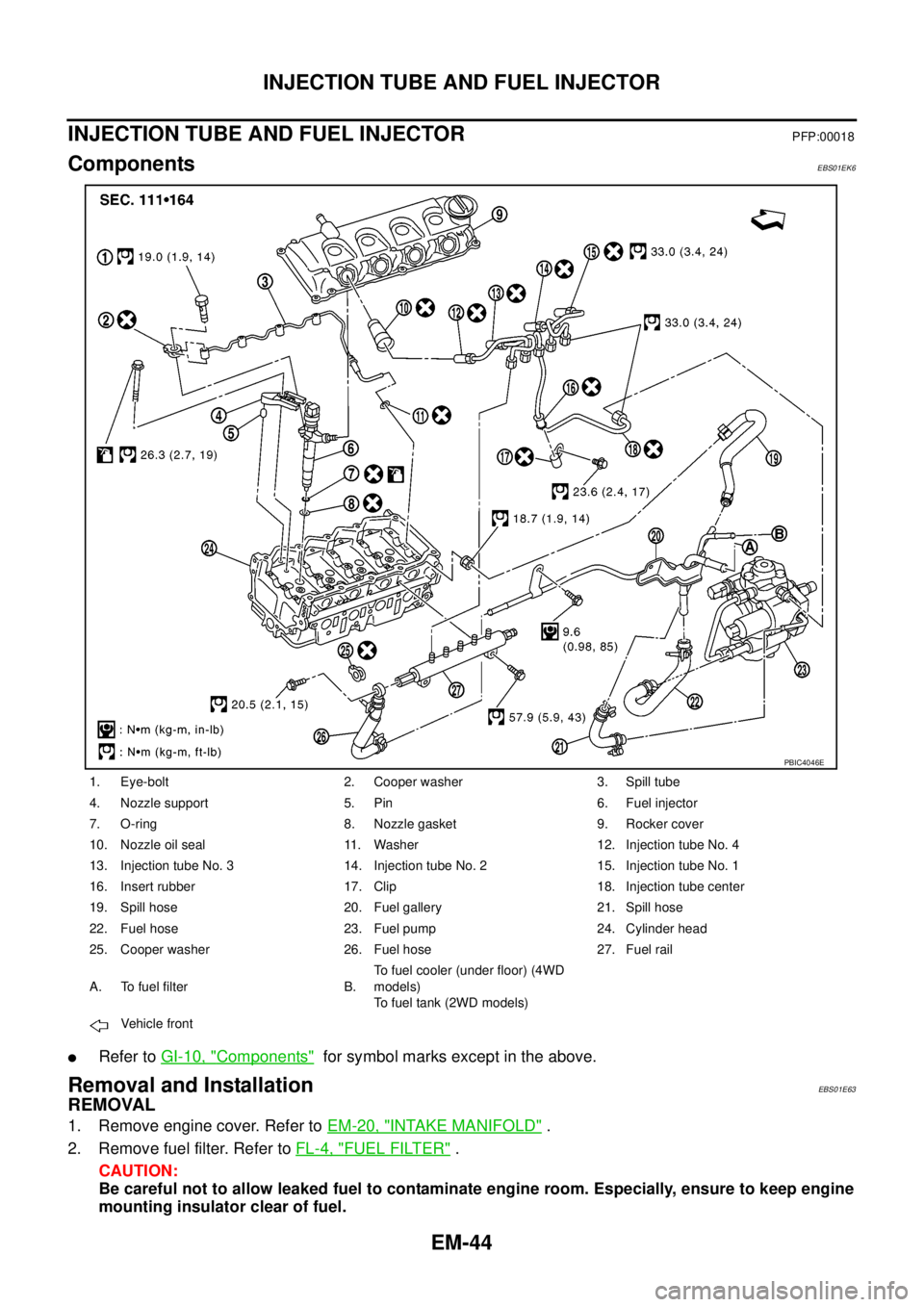

INJECTION TUBE AND FUEL INJECTOR

INJECTION TUBE AND FUEL INJECTOR

PFP:00018

ComponentsEBS01EK6

lRefer toGI-10, "Components"for symbol marks except in the above.

Removal and InstallationEBS01E63

REMOVAL

1. Remove engine cover. Refer toEM-20, "INTAKE MANIFOLD".

2. Remove fuel filter. Refer toFL-4, "

FUEL FILTER".

CAUTION:

Be careful not to allow leaked fuel to contaminate engine room. Especially, ensure to keep engine

mounting insulator clear of fuel.

1. Eye-bolt 2. Cooper washer 3. Spill tube

4. Nozzle support 5. Pin 6. Fuel injector

7. O-ring 8. Nozzle gasket 9. Rocker cover

10. Nozzle oil seal 11. Washer 12. Injection tube No. 4

13. Injection tube No. 3 14. Injection tube No. 2 15. Injection tube No. 1

16. Insert rubber 17. Clip 18. Injection tube center

19. Spill hose 20. Fuel gallery 21. Spill hose

22. Fuel hose 23. Fuel pump 24. Cylinder head

25. Cooper washer 26. Fuel hose 27. Fuel rail

A. To fuel filter B.To fuel cooler (under floor) (4WD

models)

To fuel tank (2WD models)

Vehicle front

PBIC4046E

Page 1462 of 3171

EM-80

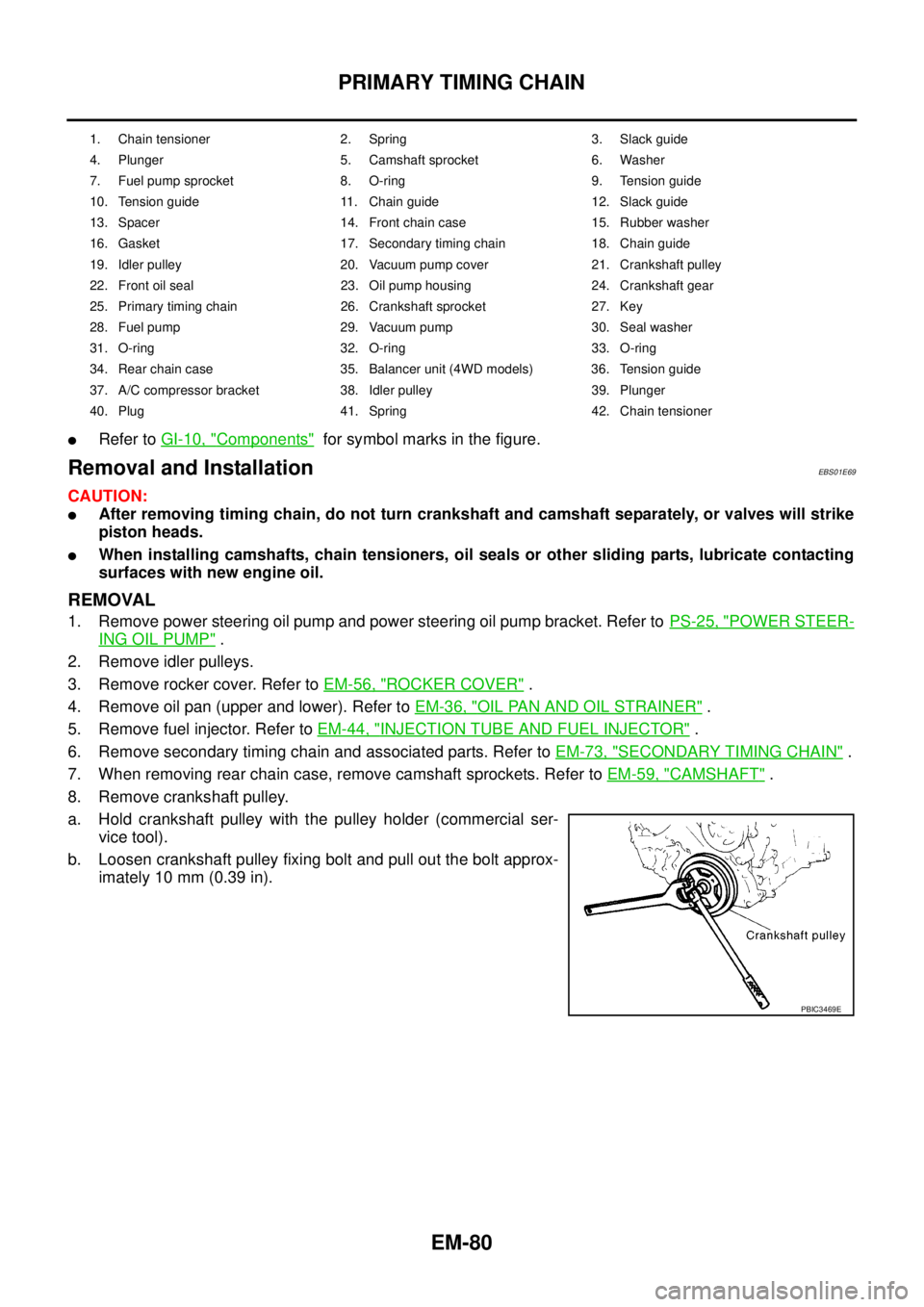

PRIMARY TIMING CHAIN

lRefer toGI-10, "Components"for symbol marks in the figure.

Removal and InstallationEBS01E69

CAUTION:

lAfter removing timing chain, do not turn crankshaft and camshaft separately, or valves will strike

piston heads.

lWhen installing camshafts, chain tensioners, oil seals or other sliding parts, lubricate contacting

surfaces with new engine oil.

REMOVAL

1. Remove power steering oil pump and power steering oil pump bracket. Refer toPS-25, "POWER STEER-

ING OIL PUMP".

2. Remove idler pulleys.

3. Remove rocker cover. Refer toEM-56, "

ROCKER COVER".

4. Remove oil pan (upper and lower). Refer toEM-36, "

OIL PAN AND OIL STRAINER".

5. Remove fuel injector. Refer toEM-44, "

INJECTION TUBE AND FUEL INJECTOR".

6. Remove secondary timing chain and associated parts. Refer toEM-73, "

SECONDARY TIMING CHAIN".

7. When removing rear chain case, remove camshaft sprockets. Refer toEM-59, "

CAMSHAFT".

8. Remove crankshaft pulley.

a. Hold crankshaft pulley with the pulley holder (commercial ser-

vice tool).

b. Loosen crankshaft pulley fixing bolt and pull out the bolt approx-

imately 10 mm (0.39 in).

1. Chain tensioner 2. Spring 3. Slack guide

4. Plunger 5. Camshaft sprocket 6. Washer

7. Fuel pump sprocket 8. O-ring 9. Tension guide

10. Tension guide 11. Chain guide 12. Slack guide

13. Spacer 14. Front chain case 15. Rubber washer

16. Gasket 17. Secondary timing chain 18. Chain guide

19. Idler pulley 20. Vacuum pump cover 21. Crankshaft pulley

22. Front oil seal 23. Oil pump housing 24. Crankshaft gear

25. Primary timing chain 26. Crankshaft sprocket 27. Key

28. Fuel pump 29. Vacuum pump 30. Seal washer

31. O-ring 32. O-ring 33. O-ring

34. Rear chain case 35. Balancer unit (4WD models) 36. Tension guide

37. A/C compressor bracket 38. Idler pulley 39. Plunger

40. Plug 41. Spring 42. Chain tensioner

PBIC3469E

Page 1463 of 3171

![NISSAN NAVARA 2005 Repair Service Manual PRIMARY TIMING CHAIN

EM-81

C

D

E

F

G

H

I

J

K

L

MA

EM

c. Using the pulley puller [SST], remove crankshaft pulley.

lUse two M6 bolts with approx. 60 mm (2.36 in) shank length

for securing crankshaft pul NISSAN NAVARA 2005 Repair Service Manual PRIMARY TIMING CHAIN

EM-81

C

D

E

F

G

H

I

J

K

L

MA

EM

c. Using the pulley puller [SST], remove crankshaft pulley.

lUse two M6 bolts with approx. 60 mm (2.36 in) shank length

for securing crankshaft pul](/img/5/57362/w960_57362-1462.png)

PRIMARY TIMING CHAIN

EM-81

C

D

E

F

G

H

I

J

K

L

MA

EM

c. Using the pulley puller [SST], remove crankshaft pulley.

lUse two M6 bolts with approx. 60 mm (2.36 in) shank length

for securing crankshaft pulley.

9. Remove oil pump housing.

lLoosen bolts in reverse order of that shown in the figure and

remove them.

lU s e t h e s e a l c u t t e r [ S S T: K V 1 0 1111 0 0 ] e t c . f o r r e m o v a l .

10. Remove crankshaft gear.

lRemove crankshaft gear (1) with the following procedure

(4WD models).

a. Make sure that No.1 piston is TDC on its compression stroke.

b. Turn the idler sub gear (3) counterclockwise with snap ring plier

(B) or suitable tool for aligning idler sub gear (3) and idler main

gear (2).

lIf idler gear rotates, hold the flat faces on balancer drive shaft

front end (4).

c. Install internal mechanism securing bolt and plate (Service part:

13012 EB30A and 13013 EB30A) (A) and tighten to the speci-

fied torque.

CAUTION:

lDo not loosen idler gear mounting bolt (5).

lOnly use the genuine internal mechanism securing bolt

and plate (A), or the idler gear (2) and (3) will be damaged.

lDo not remove internal mechanism securing bolt and

plate (A) from idler gear (2) and (3) until crankshaft gear

(1) and all of the parts in connection have been installed.

lIf internal mechanism securing bolt and plate (A) is not

installed, internal mechanism of idler gear (2) and (3) will

disengage after crankshaft gear (1) is removed. This will prohibit the balancer unit from being

reusable.

d. Apply mating marks (C) to crankshaft gear (1) and idler sub gear (3).

e. Remove crankshaft gear (1).

11. Remove front oil seal from oil pump housing.

lPunch out the seal off from the back surface of the oil pump housing using a flat-bladed screwdriver.

CAUTION:

Be careful not to damage oil pump housing.

JEM132G

PBIC3470E

: 4.0 N·m (0.41 kg-m, 35 in-lb)

PBIC3471E

Page 1466 of 3171

EM-84

PRIMARY TIMING CHAIN

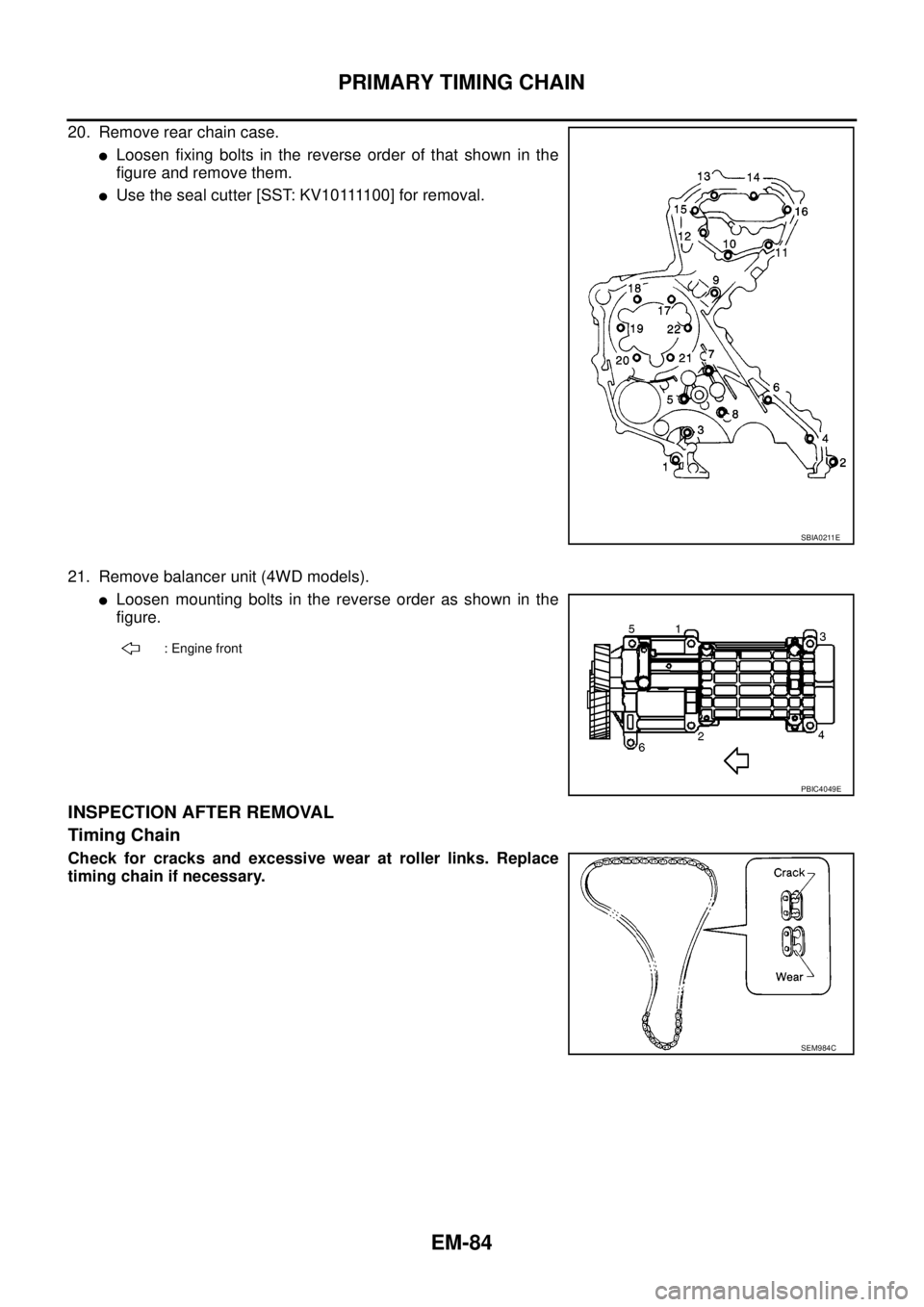

20. Remove rear chain case.

lLoosen fixing bolts in the reverse order of that shown in the

figure and remove them.

lU s e t h e s e a l c u t t e r [ S S T: K V 1 0 1111 0 0 ] f o r r e m o v a l .

21. Remove balancer unit (4WD models).

lLoosen mounting bolts in the reverse order as shown in the

figure.

INSPECTION AFTER REMOVAL

Timing Chain

Check for cracks and excessive wear at roller links. Replace

timing chain if necessary.

SBIA0211E

: Engine front

PBIC4049E

SEM984C