4WD NISSAN NAVARA 2005 Repair Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 287 of 3171

DISASSEMBLY

AT-279

D

E

F

G

H

I

J

K

L

MA

B

AT

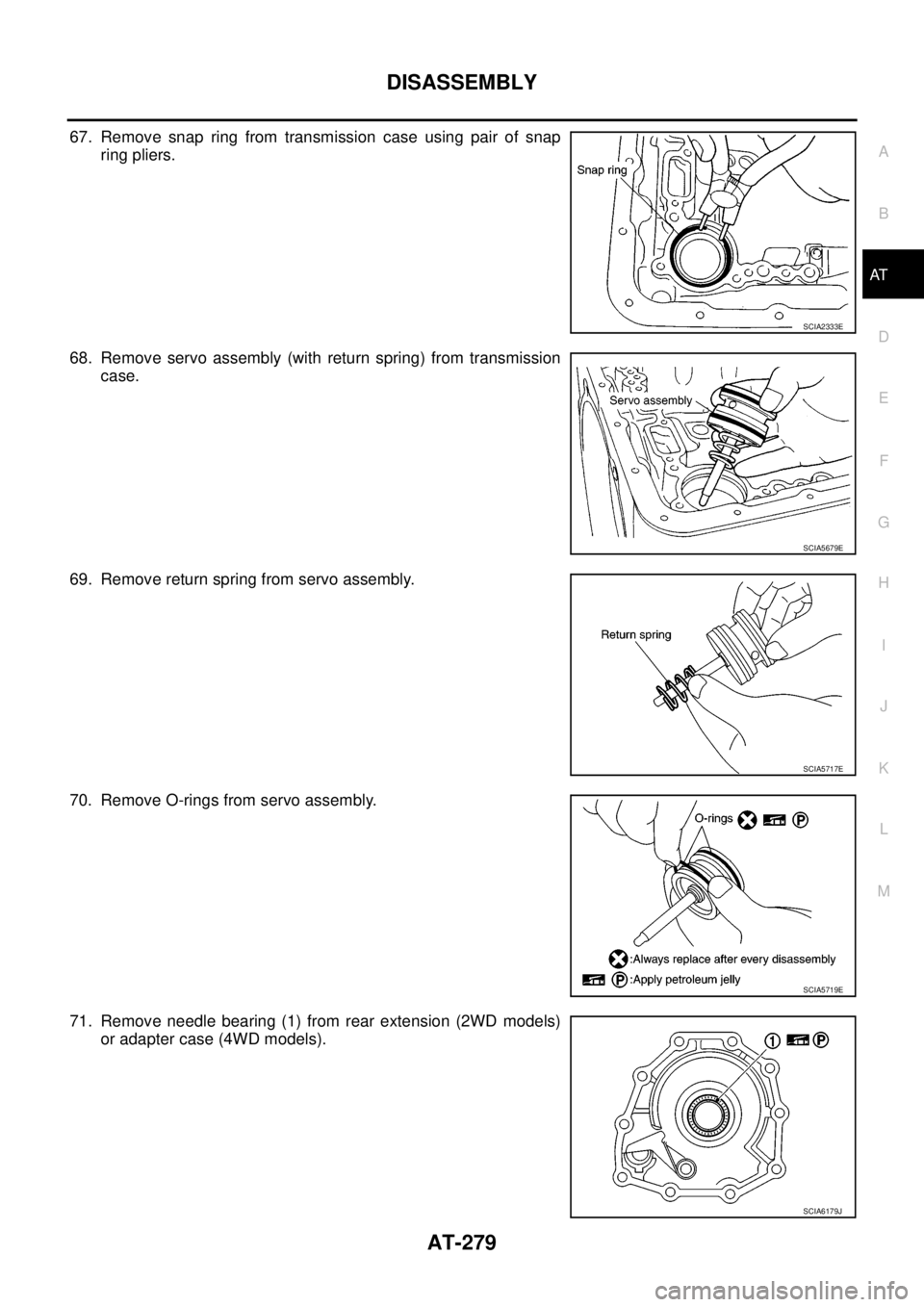

67. Remove snap ring from transmission case using pair of snap

ring pliers.

68. Remove servo assembly (with return spring) from transmission

case.

69. Remove return spring from servo assembly.

70. Remove O-rings from servo assembly.

71. Remove needle bearing (1) from rear extension (2WD models)

or adapter case (4WD models).

SCIA2333E

SCIA5679E

SCIA5717E

SCIA5719E

SCIA6179J

Page 288 of 3171

AT-280

DISASSEMBLY

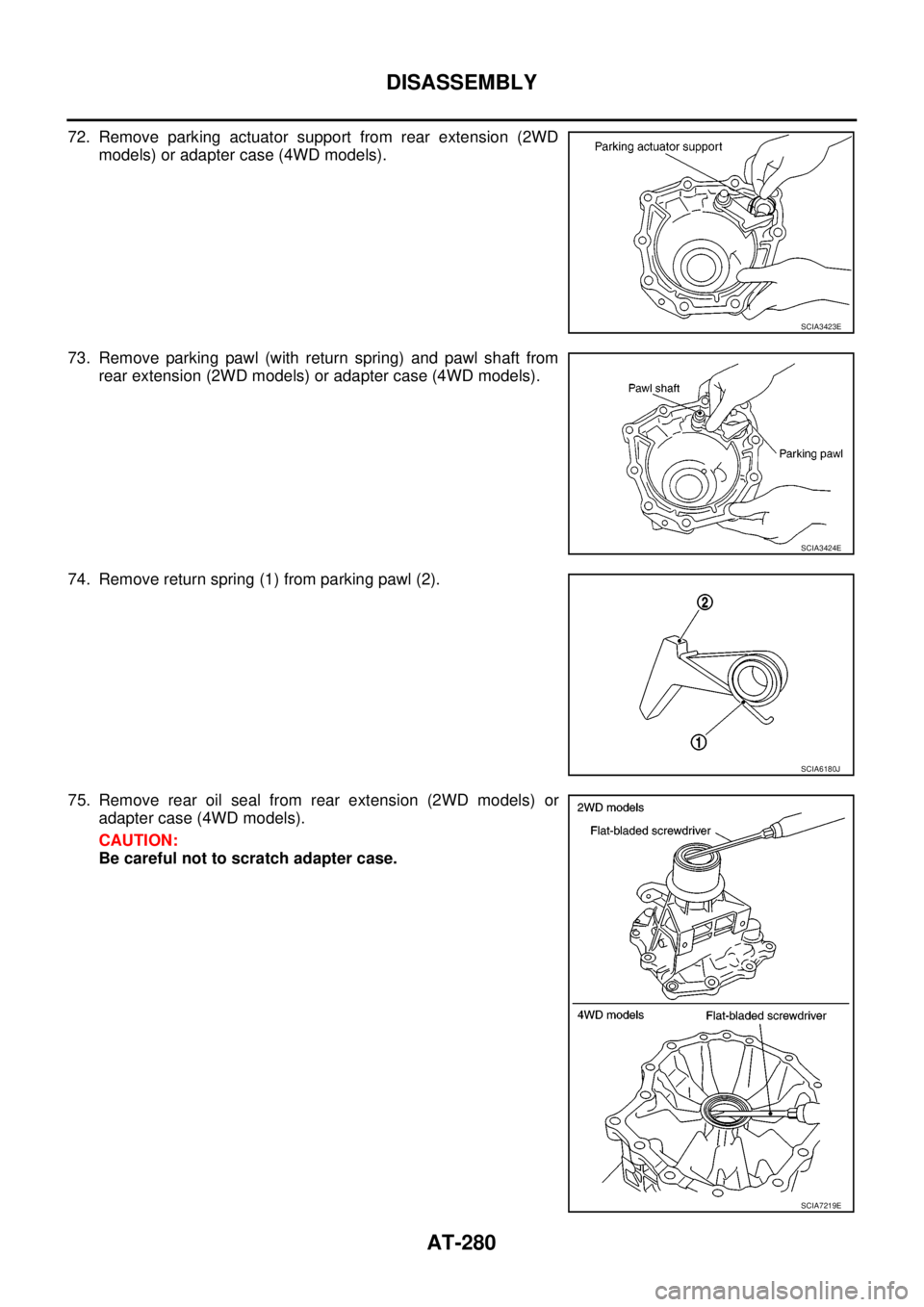

72. Remove parking actuator support from rear extension (2WD

models) or adapter case (4WD models).

73. Remove parking pawl (with return spring) and pawl shaft from

rear extension (2WD models) or adapter case (4WD models).

74. Remove return spring (1) from parking pawl (2).

75. Remove rear oil seal from rear extension (2WD models) or

adapter case (4WD models).

CAUTION:

Be careful not to scratch adapter case.

SCIA3423E

SCIA3424E

SCIA6180J

SCIA7219E

Page 313 of 3171

ASSEMBLY

AT-305

D

E

F

G

H

I

J

K

L

MA

B

AT

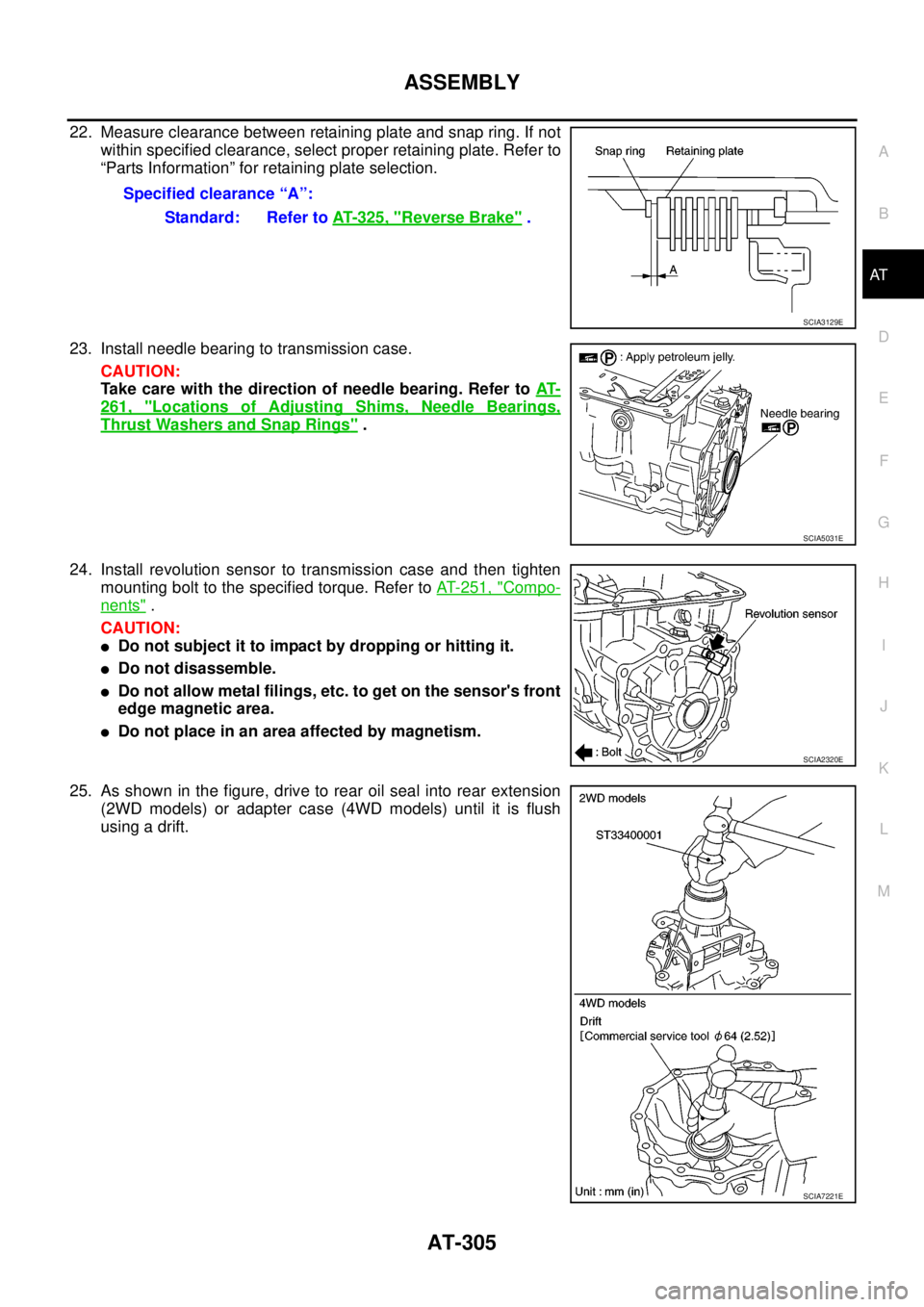

22. Measure clearance between retaining plate and snap ring. If not

within specified clearance, select proper retaining plate. Refer to

“Parts Information” for retaining plate selection.

23. Install needle bearing to transmission case.

CAUTION:

Take care with the direction of needle bearing. Refer toAT-

261, "Locations of Adjusting Shims, Needle Bearings,

Thrust Washers and Snap Rings".

24. Install revolution sensor to transmission case and then tighten

mounting bolt to the specified torque. Refer toAT- 2 5 1 , "

Compo-

nents".

CAUTION:

lDo not subject it to impact by dropping or hitting it.

lDo not disassemble.

lDo not allow metal filings, etc. to get on the sensor's front

edge magnetic area.

lDo not place in an area affected by magnetism.

25. As shown in the figure, drive to rear oil seal into rear extension

(2WD models) or adapter case (4WD models) until it is flush

usingadrift.Specified clearance “A”:

Standard: Refer toAT- 3 2 5 , "

Reverse Brake".

SCIA3129E

SCIA5031E

SCIA2320E

SCIA7221E

Page 314 of 3171

AT-306

ASSEMBLY

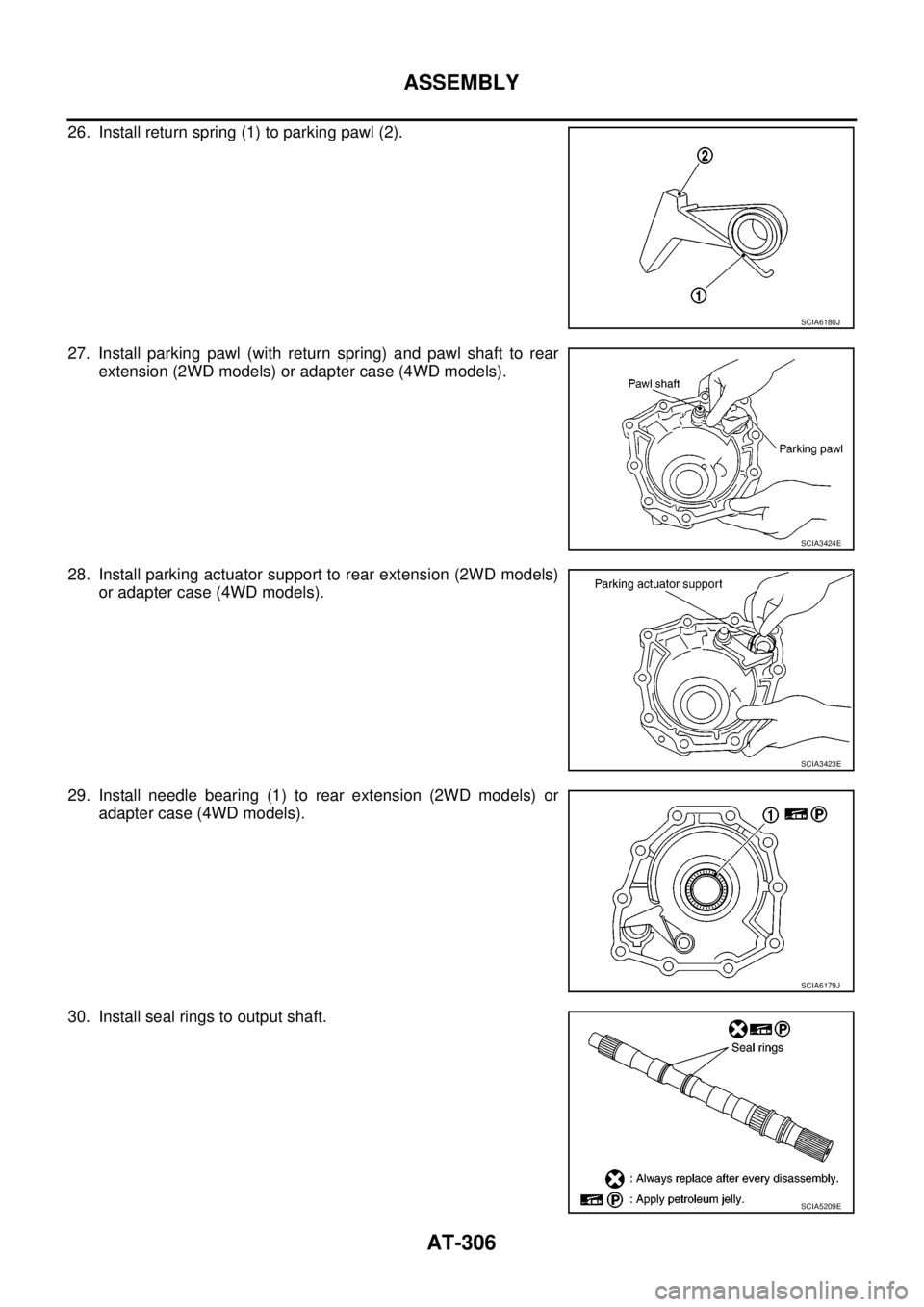

26. Install return spring (1) to parking pawl (2).

27. Install parking pawl (with return spring) and pawl shaft to rear

extension (2WD models) or adapter case (4WD models).

28. Install parking actuator support to rear extension (2WD models)

or adapter case (4WD models).

29. Install needle bearing (1) to rear extension (2WD models) or

adapter case (4WD models).

30. Install seal rings to output shaft.

SCIA6180J

SCIA3424E

SCIA3423E

SCIA6179J

SCIA5209E

Page 315 of 3171

ASSEMBLY

AT-307

D

E

F

G

H

I

J

K

L

MA

B

AT

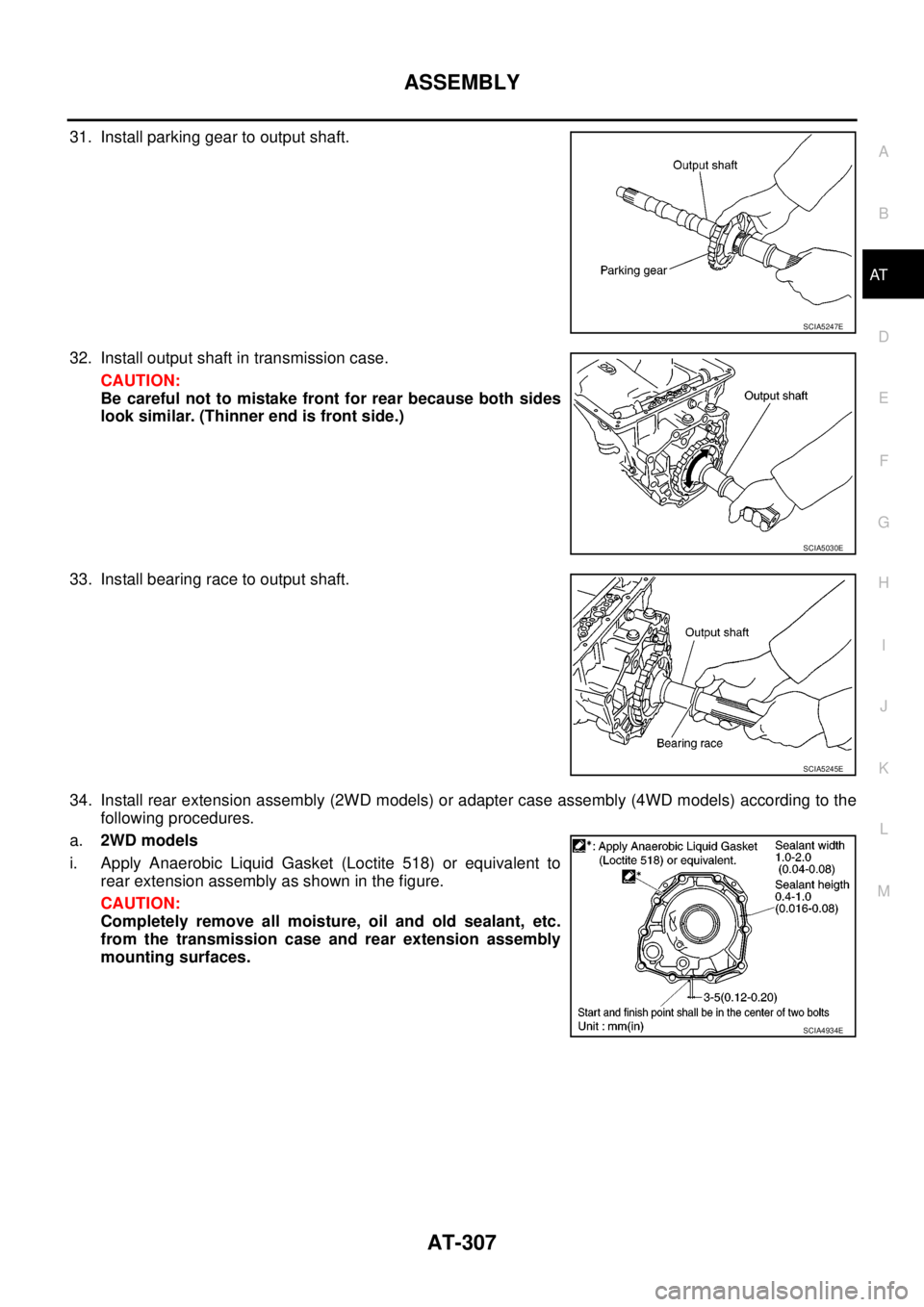

31. Install parking gear to output shaft.

32. Install output shaft in transmission case.

CAUTION:

Be careful not to mistake front for rear because both sides

look similar. (Thinner end is front side.)

33. Install bearing race to output shaft.

34. Install rear extension assembly (2WD models) or adapter case assembly (4WD models) according to the

following procedures.

a.2WD models

i. Apply Anaerobic Liquid Gasket (Loctite 518) or equivalent to

rear extension assembly as shown in the figure.

CAUTION:

Completely remove all moisture, oil and old sealant, etc.

from the transmission case and rear extension assembly

mounting surfaces.

SCIA5247E

SCIA5030E

SCIA5245E

SCIA4934E

Page 316 of 3171

AT-308

ASSEMBLY

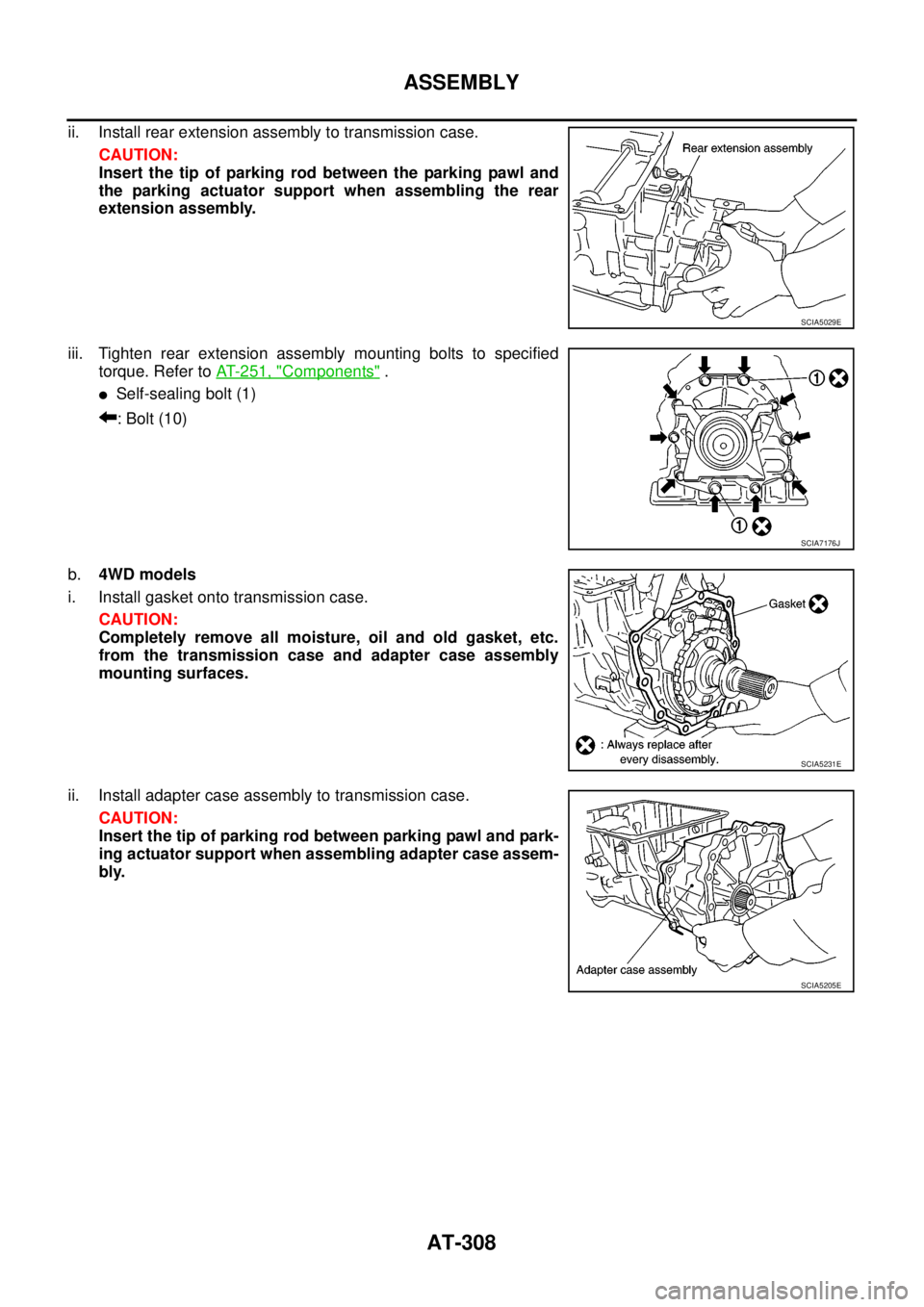

ii. Install rear extension assembly to transmission case.

CAUTION:

Insert the tip of parking rod between the parking pawl and

the parking actuator support when assembling the rear

extension assembly.

iii. Tighten rear extension assembly mounting bolts to specified

torque. Refer toAT- 2 5 1 , "

Components".

lSelf-sealing bolt (1)

:Bolt(10)

b.4WD models

i. Install gasket onto transmission case.

CAUTION:

Completely remove all moisture, oil and old gasket, etc.

from the transmission case and adapter case assembly

mounting surfaces.

ii. Install adapter case assembly to transmission case.

CAUTION:

Insert the tip of parking rod between parking pawl and park-

ing actuator support when assembling adapter case assem-

bly.

SCIA5029E

SCIA7176J

SCIA5231E

SCIA5205E

Page 331 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

AT-323

D

E

F

G

H

I

J

K

L

MA

B

AT

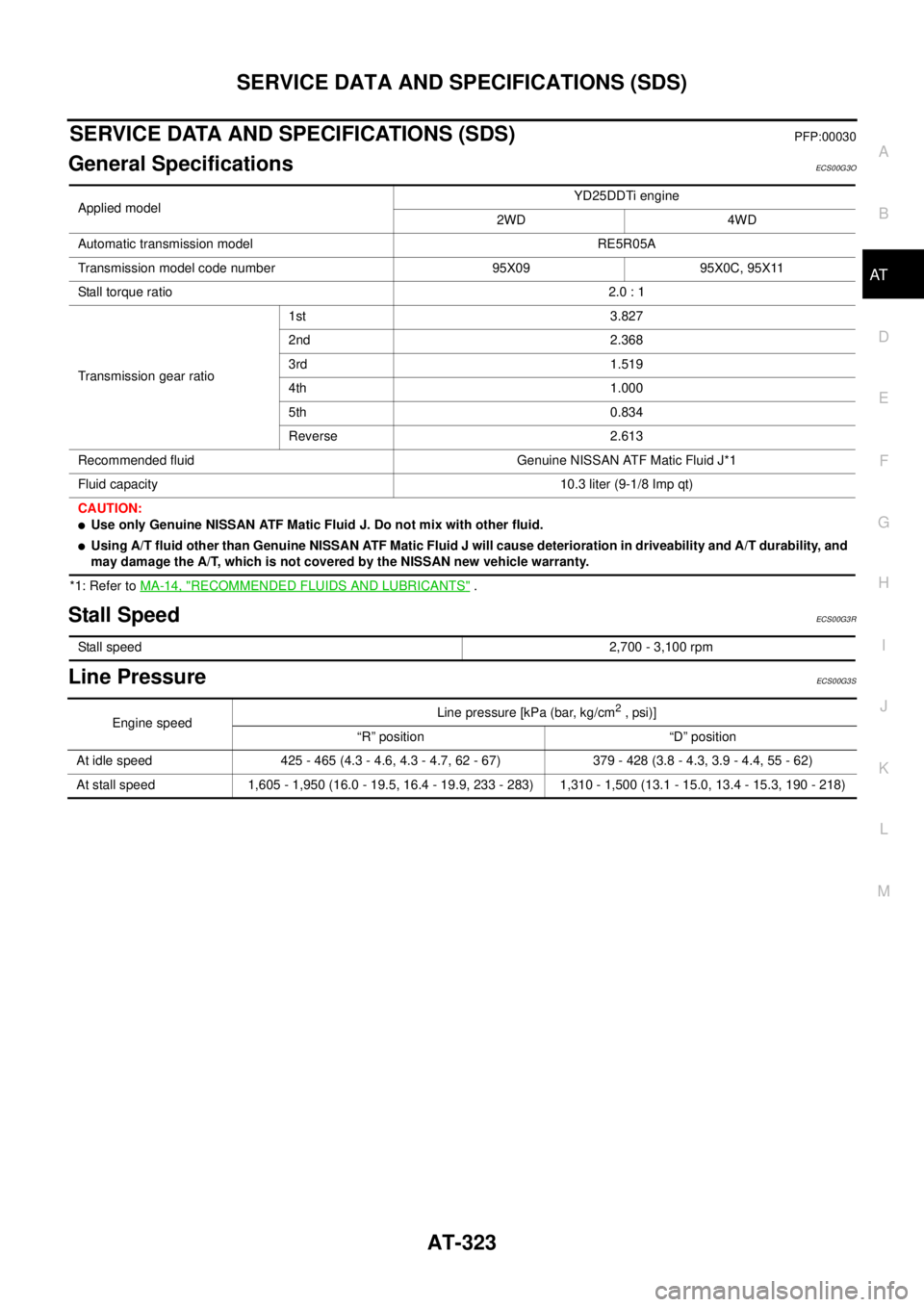

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

General SpecificationsECS00G3O

*1: Refer toMA-14, "RECOMMENDED FLUIDS AND LUBRICANTS".

Stall SpeedECS00G3R

Line PressureECS00G3S

Applied modelYD25DDTi engine

2WD 4WD

Automatic transmission model RE5R05A

Transmission model code number 95X09 95X0C, 95X11

Stall torque ratio2.0 : 1

Transmission gear ratio1st 3.827

2nd 2.368

3rd 1.519

4th 1.000

5th 0.834

Reverse 2.613

Recommended fluid Genuine NISSAN ATF Matic Fluid J*1

Fluid capacity 10.3 liter (9-1/8 Imp qt)

CAUTION:

lUse only Genuine NISSAN ATF Matic Fluid J. Do not mix with other fluid.

lUsing A/T fluid other than Genuine NISSAN ATF Matic Fluid J will cause deterioration in driveability and A/T durability, and

may damage the A/T, which is not covered by the NISSAN new vehicle warranty.

Stall speed2,700 - 3,100 rpm

Engine speedLine pressure [kPa (bar, kg/cm2,psi)]

“R” position “D” position

At idle speed 425 - 465 (4.3 - 4.6, 4.3 - 4.7, 62 - 67) 379 - 428 (3.8 - 4.3, 3.9 - 4.4, 55 - 62)

At stall speed 1,605 - 1,950 (16.0 - 19.5, 16.4 - 19.9, 233 - 283) 1,310 - 1,500 (13.1 - 15.0, 13.4 - 15.3, 190 - 218)

Page 332 of 3171

AT-324

SERVICE DATA AND SPECIFICATIONS (SDS)

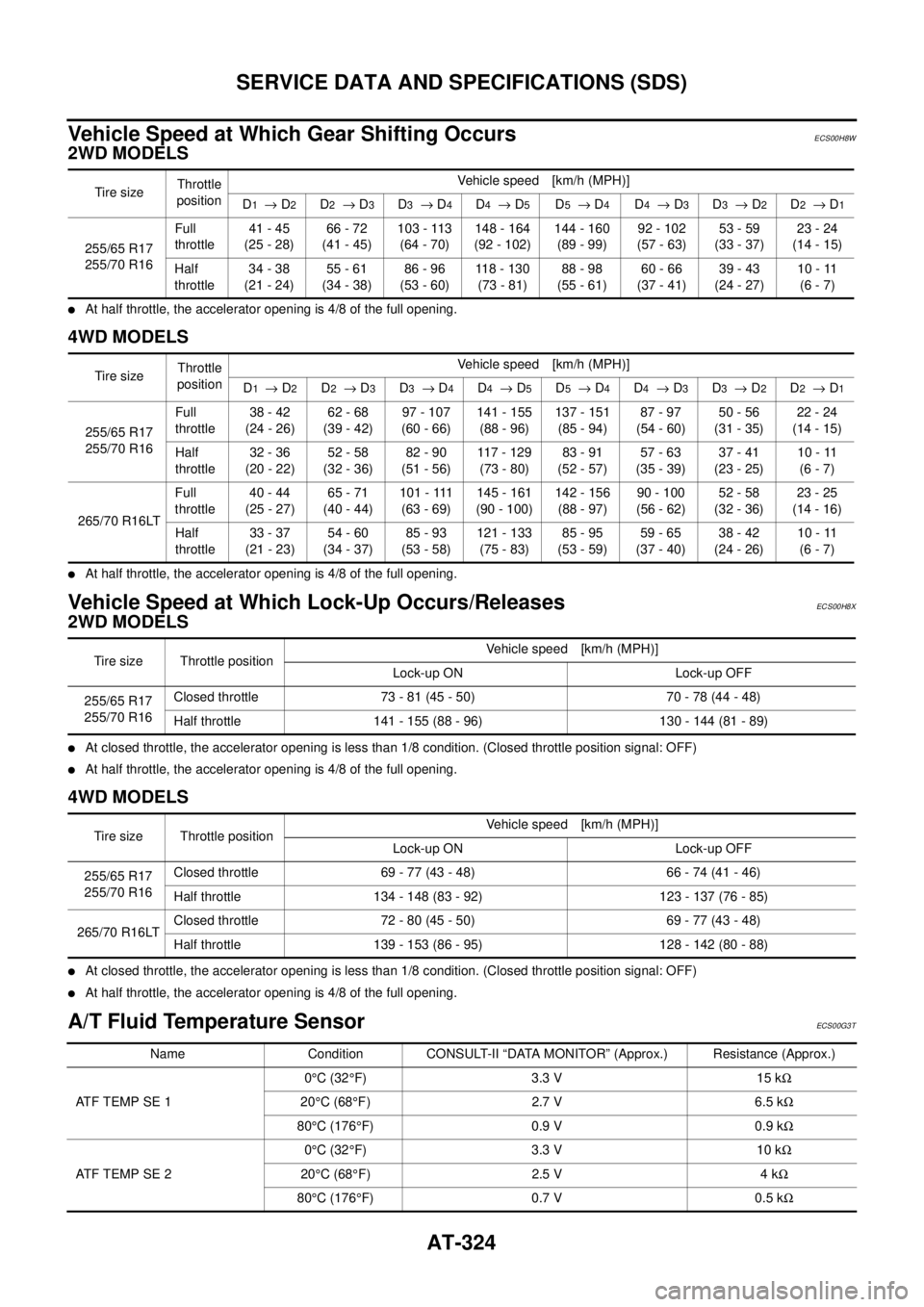

Vehicle Speed at Which Gear Shifting Occurs

ECS00H8W

2WD MODELS

lAt half throttle, the accelerator opening is 4/8 of the full opening.

4WD MODELS

lAt half throttle, the accelerator opening is 4/8 of the full opening.

Vehicle Speed at Which Lock-Up Occurs/ReleasesECS00H8X

2WD MODELS

lAt closed throttle, the accelerator opening is less than 1/8 condition. (Closed throttle position signal: OFF)

lAt half throttle, the accelerator opening is 4/8 of the full opening.

4WD MODELS

lAt closed throttle, the accelerator opening is less than 1/8 condition. (Closed throttle position signal: OFF)

lAt half throttle, the accelerator opening is 4/8 of the full opening.

A/T Fluid Temperature SensorECS00G3T

Tire sizeThrottle

positionVehicle speed [km/h (MPH)]

D1®D2D2®D3D3®D4D4®D5D5®D4D4®D3D3®D2D2®D1

255/65 R17

255/70 R16Full

throttle41 - 45

(25 - 28)66 - 72

(41 - 45)103 - 113

(64 - 70)148 - 164

(92 - 102)144 - 160

(89 - 99)92 - 102

(57 - 63)53 - 59

(33 - 37)23 - 24

(14 - 15)

Half

throttle34 - 38

(21 - 24)55 - 61

(34 - 38)86 - 96

(53 - 60)118 - 130

(73 - 81)88 - 98

(55 - 61)60 - 66

(37 - 41)39 - 43

(24 - 27)10 - 11

(6 - 7)

Tire sizeThrottle

positionVehiclespeed [km/h(MPH)]

D1®D2D2®D3D3®D4D4®D5D5®D4D4®D3D3®D2D2®D1

255/65 R17

255/70 R16Full

throttle38 - 42

(24 - 26)62 - 68

(39 - 42)97 - 107

(60 - 66)141 - 155

(88 - 96)137 - 151

(85 - 94)87 - 97

(54 - 60)50 - 56

(31 - 35)22 - 24

(14 - 15)

Half

throttle32 - 36

(20 - 22)52 - 58

(32 - 36)82 - 90

(51 - 56)117 - 129

(73 - 80)83 - 91

(52 - 57)57 - 63

(35 - 39)37 - 41

(23 - 25)10 - 11

(6 - 7)

265/70 R16LTFull

throttle40 - 44

(25 - 27)65 - 71

(40 - 44)101 - 111

(63 - 69)145 - 161

(90 - 100)142 - 156

(88 - 97)90 - 100

(56 - 62)52 - 58

(32 - 36)23 - 25

(14 - 16)

Half

throttle33 - 37

(21 - 23)54 - 60

(34 - 37)85 - 93

(53 - 58)121 - 133

(75 - 83)85 - 95

(53 - 59)59 - 65

(37 - 40)38 - 42

(24 - 26)10 - 11

(6 - 7)

Tire size Throttle positionVehicle speed [km/h (MPH)]

Lock-up ON Lock-up OFF

255/65 R17

255/70 R16Closed throttle 73 - 81 (45 - 50) 70 - 78 (44 - 48)

Half throttle 141 - 155 (88 - 96) 130 - 144 (81 - 89)

Tire size Throttle positionVehicle speed [km/h (MPH)]

Lock-up ON Lock-up OFF

255/65 R17

255/70 R16Closed throttle 69 - 77 (43 - 48) 66 - 74 (41 - 46)

Half throttle 134 - 148 (83 - 92) 123 - 137 (76 - 85)

265/70 R16LTClosed throttle 72 - 80 (45 - 50) 69 - 77 (43 - 48)

Half throttle 139 - 153 (86 - 95) 128 - 142 (80 - 88)

Name Condition CONSULT-II “DATA MONITOR” (Approx.) Resistance (Approx.)

ATFTEMPSE10°C(32°F) 3.3 V 15 kW

20°C(68°F) 2.7 V 6.5 kW

80°C(176°F) 0.9 V 0.9 kW

ATFTEMPSE20°C(32°F) 3.3 V 10 kW

20°C(68°F) 2.5V 4kW

80°C(176°F) 0.7 V 0.5 kW

Page 802 of 3171

BR-16

LOAD SENSING VALVE

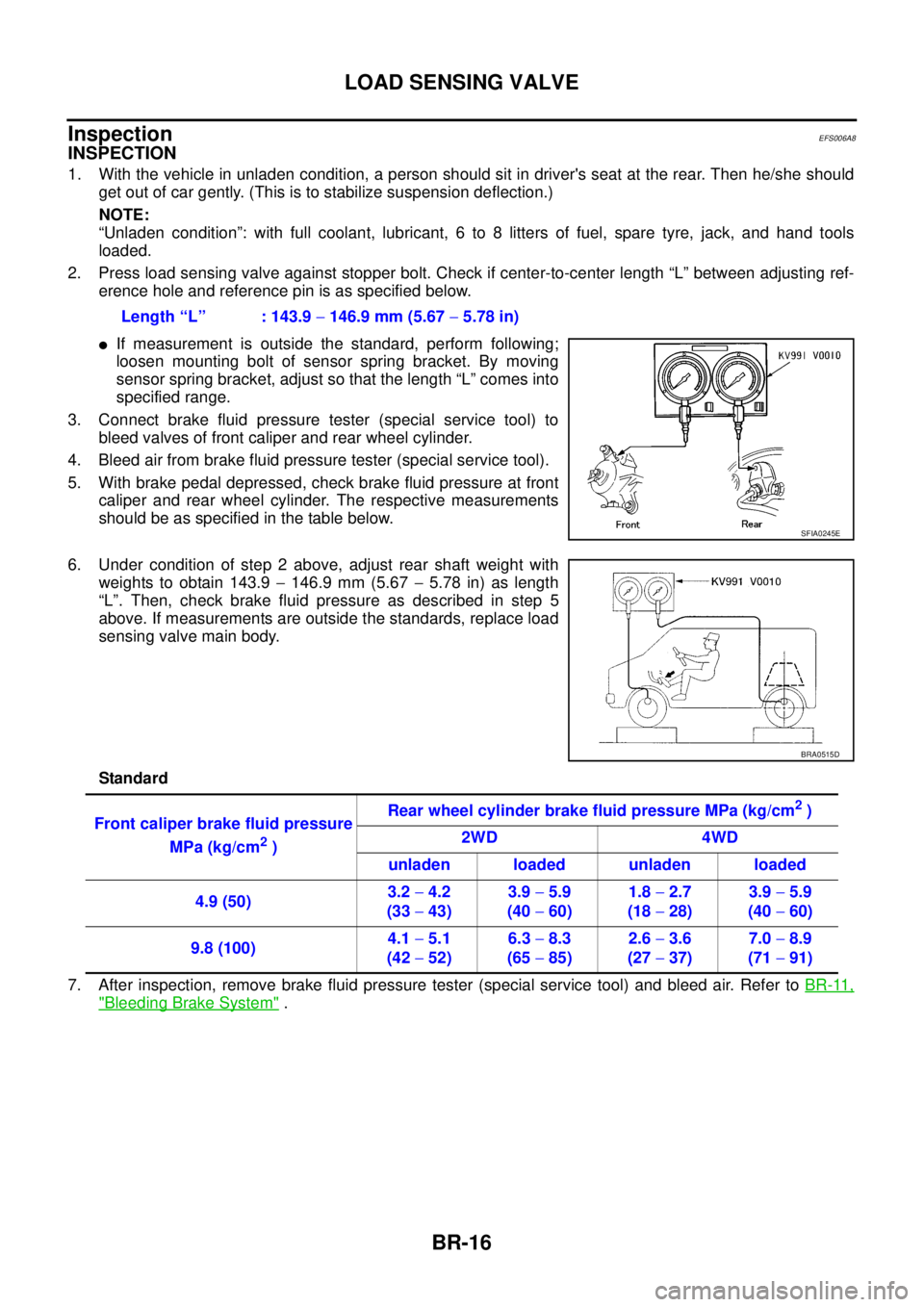

Inspection

EFS006A8

INSPECTION

1. With the vehicle in unladen condition, a person should sit in driver's seat at the rear. Then he/she should

get out of car gently. (This is to stabilize suspension deflection.)

NOTE:

“Unladen condition”: with full coolant, lubricant, 6 to 8 litters of fuel, spare tyre, jack, and hand tools

loaded.

2. Press load sensing valve against stopper bolt. Check if center-to-center length “L” between adjusting ref-

erence hole and reference pin is as specified below.

lIf measurement is outside the standard, perform following;

loosen mounting bolt of sensor spring bracket. By moving

sensor spring bracket, adjust so that the length “L” comes into

specified range.

3. Connect brake fluid pressure tester (special service tool) to

bleed valves of front caliper and rear wheel cylinder.

4. Bleed air from brake fluid pressure tester (special service tool).

5. With brake pedal depressed, check brake fluid pressure at front

caliper and rear wheel cylinder. The respective measurements

should be as specified in the table below.

6. Under condition of step 2 above, adjust rear shaft weight with

weights to obtain 143.9-146.9 mm (5.67-5.78 in) as length

“L”. Then, check brake fluid pressure as described in step 5

above. If measurements are outside the standards, replace load

sensing valve main body.

Standard

7. After inspection, remove brake fluid pressure tester (special service tool) and bleed air. Refer toBR-11,

"Bleeding Brake System". Length “L” : 143.9-146.9 mm (5.67-5.78 in)

SFIA0245E

BRA0515D

Front caliper brake fluid pressure

MPa (kg/cm

2)Rear wheel cylinder brake fluid pressure MPa (kg/cm

2)

2WD 4WD

unladen loaded unladen loaded

4.9 (50)3.2-4.2

(33-43)3.9-5.9

(40-60)1.8-2.7

(18-28)3.9-5.9

(40-60)

9.8 (100)4.1-5.1

(42-52)6.3-8.3

(65-85)2.6-3.6

(27-37)7.0-8.9

(71-91)

Page 907 of 3171

THERMOSTAT AND WATER PIPING

CO-23

C

D

E

F

G

H

I

J

K

L

MA

CO

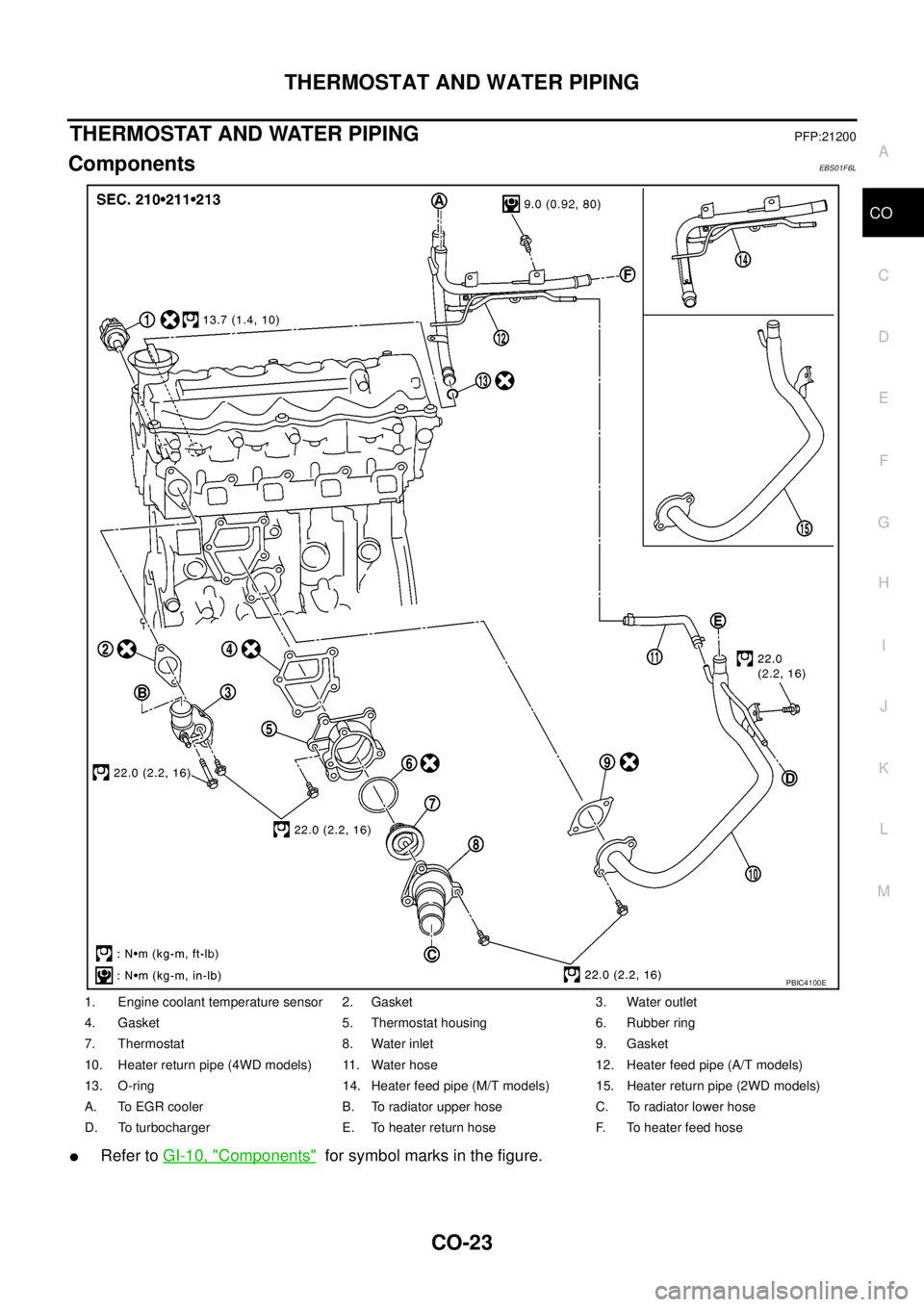

THERMOSTAT AND WATER PIPINGPFP:21200

ComponentsEBS01F6L

lRefer toGI-10, "Components"for symbol marks in the figure.

1. Engine coolant temperature sensor 2. Gasket 3. Water outlet

4. Gasket 5. Thermostat housing 6. Rubber ring

7. Thermostat 8. Water inlet 9. Gasket

10. Heater return pipe (4WD models) 11. Water hose 12. Heater feed pipe (A/T models)

13. O-ring 14. Heater feed pipe (M/T models) 15. Heater return pipe (2WD models)

A. To EGR cooler B. To radiator upper hose C. To radiator lower hose

D. To turbocharger E. To heater return hose F. To heater feed hose

PBIC4100E