NISSAN NAVARA 2005 Repair Workshop Manual

Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 3031 of 3171

TF-64

TROUBLE DIAGNOSIS FOR SYSTEM

DIAGNOSTIC PROCEDURE

1.CHECK WAIT DETECTION SWITCH SIGNAL

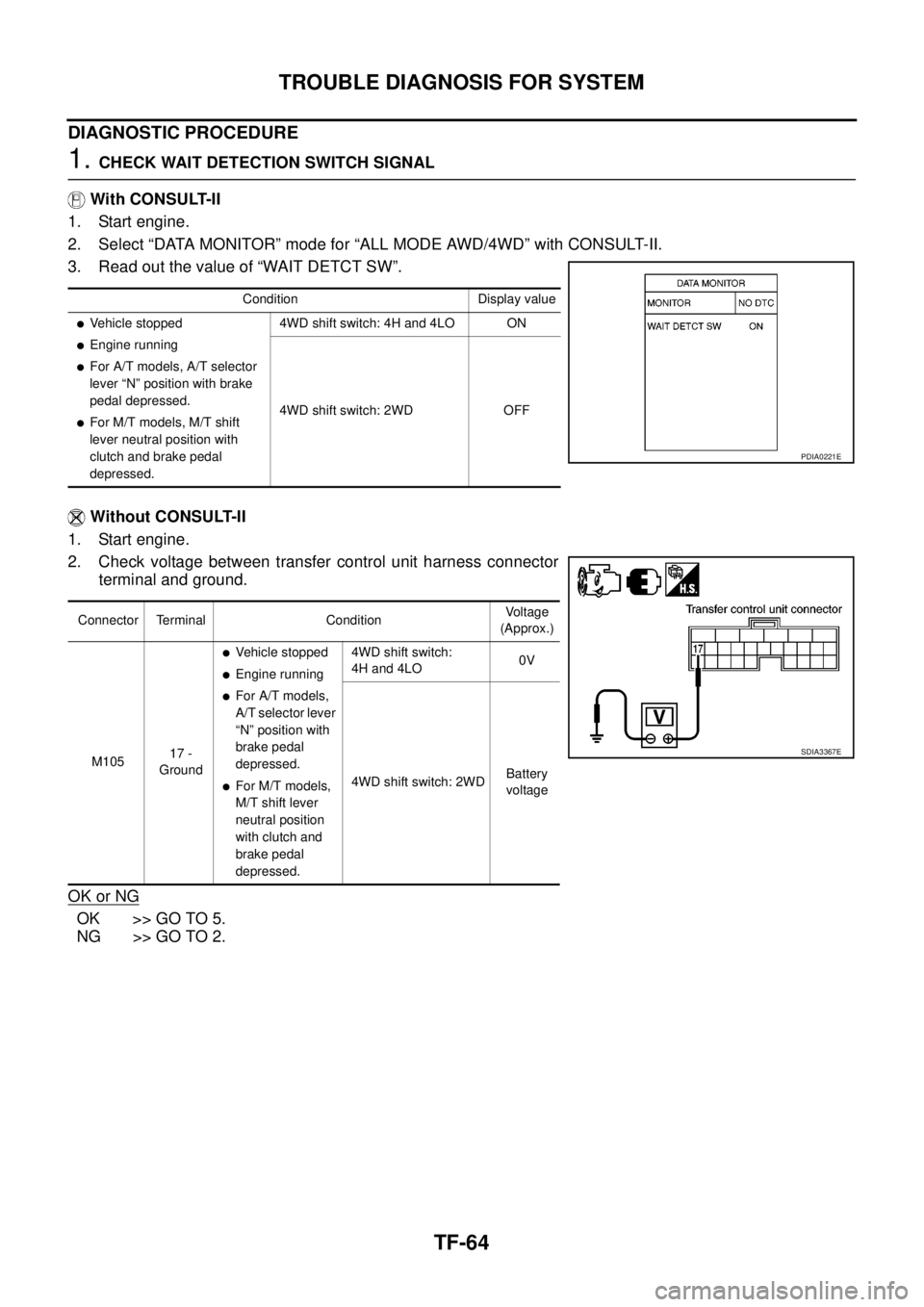

With CONSULT-II

1. Start engine.

2. Select “DATA MONITOR” mode for “ALL MODE AWD/4WD” with CONSULT-II.

3. Read out the value of “WAIT DETCT SW”.

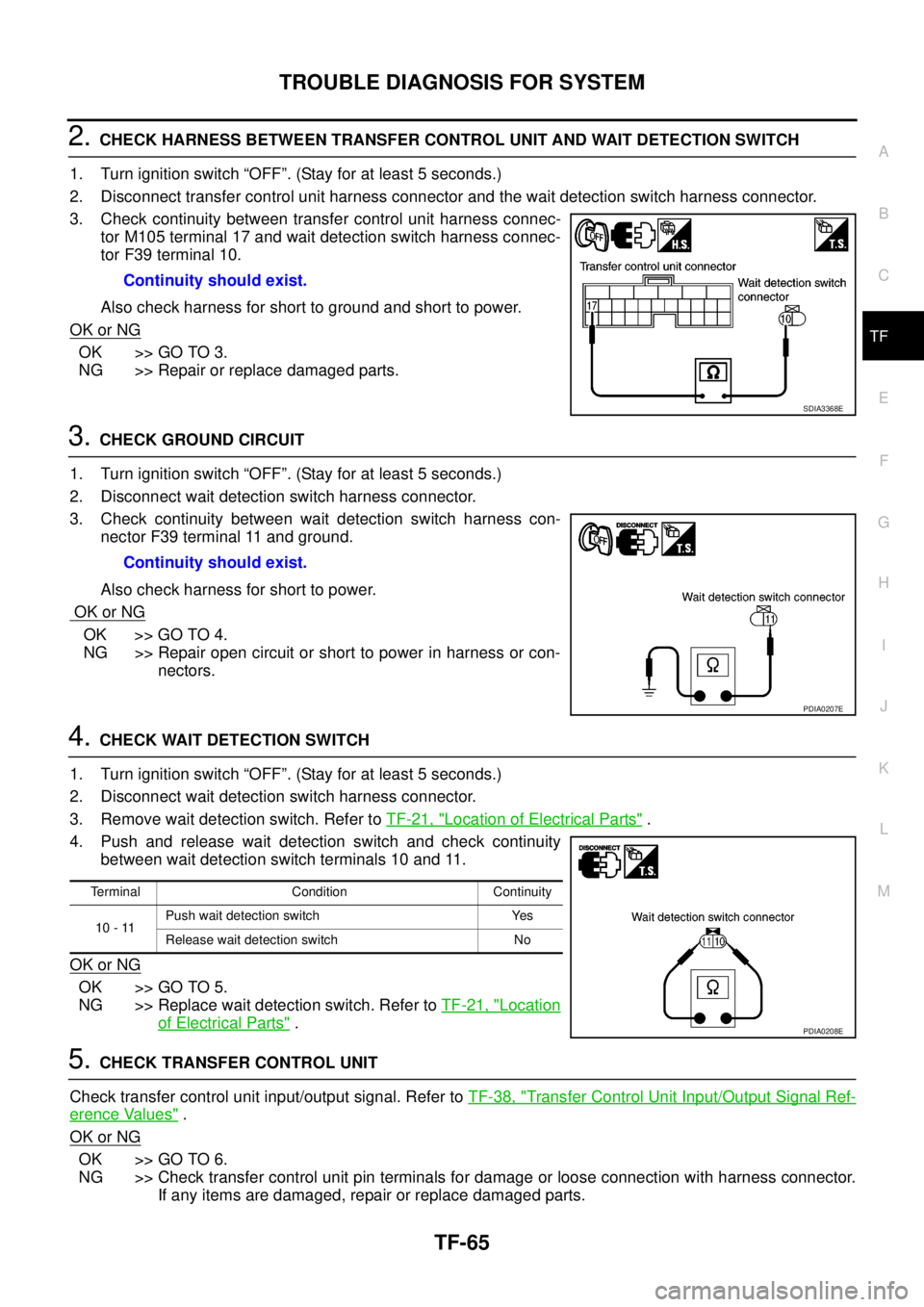

Without CONSULT-II

1. Start engine.

2. Check voltage between transfer control unit harness connector

terminal and ground.

OK or NG

OK >> GO TO 5.

NG >> GO TO 2.

Condition Display value

lVehicle stopped

lEngine running

lFor A/T models, A/T selector

lever “N” position with brake

pedal depressed.

lFor M/T models, M/T shift

lever neutral position with

clutch and brake pedal

depressed.4WD shift switch: 4H and 4LO ON

4WD shift switch: 2WD OFF

PDIA0221E

Connector Terminal ConditionVoltage

(Approx.)

M10517 -

Ground

lVehicle stopped

lEngine running

lFor A/T models,

A/T selector lever

“N” position with

brake pedal

depressed.

lFor M/T models,

M/T shift lever

neutral position

withclutchand

brake pedal

depressed.4WD shift switch:

4H and 4LO0V

4WD shift switch: 2WDBattery

voltage

SDIA3367E

Page 3032 of 3171

TROUBLE DIAGNOSIS FOR SYSTEM

TF-65

C

E

F

G

H

I

J

K

L

MA

B

TF

2.CHECK HARNESS BETWEEN TRANSFER CONTROL UNIT AND WAIT DETECTION SWITCH

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Disconnect transfer control unit harness connector and the wait detection switch harness connector.

3. Check continuity between transfer control unit harness connec-

tor M105 terminal 17 and wait detection switch harness connec-

tor F39 terminal 10.

Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3.CHECK GROUND CIRCUIT

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Disconnect wait detection switch harness connector.

3. Check continuity between wait detection switch harness con-

nector F39 terminal 11 and ground.

Also check harness for short to power.

OK or NG

OK >> GO TO 4.

NG >> Repair open circuit or short to power in harness or con-

nectors.

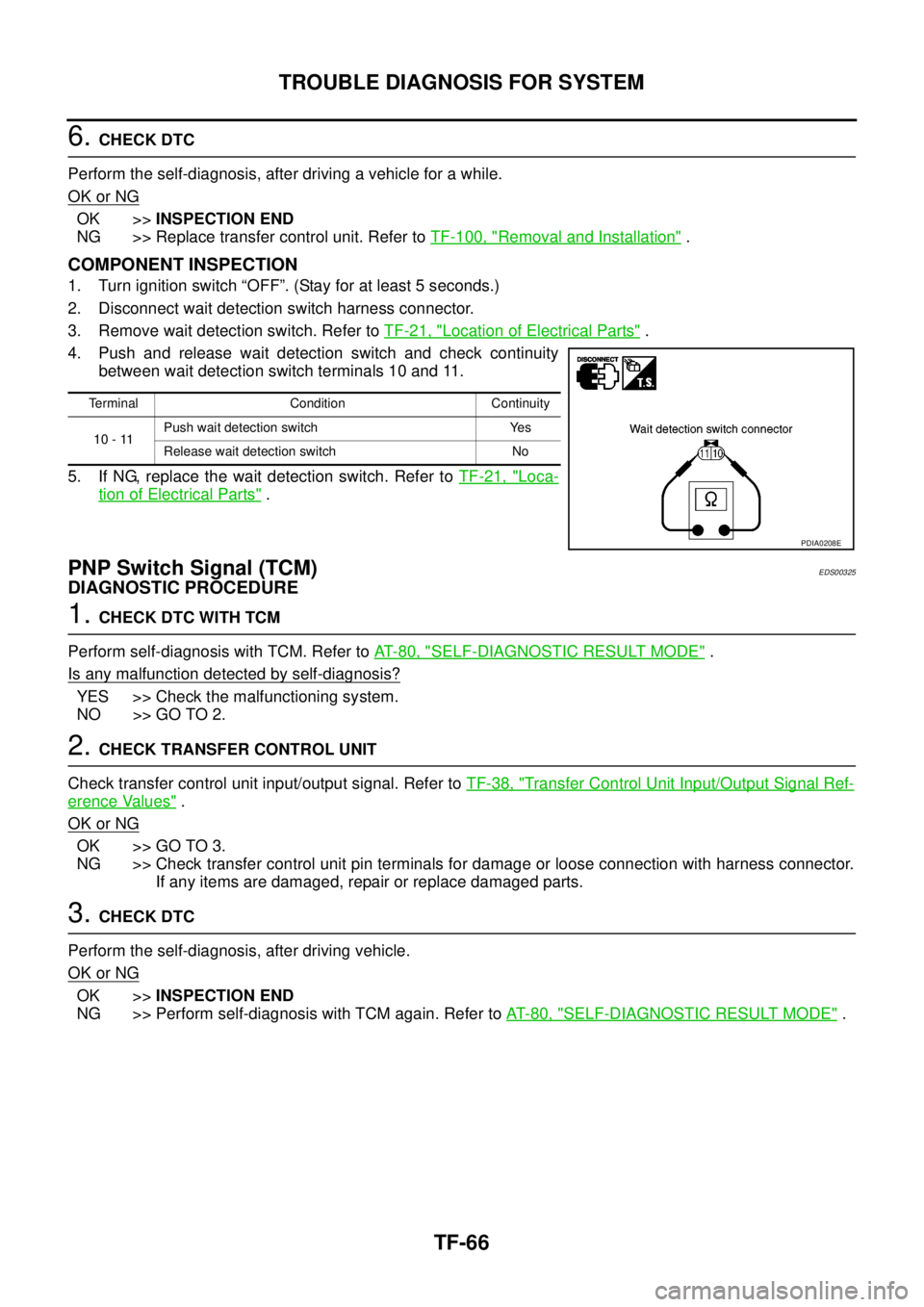

4.CHECK WAIT DETECTION SWITCH

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Disconnect wait detection switch harness connector.

3. Remove wait detection switch. Refer toTF-21, "

Location of Electrical Parts".

4. Push and release wait detection switch and check continuity

between wait detection switch terminals 10 and 11.

OK or NG

OK >> GO TO 5.

NG >> Replace wait detection switch. Refer toTF-21, "

Location

of Electrical Parts".

5.CHECK TRANSFER CONTROL UNIT

Check transfer control unit input/output signal. Refer toTF-38, "

Transfer Control Unit Input/Output Signal Ref-

erence Values".

OK or NG

OK >> GO TO 6.

NG >> Check transfer control unit pin terminals for damage or loose connection with harness connector.

If any items are damaged, repair or replace damaged parts. Continuity should exist.

SDIA3368E

Continuity should exist.

PDIA0207E

Terminal Condition Continuity

10 - 11Push wait detection switch Yes

Release wait detection switch No

PDIA0208E

Page 3033 of 3171

TF-66

TROUBLE DIAGNOSIS FOR SYSTEM

6.CHECK DTC

Perform the self-diagnosis, after driving a vehicle for a while.

OK or NG

OK >>INSPECTION END

NG >> Replace transfer control unit. Refer toTF-100, "

Removal and Installation".

COMPONENT INSPECTION

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Disconnect wait detection switch harness connector.

3. Remove wait detection switch. Refer toTF-21, "

Location of Electrical Parts".

4. Push and release wait detection switch and check continuity

between wait detection switch terminals 10 and 11.

5. If NG, replace the wait detection switch. Refer toTF-21, "

Loca-

tion of Electrical Parts".

PNP Switch Signal (TCM)EDS00325

DIAGNOSTIC PROCEDURE

1.CHECK DTC WITH TCM

Perform self-diagnosis with TCM. Refer toAT-80, "

SELF-DIAGNOSTIC RESULT MODE".

Is any malfunction detected by self-diagnosis?

YES >> Check the malfunctioning system.

NO >> GO TO 2.

2.CHECK TRANSFER CONTROL UNIT

Check transfer control unit input/output signal. Refer toTF-38, "

Transfer Control Unit Input/Output Signal Ref-

erence Values".

OK or NG

OK >> GO TO 3.

NG >> Check transfer control unit pin terminals for damage or loose connection with harness connector.

If any items are damaged, repair or replace damaged parts.

3.CHECK DTC

Perform the self-diagnosis, after driving vehicle.

OK or NG

OK >>INSPECTION END

NG >> Perform self-diagnosis with TCM again. Refer toAT-80, "

SELF-DIAGNOSTIC RESULT MODE".

Terminal Condition Continuity

10 - 11Push wait detection switch Yes

Release wait detection switch No

PDIA0208E

Page 3034 of 3171

TROUBLE DIAGNOSIS FOR SYSTEM

TF-67

C

E

F

G

H

I

J

K

L

MA

B

TF

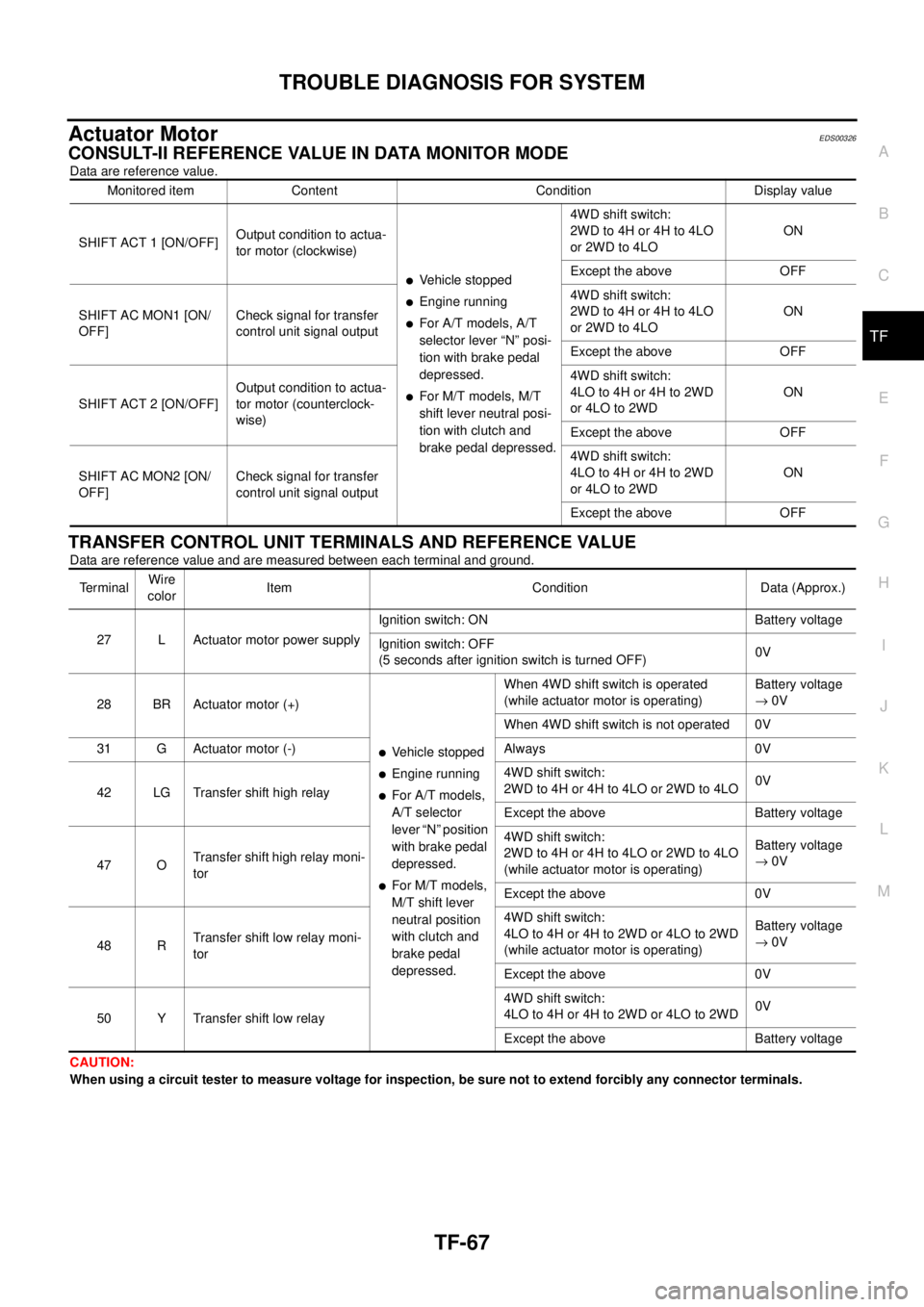

Actuator MotorEDS00326

CONSULT-II REFERENCE VALUE IN DATA MONITOR MODE

Data are reference value.

TRANSFER CONTROL UNIT TERMINALS AND REFERENCE VALUE

Data are reference value and are measured between each terminal and ground.

CAUTION:

When using a circuit tester to measure voltage for inspection, be sure not to extend forcibly any connector terminals.Monitored item Content Condition Display value

SHIFT ACT 1 [ON/OFF]Output condition to actua-

tor motor (clockwise)

lVehicle stopped

lEngine running

lFor A/T models, A/T

selector lever “N” posi-

tion with brake pedal

depressed.

lFor M/T models, M/T

shift lever neutral posi-

tion with clutch and

brake pedal depressed.4WD shift switch:

2WDto4Hor4Hto4LO

or 2WD to 4LOON

Except the above OFF

SHIFT AC MON1 [ON/

OFF]Check signal for transfer

control unit signal output4WD shift switch:

2WDto4Hor4Hto4LO

or 2WD to 4LOON

Except the above OFF

SHIFT ACT 2 [ON/OFF]Output condition to actua-

tor motor (counterclock-

wise)4WD shift switch:

4LO to 4H or 4H to 2WD

or 4LO to 2WDON

Except the above OFF

SHIFT AC MON2 [ON/

OFF]Check signal for transfer

control unit signal output4WD shift switch:

4LO to 4H or 4H to 2WD

or 4LO to 2WDON

Except the above OFF

TerminalWire

colorItem Condition Data (Approx.)

27 L Actuator motor power supplyIgnition switch: ON Battery voltage

Ignition switch: OFF

(5 seconds after ignition switch is turned OFF)0V

28 BR Actuator motor (+)

lVehicle stopped

lEngine running

lFor A/T models,

A/T selector

lever “N” position

with brake pedal

depressed.

lFor M/T models,

M/T shift lever

neutral position

with clutch and

brake pedal

depressed.When 4WD shift switch is operated

(while actuator motor is operating)Battery voltage

®0V

When 4WD shift switch is not operated 0V

31 G Actuator motor (-) Always 0V

42 LG Transfer shift high relay4WD shift switch:

2WD to 4H or 4H to 4LO or 2WD to 4LO0V

Except the above Battery voltage

47 OTransfer shift high relay moni-

tor4WD shift switch:

2WD to 4H or 4H to 4LO or 2WD to 4LO

(while actuator motor is operating)Battery voltage

®0V

Except the above 0V

48 RTransfer shift low relay moni-

tor4WD shift switch:

4LO to 4H or 4H to 2WD or 4LO to 2WD

(while actuator motor is operating)Battery voltage

®0V

Except the above 0V

50 Y Transfer shift low relay4WD shift switch:

4LO to 4H or 4H to 2WD or 4LO to 2WD0V

Except the above Battery voltage

Page 3035 of 3171

TF-68

TROUBLE DIAGNOSIS FOR SYSTEM

DIAGNOSTIC PROCEDURE

1.CHECK ACTUATOR MOTOR SIGNAL

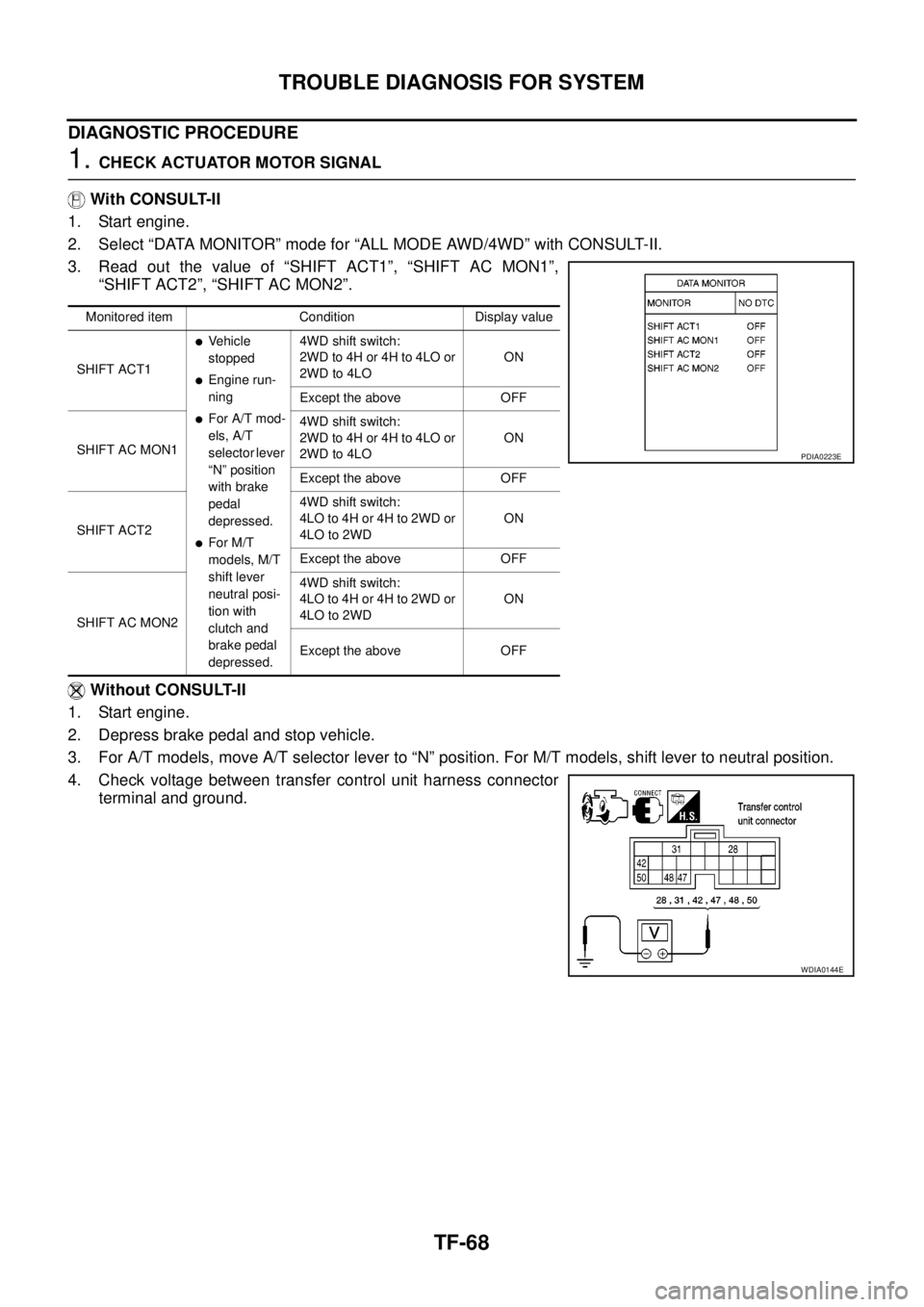

With CONSULT-II

1. Start engine.

2. Select “DATA MONITOR” mode for “ALL MODE AWD/4WD” with CONSULT-II.

3. Read out the value of “SHIFT ACT1”, “SHIFT AC MON1”,

“SHIFT ACT2”, “SHIFT AC MON2”.

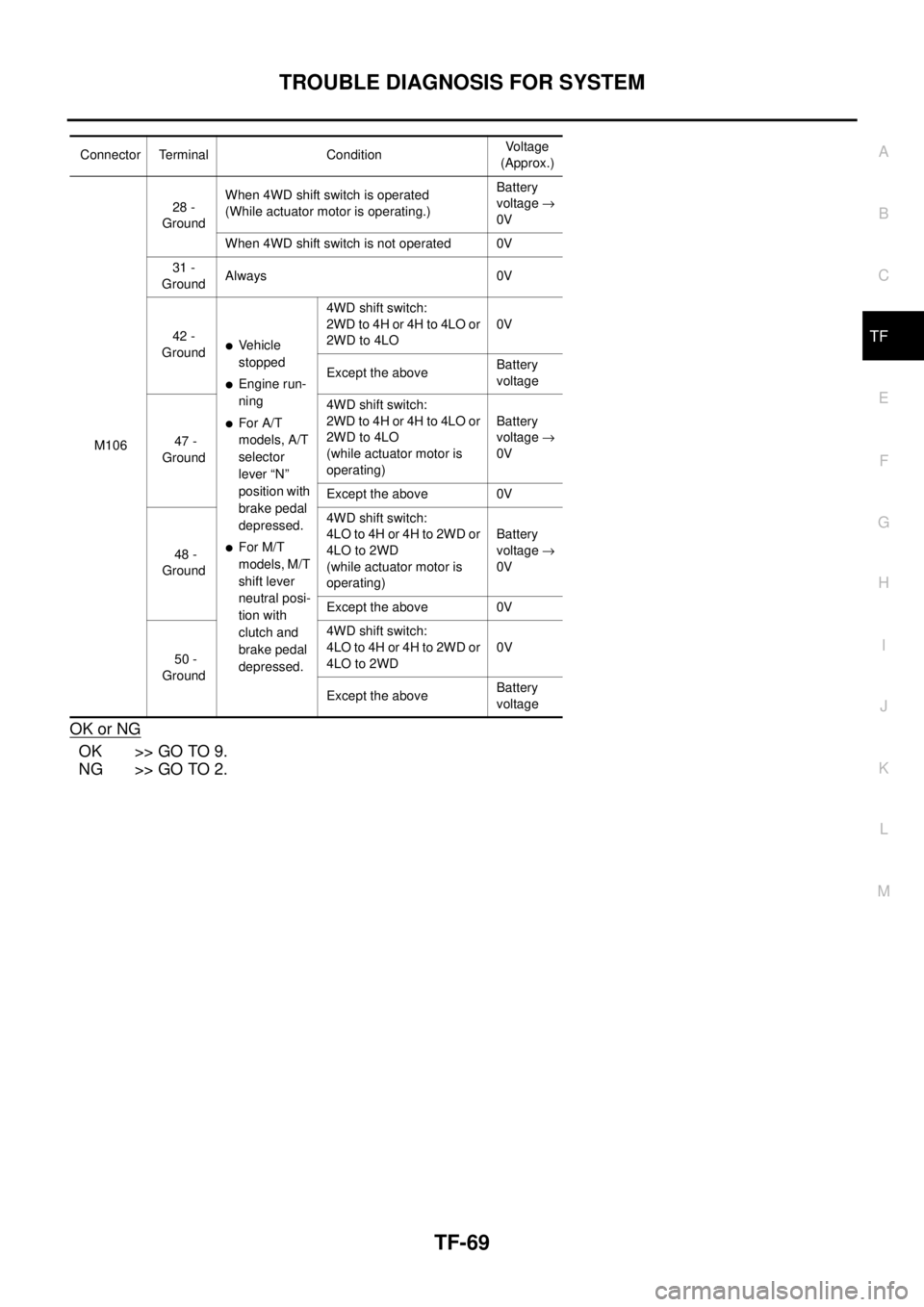

Without CONSULT-II

1. Start engine.

2. Depress brake pedal and stop vehicle.

3. For A/T models, move A/T selector lever to “N” position. For M/T models, shift lever to neutral position.

4. Check voltage between transfer control unit harness connector

terminal and ground.

Monitored item Condition Display value

SHIFT ACT1

lVehicle

stopped

lEngine run-

ning

lFor A/T mod-

els, A/T

selector lever

“N” position

with brake

pedal

depressed.

lFor M/T

models, M/T

shift lever

neutral posi-

tion with

clutch and

brake pedal

depressed.4WD shift switch:

2WD to 4H or 4H to 4LO or

2WD to 4LOON

Except the above OFF

SHIFT AC MON14WD shift switch:

2WD to 4H or 4H to 4LO or

2WD to 4LOON

Except the above OFF

SHIFT ACT24WD shift switch:

4LOto4Hor4Hto2WDor

4LO to 2WDON

Except the above OFF

SHIFT AC MON24WD shift switch:

4LOto4Hor4Hto2WDor

4LO to 2WDON

Except the above OFF

PDIA0223E

WDIA0144E

Page 3036 of 3171

TROUBLE DIAGNOSIS FOR SYSTEM

TF-69

C

E

F

G

H

I

J

K

L

MA

B

TF

OK or NG

OK >> GO TO 9.

NG >> GO TO 2.

Connector Terminal ConditionVoltage

(Approx.)

M10628 -

GroundWhen 4WD shift switch is operated

(While actuator motor is operating.)Battery

voltage®

0V

When 4WD shift switch is not operated 0V

31 -

GroundAlways 0V

42 -

Ground

lVe h ic le

stopped

lEngine run-

ning

lFor A/T

models, A/T

selector

lever “N”

position with

brake pedal

depressed.

lFor M/T

models, M/T

shift lever

neutral posi-

tion with

clutch and

brake pedal

depressed.4WD shift switch:

2WDto4Hor4Hto4LOor

2WD to 4LO0V

Except the aboveBattery

voltage

47 -

Ground4WD shift switch:

2WDto4Hor4Hto4LOor

2WD to 4LO

(while actuator motor is

operating)Battery

voltage®

0V

Except the above 0V

48 -

Ground4WD shift switch:

4LO to 4H or 4H to 2WD or

4LO to 2WD

(while actuator motor is

operating)Battery

voltage®

0V

Except the above 0V

50 -

Ground4WD shift switch:

4LO to 4H or 4H to 2WD or

4LO to 2WD0V

Except the aboveBattery

voltage

Page 3037 of 3171

TF-70

TROUBLE DIAGNOSIS FOR SYSTEM

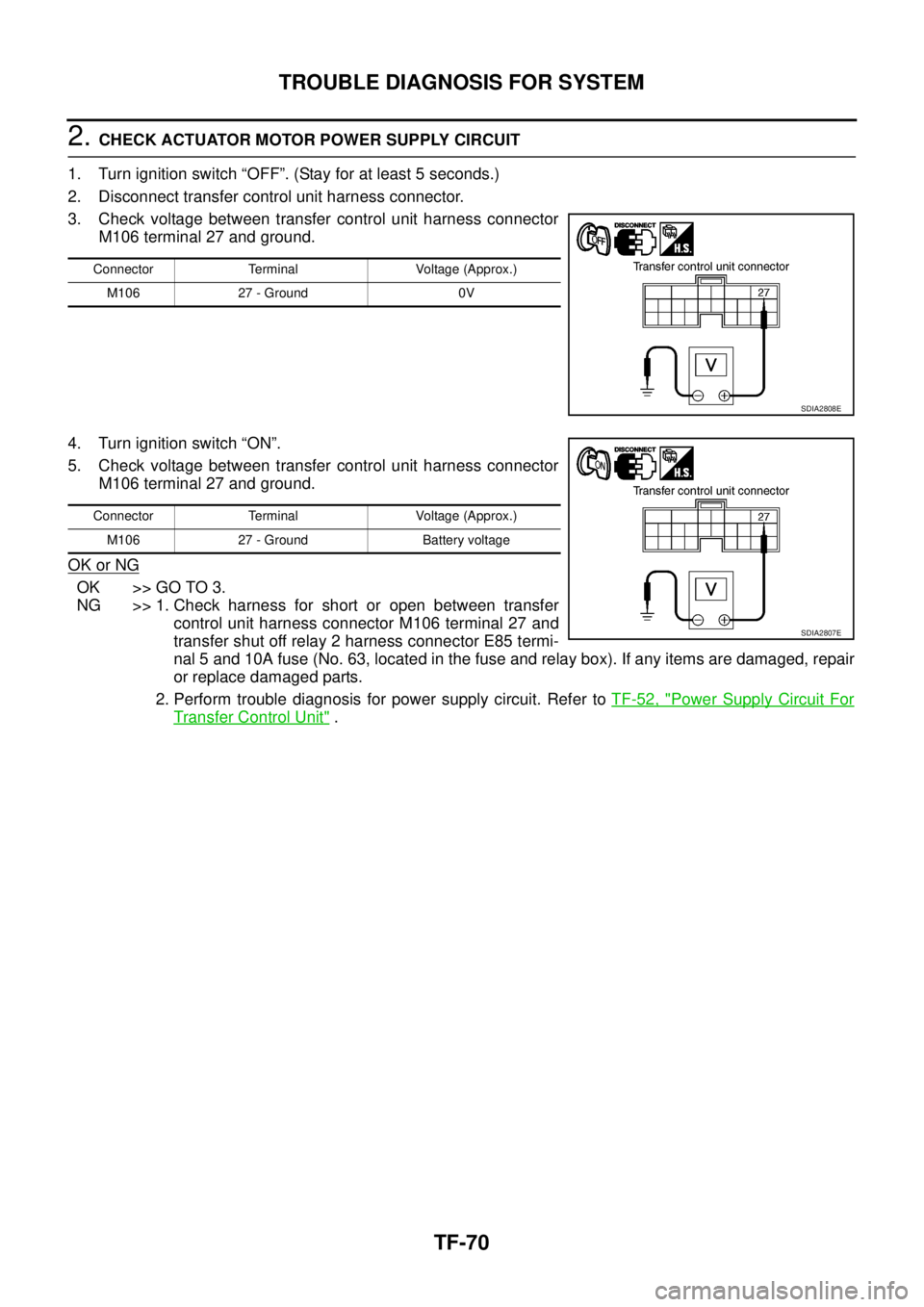

2.CHECK ACTUATOR MOTOR POWER SUPPLY CIRCUIT

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Disconnect transfer control unit harness connector.

3. Check voltage between transfer control unit harness connector

M106 terminal 27 and ground.

4. Turn ignition switch “ON”.

5. Check voltage between transfer control unit harness connector

M106 terminal 27 and ground.

OK or NG

OK >> GO TO 3.

NG >> 1. Check harness for short or open between transfer

control unit harness connector M106 terminal 27 and

transfer shut off relay 2 harness connector E85 termi-

nal 5 and 10A fuse (No. 63, located in the fuse and relay box). If any items are damaged, repair

or replace damaged parts.

2. Perform trouble diagnosis for power supply circuit. Refer toTF-52, "

Power Supply Circuit For

Transfer Control Unit".

Connector Terminal Voltage (Approx.)

M106 27 - Ground 0V

SDIA2808E

Connector Terminal Voltage (Approx.)

M106 27 - Ground Battery voltage

SDIA2807E

Page 3038 of 3171

TROUBLE DIAGNOSIS FOR SYSTEM

TF-71

C

E

F

G

H

I

J

K

L

MA

B

TF

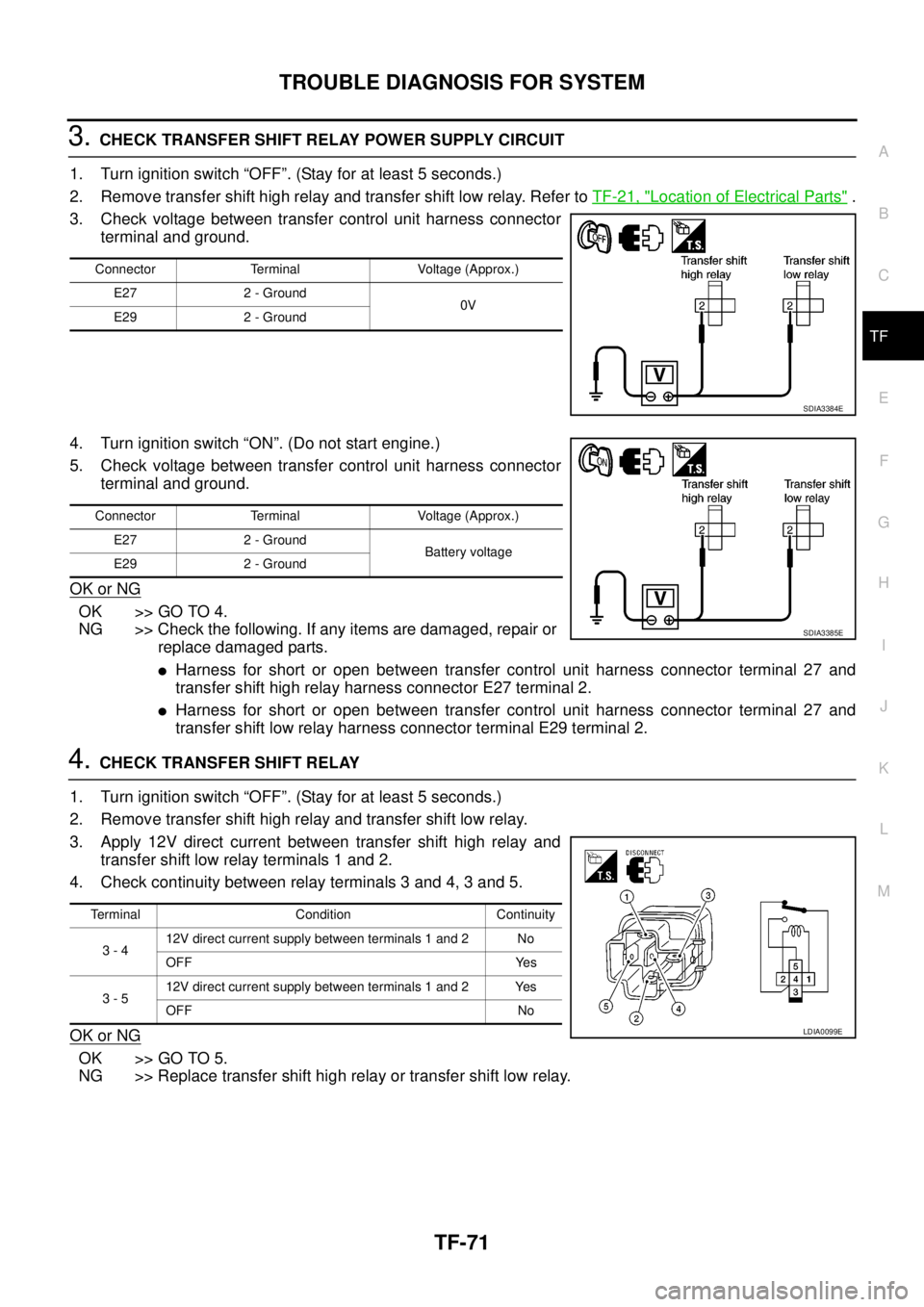

3.CHECK TRANSFER SHIFT RELAY POWER SUPPLY CIRCUIT

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Remove transfer shift high relay and transfer shift low relay. Refer toTF-21, "

Location of Electrical Parts".

3. Check voltage between transfer control unit harness connector

terminal and ground.

4. Turn ignition switch “ON”. (Do not start engine.)

5. Check voltage between transfer control unit harness connector

terminal and ground.

OK or NG

OK >> GO TO 4.

NG >> Check the following. If any items are damaged, repair or

replace damaged parts.

lHarness for short or open between transfer control unit harness connector terminal 27 and

transfer shift high relay harness connector E27 terminal 2.

lHarness for short or open between transfer control unit harness connector terminal 27 and

transfer shift low relay harness connector terminal E29 terminal 2.

4.CHECK TRANSFER SHIFT RELAY

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Remove transfer shift high relay and transfer shift low relay.

3. Apply 12V direct current between transfer shift high relay and

transfer shift low relay terminals 1 and 2.

4. Check continuity between relay terminals 3 and 4, 3 and 5.

OK or NG

OK >> GO TO 5.

NG >> Replace transfer shift high relay or transfer shift low relay.

Connector Terminal Voltage (Approx.)

E27 2 - Ground

0V

E29 2 - Ground

SDIA3384E

Connector Terminal Voltage (Approx.)

E27 2 - Ground

Battery voltage

E29 2 - Ground

SDIA3385E

Terminal Condition Continuity

3-412V direct current supply between terminals 1 and 2 No

OFF Yes

3-512V direct current supply between terminals 1 and 2 Yes

OFF No

LDIA0099E

Page 3039 of 3171

TF-72

TROUBLE DIAGNOSIS FOR SYSTEM

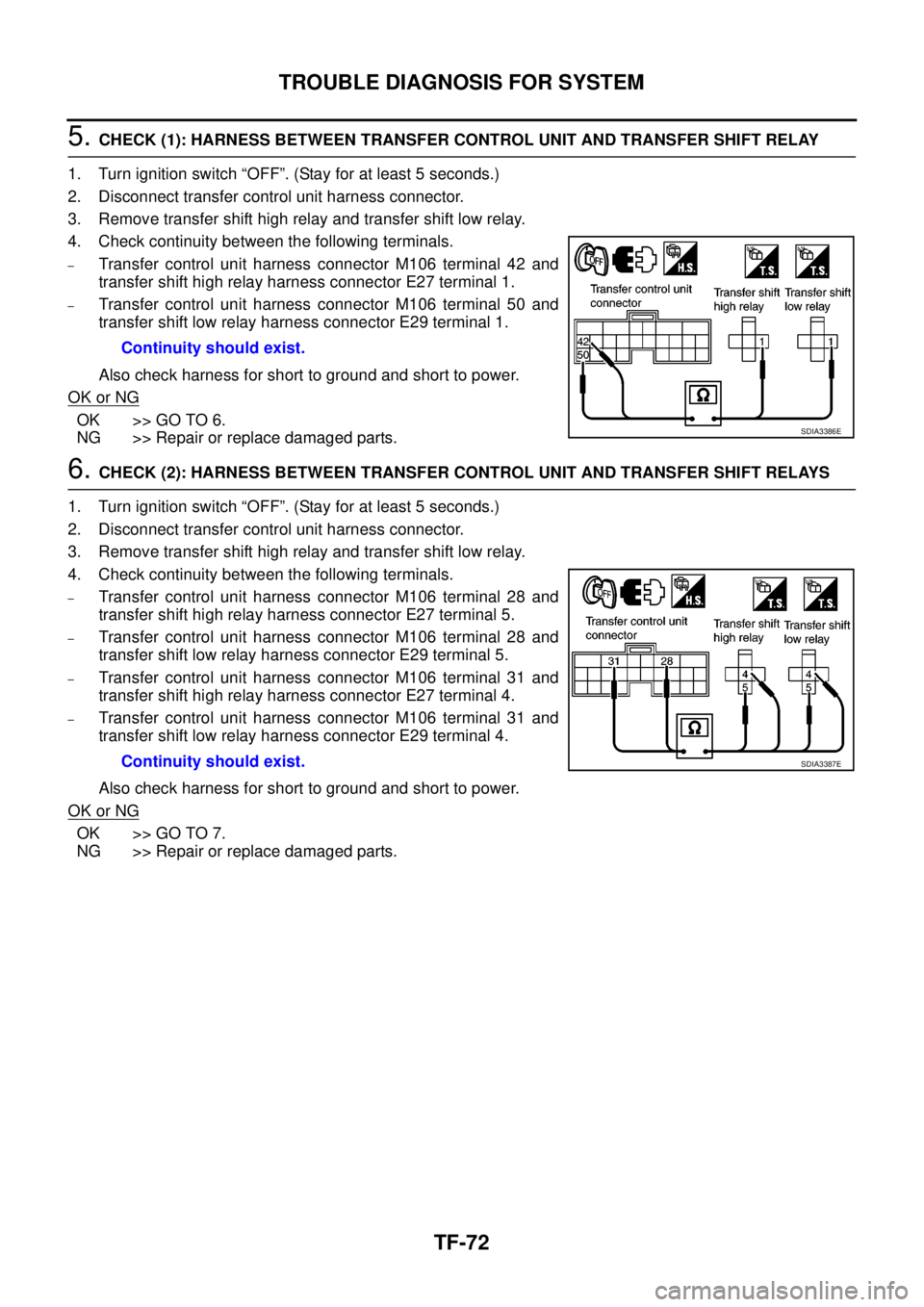

5.CHECK (1): HARNESS BETWEEN TRANSFER CONTROL UNIT AND TRANSFER SHIFT RELAY

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Disconnect transfer control unit harness connector.

3. Remove transfer shift high relay and transfer shift low relay.

4. Check continuity between the following terminals.

–Transfer control unit harness connector M106 terminal 42 and

transfer shift high relay harness connector E27 terminal 1.

–Transfer control unit harness connector M106 terminal 50 and

transfer shift low relay harness connector E29 terminal 1.

Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

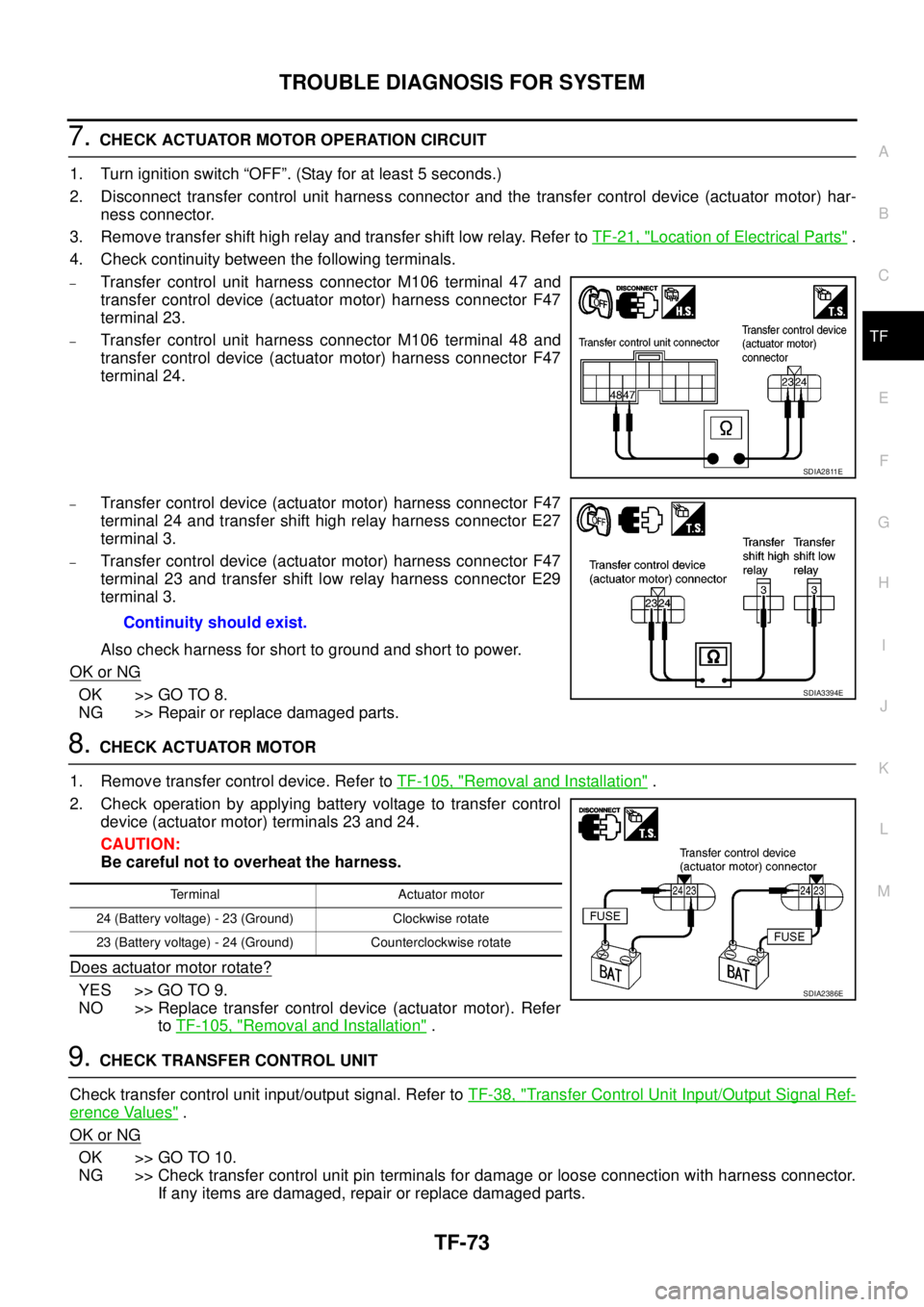

6.CHECK (2): HARNESS BETWEEN TRANSFER CONTROL UNIT AND TRANSFER SHIFT RELAYS

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Disconnect transfer control unit harness connector.

3. Remove transfer shift high relay and transfer shift low relay.

4. Check continuity between the following terminals.

–Transfer control unit harness connector M106 terminal 28 and

transfer shift high relay harness connector E27 terminal 5.

–Transfer control unit harness connector M106 terminal 28 and

transfer shift low relay harness connector E29 terminal 5.

–Transfer control unit harness connector M106 terminal 31 and

transfer shift high relay harness connector E27 terminal 4.

–Transfer control unit harness connector M106 terminal 31 and

transfer shift low relay harness connector E29 terminal 4.

Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.Continuity should exist.

SDIA3386E

Continuity should exist.SDIA3387E

Page 3040 of 3171

TROUBLE DIAGNOSIS FOR SYSTEM

TF-73

C

E

F

G

H

I

J

K

L

MA

B

TF

7.CHECK ACTUATOR MOTOR OPERATION CIRCUIT

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Disconnect transfer control unit harness connector and the transfer control device (actuator motor) har-

ness connector.

3. Remove transfer shift high relay and transfer shift low relay. Refer toTF-21, "

Location of Electrical Parts".

4. Check continuity between the following terminals.

–Transfer control unit harness connector M106 terminal 47 and

transfer control device (actuator motor) harness connector F47

terminal 23.

–Transfer control unit harness connector M106 terminal 48 and

transfer control device (actuator motor) harness connector F47

terminal 24.

–Transfer control device (actuator motor) harness connector F47

terminal 24 and transfer shift high relay harness connector E27

terminal 3.

–Transfer control device (actuator motor) harness connector F47

terminal 23 and transfer shift low relay harness connector E29

terminal 3.

Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 8.

NG >> Repair or replace damaged parts.

8.CHECK ACTUATOR MOTOR

1. Remove transfer control device. Refer toTF-105, "

Removal and Installation".

2. Check operation by applying battery voltage to transfer control

device (actuator motor) terminals 23 and 24.

CAUTION:

Be careful not to overheat the harness.

Does actuator motor rotate?

YES >> GO TO 9.

NO >> Replace transfer control device (actuator motor). Refer

toTF-105, "

Removal and Installation".

9.CHECK TRANSFER CONTROL UNIT

Check transfer control unit input/output signal. Refer toTF-38, "

Transfer Control Unit Input/Output Signal Ref-

erence Values".

OK or NG

OK >> GO TO 10.

NG >> Check transfer control unit pin terminals for damage or loose connection with harness connector.

If any items are damaged, repair or replace damaged parts.

SDIA2811E

Continuity should exist.

SDIA3394E

Terminal Actuator motor

24 (Battery voltage) - 23 (Ground) Clockwise rotate

23 (Battery voltage) - 24 (Ground) Counterclockwise rotate

SDIA2386E