NISSAN NAVARA 2005 Repair Workshop Manual

Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 481 of 3171

REFRIGERANT LINES

ATC-147

C

D

E

F

G

H

I

K

L

MA

B

AT C

CAUTION:

lReplace the O-ring of the low-pressure flexible A/C hose with a new one, then apply compressor

oil to it for installation.

lAfter charging refrigerant, check for leaks.

Removal and Installation for Low-pressure A/C PipeEJS006CS

REMOVAL

1. Discharge the refrigerant. Refer toATC-138, "HFC-134a (R-134a) Service Procedure".

2. Disconnect the heater pump connector.

3. Remove the heater pump from the bracket and reposition out of the way. Do not disconnect the heater

hoses from the heater pump.

4. Remove the low-pressure A/C pipe. Refer toATC-140, "

Components".

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

Refer toATC-140, "

Components".

CAUTION:

lReplace the O-ring of the low-pressure A/C pipe with a new one, then apply compressor oil to it for

installation.

lAfter charging refrigerant, check for leaks.

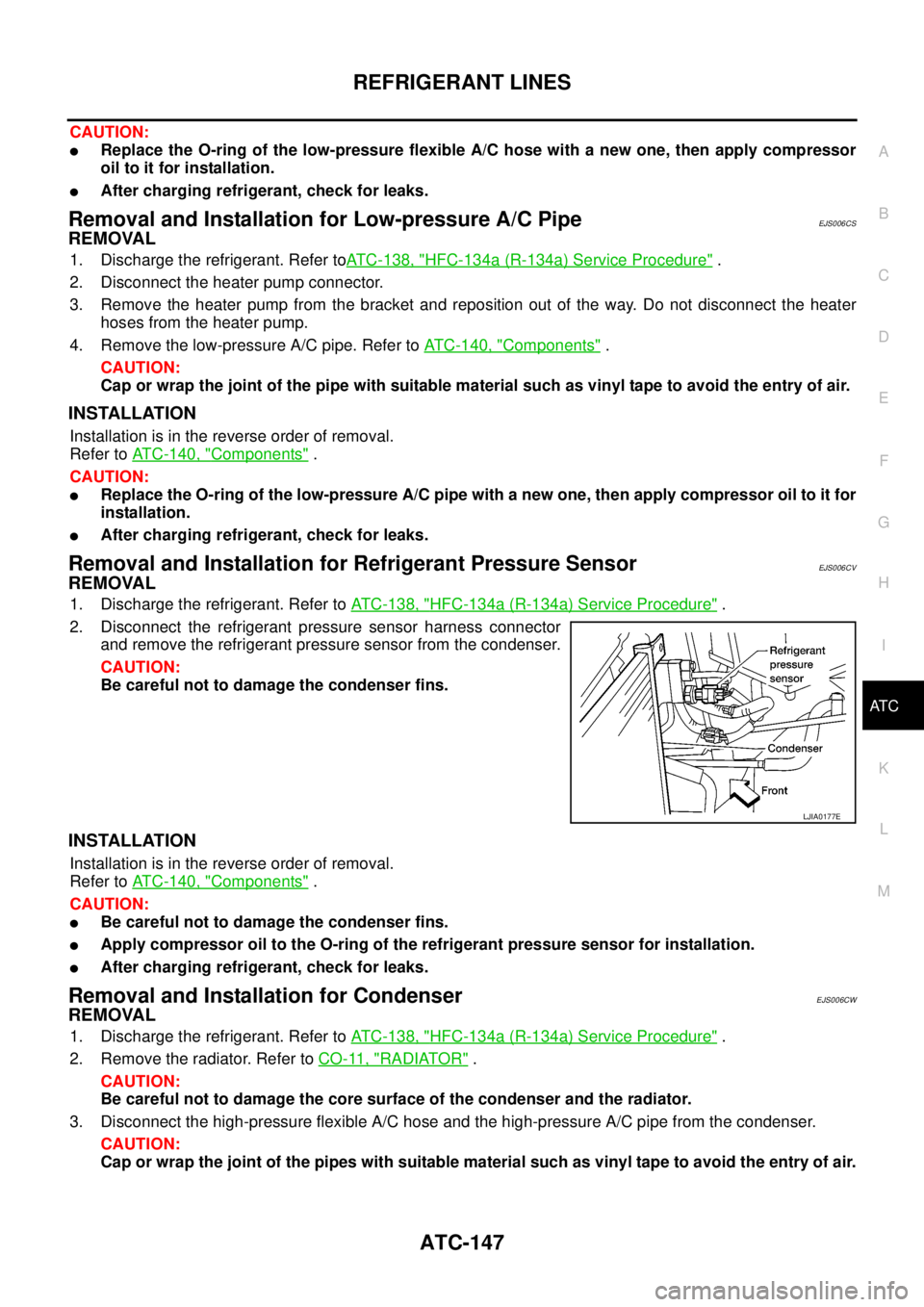

Removal and Installation for Refrigerant Pressure SensorEJS006CV

REMOVAL

1. Discharge the refrigerant. Refer toATC-138, "HFC-134a (R-134a) Service Procedure".

2. Disconnect the refrigerant pressure sensor harness connector

and remove the refrigerant pressure sensor from the condenser.

CAUTION:

Be careful not to damage the condenser fins.

INSTALLATION

Installation is in the reverse order of removal.

Refer toATC-140, "

Components".

CAUTION:

lBe careful not to damage the condenser fins.

lApply compressor oil to the O-ring of the refrigerant pressure sensor for installation.

lAfter charging refrigerant, check for leaks.

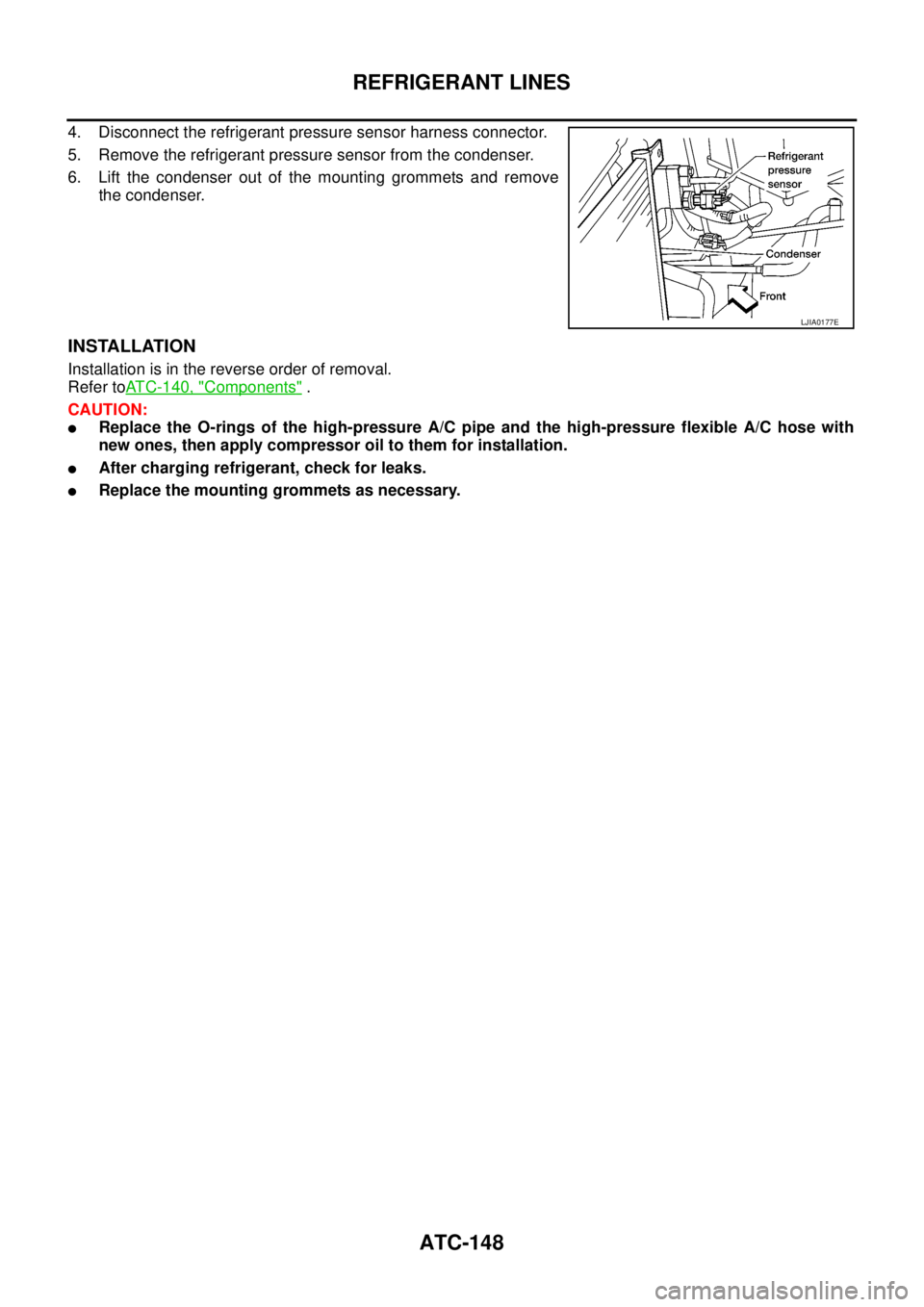

Removal and Installation for CondenserEJS006CW

REMOVAL

1. Discharge the refrigerant. Refer toATC-138, "HFC-134a (R-134a) Service Procedure".

2. Remove the radiator. Refer toCO-11, "

RADIATOR".

CAUTION:

Be careful not to damage the core surface of the condenser and the radiator.

3. Disconnect the high-pressure flexible A/C hose and the high-pressure A/C pipe from the condenser.

CAUTION:

Cap or wrap the joint of the pipes with suitable material such as vinyl tape to avoid the entry of air.

LJIA0177E

Page 482 of 3171

ATC-148

REFRIGERANT LINES

4. Disconnect the refrigerant pressure sensor harness connector.

5. Remove the refrigerant pressure sensor from the condenser.

6. Lift the condenser out of the mounting grommets and remove

the condenser.

INSTALLATION

Installation is in the reverse order of removal.

Refer toATC-140, "

Components".

CAUTION:

lReplace the O-rings of the high-pressure A/C pipe and the high-pressure flexible A/C hose with

new ones, then apply compressor oil to them for installation.

lAfter charging refrigerant, check for leaks.

lReplace the mounting grommets as necessary.

LJIA0177E

Page 483 of 3171

REFRIGERANT LINES

ATC-149

C

D

E

F

G

H

I

K

L

MA

B

AT C

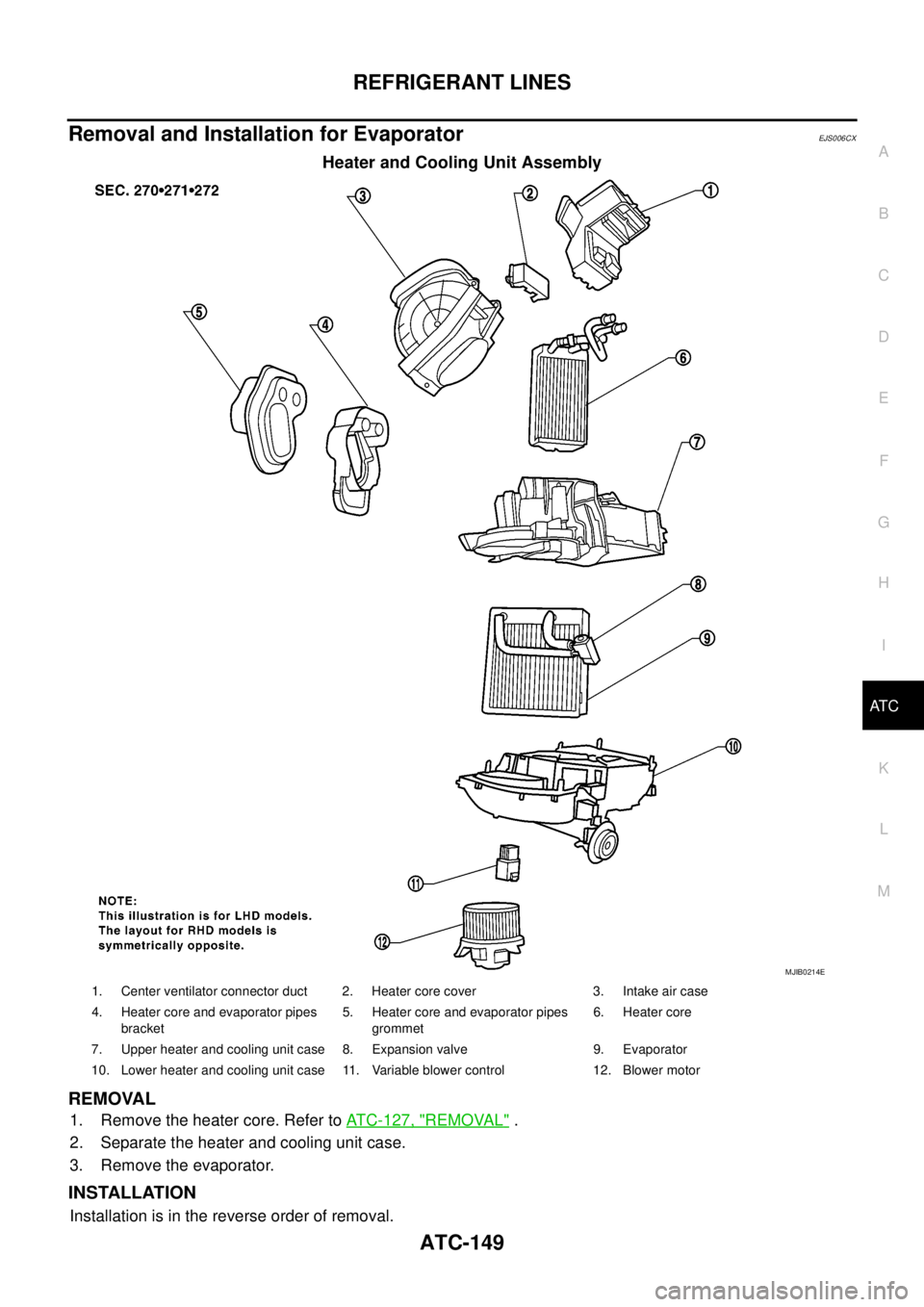

Removal and Installation for EvaporatorEJS006CX

Heater and Cooling Unit Assembly

REMOVAL

1. Remove the heater core. Refer toATC-127, "REMOVAL".

2. Separate the heater and cooling unit case.

3. Remove the evaporator.

INSTALLATION

Installation is in the reverse order of removal.

MJIB0214E

1. Center ventilator connector duct 2. Heater core cover 3. Intake air case

4. Heater core and evaporator pipes

bracket5. Heater core and evaporator pipes

grommet6. Heater core

7. Upper heater and cooling unit case 8. Expansion valve 9. Evaporator

10. Lower heater and cooling unit case 11. Variable blower control 12. Blower motor

Page 484 of 3171

ATC-150

REFRIGERANT LINES

CAUTION:

Replace the O-rings on the A/C low-pressure flexible A/C hose and the high-pressure A/C pipe with

new ones. Apply compressor oil to the O-rings for installation.

Removal and Installation for Expansion ValveEJS006CZ

REMOVAL

1. Discharge the refrigerant. Refer toATC-138, "HFC-134a (R-134a) Service Procedure".

2. Remove the heater and cooling unit assembly. Refer toATC-126, "

REMOVAL".

3. Remove the heater core and evaporator pipes grommet.

4. Remove the expansion valve.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

lReplace the O-rings on then expansion valve and the A/C refrigerant pipes with new ones, then

apply compressor oil to them for installation.

lAfter charging refrigerant, check for leaks.

Checking for Refrigerant LeaksEJS006D1

Perform a visual inspection of all refrigeration parts, fittings, hoses and components for signs of A/C lubricant

leakage, damage and corrosion. A/C lubricant leakage may indicate an area of refrigerant leakage. Allow

extra inspection time in these areas when using either an electronic refrigerant leak detector or fluorescent

dye leak detector.

If dye is observed, confirm the leak with an electronic refrigerant leak detector. It is possible a prior leak was

repaired and not properly cleaned.

When searching for leaks, do not stop when one leak is found but continue to check for additional leaks at all

system components and connections.

When searching for refrigerant leaks using an electronic leak detector, move the probe along the suspected

leak area at 1 to 2 inches per second and no further than 1/4 inch from the component.

CAUTION:

Moving the electronic leak detector probe slower and closer to the suspected leak area will improve

the chances of finding a leak.

Checking System for Leaks Using the Fluorescent Leak DetectorEJS006D2

1. Check A/C system for leaks using the UV lamp and safety goggles [SST: J-42220] in a low sunlight area

(area without windows preferable). Illuminate all components, fittings and lines. The dye will appear as a

bright green/yellow area at the point of leakage. Fluorescent dye observed at the evaporator drain open-

ing indicates an evaporator core assembly (tubes, core or expansion valve) leak.

2. If the suspected area is difficult to see, use an adjustable mirror or wipe the area with a clean shop rag or

cloth, with the UV lamp for dye residue.

3. After the leak is repaired, remove any residual dye using dye cleaner [SST: J-43872] to prevent future mis-

diagnosis.

4. Perform a system performance check and verify the leak repair with an approved electronic refrigerant

leak detector.

NOTE:

Other gases in the work area or substances on the A/C components, for example, anti-freeze, windshield

washer fluid, solvents and lubricants, may falsely trigger the leak detector. Make sure the surfaces to be

checked are clean.

Cleanwithadryclothorblowoffwithshopair.

Do not allow the sensor tip of the detector to contact with any substance. This can also cause false readings

and may damage the detector.Expansion valve bolts : 4 N·m (0.41 kg-m, 35 in-lb)

A/C refrigerant pipe to expansion valve bolt : Refer toATC-140, "

Components"

.

Page 485 of 3171

REFRIGERANT LINES

ATC-151

C

D

E

F

G

H

I

K

L

MA

B

AT C

Dye InjectionEJS006D3

(This procedure is only necessary when recharging the system or when the compressor has seized and was

replaced.)

1. Check A/C system static (at rest) pressure. Pressure must be at least 345 kPa (3.45 bar, 3.52 kg/cm

2,50

psi).

2. Pour one bottle (1/4 ounce / 7.4 cc) of the A/C refrigerant dye into the injector tool [SST: J-41459].

3. Connect the injector tool to the A/C Low-pressure side service fitting.

4. Start engine and switch A/C ON.

5. When the A/C operating (compressor running), inject one bottle (1/4 ounce / 7.4 cc) of fluorescent dye

through the low-pressure service valve using dye injector tool J-41459 (refer to the manufacture’s operat-

ing instructions).

6. With the engine still running, disconnect the injector tool from the service fitting.

CAUTION:

Be careful the A/C system or replacing a component, pour the dye directly into the open system

connection and proceed with the service procedures.

7. Operate the A/C system for a minimum of 20 minutes to mix the dye with the system oil. Depending on the

leak size, operating conditions and location of the leak, it may take from minutes to days for the dye to

penetrate a leak and become visible.

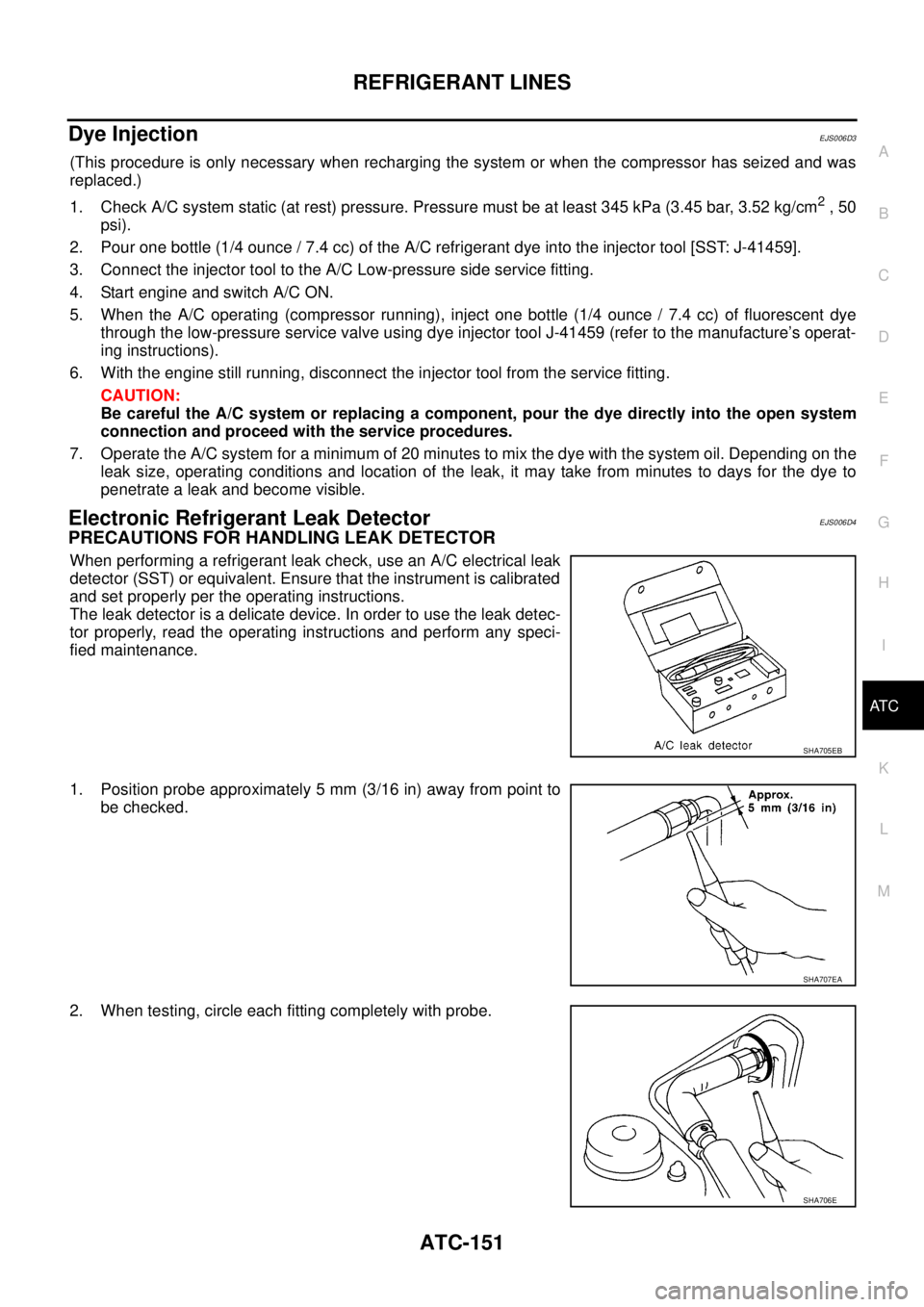

Electronic Refrigerant Leak DetectorEJS006D4

PRECAUTIONS FOR HANDLING LEAK DETECTOR

When performing a refrigerant leak check, use an A/C electrical leak

detector (SST) or equivalent. Ensure that the instrument is calibrated

and set properly per the operating instructions.

The leak detector is a delicate device. In order to use the leak detec-

tor properly, read the operating instructions and perform any speci-

fied maintenance.

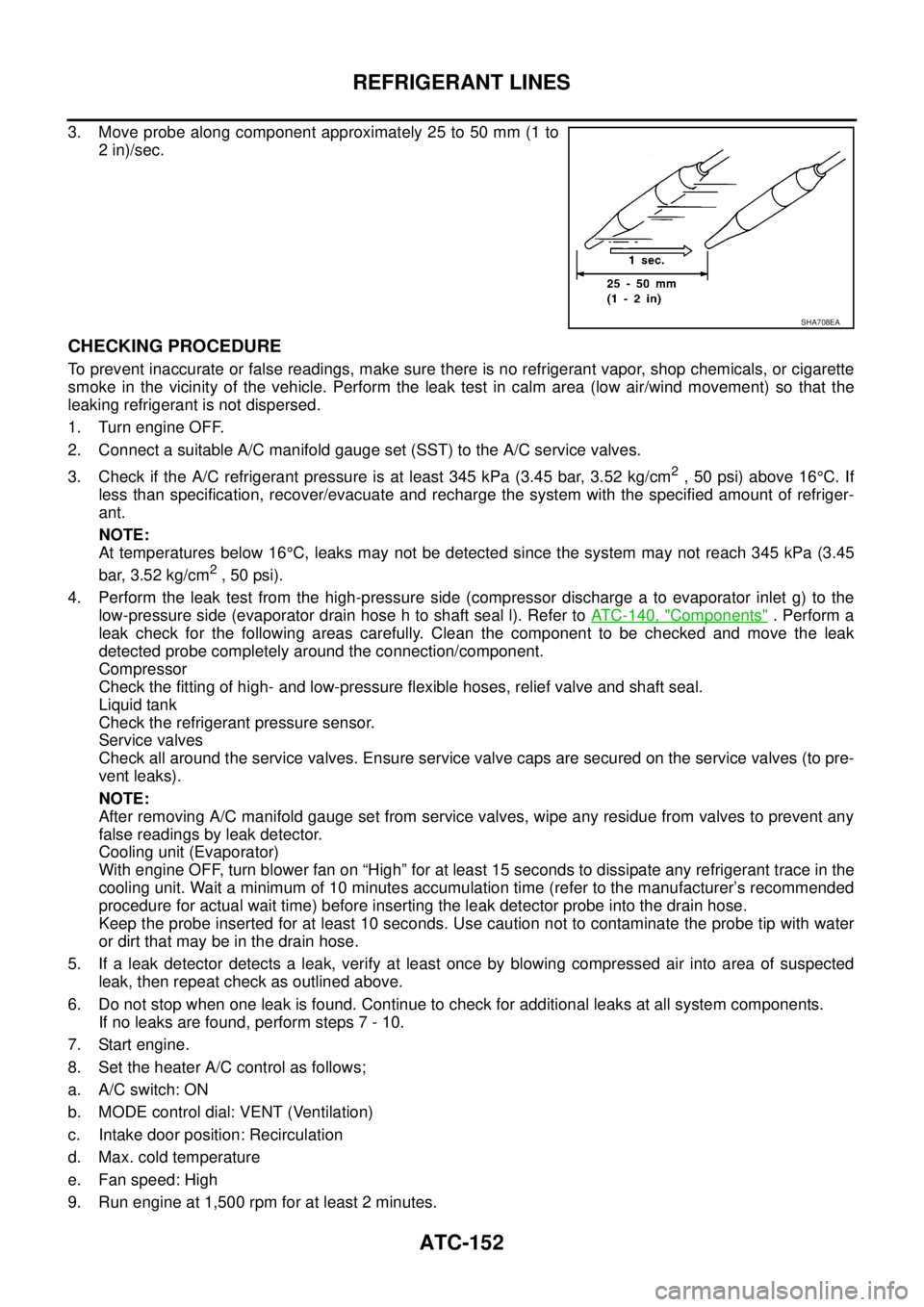

1. Position probe approximately 5 mm (3/16 in) away from point to

be checked.

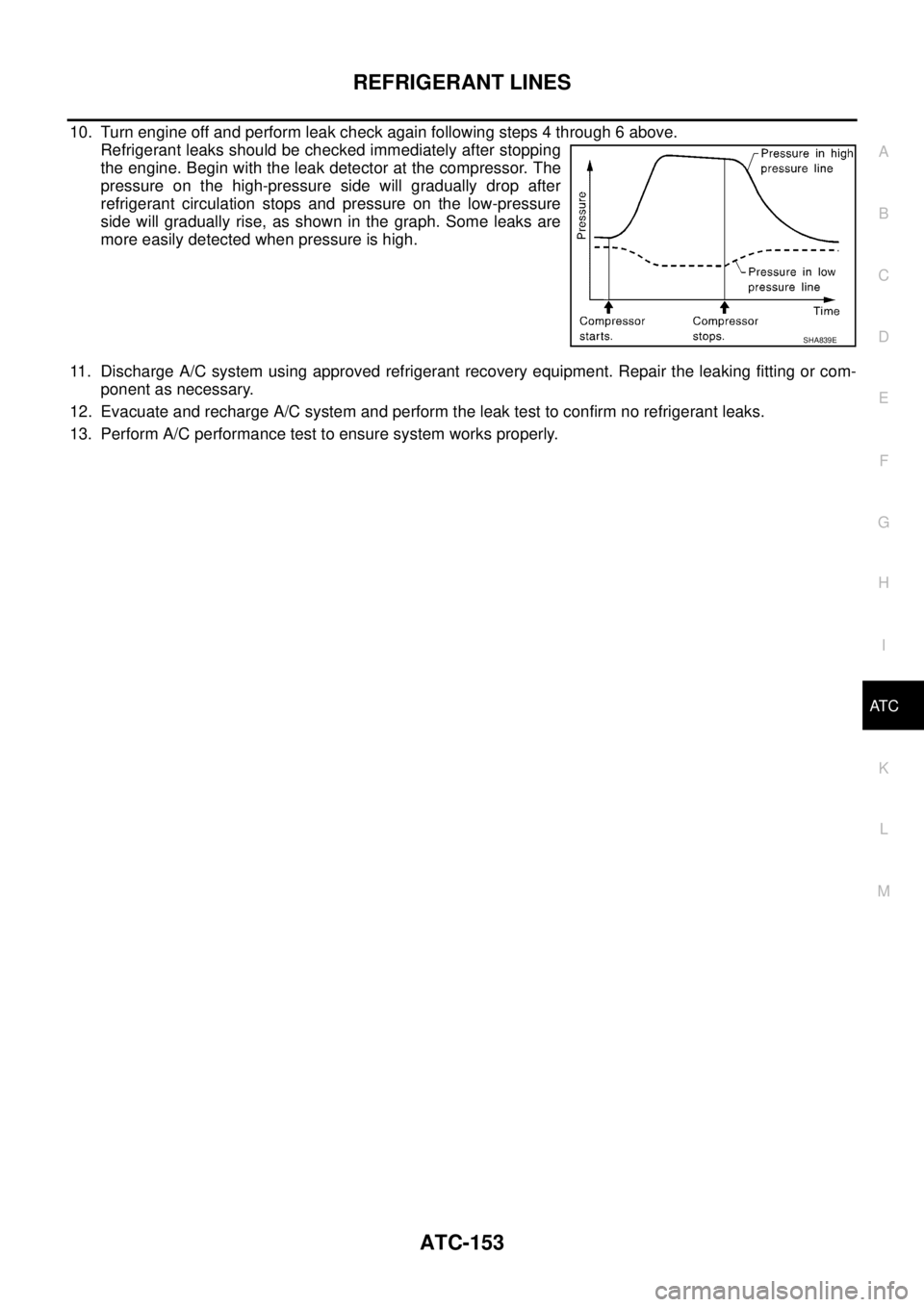

2. When testing, circle each fitting completely with probe.

SHA705EB

SHA707EA

SHA706E

Page 486 of 3171

ATC-152

REFRIGERANT LINES

3. Move probe along component approximately 25 to 50 mm (1 to

2 in)/sec.

CHECKING PROCEDURE

To prevent inaccurate or false readings, make sure there is no refrigerant vapor, shop chemicals, or cigarette

smoke in the vicinity of the vehicle. Perform the leak test in calm area (low air/wind movement) so that the

leaking refrigerant is not dispersed.

1. Turn engine OFF.

2. Connect a suitable A/C manifold gauge set (SST) to the A/C service valves.

3. Check if the A/C refrigerant pressure is at least 345 kPa (3.45 bar, 3.52 kg/cm

2,50psi)above16°C. If

less than specification, recover/evacuate and recharge the system with the specified amount of refriger-

ant.

NOTE:

At temperatures below 16°C, leaks may not be detected since the system may not reach 345 kPa (3.45

bar, 3.52 kg/cm

2,50psi).

4. Perform the leak test from the high-pressure side (compressor discharge a to evaporator inlet g) to the

low-pressure side (evaporator drain hose h to shaft seal l). Refer toATC-140, "

Components". Perform a

leak check for the following areas carefully. Clean the component to be checked and move the leak

detected probe completely around the connection/component.

Compressor

Check the fitting of high- and low-pressure flexible hoses, relief valve and shaft seal.

Liquid tank

Check the refrigerant pressure sensor.

Service valves

Check all around the service valves. Ensure service valve caps are secured on the service valves (to pre-

vent leaks).

NOTE:

After removing A/C manifold gauge set from service valves, wipe any residue from valves to prevent any

false readings by leak detector.

Cooling unit (Evaporator)

With engine OFF, turn blower fan on “High” for at least 15 seconds to dissipate any refrigerant trace in the

cooling unit. Wait a minimum of 10 minutes accumulation time (refer to the manufacturer’s recommended

procedure for actual wait time) before inserting the leak detector probe into the drain hose.

Keep the probe inserted for at least 10 seconds. Use caution not to contaminate the probe tip with water

or dirt that may be in the drain hose.

5. If a leak detector detects a leak, verify at least once by blowing compressed air into area of suspected

leak, then repeat check as outlined above.

6. Do not stop when one leak is found. Continue to check for additional leaks at all system components.

If no leaks are found, perform steps 7 - 10.

7. Start engine.

8. Set the heater A/C control as follows;

a. A/C switch: ON

b. MODE control dial: VENT (Ventilation)

c. Intake door position: Recirculation

d. Max. cold temperature

e. Fan speed: High

9. Run engine at 1,500 rpm for at least 2 minutes.

SHA708EA

Page 487 of 3171

REFRIGERANT LINES

ATC-153

C

D

E

F

G

H

I

K

L

MA

B

AT C

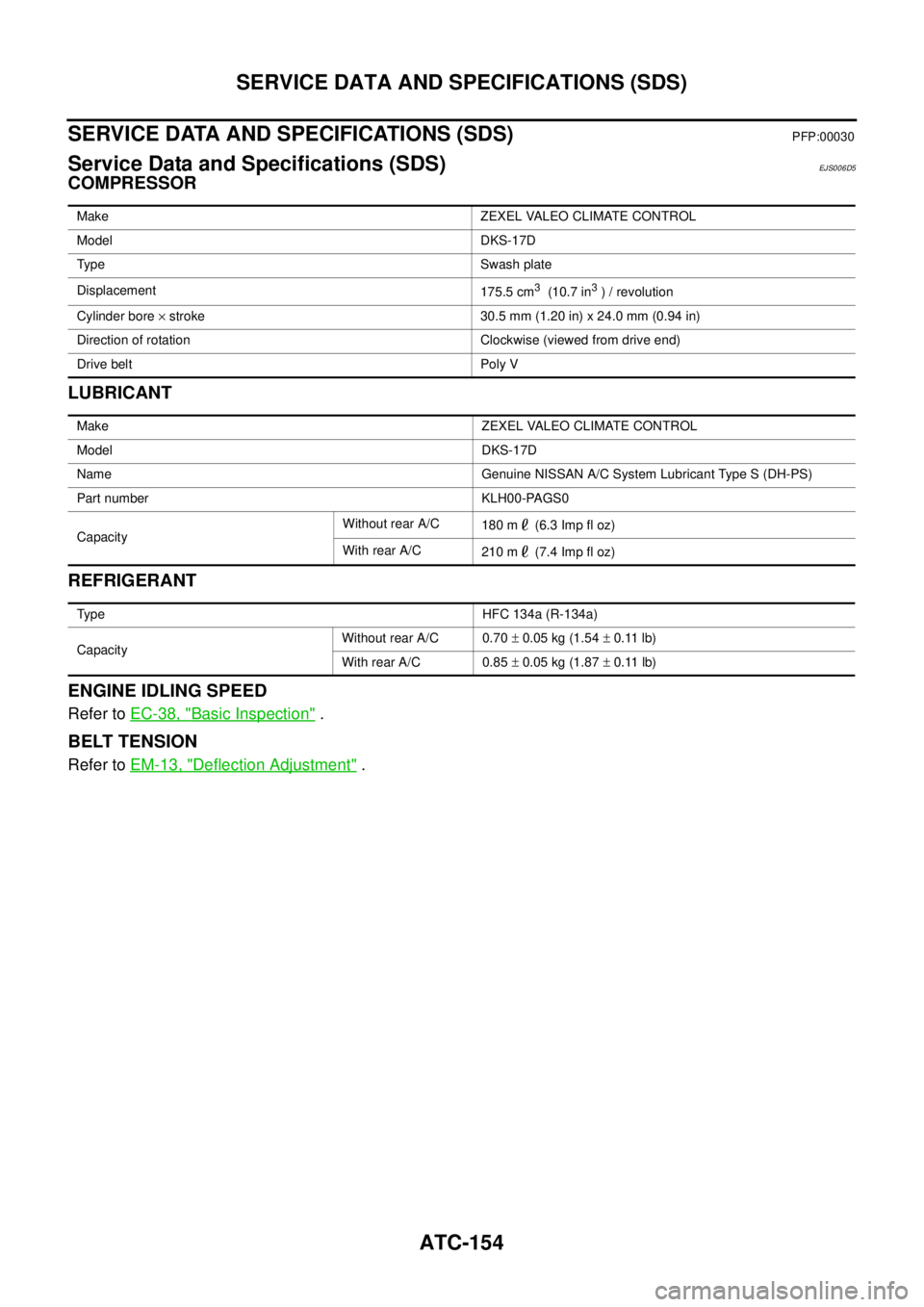

10. Turn engine off and perform leak check again following steps 4 through 6 above.

Refrigerant leaks should be checked immediately after stopping

the engine. Begin with the leak detector at the compressor. The

pressure on the high-pressure side will gradually drop after

refrigerant circulation stops and pressure on the low-pressure

side will gradually rise, as shown in the graph. Some leaks are

more easily detected when pressure is high.

11. Discharge A/C system using approved refrigerant recovery equipment. Repair the leaking fitting or com-

ponent as necessary.

12. Evacuate and recharge A/C system and perform the leak test to confirm no refrigerant leaks.

13. Perform A/C performance test to ensure system works properly.

SHA839E

Page 488 of 3171

ATC-154

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

Service Data and Specifications (SDS)EJS006D5

COMPRESSOR

LUBRICANT

REFRIGERANT

ENGINE IDLING SPEED

Refer toEC-38, "Basic Inspection".

BELT TENSION

Refer toEM-13, "Deflection Adjustment".

Make ZEXEL VALEO CLIMATE CONTROL

Model DKS-17D

Type Swash plate

Displacement

175.5 cm

3(10.7 in3)/revolution

Cylinder bore´stroke 30.5 mm (1.20 in) x 24.0 mm (0.94 in)

Direction of rotation Clockwise (viewed from drive end)

Drive belt Poly V

Make ZEXEL VALEO CLIMATE CONTROL

Model DKS-17D

Name Genuine NISSAN A/C System Lubricant Type S (DH-PS)

Part number KLH00-PAGS0

CapacityWithout rear A/C

180 m (6.3 Imp fl oz)

With rear A/C

210 m (7.4 Imp fl oz)

Type HFC 134a (R-134a)

CapacityWithout rear A/C 0.70±0.05 kg (1.54±0.11 lb)

With rear A/C 0.85±0.05 kg (1.87±0.11 lb)

Page 489 of 3171

AV-1

AUDIO-VISUAL SYSTEM

K ELECTRICAL

CONTENTS

C

D

E

F

G

H

I

J

L

M

SECTIONAV

A

B

AV

AUDIO-VISUAL SYSTEM

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 3

Wiring Diagrams and Trouble Diagnosis .................. 3

SYSTEM DESCRIPTION ............................................ 4

System Functions ..................................................... 4

AUDIO ................................................................... 4

NATS AUDIO LINK (WITHOUT NAVIGATION

SYSTEM) .............................................................. 4

VEHICLE INFORMATION SYSTEM ..................... 5

NAVIGATION SYSTEM ......................................... 5

HANDS-FREE PHONE ......................................... 7

Component Description ............................................ 8

AUDIO UNIT ......................................................... 8

NAVI CONTROL UNIT .......................................... 8

GPS ANTENNA .................................................... 9

DISPLAY UNIT ...................................................... 9

AV SWITCH .......................................................... 9

Component Parts Location ..................................... 10

Location Of Antenna .............................................. 10

Schematic — AUDIO — / With 1CD Player Type... 12

Wiring Diagram — AUDIO — / With 1CD Player Type

... 13

Schematic — AUDIO — / With 6CD Player Type... 16

Wiring Diagram — AUDIO — / With 6CD Player Type

... 17

Schematic — NAVI — ............................................ 20

Wiring Diagram — NAVI — .................................... 21

Schematic — NAVI — / COMM .............................. 28

Wiring Diagram — NAVI — / COMM ...................... 29

Wiring Diagram — TELEPHONE (PRE WIRE) —

/ Without NAVI ........................................................ 32

CAN Communication .............................................. 33

SYSTEM DESCRIPTION .................................... 33

TERMINALS AND REFERENCE VALUE FOR CON-

TROL UNIT ............................................................... 34

Audio Unit (1CD Player Type) ................................ 34

Audio Unit (6CD Player Type) Without NAVI .......... 35Audio Unit (With NAVI) ........................................... 37

NAVI Control Unit ................................................... 38

Display Unit ............................................................ 41

DIAGNOSIS SYSTEM ............................................... 44

Navigation System Diagnosis Function .................. 44

On Bord Self-Diagnosis Function ........................... 44

DESCRIPTION .................................................... 44

DIAGNOSIS ITEM ............................................... 44

OPERATION PROCEDURE ................................ 45

Self Diagnosis Mode ............................................... 46

ERROR DETECTION RANGE OF SELF-DIAG-

NOSIS MODE ..................................................... 47

DIAGNOSIS RESULTS ....................................... 47

Confirmation/Adjustment Mode .............................. 48

SCREEN TROUBLE DIAGNOSIS ...................... 49

VEHICLE SIGNALS ............................................ 49

SPEAKER TEST ................................................. 50

NAVIGATION ....................................................... 50

ERROR HISTORY ............................................... 51

VEHICLE CAN DIAGNOSIS ............................... 53

AV COMM DIAGNOSIS ....................................... 54

HANDSFREE PHONE ........................................ 54

BLUETOOTH ....................................................... 54

DELETE UNIT CONNECTION LOG ................... 55

CONSULT-II Functions ........................................... 56

CONSULT-II FUNCTIONS ................................... 56

CONSULT-II BASIC OPERATION PROCEDURE

... 56

SELF-DIAG RESULTS ........................................ 56

DATA MONITOR ................................................. 58

AV COMM MONITOR .......................................... 59

ECU PART NUMBER .......................................... 60

TROUBLE DIAGNOSIS ............................................ 61

Navigation System .................................................. 61

RGB Image ............................................................. 61

Voice Activated Control System ............................. 62

Steering Wheel Switch ............................................ 63

Component Parts Inspection .................................. 63

STEERING WHEEL SWITCH UNIT INSPEC-

Page 490 of 3171

AV-2

TION .................................................................... 63

Example of Symptoms Not Malfunction .................. 65

BASIC OPERATION ............................................ 65

VEHICLE ICON ................................................... 65

MAP DVD-ROM ................................................... 66

ROUTE CALCULATION AND VISUAL GUID-

ANCE ................................................................... 66

VOICE GUIDANCE ............................................. 67

VOICE RECOGNITION ....................................... 67

EXAMPLES OF CURRENT LOCATION MARK

DISPLACEMENT ................................................. 68

THE CURRENT POSITION MARK SHOWS A

POSITION THAT IS COMPLETELY INCOR-

RECT. .................................................................. 71

THE CURRENT POSITION MARK JUMPS. ....... 72

THE CURRENT LOCATION MARK IS IN A

RIVER OR THE SEA. .......................................... 72

CURRENT LOCATION MARK ROTATES WITH-

OUT OPERATION ............................................... 72

WHEN DRIVING ON THE SAME ROAD, SOME-

TIMES THE CURRENT LOCATION MARK IS IN

THE CORRECT PLACE AND SOMETIMES IT IS

IN THE INCORRECT PLACE. ............................. 72

LOCATION CORRECTION BY MAP MATCHING

IS SLOW. ............................................................. 72

ALTHOUGH THE GPS RECEIVING DISPLAY IS

GREEN, THE VEHICLE MARK DOES NOT

RETURN TO THE CORRECT LOCATION. ......... 72

THE NAME OF THE CURRENT PLACE IS NOT

DISPLAYED. ........................................................ 72

THE DISPLAY IS DIFFERENT BETWEEN BIRD-

VIEW® AND (FLAT) MAP DISPLAY. ................... 72

REMOVAL AND INSTALLATION ............................. 73

Auido Unit (1CD Player Type) ................................ 73

REMOVAL ........................................................... 73INSTALLATION .................................................... 73

Audio Unit ( 6CD Player Type ) Without NAVI ........ 73

REMOVAL ............................................................ 73

INSTALLATION .................................................... 73

Audio Unit (6CD Player Type) With NAVI ............... 74

REMOVAL ............................................................ 74

INSTALLATION .................................................... 74

Front Door Speaker ................................................ 74

REMOVAL ............................................................ 74

INSTALLATION .................................................... 74

Rear Door Speaker ................................................. 74

REMOVAL ............................................................ 74

INSTALLATION .................................................... 74

Tweeter ................................................................... 75

REMOVAL ............................................................ 75

INSTALLATION .................................................... 75

Roof Antenna .......................................................... 75

REMOVAL ............................................................ 75

INSTALLATION .................................................... 75

NAVI Control Unit .................................................... 75

REMOVAL ............................................................ 75

INSTALLATION .................................................... 75

GPS Antenna .......................................................... 76

REMOVAL ............................................................ 76

INSTALLATION .................................................... 76

Display Unit ............................................................. 77

REMOVAL ............................................................ 77

INSTALLATION .................................................... 77

AV Switch ................................................................ 77

REMOVAL ............................................................ 77

INSTALLATION .................................................... 77

Microphone ............................................................. 77

REMOVAL ............................................................ 77

INSTALLATION .................................................... 77