NISSAN NAVARA 2005 Repair Workshop Manual

Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 891 of 3171

ENGINE COOLANT

CO-7

C

D

E

F

G

H

I

J

K

L

MA

CO

ENGINE COOLANTPFP:KQ100

InspectionEBS01E6P

LEVEL CHECK

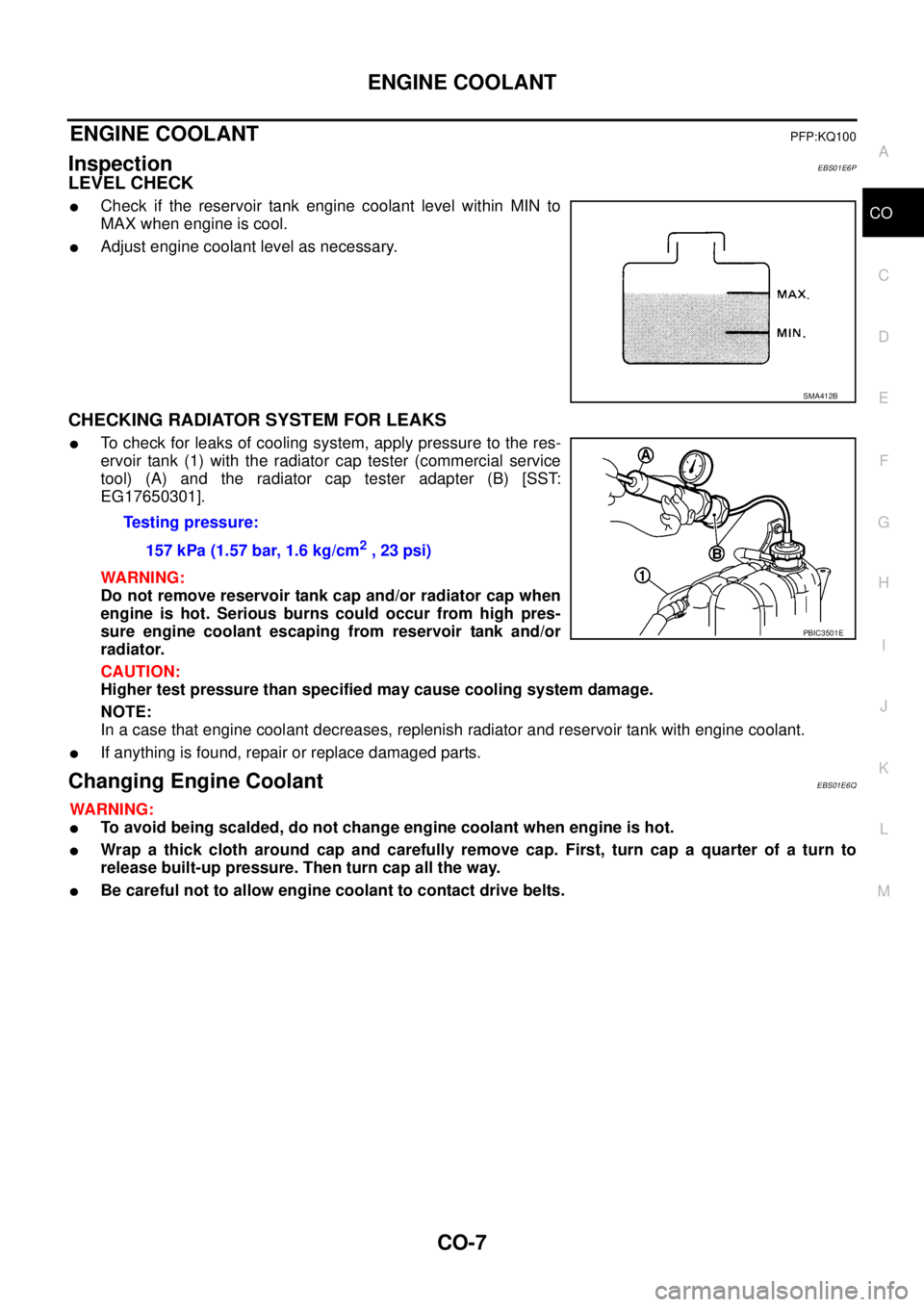

lCheck if the reservoir tank engine coolant level within MIN to

MAX when engine is cool.

lAdjust engine coolant level as necessary.

CHECKING RADIATOR SYSTEM FOR LEAKS

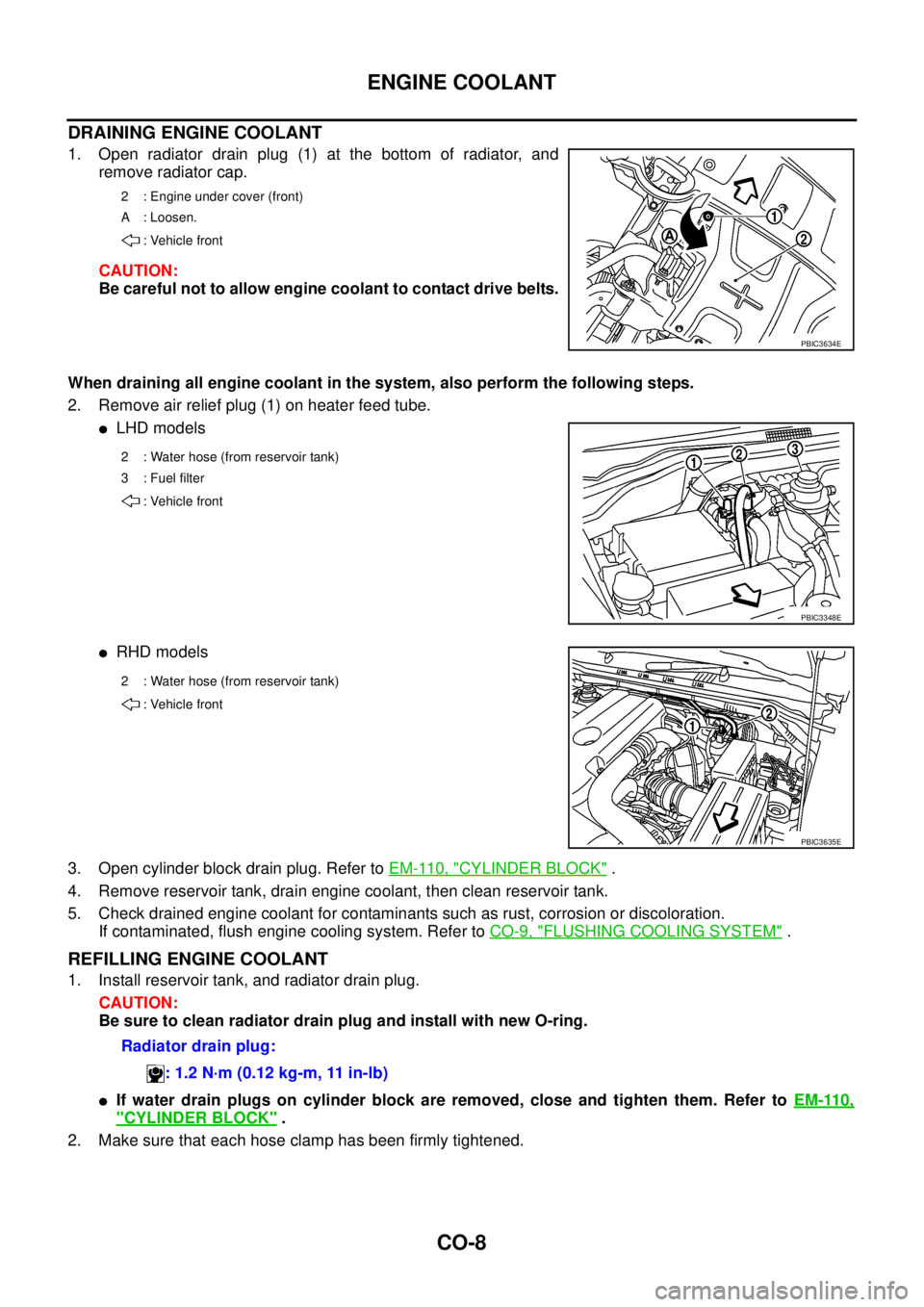

lTo check for leaks of cooling system, apply pressure to the res-

ervoir tank (1) with the radiator cap tester (commercial service

tool) (A) and the radiator cap tester adapter (B) [SST:

EG17650301].

WARNING:

Do not remove reservoir tank cap and/or radiator cap when

engine is hot. Serious burns could occur from high pres-

sure engine coolant escaping from reservoir tank and/or

radiator.

CAUTION:

Higher test pressure than specified may cause cooling system damage.

NOTE:

In a case that engine coolant decreases, replenish radiator and reservoir tank with engine coolant.

lIf anything is found, repair or replace damaged parts.

Changing Engine CoolantEBS01E6Q

WARNING:

lTo avoid being scalded, do not change engine coolant when engine is hot.

lWrap a thick cloth around cap and carefully remove cap. First, turn cap a quarter of a turn to

release built-up pressure. Then turn cap all the way.

lBe careful not to allow engine coolant to contact drive belts.

SMA412B

Testing pressure:

157 kPa (1.57 bar, 1.6 kg/cm

2,23psi)

PBIC3501E

Page 892 of 3171

CO-8

ENGINE COOLANT

DRAINING ENGINE COOLANT

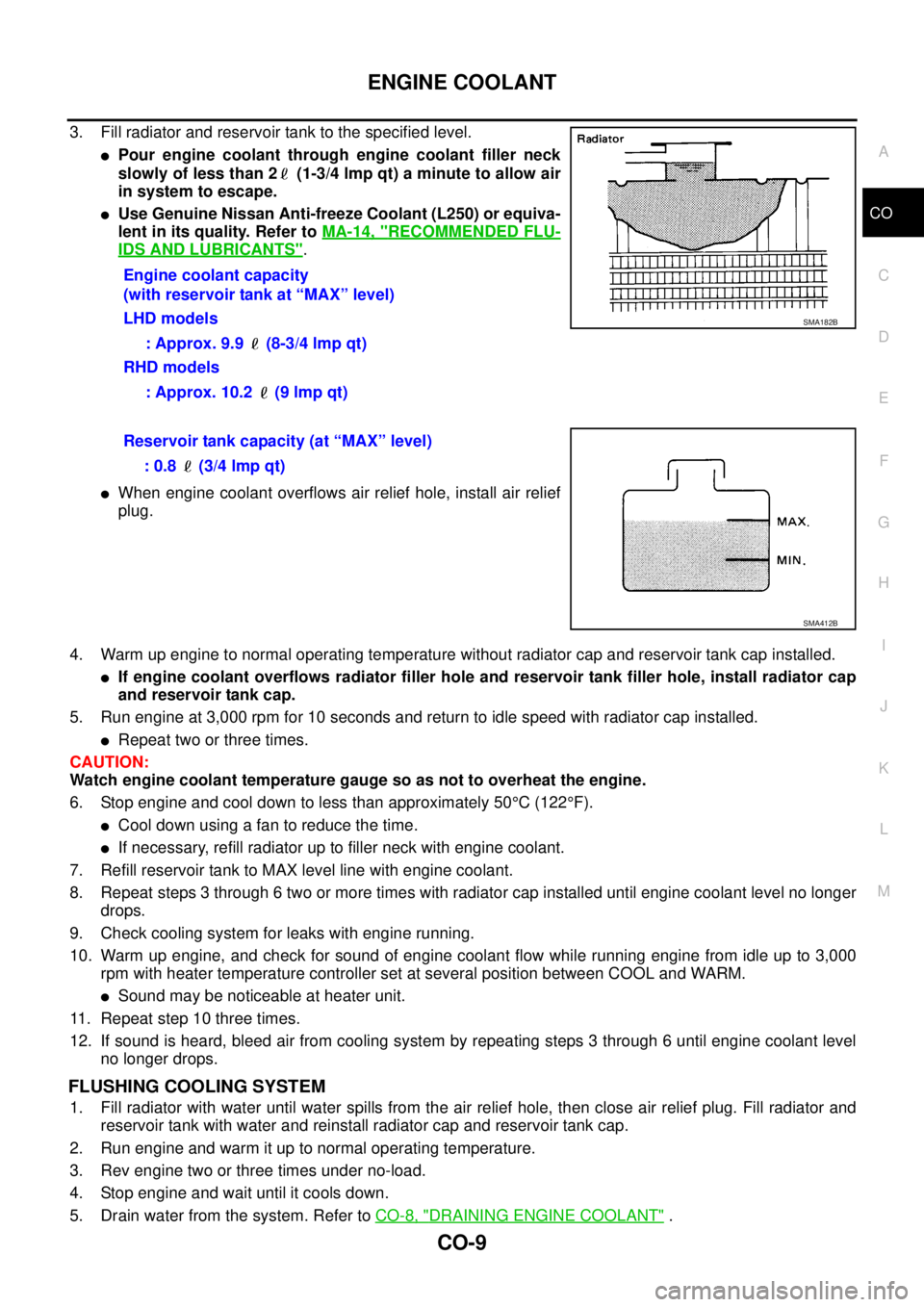

1. Open radiator drain plug (1) at the bottom of radiator, and

remove radiator cap.

CAUTION:

Be careful not to allow engine coolant to contact drive belts.

When draining all engine coolant in the system, also perform the following steps.

2. Remove air relief plug (1) on heater feed tube.

lLHD models

lRHD models

3. Open cylinder block drain plug. Refer toEM-110, "

CYLINDER BLOCK".

4. Remove reservoir tank, drain engine coolant, then clean reservoir tank.

5. Check drained engine coolant for contaminants such as rust, corrosion or discoloration.

If contaminated, flush engine cooling system. Refer toCO-9, "

FLUSHING COOLING SYSTEM".

REFILLING ENGINE COOLANT

1. Install reservoir tank, and radiator drain plug.

CAUTION:

Be sure to clean radiator drain plug and install with new O-ring.

lIf water drain plugs on cylinder block are removed, close and tighten them. Refer toEM-110,

"CYLINDER BLOCK".

2. Make sure that each hose clamp has been firmly tightened.

2 : Engine under cover (front)

A : Loosen.

: Vehicle front

PBIC3634E

2 : Water hose (from reservoir tank)

3 : Fuel filter

: Vehicle front

PBIC3348E

2 : Water hose (from reservoir tank)

: Vehicle front

PBIC3635E

Radiator drain plug:

: 1.2 N·m (0.12 kg-m, 11 in-lb)

Page 893 of 3171

ENGINE COOLANT

CO-9

C

D

E

F

G

H

I

J

K

L

MA

CO

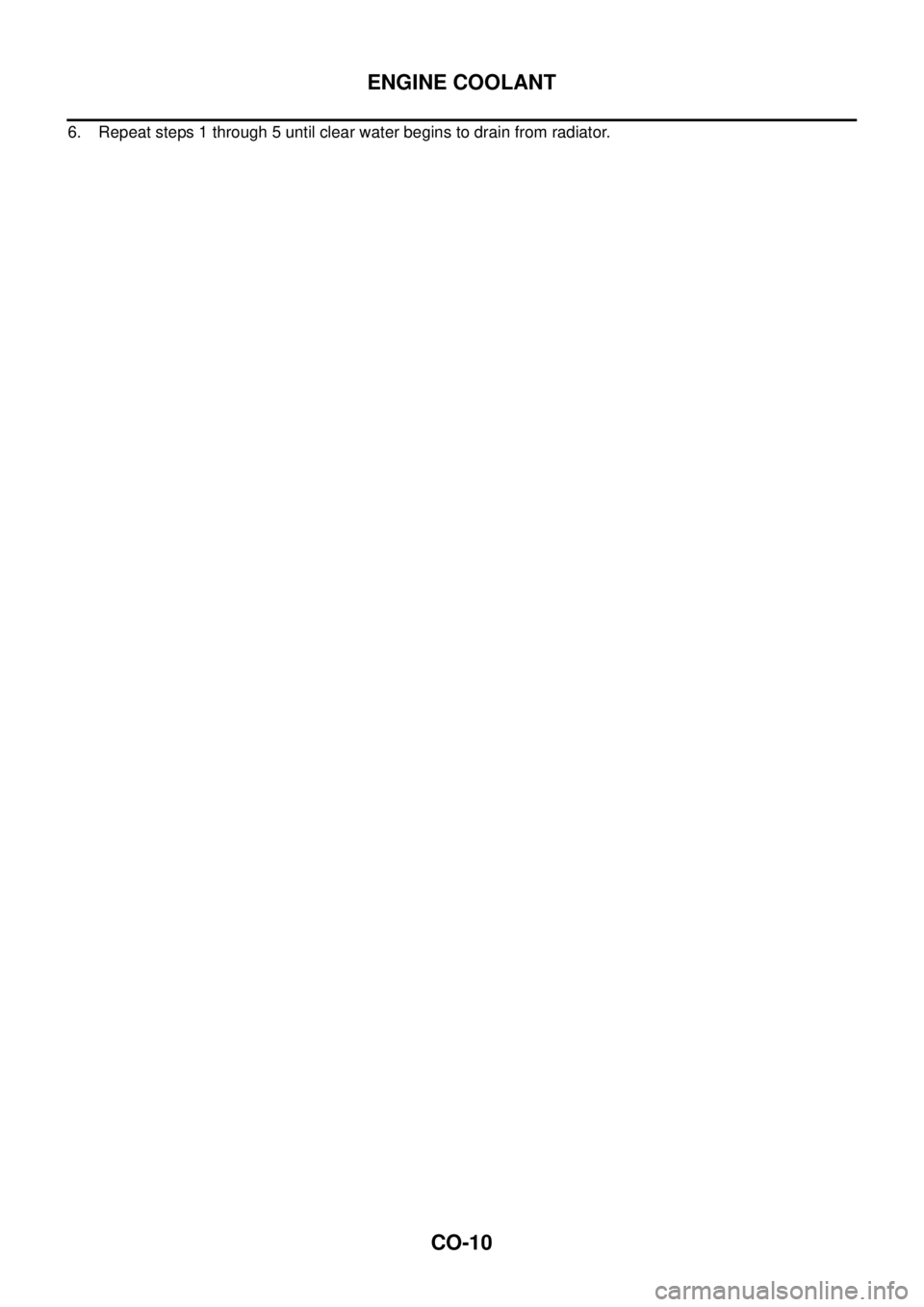

3. Fill radiator and reservoir tank to the specified level.

lPour engine coolant through engine coolant filler neck

slowly of less than 2 (1-3/4 lmp qt) a minute to allow air

in system to escape.

lUse Genuine Nissan Anti-freeze Coolant (L250) or equiva-

lent in its quality. Refer toMA-14, "

RECOMMENDED FLU-

IDS AND LUBRICANTS".

lWhen engine coolant overflows air relief hole, install air relief

plug.

4. Warm up engine to normal operating temperature without radiator cap and reservoir tank cap installed.

lIf engine coolant overflows radiator filler hole and reservoir tank filler hole, install radiator cap

and reservoir tank cap.

5. Run engine at 3,000 rpm for 10 seconds and return to idle speed with radiator cap installed.

lRepeat two or three times.

CAUTION:

Watch engine coolant temperature gauge so as not to overheat the engine.

6. Stop engine and cool down to less than approximately 50°C(122°F).

lCool down using a fan to reduce the time.

lIf necessary, refill radiator up to filler neck with engine coolant.

7. Refill reservoir tank to MAX level line with engine coolant.

8. Repeat steps 3 through 6 two or more times with radiator cap installed until engine coolant level no longer

drops.

9. Check cooling system for leaks with engine running.

10. Warm up engine, and check for sound of engine coolant flow while running engine from idle up to 3,000

rpm with heater temperature controller set at several position between COOL and WARM.

lSound may be noticeable at heater unit.

11. Repeat step 10 three times.

12. If sound is heard, bleed air from cooling system by repeating steps 3 through 6 until engine coolant level

no longer drops.

FLUSHING COOLING SYSTEM

1. Fill radiator with water until water spills from the air relief hole, then close air relief plug. Fill radiator and

reservoir tank with water and reinstall radiator cap and reservoir tank cap.

2. Run engine and warm it up to normal operating temperature.

3. Rev engine two or three times under no-load.

4. Stop engine and wait until it cools down.

5. Drain water from the system. Refer toCO-8, "

DRAINING ENGINE COOLANT". Engine coolant capacity

(with reservoir tank at “MAX” level)

LHD models

: Approx. 9.9 (8-3/4 lmp qt)

RHD models

: Approx. 10.2 (9 lmp qt)

SMA182B

Reservoir tank capacity (at “MAX” level)

: 0.8 (3/4 lmp qt)

SMA412B

Page 894 of 3171

CO-10

ENGINE COOLANT

6. Repeat steps 1 through 5 until clear water begins to drain from radiator.

Page 895 of 3171

RADIATOR

CO-11

C

D

E

F

G

H

I

J

K

L

MA

CO

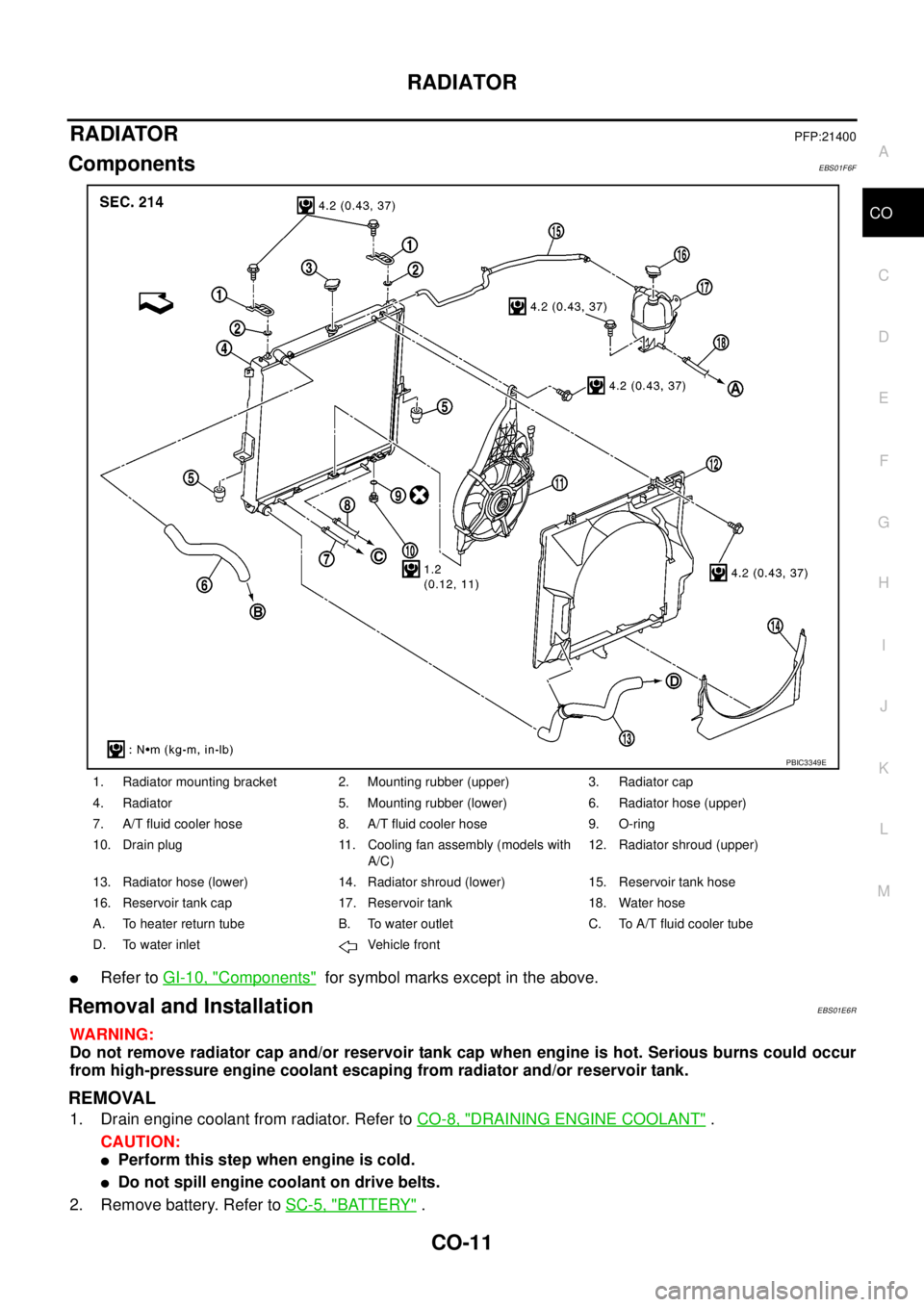

RADIATORPFP:21400

ComponentsEBS01F6F

lRefer toGI-10, "Components"for symbol marks except in the above.

Removal and InstallationEBS01E6R

WARNING:

Do not remove radiator cap and/or reservoir tank cap when engine is hot. Serious burns could occur

from high-pressure engine coolant escaping from radiator and/or reservoir tank.

REMOVAL

1. Drain engine coolant from radiator. Refer toCO-8, "DRAINING ENGINE COOLANT".

CAUTION:

lPerform this step when engine is cold.

lDo not spill engine coolant on drive belts.

2. Remove battery. Refer toSC-5, "

BATTERY".

1. Radiator mounting bracket 2. Mounting rubber (upper) 3. Radiator cap

4. Radiator 5. Mounting rubber (lower) 6. Radiator hose (upper)

7. A/T fluid cooler hose 8. A/T fluid cooler hose 9. O-ring

10. Drain plug 11. Cooling fan assembly (models with

A/C)12. Radiator shroud (upper)

13. Radiator hose (lower) 14. Radiator shroud (lower) 15. Reservoir tank hose

16. Reservoir tank cap 17. Reservoir tank 18. Water hose

A. To heater return tube B. To water outlet C. To A/T fluid cooler tube

D. To water inlet Vehicle front

PBIC3349E

Page 896 of 3171

CO-12

RADIATOR

3. Remove engine cover. Refer toEM-20, "INTAKE MANIFOLD".

4. Remove air inlet hoses between engine to charge air cooler. Refer toEM-18, "

CHARGE AIR COOLER".

5. Disconnect radiator hose (upper and lower) and reservoir tank hose.

CAUTION:

Be careful not to allow engine coolant to contact drive belts.

6. Remove reservoir tank.

7. Remove cooling fans (crankshaft driven type and motor driven type) and radiator shrouds (upper and

lower). Refer toCO-19, "

COOLING FAN".

8. Disconnect A/T fluid cooler hoses. (A/T models)

lInstall blind plug to avoid leakage of A/T fluid.

9. Remove radiator mounting brackets.

10. Remove the two A/C condenser bolts. (models with A/C)

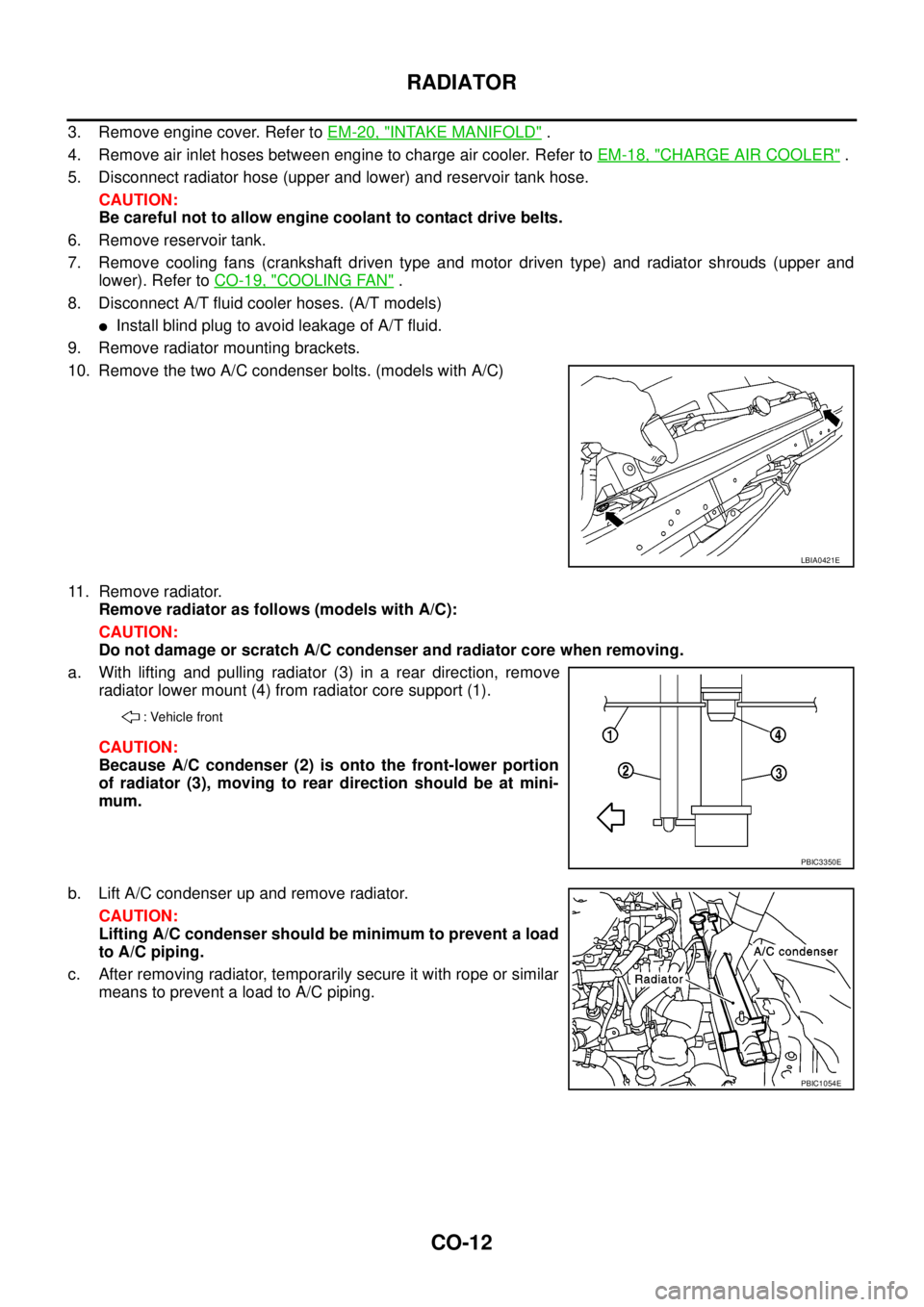

11. Remove radiator.

Remove radiator as follows (models with A/C):

CAUTION:

Do not damage or scratch A/C condenser and radiator core when removing.

a. With lifting and pulling radiator (3) in a rear direction, remove

radiator lower mount (4) from radiator core support (1).

CAUTION:

Because A/C condenser (2) is onto the front-lower portion

of radiator (3), moving to rear direction should be at mini-

mum.

b. Lift A/C condenser up and remove radiator.

CAUTION:

Lifting A/C condenser should be minimum to prevent a load

to A/C piping.

c. After removing radiator, temporarily secure it with rope or similar

means to prevent a load to A/C piping.

LBIA0421E

: Vehicle front

PBIC3350E

PBIC1054E

Page 897 of 3171

RADIATOR

CO-13

C

D

E

F

G

H

I

J

K

L

MA

CO

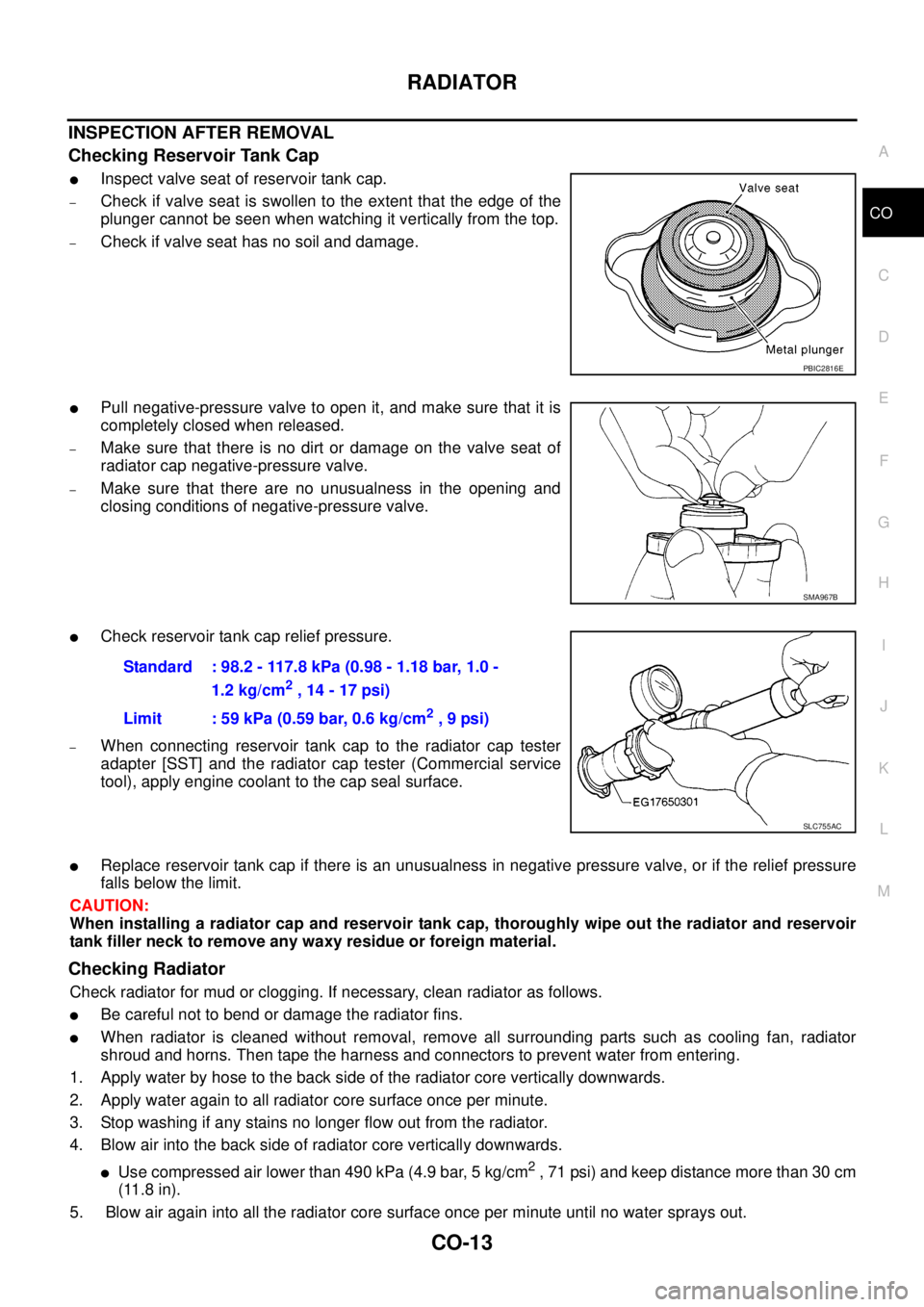

INSPECTION AFTER REMOVAL

Checking Reservoir Tank Cap

lInspect valve seat of reservoir tank cap.

–Check if valve seat is swollen to the extent that the edge of the

plunger cannot be seen when watching it vertically from the top.

–Check if valve seat has no soil and damage.

lPull negative-pressure valve to open it, and make sure that it is

completely closed when released.

–Make sure that there is no dirt or damage on the valve seat of

radiator cap negative-pressure valve.

–Make sure that there are no unusualness in the opening and

closing conditions of negative-pressure valve.

lCheck reservoir tank cap relief pressure.

–When connecting reservoir tank cap to the radiator cap tester

adapter [SST] and the radiator cap tester (Commercial service

tool), apply engine coolant to the cap seal surface.

lReplace reservoir tank cap if there is an unusualness in negative pressure valve, or if the relief pressure

falls below the limit.

CAUTION:

When installing a radiator cap and reservoir tank cap, thoroughly wipe out the radiator and reservoir

tank filler neck to remove any waxy residue or foreign material.

Checking Radiator

Check radiator for mud or clogging. If necessary, clean radiator as follows.

lBe careful not to bend or damage the radiator fins.

lWhen radiator is cleaned without removal, remove all surrounding parts such as cooling fan, radiator

shroud and horns. Then tape the harness and connectors to prevent water from entering.

1. Apply water by hose to the back side of the radiator core vertically downwards.

2. Apply water again to all radiator core surface once per minute.

3. Stop washing if any stains no longer flow out from the radiator.

4. Blow air into the back side of radiator core vertically downwards.

lUse compressed air lower than 490 kPa (4.9 bar, 5 kg/cm2, 71 psi) and keep distance more than 30 cm

(11.8 in).

5. Blow air again into all the radiator core surface once per minute until no water sprays out.

PBIC2816E

SMA967B

Standard : 98.2 - 117.8 kPa (0.98 - 1.18 bar, 1.0 -

1.2 kg/cm

2,14-17psi)

Limit : 59 kPa (0.59 bar, 0.6 kg/cm

2,9psi)

SLC755AC

Page 898 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual CO-14

RADIATOR

INSTALLATION

Installation is the reverse order of removal.

INSPECTION AFTER INSTALLATION

lCheck for leaks of engine coolant using the radiator cap tester adapter [SST: EG17650301] and t NISSAN NAVARA 2005 Repair Workshop Manual CO-14

RADIATOR

INSTALLATION

Installation is the reverse order of removal.

INSPECTION AFTER INSTALLATION

lCheck for leaks of engine coolant using the radiator cap tester adapter [SST: EG17650301] and t](/img/5/57362/w960_57362-897.png)

CO-14

RADIATOR

INSTALLATION

Installation is the reverse order of removal.

INSPECTION AFTER INSTALLATION

lCheck for leaks of engine coolant using the radiator cap tester adapter [SST: EG17650301] and the radia-

tor cap tester (commercial service tool). Refer toCO-7, "

CHECKING RADIATOR SYSTEM FOR LEAKS".

lStart and warm up engine. Visually check if there is no leaks of engine coolant.

Page 899 of 3171

RADIATOR (ALUMINUM TYPE)

CO-15

C

D

E

F

G

H

I

J

K

L

MA

CO

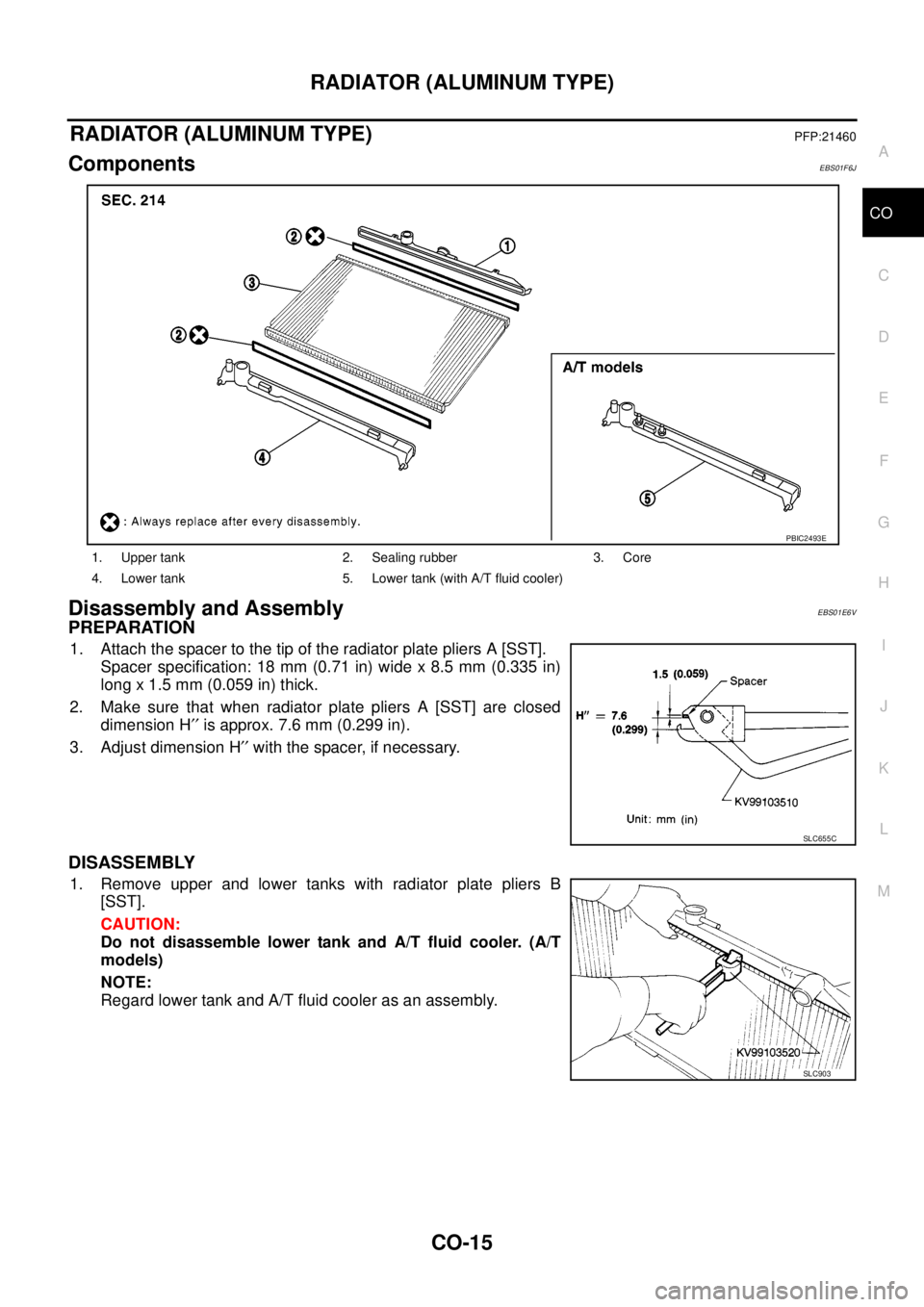

RADIATOR (ALUMINUM TYPE)PFP:21460

ComponentsEBS01F6J

Disassembly and AssemblyEBS01E6V

PREPARATION

1. Attach the spacer to the tip of the radiator plate pliers A [SST].

Spacer specification: 18 mm (0.71 in) wide x 8.5 mm (0.335 in)

long x 1.5 mm (0.059 in) thick.

2. Make sure that when radiator plate pliers A [SST] are closed

dimension H¢¢is approx. 7.6 mm (0.299 in).

3. Adjust dimension H¢¢with the spacer, if necessary.

DISASSEMBLY

1. Remove upper and lower tanks with radiator plate pliers B

[SST].

CAUTION:

Do not disassemble lower tank and A/T fluid cooler. (A/T

models)

NOTE:

Regard lower tank and A/T fluid cooler as an assembly.

1. Upper tank 2. Sealing rubber 3. Core

4. Lower tank 5. Lower tank (with A/T fluid cooler)

PBIC2493E

SLC655C

SLC903

Page 900 of 3171

CO-16

RADIATOR (ALUMINUM TYPE)

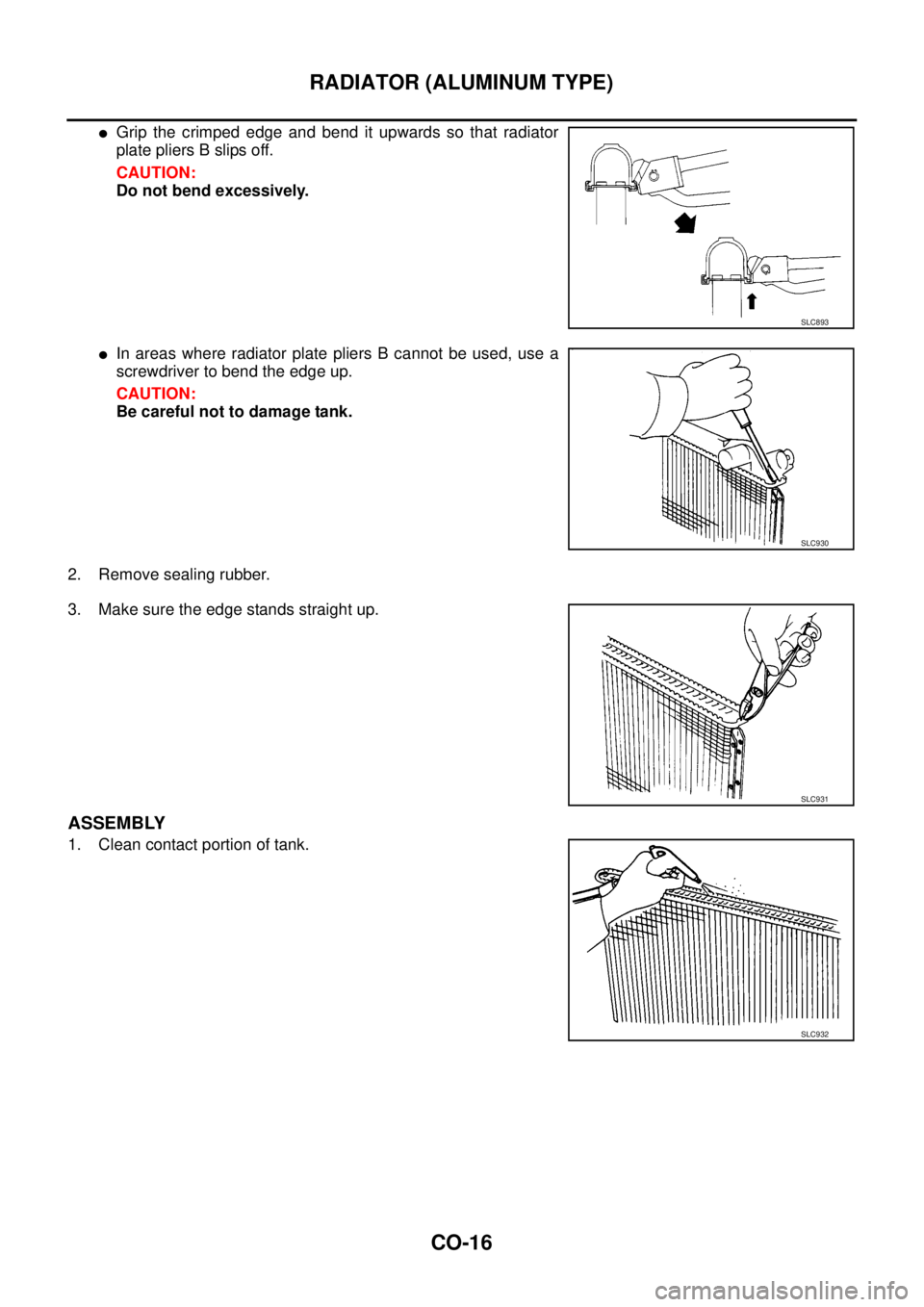

lGrip the crimped edge and bend it upwards so that radiator

plate pliers B slips off.

CAUTION:

Do not bend excessively.

lIn areas where radiator plate pliers B cannot be used, use a

screwdriver to bend the edge up.

CAUTION:

Be careful not to damage tank.

2. Remove sealing rubber.

3. Make sure the edge stands straight up.

ASSEMBLY

1. Clean contact portion of tank.

SLC893

SLC930

SLC931

SLC932