NISSAN NAVARA 2005 Repair Workshop Manual

Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 871 of 3171

CLUTCH PEDAL

CL-7

D

E

F

G

H

I

J

K

L

MA

B

CL

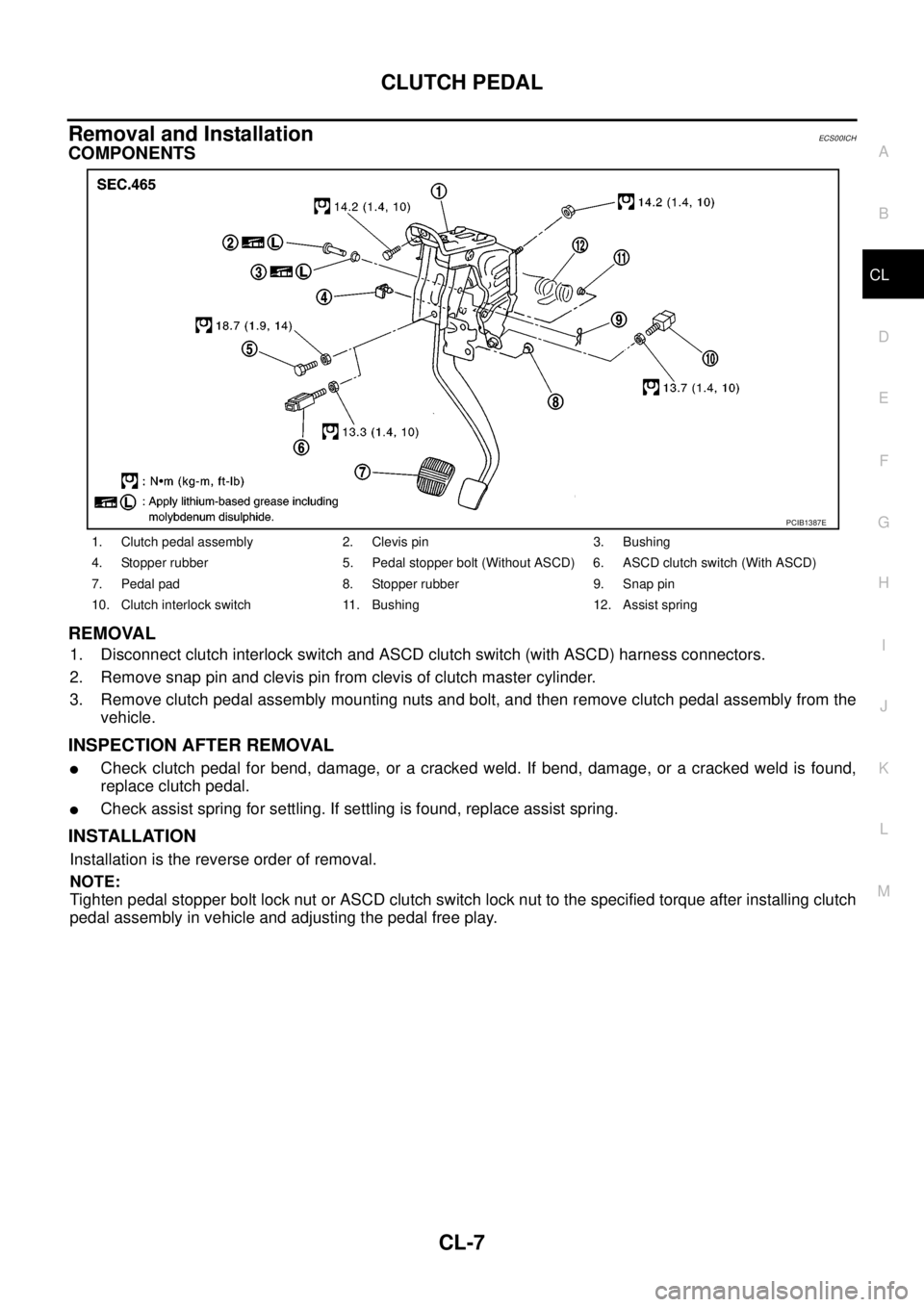

Removal and InstallationECS00ICH

COMPONENTS

REMOVAL

1. Disconnect clutch interlock switch and ASCD clutch switch (with ASCD) harness connectors.

2. Remove snap pin and clevis pin from clevis of clutch master cylinder.

3. Remove clutch pedal assembly mounting nuts and bolt, and then remove clutch pedal assembly from the

vehicle.

INSPECTION AFTER REMOVAL

lCheck clutch pedal for bend, damage, or a cracked weld. If bend, damage, or a cracked weld is found,

replace clutch pedal.

lCheck assist spring for settling. If settling is found, replace assist spring.

INSTALLATION

Installation is the reverse order of removal.

NOTE:

Tighten pedal stopper bolt lock nut or ASCD clutch switch lock nut to the specified torque after installing clutch

pedal assembly in vehicle and adjusting the pedal free play.

1. Clutch pedal assembly 2. Clevis pin 3. Bushing

4. Stopper rubber 5. Pedal stopper bolt (Without ASCD) 6. ASCD clutch switch (With ASCD)

7. Pedal pad 8. Stopper rubber 9. Snap pin

10. Clutch interlock switch 11. Bushing 12. Assist spring

PCIB1387E

Page 872 of 3171

CL-8

CLUTCH FLUID

CLUTCH FLUID

PFP:00017

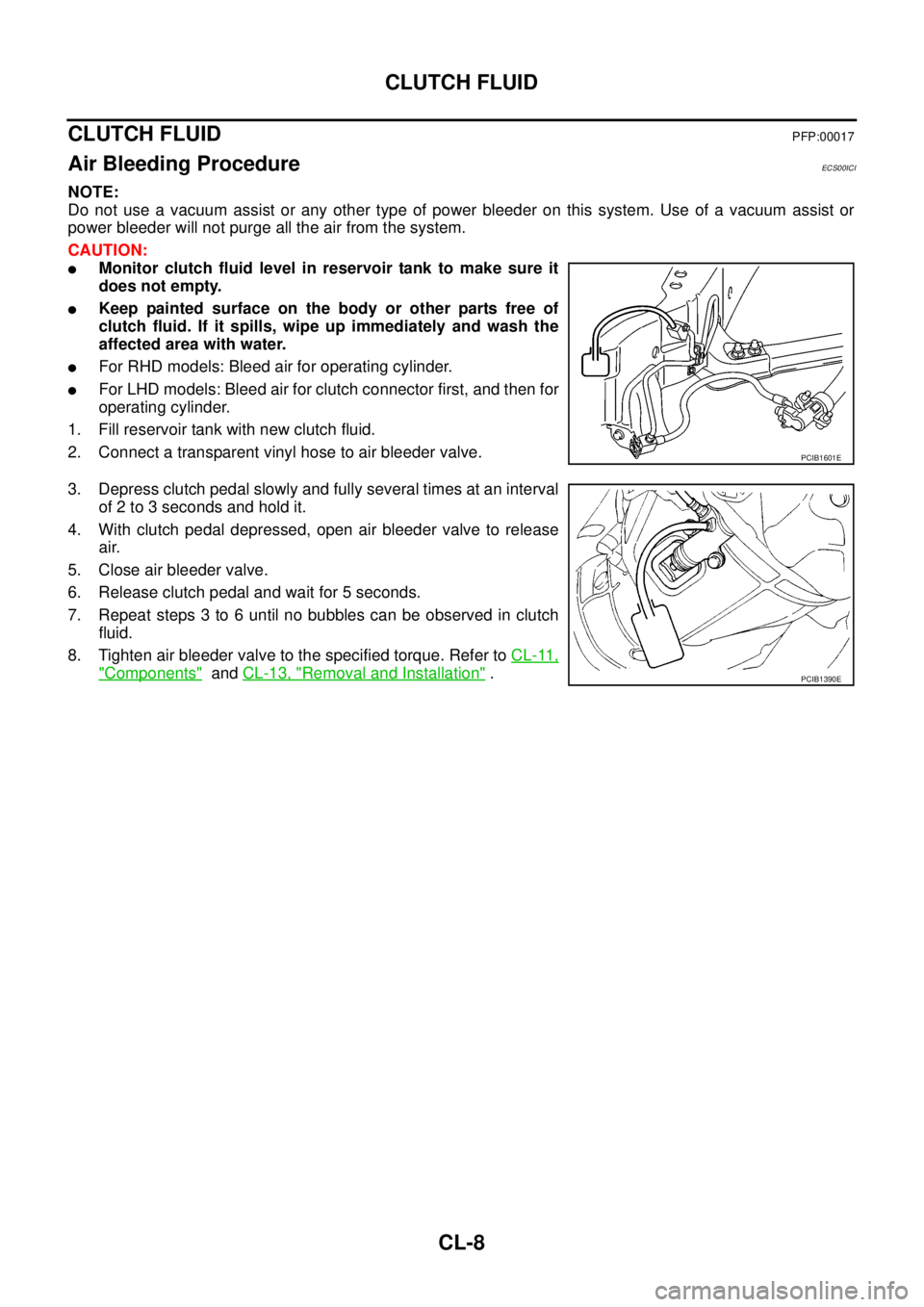

Air Bleeding ProcedureECS00ICI

NOTE:

Do not use a vacuum assist or any other type of power bleeder on this system. Use of a vacuum assist or

power bleeder will not purge all the air from the system.

CAUTION:

lMonitor clutch fluid level in reservoir tank to make sure it

does not empty.

lKeep painted surface on the body or other parts free of

clutch fluid. If it spills, wipe up immediately and wash the

affected area with water.

lFor RHD models: Bleed air for operating cylinder.

lFor LHD models: Bleed air for clutch connector first, and then for

operating cylinder.

1. Fill reservoir tank with new clutch fluid.

2. Connect a transparent vinyl hose to air bleeder valve.

3. Depress clutch pedal slowly and fully several times at an interval

of 2 to 3 seconds and hold it.

4. With clutch pedal depressed, open air bleeder valve to release

air.

5. Close air bleeder valve.

6. Release clutch pedal and wait for 5 seconds.

7. Repeat steps 3 to 6 until no bubbles can be observed in clutch

fluid.

8. Tighten air bleeder valve to the specified torque. Refer toCL-11,

"Components"andCL-13, "Removal and Installation".

PCIB1601E

PCIB1390E

Page 873 of 3171

CLUTCH MASTER CYLINDER

CL-9

D

E

F

G

H

I

J

K

L

MA

B

CL

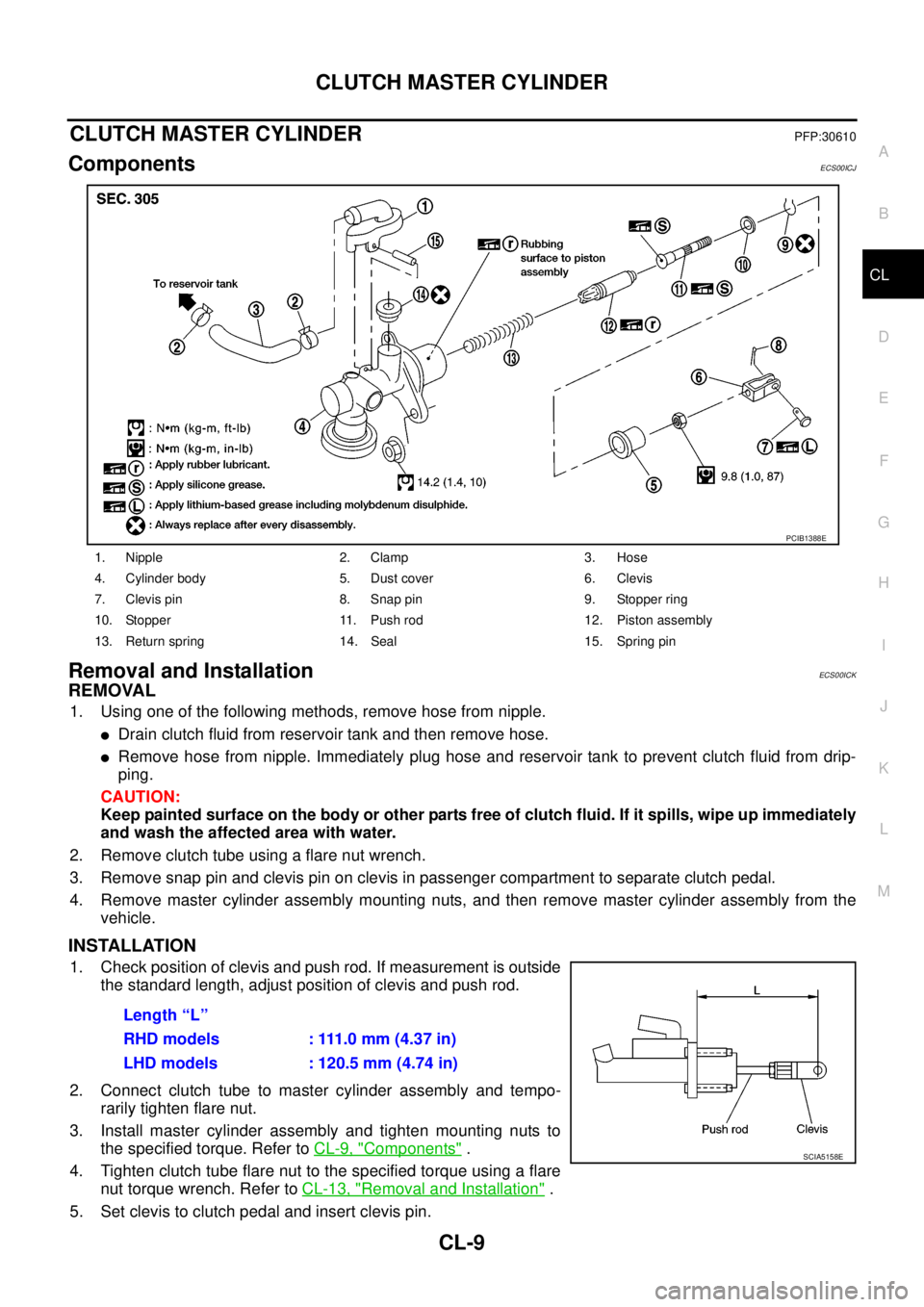

CLUTCH MASTER CYLINDERPFP:30610

ComponentsECS00ICJ

Removal and InstallationECS00ICK

REMOVAL

1. Using one of the following methods, remove hose from nipple.

lDrain clutch fluid from reservoir tank and then remove hose.

lRemove hose from nipple. Immediately plug hose and reservoir tank to prevent clutch fluid from drip-

ping.

CAUTION:

Keep painted surface on the body or other parts free of clutch fluid. If it spills, wipe up immediately

and wash the affected area with water.

2. Remove clutch tube using a flare nut wrench.

3. Remove snap pin and clevis pin on clevis in passenger compartment to separate clutch pedal.

4. Remove master cylinder assembly mounting nuts, and then remove master cylinder assembly from the

vehicle.

INSTALLATION

1. Check position of clevis and push rod. If measurement is outside

the standard length, adjust position of clevis and push rod.

2. Connect clutch tube to master cylinder assembly and tempo-

rarily tighten flare nut.

3. Install master cylinder assembly and tighten mounting nuts to

the specified torque. Refer toCL-9, "

Components".

4. Tightenclutchtubeflarenuttothespecifiedtorqueusingaflare

nut torque wrench. Refer toCL-13, "

Removal and Installation".

5. Set clevis to clutch pedal and insert clevis pin.

1. Nipple 2. Clamp 3. Hose

4. Cylinder body 5. Dust cover 6. Clevis

7. Clevis pin 8. Snap pin 9. Stopper ring

10. Stopper 11. Push rod 12. Piston assembly

13. Return spring 14. Seal 15. Spring pin

PCIB1388E

Length “L”

RHD models : 111.0 mm (4.37 in)

LHD models : 120.5 mm (4.74 in)

SCIA5158E

Page 874 of 3171

CL-10

CLUTCH MASTER CYLINDER

6. Attach snap pin to clevis pin.

7. Install hose to nipple.

8. After completing this procedure, inspect and adjust for clutch pedal and then bleed the air from the clutch

hydraulic system. Refer toCL-6, "

On-Vehicle Inspection and Adjustment"andCL-8, "Air Bleeding Proce-

dure".

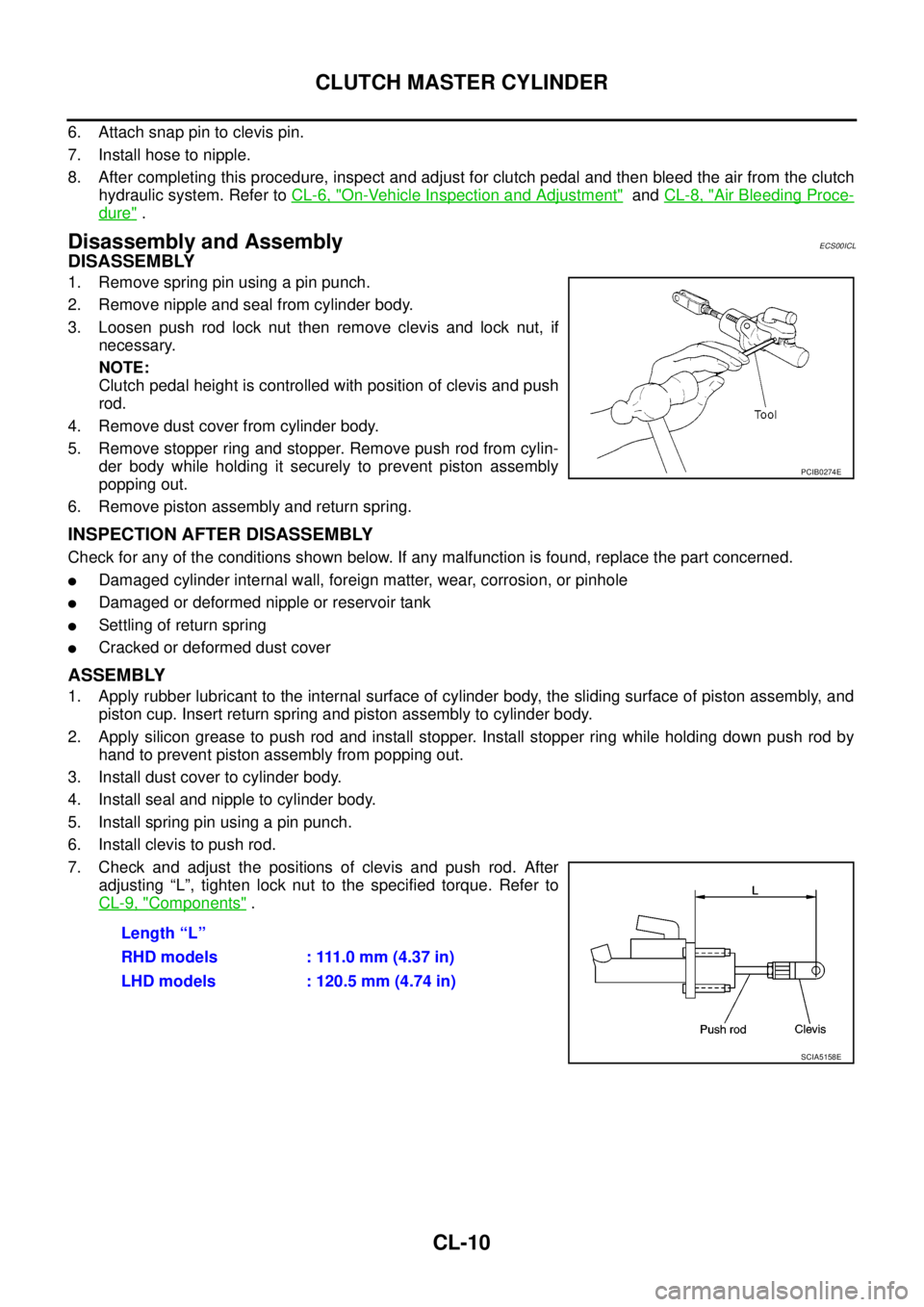

Disassembly and AssemblyECS00ICL

DISASSEMBLY

1. Remove spring pin using a pin punch.

2. Remove nipple and seal from cylinder body.

3. Loosen push rod lock nut then remove clevis and lock nut, if

necessary.

NOTE:

Clutch pedal height is controlled with position of clevis and push

rod.

4. Remove dust cover from cylinder body.

5. Remove stopper ring and stopper. Remove push rod from cylin-

der body while holding it securely to prevent piston assembly

popping out.

6. Remove piston assembly and return spring.

INSPECTION AFTER DISASSEMBLY

Check for any of the conditions shown below. If any malfunction is found, replace the part concerned.

lDamaged cylinder internal wall, foreign matter, wear, corrosion, or pinhole

lDamaged or deformed nipple or reservoir tank

lSettling of return spring

lCracked or deformed dust cover

ASSEMBLY

1. Apply rubber lubricant to the internal surface of cylinder body, the sliding surface of piston assembly, and

piston cup. Insert return spring and piston assembly to cylinder body.

2. Apply silicon grease to push rod and install stopper. Install stopper ring while holding down push rod by

hand to prevent piston assembly from popping out.

3. Install dust cover to cylinder body.

4. Install seal and nipple to cylinder body.

5. Install spring pin using a pin punch.

6. Install clevis to push rod.

7. Check and adjust the positions of clevis and push rod. After

adjusting “L”, tighten lock nut to the specified torque. Refer to

CL-9, "

Components".

PCIB0274E

Length “L”

RHD models : 111.0 mm (4.37 in)

LHD models : 120.5 mm (4.74 in)

SCIA5158E

Page 875 of 3171

OPERATING CYLINDER

CL-11

D

E

F

G

H

I

J

K

L

MA

B

CL

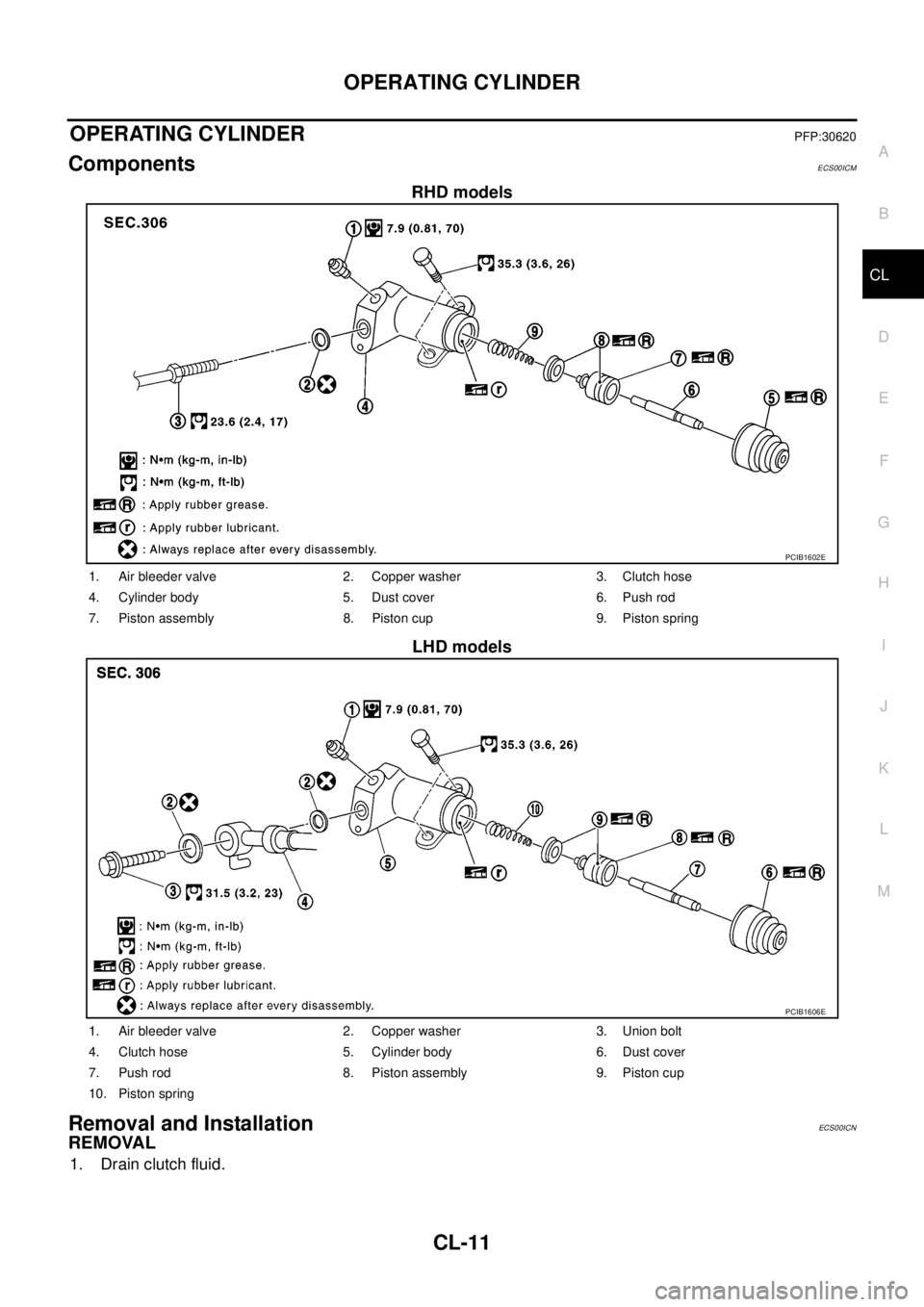

OPERATING CYLINDERPFP:30620

ComponentsECS00ICM

RHD models

LHD models

Removal and InstallationECS00ICN

REMOVAL

1. Drain clutch fluid.

PCIB1602E

1. Air bleeder valve 2. Copper washer 3. Clutch hose

4. Cylinder body 5. Dust cover 6. Push rod

7. Piston assembly 8. Piston cup 9. Piston spring

PCIB1606E

1. Air bleeder valve 2. Copper washer 3. Union bolt

4. Clutch hose 5. Cylinder body 6. Dust cover

7. Push rod 8. Piston assembly 9. Piston cup

10. Piston spring

Page 876 of 3171

CL-12

OPERATING CYLINDER

CAUTION:

Keep painted surface on the body or other parts free of clutch fluid. If it spills, wipe up immediately

and wash the affected area with water.

2. Remove clutch hose from operating cylinder assembly.

3. Remove operating cylinder assembly mounting bolts, and then remove operating cylinder assembly from

the vehicle.

INSTALLATION

Note the following, and install in the reverse order of removal.

lInstall clutch hose with care so that it will not be bent or twisted.

lTightenclutchhosetothespecifiedtorque.

CAUTION:

Do not reuse copper washer.

lAfter completing the procedure, bleed the air from the clutch hydraulic system. Refer toCL-8, "Air Bleed-

ing Procedure".

Disassembly and AssemblyECS00ICO

DISASSEMBLY

lRemove dust cover and push rod. Then remove piston, piston cup and piston spring from cylinder body.

INSPECTION AFTER DISASSEMBLY

Check for any of the conditions shown below. If any malfunction is found, replace the part concerned.

lDamage to cylinder internal surface or piston sliding surface. Foreign matter, wear, corrosion, or pinhole

lSettling of piston spring

lCracked or deformed dust cover

ASSEMBLY

1. Apply rubber lubricant to cylinder body internal surface and rubber grease to piston cup and piston. Insert

piston assembly and piston spring into cylinder body.

2. Apply rubber grease to dust cover and then install push rod and dust cover.

Page 877 of 3171

CLUTCH PIPING

CL-13

D

E

F

G

H

I

J

K

L

MA

B

CL

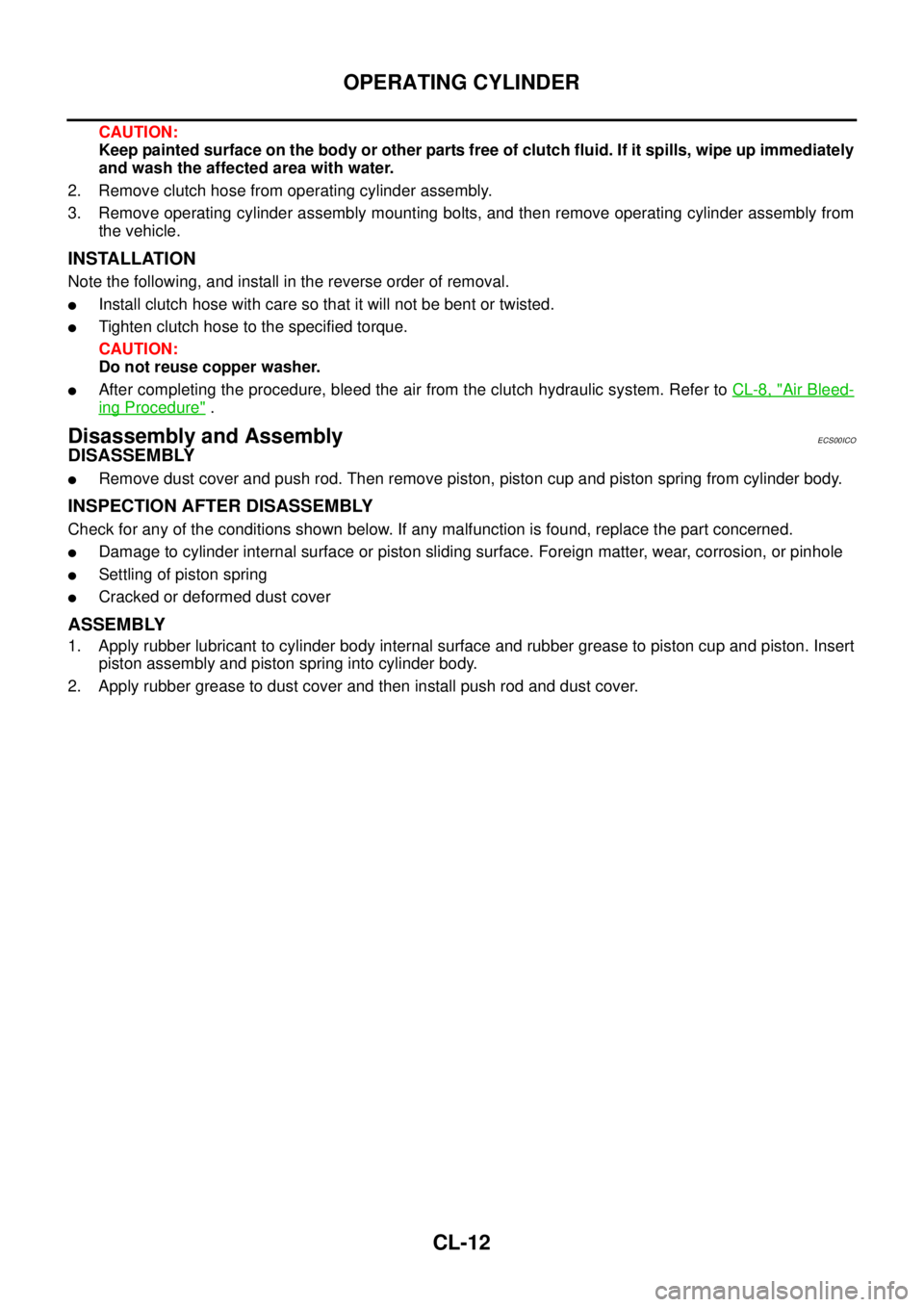

CLUTCH PIPINGPFP:30650

Removal and InstallationECS00ICP

RHD models

LHD models

Carefully observe the following steps during clutch tube removal and installation.

CAUTION:

Keep painted surface on the body or other parts free of clutch fluid. If it spills, wipe up immediately

and wash the affected area with water.

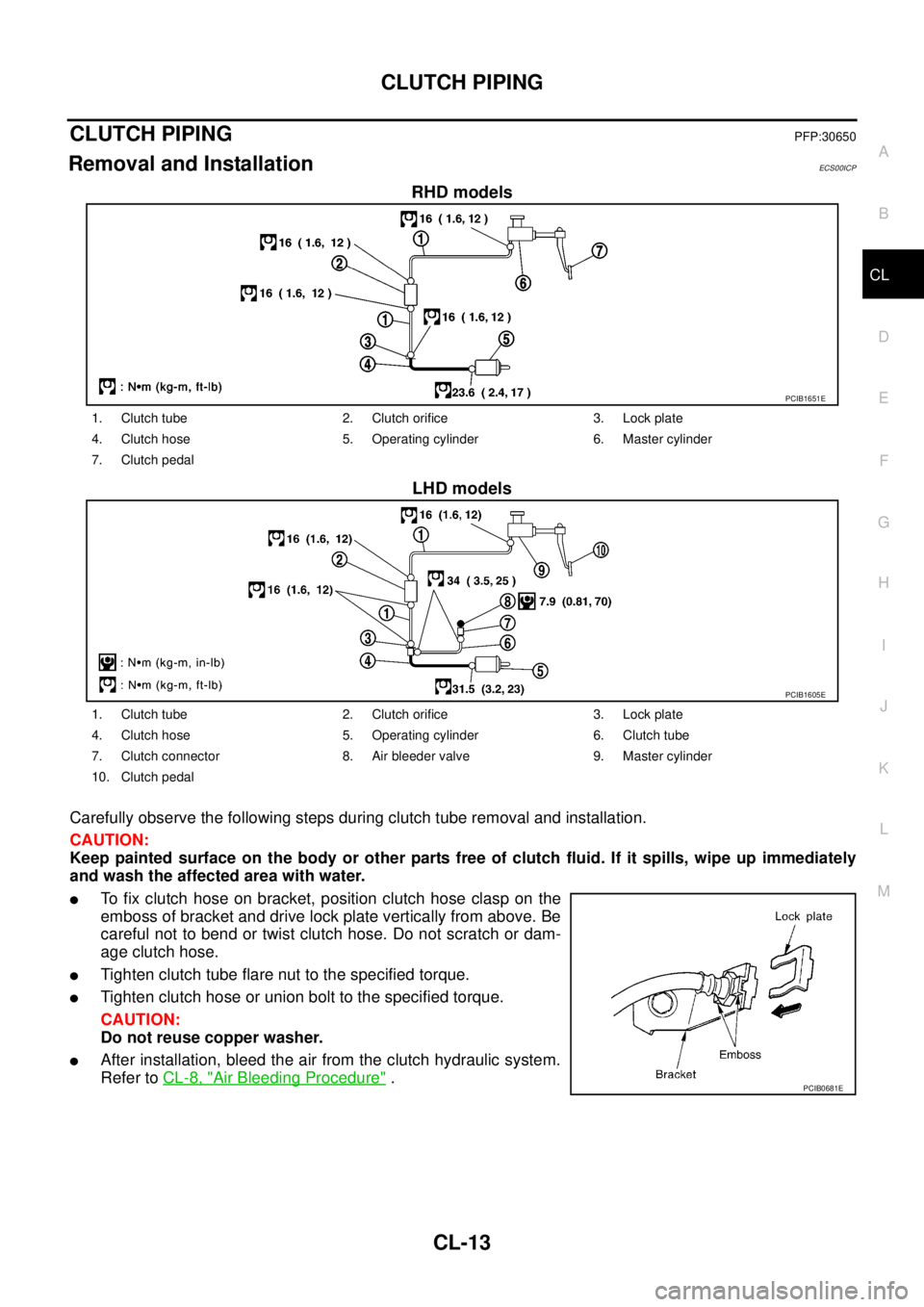

lTo fix clutch hose on bracket, position clutch hose clasp on the

emboss of bracket and drive lock plate vertically from above. Be

careful not to bend or twist clutch hose. Do not scratch or dam-

age clutch hose.

lTighten clutch tube flare nut to the specified torque.

lTighten clutch hose or union bolt to the specified torque.

CAUTION:

Do not reuse copper washer.

lAfter installation, bleed the air from the clutch hydraulic system.

Refer toCL-8, "

Air Bleeding Procedure".

PCIB1651E

1. Clutch tube 2. Clutch orifice 3. Lock plate

4. Clutch hose 5. Operating cylinder 6. Master cylinder

7. Clutch pedal

PCIB1605E

1. Clutch tube 2. Clutch orifice 3. Lock plate

4. Clutch hose 5. Operating cylinder 6. Clutch tube

7. Clutch connector 8. Air bleeder valve 9. Master cylinder

10. Clutch pedal

PCIB0681E

Page 878 of 3171

CL-14

CLUTCH RELEASE MECHANISM

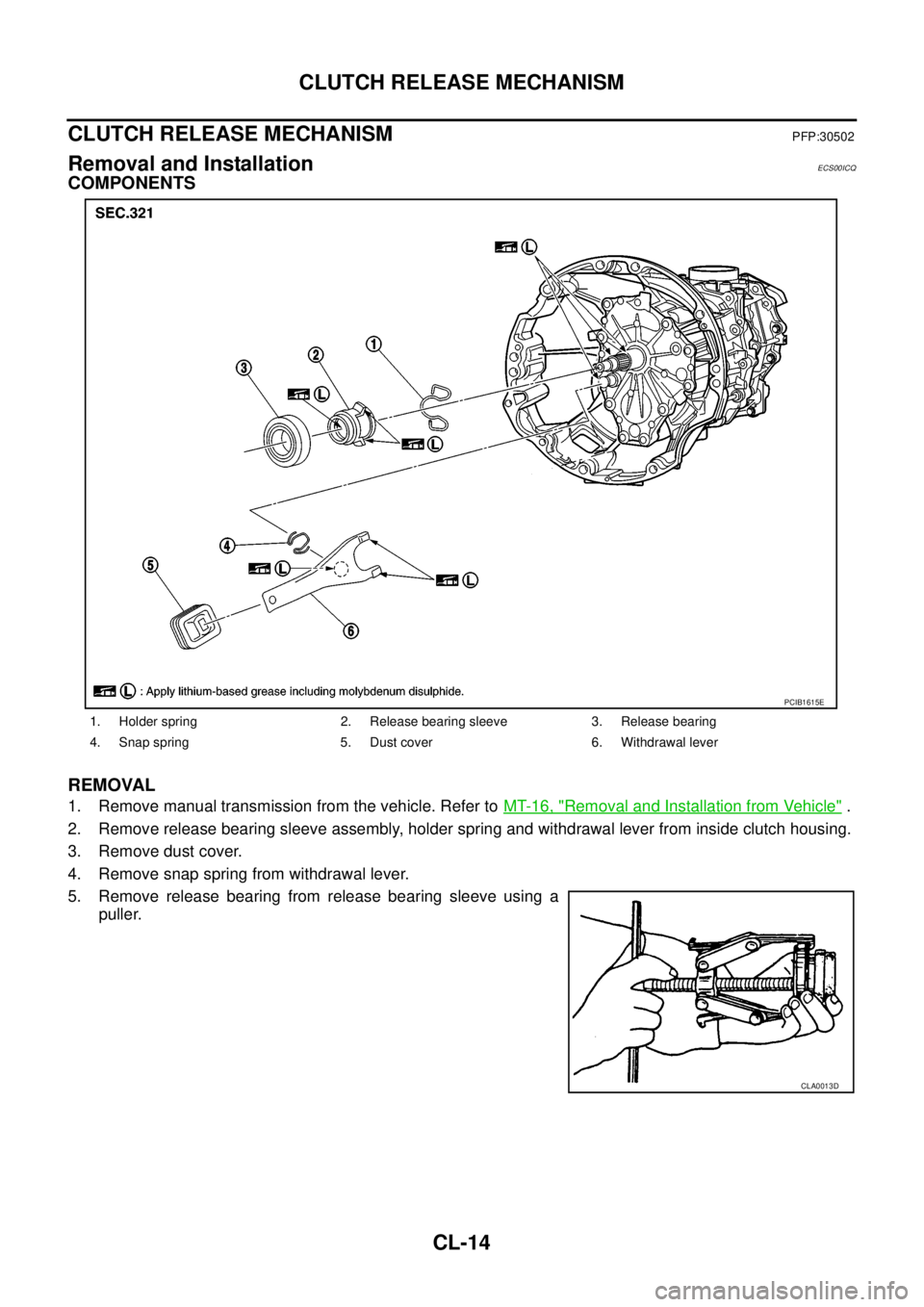

CLUTCH RELEASE MECHANISM

PFP:30502

Removal and InstallationECS00ICQ

COMPONENTS

REMOVAL

1. Remove manual transmission from the vehicle. Refer toMT-16, "Removal and Installation from Vehicle".

2. Remove release bearing sleeve assembly, holder spring and withdrawal lever from inside clutch housing.

3. Remove dust cover.

4. Remove snap spring from withdrawal lever.

5. Remove release bearing from release bearing sleeve using a

puller.

1. Holder spring 2. Release bearing sleeve 3. Release bearing

4. Snap spring 5. Dust cover 6. Withdrawal lever

PCIB1615E

CLA0013D

Page 879 of 3171

CLUTCH RELEASE MECHANISM

CL-15

D

E

F

G

H

I

J

K

L

MA

B

CL

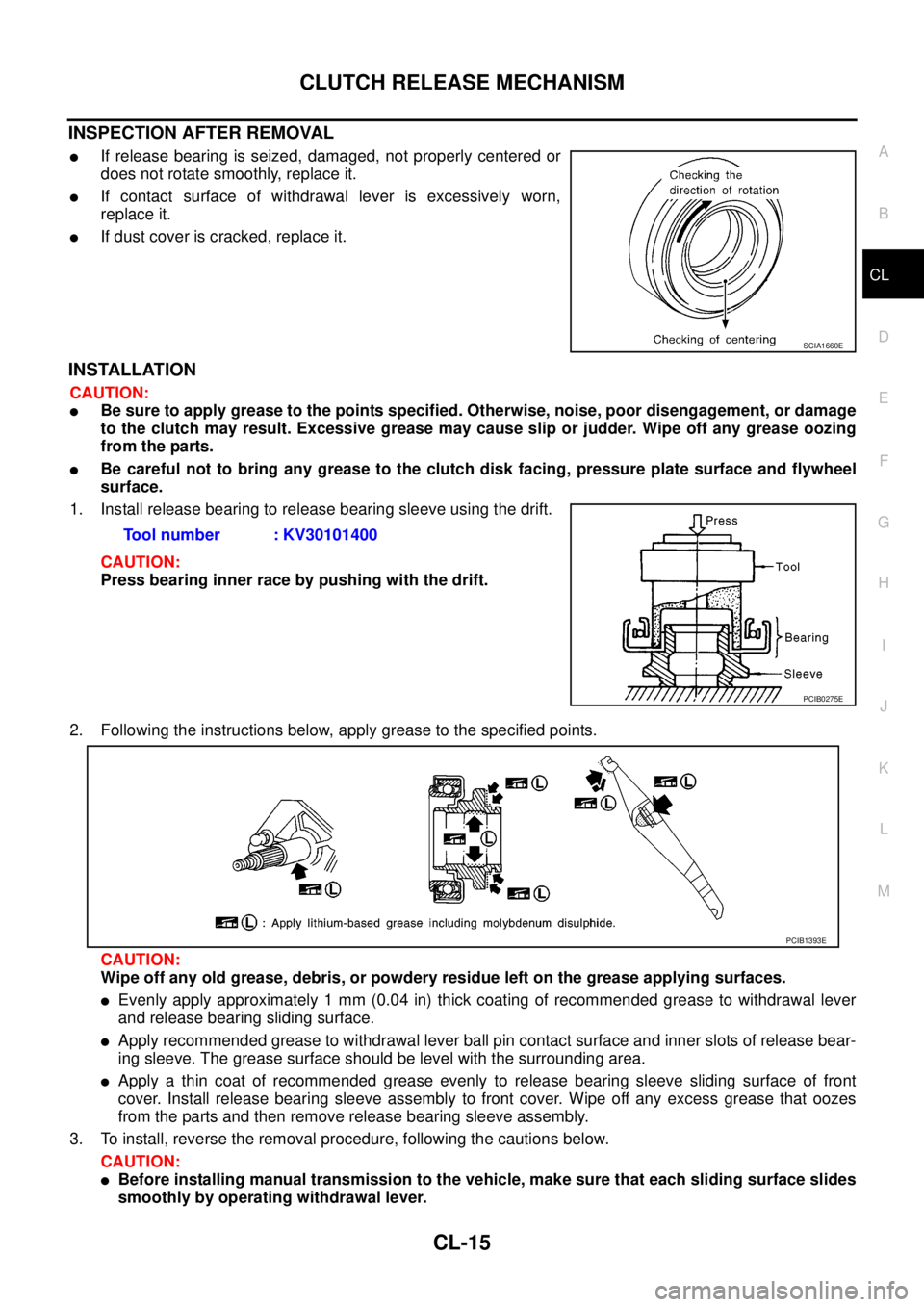

INSPECTION AFTER REMOVAL

lIf release bearing is seized, damaged, not properly centered or

does not rotate smoothly, replace it.

lIf contact surface of withdrawal lever is excessively worn,

replace it.

lIf dust cover is cracked, replace it.

INSTALLATION

CAUTION:

lBe sure to apply grease to the points specified. Otherwise, noise, poor disengagement, or damage

to the clutch may result. Excessive grease may cause slip or judder. Wipe off any grease oozing

from the parts.

lBe careful not to bring any grease to the clutch disk facing, pressure plate surface and flywheel

surface.

1. Install release bearing to release bearing sleeve using the drift.

CAUTION:

Press bearing inner race by pushing with the drift.

2. Following the instructions below, apply grease to the specified points.

CAUTION:

Wipe off any old grease, debris, or powdery residue left on the grease applying surfaces.

lEvenly apply approximately 1 mm (0.04 in) thick coating of recommended grease to withdrawal lever

and release bearing sliding surface.

lApply recommended grease to withdrawal lever ball pin contact surface and inner slots of release bear-

ing sleeve. The grease surface should be level with the surrounding area.

lApply a thin coat of recommended grease evenly to release bearing sleeve sliding surface of front

cover. Install release bearing sleeve assembly to front cover. Wipe off any excess grease that oozes

from the parts and then remove release bearing sleeve assembly.

3. To install, reverse the removal procedure, following the cautions below.

CAUTION:

lBefore installing manual transmission to the vehicle, make sure that each sliding surface slides

smoothly by operating withdrawal lever.

SCIA1660E

Tool number : KV30101400

PCIB0275E

PCIB1393E

Page 880 of 3171

CL-16

CLUTCH RELEASE MECHANISM

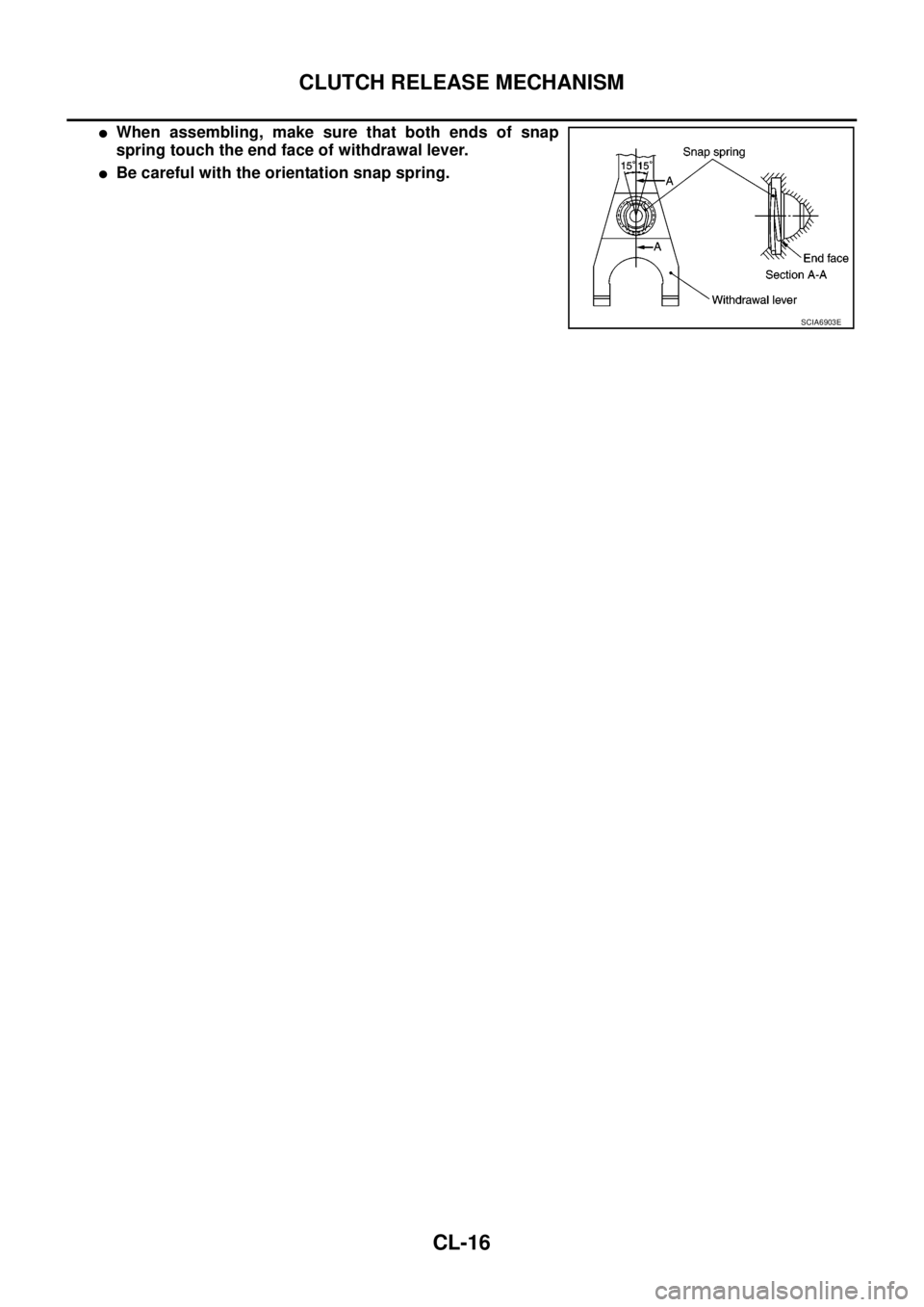

lWhen assembling, make sure that both ends of snap

spring touch the end face of withdrawal lever.

lBe careful with the orientation snap spring.

SCIA6903E