cooling NISSAN NOTE 2016 Service Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 2633 of 3641

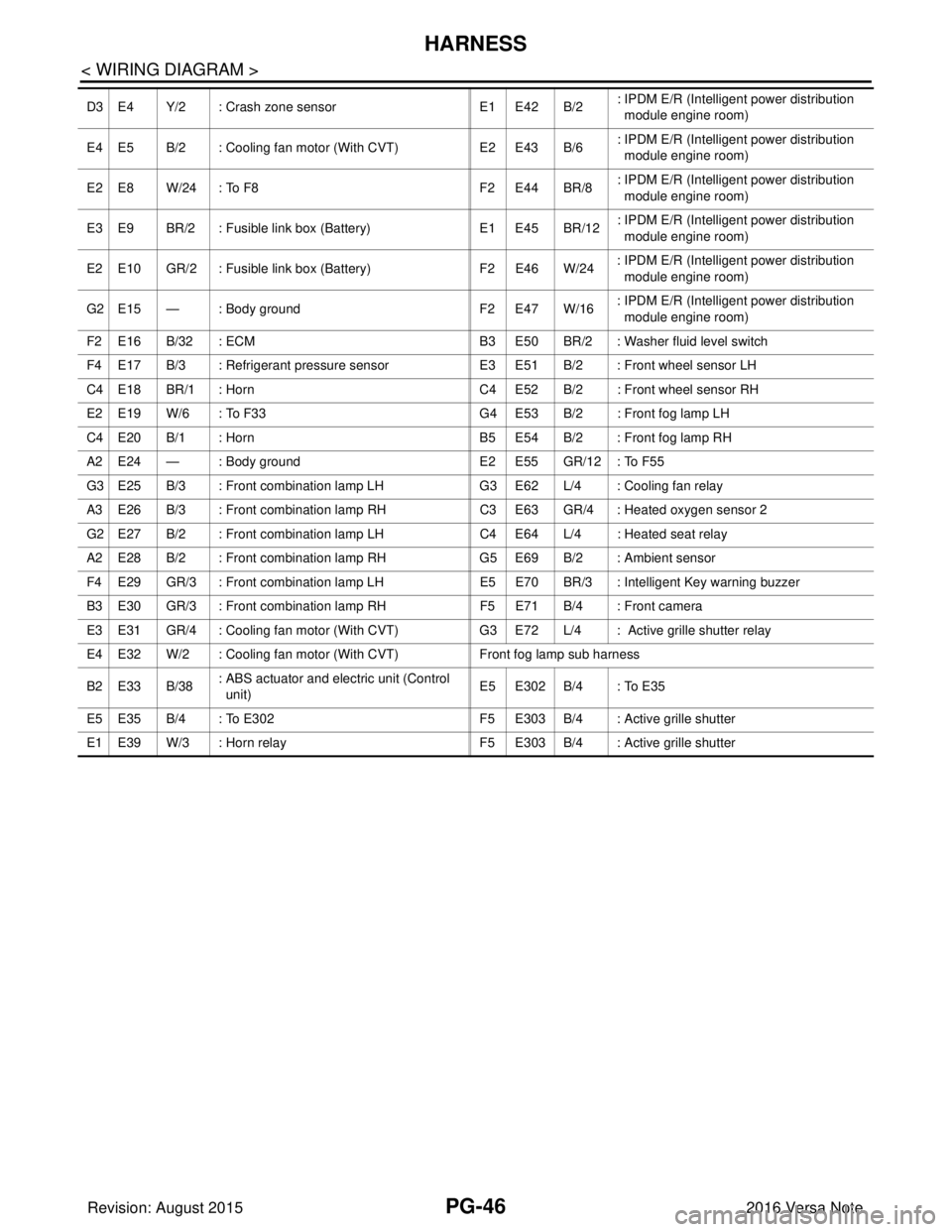

PG-46

< WIRING DIAGRAM >

HARNESS

D3 E4 Y/2 : Crash zone sensorE1 E42 B/2: IPDM E/R (Intelligent power distribution

module engine room)

E4 E5 B/2 : Cooling fan motor (With CVT)E2 E43 B/6: IPDM E/R (Intelligent power distribution

module engine room)

E2 E8 W/24 : To F8 F2 E44 BR/8: IPDM E/R (Intelligent power distribution

module engine room)

E3 E9 BR/2 : Fusible link b o x ( B a t t e r y )E 1 E 4 5 B R / 1 2: IPDM E/R (Intelligent power distribution

module engine room)

E2 E10 GR/2 : Fusible link box (Battery) F2 E46 W/24: IPDM E/R (Intelligent power distribution

module engine room)

G 2 E 1 5 — : B o d y g r o u n d F 2 E 4 7 W / 1 6: IPDM E/R (Intelligent power distribution

module engine room)

F 2 E 1 6 B / 3 2 : E C M B 3 E 5 0 B R / 2 : W a s h e r f l u i d l e v e l s w i t c h

F4 E17 B/3 : Refrigerant pressure sensor E3 E51 B/2 : Front wheel sensor LH

C4 E18 BR/1 : Horn C4 E52 B/2 : Front wheel sensor RH

E 2 E 1 9 W / 6 : To F 3 3 G 4 E 5 3 B / 2 : F r o n t f o g l a m p L H

C 4 E 2 0 B / 1 : H o r n B 5 E 5 4 B / 2 : F r o n t f o g l a m p R H

A2 E24 — : Body ground E2 E55 GR/12 : To F55

G3 E25 B/3 : Front combination lamp LH G3 E62 L/4 : Cooling fan relay

A3 E26 B/3 : Front combination lamp RH C3 E63 GR/4 : Heated oxygen sensor 2

G2 E27 B/2 : Front combination lamp LH C4 E64 L/4 : Heated seat relay

A2 E28 B/2 : Front combinati on lamp RHG5 E69 B/2 : Ambient sensor

F4 E29 GR/3 : Front combination lamp LH E5 E70 BR/3 : Intelligent Key warning buzzer

B3 E30 GR/3 : Front combination lamp RH F5 E71 B/4 : Front camera

E3 E31 GR/4 : Cooling fan motor (With CVT) G3 E72 L/4 : Active grille shutter relay

E4 E32 W/2 : Cooling fan motor (With CVT) Front fog lamp sub harness

B2 E33 B/38 : ABS actuator and electric unit (Control

unit) E5 E302 B/4 : To E35

E5 E35 B/4 : To E302 F5 E303 B/4 : Active grille shutter

E1 E39 W/3 : Horn relay F5 E303 B/4 : Active grille shutter

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2984 of 3641

![NISSAN NOTE 2016 Service Owners Manual DIAGNOSIS SYSTEM (IPDM E/R)SEC-127

< SYSTEM DESCRIPTION > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis DescriptionINFOID:0000000012542533

AU NISSAN NOTE 2016 Service Owners Manual DIAGNOSIS SYSTEM (IPDM E/R)SEC-127

< SYSTEM DESCRIPTION > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis DescriptionINFOID:0000000012542533

AU](/img/5/57363/w960_57363-2983.png)

DIAGNOSIS SYSTEM (IPDM E/R)SEC-127

< SYSTEM DESCRIPTION > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis DescriptionINFOID:0000000012542533

AUTO ACTIVE TEST

Description

In auto active test, the IPDM E/R sends a drive signal to the following systems to check their operation:

• Front wiper (LO, HI)

• Parking lamp

• Side marker lamp

• License plate lamp

• Tail lamp

• Front fog lamp

• Headlamp (LO, HI)

• A/C compressor (magnet clutch)

• Cooling fan

Operation Procedure

NOTE:

Never perform auto active test in the following conditions:

• Passenger door is open

• CONSULT is connected

1. Close the hood and lift the wiper arms from the windshield. (Prevent windshield damage due to wiper

operation)

NOTE:

When auto active test is performed with hood opened, sprinkle water on windshield beforehand.

2. Turn the ignition switch OFF.

3. Turn the ignition switch ON, and within 20 seconds, pr ess the driver door switch 10 times. Then turn the

ignition switch OFF.

4. Turn the ignition switch ON within 10 seconds. Af ter that the horn sounds once and the auto active test

starts.

5. After a series of the following operations is repeated 3 times, auto active test is completed.

NOTE:

• When auto active test has to be cancelled halfw ay through test, turn the ignition switch OFF.

• When auto active test is not activated, door swit ch may be the cause. Check door switch. Refer to DLK-98,

"ComponentFunctionCheck" (with Intelligent Key system) or DLK-232, "ComponentFunctionCheck"

(without Intelligent Key system).

Inspection in Auto Active Test

When auto active test is actuated, the following operation sequence is repeated 3 times.

Operation se-

quence Inspection location

Operation

1 Front wiper LO for 5 seconds → HI for 5 seconds

2 •Parking lamp

• Side marker lamp

• License plate lamp

• Tail lamp

• Front fog lamp (if equipped) 10 seconds

3 Headlamp LO for 10 seconds →HI ON ⇔ OFF 5 times

4 A/C compressor (magnet clutch) ON ⇔ OFF 5 times

5 Cooling fan LO for 5 seconds → MID for 3 seconds → HI for 2 seconds

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2985 of 3641

![NISSAN NOTE 2016 Service Owners Manual SEC-128

< SYSTEM DESCRIPTION >[WITHOUT INTELLIGENT KEY SYSTEM]

DIAGNOSIS SYSTEM (IPDM E/R)

Concept of Auto Active Test

• IPDM E/R starts the auto active test with the door

switch signals transmitte NISSAN NOTE 2016 Service Owners Manual SEC-128

< SYSTEM DESCRIPTION >[WITHOUT INTELLIGENT KEY SYSTEM]

DIAGNOSIS SYSTEM (IPDM E/R)

Concept of Auto Active Test

• IPDM E/R starts the auto active test with the door

switch signals transmitte](/img/5/57363/w960_57363-2984.png)

SEC-128

< SYSTEM DESCRIPTION >[WITHOUT INTELLIGENT KEY SYSTEM]

DIAGNOSIS SYSTEM (IPDM E/R)

Concept of Auto Active Test

• IPDM E/R starts the auto active test with the door

switch signals transmitted by BCM via CAN communica-

tion. Therefore, the CAN communication line between IPDM E/R and BCM is considered normal if the auto

active test starts successfully.

• The auto active test facilitates troubleshooting if any systems controlled by IPDM E/R cannot be operated.

Diagnosis Chart in Auto Active Test

CONSULT Function (IPDM E/R)INFOID:0000000012542534

APPLICATION ITEM

CONSULT performs the following functions via CAN communication with IPDM E/R.

AWMIA1737GB

Symptom Inspection contentsPossible cause

Any of the following components do not operate:

•Parking lamp

• Side marker lamp

• License plate lamp

•Tail lamp

• Front fog lamp

• Headlamp (HI, LO)

• Front wiper (HI, LO) Perform auto active test.

Does the applicable system op-

erate?YES BCM signal input circuit

NO • Lamp or motor

• Lamp or motor ground circuit

• Harness or connector between

IPDM E/R and applicable system

• IPDM E/R

A/C compressor does not operate Perform auto active test.

Does the magnet clutch oper-

ate?YES

• BCM signal input circuit

• CAN communication signal be-

tween BCM and ECM

• CAN communication signal be-

tween ECM and IPDM E/R

NO • Magnet clutch

• Harness or connector between

IPDM E/R and magnet clutch

• IPDM E/R

Cooling fan does not operate Perform auto active test.

Does the cooling fan operate?YES

• ECM signal input circuit

• CAN communication signal be-

tween ECM and IPDM E/R

NO • Cooling fan motor

• Harness or connector between

IPDM E/R and cooling fan motor

• IPDM E/R

Direct Diagnostic Mode Description

ECU Identification The IPDM E/R part number is displayed.

Self Diagnostic Result The IPDM E/R self diagnostic results are displayed.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2986 of 3641

![NISSAN NOTE 2016 Service Owners Manual DIAGNOSIS SYSTEM (IPDM E/R)SEC-129

< SYSTEM DESCRIPTION > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

ECU IDENTIFICATION

The IPDM E/R part number is displayed.

SELF DIAGNOSTIC R NISSAN NOTE 2016 Service Owners Manual DIAGNOSIS SYSTEM (IPDM E/R)SEC-129

< SYSTEM DESCRIPTION > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

ECU IDENTIFICATION

The IPDM E/R part number is displayed.

SELF DIAGNOSTIC R](/img/5/57363/w960_57363-2985.png)

DIAGNOSIS SYSTEM (IPDM E/R)SEC-129

< SYSTEM DESCRIPTION > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

ECU IDENTIFICATION

The IPDM E/R part number is displayed.

SELF DIAGNOSTIC RESULT

Refer to PCS-20, "DTCIndex".

DATA MONITOR

ACTIVE TEST

Data Monitor The IPDM E/R input/output data is displayed in real time.

Active Test The IPDM E/R activates outputs to test components.

CAN Diag Support Mntr The result of transmit/receive diagnosis of CAN communication is displayed.

Direct Diagnostic Mode

Description

Monitor Item [Unit]Main

Signals Description

MOTOR FAN REQ [1/2/3/4] ×Indicates cooling fan speed signal received from ECM on CAN communication

line

AC COMP REQ [On/Off] ×Indicates A/C compressor request signal received from ECM on CAN commu-

nication line

TAIL&CLR REQ [On/Off] ×Indicates position light request signal

received from BCM on CAN communica-

tion line

HL LO REQ [On/Off] ×Indicates low beam request signal received from BCM on CAN communication

line

HL HI REQ [On/Off] ×Indicates high beam request signal received from BCM on CAN communication

line

FR FOG REQ [On/Off] ×Indicates front fog light request signal received from BCM on CAN communica-

tion line

FR WIP REQ [Stop/1LOW/Low/Hi] ×Indicates front wiper request signal received from BCM on CAN communication

line

WIP AUTO STOP [STOP P/ACT P] ×Indicates condition of front wiper auto stop signal

WIP PROT [Off/BLOCK] ×Indicates condition of front wiper fail-safe operation

IGN RLY1 -REQ [On/Off] Indicates ignition switch ON signal received from BCM on CAN communication

line

IGN RLY [On/Off] ×Indicates condition of ignition relay

PUSH SW [On/Off] Indicates condition of push-button ignition switch

INTER/NP SW [On/Off] Indicates condition of CVT shift position

ST RLY CONT [On/Off] Indicates starter relay status signal received from BCM on CAN communication

line

IHBT RLY -REQ [On/Off] Indicates starter control relay signal received from BCM on CAN communication

line

ST/INHI RLY [Off/ ST /INHI] Indicates condition of starter relay and starter control relay

DETENT SW [On/Off] Indicates condition of CVT shift selector (park position switch)

DTRL REQ [Off] Indicates daytime running light request signal received from BCM on CAN com-

munication line

THFT HRN REQ [On/Off] Indicates theft warning horn request signal received from BCM on CAN commu-

nication line

HORN CHIRP [On/Off] Indicates horn reminder signal received from BCM on CAN communication line

Test item Description

HORN This test is able to check horn operation [On].

FRONT WIPER This test is able to check wiper motor operation [Hi/Lo/Off].

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2987 of 3641

![NISSAN NOTE 2016 Service Owners Manual SEC-130

< SYSTEM DESCRIPTION >[WITHOUT INTELLIGENT KEY SYSTEM]

DIAGNOSIS SYSTEM (IPDM E/R)

CAN DIAG SUPPORT MNTR

Refer to

LAN-13, "CAN Diagnostic Support Monitor".

MOTOR FAN This test is able to chec NISSAN NOTE 2016 Service Owners Manual SEC-130

< SYSTEM DESCRIPTION >[WITHOUT INTELLIGENT KEY SYSTEM]

DIAGNOSIS SYSTEM (IPDM E/R)

CAN DIAG SUPPORT MNTR

Refer to

LAN-13, "CAN Diagnostic Support Monitor".

MOTOR FAN This test is able to chec](/img/5/57363/w960_57363-2986.png)

SEC-130

< SYSTEM DESCRIPTION >[WITHOUT INTELLIGENT KEY SYSTEM]

DIAGNOSIS SYSTEM (IPDM E/R)

CAN DIAG SUPPORT MNTR

Refer to

LAN-13, "CAN Diagnostic Support Monitor".

MOTOR FAN This test is able to check cooling fan operation [4/3/2/1].

EXTERNAL LAMPS This test is able to check external lamp operation [Fog/Hi/Lo/TAIL/Off].

Te s t i t e m

D e s c r i p t i o n

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3266 of 3641

![NISSAN NOTE 2016 Service Owners Manual TRANSAXLE ASSEMBLYTM-25

< UNIT REMOVAL AND INSTALLATION > [5MT: RS5F91R]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

• Do not reuse self-tapping bolt.

• Tighten transaxle assembly bolts to the specified torqu NISSAN NOTE 2016 Service Owners Manual TRANSAXLE ASSEMBLYTM-25

< UNIT REMOVAL AND INSTALLATION > [5MT: RS5F91R]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

• Do not reuse self-tapping bolt.

• Tighten transaxle assembly bolts to the specified torqu](/img/5/57363/w960_57363-3265.png)

TRANSAXLE ASSEMBLYTM-25

< UNIT REMOVAL AND INSTALLATION > [5MT: RS5F91R]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

• Do not reuse self-tapping bolt.

• Tighten transaxle assembly bolts to the specified torque. The illus- tration is the view from the engine.

InspectionINFOID:0000000012430963

INSPECTION AFTER INSTALLATION

• Check the operation of the control linkage. Refer to TM-21, "Inspection".

• Before starting engine, check oil/fluid levels incl uding engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-11, "

Fluids and Lubricants".

• Use procedure below to check for fuel leaks.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leaks at connection points.

• Start engine. With engine speed increased, check again for fuel leaks at connection points.

• Run engine to check for unusual noise and vibration. NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal and installation, slack in the guide

may generate a pounding noise during and just after engine start. However, this is normal. Noise will stop

after hydraulic pressure rises.

• Warm up engine thoroughly to make sure there is no lea ks of fuel, exhaust gas, or any oils/fluids including

engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to spec-

ified level, if necessary.

• Summary of the inspection items:

*Power steering fluid, brake fluid, etc.

Bolt symbol

ABC D

Insertion direction Transaxle to

engine Engine to transaxle

Quantity 2321

Bolt length

() mm (in) 55 (2.17)

49 (1.93) 69 (2.72)

Tightening torque

N·m (kg-m, ft-lb) 48.0 (4.9, 35)

JPDIC0813ZZ

Item

Before starting engine Engine runningAfter engine stopped

Engine coolant LevelLeaks Level

Engine oil LevelLeaks Level

Transmission/

transaxle fluid CVT Models

LeaksLevel/Leaks Leaks

M/T Models Level/Leaks LeaksLevel/Leaks

Other oils and fluids* LevelLeaks Level

Fuel LeaksLeaks Leaks

Exhaust gas —Leaks —

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3315 of 3641

![NISSAN NOTE 2016 Service Owners Manual TM-74

< SYSTEM DESCRIPTION >[CVT: RE0F11A]

STRUCTURE AND OPERATION

FLUID COOLER & FL

UID WARMER SYSTEM

FLUID COOLER & FLUID WARMER SYSTEM : System DescriptionINFOID:0000000012431015

CVT FLUID COOLER NISSAN NOTE 2016 Service Owners Manual TM-74

< SYSTEM DESCRIPTION >[CVT: RE0F11A]

STRUCTURE AND OPERATION

FLUID COOLER & FL

UID WARMER SYSTEM

FLUID COOLER & FLUID WARMER SYSTEM : System DescriptionINFOID:0000000012431015

CVT FLUID COOLER](/img/5/57363/w960_57363-3314.png)

TM-74

< SYSTEM DESCRIPTION >[CVT: RE0F11A]

STRUCTURE AND OPERATION

FLUID COOLER & FL

UID WARMER SYSTEM

FLUID COOLER & FLUID WARMER SYSTEM : System DescriptionINFOID:0000000012431015

CVT FLUID COOLER SCHEMATIC

COMPONENT DESCRIPTION

CVT Oil Warmer

• The CVT oil warmer (1) is installed on the front part of transaxle

assembly.

• When engine is started while engine and CVT are cold, engine coolant temperature rises more quickly than CVT fluid tempera-

ture. CVT oil warmer is provided with two circuits for CVT and

engine coolant respectively so that warmed engine coolant warms

CVT quickly. This helps shorten CVT warming up time, improving

fuel economy.

• A cooling effect is obtained when CVT fluid temperature is high.

CVT Fluid Cooler (Water-cooling)

• The CVT fluid cooler (water-cooling) is installed in the radiator side tank (right side).

• CVT fluid is cooled by engine coolant.

SHIFT LOCK SYSTEM

Manual valve Distributes the clutch and brake operation pressures (pilot pressure) corresponding to

each shift position.

High clutch/reverse brake switching valve Switches the circuit for the high clutch and the reverse brake.

Torque converter clutch control valve It is operated with the torque converter clutch solenoid valve and it adjusts the tighten-

ing pressure and non-tightening pressure of the torque converter clutch piston of the

torque converter.

Primary pressure control valve It is operated with the primary pressure solenoid valve and adjusts the feed pressure to

the primary pulley.

Primary pressure solenoid valve TM-65, "

CVT CONTROL SYSTEM : Primary Pressure Solenoid Valve"

Low brake solenoid valve TM-65, "CVT CONTROL SYSTEM : Low Brake Solenoid Valve"

High clutch & reverse brake solenoid valveTM-66, "CVT CONTROL SYSTEM : High Clutch & Reverse Brake Solenoid Valve"

Torque converter clutch solenoid valve TM-66, "CVT CONTROL SYSTEM : Torque Converter Clutch Solenoid Valve"

Line pressure solenoid valve TM-66, "CVT CONTROL SYSTEM : Line Pressure Solenoid Valve"

Part name Function

JSDIA4074GB

JSDIA2586ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3503 of 3641

![NISSAN NOTE 2016 Service Owners Manual TM-262

< UNIT REMOVAL AND INSTALLATION >[CVT: RE0F11A]

TRANSMISSION ASSEMBLY

INSPECTION AFTER INSTALLATION

Check the following items:

• For CVT position, refer to

TM-232, "

Inspection".

• Before NISSAN NOTE 2016 Service Owners Manual TM-262

< UNIT REMOVAL AND INSTALLATION >[CVT: RE0F11A]

TRANSMISSION ASSEMBLY

INSPECTION AFTER INSTALLATION

Check the following items:

• For CVT position, refer to

TM-232, "

Inspection".

• Before](/img/5/57363/w960_57363-3502.png)

TM-262

< UNIT REMOVAL AND INSTALLATION >[CVT: RE0F11A]

TRANSMISSION ASSEMBLY

INSPECTION AFTER INSTALLATION

Check the following items:

• For CVT position, refer to

TM-232, "

Inspection".

• Before starting engine, check oil/fluid levels incl uding engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-11, "

Fluids and Lubricants".

• Use procedure below to check for fuel leakage.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

• Start engine. With engine speed increased, che ck again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration. NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal and installation, slack in the guide

may generate a pounding noise during and just after engine start. However, this is normal. Noise will stop

after hydraulic pressure rises.

• Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gas, or any oils/fluids including engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to spec- ified level, if necessary.

• Summary of the inspection items:

*Power steering fluid, brake fluid, etc.

ADJUSTMENT AFTER INSTALLATION

• Adjust the CVT fluid level. TM-229, "Adjustment".

• Perform "ADDITIONAL SERVICE WHEN REPL ACING TRANSAXLE ASSEMBLY". Refer to TM-127,

"Description".

ItemBefore starting engine Engine runningAfter engine stopped

Engine coolant LevelLeakage Level

Engine oil LevelLeakage Level

Transmission/

transaxle fluid A/T and CVT Models

LeakageLevel/Leakage Leakage

M/T Models Level/Leakage LeakageLevel/Leakage

Other oils and fluids* LevelLeakage Level

Fuel LeakageLeakageLeakage

Exhaust gas —Leakage —

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3511 of 3641

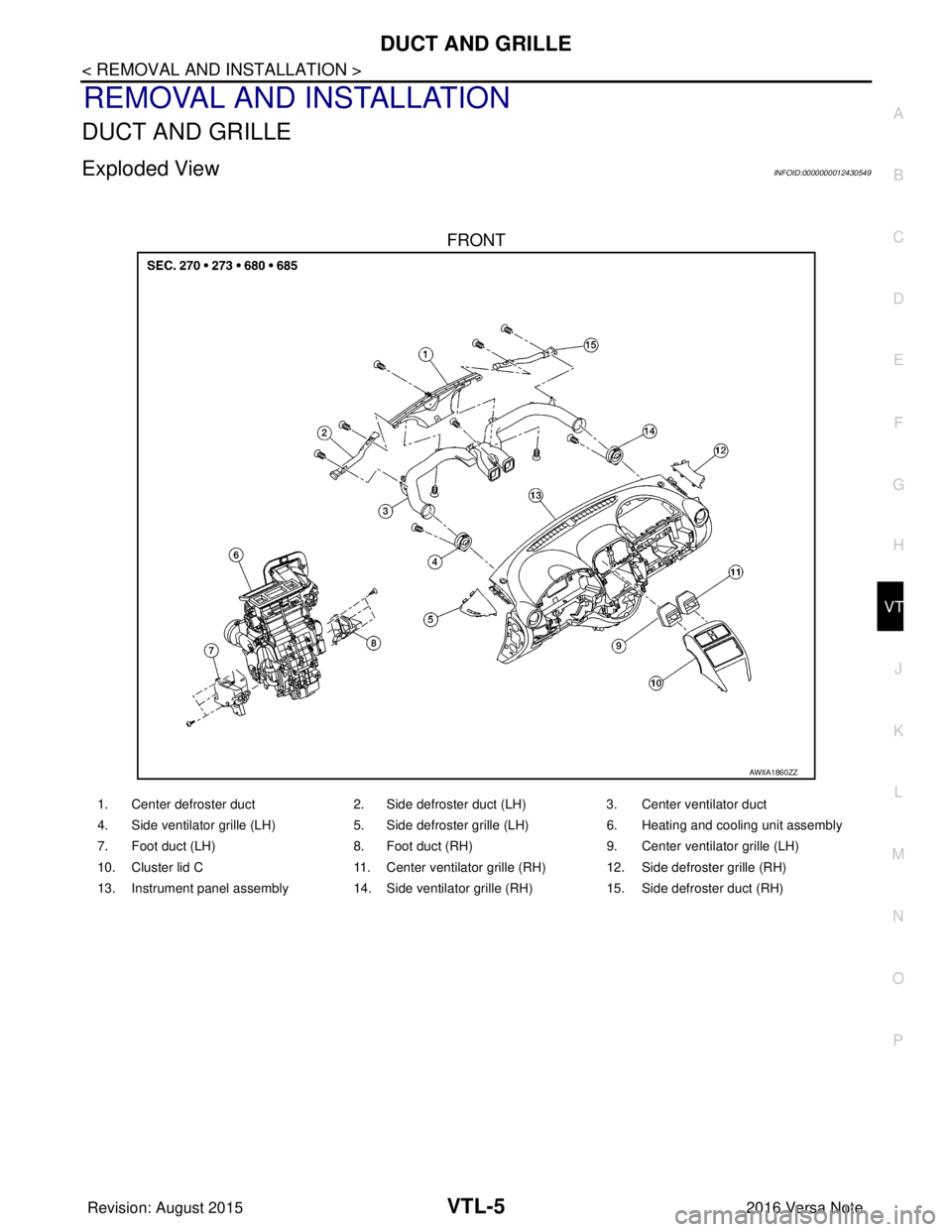

DUCT AND GRILLEVTL-5

< REMOVAL AND INSTALLATION >

C

DE

F

G H

J

K L

M A

B

VTL

N

O P

REMOVAL AND INSTALLATION

DUCT AND GRILLE

Exploded ViewINFOID:0000000012430549

FRONT

AWIIA1860ZZ

1. Center defroster duct 2. Side defroster duct (LH)3. Center ventilator duct

4. Side ventilator grille (LH) 5. Side defroster grille (LH)6. Heating and cooling unit assembly

7. Foot duct (LH) 8. Foot duct (RH)9. Center ventilator grille (LH)

10. Cluster lid C 11. Center ventilator grille (RH) 12. Side defroster grille (RH)

13. Instrument panel assembly 14. Side ventilator grille (RH) 15. Side defroster duct (RH)

Revision: August 2015 2016 Versa Note

cardiagn.com

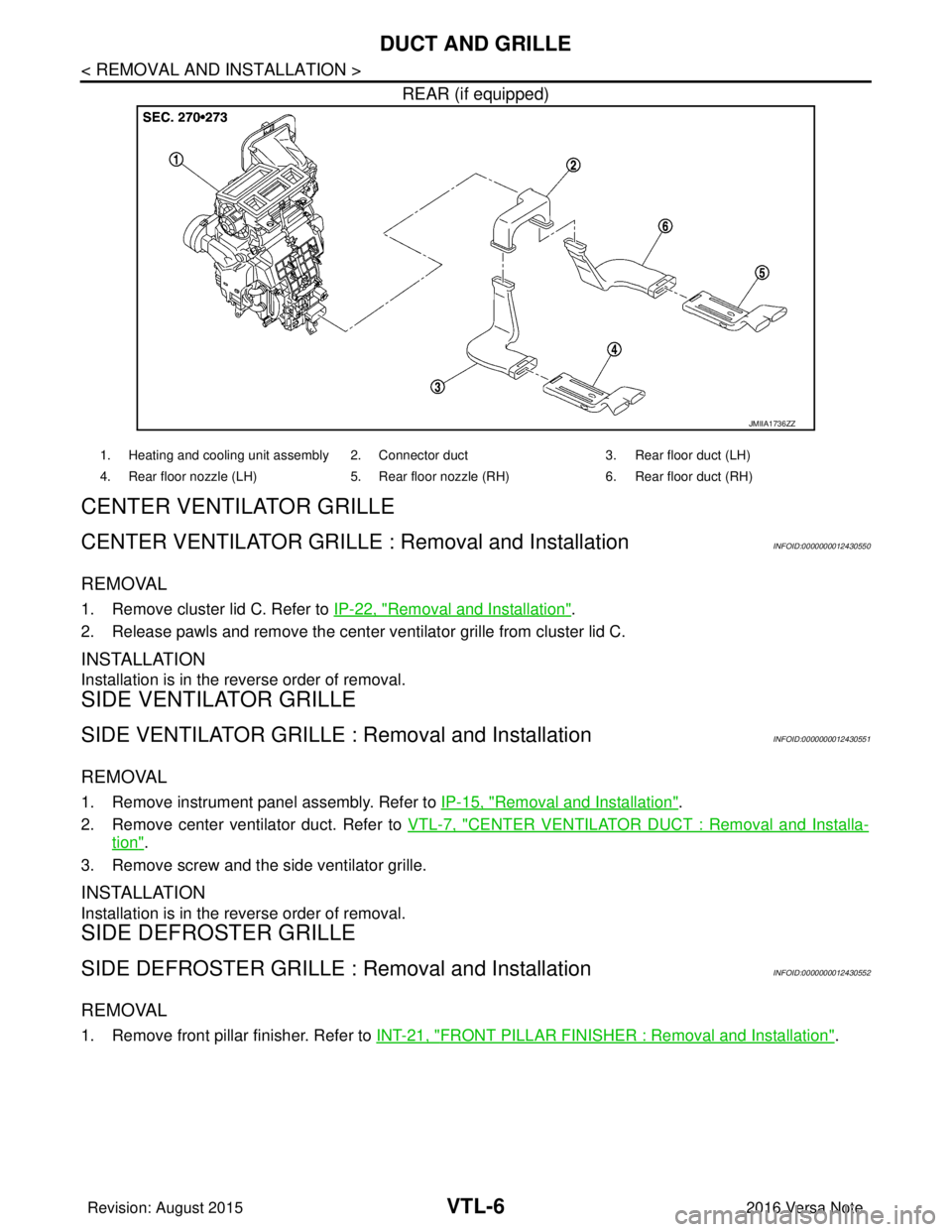

Page 3512 of 3641

VTL-6

< REMOVAL AND INSTALLATION >

DUCT AND GRILLE

REAR (if equipped)

CENTER VENTILAT O R G R I L L E

CENTER VENTILATOR GRILLE : Removal and InstallationINFOID:0000000012430550

REMOVAL

1. Remove cluster lid C. Refer to IP-22, "Removal and Installation".

2. Release pawls and remove the center ventilator grille from cluster lid C.

INSTALLATION

Installation is in the reverse order of removal.

SIDE VENTILATOR GRILLE

SIDE VENTILATOR GRILLE : Removal and InstallationINFOID:0000000012430551

REMOVAL

1. Remove instrument panel assembly. Refer to IP-15, "Removal and Installation".

2. Remove center ventilator duct. Refer to VTL-7, "

CENTER VENTILATOR DUCT : Removal and Installa-

tion".

3. Remove screw and the side ventilator grille.

INSTALLATION

Installation is in the reverse order of removal.

SIDE DEFROSTER GRILLE

SIDE DEFROSTER GRILLE : Removal and InstallationINFOID:0000000012430552

REMOVAL

1. Remove front pillar finisher. Refer to INT-21, "FRONT PILLAR FINISHER : Removal and Installation".

JMIIA1736ZZ

1. Heating and cooling unit assembly 2. Connector duct 3. Rear floor duct (LH)

4. Rear floor nozzle (LH) 5. Rear floor nozzle (RH) 6. Rear floor duct (RH)

Revision: August 2015 2016 Versa Note

cardiagn.com