cvt NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 2324 of 3641

PERIODIC MAINTENANCEMA-9

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

NOTE:

•

Maintenance items with “ ” shoul d be performed more frequently according to “Maintenance Under Severe Driving Condi-

tions”.

• (1) Use only Genuine NISSAN CVT fluid. If towing a trailer, using a camper or a car-top carrier, of driving on rough or muddy roads,

inspect CVT fluid deterioration at NISSAN dealers every 60,000 miles (96,000 km), then change CVT fluid if necessary. And if th e

inspection is not performed, change (not just inspect) CVT fluid every 60,000 miles (96,000 km). Using transmission fluid other than

Genuine NISSAN CVT fluid will damage the CVT, which is not covered by the NISSAN new vehicle limited warranty.

• (2) If tower a trailer, using a camper or car-top carrier, or driving on rough or muddy roads, change (not just inspect) oil a t every 20,000

miles (32,000 km) or 24 months.

• (3) Refer to "Tire rotation" under "GENERAL MAINTENANCE" heading earlier in this section.

MAINTENANCE UNDER SEVERE DRIVING CONDITIONS

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle is

mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

Severe driving conditions

• Repeated short trips of less than 5 miles (8 km).

• Repeated short trips of less than 10 miles (16 km) wi th outside temperatures remaining below freezing.

• Operating in hot weather in stop-and-go "rush hour" traffic.

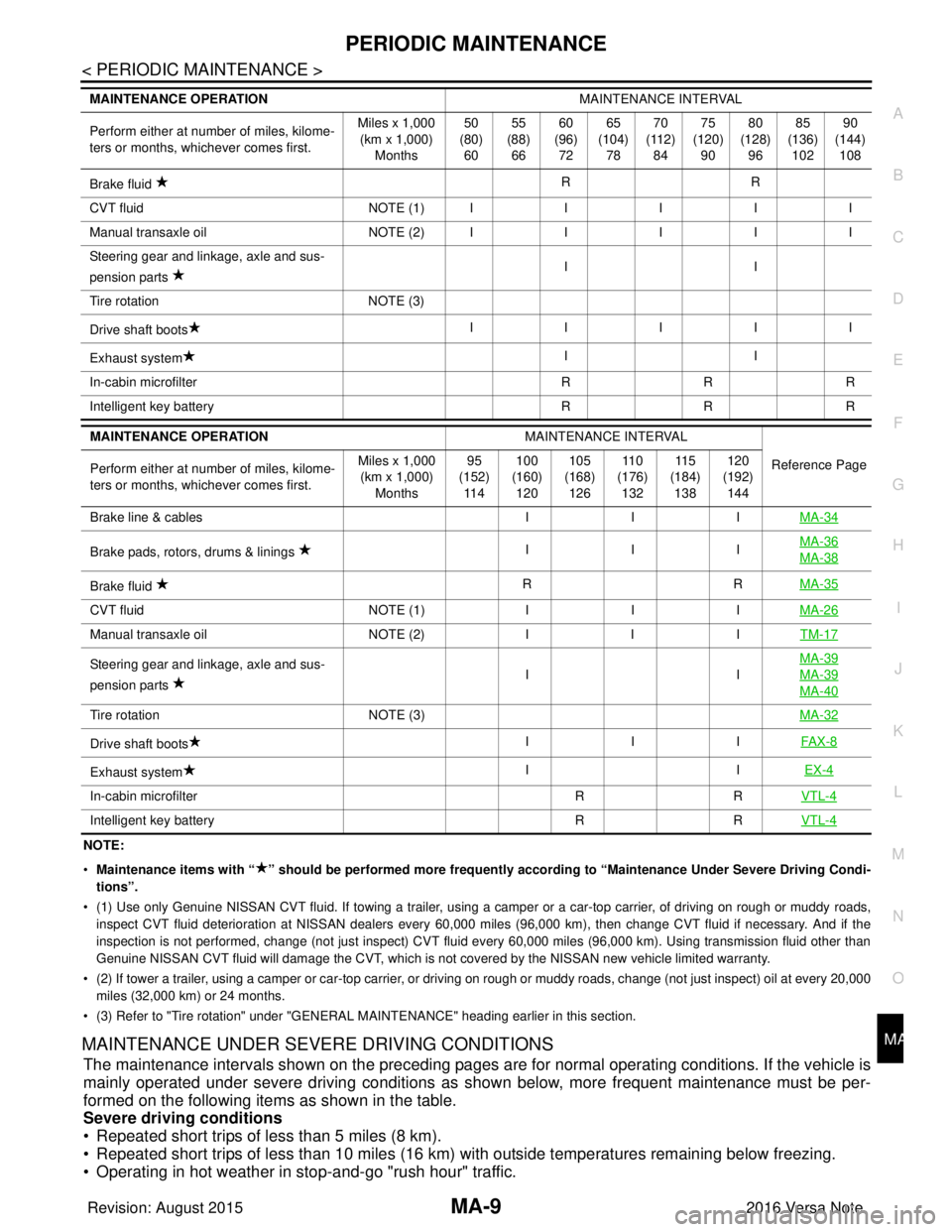

Brake fluid RR

C VT flu id NO TE (1)IIIII

M anu al t ra nsa xle o il NO TE (2)IIIII

Steering gear and linkage, axle and sus-

pension parts II

Tire rotation NOTE (3)

Drive shaft boots IIIII

Exhaust system II

In-cabin microfilter RRR

Intelligent key battery RRR

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference Page

Perform either at number of miles, kilome-

ters or months, whichever comes first. Miles x 1,000

(km x 1,000) Months 95

(152) 11 4 100

(160) 120 105

(168) 126 11 0

(176) 132 11 5

(184) 138 120

(192) 144

Brake line & cables IIIMA-34

Brake pads, rotors, drums & linings IIIMA-36MA-38

Brake fluid

RR

MA-35

CVT fluid NOTE (1)IIIMA-26

Manual transaxle oil NOTE (2)IIITM-17

Steering gear and linkage, axle and sus-

pension parts IIMA-39MA-39

MA-40

Tire rotation

NOTE (3) MA-32

Drive shaft boots III

FAX-8

Exhaust system II

EX-4

In-cabin microfilter RRVTL-4

Intelligent key battery RRVTL-4

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform either at number of miles, kilome-

ters or months, whichever comes first. Miles x 1,000

(km x 1,000)

Months 50

(80)

60 55

(88)

66 60

(96)

72 65

(104)

78 70

(112)

84 75

(120)

90 80

(128)

96 85

(136)

102 90

(144)

108

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2326 of 3641

RECOMMENDED FLUIDS AND LUBRICANTSMA-11

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

RECOMMENDED FLUIDS AND LUBRICANTS

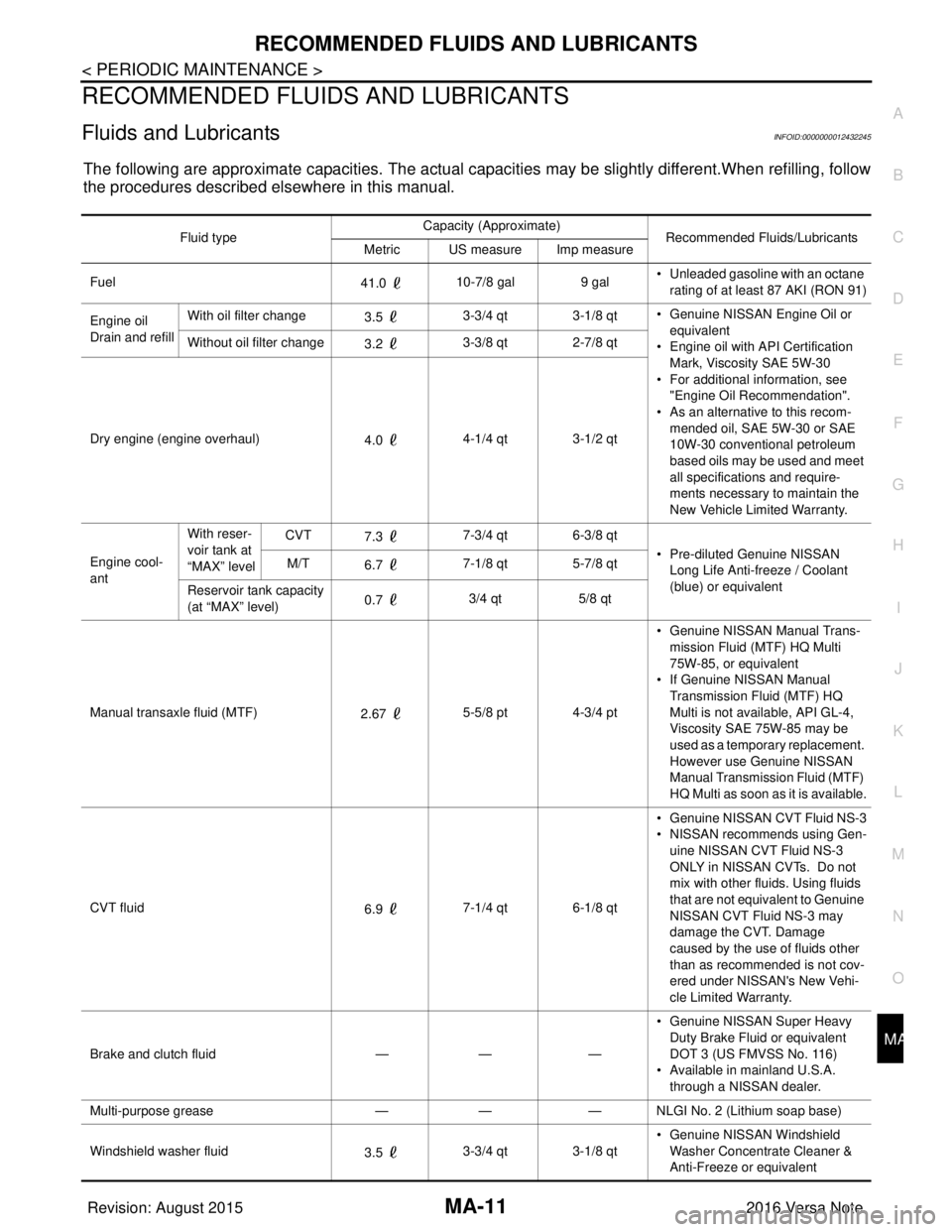

Fluids and LubricantsINFOID:0000000012432245

The following are approximate capacities. The actual capa

cities may be slightly different.When refilling, follow

the procedures described elsewhere in this manual.

Fluid type Capacity (Approximate)

Recommended Fluids/Lubricants

Metric US measure Imp measure

Fuel 41.0 10-7/8 gal

9 gal• Unleaded gasoline with an octane

rating of at least 87 AKI (RON 91)

Engine oil

Drain and refill With oil filter change

3.5 3-3/4 qt 3-1/8 qt

• Genuine NISSAN Engine Oil or

equivalent

• Engine oil with API Certification

Mark, Viscosity SAE 5W-30

• For additional information, see "Engine Oil Recommendation".

• As an alternative to this recom-

mended oil, SAE 5W-30 or SAE

10W-30 conventional petroleum

based oils may be used and meet

all specifications and require-

ments necessary to maintain the

New Vehicle Limited Warranty.

Without oil filter change

3.2 3-3/8 qt 2-7/8 qt

Dry engine (engine overhaul) 4.0 4-1/4 qt 3-1/2 qt

Engine cool-

ant With reser-

voir tank at

“MAX” level

CVT

7.3 7-3/4 qt 6-3/8 qt

• Pre-diluted Genuine NISSAN Long Life Anti-freeze / Coolant

(blue) or equivalent

M/T

6.7 7-1/8 qt 5-7/8 qt

Reservoir tank capacity

(at “MAX” level) 0.7

3/4 qt

5/8 qt

Manual transaxle fluid (MTF) 2.67 5-5/8 pt 4-3/4 pt • Genuine NISSAN

Manual Trans-

mission Fluid (MTF) HQ Multi

75W-85, or equivalent

• If Genuine NISSAN Manual

Transmission Fluid (MTF) HQ

Multi is not available, API GL-4,

Viscosity SAE 75W-85 may be

used as a temporary replacement.

However use Genuine NISSAN

Manual Transmission Fluid (MTF)

HQ Multi as soon as it is available.

CVT fluid 6.9 7-1/4 qt 6-1/8 qt • Genuine NISSAN CVT Fluid NS-3

• NISSAN recommends using Gen-

uine NISSAN CVT Fluid NS-3

ONLY in NISSAN CVTs. Do not

mix with other fluids. Using fluids

that are not equivalent to Genuine

NISSAN CVT Fluid NS-3 may

damage the CVT. Damage

caused by the use of fluids other

than as recommended is not cov-

ered under NISSAN's New Vehi-

cle Limited Warranty.

Brake and clutch fluid —— —• Genuine NISSAN Super Heavy

Duty Brake Fluid or equivalent

DOT 3 (US FMVSS No. 116)

• Available in mainland U.S.A.

through a NISSAN dealer.

Multi-purpose grease —— — NLGI No. 2 (Lithium soap base)

Windshield washer fluid 3.5 3-3/4 qt 3-1/8 qt • Genuine NISSAN Windshield

Washer Concentrate Cleaner &

Anti-Freeze or equivalent

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2341 of 3641

MA-26

< PERIODIC MAINTENANCE >

CHASSIS AND BODY MAINTENANCE

CHASSIS AND BODY MAINTENANCE

EXHAUST SYSTEM

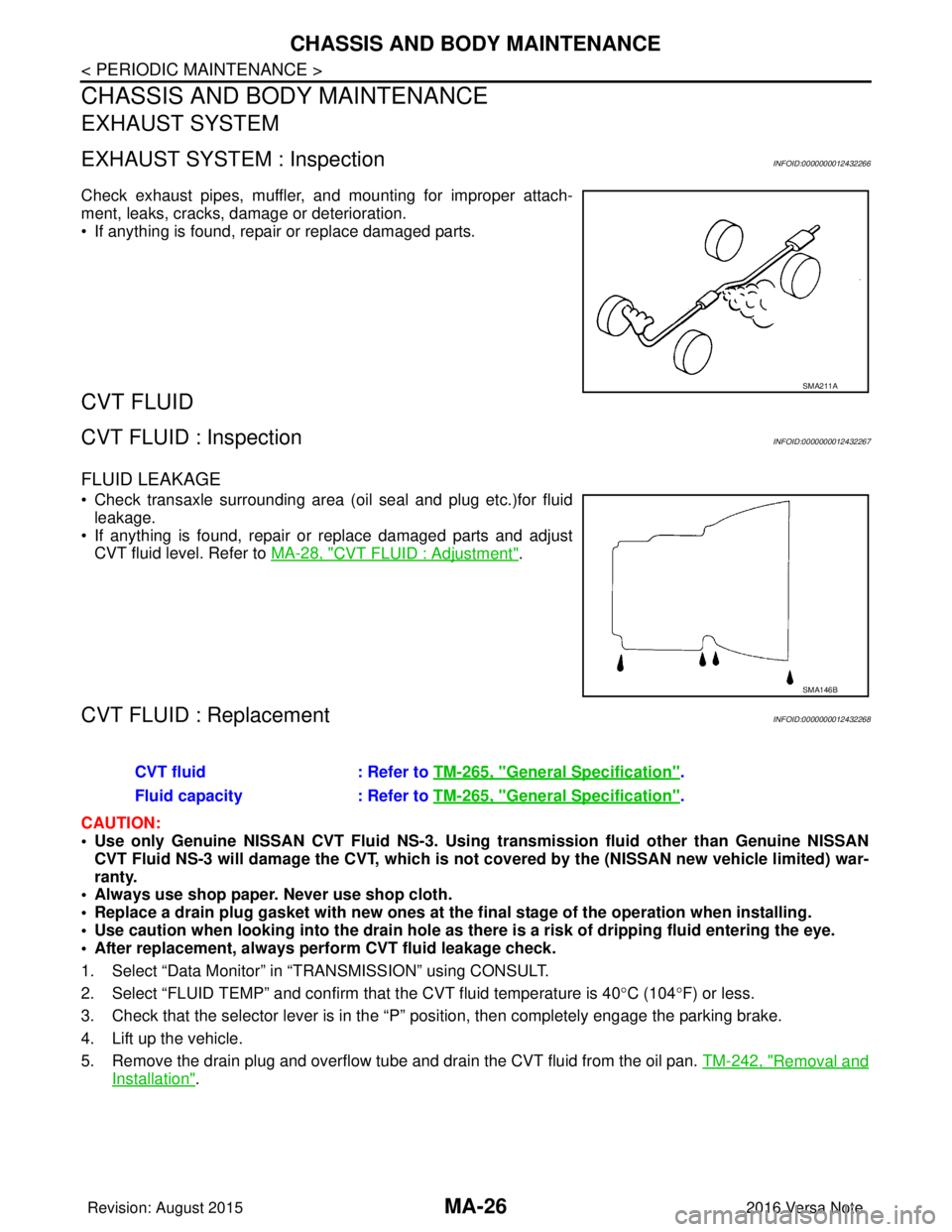

EXHAUST SYSTEM : InspectionINFOID:0000000012432266

Check exhaust pipes, muffler, and mounting for improper attach-

ment, leaks, cracks, damage or deterioration.

• If anything is found, repair or replace damaged parts.

CVT FLUID

CVT FLUID : InspectionINFOID:0000000012432267

FLUID LEAKAGE

• Check transaxle surrounding area (oil seal and plug etc.)for fluidleakage.

• If anything is found, repair or replace damaged parts and adjust CVT fluid level. Refer to MA-28, "

CVT FLUID : Adjustment".

CVT FLUID : ReplacementINFOID:0000000012432268

CAUTION:

• Use only Genuine NISSAN CVT Fluid NS-3. Using transmission fluid other than Genuine NISSAN

CVT Fluid NS-3 will damage the CVT, which is not covered by the (NISSAN new vehicle limited) war-

ranty.

• Always use shop paper. Never use shop cloth.

• Replace a drain plug gasket with new ones at the final stage of the operation when installing.

• Use caution when looking into the drain hole as th ere is a risk of dripping fluid entering the eye.

• After replacement, always perform CVT fluid leakage check.

1. Select “Data Monitor” in “T RANSMISSION” using CONSULT.

2. Select “FLUID TEMP” and confirm t hat the CVT fluid temperature is 40°C (104° F) or less.

3. Check that the selector lever is in the “P ” position, then completely engage the parking brake.

4. Lift up the vehicle.

5. Remove the drain plug and overflow tube and drain the CVT fluid from the oil pan. TM-242, "

Removal and

Installation".

SMA211A

SMA146B

CVT fluid: Refer to TM-265, "General Specification".

Fluid capacity : Refer to TM-265, "

General Specification".

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2342 of 3641

CHASSIS AND BODY MAINTENANCEMA-27

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

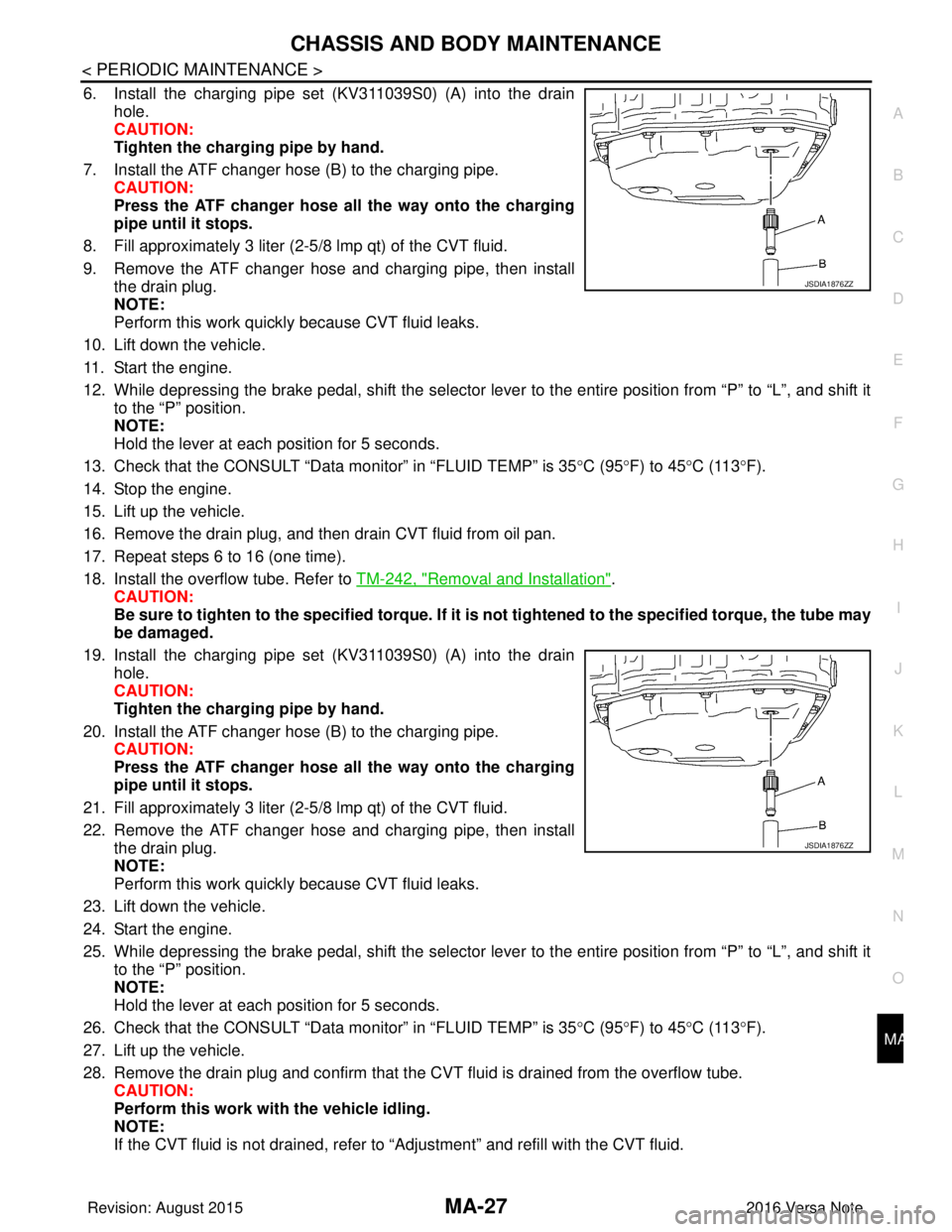

6. Install the charging pipe set (KV311039S0) (A) into the drain

hole.

CAUTION:

Tighten the charging pipe by hand.

7. Install the ATF changer hose (B) to the charging pipe. CAUTION:

Press the ATF changer hose all the way onto the charging

pipe until it stops.

8. Fill approximately 3 liter (2-5 /8 lmp qt) of the CVT fluid.

9. Remove the ATF changer hose and charging pipe, then install the drain plug.

NOTE:

Perform this work quickly because CVT fluid leaks.

10. Lift down the vehicle.

11. Start the engine.

12. While depressing the brake pedal, shift the selector leve r to the entire position from “P” to “L”, and shift it

to the “P” position.

NOTE:

Hold the lever at each position for 5 seconds.

13. Check that the CONSULT “Data monitor” in “FLUID TEMP” is 35°C (95°F) to 45 °C (113 °F).

14. Stop the engine.

15. Lift up the vehicle.

16. Remove the drain plug, and then drain CVT fluid from oil pan.

17. Repeat steps 6 to 16 (one time).

18. Install the overflow tube. Refer to TM-242, "

Removal and Installation".

CAUTION:

Be sure to tighten to the specified torque. If it is not tightened to the specified torque, the tube may

be damaged.

19. Install the charging pipe set (KV311039S0) (A) into the drain hole.

CAUTION:

Tighten the charging pipe by hand.

20. Install the ATF changer hose (B) to the charging pipe. CAUTION:

Press the ATF changer hose all the way onto the charging

pipe until it stops.

21. Fill approximately 3 liter (2-5 /8 lmp qt) of the CVT fluid.

22. Remove the ATF changer hose and charging pipe, then install the drain plug.

NOTE:

Perform this work quickly because CVT fluid leaks.

23. Lift down the vehicle.

24. Start the engine.

25. While depressing the brake pedal, shift the selector leve r to the entire position from “P” to “L”, and shift it

to the “P” position.

NOTE:

Hold the lever at each position for 5 seconds.

26. Check that the CONSULT “Data monitor” in “FLUID TEMP” is 35°C (95°F) to 45 °C (113 °F).

27. Lift up the vehicle.

28. Remove the drain plug and confirm that the CV T fluid is drained from the overflow tube.

CAUTION:

Perform this work with the vehicle idling.

NOTE:

If the CVT fluid is not drained, refer to “Adjustment” and refill with the CVT fluid.

JSDIA1876ZZ

JSDIA1876ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2343 of 3641

MA-28

< PERIODIC MAINTENANCE >

CHASSIS AND BODY MAINTENANCE

29. When the flow of CVT fluid slows to a drip, tighten the drain plug to the specified torque. TM-242,

"Removal and Installation".

CAUTION:

Never reuse drain plug gasket.

30. Lift down the vehicle.

31. Select “Work Support” in “TRANSMISSION” using CONSULT.

32. Select “CONFORM CVTF DETERIORTN”.

33. Select “Erase”.

34. Stop the engine.

CVT FLUID : AdjustmentINFOID:0000000012432269

CAUTION:

• Use only Genuine NISSAN CVT Fluid NS-3. Using transmission fluid other than Genuine NISSAN

CVT Fluid NS-3 will damage the CVT, which is not covered by the (NISSAN new vehicle limited) war-

ranty.

• During adjustment of the CVT fluid level, check CO NSULT so that the oil temperature may be main-

tained from 35 to 45 °C (95 to 113 °F).

• Use caution when looking into the drain hole as th ere is a risk of dripping fluid entering the eye.

1. Check that the selector lever is in the “P ” position, then completely engage the parking brake.

2. Start the engine.

3. Adjust the CVT fluid temperature to be approximately 40 °C (104° F).

NOTE:

The CVT fluid is largely affected by temperature. Therefore be sure to use CONSULT and check the

“FLUID TEMP” under “TRANSMISSION” in “Data Monitor” while adjusting.

4. While depressing the brake pedal, shift the selector lever to the entire position from “P” to “L”, and shift it to the “P” position.

NOTE:

Hold the lever at each position for 5 seconds.

5. Lift up the vehicle.

6. Check that there is no CVT fluid leakage.

7. Remove the drain plug. Refer to TM-242, "

Removal and Installation".

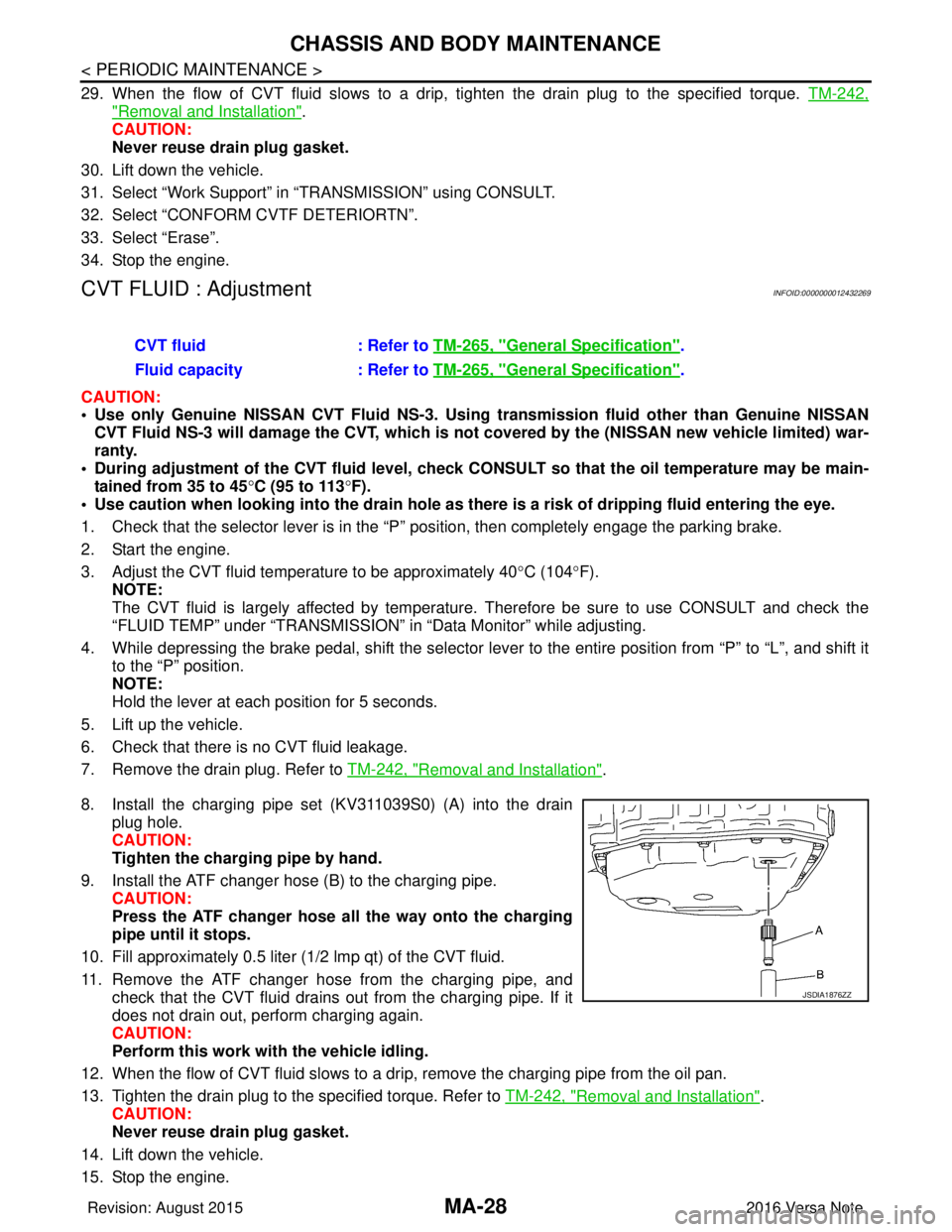

8. Install the charging pipe set (KV311039S0) (A) into the drain plug hole.

CAUTION:

Tighten the charging pipe by hand.

9. Install the ATF changer hose (B) to the charging pipe. CAUTION:

Press the ATF changer hose all the way onto the charging

pipe until it stops.

10. Fill approximately 0.5 liter (1/2 lmp qt) of the CVT fluid.

11. Remove the ATF changer hose from the charging pipe, and check that the CVT fluid drains out from the charging pipe. If it

does not drain out, perform charging again.

CAUTION:

Perform this work with the vehicle idling.

12. When the flow of CVT fluid slows to a drip, remove the charging pipe from the oil pan.

13. Tighten the drain plug to the specified torque. Refer to TM-242, "

Removal and Installation".

CAUTION:

Never reuse drain plug gasket.

14. Lift down the vehicle.

15. Stop the engine. CVT fluid

: Refer to TM-265, "

General Specification".

Fluid capacity : Refer to TM-265, "

General Specification".

JSDIA1876ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2366 of 3641

![NISSAN NOTE 2016 Service Repair Manual MWI-8

< SYSTEM DESCRIPTION >[TYPE A]

COMPONENT PARTS

SYSTEM DESCRIPTION

COMPONENT PARTS

METER SYSTEM

METER SYSTEM : Component Parts LocationINFOID:0000000012432541

A. Combination meter

B. View with re NISSAN NOTE 2016 Service Repair Manual MWI-8

< SYSTEM DESCRIPTION >[TYPE A]

COMPONENT PARTS

SYSTEM DESCRIPTION

COMPONENT PARTS

METER SYSTEM

METER SYSTEM : Component Parts LocationINFOID:0000000012432541

A. Combination meter

B. View with re](/img/5/57363/w960_57363-2365.png)

MWI-8

< SYSTEM DESCRIPTION >[TYPE A]

COMPONENT PARTS

SYSTEM DESCRIPTION

COMPONENT PARTS

METER SYSTEM

METER SYSTEM : Component Parts LocationINFOID:0000000012432541

A. Combination meter

B. View with rear lower seat cushion and inspection hole

cover removed.

No. Component Function

1. Parking brake switch Transmits the parking brake switch signal to the combination meter.

2. ABS actuator and electric unit

(control unit) Transmits the vehicle speed signal to the combination meter via CAN communication.

Refer to BRC-7, "

Component Parts Location" for detailed installation location.

3. Washer fluid level switch Transmits the washer fluid level switch signal to the combination meter (for Canada).

Refer to WW-6, "

Component Parts Location" for detailed installation location.

4. Engine oil pressure sensor Transmits the engine oil pressure sensor signal to the ECM.

Refer to EM-93, "

Exploded View" for detailed installation location.

5. TCM Transmits the shift position signal to the combination meter via CAN communication

(with CVT).

Refer to TM-61, "

CVT CONTROL SYSTEM : Co

mponent Parts Location" for detailed

installation location.

AWNIA3135ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2375 of 3641

![NISSAN NOTE 2016 Service Repair Manual MWI

DIAGNOSIS SYSTEM (COMBINATION METER)MWI-17

< SYSTEM DESCRIPTION > [TYPE A]

C

D

E

F

G H

I

J

K L

M B A

O P

DIAGNOSIS SYSTEM (C OMBINATION METER)

On Board Diagnosis FunctionINFOID:0000000012432552

ON NISSAN NOTE 2016 Service Repair Manual MWI

DIAGNOSIS SYSTEM (COMBINATION METER)MWI-17

< SYSTEM DESCRIPTION > [TYPE A]

C

D

E

F

G H

I

J

K L

M B A

O P

DIAGNOSIS SYSTEM (C OMBINATION METER)

On Board Diagnosis FunctionINFOID:0000000012432552

ON](/img/5/57363/w960_57363-2374.png)

MWI

DIAGNOSIS SYSTEM (COMBINATION METER)MWI-17

< SYSTEM DESCRIPTION > [TYPE A]

C

D

E

F

G H

I

J

K L

M B A

O P

DIAGNOSIS SYSTEM (C OMBINATION METER)

On Board Diagnosis FunctionINFOID:0000000012432552

ON BOARD DIAGNOSIS ITEM

Information display, speedometer and tachometer can be checked in self-diagnosis mode.

STARTING COMBINATION ME TER SELF-DIAGNOSIS MODE

METHOD OF STARTING

1. Turn ignition switch ON, and switch the trip meter to “trip A” or “trip B”.

2. Turn ignition switch to OFF.

3. While pressing the meter control switch (1), turn the ignition

switch ON.

4. Make sure that the trip meter displays “0000.0”.

5. Press the meter control switch (1) at least 3 times. (Within 7 sec- onds after the ignition switch is turned ON).

6. The combination meter is turned to self-diagnosis mode. • All segments of the information display and shift position indi-cator (A) for CVT models are displayed.

NOTE:

• Check combination meter power supply and ground circui t when the self-diagnosis mode of the combination

meter does not start. replace combination meter if power supply and ground circuit are normal.

• If any of the segments are not disp layed, replace combination meter.

7. Each meter activates by pressing the meter control switch.

JSNIA3904ZZ

JSNIA3900ZZ

AWNIA2440ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2417 of 3641

![NISSAN NOTE 2016 Service Repair Manual MWI

COMPONENT PARTSMWI-59

< SYSTEM DESCRIPTION > [TYPE B]

C

D

E

F

G H

I

J

K L

M B A

O P

METER SYSTEM : Combination MeterINFOID:0000000012432600

The combination meter controls the following items a cco NISSAN NOTE 2016 Service Repair Manual MWI

COMPONENT PARTSMWI-59

< SYSTEM DESCRIPTION > [TYPE B]

C

D

E

F

G H

I

J

K L

M B A

O P

METER SYSTEM : Combination MeterINFOID:0000000012432600

The combination meter controls the following items a cco](/img/5/57363/w960_57363-2416.png)

MWI

COMPONENT PARTSMWI-59

< SYSTEM DESCRIPTION > [TYPE B]

C

D

E

F

G H

I

J

K L

M B A

O P

METER SYSTEM : Combination MeterINFOID:0000000012432600

The combination meter controls the following items a ccording to the signals received from each unit via CAN

communication and the signals from switches and sensors:

• Measuring instruments

• Indicator lamps

• Warning lamps

• Meter illumination control

• Information display

ARRANGEMENT OF COMBINATION METER

3. Washer fluid level switch Transmits the washer fluid level switch signal to the combination meter (for Cana-

da).

Refer to

WW-6, "

Component Parts Location" for detailed installation location.

4. Engine oil pressure sensor Transmits the engine oil pressure sensor signal to the ECM.

Refer to

EM-93, "

Exploded View" for detailed installation location.

5. Ambient sensor Transmits the ambient sensor signal to the combination meter.

6. TCM Transmits the shift position signal to the combination meter via CAN communica-

tion (with CVT).

Refer to

TM-61, "

CVT CONTROL SYSTEM : Component Parts Location" for de-

tailed installation location.

7. ECM Transmits the following signals to the combination meter via CAN communication:

• Engine speed signal

• Engine coolant temperature signal

• Fuel consumption monitor signal

• Engine oil pressure sensor signal

Refer to

EC-14, "

ENGINE CONTROL SYSTEM : ComponentPartsLocation" for

detailed installation location.

8. BCM Transmits the following signals to the combination meter via CAN communication:

• Door switch signal

• Buzzer signal

Refer to

BCS-6, "

BODY CONTROL SYSTEM : Component Parts Location" (with

Intelligent Key system) or BCS-77, "

BODY CONTROL SYSTEM : Component

Parts Location" (without Intelligent Key system) for detailed installation location.

9. Steering wheel audio control switches

(meter control switch) Transmits the meter control switch signal to the combination meter.

10. Combination meter Refer to MWI-59, "

METER SYSTEM : Combination Meter".

11 . Fuel level sensor unit and fuel pump (fuel

level sensor) Transmits the fuel level sensor signal to the combination meter.

No.

Component Function

AWNIA3630ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2483 of 3641

SQUEAK AND RATTLE TROUBLE DIAGNOSESMIR-9

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

MIR

N

O P

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or lo cation of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-clutch on M/T model, drive position on CVT and A/T models).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

• Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

• If it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, check ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pinpoint the source of the noise, use a listening tool (Chassis Ear: J-39570, Engine Ear: J-39565 and mechanic's stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by: • removing the components in the area that you suspect the noise is coming from.Do not use too much force when removing clips and fasteners, otherwise clips and fasteners can be

broken or lost during the repair, resulting in the creation of new noise.

• tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only

temporarily.

• feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

• placing a piece of paper between components that you suspect are causing the noise.

• looking for loose components and contact marks. Refer to MIR-9, "

Generic Squeak and Rattle Troubleshooting".

REPAIR THE CAUSE

• If the cause is a loose component, tighten the component securely.

• If the cause is insufficient clearance between components:

- separate components by repositioning or loos ening and retightening the component, if possible.

- insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or urethane tape. A NISSAN Squeak and Rattle Kit (J-50397) is available through your authorized NISSAN Parts Depart-

ment.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

NOTE:

• Always check with the Parts Department for the latest parts information.

• The materials contained in the NISSAN Squeak and Rattle Kit (J-50397) are listed on the inside cover of the

kit; and can each be ordered separately as needed.

• The following materials not found in the kit can also be used to repair squeaks and rattles.

- SILICONE GREASE: Use instead of UHMW tape that will be visible or does not fit. The silicone grease will

only last a few months.

- SILICONE SPRAY: Use when grease cannot be applied.

- DUCT TAPE: Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingINFOID:0000000012432087

Refer to Table of Contents for specific component removal and installation information.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2509 of 3641

![NISSAN NOTE 2016 Service Repair Manual PCS-6

< SYSTEM DESCRIPTION >[IPDM E/R]

SYSTEM

RELAY CONTROL SYSTEM : Fail-safe

INFOID:0000000012433269

CAN COMMUNICATION CONTROL

When CAN communication with ECM and BCM is impossible, IPDM E/R perform NISSAN NOTE 2016 Service Repair Manual PCS-6

< SYSTEM DESCRIPTION >[IPDM E/R]

SYSTEM

RELAY CONTROL SYSTEM : Fail-safe

INFOID:0000000012433269

CAN COMMUNICATION CONTROL

When CAN communication with ECM and BCM is impossible, IPDM E/R perform](/img/5/57363/w960_57363-2508.png)

PCS-6

< SYSTEM DESCRIPTION >[IPDM E/R]

SYSTEM

RELAY CONTROL SYSTEM : Fail-safe

INFOID:0000000012433269

CAN COMMUNICATION CONTROL

When CAN communication with ECM and BCM is impossible, IPDM E/R performs fail-safe control. After CAN

communication recovers normally, it also returns to normal control.

If No CAN Communication Is Available With ECM

If No CAN Communication Is Available With BCM

Control relay Input/outputTransmit unit Control part Reference page

• Headlamp low relay

• Headlamp high relay • Low beam request signal

• High beam request signal

BCM (CAN)

• Headlamp LO

• Headlamp HI EXL-8

Tail lamp relay

Position light request signal BCM (CAN) •Parking lamp

• Side marker lamp

• License plate lamp

• Tail lamp

EXL-11

Illuminations

INL-9

• Front wiper relay

• Front wiper high relayFront wiper request signal BCM (CAN)

Front wiper motorWW-8Front wiper stop position sig-

nal Front wiper motor

Starter control relay Starter control relay signal BCM (CAN)

Starter motorSTR-8

(without Intelli-

gent Key)

STR-9

(with Intelligent

Key)

Transmission range switch

signal (CVT models)

Transmission range

switch

Clutch interlock switch signal

(M/T models) Clutch interlock switch

• Cooling fan low relay

• Cooling fan high relay Cooling fan speed request sig-

nal

ECM (CAN)

Cooling fan EC-38

A/C relayA/C compressor request sig-

nal

ECM (CAN)A/C compressor

(Magnet clutch)

HAC-11

Ignition relay-1Ignition switch ON signal BCM (CAN)

Each control unit,

sensor, actuator and

relay (Ignition power

supply) EC-35Vehicle speed signal (Meter)

Combination meter

(CAN)

Push-button ignition switch

signal Push-button ignition

switch

Control part

Fail-safe operation

Cooling fan • The cooling fan relay turn ON when the ignition switch is turned ON (Cooling fan HI operation)

• The cooling fan relay turn OFF when the ignition switch is turned OFF

A/C compressor A/C relay OFF

Generator Outputs the power generation command signal (PWM signal) 0%

Control part Fail-safe operation

Headlamp • Turns ON the headlamp low relay when the ignition switch is turned ON

• Turns OFF the headlamp low relay when the ignition switch is turned OFF

• Headlamp high relay OFF

•Parking lamp

• Side marker lamp

• License plate lamp

• Illumination

• Tail lamp • Turns ON the tail lamp relay when the ignition switch is turned ON

• Turns OFF the tail lamp relay when the ignition switch is turned OFF

Revision: August 2015

2016 Versa Note

cardiagn.com