cvt NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 2077 of 3641

SQUEAK AND RATTLE TROUBLE DIAGNOSESIP-9

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

IP

N

O P

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or lo cation of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-clutch on M/T model, drive position on CVT and A/T models).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

• Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

• If it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, check ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pinpoint the source of the noise, use a listening tool (Chassis Ear: J-39570, Engine Ear: J-39565 and mechanic's stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by: • removing the components in the area that you suspect the noise is coming from.Do not use too much force when removing clips and fasteners, otherwise clips and fasteners can be

broken or lost during the repair, resulting in the creation of new noise.

• tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only

temporarily.

• feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

• placing a piece of paper between components that you suspect are causing the noise.

• looking for loose components and contact marks. Refer to IP-9, "

Generic Squeak and Rattle Troubleshooting".

REPAIR THE CAUSE

• If the cause is a loose component, tighten the component securely.

• If the cause is insufficient clearance between components:

- separate components by repositioning or loos ening and retightening the component, if possible.

- insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or urethane tape. A NISSAN Squeak and Rattle Kit (J-50397) is available through your authorized NISSAN Parts Depart-

ment.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

NOTE:

• Always check with the Parts Department for the latest parts information.

• The materials contained in the NISSAN Squeak and Rattle Kit (J-50397) are listed on the inside cover of the

kit; and can each be ordered separately as needed.

• The following materials not found in the kit can also be used to repair squeaks and rattles.

- SILICONE GREASE: Use instead of UHMW tape that will be visible or does not fit. The silicone grease will

only last a few months.

- SILICONE SPRAY: Use when grease cannot be applied.

- DUCT TAPE: Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingINFOID:0000000012430775

Refer to Table of Contents for specific component removal and installation information.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2086 of 3641

IP-18

< REMOVAL AND INSTALLATION >

CENTER CONSOLE ASSEMBLY

CENTER CONSOLE ASSEMBLY

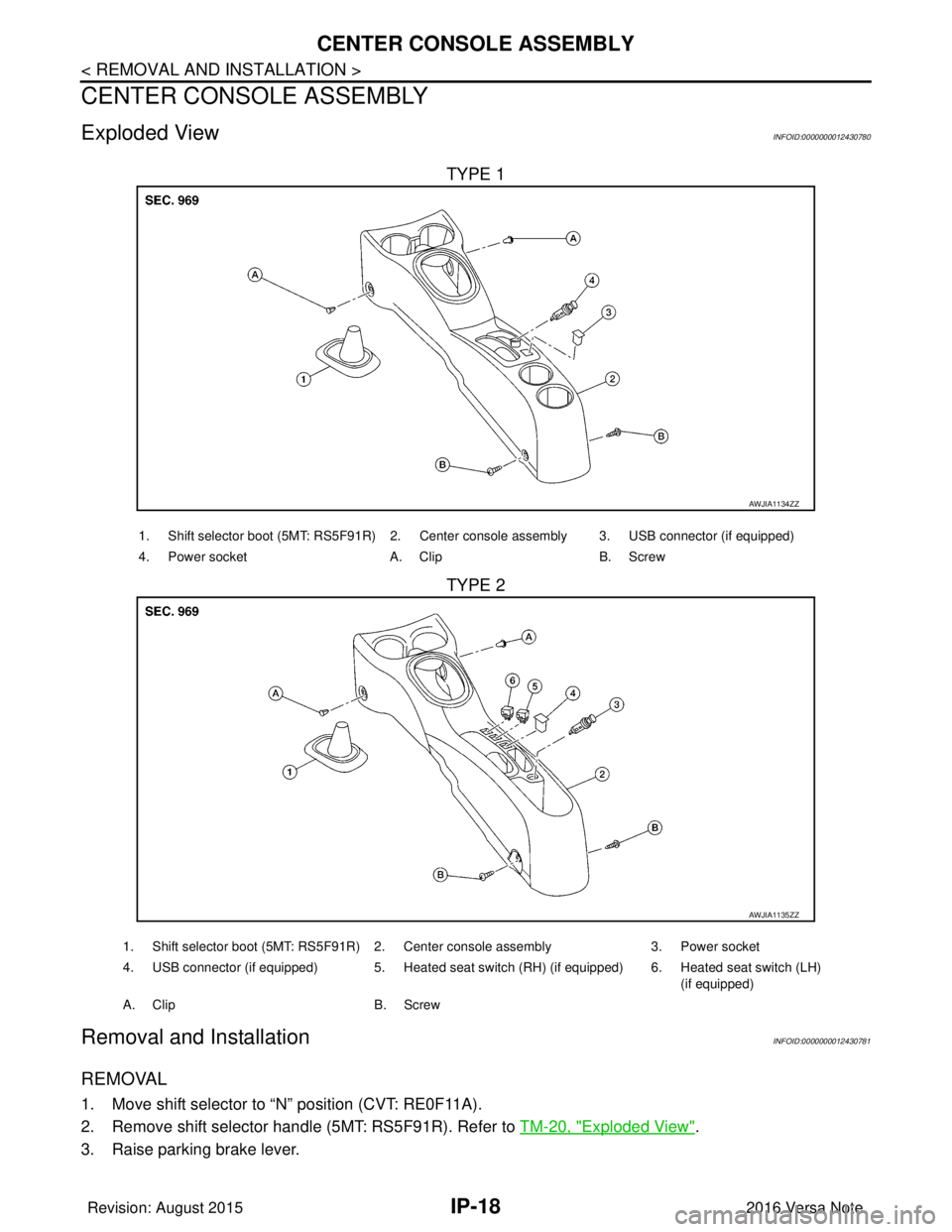

Exploded ViewINFOID:0000000012430780

TYPE 1

TYPE 2

Removal and InstallationINFOID:0000000012430781

REMOVAL

1. Move shift selector to “N” position (CVT: RE0F11A).

2. Remove shift selector handle (5MT: RS5F91R). Refer to TM-20, "

Exploded View".

3. Raise parking brake lever.

AWJIA1134ZZ

1. Shift selector boot (5MT: RS5F91R) 2. Center console assembly 3. USB connector (if equipped)

4. Power socket A. Clip B. Screw

AWJIA1135ZZ

1. Shift selector boot (5MT: RS5F91R) 2. Center console assembly 3. Power socket

4. USB connector (if equipped) 5. Heated seat switch (RH) (if equipped) 6. Heated seat switch (LH) (if equipped)

A. Clip B. Screw

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2107 of 3641

![NISSAN NOTE 2016 Service Repair Manual DIAGNOSIS SYSTEM (BCM) (WITH INTELLIGENT KEY SYSTEM)

INL-13

< SYSTEM DESCRIPTION >

C

D E

F

G H

I

J

K

M A

B

INL

N

O P

ACTIVE TEST

BRAKE SW 2 [On/Off] Indicates condition of brake switch.

DETE/CANCL SW NISSAN NOTE 2016 Service Repair Manual DIAGNOSIS SYSTEM (BCM) (WITH INTELLIGENT KEY SYSTEM)

INL-13

< SYSTEM DESCRIPTION >

C

D E

F

G H

I

J

K

M A

B

INL

N

O P

ACTIVE TEST

BRAKE SW 2 [On/Off] Indicates condition of brake switch.

DETE/CANCL SW](/img/5/57363/w960_57363-2106.png)

DIAGNOSIS SYSTEM (BCM) (WITH INTELLIGENT KEY SYSTEM)

INL-13

< SYSTEM DESCRIPTION >

C

D E

F

G H

I

J

K

M A

B

INL

N

O P

ACTIVE TEST

BRAKE SW 2 [On/Off] Indicates condition of brake switch.

DETE/CANCL SW [On/Off] ×Indicates condition of P (park) position.

SFT PN/N SW [On/Off] ×Indicates condition of P (park) or N (neutral) position.

UNLK SEN -DR [On/Off] ×Indicates condition of door unlock sensor.

PUSH SW -IPDM [On/Off] Indicates condition of push-button ignition switch received from IPDM E/R on

CAN communication line.

IGN RLY1 -F/B [On/Off] Indicates condition of ignition relay 1 received from IPDM E/R on CAN commu-

nication line.

DETE SW -IPDM [On/Off] Indicates condition of detent switch received from TCM on CAN communication

line.

SFT PN -IPDM [On/Off] Indicates condition of P (park) or N (neutral) position from TCM on CAN com-

munication line.

SFT P -MET [On/Off] Indicates condition of P (park) position from TCM on CAN communication line.

SFT N -MET [On/Off] Indicates condition of N (neutral) position from IPDM E/R on CAN communica-

tion line.

ENGINE STATE [Stop/Start/Crank/Run] ×Indicates condition of engine state from ECM on CAN communication line.

VEH SPEED 1 [mph/km/h] ×Indicates condition of vehicle speed si

gnal received from ABS on CAN commu-

nication line.

VEH SPEED 2 [mph/km/h] ×Indicates condition of vehicle speed signal received from combination meter on

CAN communication line.

DOOR STAT -DR [LOCK/READY/UNLK] ×Indicates condition of driver side door status.

DOOR STAT -AS [LOCK/READY/UNLK] ×Indicates condition of passenger side door status.

ID OK FLAG [Set/Reset] Indicates condition of Intelligent Key ID.

PRMT ENG STRT [Set/Reset] Indicates condition of engine start possibility.

RKE OPE COUN1 [0-19] ×When remote keyless entry receiver receives the signal transmitted while oper-

ating on Intelligent Key, the numerical value start changing.

RKE OPE COUN2 [0-19] ×When remote keyless entry receiver receives the signal transmitted while oper-

ating on Intelligent Key, the numerical value start changing.

RKE-LOCK [On/Off] Indicates condition of lock signal from Intelligent Key.

RKE-UNLOCK [On/Off] Indicates condition of unlock signal from Intelligent Key.

RKE-PANIC [On/Off] Indicates condition of panic signal from Intelligent Key.

RKE-MODE CHG [On/Off] Indicates condition of mode change signal from Intelligent Key.

Monitor Item [Unit]

Main Description

Test Item Description

INSIDE BUZZER This test is able to check combination meter warning chime operation [Take Out/Knob/Key/

Off].

LCD This test is able to check combination me

ter display information [Off/LK WN/OUTKEY/NO

KY/BATT/INSRT/SFT P/ROTAT/ID NG/B&P I/B&P N].

BATTERY SAVER This test is able to check battery saver operation [On/Off].

ENGINE SW ILLUMI This test is able to check push-button ignition switch START indicator operation [On/Off].

PUSH SWITCH INDICATOR This test is able to check push-button ignition switch indicator operation [On/Off].

INT LAMP This test is able to check interior room lamp operation [On/Off].

INDICATOR This test is able to check combination mete r warning lamp operation [KEY ON/KEY IND/Off].

FLASHER This test is able to check hazard lamp operation [LH/RH/Off].

OUTSIDE BUZZER This test is able to check Intelligent Key warning buzzer operation [On/Off].

HORN This test is able to check horn operation [On].

P RANGE This test is able to check CVT shift selector illumination operation [On/Off].

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2161 of 3641

INT-10

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or lo cation of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-clutch on M/T model, drive position on CVT and A/T models).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

• Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

• If it is difficult to duplicate the noise, drive the v ehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, chec k ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follo w the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pi npoint the source of the noise, use a listening tool

(Chassis Ear: J-39570, Engine Ear: J-39565 and mechanic's stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by: • removing the components in the area that you suspect the noise is coming from.Do not use too much force when removing clips and fasteners, otherwise clips and fasteners can be

broken or lost during the repair, resulting in the creation of new noise.

• tapping or pushing/pulling the component that you suspect is causing the noise. Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only

temporarily.

• feeling for a vibration with your hand by touching the component(s) that you suspec t is (are) causing the

noise.

• placing a piece of paper between components that you suspect are causing the noise.

• looking for loose components and contact marks.

Refer to INT-10, "

Generic Squeak and Rattle Troubleshooting".

REPAIR THE CAUSE

• If the cause is a loose component, tighten the component securely.

• If the cause is insufficient clearance between components:

- separate components by repositioning or loos ening and retightening the component, if possible.

- insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or urethane tape. A NISSAN Squeak and Rattle Kit (J-50397) is av ailable through your authorized NISSAN Parts Depart-

ment.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

NOTE:

• Always check with the Parts Department for the latest parts information.

• The materials contained in the NISSAN Squeak and Rattle Kit (J-50397) are listed on the inside cover of the

kit; and can each be ordered separately as needed.

• The following materials not found in the kit can also be used to repair squeaks and rattles.

- SILICONE GREASE: Use instead of UHMW tape that will be visible or does not fit. The silicone grease will only last a few months.

- SILICONE SPRAY: Use when grease cannot be applied.

- DUCT TAPE: Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingINFOID:0000000012431858

Refer to Table of Contents for specific component removal and installation information.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2179 of 3641

INT-28

< REMOVAL AND INSTALLATION >

FLOOR TRIM

6. Disconnect negative and positive battery terminals, then wait at least three minutes. Refer to PG-70,

"Removal and Installation (Battery)".

WARNING:

Before servicing the SRS, turn th e ignition switch off, disconnect both battery terminals then wait

at least three minutes.

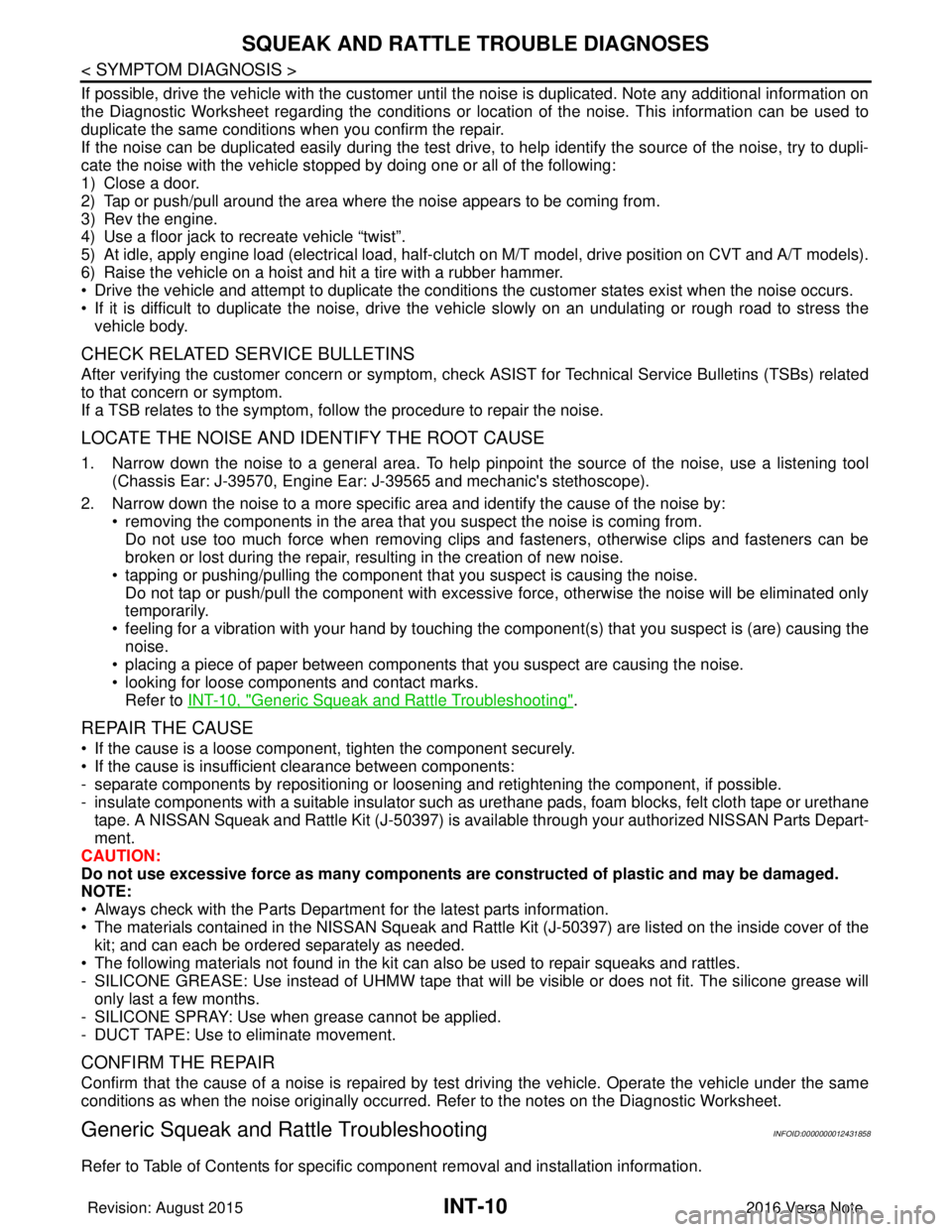

7. Disconnect the harness connector (A ) from the seat belt retrac-

tor (1).

WARNING:

• Do not drop the seat belt retractor. Always handle it with care.

• Always point pretensioner cylinder away from body when handling.

CAUTION:

• For removing/installing the shoulder belt pre-tensioner harness connector, insert a thin screwdriver wrapped in

tape into the notch, then lift the lock and remove the har-

ness connector as shown.

• Install the harness connector with the lock raised, and push the lock into the harness connector as shown.

• After installing the harness connector, check that the lock

is pushed in securely.

8. Remove seat belt lower anchor bolt. CAUTION:

Before removing the seat belt lower anchor bolt , note the positions of washers and spacers for

correct installation.

9. Remove diagnosis sensor unit. Refer to SR-30, "

Removal and Installation".

10. Remove shift selector. Refer to TM-20, "

Exploded View" (5MT) or TM-231, "Removal and Installation"

(CVT).

11. Remove A/C unit assembly bolt (C) and bracket (1) from vehicle.

12. Remove instrument panel lower bracket bolt (B) and screw (A) and reposition bracket as necessary to remove floor trim.

ALHIA0316ZZ

PHIA0953J

ALJIA0712ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2217 of 3641

![NISSAN NOTE 2016 Service Repair Manual LAN

SYSTEMLAN-29

< SYSTEM DESCRIPTION > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

*: These are the only control units wired with both ends of CAN communication system.

CAN COMMUNICATION SYSTEM : CAN

System NISSAN NOTE 2016 Service Repair Manual LAN

SYSTEMLAN-29

< SYSTEM DESCRIPTION > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

*: These are the only control units wired with both ends of CAN communication system.

CAN COMMUNICATION SYSTEM : CAN

System](/img/5/57363/w960_57363-2216.png)

LAN

SYSTEMLAN-29

< SYSTEM DESCRIPTION > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

*: These are the only control units wired with both ends of CAN communication system.

CAN COMMUNICATION SYSTEM : CAN

System Specification ChartINFOID:0000000012433348

Determine CAN system type from the following specification chart.

NOTE:

Refer to LAN-16, "

Trouble Diagnosis Flow Chart" for how to use CAN system specification chart.

×: Applicable

VEHICLE EQUIPMENT IDENTIFICATION INFORMATION

NOTE:

Check CAN system type from the vehicle shape and equipment.

Noise filter It eliminates noise of CAN communication signal.

Termination circuit

*

(Resistance of approx. 120 Ω) Generates a potential difference between CAN-H and CAN-L.

Component

System description

Body type Hatch back

Axle 2WD

Engine HR16DE

Transmission M/T CVT

Brake control VDC

Around view monitor system ××

Navigation system ×××

CAN system type 501502 503505 504

CAN communication control unit

ECM ×××××

ABS actuator and electric unit (control unit) ×××××

IPDM E/R ×××××

TCM ×××

Around view monitor control unit ××

Air bag diagnosis sensor unit ×××××

AV c o n t r o l u n i t ×××

Data link connector ×××××

EPS control unit ×××××

Combination meter ×××××

Steering angle sensor ×××××

BCM ×××××

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2218 of 3641

![NISSAN NOTE 2016 Service Repair Manual LAN-30

< SYSTEM DESCRIPTION >[CAN]

SYSTEM

CAN COMMUNICATION SYSTEM : CA N Communication Signal Chart

INFOID:0000000012433349

Refer to LAN-15, "How to Use CAN Communication Signal Chart" for how to use NISSAN NOTE 2016 Service Repair Manual LAN-30

< SYSTEM DESCRIPTION >[CAN]

SYSTEM

CAN COMMUNICATION SYSTEM : CA N Communication Signal Chart

INFOID:0000000012433349

Refer to LAN-15, "How to Use CAN Communication Signal Chart" for how to use](/img/5/57363/w960_57363-2217.png)

LAN-30

< SYSTEM DESCRIPTION >[CAN]

SYSTEM

CAN COMMUNICATION SYSTEM : CA N Communication Signal Chart

INFOID:0000000012433349

Refer to LAN-15, "How to Use CAN Communication Signal Chart" for how to use CAN communication signal

chart.

NOTE:

• Refer to LAN-21, "

Abbreviation List" for the abbreviations of the connecting units.

• The air bag diagnosis sensor unit and AV control unit uses CAN communication only for communicating with

the diagnostic tool (not with other connected control units).

T: Transmit R: Receive

NAVI switches Side camera LH

With navigation system With around view monitor system

ALMIA0821ZZ

Signal nameECM

ABS

IPDM-E TCM

AV M EPS

M&A

STRG BCM

Accelerator pedal position signal T RR

A/C compressor request signal TR

Closed throttle position signal TR

Cooling fan speed request signal TR

ECO pedal guide signal TR

Engine and CVT integrated control signal TR

RT

Engine coolant temperature signal TR R R

Engine speed signal T RR R

Engine status signal T RR R

Fuel filler cap warning display signal TR

N idle instruction signal TR

RT

Malfunctioning indicator lamp signal TR

RT

Oil pressure warning lamp signal TR

Power generation command value signal TR

ABS warning lamp signal TR

VDC warning lamp signal TR

VDC OFF indicator lamp signal TR

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2316 of 3641

MA-1

MAINTENANCE

C

DE

F

G H

I

J

K L

M B

MA

SECTION MA

N

O A

CONTENTS

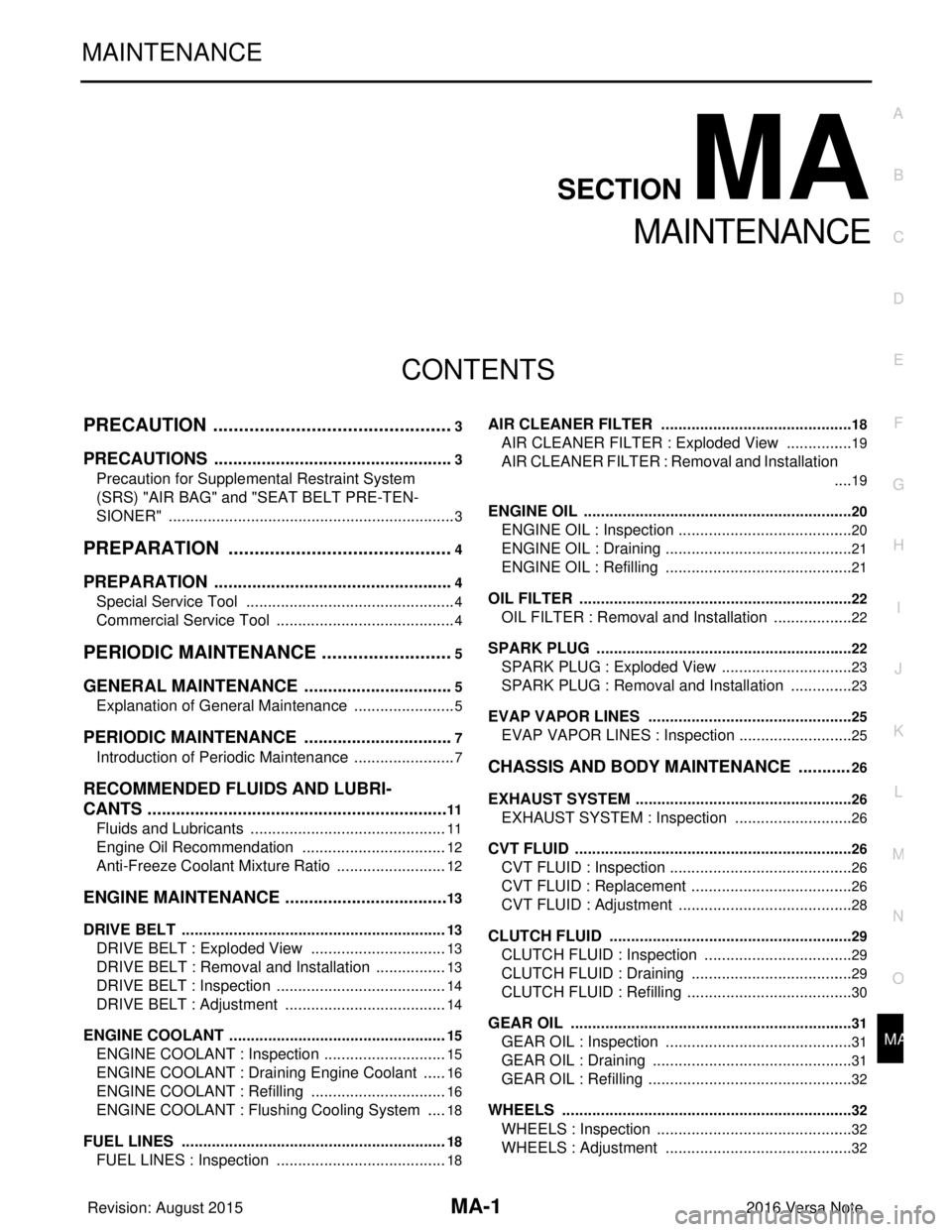

MAINTENANCE

PRECAUTION .......

........................................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................4

PERIODIC MAINTENANCE ..........................5

GENERAL MAINTE NANCE ........................... .....5

Explanation of General Maintenance .................. ......5

PERIODIC MAINTENANCE ................................7

Introduction of Periodic Maintenance .................. ......7

RECOMMENDED FLUIDS AND LUBRI-

CANTS ................................................................

11

Fluids and Lubricants .......................................... ....11

Engine Oil Recommendation ..................................12

Anti-Freeze Coolant Mixture Ratio ..........................12

ENGINE MAINTENANCE ...................................13

DRIVE BELT .......................................................... ....13

DRIVE BELT : Exploded View ................................13

DRIVE BELT : Removal and Installation .................13

DRIVE BELT : Inspection .................................... ....14

DRIVE BELT : Adjustment ......................................14

ENGINE COOLANT ............................................... ....15

ENGINE COOLANT : Inspection .............................15

ENGINE COOLANT : Draining Engine Coolant ......16

ENGINE COOLANT : Refilling ................................16

ENGINE COOLANT : Flushing Cooling System .....18

FUEL LINES .......................................................... ....18

FUEL LINES : Inspection ........................................18

AIR CLEANER FILTER ......................................... ....18

AIR CLEANER FILTER : Exploded View ................19

AIR CLEANER FILTER : Removal and Installation

....

19

ENGINE OIL ........................................................... ....20

ENGINE OIL : Inspection .........................................20

ENGINE OIL : Draining ............................................21

ENGINE OIL : Refilling ............................................21

OIL FILTER ............................................................ ....22

OIL FILTER : Removal and Installation ...................22

SPARK PLUG ........................................................ ....22

SPARK PLUG : Exploded View ...............................23

SPARK PLUG : Removal and Installation ...............23

EVAP VAPOR LINES ............................................ ....25

EVAP VAPOR LINES : Inspection ...........................25

CHASSIS AND BODY MAINTENANCE ...........26

EXHAUST SYSTEM . ..................................................26

EXHAUST SYSTEM : Inspec tion ............................26

CVT FLUID ............................................................. ....26

CVT FLUID : Inspection ...........................................26

CVT FLUID : Replacement ......................................26

CVT FLUID : Adjustment .........................................28

CLUTCH FLUID ..................................................... ....29

CLUTCH FLUID : Inspection ...................................29

CLUTCH FLUID : Draining ......................................29

CLUTCH FLUID : Refilling .......................................30

GEAR OIL .............................................................. ....31

GEAR OIL : Inspection ............................................31

GEAR OIL : Draining ...............................................31

GEAR OIL : Refilling ................................................32

WHEELS ................................................................ ....32

WHEELS : Inspection ..............................................32

WHEELS : Adjustment ............................................32

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2321 of 3641

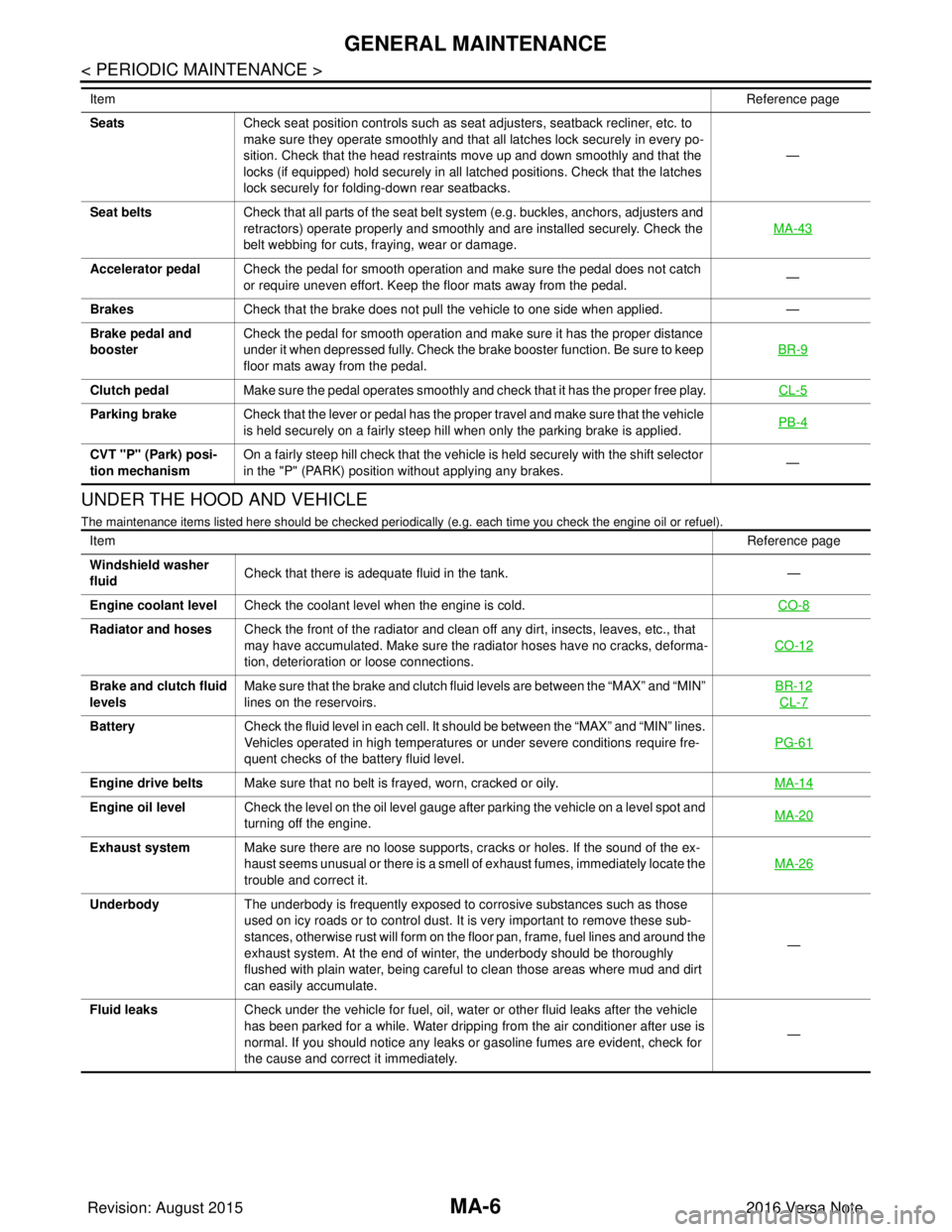

MA-6

< PERIODIC MAINTENANCE >

GENERAL MAINTENANCE

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically (e.g. each time you check the engine oil or refuel).

SeatsCheck seat position controls such as seat adjusters, seatback recliner, etc. to

make sure they operate smoothly and that all latches lock securely in every po-

sition. Check that the head restraints move up and down smoothly and that the

locks (if equipped) hold securely in all latched positions. Check that the latches

lock securely for folding-down rear seatbacks. —

Seat belts Check that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly and are installed securely. Check the

belt webbing for cuts, fraying, wear or damage. MA-43

Accelerator pedal

Check the pedal for smooth operation and make sure the pedal does not catch

or require uneven effort. Keep the floor mats away from the pedal. —

Brakes Check that the brake does not pull the vehicle to one side when applied. —

Brake pedal and

booster Check the pedal for smooth operation and make sure it has the proper distance

under it when depressed fully. Check the brake booster function. Be sure to keep

floor mats away from the pedal. BR-9

Clutch pedal

Make sure the pedal operates smoothly and check that it has the proper free play. CL-5

Parking brakeCheck that the lever or pedal has the proper travel and make sure that the vehicle

is held securely on a fairly steep hill when only the parking brake is applied. PB-4

CVT "P" (Park) posi-

tion mechanismOn a fairly steep hill check that the vehicle is held securely with the shift selector

in the "P" (PARK) position without applying any brakes.

—

Item

Reference page

Item Reference page

Windshield washer

fluid Check that there is adequate fluid in the tank.

—

Engine coolant level Check the coolant level when the engine is cold. CO-8

Radiator and hosesCheck the front of the radiator and clean off any dirt, insects, leaves, etc., that

may have accumulated. Make sure the radiator hoses have no cracks, deforma-

tion, deterioration or loose connections. CO-12

Brake and clutch fluid

levelsMake sure that the brake and clutch fluid levels are between the “MAX” and “MIN”

lines on the reservoirs. BR-12

CL-7

Battery

Check the fluid level in each cell. It should be between the “MAX” and “MIN” lines.

Vehicles operated in high temperatures or under severe conditions require fre-

quent checks of the battery fluid level. PG-61

Engine drive belts

Make sure that no belt is frayed, worn, cracked or oily. MA-14

Engine oil levelCheck the level on the oil level gauge after parking the vehicle on a level spot and

turning off the engine. MA-20

Exhaust system

Make sure there are no loose supports, cracks or holes. If the sound of the ex-

haust seems unusual or there is a smell of exhaust fumes, immediately locate the

trouble and correct it. MA-26

Underbody

The underbody is frequently exposed to corrosive substances such as those

used on icy roads or to control dust. It is very important to remove these sub-

stances, otherwise rust will form on the floor pan, frame, fuel lines and around the

exhaust system. At the end of winter, the underbody should be thoroughly

flushed with plain water, being careful to clean those areas where mud and dirt

can easily accumulate. —

Fluid leaks Check under the vehicle for fuel, oil, water or other fluid leaks after the vehicle

has been parked for a while. Water dripping from the air conditioner after use is

normal. If you should notice any leaks or gasoline fumes are evident, check for

the cause and correct it immediately. —

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 2323 of 3641

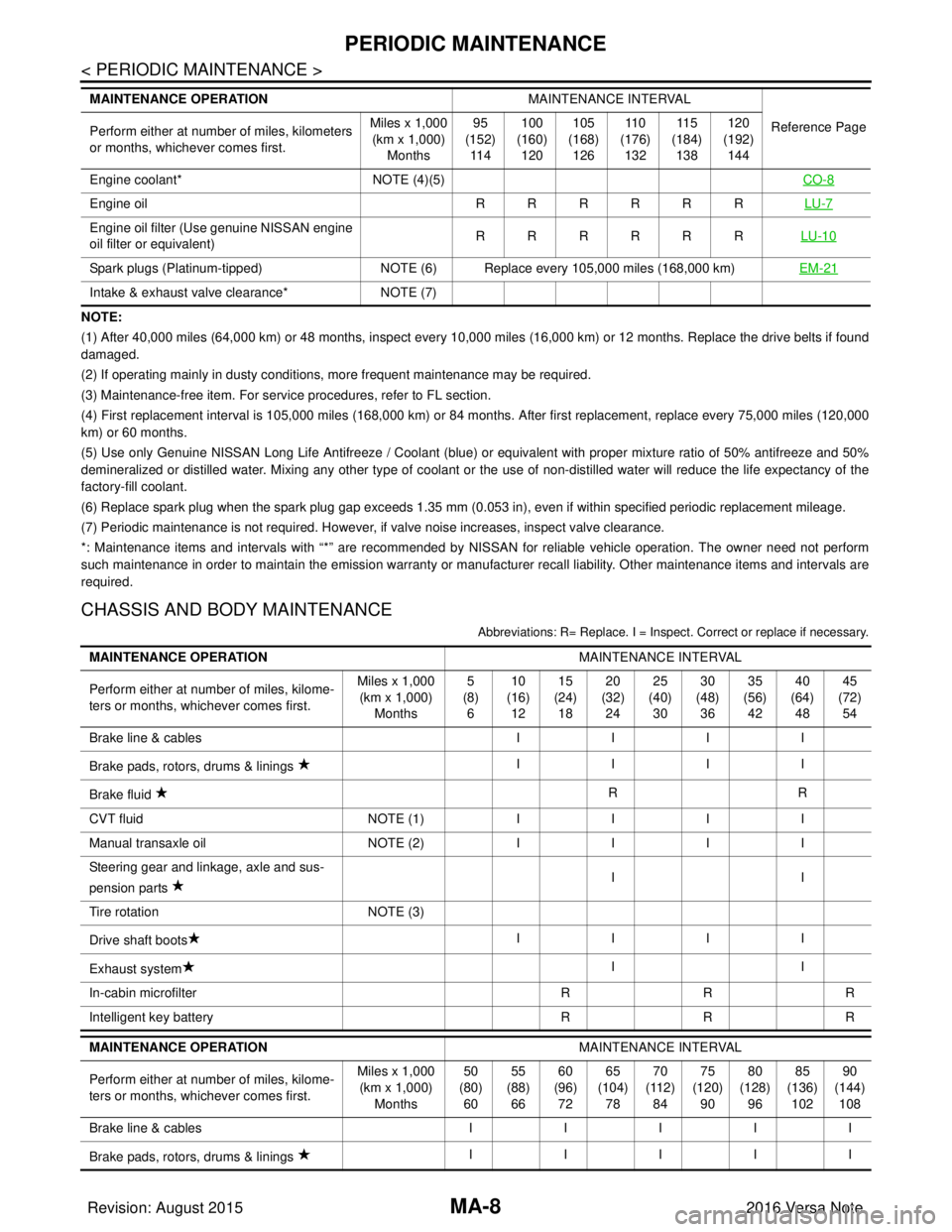

MA-8

< PERIODIC MAINTENANCE >

PERIODIC MAINTENANCE

NOTE:

(1) After 40,000 miles (64,000 km) or 48 months, inspect every 10,000 miles (16,000 km) or 12 months. Replace the drive belts if found

damaged.

(2) If operating mainly in dusty conditions, more frequent maintenance may be required.

(3) Maintenance-free item. For service procedures, refer to FL section.

(4) First replacement interval is 105,000 miles (168,000 km) or 84 months. After first replacement, replace every 75,000 miles (120,000

km) or 60 months.

(5) Use only Genuine NISSAN Long Life Antifreeze / Coolant (blue) or equivalent with proper mixture ratio of 50% antifreeze and 50%

demineralized or distilled water. Mixing any other type of coolant or the use of non-distilled water will reduce the life expec tancy of the

factory-fill coolant.

(6) Replace spark plug when the spark plug gap exceeds 1.35 mm (0.053 in), even if within specified periodic replacement mileag e.

(7) Periodic maintenance is not required. However, if valve noise increases, inspect valve clearance.

*: Maintenance items and intervals with “*” are recommended by NISSAN for reli able vehicle operation. The owner need not perform

such maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and inter vals are

required.

CHASSIS AND BODY MAINTENANCE

Abbreviations: R= Replace. I = Inspec t. Correct or replace if necessary.

Engine coolant* NOTE (4)(5) CO-8

Engine oil RRRRRRLU-7

Engine oil filter (Use genuine NISSAN engine

oil filter or equivalent) RRRRRR

LU-10

Spark plugs (Platinum-tipped)NOTE (6) Replace every 105,000 miles (168,000 km) EM-21

Intake & exhaust valve clearance*NOTE (7)

MAINTENANCE OPERATION

MAINTENANCE INTERVAL

Reference Page

Perform either at number of miles, kilometers

or months, whichever comes first. Miles x 1,000

(km x 1,000)

Months 95

(152)

11 4 100

(160)

120 105

(168)

126 11 0

(176)

132 11 5

(184)

138 120

(192)

144

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform either at number of miles, kilome-

ters or months, whichever comes first. Miles x 1,000

(km x 1,000)

Months 5

(8)

6 10

(16)

12 15

(24)

18 20

(32)

24 25

(40)

30 30

(48)

36 35

(56)

42 40

(64)

48 45

(72)

54

Brake line & cables IIII

Brake pads, rotors, drums & linings IIII

Brake fluid RR

CVT fluid NOTE (1)IIII

Manual transaxle oil NOTE (2)IIII

Steering gear and linkage, axle and sus-

pension parts II

Tire rotation NOTE (3)

Drive shaft boots IIII

Exhaust system II

In-cabin microfilter RRR

Intelligent key battery RRR

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform either at number of miles, kilome-

ters or months, whichever comes first. Miles x 1,000

(km x 1,000) Months 50

(80) 60 55

(88) 66 60

(96) 72 65

(104) 78 70

(112) 84 75

(120) 90 80

(128) 96 85

(136) 102 90

(144) 108

Brake line & cables III II

Brake pads, rotors, drums & linings IIIII

Revision: August 2015

2016 Versa Note

cardiagn.com