battery NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 2142 of 3641

INL-48

< DTC/CIRCUIT DIAGNOSIS >

PUSH-BUTTON IGNITION SWITCH ILLUMINATION CIRCUIT

PUSH-BUTTON IGNITION SWITCH ILLUMINATION CIRCUIT

DescriptionINFOID:0000000012432748

Provides the power supply and the ground to control the push-button ignition switch illumination.

Component Function CheckINFOID:0000000012432749

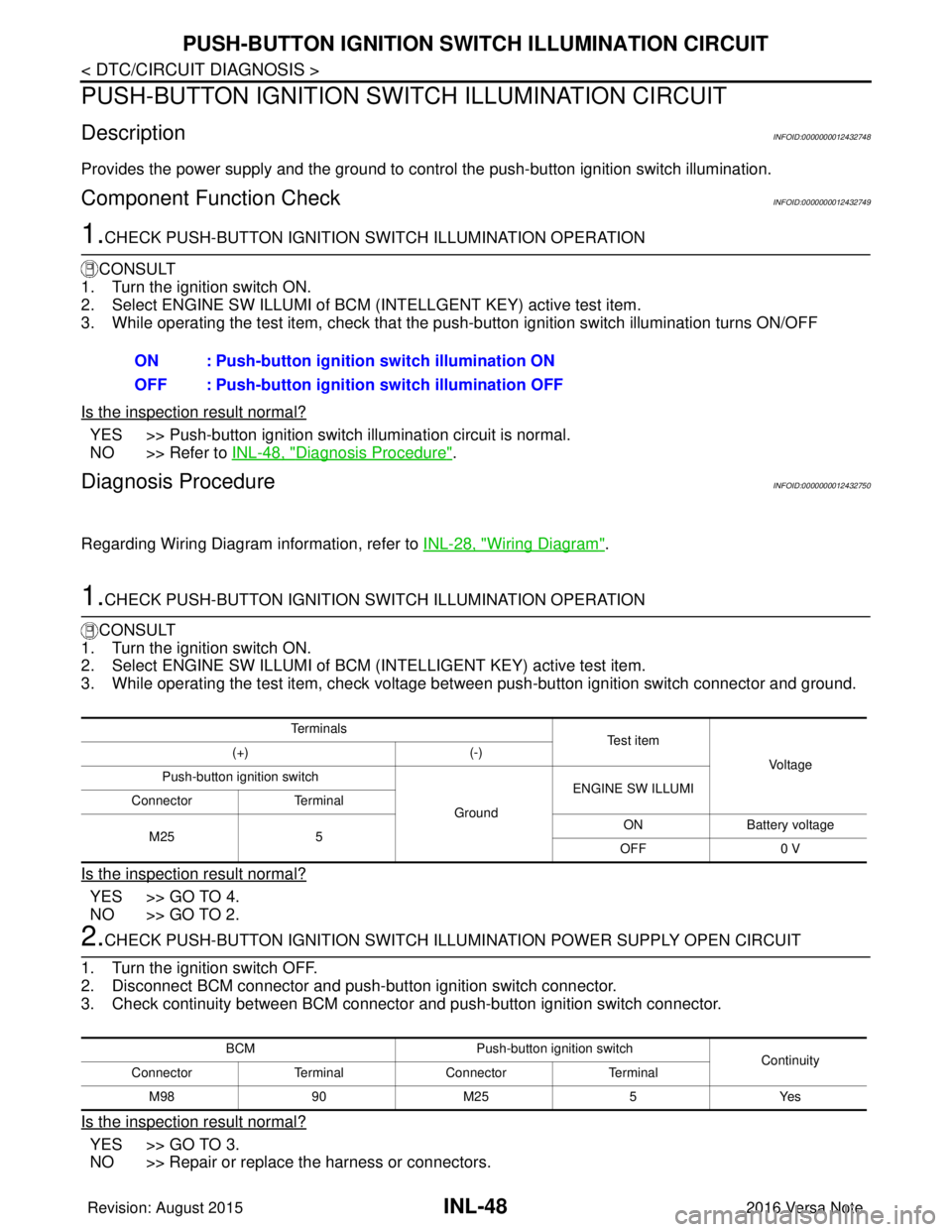

1.CHECK PUSH-BUTTON IGNITION SWITCH ILLUMINATION OPERATION

CONSULT

1. Turn the ignition switch ON.

2. Select ENGINE SW ILLUMI of BCM (I NTELLGENT KEY) active test item.

3. While operating the test item, check that the push-button ignition switch illumination turns ON/OFF

Is the inspection result normal?

YES >> Push-button ignition switch illumination circuit is normal.

NO >> Refer to INL-48, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000012432750

Regarding Wiring Diagram information, refer to INL-28, "Wiring Diagram".

1.CHECK PUSH-BUTTON IGNITION SWITCH ILLUMINATION OPERATION

CONSULT

1. Turn the ignition switch ON.

2. Select ENGINE SW ILLUMI of BCM (INTELLIGENT KEY) active test item.

3. While operating the test item, check voltage bet ween push-button ignition switch connector and ground.

Is the inspection result normal?

YES >> GO TO 4.

NO >> GO TO 2.

2.CHECK PUSH-BUTTON IGNITION SWITCH ILLUMINATION POWER SUPPLY OPEN CIRCUIT

1. Turn the ignition switch OFF.

2. Disconnect BCM connector and push-button ignition switch connector.

3. Check continuity between BCM connector and push-button ignition switch connector.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace the harness or connectors. ON : Push-button ignition switch illumination ON

OFF : Push-button ignition

switch illumination OFF

Te r m i n a l s

Te s t i t e m

Vo l ta g e

(+)

(-)

Push-button ignition switch

GroundENGINE SW ILLUMI

Connector Terminal

M25 5 ON

Battery voltage

OFF 0 V

BCM Push-button ignition switch

Continuity

Connector TerminalConnector Terminal

M 989 0M 25 5 Y es

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2144 of 3641

INL-50

< SYMPTOM DIAGNOSIS >

INTERIOR LIGHTING SYSTEM SYMPTOMS

SYMPTOM DIAGNOSIS

INTERIOR LIGHTING SYSTEM SYMPTOMS

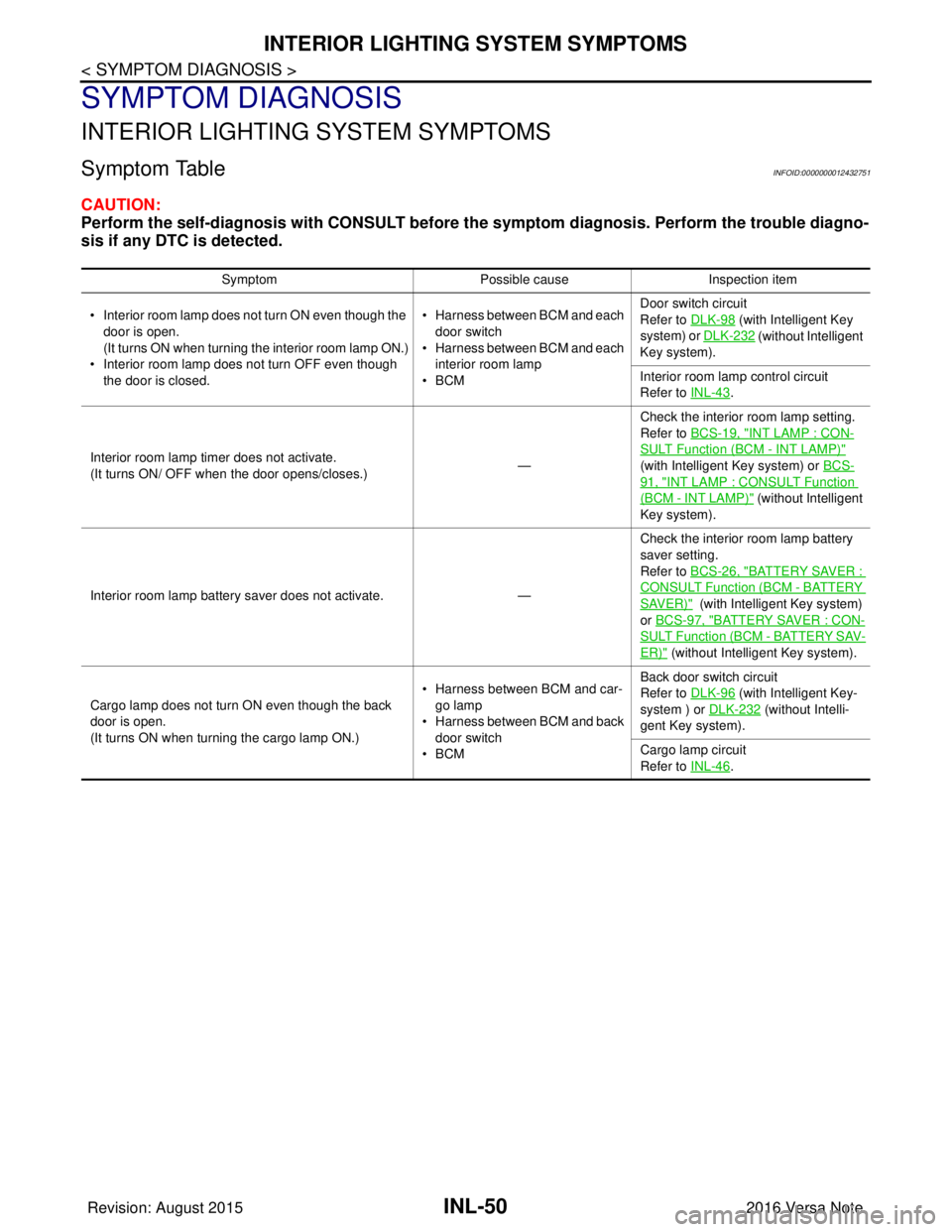

Symptom TableINFOID:0000000012432751

CAUTION:

Perform the self-diagnosis with CONSULT before the symptom diagnosis. Perform the trouble diagno-

sis if any DTC is detected.

Symptom Possible causeInspection item

• Interior room lamp does not turn ON even though the door is open.

(It turns ON when turning the interior room lamp ON.)

• Interior room lamp does not turn OFF even though

the door is closed. • Harness between BCM and each

door switch

• Harness between BCM and each interior room lamp

•BCM Door switch circuit

Refer to DLK-98

(with Intelligent Key

system) or DLK-232

(without Intelligent

Key system).

Interior room lamp control circuit

Refer to INL-43

.

Interior room lamp timer does not activate.

(It turns ON/ OFF when the door opens/closes.) —Check the interior room lamp setting.

Refer to BCS-19, "

INT LAMP : CON-

SULT Function (BCM - INT LAMP)"

(with Intelligent Key system) or BCS-

91, "INT LAMP : CONSULT Function

(BCM - INT LAMP)" (without Intelligent

Key system).

Interior room lamp battery saver does not activate. — Check the interior room lamp battery

saver setting.

Refer to BCS-26, "

BATTERY SAVER :

CONSULT Function (BCM - BATTERY

SAVER)" (with Intelligent Key system)

or BCS-97, "

BATTERY SAVER : CON-

SULT Function (BCM - BATTERY SAV-

ER)" (without Intelligent Key system).

Cargo lamp does not turn ON even though the back

door is open.

(It turns ON when turning the cargo lamp ON.) • Harness between BCM and car-

go lamp

• Harness between BCM and back

door switch

•BCM Back door switch circuit

Refer to DLK-96

(with Intelligent Key-

system ) or DLK-232

(without Intelli-

gent Key system).

Cargo lamp circuit

Refer to INL-46

.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2154 of 3641

PRECAUTIONSINT-3

< PRECAUTION >

C

DE

F

G H

I

K L

M A

B

INT

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012431852

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery and wait at least three mi nutes before performing any service.

Precaution for WorkINFOID:0000000012431853

• When removing or disassembling each component, be ca reful not to damage or deform it. If a component

may be subject to interference, be sure to protect it with a shop cloth.

• When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component with a shop cloth or vinyl tape to protect it.

• Protect the removed parts with a shop cloth and prevent them from being dropped.

• Replace a deformed or damaged clip.

• If a part is specified as a non-reusabl e part, always replace it with a new one.

• Be sure to tighten bolts and nuts securely to the specified torque.

• After installation is complete, be sure to check that each part works properly.

• Follow the steps below to clean components:

- Water soluble dirt:

• Dip a soft cloth into lukewarm water, wring the water out of the cloth and wipe the dirty area.

• Then rub with a soft, dry cloth.

-Oily dirt:

• Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%) and wipe the dirty

area.

• Then dip a cloth into fresh water, wring the water out of the cloth and wipe the detergent off.

• Then rub with a soft, dry cloth.

- Do not use organic solvent such as thinner, benzene, alcohol or gasoline.

- For genuine leather seats, use a genuine leather seat cleaner.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2178 of 3641

FLOOR TRIMINT-27

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

K L

M A

B

INT

N

O P

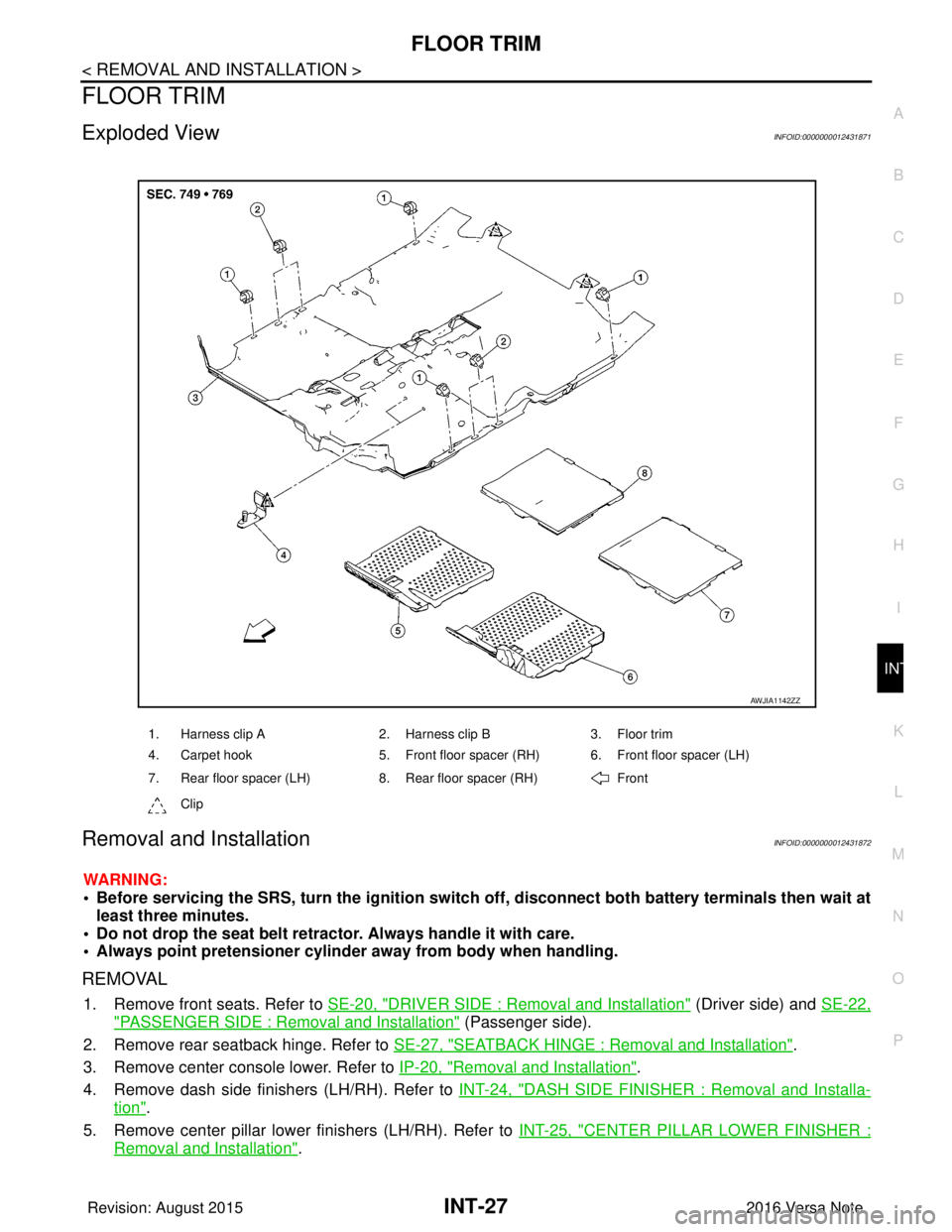

FLOOR TRIM

Exploded ViewINFOID:0000000012431871

Removal and InstallationINFOID:0000000012431872

WARNING:

• Before servicing the SRS, turn the ignition switch off, disconnect both battery terminals then wait at

least three minutes.

• Do not drop the seat belt retractor. Always handle it with care.

• Always point pretensioner cylinder away from body when handling.

REMOVAL

1. Remove front seats. Refer to SE-20, "DRIVER SIDE : Removal and Installation" (Driver side) and SE-22,

"PASSENGER SIDE : Removal and Installation" (Passenger side).

2. Remove rear seatback hinge. Refer to SE-27, "

SEATBACK HINGE : Removal and Installation".

3. Remove center console lower. Refer to IP-20, "

Removal and Installation".

4. Remove dash side finishers (LH/RH). Refer to INT-24, "

DASH SIDE FINISHER : Removal and Installa-

tion".

5. Remove center pillar lower finishers (LH/RH). Refer to INT-25, "

CENTER PILLAR LOWER FINISHER :

Removal and Installation".

1. Harness clip A2. Harness clip B3. Floor trim

4. Carpet hook 5. Front floor spacer (RH) 6. Front floor spacer (LH)

7. Rear floor spacer (LH) 8. Rear floor spacer (RH) Front

Clip

AWJIA1142ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2179 of 3641

INT-28

< REMOVAL AND INSTALLATION >

FLOOR TRIM

6. Disconnect negative and positive battery terminals, then wait at least three minutes. Refer to PG-70,

"Removal and Installation (Battery)".

WARNING:

Before servicing the SRS, turn th e ignition switch off, disconnect both battery terminals then wait

at least three minutes.

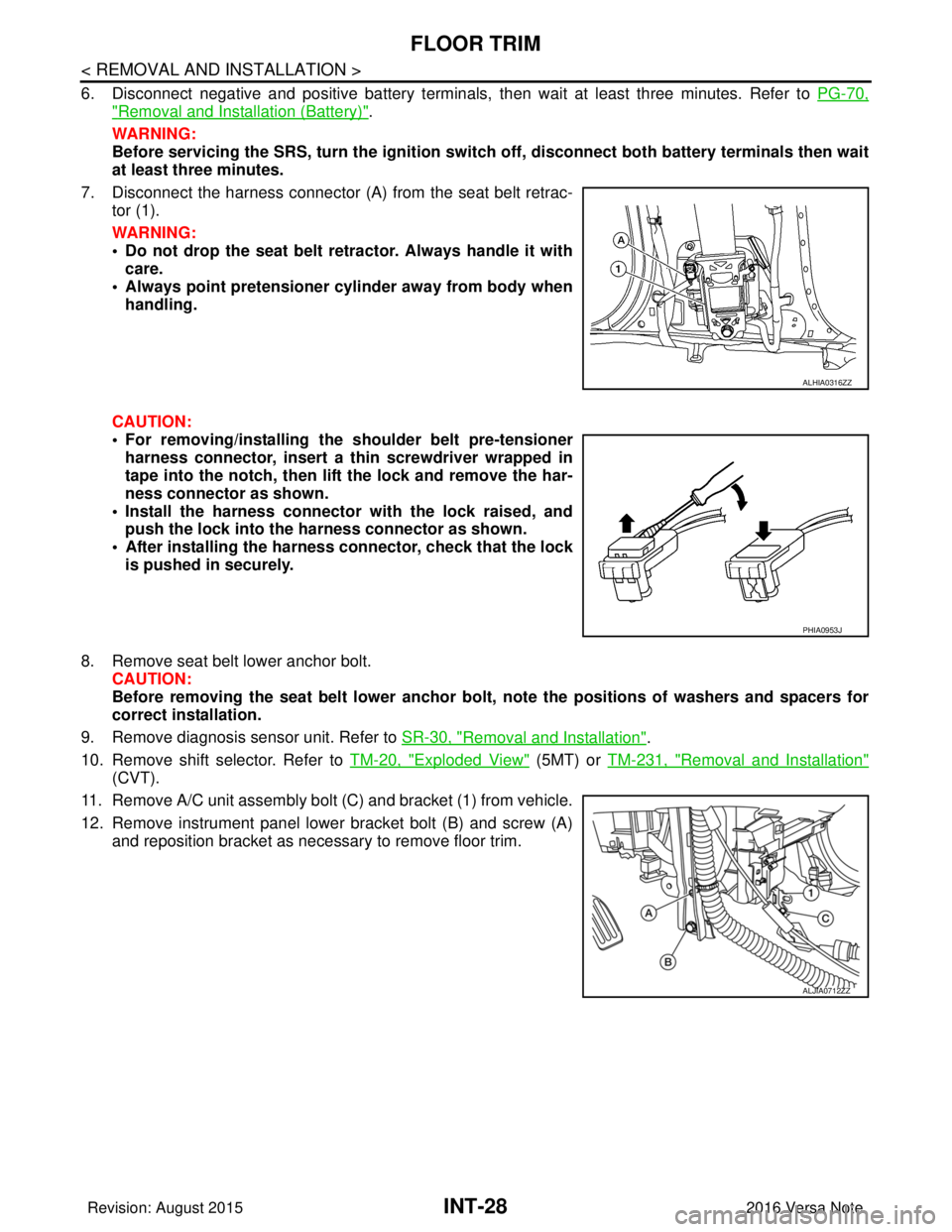

7. Disconnect the harness connector (A ) from the seat belt retrac-

tor (1).

WARNING:

• Do not drop the seat belt retractor. Always handle it with care.

• Always point pretensioner cylinder away from body when handling.

CAUTION:

• For removing/installing the shoulder belt pre-tensioner harness connector, insert a thin screwdriver wrapped in

tape into the notch, then lift the lock and remove the har-

ness connector as shown.

• Install the harness connector with the lock raised, and push the lock into the harness connector as shown.

• After installing the harness connector, check that the lock

is pushed in securely.

8. Remove seat belt lower anchor bolt. CAUTION:

Before removing the seat belt lower anchor bolt , note the positions of washers and spacers for

correct installation.

9. Remove diagnosis sensor unit. Refer to SR-30, "

Removal and Installation".

10. Remove shift selector. Refer to TM-20, "

Exploded View" (5MT) or TM-231, "Removal and Installation"

(CVT).

11. Remove A/C unit assembly bolt (C) and bracket (1) from vehicle.

12. Remove instrument panel lower bracket bolt (B) and screw (A) and reposition bracket as necessary to remove floor trim.

ALHIA0316ZZ

PHIA0953J

ALJIA0712ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2194 of 3641

![NISSAN NOTE 2016 Service Repair Manual LAN-6

< PRECAUTION >[CAN FUNDAMENTAL]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precautions for Trouble DiagnosisINFOID:0000000012433328

CAUTION:

Follow the instructions listed below. Fail

ure to do this may NISSAN NOTE 2016 Service Repair Manual LAN-6

< PRECAUTION >[CAN FUNDAMENTAL]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precautions for Trouble DiagnosisINFOID:0000000012433328

CAUTION:

Follow the instructions listed below. Fail

ure to do this may](/img/5/57363/w960_57363-2193.png)

LAN-6

< PRECAUTION >[CAN FUNDAMENTAL]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precautions for Trouble DiagnosisINFOID:0000000012433328

CAUTION:

Follow the instructions listed below. Fail

ure to do this may cause damage to parts:

• Never apply 7.0 V or more to the measurement terminal.

• Use a tester with open terminal voltage of 7.0 V or less.

• Turn the ignition switch OFF and disconnect th e battery cable from the negative terminal when

checking the harness.

Precautions for Harness RepairINFOID:0000000012433329

• Solder the repaired area and wrap tape around the soldered area. NOTE:

A fray of twisted lines must be within 110 mm (4.33 in).

• Bypass connection is never allowed at the repaired area. NOTE:

Bypass connection may cause CAN communication error. The

spliced wire becomes separated and the characteristics of twisted

line are lost.

• Replace the applicable harness as an assembly if error is detected on the shield lines of CAN communica- tion line.

SKIB8766E

SKIB8767E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2197 of 3641

![NISSAN NOTE 2016 Service Repair Manual LAN

TROUBLE DIAGNOSISLAN-9

< SYSTEM DESCRIPTION > [CAN FUNDAMENTAL]

C

D

E

F

G H

I

J

K L

B A

O P

N

TROUBLE DIAGNOSIS

Component DescriptionINFOID:0000000012433332

Condition of Error DetectionINFOID:0000 NISSAN NOTE 2016 Service Repair Manual LAN

TROUBLE DIAGNOSISLAN-9

< SYSTEM DESCRIPTION > [CAN FUNDAMENTAL]

C

D

E

F

G H

I

J

K L

B A

O P

N

TROUBLE DIAGNOSIS

Component DescriptionINFOID:0000000012433332

Condition of Error DetectionINFOID:0000](/img/5/57363/w960_57363-2196.png)

LAN

TROUBLE DIAGNOSISLAN-9

< SYSTEM DESCRIPTION > [CAN FUNDAMENTAL]

C

D

E

F

G H

I

J

K L

B A

O P

N

TROUBLE DIAGNOSIS

Component DescriptionINFOID:0000000012433332

Condition of Error DetectionINFOID:0000000012433333

DTC (e.g. U1000 and U1001) of CAN communication is

indicated on SELF-DIAG RESULTS on CONSULT if a

CAN communication signal is not transmitted or received between units for 2 seconds or more.

CAN COMMUNICATION SYSTEM ERROR

• CAN communication line open (CAN-H, CAN-L, or both)

• CAN communication line short (ground, betw een CAN communication lines, other harnesses)

• Error of CAN communication control circuit of the unit connected to CAN communication line

WHEN DTC OF CAN COMMUNICATION IS INDICATED EVEN THOUGH CAN COMMUNICATION

SYSTEM IS NORMAL

• Removal/installation of parts: Error may be detec ted when removing and installing CAN communication unit

and related parts while turning the ignition switch ON. (A DTC except for CAN communication may be

detected.)

• Fuse blown out (removed): CAN communication of the unit may cease.

• Voltage drop: Error may be detected if voltage drops due to discharged battery when turning the ignition switch ON (Depending on the control unit which carries out CAN communication).

• Error may be detected if the power supply circuit of the control unit, which carries out CAN communication,

malfunctions (Depending on the control unit which carries out CAN communication).

• Error may be detected if reprogramming is not completed normally.

NOTE:

CAN communication system is normal if DTC of CAN communication is indicated on SELF-DIAG RESULTS of

CONSULT under the above conditions. Erase the memory of the self-diagnosis of each control unit.

JSMIA0527GB

Component Description

Main line CAN communication line between splices

Branch line CAN communication line between splice and a control unit

Splice A point connecting a branch line with a main line

Termination circuit Circuit connected across the CAN communication system. (Resistor)

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2205 of 3641

![NISSAN NOTE 2016 Service Repair Manual LAN

DIAGNOSIS AND REPAIR WORKFLOWLAN-17

< BASIC INSPECTION > [CAN FUNDAMENTAL]

C

D

E

F

G H

I

J

K L

B A

O P

N

• When a CAN communication system error is present, multiple control units may malfunctio NISSAN NOTE 2016 Service Repair Manual LAN

DIAGNOSIS AND REPAIR WORKFLOWLAN-17

< BASIC INSPECTION > [CAN FUNDAMENTAL]

C

D

E

F

G H

I

J

K L

B A

O P

N

• When a CAN communication system error is present, multiple control units may malfunctio](/img/5/57363/w960_57363-2204.png)

LAN

DIAGNOSIS AND REPAIR WORKFLOWLAN-17

< BASIC INSPECTION > [CAN FUNDAMENTAL]

C

D

E

F

G H

I

J

K L

B A

O P

N

• When a CAN communication system error is present, multiple control units may malfunction or go into fail-

safe mode.

• Indication of the combination meter is important to detect the root cause because it is the most obvious to

the customer, and it performs CAN communication with many units.

>> GO TO 2.

2.INSPECTION OF VEHICLE CONDITION

Check whether the symptom is reproduced or not.

NOTE:

Do not turn the ignition switch OFF or disconnect the 12V battery cable while reproducing the error. The error

may temporarily correct itself, making it difficult to determine the root cause.

>> GO TO 3.

3.CHECK OF CAN SYSTEM TYPE (H OW TO USE CAN SYSTEM TYPE SPECIFICATION CHART)

Determine CAN system type based on vehicle equipment.

NOTE:

• This chart is used if CONSULT does not automatically recognize CAN system type.

• There are two styles for CAN system type specification charts. Depending on the number of available sys- tem types, either style A or style B may be used.

• CAN System Type Specification Chart (Style A) NOTE:

SKIB8717E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2210 of 3641

![NISSAN NOTE 2016 Service Repair Manual LAN-22

< PRECAUTION >[CAN]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012433342

The Supplemental Rest NISSAN NOTE 2016 Service Repair Manual LAN-22

< PRECAUTION >[CAN]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012433342

The Supplemental Rest](/img/5/57363/w960_57363-2209.png)

LAN-22

< PRECAUTION >[CAN]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012433342

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Precautions for Trouble DiagnosisINFOID:0000000012433343

CAUTION:

Follow the instructions listed below. Fail ure to do this may cause damage to parts:

• Never apply 7.0 V or more to the measurement terminal.

• Use a tester with open terminal voltage of 7.0 V or less.

• Turn the ignition switch OFF and disconnect th e battery cable from the negative terminal when

checking the harness.

Precautions for Harness RepairINFOID:0000000012433344

• Solder the repaired area and wrap tape around the soldered area. NOTE:

A fray of twisted lines must be within 110 mm (4.33 in).

SKIB8766E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2229 of 3641

![NISSAN NOTE 2016 Service Repair Manual LAN

MAIN LINE BETWEEN IPDM-E AND DLC CIRCUITLAN-41

< DTC/CIRCUIT DIAGNOSIS > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

MAIN LINE BETWEEN IPDM-E AND DLC CIRCUIT

Diagnosis ProcedureINFOID:0000000012433355

1.C NISSAN NOTE 2016 Service Repair Manual LAN

MAIN LINE BETWEEN IPDM-E AND DLC CIRCUITLAN-41

< DTC/CIRCUIT DIAGNOSIS > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

MAIN LINE BETWEEN IPDM-E AND DLC CIRCUIT

Diagnosis ProcedureINFOID:0000000012433355

1.C](/img/5/57363/w960_57363-2228.png)

LAN

MAIN LINE BETWEEN IPDM-E AND DLC CIRCUITLAN-41

< DTC/CIRCUIT DIAGNOSIS > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

MAIN LINE BETWEEN IPDM-E AND DLC CIRCUIT

Diagnosis ProcedureINFOID:0000000012433355

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cabl e from the negative terminal.

3. Check the following terminals and connectors for damage, bend and loose connection (connector side

and harness side).

- Harness connector E7

- Harness connector M69

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS CONTI NUITY (OPEN CIRCUIT)

1. Disconnect the following harness connectors.

- IPDM E/R

- Harness connectors E7 and M69

2. Check the continuity between the IPDM E/R harness connector and the harness connector.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair the main line between the IPDM E/R and the harness connector E7.

3.CHECK HARNESS CONTI NUITY (OPEN CIRCUIT)

Check the continuity between the harness connector and the data link connector.

Is the inspection result normal?

YES (Present error)>>Check CA N system type decision again.

YES (Past error)>>Error was detected in the main line between the IPDM E/R and the data link connector.

NO >> Repair the main line between the harness connector M69 and the data link connector.

IPDM E/R harness connector Harness connector

Continuity

Connector No. Terminal No.Connector No. Terminal No.

E46 62

E721A

Existed

61 20AExisted

Harness connector Data link connector

Continuity

Connector No. Terminal No.Connector No. Terminal No.

M69 21A

M22 6

Existed

20A 14Existed

Revision: August 2015 2016 Versa Note

cardiagn.com