Display NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 3056 of 3641

INSPECTION AND ADJUSTMENTSRC-39

< BASIC INSPECTION >

C

DE

F

G

I

J

K L

M A

B

SRC

N

O P

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPL ACING CONTROL UNIT : Description

INFOID:0000000012430612

Always perform zero point reset using CONSULT when removing and installing the passenger seat or servic-

ing the occupant classification system. If zero point reset is not performed the OCS may not operate normally,

which may increase the risk of serious injury in a collision.

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Special Repair Re-

quirement

INFOID:0000000012430613

WORK PROCEDURE WHEN REPLACING CONTROL UNIT

1.PERFORM ZERO POINT RESET

Perform zero point reset. Refer to SRC-39, "

ZERO POINT RESET : Special Repair Requirement".

Is zero point reset performed normally?

YES >> INSPECTION END

NO >> Check condition as per the following, and perform zero point reset again. • Passenger seat is occupied by an object.

• Excessive vibration is applied while performing zero point reset.

• Occupant detection system is malfunctioning.NOTE:

If “Incomplete” is displayed on “zero point reset cu rrent status”, zero point reset is not completed

normally. Check the condition as per the following and perform zero point reset again.

• Passenger seat is occupied by an object.

• Excessive vibration is applied while performing zero point reset.

• Occupant detection system is malfunctioning.

ZERO POINT RESET

ZERO POINT RESET : DescriptionINFOID:0000000012430614

Zero point reset is an initializing procedure for occupant detection sensor that must be performed when replac-

ing or removing and installing passenger seat.

If zero point reset is not performed, the initializati on is incomplete and Occupant Detection System does not

operate normally.

NOTE:

• When zero point reset is performed once after removal and installation of passenger seat, CONSULT dis- plays “complete”.

• When reinstalling passenger seat after removal, the initial value for occupant detection sensor changes, and

Occupant Detection System does not operate normally.

• Always perform zero point reset after performing the work as per the following.

- Reinstallation of passenger seat

- Installation of passenger seat that is zero point reset complete

- Installation of passenger seat that is zero point reset in complete

ZERO POINT RESET : Special Repair RequirementINFOID:0000000012430615

1.PERFORM ZERO POINT RESET

1. Perform zero point reset. NOTE:

When performing zero point reset, be careful of the items described as per the following.

• Perform zero point reset after installing passenger seat to the vehicle

• Do not put any objects on passenger seat

• Do not apply excessive vibration to the vehicle

• Do not touch the vehicle

• Do not tilt the vehicle

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3057 of 3641

SRC-40

< BASIC INSPECTION >

INSPECTION AND ADJUSTMENT

2. Select start on “Zero point reset function” screen from, WORK SUPPORT of CONSULT “OCCUPANT

DETECTION”.

3. “Zero point reset” starts.

>> GO TO 2.

2.CONFIRMATION OF SETTING

1. Proceed to “Zero point reset function” screen from work support of CONSULT “OCCUPANT DETEC-

TION”.

2. Check that “Complete” or “Incomplete” is displayed on “Zero point reset status”.

CAUTION:

• “Complete” is displayed on “zero point reset current status” if the seat is reinstalled by seat removal

and installation, or “zero point reset” is already performed.

• “Zero point reset current status” displays “Incompl ete” if a new seat is installed. When turning key

switch ON without performing zero point reset , front passenger air bag OFF indicator turns ON.

When zero point reset is performed, front passenger air bag OFF indicator turns OFF.

• Air bag warning lamp blinks in user mode only.

• Air bag sensor unit does not record whethe r or not zero point reset is performed.

Is condition

“ALREADY PERFORMED”?

YES >> Print out “ZERO POINT RESET CURRENT STATUS” screen, and inspection end.

NO >> Check condition as per the following, and perform zero point reset again. • Passenger seat is occupied by an object.

• Excessive vibration is applied while performing zero point reset.

• Occupant detection system is malfunctioning.NOTE:

If “Incomplete” is displayed on “zero point reset cu rrent status”, zero point reset is not completed

normally. Check the condition as per the following and perform zero point reset again.

• Passenger seat is occupied by an object.

• Excessive vibration is applied while performing zero point reset.

• Occupant detection system is malfunctioning.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3111 of 3641

SRC-94

< DTC/CIRCUIT DIAGNOSIS >

U1000 CAN COMM CIRCUIT

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000012430674

CAN (Controller Area Network) is a serial communication system for real time application. It is an on-vehicle

multiplex communication system with high data communication speed and excellent error detection ability.

Many electronic control units are equipped into vehicl es, and each control unit shares information and links

with other control units during operation. With CAN co mmunication, control units are connected with two com-

munication lines (CAN-H line, CAN-L line) allowing a hi gh rate of information transmission with less wiring.

Each control unit transmits and receives data but selectively reads required data only. Refer to LAN-30, "

CAN

COMMUNICATION SYSTEM : CAN Communication Signal Chart".

DTC LogicINFOID:0000000012430675

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM SELF-DIAGNOSIS

1. Turn ignition switch ON and wait for 7 seconds or more.

2. Using CONSULT, perform SELF-DIAGNOSIS RESULTS of AIR BAG.

3. Check if any DTC is displayed in the self-diagnosis results.

Is DTC detected?

YES >> Refer to SRC-94, "Diagnosis Procedure".

NO >> Refer to GI-42, "

Intermittent Incident".

Diagnosis ProcedureINFOID:0000000012430676

1.CHECK CAN COMMUNICATION SYSTEM

Check CAN communication system. Refer to LAN-16, "

Trouble Diagnosis Flow Chart".

>> Inspection End.

CONSULT name DTCDTC detecting condition Repair order

CAN COMMUNICATION FAILURE U1000 When air bag diagnosis sensor unit is not

transmitting or receiving CAN communi-

cation signals for 2 or more seconds.Refer to SRC-94, "

Diagnosis

Procedure".

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 3112 of 3641

U1010 CONTROL UNIT (CAN)SRC-95

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G

I

J

K L

M A

B

SRC

N

O P

U1010 CONTROL UNIT (CAN)

DescriptionINFOID:0000000012430677

Air bag diagnosis sensor performs self-tests on key ON. If CAN communication failure within control unit is

detected, DTC is set.

DTC LogicINFOID:0000000012430678

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM SELF-DIAGNOSIS

1. Turn ignition switch ON.

2. Using CONSULT, perform SELF DIAGNOSIS RESULTS of AIR BAG.

3. Check if DTC is displayed in the self-diagnosis results.

Is DTC detected?

YES >> Refer to SRC-95, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000012430679

1.REPLACE AIR BAG DIAGNOSIS SENSOR UNIT

Replace air bag diagnosis sensor unit. Refer to SR-30, "

Removal and Installation".

>> Inspection End.

CONSULT name DTCDTC detecting condition Repair order

CAN CONTROL UNIT FAILURE U1010CAN communication error is detected in

control unit. Refer to SRC-95, "

Diagnosis

Procedure".

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 3190 of 3641

STC-6

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (EPS CONTROL UNIT)

DIAGNOSIS SYSTEM (EPS CONTROL UNIT)

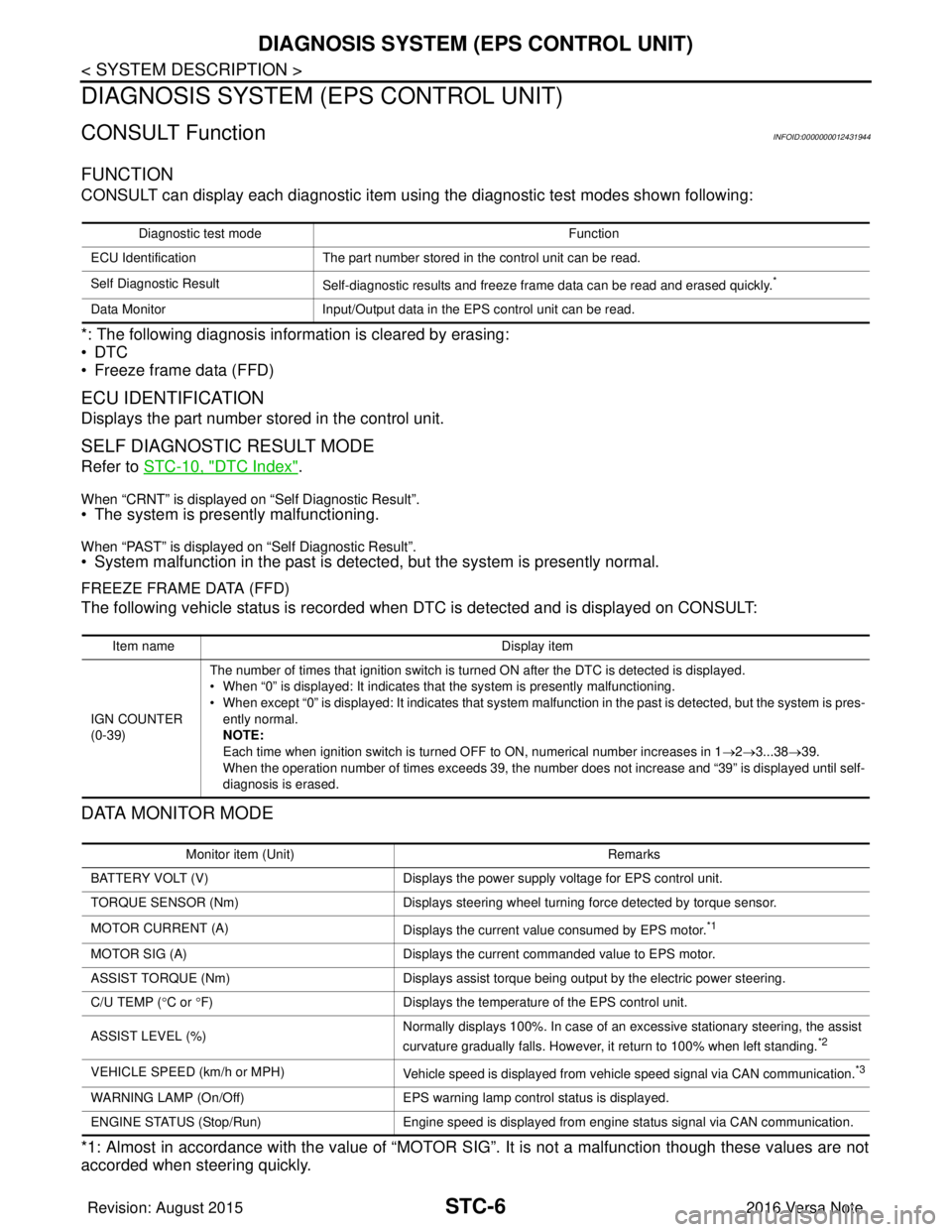

CONSULT FunctionINFOID:0000000012431944

FUNCTION

CONSULT can display each diagnostic item usi ng the diagnostic test modes shown following:

*: The following diagnosis information is cleared by erasing:

•DTC

• Freeze frame data (FFD)

ECU IDENTIFICATION

Displays the part number stored in the control unit.

SELF DIAGNOSTIC RESULT MODE

Refer to STC-10, "DTC Index".

When “CRNT” is displayed on “Self Diagnostic Result”.

• The system is presently malfunctioning.

When “PAST” is displayed on “Self Diagnostic Result”.• System malfunction in the past is detect ed, but the system is presently normal.

FREEZE FRAME DATA (FFD)

The following vehicle status is recorded when DTC is detected and is displayed on CONSULT:

DATA MONITOR MODE

*1: Almost in accordance with the value of “MOTOR S IG”. It is not a malfunction though these values are not

accorded when steering quickly.

Diagnostic test mode Function

ECU Identification The part number stored in the control unit can be read.

Self Diagnostic Result Self-diagnostic results and freeze frame data can be read and erased quickly.

*

Data MonitorInput/Output data in the EPS control unit can be read.

Item name Display item

IGN COUNTER

(0-39) The number of times that ignition switch is tu

rned ON after the DTC is detected is displayed.

• When “0” is displayed: It indicates that the system is presently malfunctioning.

• When except “0” is displayed: It indicates that system malfunction in the past is detected, but the system is pres-

ently normal.

NOTE:

Each time when ignition switch is turned OFF to ON, numerical number increases in 1 →2→3...38 →39.

When the operation number of times exceeds 39, the number does not increase and “39” is displayed until self-

diagnosis is erased.

Monitor item (Unit) Remarks

BATTERY VOLT (V) Displays the power supply voltage for EPS control unit.

TORQUE SENSOR (Nm) Displays steering wheel turning force detected by torque sensor.

MOTOR CURRENT (A) Displays the current value consumed by EPS motor.

*1

MOTOR SIG (A) Displays the current commanded value to EPS motor.

ASSIST TORQUE (Nm) Displays assist torque being output by the electric power steering.

C/U TEMP ( °C or °F) Displays the temperature of the EPS control unit.

ASSIST LEVEL (%) Normally displays 100%. In case of an excessive stationary steering, the assist

curvature gradually falls. However, it return to 100% when left standing.

*2

VEHICLE SPEED (km/h or MPH)

Vehicle speed is displayed from vehicle speed signal via CAN communication.*3

WARNING LAMP (On/Off)EPS warning lamp control status is displayed.

ENGINE STATUS (Stop/Run) Engine speed is displayed from engine status signal via CAN communication.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3191 of 3641

DIAGNOSIS SYSTEM (EPS CONTROL UNIT)

STC-7

< SYSTEM DESCRIPTION >

C

D E

F

H I

J

K L

M A

B

STC

N

O P

*2: Normally displays 100%. In case of an excessive stationary steering, the assist curvature gradually falls.

However, it returns to 100% when left standing.

*3: It is not a malfunction, though it might not be corresponding just after ignition switch in turned ON.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3192 of 3641

STC-8

< ECU DIAGNOSIS INFORMATION >

EPS CONTROL UNIT

ECU DIAGNOSIS INFORMATION

EPS CONTROL UNIT

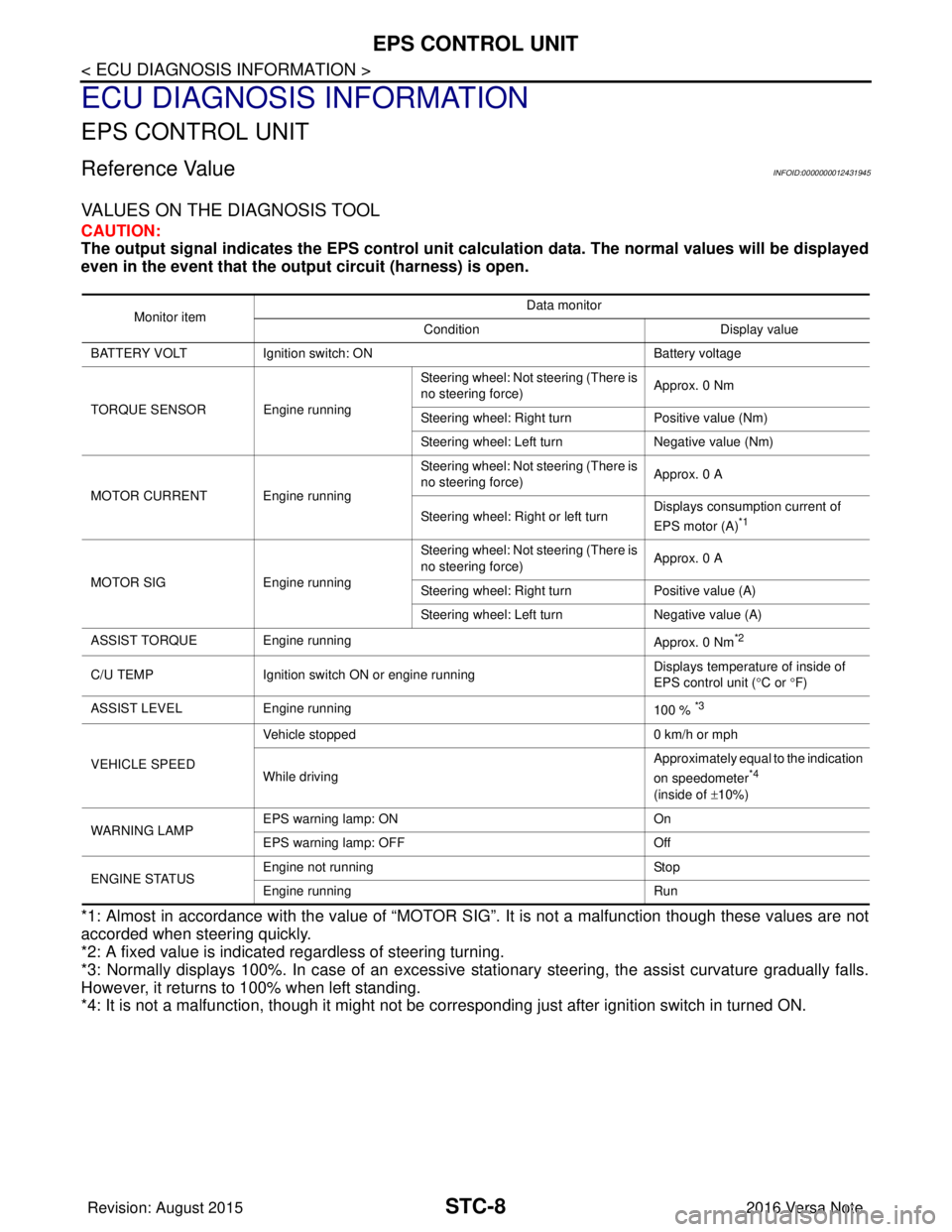

Reference ValueINFOID:0000000012431945

VALUES ON THE DIAGNOSIS TOOL

CAUTION:

The output signal indicates the EPS control unit calculation data. The normal values will be displayed

even in the event that the output circuit (harness) is open.

*1: Almost in accordance with the value of “MOTOR S IG”. It is not a malfunction though these values are not

accorded when steering quickly.

*2: A fixed value is indicated regardless of steering turning.

*3: Normally displays 100%. In case of an excessive stat ionary steering, the assist curvature gradually falls.

However, it returns to 100% when left standing.

*4: It is not a malfunction, though it might not be co rresponding just after ignition switch in turned ON.

Monitor item Data monitor

Condition Display value

BATTERY VOLT Ignition switch: ON Battery voltage

TORQUE SENSOR Engine running Steering wheel: Not

steering (There is

no steering force) Approx. 0 Nm

Steering wheel: Right turn Positive value (Nm)

Steering wheel: Left turn Negative value (Nm)

MOTOR CURRENT Engine running Steering wheel: Not

steering (There is

no steering force) Approx. 0 A

Steering wheel: Right or left turn Displays consumption current of

EPS motor (A)

*1

MOTOR SIG

Engine runningSteering wheel: Not

steering (There is

no steering force) Approx. 0 A

Steering wheel: Right turn Positive value (A)

Steering wheel: Left turn Negative value (A)

ASSIST TORQUE Engine running Approx. 0 Nm

*2

C/U TEMPIgnition switch ON or engine running Displays temperature of inside of

EPS control unit (

°C or °F)

ASSIST LEVEL Engine running

100 %

*3

VEHICLE SPEEDVehicle stopped

0 km/h or mph

While driving Approximately equal to the indication

on speedometer*4

(inside of ±

10%)

WARNING LAMP EPS warning lamp: ON

On

EPS warning lamp: OFF Off

ENGINE STATUS Engine not running

Stop

Engine running Run

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3202 of 3641

STC-18

< DTC/CIRCUIT DIAGNOSIS >

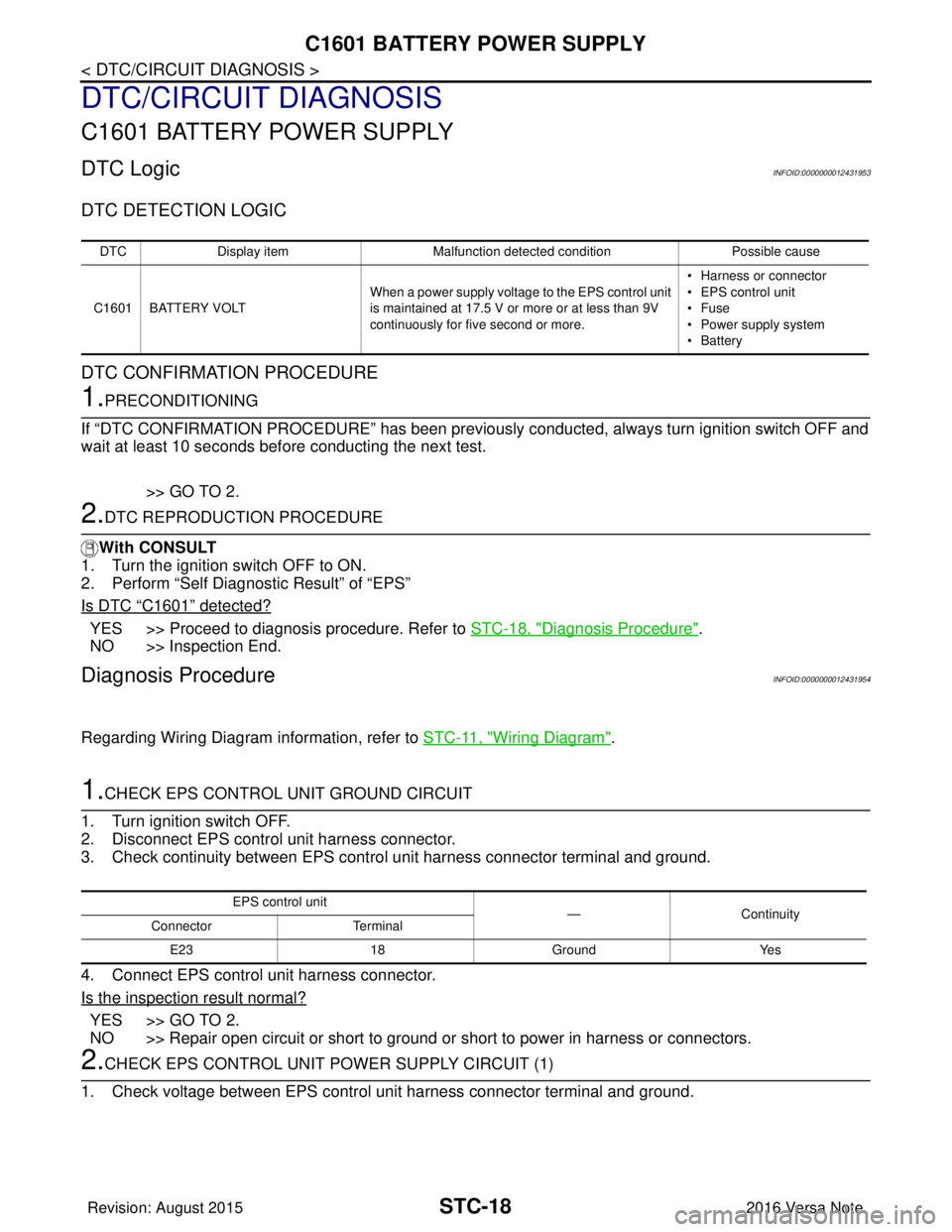

C1601 BATTERY POWER SUPPLY

DTC/CIRCUIT DIAGNOSIS

C1601 BATTERY POWER SUPPLY

DTC LogicINFOID:0000000012431953

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.DTC REPRODUCTION PROCEDURE

With CONSULT

1. Turn the ignition switch OFF to ON.

2. Perform “Self Diagnostic Result” of “EPS”

Is DTC

“C1601” detected?

YES >> Proceed to diagnosis procedure. Refer to STC-18, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000012431954

Regarding Wiring Diagram information, refer to STC-11, "Wiring Diagram".

1.CHECK EPS CONTROL UNIT GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect EPS control unit harness connector.

3. Check continuity between EPS contro l unit harness connector terminal and ground.

4. Connect EPS control unit harness connector.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

2.CHECK EPS CONTROL UNIT PO WER SUPPLY CIRCUIT (1)

1. Check voltage between EPS control unit harness connector terminal and ground.

DTC Display item Malfunction detected condition Possible cause

C1601 BATTERY VOLT When a power supply voltage to the EPS control unit

is maintained at 17.5 V or more or at less than 9V

continuously for five second or more. • Harness or connector

• EPS control unit

•Fuse

• Power supply system

•Battery

EPS control unit

—Con tin uit y

Connector Terminal

E23 18Ground Yes

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3205 of 3641

C1604 TORQUE SENSORSTC-21

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

H I

J

K L

M A

B

STC

N

O P

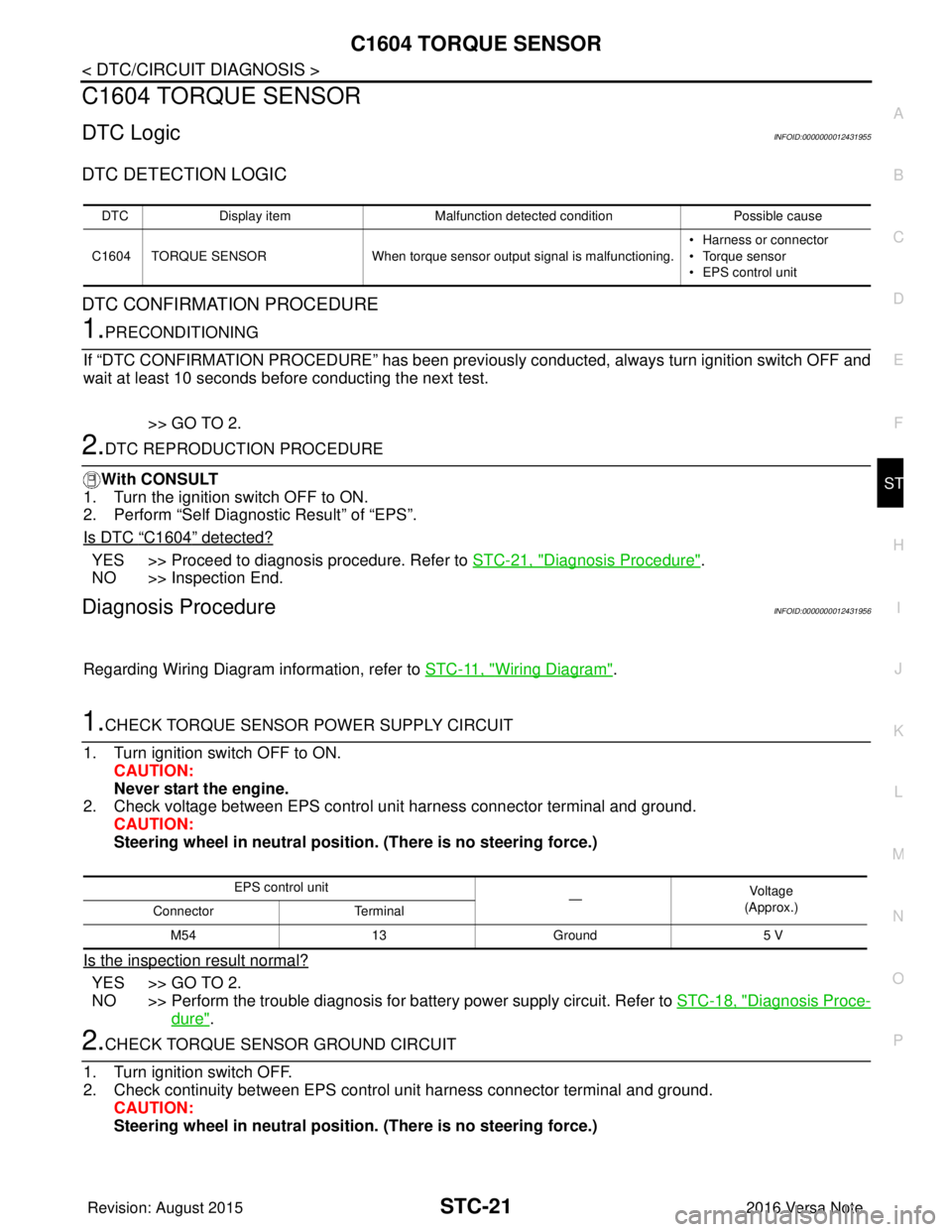

C1604 TORQUE SENSOR

DTC LogicINFOID:0000000012431955

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.DTC REPRODUCTION PROCEDURE

With CONSULT

1. Turn the ignition switch OFF to ON.

2. Perform “Self Diagnostic Result” of “EPS”.

Is DTC

“C1604” detected?

YES >> Proceed to diagnosis procedure. Refer to STC-21, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000012431956

Regarding Wiring Diagram information, refer to STC-11, "Wiring Diagram".

1.CHECK TORQUE SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF to ON. CAUTION:

Never start the engine.

2. Check voltage between EPS control unit harness connector terminal and ground.

CAUTION:

Steering wheel in neutral position . (There is no steering force.)

Is the inspection result normal?

YES >> GO TO 2.

NO >> Perform the trouble diagnosis for battery power supply circuit. Refer to STC-18, "

Diagnosis Proce-

dure".

2.CHECK TORQUE SENSOR GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between EPS control unit harness connector terminal and ground. CAUTION:

Steering wheel in neutral position . (There is no steering force.)

DTCDisplay item Malfunction detected condition Possible cause

C1604 TORQUE SENSOR When torque sensor output signal is malfunctioning. • Harness or connector

• Torque sensor

• EPS control unit

EPS control unit

—Vo l ta g e

(Approx.)

Connector Terminal

M54 13Ground 5 V

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3207 of 3641

C1606 EPS MOTORSTC-23

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

H I

J

K L

M A

B

STC

N

O P

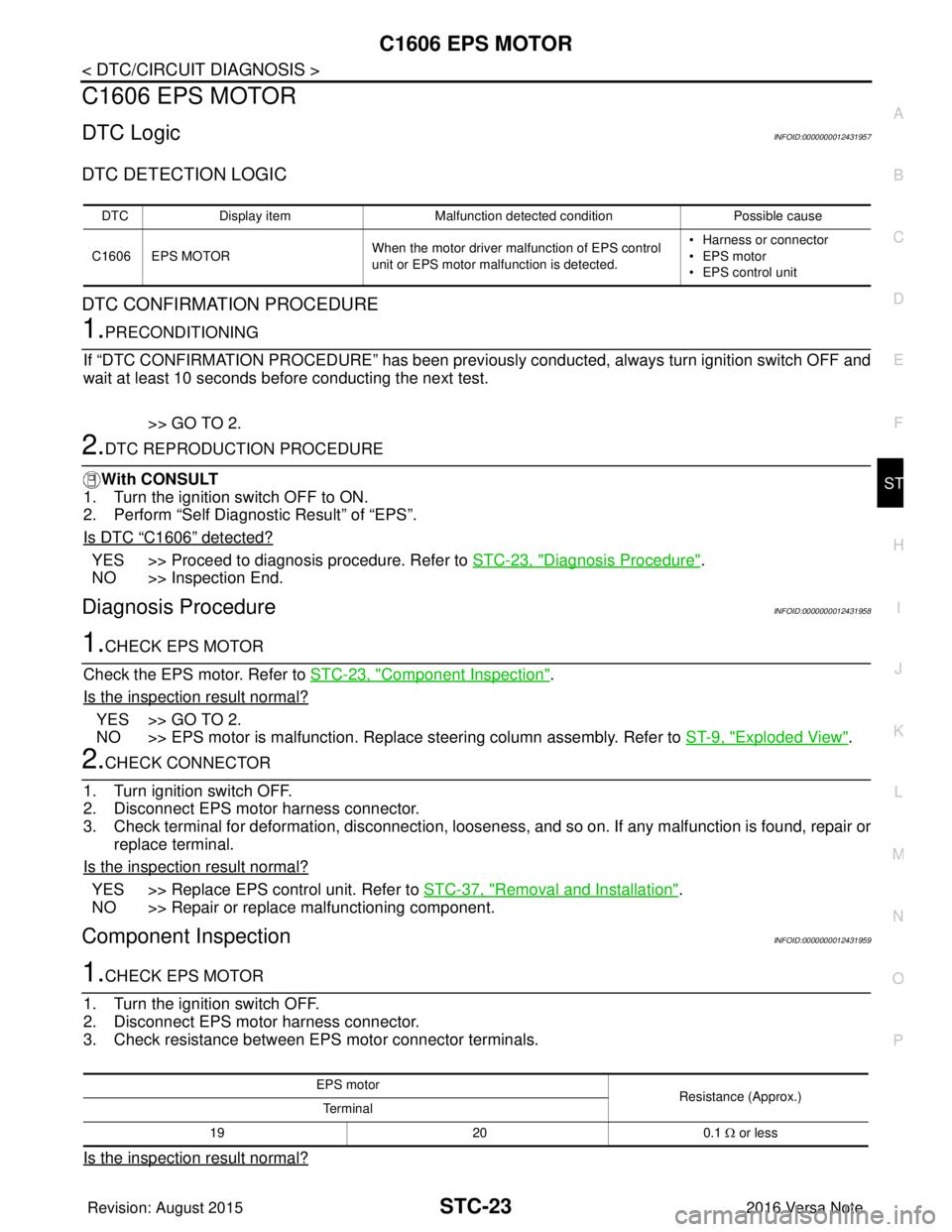

C1606 EPS MOTOR

DTC LogicINFOID:0000000012431957

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.DTC REPRODUCTION PROCEDURE

With CONSULT

1. Turn the ignition switch OFF to ON.

2. Perform “Self Diagnostic Result” of “EPS”.

Is DTC

“C1606” detected?

YES >> Proceed to diagnosis procedure. Refer to STC-23, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000012431958

1.CHECK EPS MOTOR

Check the EPS motor. Refer to STC-23, "

Component Inspection".

Is the inspection result normal?

YES >> GO TO 2.

NO >> EPS motor is malfunction. Replace steering column assembly. Refer to ST-9, "

Exploded View".

2.CHECK CONNECTOR

1. Turn ignition switch OFF.

2. Disconnect EPS motor harness connector.

3. Check terminal for deformation, disconnection, looseness, and so on. If any malfunction is found, repair or replace terminal.

Is the inspection result normal?

YES >> Replace EPS control unit. Refer to STC-37, "Removal and Installation".

NO >> Repair or replace malfunctioning component.

Component Inspection INFOID:0000000012431959

1.CHECK EPS MOTOR

1. Turn the ignition switch OFF.

2. Disconnect EPS motor harness connector.

3. Check resistance between EPS motor connector terminals.

Is the inspection result normal?

DTC Display item Malfunction detected condition Possible cause

C1606 EPS MOTOR When the motor driver malfunction of EPS control

unit or EPS motor malfunction is detected. • Harness or connector

• EPS motor

• EPS control unit

EPS motor

Resistance (Approx.)

Te r m i n a l

19 200.1 Ω or less

Revision: August 2015 2016 Versa Note

cardiagn.com