NISSAN NOTE 2016 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 641 of 3641

CLUTCH PIPINGCL-15

< REMOVAL AND INSTALLATION >

CEF

G H

I

J

K L

M A

B

CL

N

O P

CLUTCH PIPING

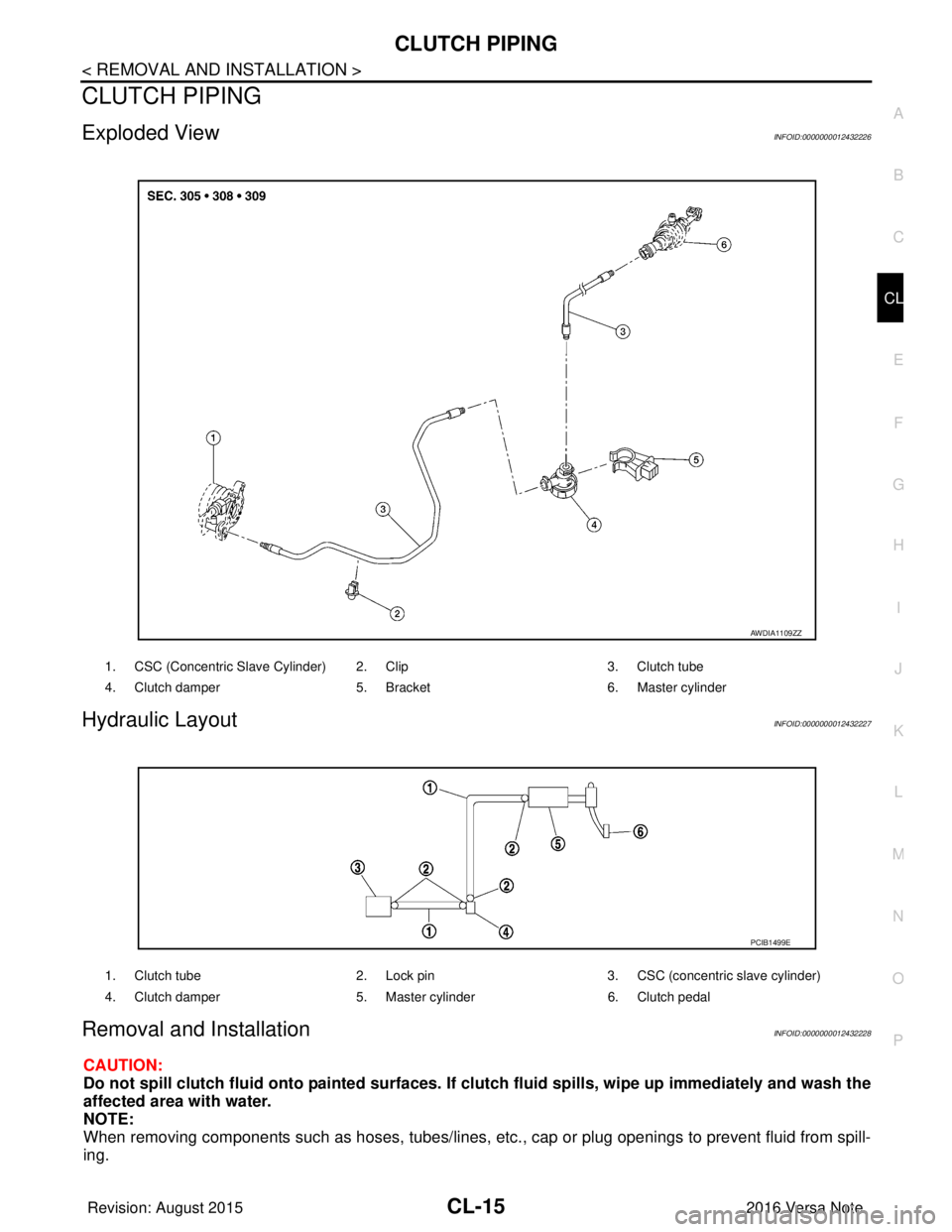

Exploded ViewINFOID:0000000012432226

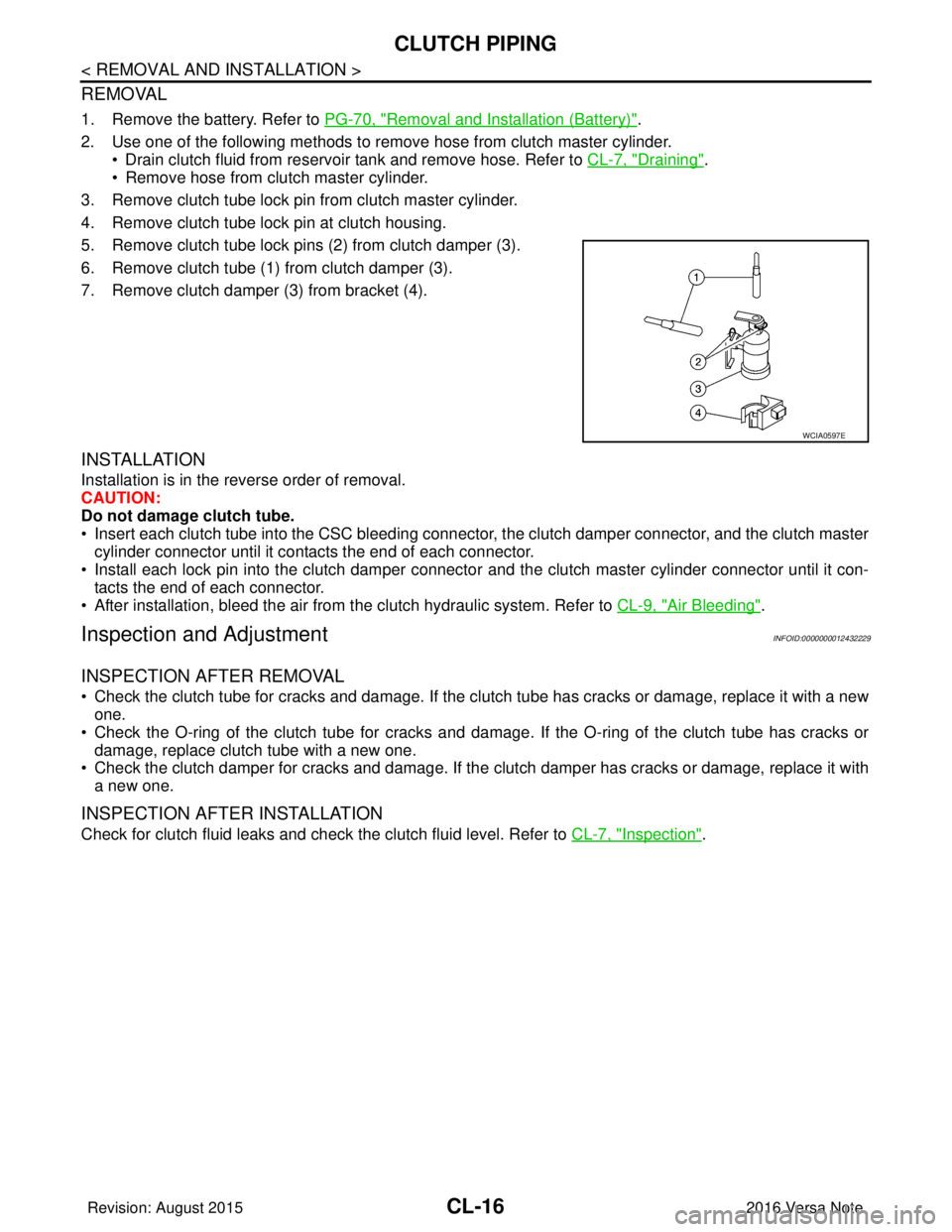

Hydraulic LayoutINFOID:0000000012432227

Removal and InstallationINFOID:0000000012432228

CAUTION:

Do not spill clutch fluid onto painted surfaces. If clutch fluid spills, wipe up immediately and wash the

affected area with water.

NOTE:

When removing components such as hoses, tubes/lines, etc. , cap or plug openings to prevent fluid from spill-

ing.

1. CSC (Concentric Slave Cylinder) 2. Clip 3. Clutch tube

4. Clutch damper 5. Bracket6. Master cylinder

AWDIA1109ZZ

1. Clutch tube 2. Lock pin3. CSC (concentric slave cylinder)

4. Clutch damper 5. Master cylinder6. Clutch pedal

PCIB1499E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 642 of 3641

CL-16

< REMOVAL AND INSTALLATION >

CLUTCH PIPING

REMOVAL

1. Remove the battery. Refer to PG-70, "Removal and Installation (Battery)".

2. Use one of the following methods to remove hose from clutch master cylinder. • Drain clutch fluid from reservoir tank and remove hose. Refer to CL-7, "

Draining".

• Remove hose from clutch master cylinder.

3. Remove clutch tube lock pin from clutch master cylinder.

4. Remove clutch tube lock pin at clutch housing.

5. Remove clutch tube lock pins (2) from clutch damper (3).

6. Remove clutch tube (1) from clutch damper (3).

7. Remove clutch damper (3) from bracket (4).

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Do not damage clutch tube.

• Insert each clutch tube into the CSC bleeding connector, the clutch damper connector, and the clutch master cylinder connector until it contacts the end of each connector.

• Install each lock pin into the clutch damper connecto r and the clutch master cylinder connector until it con-

tacts the end of each connector.

• After installation, bleed the air from the clutch hydraulic system. Refer to CL-9, "

Air Bleeding".

Inspection and AdjustmentINFOID:0000000012432229

INSPECTION AFTER REMOVAL

• Check the clutch tube for cracks and damage. If the cl utch tube has cracks or damage, replace it with a new

one.

• Check the O-ring of the clutch tube for cracks and dam age. If the O-ring of the clutch tube has cracks or

damage, replace clutch tube with a new one.

• Check the clutch damper for cracks and damage. If the clutch damper has cracks or damage, replace it with

a new one.

INSPECTION AFTER INSTALLATION

Check for clutch fluid leaks and check the clutch fluid level. Refer to CL-7, "Inspection".

WCIA0597E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 643 of 3641

CSC (CONCENTRIC SLAVE CYLINDER)CL-17

< UNIT REMOVAL AND INSTALLATION >

CEF

G H

I

J

K L

M A

B

CL

N

O P

UNIT REMOVAL AND INSTALLATION

CSC (CONCENTRIC SLAVE CYLINDER)

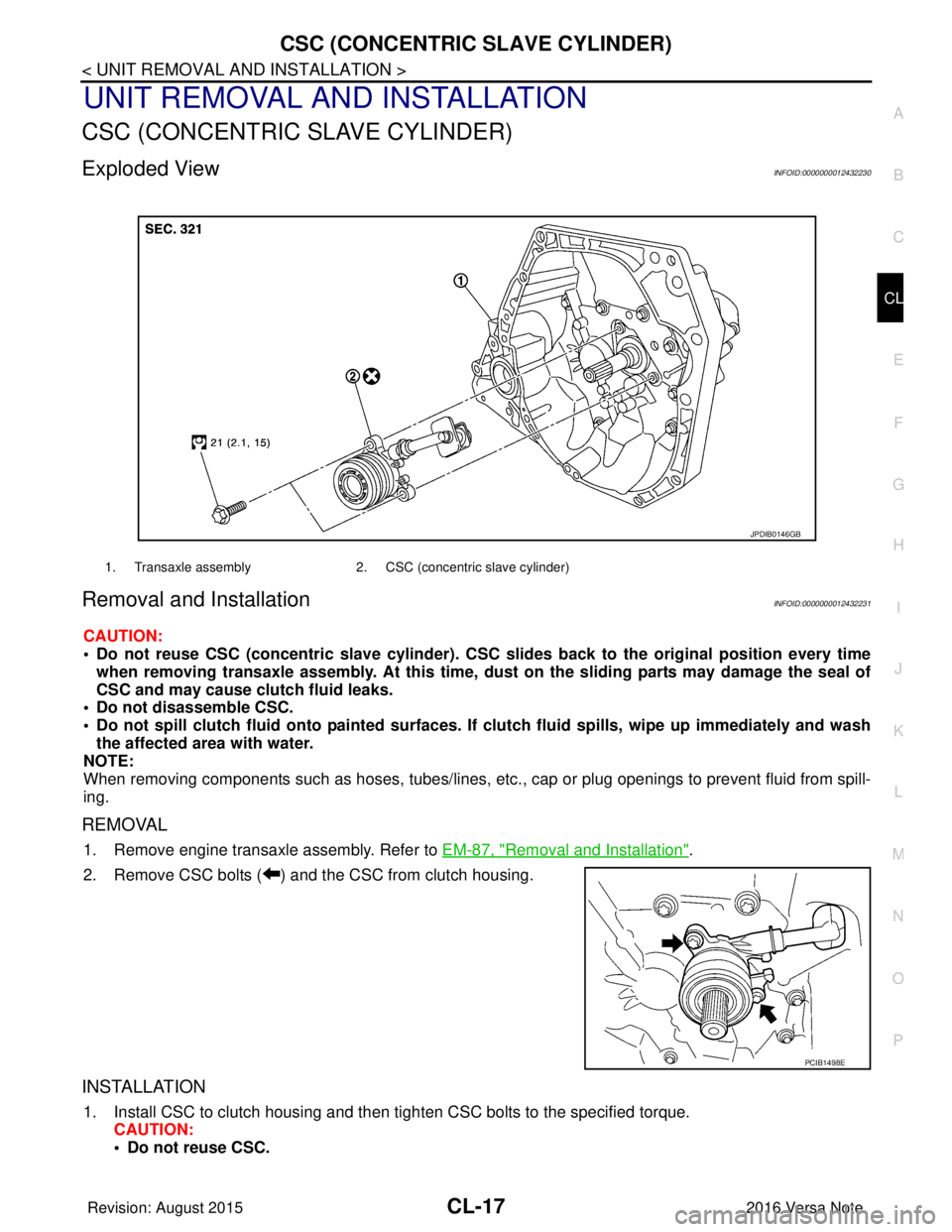

Exploded ViewINFOID:0000000012432230

Removal and InstallationINFOID:0000000012432231

CAUTION:

• Do not reuse CSC (concentric slave cylinder). CSC slides back to the original position every time

when removing transaxle assembly. At this time, du st on the sliding parts may damage the seal of

CSC and may cause clutch fluid leaks.

• Do not disassemble CSC.

• Do not spill clutch fluid onto pa inted surfaces. If clutch fluid spills, wipe up immediately and wash

the affected area with water.

NOTE:

When removing components such as hoses, tubes/lines, etc. , cap or plug openings to prevent fluid from spill-

ing.

REMOVAL

1. Remove engine transaxle assembly. Refer to EM-87, "Removal and Installation".

2. Remove CSC bolts ( ) and the CSC from clutch housing.

INSTALLATION

1. Install CSC to clutch housing and then tighten CSC bolts to the specified torque. CAUTION:

• Do not reuse CSC.

1. Transaxle assembly 2. CSC (concentric slave cylinder)

JPDIB0146GB

PCIB1498E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 644 of 3641

CL-18

< UNIT REMOVAL AND INSTALLATION >

CSC (CONCENTRIC SLAVE CYLINDER)

• Do not insert and operate CSC when transaxle is removed. Piston and stopper of CSC compo-nents may fall off.

2. Install engine and transaxle assembly. Refer to EM-87, "

Removal and Installation".

Inspection and AdjustmentINFOID:0000000012432232

INSPECTION AFTER INSTALLATION

Check for clutch fluid leaks and clutch fluid level. Refer to CL-7, "Inspection".

ADJUSTMENT AFTER INSTALLATION

Perform the air bleeding. Refer to CL-9, "Air Bleeding".

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 645 of 3641

CLUTCH DISC AND CLUTCH COVERCL-19

< UNIT REMOVAL AND INSTALLATION >

CEF

G H

I

J

K L

M A

B

CL

N

O P

CLUTCH DISC AND CLUTCH COVER

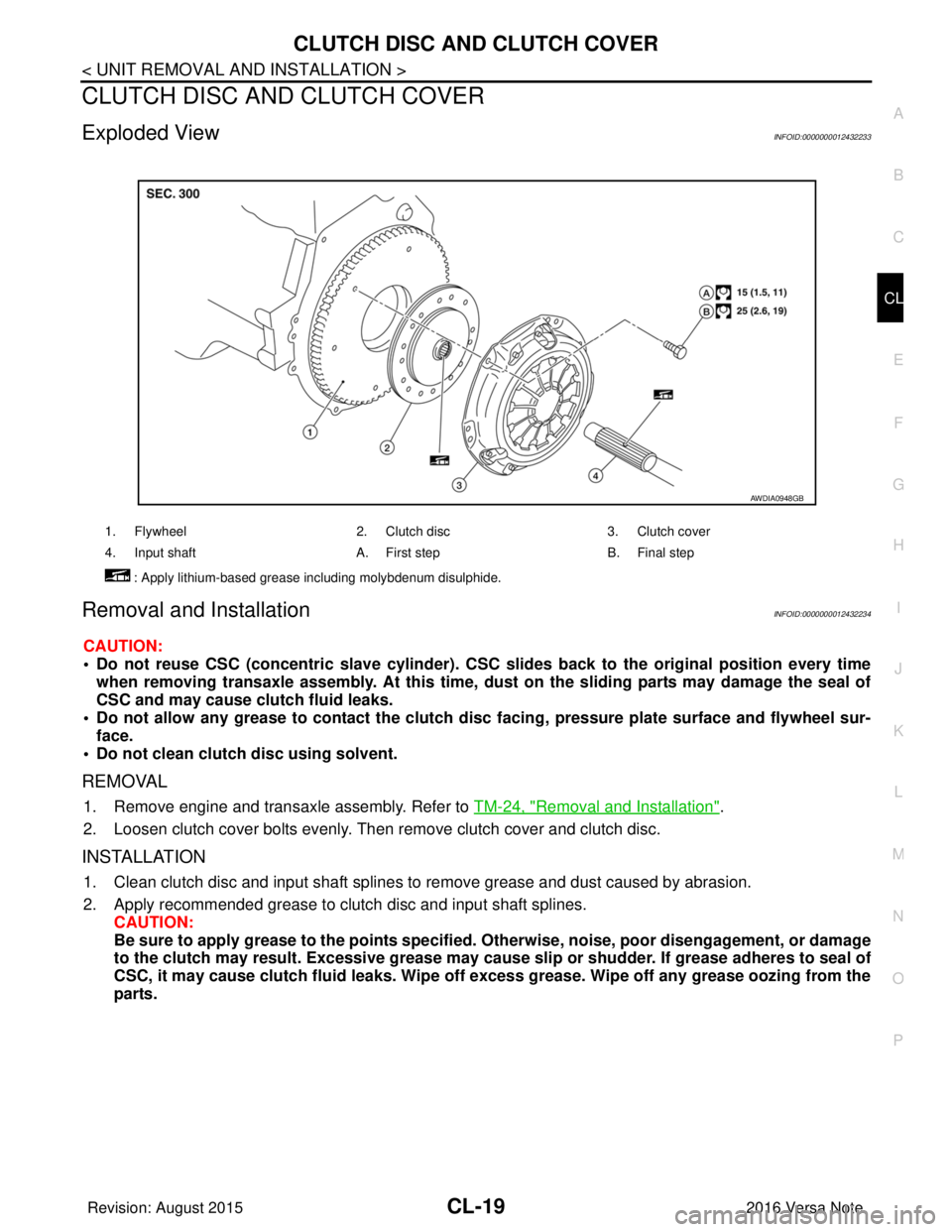

Exploded ViewINFOID:0000000012432233

Removal and InstallationINFOID:0000000012432234

CAUTION:

• Do not reuse CSC (concentric slave cylinder). CSC slides back to the original position every time

when removing transaxle assembly. At this time, du st on the sliding parts may damage the seal of

CSC and may cause clutch fluid leaks.

• Do not allow any grease to contact the clutch di sc facing, pressure plate surface and flywheel sur-

face.

• Do not clean clutch disc using solvent.

REMOVAL

1. Remove engine and transaxle assembly. Refer to TM-24, "Removal and Installation".

2. Loosen clutch cover bolts evenly. Then remove clutch cover and clutch disc.

INSTALLATION

1. Clean clutch disc and input shaft splines to remove grease and dust caused by abrasion.

2. Apply recommended grease to clutch disc and input shaft splines. CAUTION:

Be sure to apply grease to the points specified. Otherwise, noise, poor disengagement, or damage

to the clutch may result. Excessi ve grease may cause slip or shudder. If grease adheres to seal of

CSC, it may cause clutch fluid leaks. Wipe off excess grease. Wipe off any grease oozing from the

parts.

1. Flywheel 2. Clutch disc3. Clutch cover

4. Input shaft A. First stepB. Final step

: Apply lithium-based grease including molybdenum disulphide.

AWDIA0948GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 646 of 3641

CL-20

< UNIT REMOVAL AND INSTALLATION >

CLUTCH DISC AND CLUTCH COVER

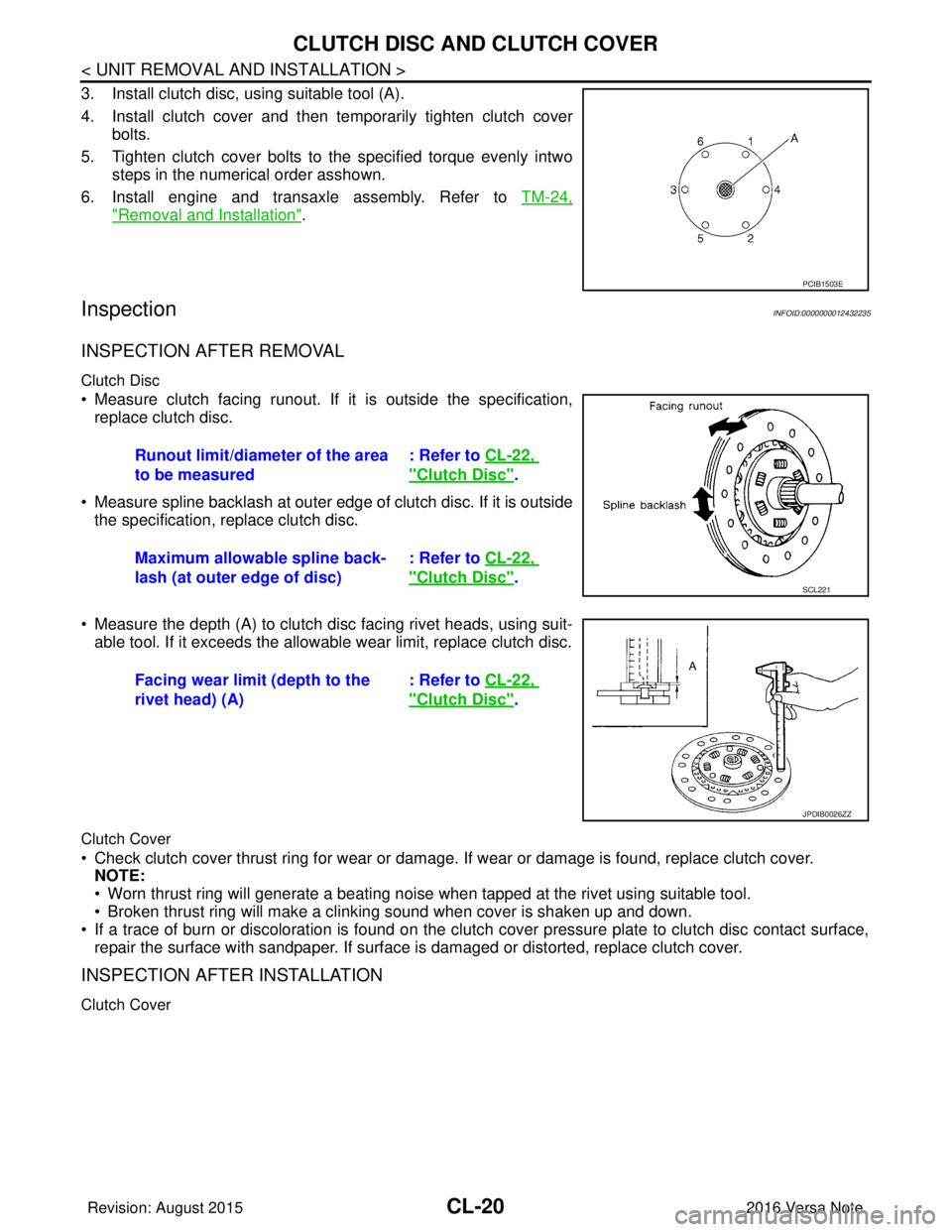

3. Install clutch disc, using suitable tool (A).

4. Install clutch cover and then temporarily tighten clutch coverbolts.

5. Tighten clutch cover bolts to the specified torque evenly intwo steps in the numerical order asshown.

6. Install engine and transaxle assembly. Refer to TM-24,

"Removal and Installation".

InspectionINFOID:0000000012432235

INSPECTION AFTER REMOVAL

Clutch Disc

• Measure clutch facing runout. If it is outside the specification,

replace clutch disc.

• Measure spline backlash at outer edge of clutch disc. If it is outside the specification, replace clutch disc.

• Measure the depth (A) to clutch disc facing rivet heads, using suit- able tool. If it exceeds the allowable wear limit, replace clutch disc.

Clutch Cover

• Check clutch cover thrust ring for wear or damage. If wear or damage is found, replace clutch cover.

NOTE:

• Worn thrust ring will generate a beating noise when tapped at the rivet using suitable tool.

• Broken thrust ring will make a clinking sound when cover is shaken up and down.

• If a trace of burn or discoloration is found on the clutch cover pressure plate to clutch disc contact surface,

repair the surface with sandpaper. If surface is damaged or distorted, replace clutch cover.

INSPECTION AFTER INSTALLATION

Clutch Cover

PCIB1503E

Runout limit/diameter of the area

to be measured : Refer to

CL-22,

"Clutch Disc".

Maximum allowable spline back-

lash (at outer edge of disc) : Refer to

CL-22,

"Clutch Disc".SCL221

Facing wear limit (depth to the

rivet head) (A) : Refer to

CL-22,

"Clutch Disc".

JPDIB0026ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 647 of 3641

CLUTCH DISC AND CLUTCH COVERCL-21

< UNIT REMOVAL AND INSTALLATION >

CEF

G H

I

J

K L

M A

B

CL

N

O P

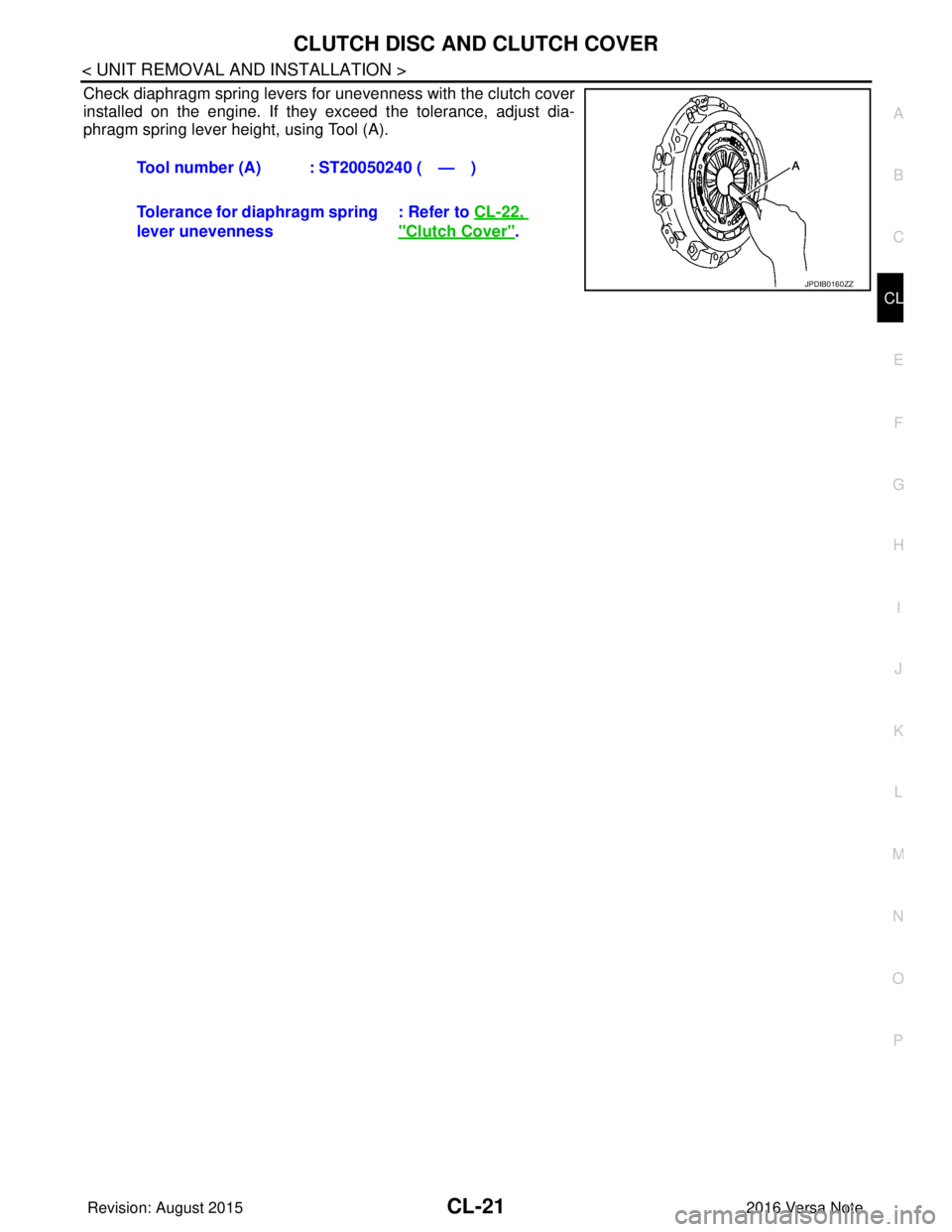

Check diaphragm spring levers for unevenness with the clutch cover

installed on the engine. If they exceed the tolerance, adjust dia-

phragm spring lever height, using Tool (A). Tool number (A) : ST20050240 ( — )

Tolerance for diaphragm spring

lever unevenness : Refer to

CL-22,

"Clutch Cover".

JPDIB0160ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 648 of 3641

CL-22

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

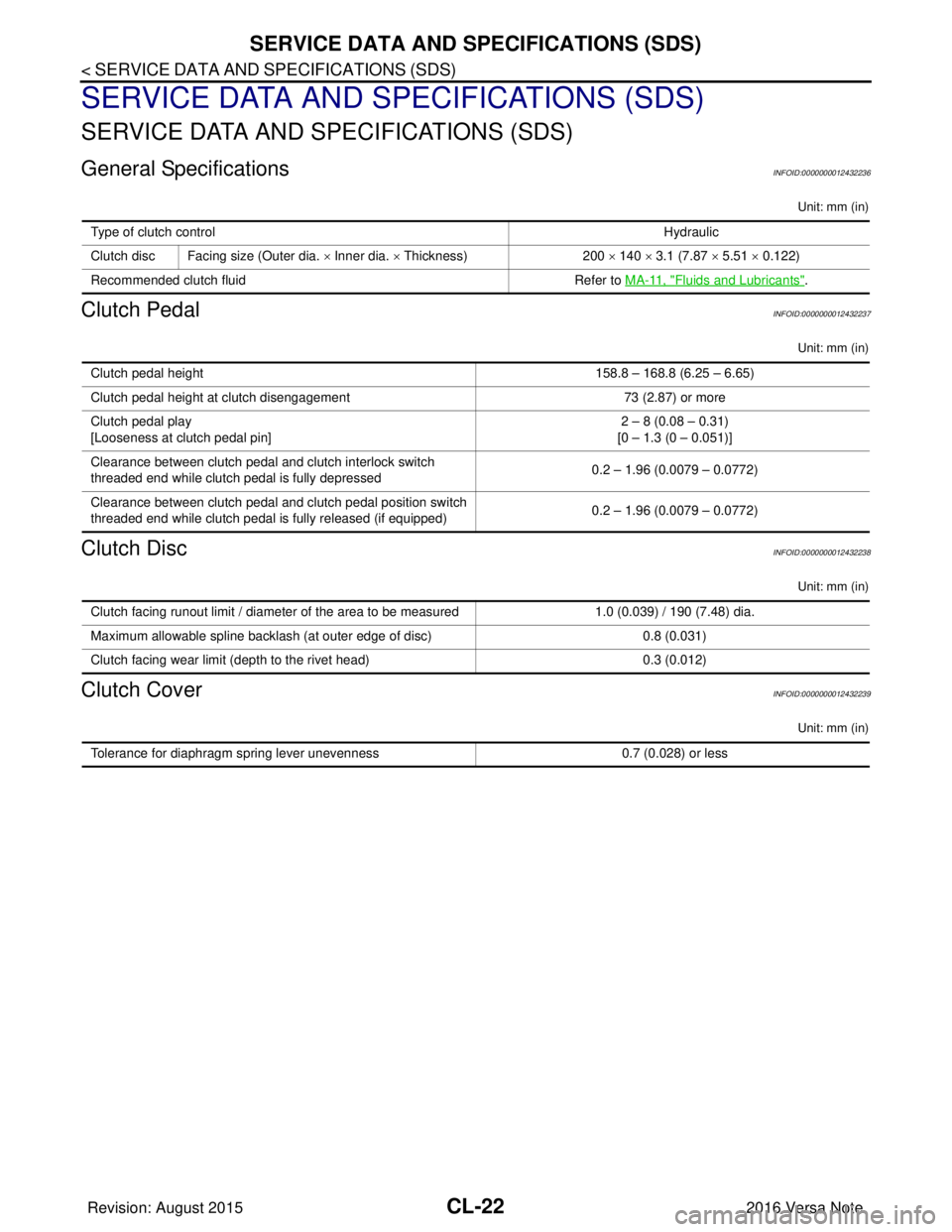

General SpecificationsINFOID:0000000012432236

Unit: mm (in)

Clutch PedalINFOID:0000000012432237

Unit: mm (in)

Clutch DiscINFOID:0000000012432238

Unit: mm (in)

Clutch CoverINFOID:0000000012432239

Unit: mm (in)

Type of clutch controlHydraulic

Clutch disc Facing size (Outer dia. × Inner dia. × Thickness) 200 × 140 × 3.1 (7.87 × 5.51 × 0.122)

Recommended clutch fluid Refer to MA-11, "

Fluids and Lubricants".

Clutch pedal height 158.8 – 168.8 (6.25 – 6.65)

Clutch pedal height at clutch disengagement 73 (2.87) or more

Clutch pedal play

[Looseness at clutch pedal pin] 2 – 8 (0.08 – 0.31)

[0 – 1.3 (0 – 0.051)]

Clearance between clutch pedal and clutch interlock switch

threaded end while clutch pedal is fully depressed 0.2 – 1.96 (0.0079 – 0.0772)

Clearance between clutch pedal and clutch pedal position switch

threaded end while clutch pedal is fully released (if equipped) 0.2 – 1.96 (0.0079 – 0.0772)

Clutch facing runout limit / diameter of the area to be measured

1.0 (0.039) / 190 (7.48) dia.

Maximum allowable spline backlash (at outer edge of disc) 0.8 (0.031)

Clutch facing wear limit (depth to the rivet head) 0.3 (0.012)

Tolerance for diaphragm spring lever unevenness0.7 (0.028) or less

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 649 of 3641

CCS-1

CRUISE CONTROL & DRIVER ASSISTANCE

C

DE

F

G H

I

J

K L

M B

CCS

SECTION CCS

N

P A

CONTENTS

CRUISE CONTROL SYSTEM

ASCD

PRECAUTION ....... ........................................

2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

SYSTEM DESCRIPTION ..............................3

AUTOMATIC SPEED CONTROL DEVICE

(ASCD) ...............................................................

3

Information ........................................................... .....3

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 650 of 3641

![NISSAN NOTE 2016 Service Repair Manual CCS-2

< PRECAUTION >[ASCD]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012542559

The Supplemental Rest NISSAN NOTE 2016 Service Repair Manual CCS-2

< PRECAUTION >[ASCD]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012542559

The Supplemental Rest](/img/5/57363/w960_57363-649.png)

CCS-2

< PRECAUTION >[ASCD]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012542559

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Revision: August 2015 2016 Versa Note

cardiagn.com