Check NISSAN PATROL 1998 Y61 / 5.G Electrical System Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 326, PDF Size: 11.36 MB

Page 118 of 326

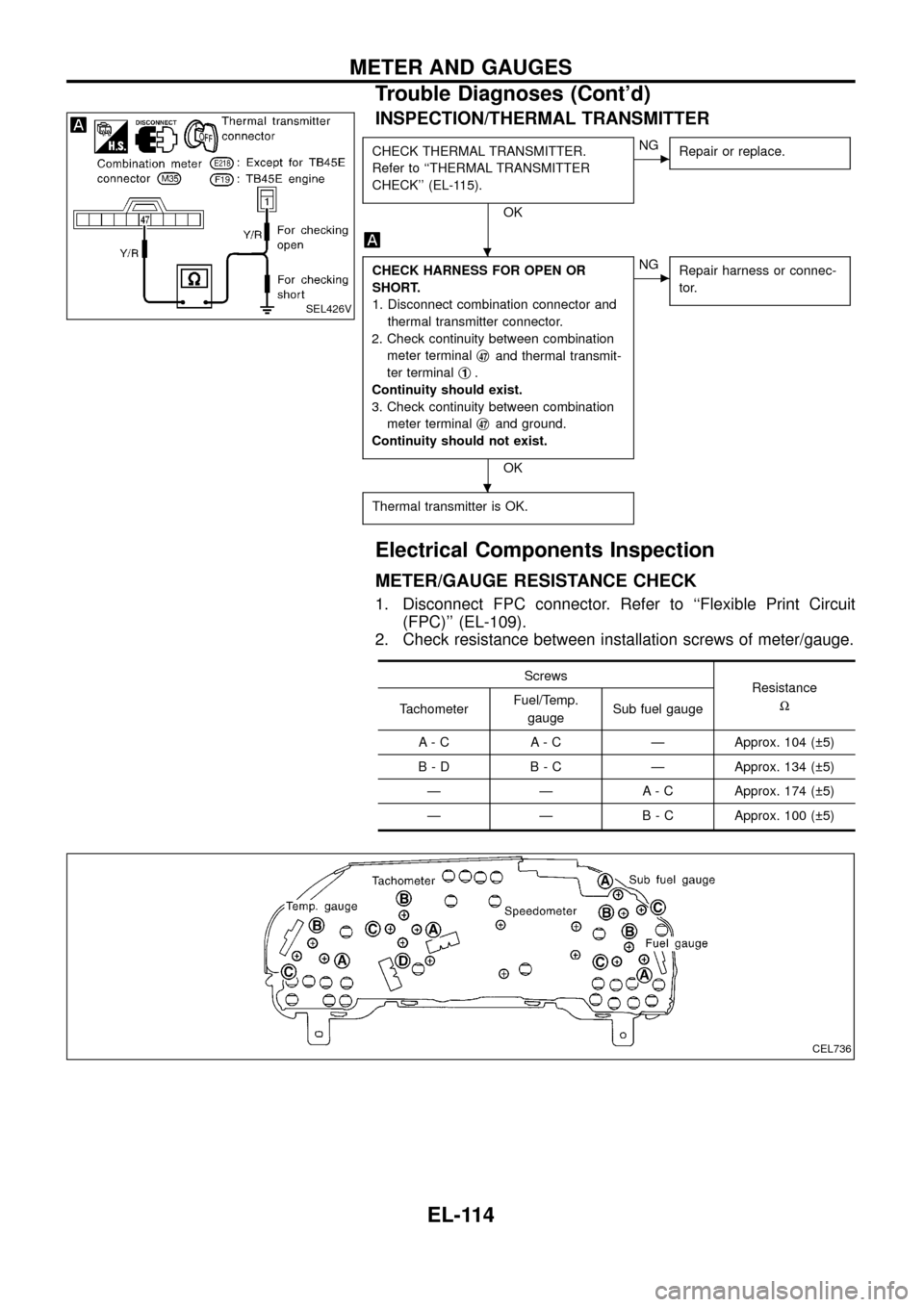

INSPECTION/THERMAL TRANSMITTER

CHECK THERMAL TRANSMITTER.

Refer to ``THERMAL TRANSMITTER

CHECK'' (EL-115).

OK

cNG

Repair or replace.

CHECK HARNESS FOR OPEN OR

SHORT.

1. Disconnect combination connector and

thermal transmitter connector.

2. Check continuity between combination

meter terminalj

47and thermal transmit-

ter terminalj

1.

Continuity should exist.

3. Check continuity between combination

meter terminalj

47and ground.

Continuity should not exist.

OK

cNG

Repair harness or connec-

tor.

Thermal transmitter is OK.

Electrical Components Inspection

METER/GAUGE RESISTANCE CHECK

1. Disconnect FPC connector. Refer to ``Flexible Print Circuit

(FPC)'' (EL-109).

2. Check resistance between installation screws of meter/gauge.

Screws

Resistance

W

TachometerFuel/Temp.

gaugeSub fuel gauge

A - C A - C Ð Approx. 104 ( 5)

B - D B - C Ð Approx. 134 ( 5)

Ð Ð A - C Approx. 174 ( 5)

Ð Ð B - C Approx. 100 ( 5)

SEL426V

CEL736

.

.

METER AND GAUGES

Trouble Diagnoses (Cont'd)

EL-114

Page 119 of 326

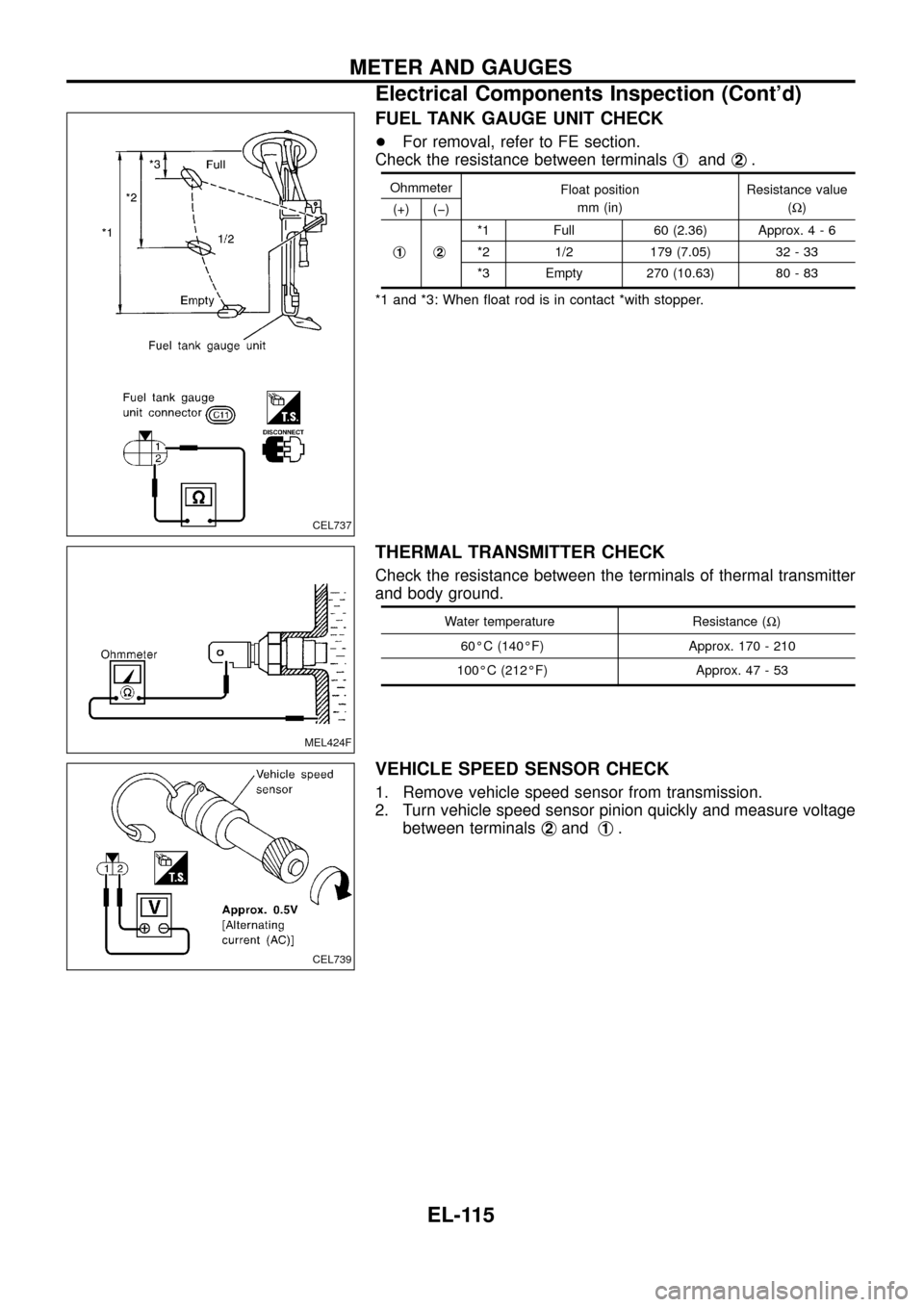

FUEL TANK GAUGE UNIT CHECK

+For removal, refer to FE section.

Check the resistance between terminalsj

1andj2.

Ohmmeter

Float position

mm (in)Resistance value

(W)

(+) (þ)

j

1j2

*1 Full 60 (2.36) Approx.4-6

*2 1/2 179 (7.05) 32 - 33

*3 Empty 270 (10.63) 80 - 83

*1 and *3: When ¯oat rod is in contact *with stopper.

THERMAL TRANSMITTER CHECK

Check the resistance between the terminals of thermal transmitter

and body ground.

Water temperature Resistance (W)

60ÉC (140ÉF) Approx. 170 - 210

100ÉC (212ÉF) Approx. 47 - 53

VEHICLE SPEED SENSOR CHECK

1. Remove vehicle speed sensor from transmission.

2. Turn vehicle speed sensor pinion quickly and measure voltage

between terminalsj

2andj1.

CEL737

MEL424F

CEL739

METER AND GAUGES

Electrical Components Inspection (Cont'd)

EL-115

Page 122 of 326

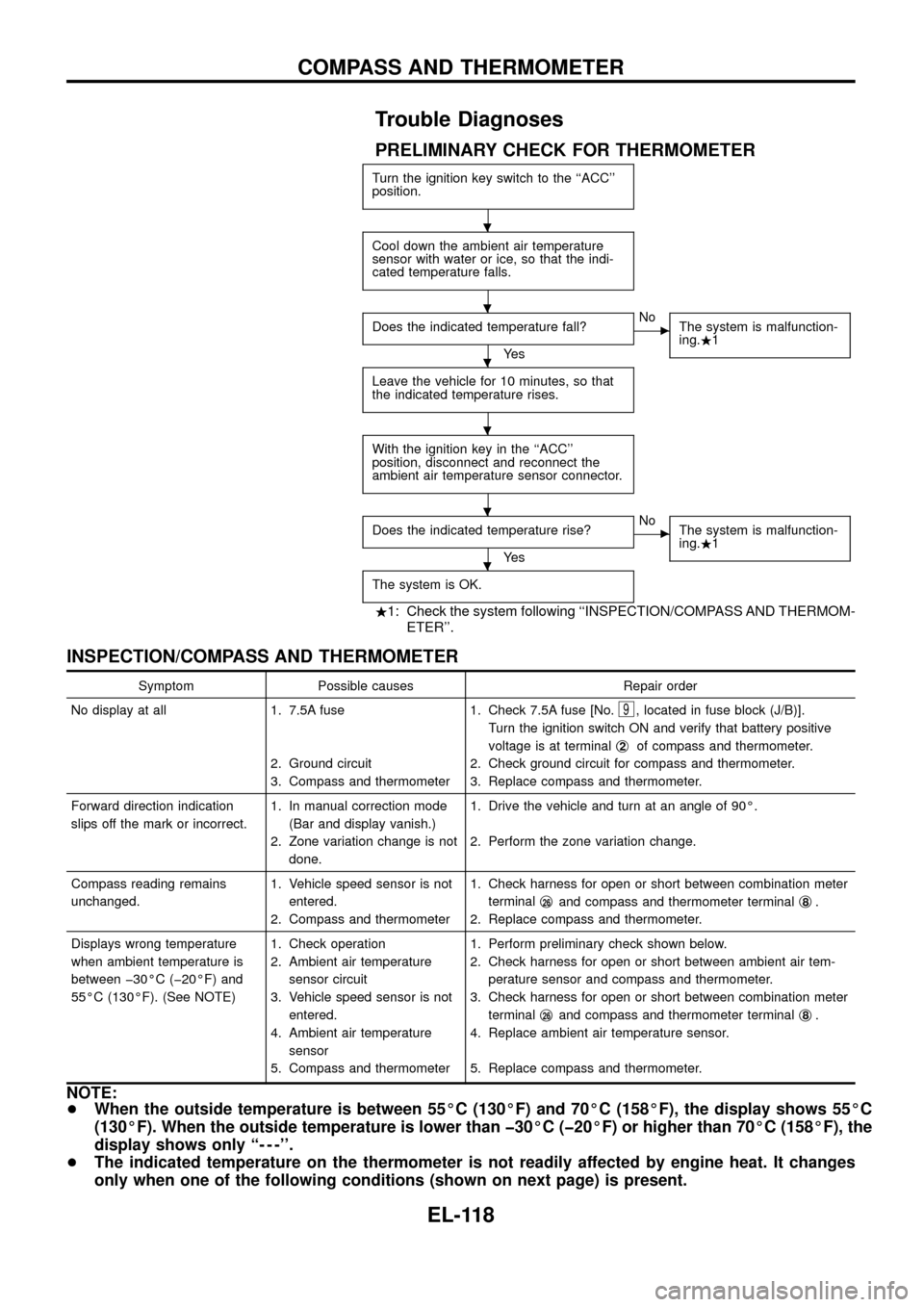

Trouble Diagnoses

PRELIMINARY CHECK FOR THERMOMETER

Turn the ignition key switch to the ``ACC''

position.

Cool down the ambient air temperature

sensor with water or ice, so that the indi-

cated temperature falls.

Does the indicated temperature fall?

Ye s

cNo

The system is malfunction-

ing..1

Leave the vehicle for 10 minutes, so that

the indicated temperature rises.

With the ignition key in the ``ACC''

position, disconnect and reconnect the

ambient air temperature sensor connector.

Does the indicated temperature rise?

Ye s

cNo

The system is malfunction-

ing..1

The system is OK.

.1: Check the system following ``INSPECTION/COMPASS AND THERMOM-

ETER''.

INSPECTION/COMPASS AND THERMOMETER

Symptom Possible causes Repair order

No display at all 1. 7.5A fuse

2. Ground circuit

3. Compass and thermometer1. Check 7.5A fuse [No.

9, located in fuse block (J/B)].

Turn the ignition switch ON and verify that battery positive

voltage is at terminalj

2of compass and thermometer.

2. Check ground circuit for compass and thermometer.

3. Replace compass and thermometer.

Forward direction indication

slips off the mark or incorrect.1. In manual correction mode

(Bar and display vanish.)

2. Zone variation change is not

done.1. Drive the vehicle and turn at an angle of 90É.

2. Perform the zone variation change.

Compass reading remains

unchanged.1. Vehicle speed sensor is not

entered.

2. Compass and thermometer1. Check harness for open or short between combination meter

terminalj

26and compass and thermometer terminalj8.

2. Replace compass and thermometer.

Displays wrong temperature

when ambient temperature is

between þ30ÉC (þ20ÉF) and

55ÉC (130ÉF). (See NOTE)1. Check operation

2. Ambient air temperature

sensor circuit

3. Vehicle speed sensor is not

entered.

4. Ambient air temperature

sensor

5. Compass and thermometer1. Perform preliminary check shown below.

2. Check harness for open or short between ambient air tem-

perature sensor and compass and thermometer.

3. Check harness for open or short between combination meter

terminalj

26and compass and thermometer terminalj8.

4. Replace ambient air temperature sensor.

5. Replace compass and thermometer.

NOTE:

+When the outside temperature is between 55ÉC (130ÉF) and 70ÉC (158ÉF), the display shows 55ÉC

(130ÉF). When the outside temperature is lower than þ30ÉC (þ20ÉF) or higher than 70ÉC (158ÉF), the

display shows only ``- - -''.

+The indicated temperature on the thermometer is not readily affected by engine heat. It changes

only when one of the following conditions (shown on next page) is present.

.

.

.

.

.

.

COMPASS AND THERMOMETER

EL-118

Page 138 of 326

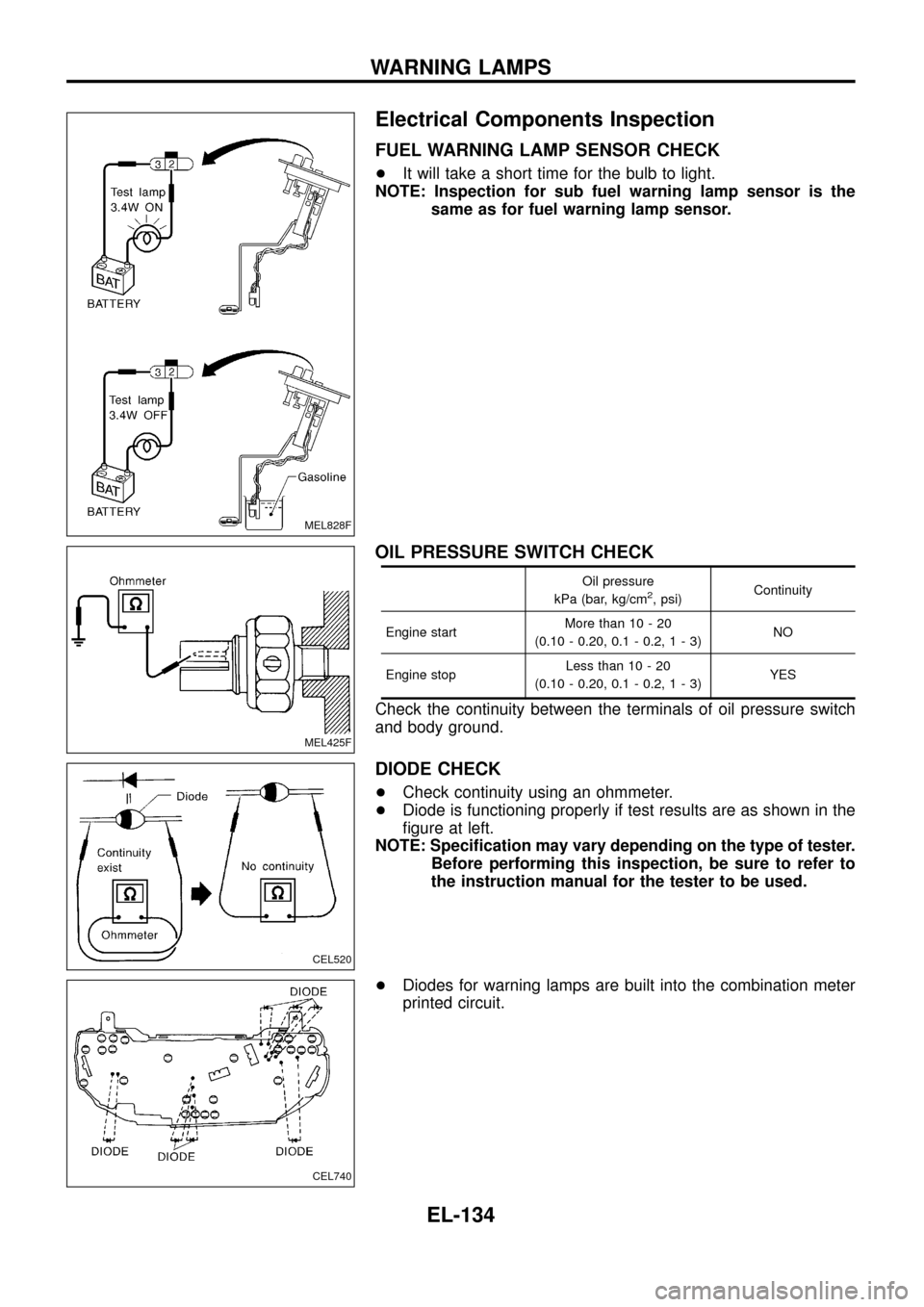

Electrical Components Inspection

FUEL WARNING LAMP SENSOR CHECK

+It will take a short time for the bulb to light.

NOTE: Inspection for sub fuel warning lamp sensor is the

same as for fuel warning lamp sensor.

OIL PRESSURE SWITCH CHECK

Oil pressure

kPa (bar, kg/cm2, psi)Continuity

Engine startMore than 10 - 20

(0.10 - 0.20, 0.1 - 0.2,1-3)NO

Engine stopLess than 10 - 20

(0.10 - 0.20, 0.1 - 0.2,1-3)YES

Check the continuity between the terminals of oil pressure switch

and body ground.

DIODE CHECK

+Check continuity using an ohmmeter.

+Diode is functioning properly if test results are as shown in the

®gure at left.

NOTE: Speci®cation may vary depending on the type of tester.

Before performing this inspection, be sure to refer to

the instruction manual for the tester to be used.

+Diodes for warning lamps are built into the combination meter

printed circuit.

MEL828F

MEL425F

CEL520

CEL740

WARNING LAMPS

EL-134

Page 142 of 326

Trouble Diagnoses

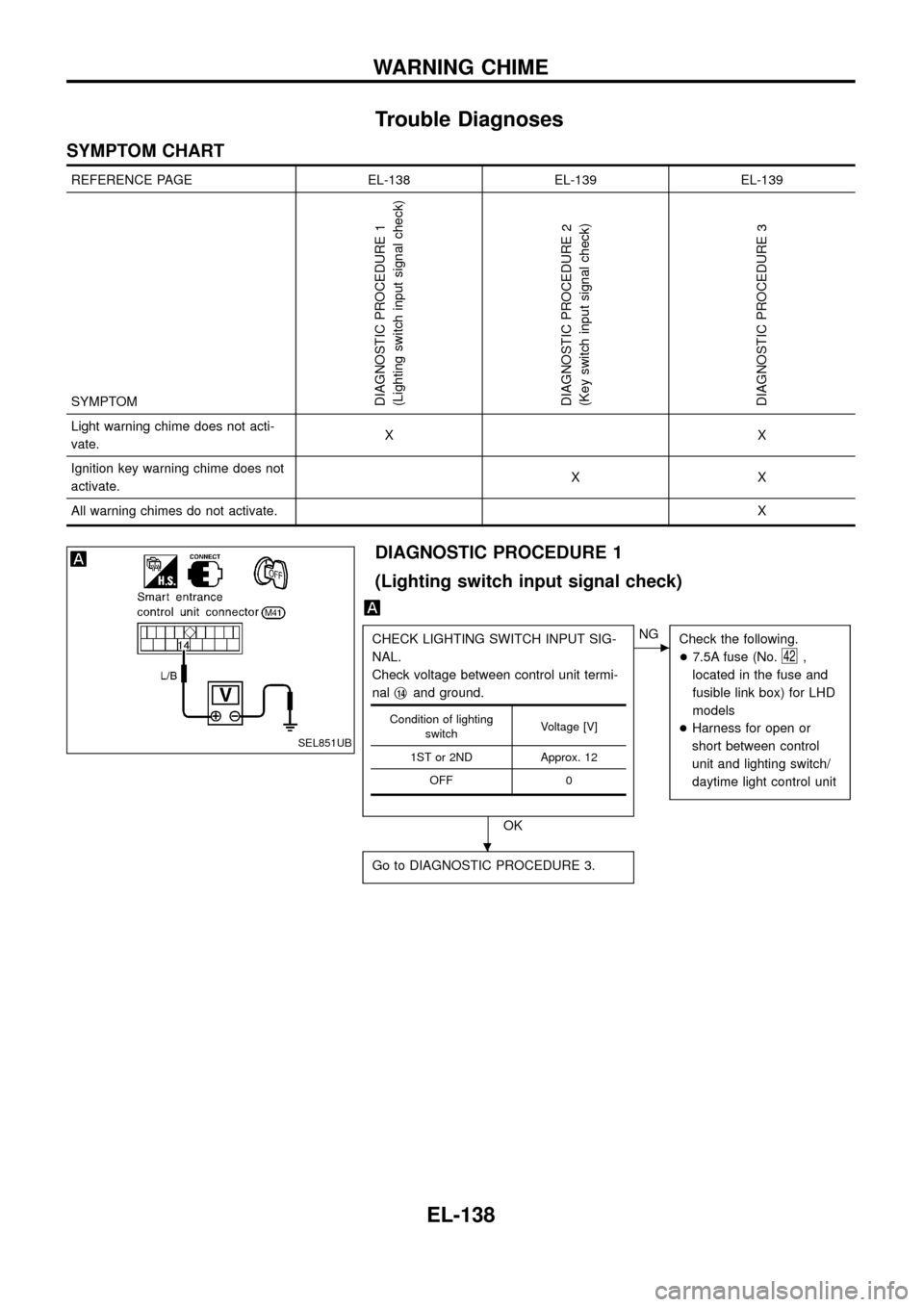

SYMPTOM CHART

REFERENCE PAGE EL-138 EL-139 EL-139

SYMPTOM

DIAGNOSTIC PROCEDURE 1

(Lighting switch input signal check)

DIAGNOSTIC PROCEDURE 2

(Key switch input signal check)

DIAGNOSTIC PROCEDURE 3

Light warning chime does not acti-

vate.XX

Ignition key warning chime does not

activate.XX

All warning chimes do not activate.X

DIAGNOSTIC PROCEDURE 1

(Lighting switch input signal check)

CHECK LIGHTING SWITCH INPUT SIG-

NAL.

Check voltage between control unit termi-

nalj

14and ground.

OK

cNG

Check the following.

+7.5A fuse (No.

42,

located in the fuse and

fusible link box) for LHD

models

+Harness for open or

short between control

unit and lighting switch/

daytime light control unit

Go to DIAGNOSTIC PROCEDURE 3.

Condition of lighting

switchVoltage [V]

1ST or 2ND Approx. 12

OFF 0

SEL851UB

.

WARNING CHIME

EL-138

Page 143 of 326

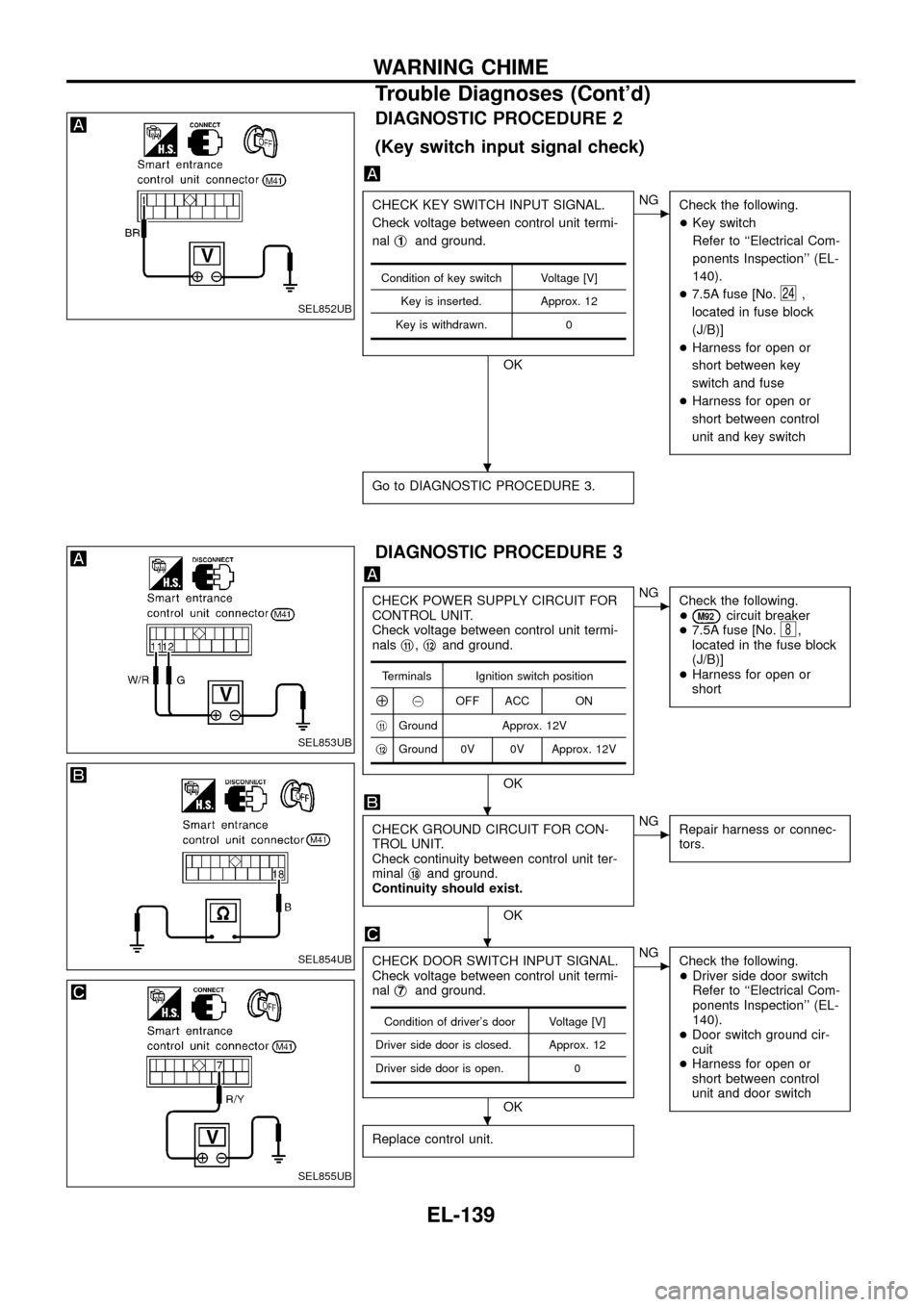

DIAGNOSTIC PROCEDURE 2

(Key switch input signal check)

CHECK KEY SWITCH INPUT SIGNAL.

Check voltage between control unit termi-

nalj

1and ground.

OK

cNG

Check the following.

+Key switch

Refer to ``Electrical Com-

ponents Inspection'' (EL-

140).

+7.5A fuse [No.

24,

located in fuse block

(J/B)]

+Harness for open or

short between key

switch and fuse

+Harness for open or

short between control

unit and key switch

Go to DIAGNOSTIC PROCEDURE 3.

Condition of key switch Voltage [V]

Key is inserted. Approx. 12

Key is withdrawn. 0

DIAGNOSTIC PROCEDURE 3

CHECK POWER SUPPLY CIRCUIT FOR

CONTROL UNIT.

Check voltage between control unit termi-

nalsj

11,j12and ground.

OK

cNG

Check the following.

+

M92circuit breaker

+7.5A fuse [No.8,

located in the fuse block

(J/B)]

+Harness for open or

short

CHECK GROUND CIRCUIT FOR CON-

TROL UNIT.

Check continuity between control unit ter-

minalj

18and ground.

Continuity should exist.

OK

cNG

Repair harness or connec-

tors.

CHECK DOOR SWITCH INPUT SIGNAL.

Check voltage between control unit termi-

nalj

7and ground.

OK

cNG

Check the following.

+Driver side door switch

Refer to ``Electrical Com-

ponents Inspection'' (EL-

140).

+Door switch ground cir-

cuit

+Harness for open or

short between control

unit and door switch

Replace control unit.

Terminals Ignition switch position

Å@OFF ACC ON

j

11Ground Approx. 12V

j

12Ground 0V 0V Approx. 12V

Condition of driver's door Voltage [V]

Driver side door is closed. Approx. 12

Driver side door is open. 0

SEL852UB

SEL853UB

SEL854UB

SEL855UB

.

.

.

.

WARNING CHIME

Trouble Diagnoses (Cont'd)

EL-139

Page 144 of 326

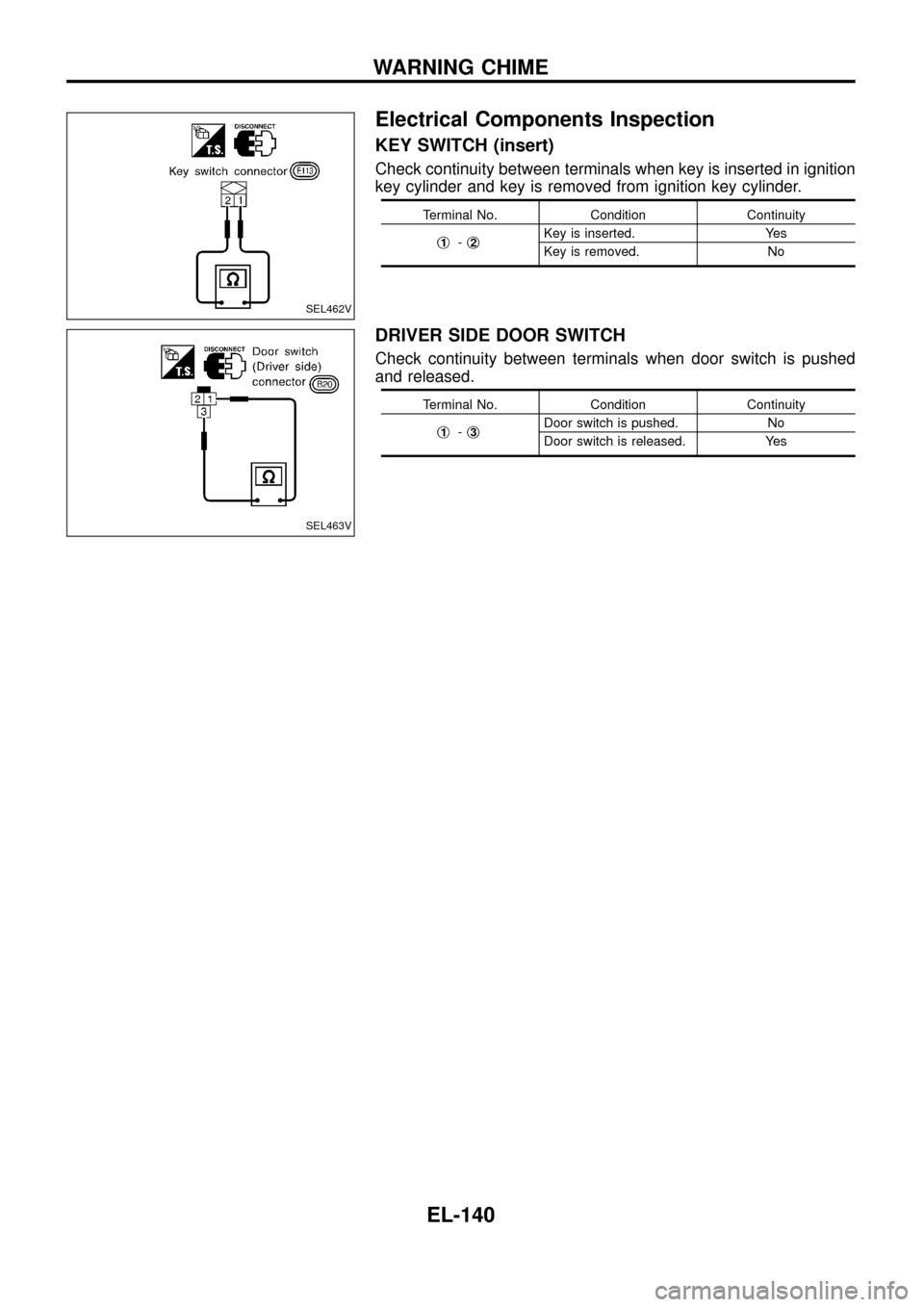

Electrical Components Inspection

KEY SWITCH (insert)

Check continuity between terminals when key is inserted in ignition

key cylinder and key is removed from ignition key cylinder.

Terminal No. Condition Continuity

j

1-j2Key is inserted. Yes

Key is removed. No

DRIVER SIDE DOOR SWITCH

Check continuity between terminals when door switch is pushed

and released.

Terminal No. Condition Continuity

j

1-j3Door switch is pushed. No

Door switch is released. Yes

SEL462V

SEL463V

WARNING CHIME

EL-140

Page 156 of 326

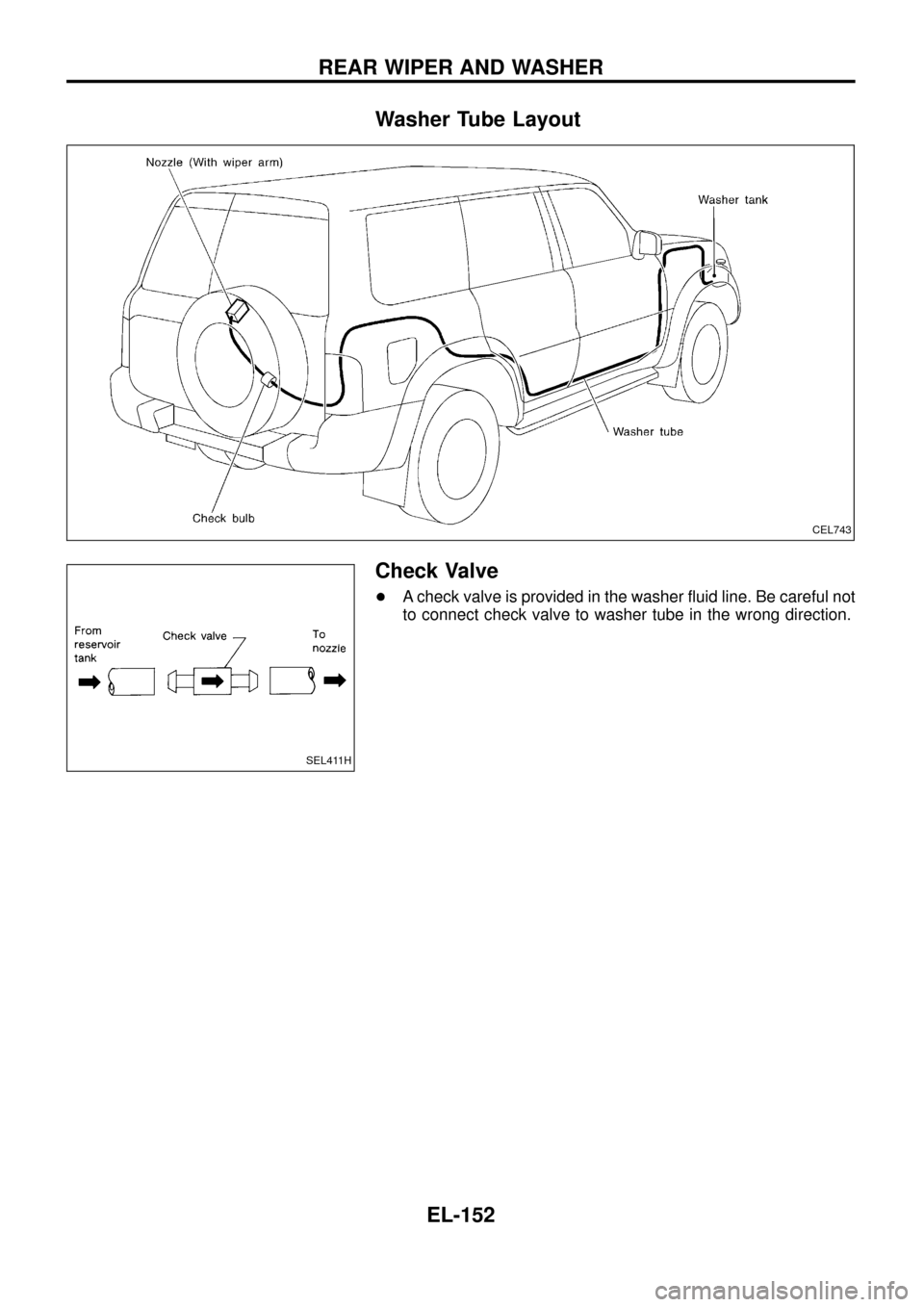

Washer Tube Layout

Check Valve

+A check valve is provided in the washer ¯uid line. Be careful not

to connect check valve to washer tube in the wrong direction.

CEL743

SEL411H

REAR WIPER AND WASHER

EL-152

Page 158 of 326

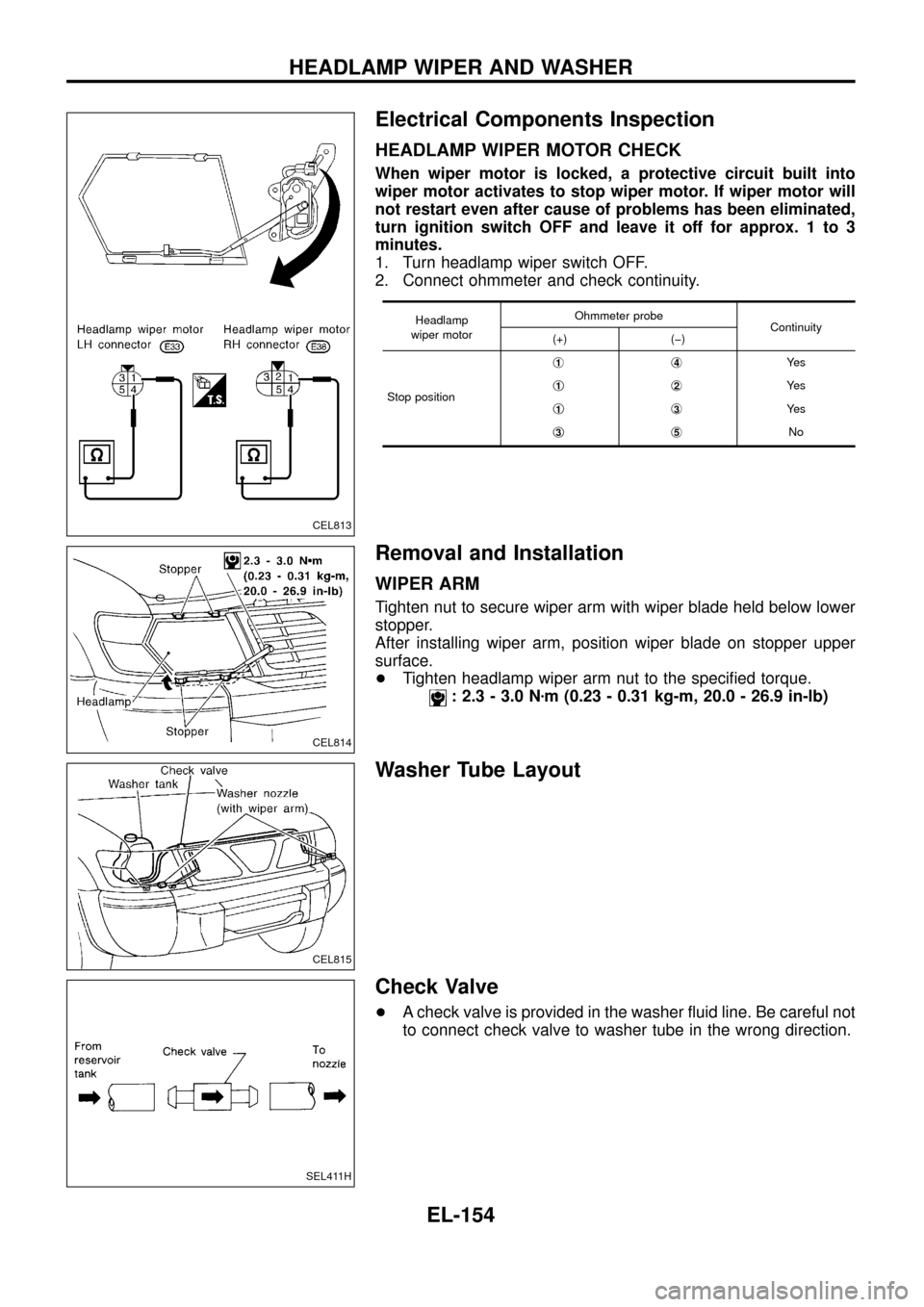

Electrical Components Inspection

HEADLAMP WIPER MOTOR CHECK

When wiper motor is locked, a protective circuit built into

wiper motor activates to stop wiper motor. If wiper motor will

not restart even after cause of problems has been eliminated,

turn ignition switch OFF and leave it off for approx. 1 to 3

minutes.

1. Turn headlamp wiper switch OFF.

2. Connect ohmmeter and check continuity.

Headlamp

wiper motorOhmmeter probe

Continuity

(+) (þ)

Stop positionj

1j4Ye s

j

1j2Ye s

j

1j3Ye s

j

3j5No

Removal and Installation

WIPER ARM

Tighten nut to secure wiper arm with wiper blade held below lower

stopper.

After installing wiper arm, position wiper blade on stopper upper

surface.

+Tighten headlamp wiper arm nut to the speci®ed torque.

: 2.3 - 3.0 Nzm (0.23 - 0.31 kg-m, 20.0 - 26.9 in-lb)

Washer Tube Layout

Check Valve

+A check valve is provided in the washer ¯uid line. Be careful not

to connect check valve to washer tube in the wrong direction.

CEL813

CEL814

CEL815

SEL411H

HEADLAMP WIPER AND WASHER

EL-154

Page 167 of 326

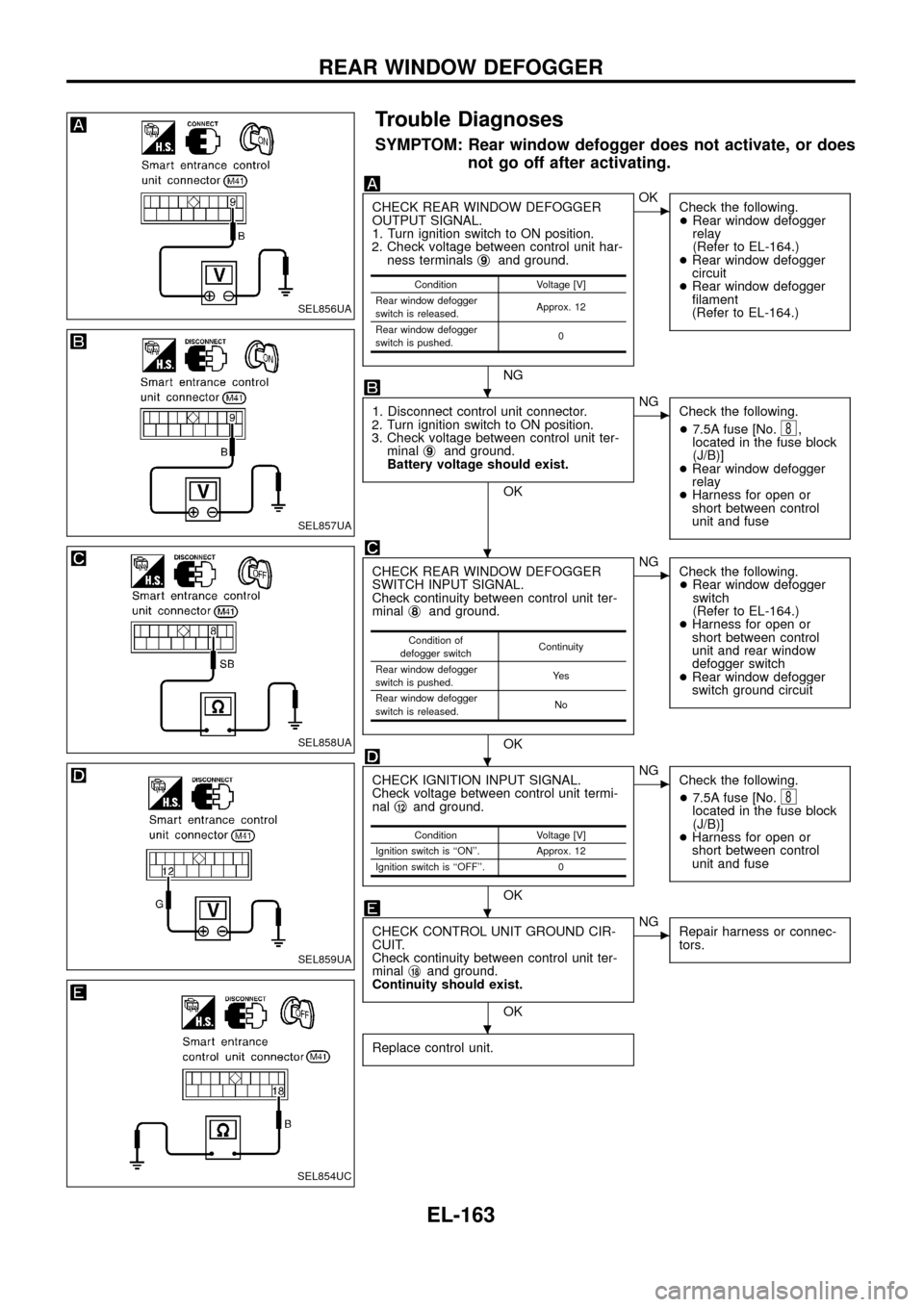

Trouble Diagnoses

SYMPTOM: Rear window defogger does not activate, or does

not go off after activating.

CHECK REAR WINDOW DEFOGGER

OUTPUT SIGNAL.

1. Turn ignition switch to ON position.

2. Check voltage between control unit har-

ness terminalsj

9and ground.

NG

cOK

Check the following.

+Rear window defogger

relay

(Refer to EL-164.)

+Rear window defogger

circuit

+Rear window defogger

®lament

(Refer to EL-164.)

1. Disconnect control unit connector.

2. Turn ignition switch to ON position.

3. Check voltage between control unit ter-

minalj

9and ground.

Battery voltage should exist.

OK

cNG

Check the following.

+7.5A fuse [No.

8,

located in the fuse block

(J/B)]

+Rear window defogger

relay

+Harness for open or

short between control

unit and fuse

CHECK REAR WINDOW DEFOGGER

SWITCH INPUT SIGNAL.

Check continuity between control unit ter-

minalj

8and ground.

OK

cNG

Check the following.

+Rear window defogger

switch

(Refer to EL-164.)

+Harness for open or

short between control

unit and rear window

defogger switch

+Rear window defogger

switch ground circuit

CHECK IGNITION INPUT SIGNAL.

Check voltage between control unit termi-

nalj

12and ground.

OK

cNG

Check the following.

+7.5A fuse [No.

8located in the fuse block

(J/B)]

+Harness for open or

short between control

unit and fuse

CHECK CONTROL UNIT GROUND CIR-

CUIT.

Check continuity between control unit ter-

minalj

18and ground.

Continuity should exist.

OK

cNG

Repair harness or connec-

tors.

Replace control unit.

Condition Voltage [V]

Rear window defogger

switch is released.Approx. 12

Rear window defogger

switch is pushed.0

Condition of

defogger switchContinuity

Rear window defogger

switch is pushed.Ye s

Rear window defogger

switch is released.No

Condition Voltage [V]

Ignition switch is ``ON''. Approx. 12

Ignition switch is ``OFF''. 0

SEL856UA

SEL857UA

SEL858UA

SEL859UA

SEL854UC

.

.

.

.

.

REAR WINDOW DEFOGGER

EL-163