NISSAN PATROL 2000 Electronic Repair Manual

PATROL 2000

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57367/w960_57367-0.png

NISSAN PATROL 2000 Electronic Repair Manual

Trending: ESP, Defogger, height adjustment, fuel type, wiring diagram, AUX, four wheel drive

Page 161 of 1033

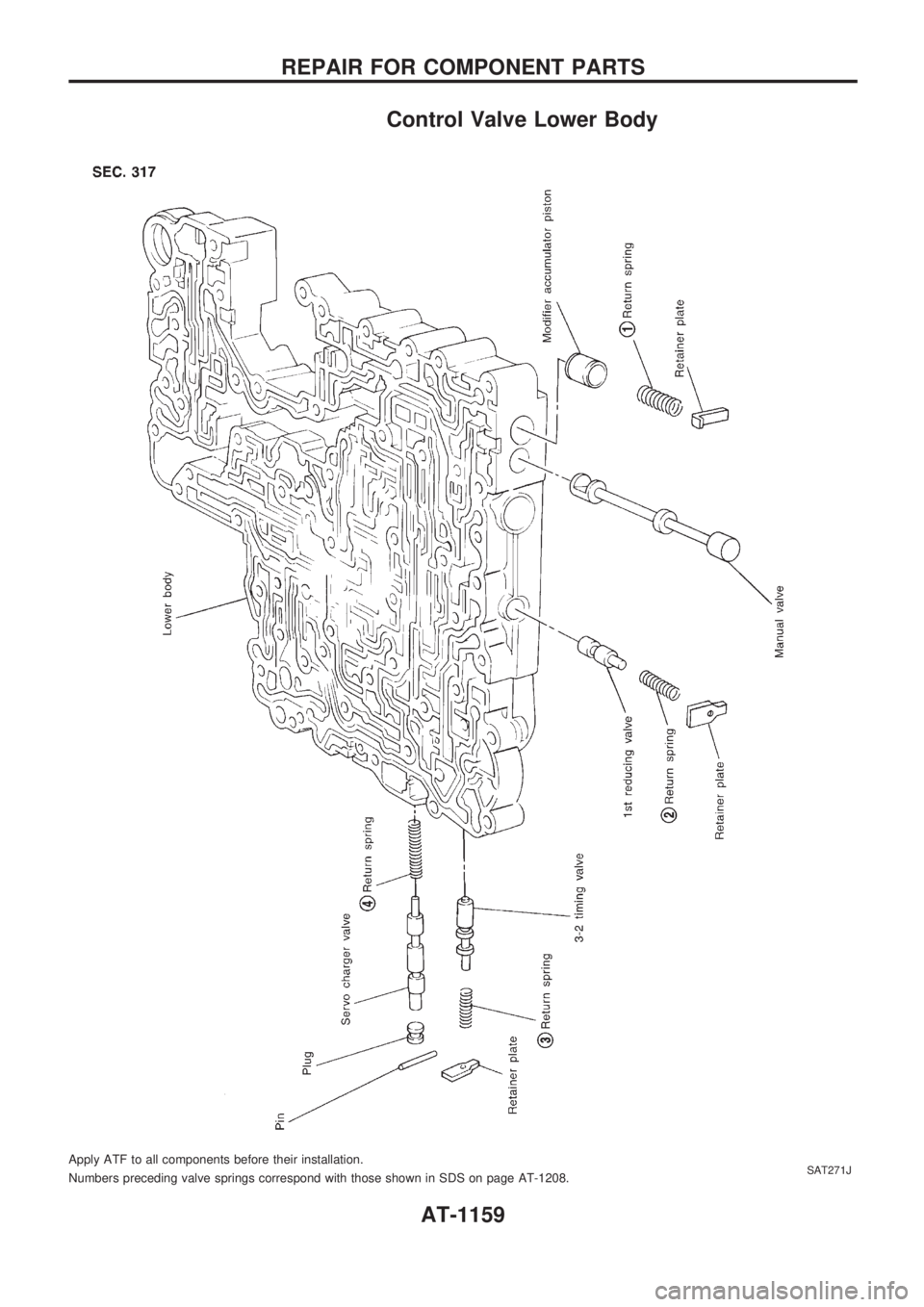

Control Valve Lower Body

Apply ATF to all components before their installation.

Numbers preceding valve springs correspond with those shown in SDS on page AT-1208.SAT271J

REPAIR FOR COMPONENT PARTS

AT-1159

Page 162 of 1033

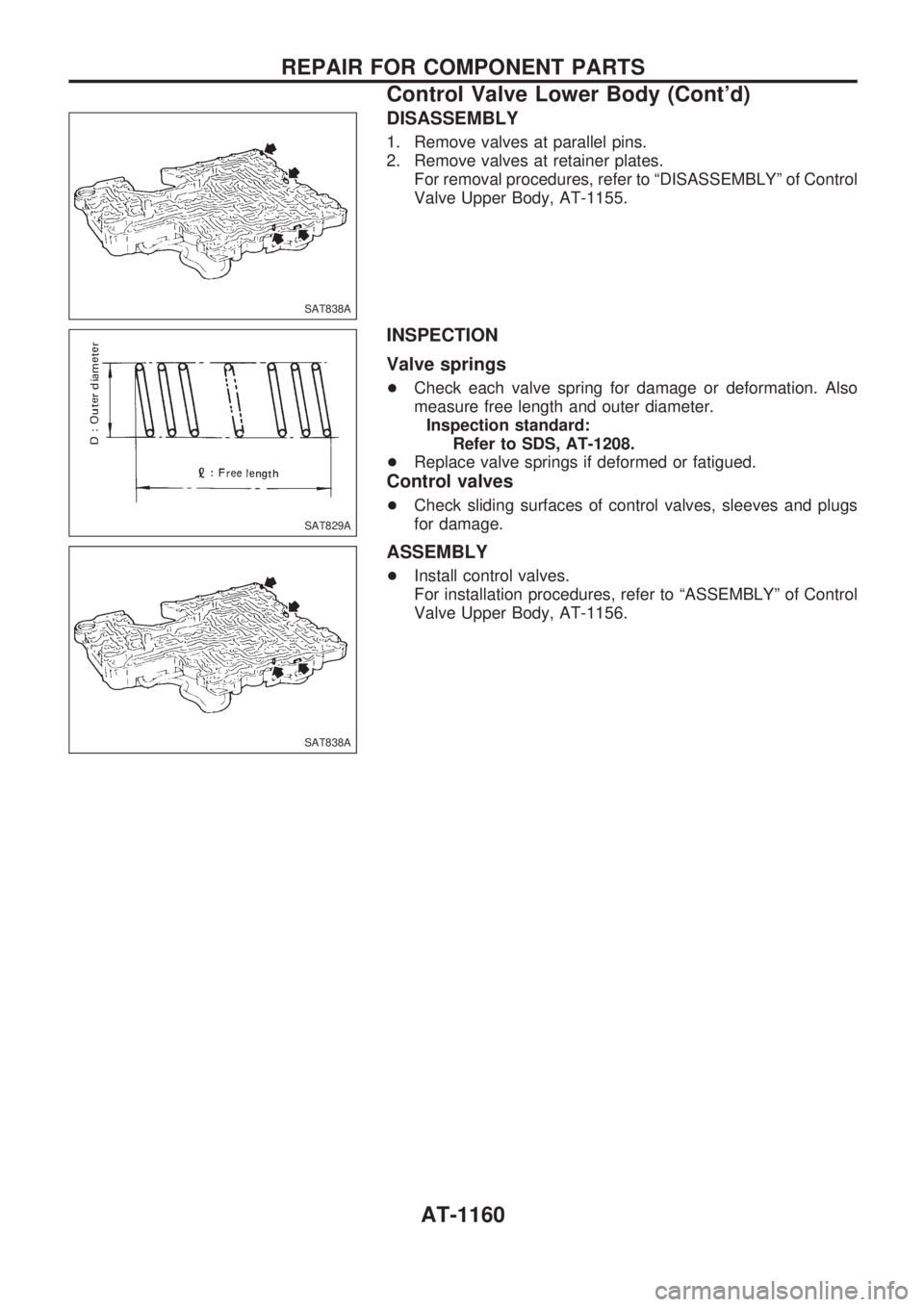

DISASSEMBLY

1. Remove valves at parallel pins.

2. Remove valves at retainer plates.

For removal procedures, refer to ªDISASSEMBLYº of Control

Valve Upper Body, AT-1155.

INSPECTION

Valve springs

+Check each valve spring for damage or deformation. Also

measure free length and outer diameter.

Inspection standard:

Refer to SDS, AT-1208.

+Replace valve springs if deformed or fatigued.

Control valves

+Check sliding surfaces of control valves, sleeves and plugs

for damage.

ASSEMBLY

+Install control valves.

For installation procedures, refer to ªASSEMBLYº of Control

Valve Upper Body, AT-1156.

SAT838A

SAT829A

SAT838A

REPAIR FOR COMPONENT PARTS

Control Valve Lower Body (Cont'd)

AT-1160

Page 163 of 1033

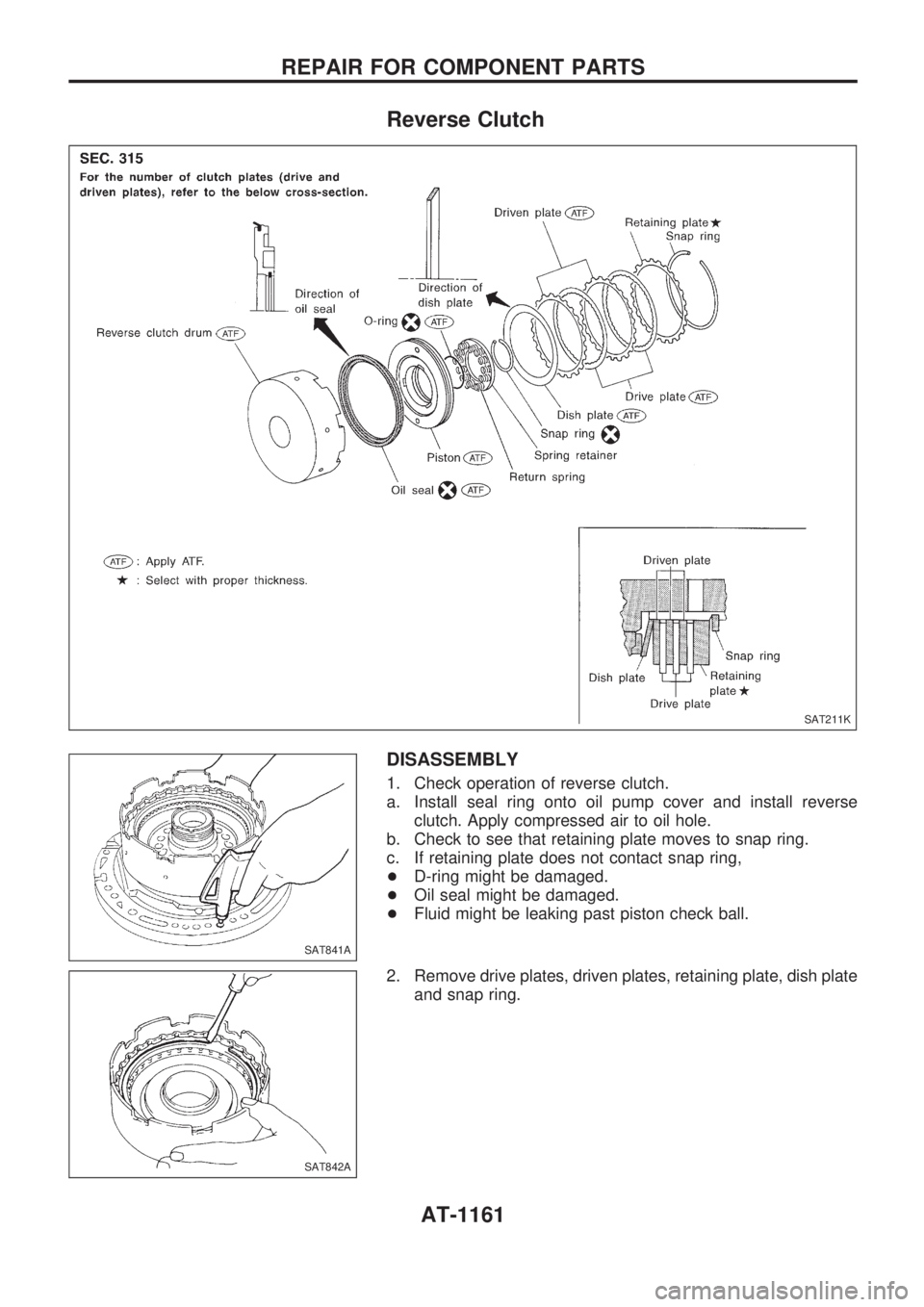

Reverse Clutch

DISASSEMBLY

1. Check operation of reverse clutch.

a. Install seal ring onto oil pump cover and install reverse

clutch. Apply compressed air to oil hole.

b. Check to see that retaining plate moves to snap ring.

c. If retaining plate does not contact snap ring,

+D-ring might be damaged.

+Oil seal might be damaged.

+Fluid might be leaking past piston check ball.

2. Remove drive plates, driven plates, retaining plate, dish plate

and snap ring.

SAT211K

SAT841A

SAT842A

REPAIR FOR COMPONENT PARTS

AT-1161

Page 164 of 1033

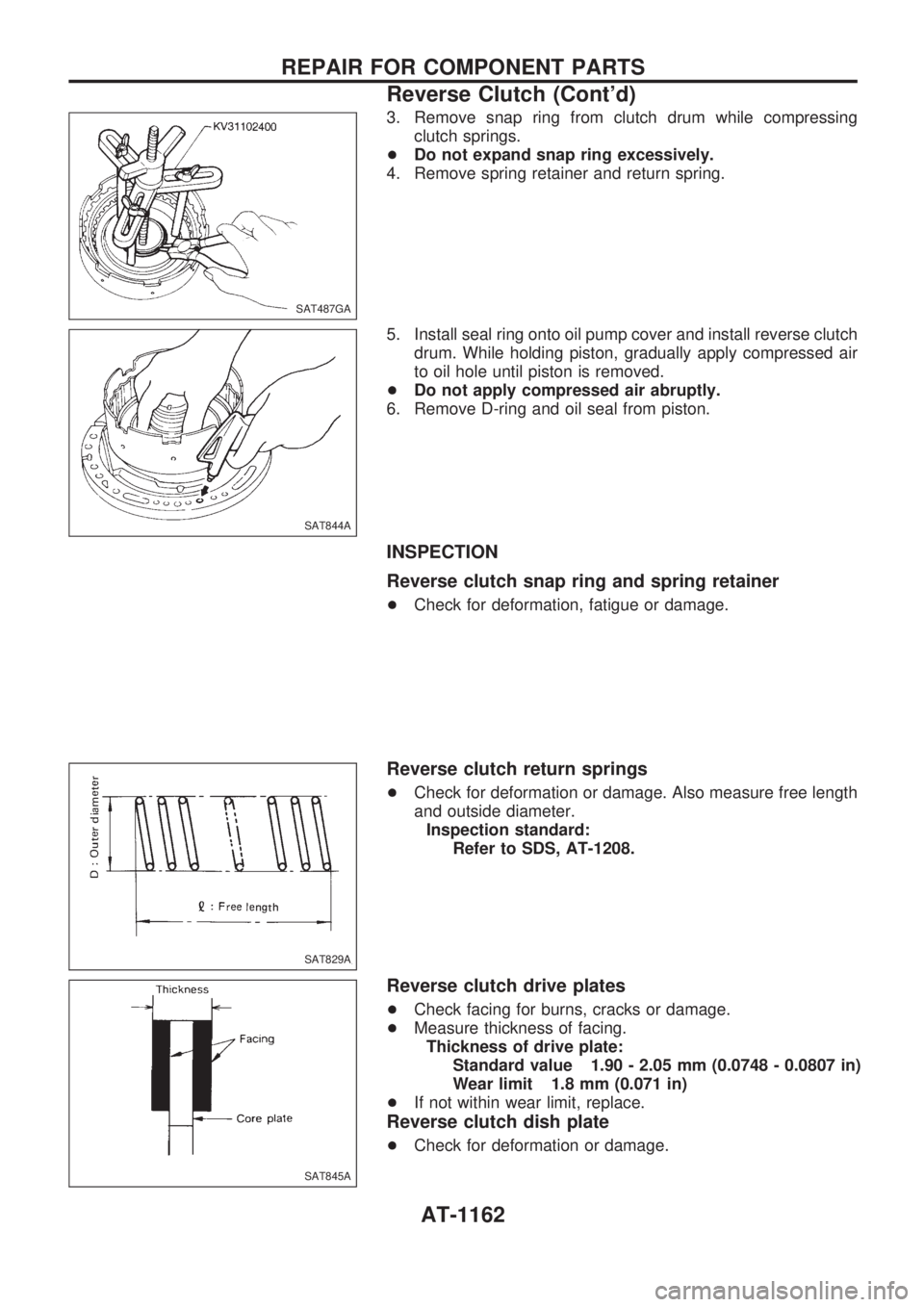

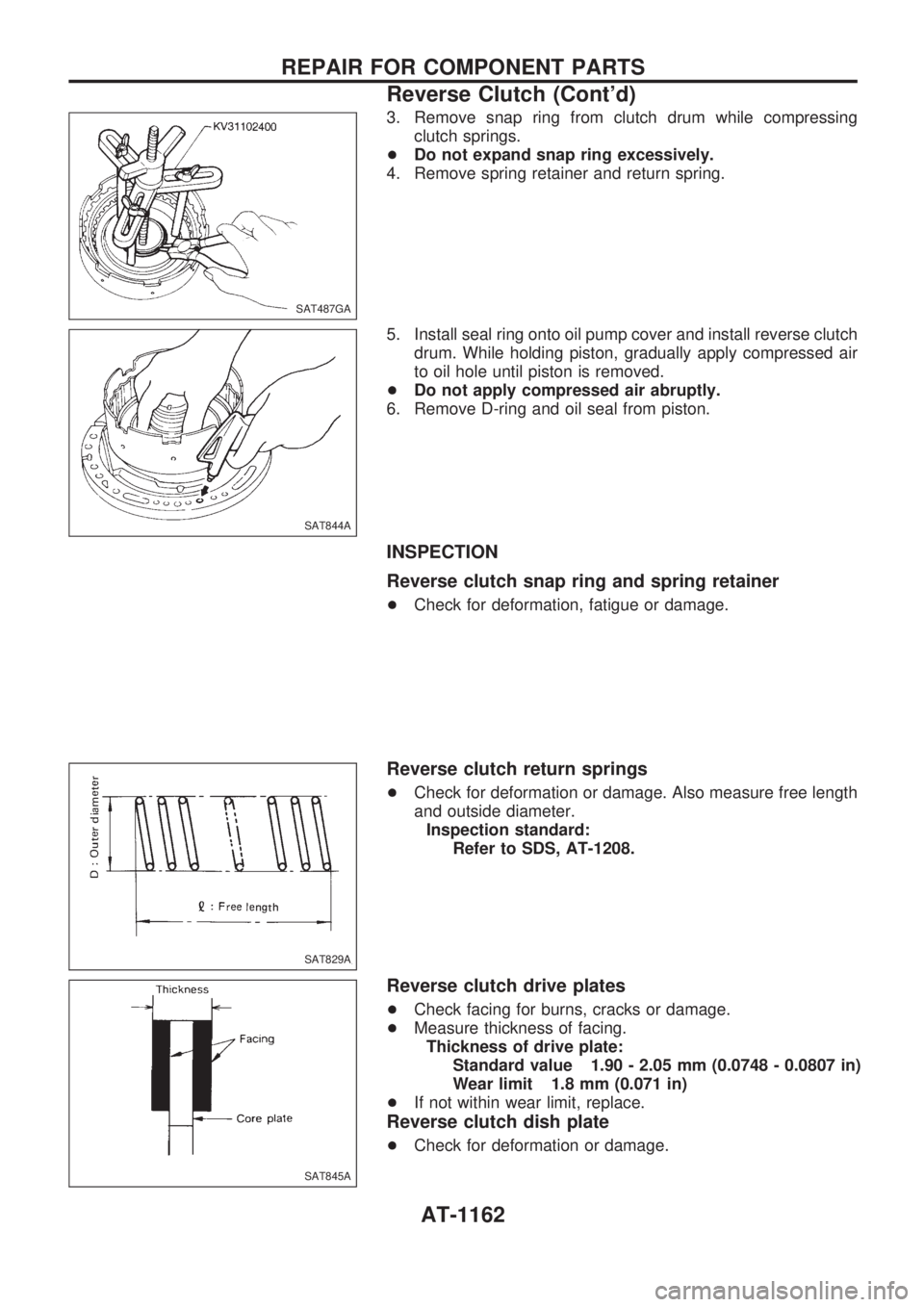

3. Remove snap ring from clutch drum while compressing

clutch springs.

+Do not expand snap ring excessively.

4. Remove spring retainer and return spring.

5. Install seal ring onto oil pump cover and install reverse clutch

drum. While holding piston, gradually apply compressed air

to oil hole until piston is removed.

+Do not apply compressed air abruptly.

6. Remove D-ring and oil seal from piston.

INSPECTION

Reverse clutch snap ring and spring retainer

+Check for deformation, fatigue or damage.

Reverse clutch return springs

+Check for deformation or damage. Also measure free length

and outside diameter.

Inspection standard:

Refer to SDS, AT-1208.

Reverse clutch drive plates

+Check facing for burns, cracks or damage.

+Measure thickness of facing.

Thickness of drive plate:

Standard value 1.90 - 2.05 mm (0.0748 - 0.0807 in)

Wear limit 1.8 mm (0.071 in)

+If not within wear limit, replace.

Reverse clutch dish plate

+Check for deformation or damage.

SAT487GA

SAT844A

SAT829A

SAT845A

REPAIR FOR COMPONENT PARTS

Reverse Clutch (Cont'd)

AT-1162

Page 165 of 1033

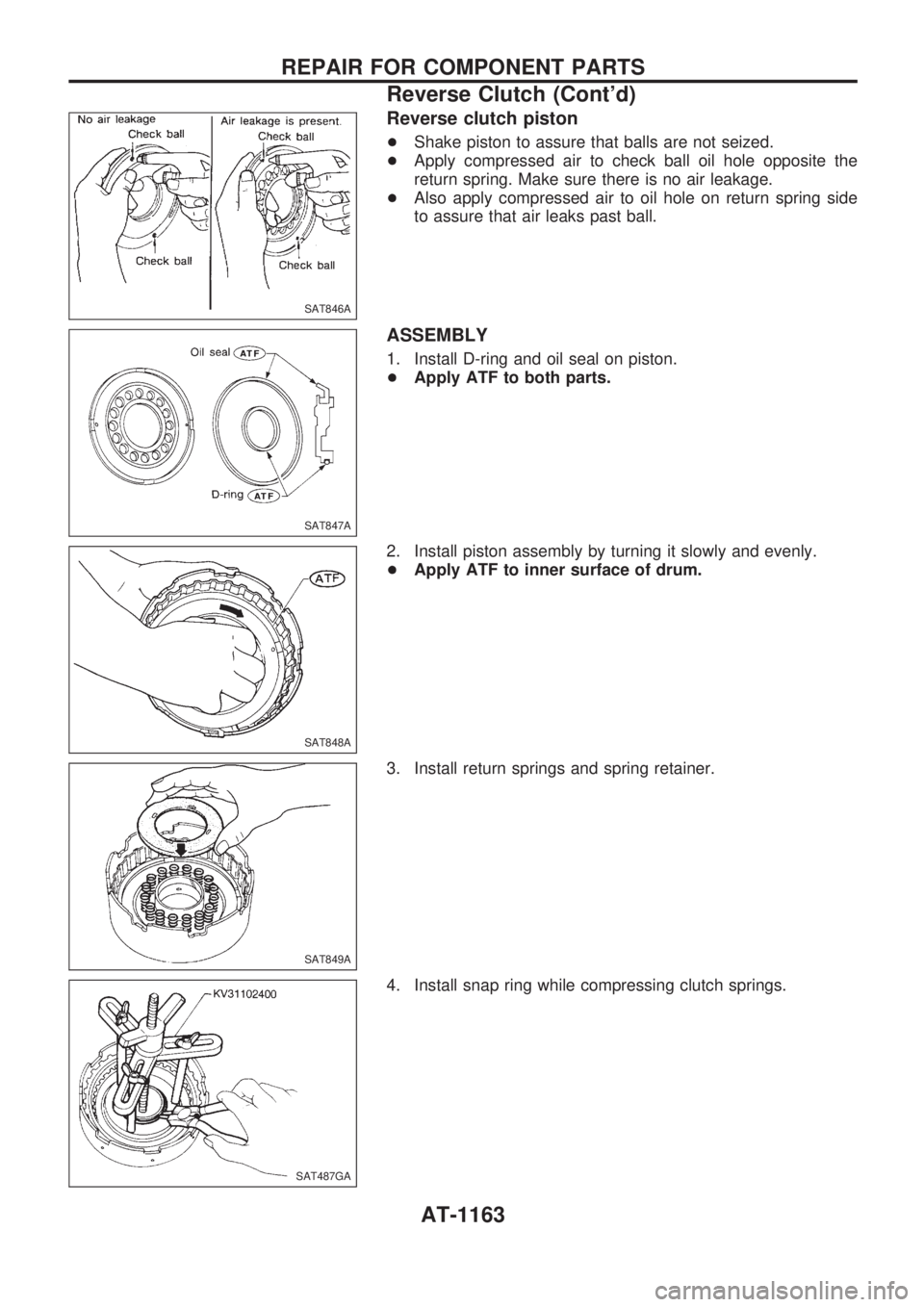

Reverse clutch piston

+Shake piston to assure that balls are not seized.

+Apply compressed air to check ball oil hole opposite the

return spring. Make sure there is no air leakage.

+Also apply compressed air to oil hole on return spring side

to assure that air leaks past ball.

ASSEMBLY

1. Install D-ring and oil seal on piston.

+Apply ATF to both parts.

2. Install piston assembly by turning it slowly and evenly.

+Apply ATF to inner surface of drum.

3. Install return springs and spring retainer.

4. Install snap ring while compressing clutch springs.

SAT846A

SAT847A

SAT848A

SAT849A

SAT487GA

REPAIR FOR COMPONENT PARTS

Reverse Clutch (Cont'd)

AT-1163

Page 166 of 1033

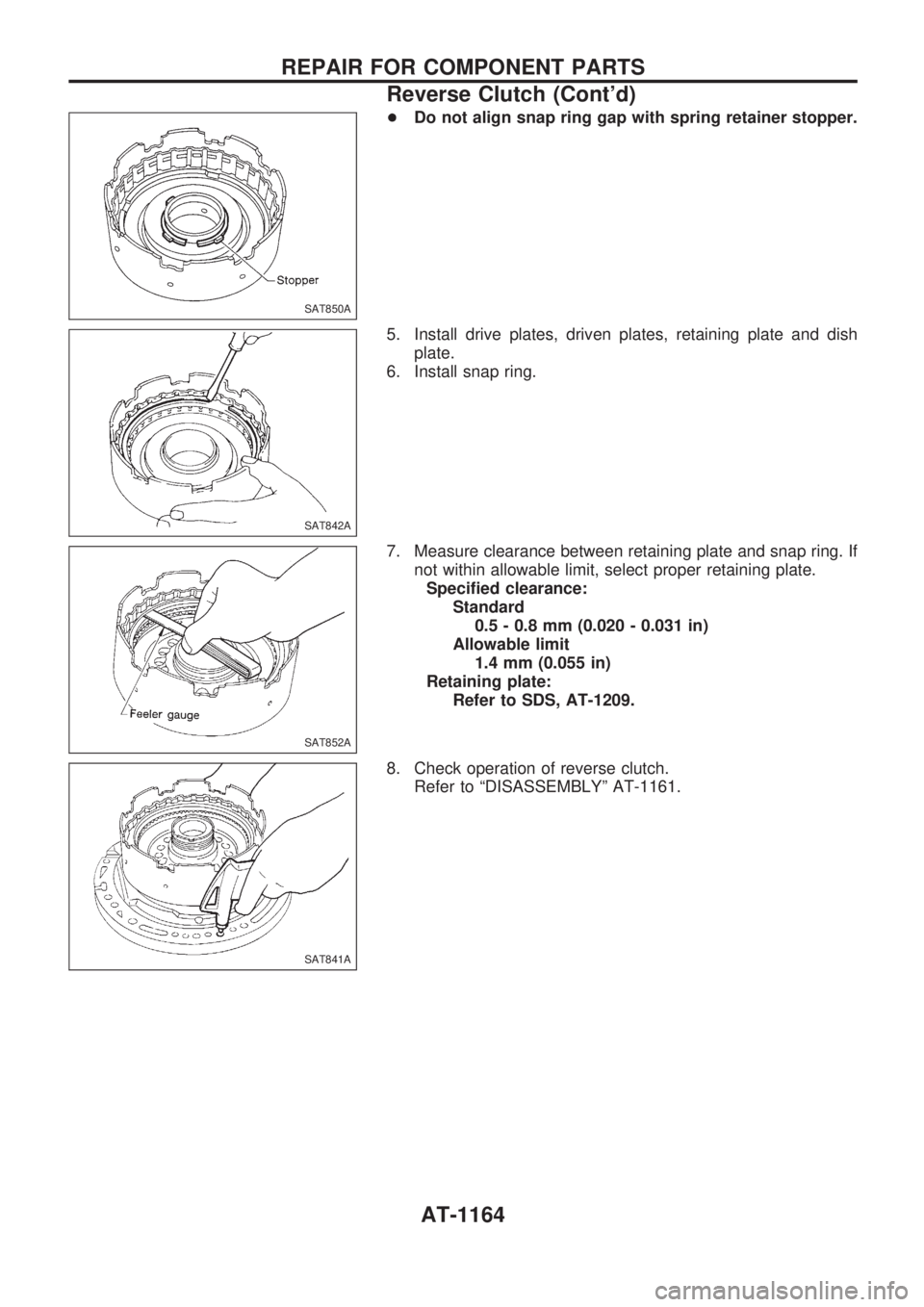

+Do not align snap ring gap with spring retainer stopper.

5. Install drive plates, driven plates, retaining plate and dish

plate.

6. Install snap ring.

7. Measure clearance between retaining plate and snap ring. If

not within allowable limit, select proper retaining plate.

Specified clearance:

Standard

0.5 - 0.8 mm (0.020 - 0.031 in)

Allowable limit

1.4 mm (0.055 in)

Retaining plate:

Refer to SDS, AT-1209.

8. Check operation of reverse clutch.

Refer to ªDISASSEMBLYº AT-1161.

SAT850A

SAT842A

SAT852A

SAT841A

REPAIR FOR COMPONENT PARTS

Reverse Clutch (Cont'd)

AT-1164

Page 167 of 1033

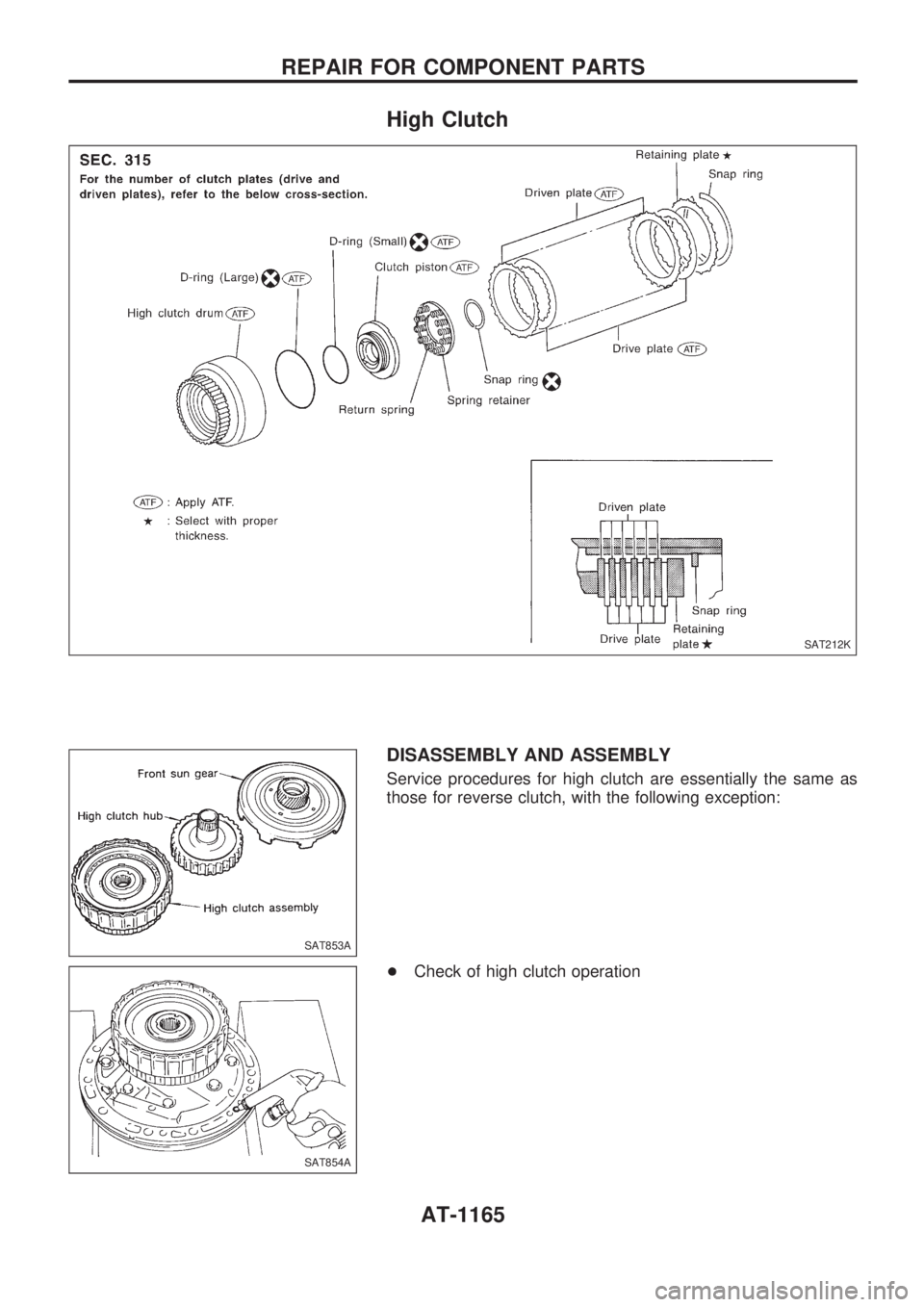

High Clutch

DISASSEMBLY AND ASSEMBLY

Service procedures for high clutch are essentially the same as

those for reverse clutch, with the following exception:

+Check of high clutch operation

SAT212K

SAT853A

SAT854A

REPAIR FOR COMPONENT PARTS

AT-1165

Page 168 of 1033

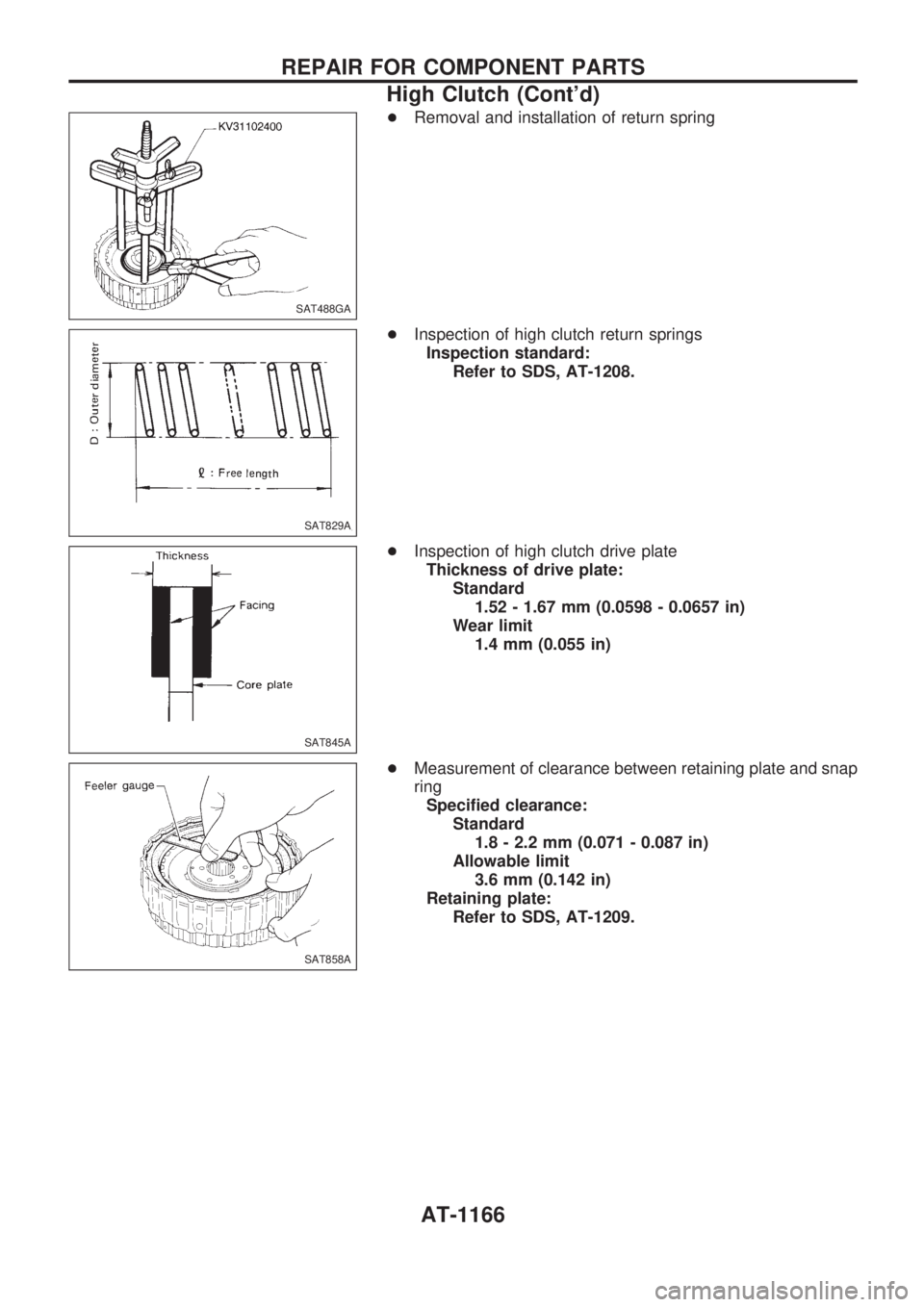

+Removal and installation of return spring

+Inspection of high clutch return springs

Inspection standard:

Refer to SDS, AT-1208.

+Inspection of high clutch drive plate

Thickness of drive plate:

Standard

1.52 - 1.67 mm (0.0598 - 0.0657 in)

Wear limit

1.4 mm (0.055 in)

+Measurement of clearance between retaining plate and snap

ring

Specified clearance:

Standard

1.8 - 2.2 mm (0.071 - 0.087 in)

Allowable limit

3.6 mm (0.142 in)

Retaining plate:

Refer to SDS, AT-1209.

SAT488GA

SAT829A

SAT845A

SAT858A

REPAIR FOR COMPONENT PARTS

High Clutch (Cont'd)

AT-1166

Page 169 of 1033

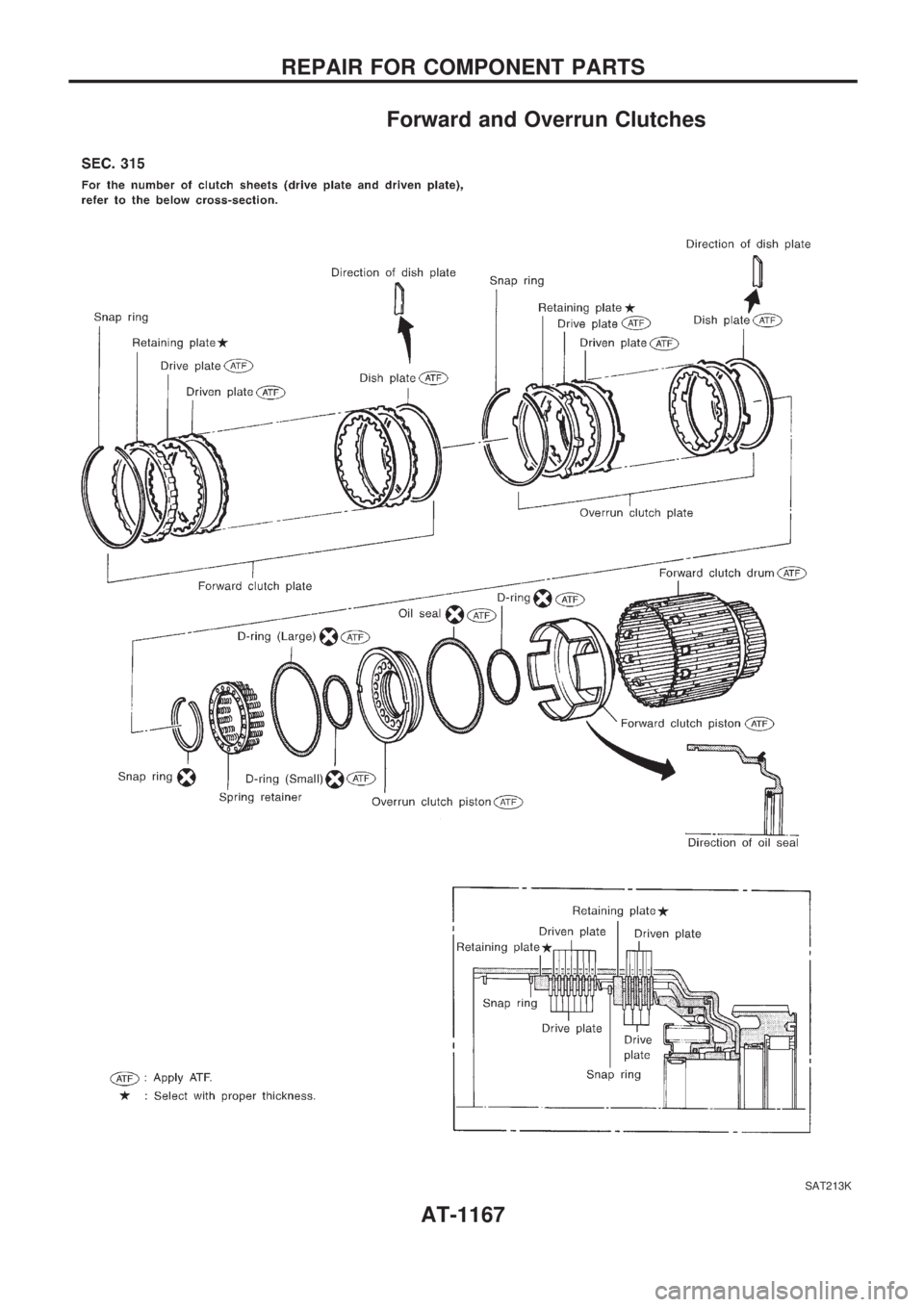

Forward and Overrun Clutches

SAT213K

REPAIR FOR COMPONENT PARTS

AT-1167

Page 170 of 1033

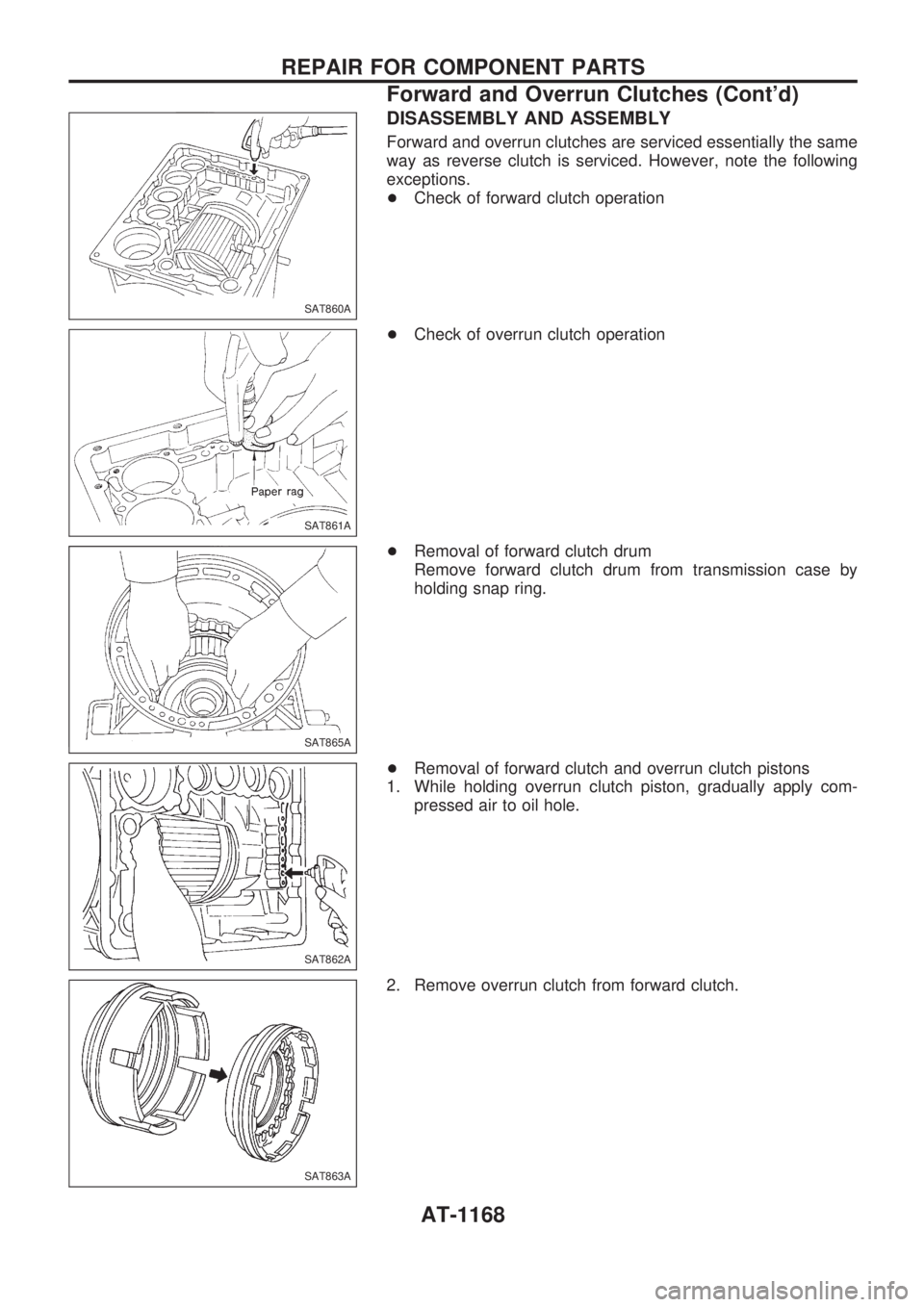

DISASSEMBLY AND ASSEMBLY

Forward and overrun clutches are serviced essentially the same

way as reverse clutch is serviced. However, note the following

exceptions.

+Check of forward clutch operation

+Check of overrun clutch operation

+Removal of forward clutch drum

Remove forward clutch drum from transmission case by

holding snap ring.

+Removal of forward clutch and overrun clutch pistons

1. While holding overrun clutch piston, gradually apply com-

pressed air to oil hole.

2. Remove overrun clutch from forward clutch.

SAT860A

SAT861A

SAT865A

SAT862A

SAT863A

REPAIR FOR COMPONENT PARTS

Forward and Overrun Clutches (Cont'd)

AT-1168

Trending: load capacity, fuel filter, emergency towing, wheelbase, change wheel, mirror, low oil pressure