NISSAN PATROL 2000 Electronic Repair Manual

PATROL 2000

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57367/w960_57367-0.png

NISSAN PATROL 2000 Electronic Repair Manual

Trending: height, fuel cap, dimensions, automatic transmission, fuse box location, torque, sun

Page 171 of 1033

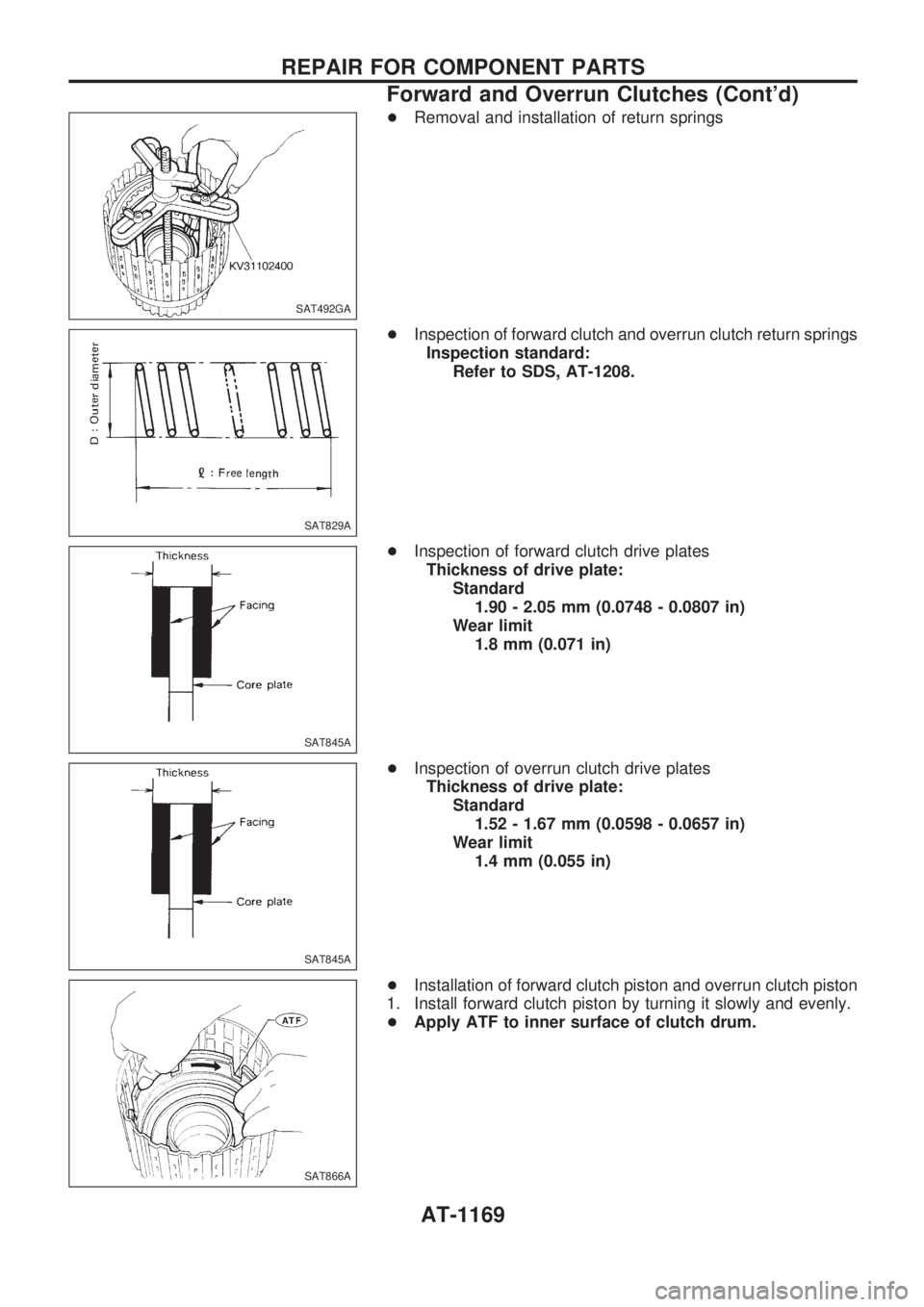

+Removal and installation of return springs

+Inspection of forward clutch and overrun clutch return springs

Inspection standard:

Refer to SDS, AT-1208.

+Inspection of forward clutch drive plates

Thickness of drive plate:

Standard

1.90 - 2.05 mm (0.0748 - 0.0807 in)

Wear limit

1.8 mm (0.071 in)

+Inspection of overrun clutch drive plates

Thickness of drive plate:

Standard

1.52 - 1.67 mm (0.0598 - 0.0657 in)

Wear limit

1.4 mm (0.055 in)

+Installation of forward clutch piston and overrun clutch piston

1. Install forward clutch piston by turning it slowly and evenly.

+Apply ATF to inner surface of clutch drum.

SAT492GA

SAT829A

SAT845A

SAT845A

SAT866A

REPAIR FOR COMPONENT PARTS

Forward and Overrun Clutches (Cont'd)

AT-1169

Page 172 of 1033

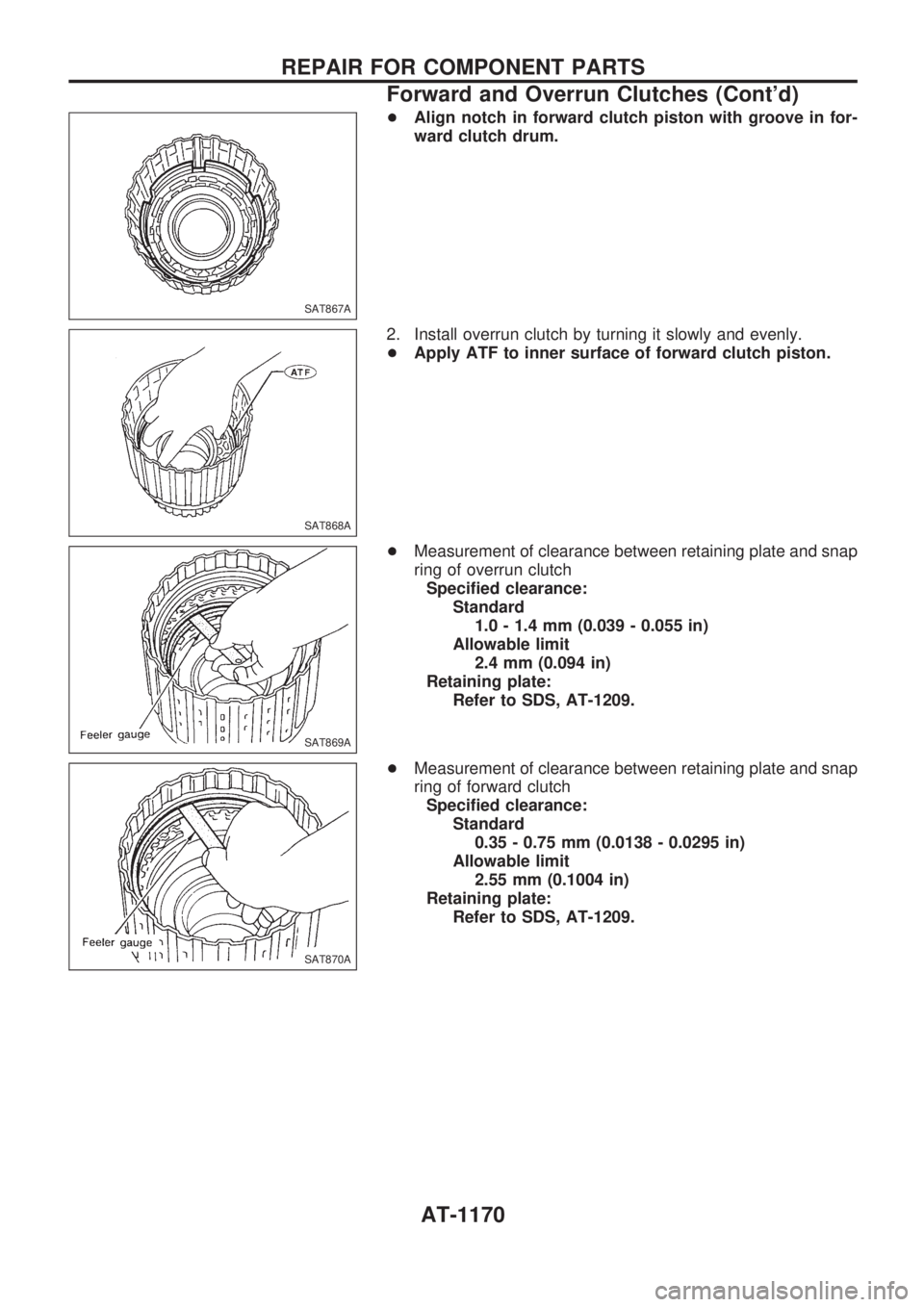

+Align notch in forward clutch piston with groove in for-

ward clutch drum.

2. Install overrun clutch by turning it slowly and evenly.

+Apply ATF to inner surface of forward clutch piston.

+Measurement of clearance between retaining plate and snap

ring of overrun clutch

Specified clearance:

Standard

1.0 - 1.4 mm (0.039 - 0.055 in)

Allowable limit

2.4 mm (0.094 in)

Retaining plate:

Refer to SDS, AT-1209.

+Measurement of clearance between retaining plate and snap

ring of forward clutch

Specified clearance:

Standard

0.35 - 0.75 mm (0.0138 - 0.0295 in)

Allowable limit

2.55 mm (0.1004 in)

Retaining plate:

Refer to SDS, AT-1209.

SAT867A

SAT868A

SAT869A

SAT870A

REPAIR FOR COMPONENT PARTS

Forward and Overrun Clutches (Cont'd)

AT-1170

Page 173 of 1033

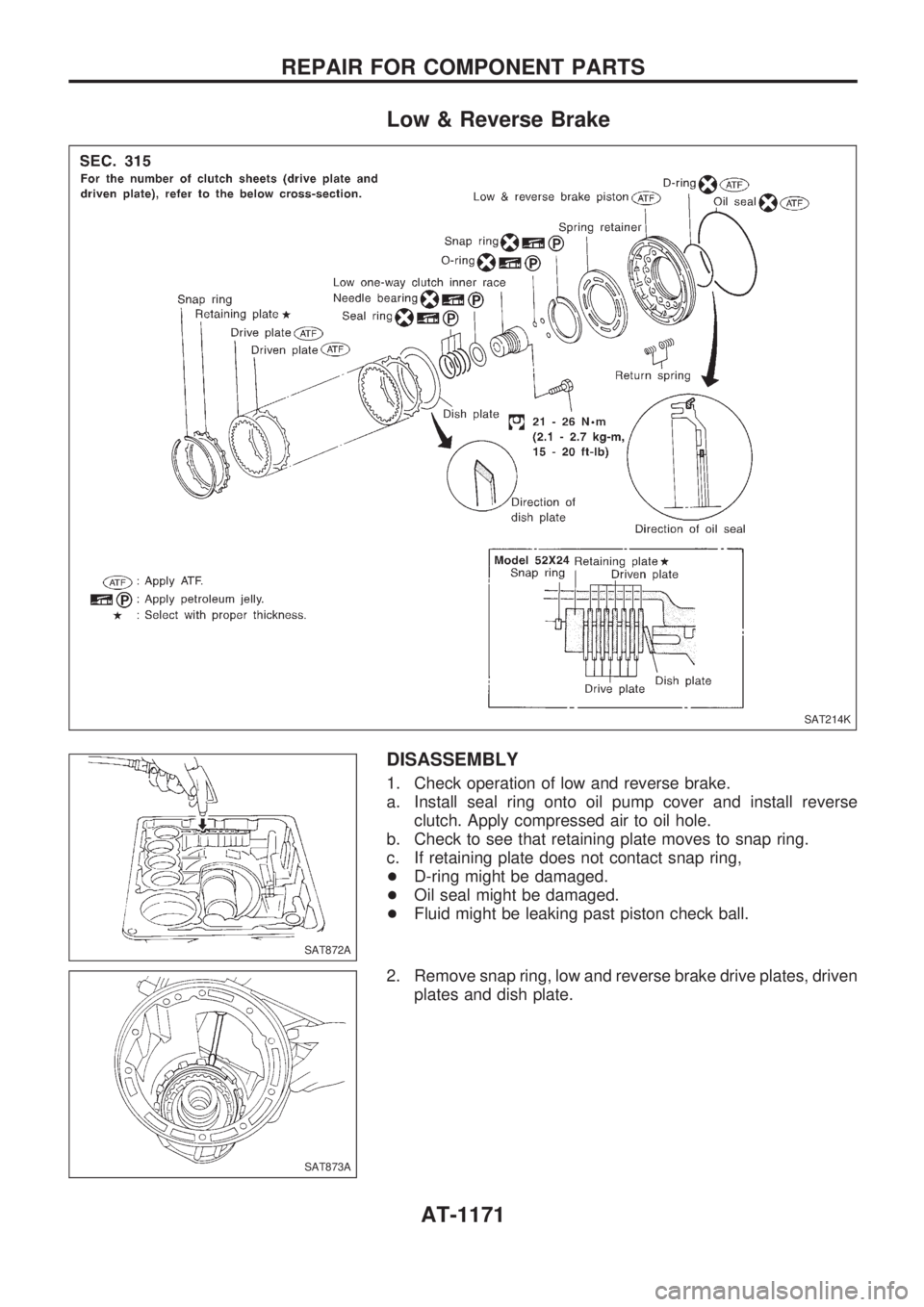

Low & Reverse Brake

DISASSEMBLY

1. Check operation of low and reverse brake.

a. Install seal ring onto oil pump cover and install reverse

clutch. Apply compressed air to oil hole.

b. Check to see that retaining plate moves to snap ring.

c. If retaining plate does not contact snap ring,

+D-ring might be damaged.

+Oil seal might be damaged.

+Fluid might be leaking past piston check ball.

2. Remove snap ring, low and reverse brake drive plates, driven

plates and dish plate.

SAT214K

SAT872A

SAT873A

REPAIR FOR COMPONENT PARTS

AT-1171

Page 174 of 1033

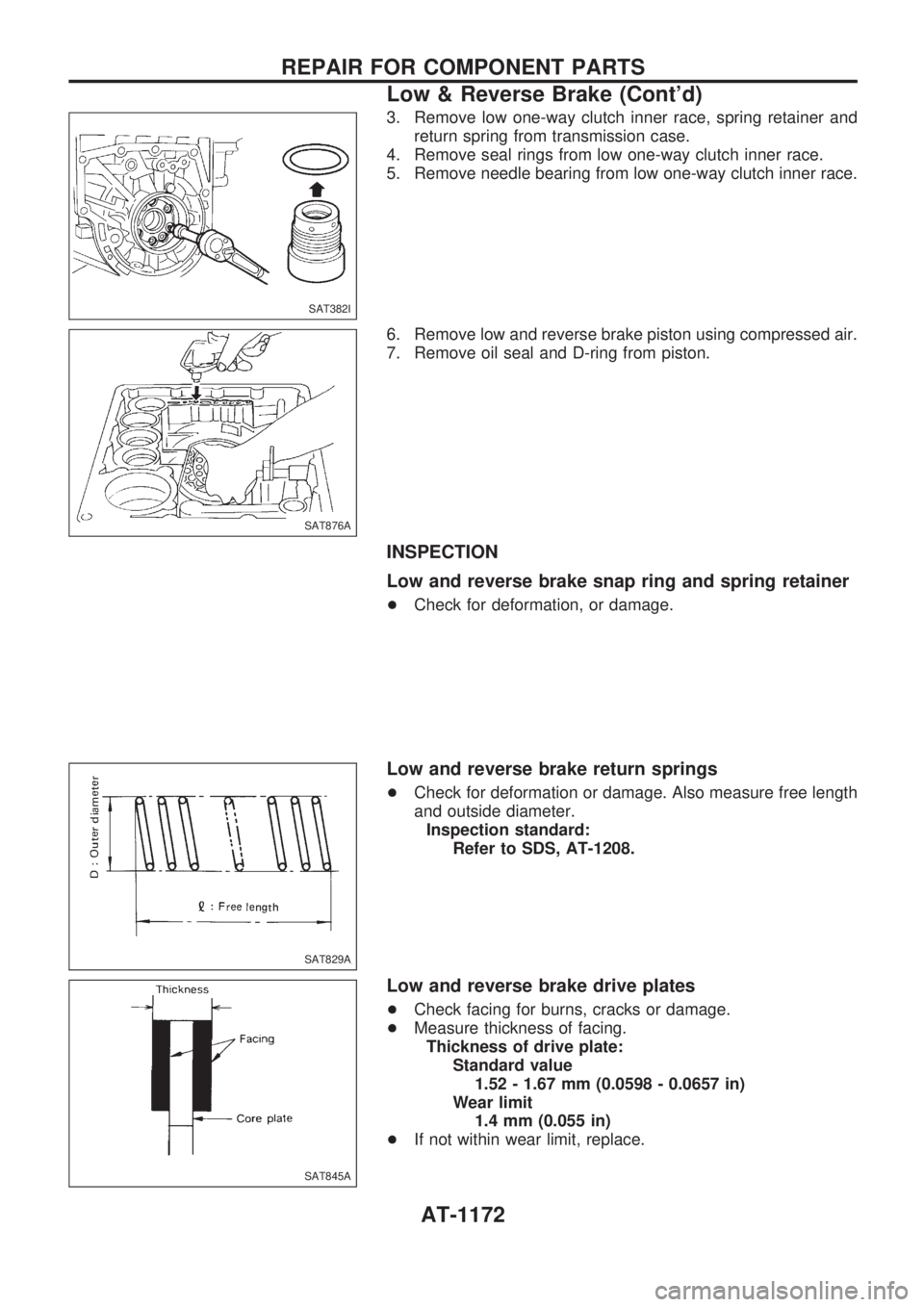

3. Remove low one-way clutch inner race, spring retainer and

return spring from transmission case.

4. Remove seal rings from low one-way clutch inner race.

5. Remove needle bearing from low one-way clutch inner race.

6. Remove low and reverse brake piston using compressed air.

7. Remove oil seal and D-ring from piston.

INSPECTION

Low and reverse brake snap ring and spring retainer

+Check for deformation, or damage.

Low and reverse brake return springs

+Check for deformation or damage. Also measure free length

and outside diameter.

Inspection standard:

Refer to SDS, AT-1208.

Low and reverse brake drive plates

+Check facing for burns, cracks or damage.

+Measure thickness of facing.

Thickness of drive plate:

Standard value

1.52 - 1.67 mm (0.0598 - 0.0657 in)

Wear limit

1.4 mm (0.055 in)

+If not within wear limit, replace.

SAT382I

SAT876A

SAT829A

SAT845A

REPAIR FOR COMPONENT PARTS

Low & Reverse Brake (Cont'd)

AT-1172

Page 175 of 1033

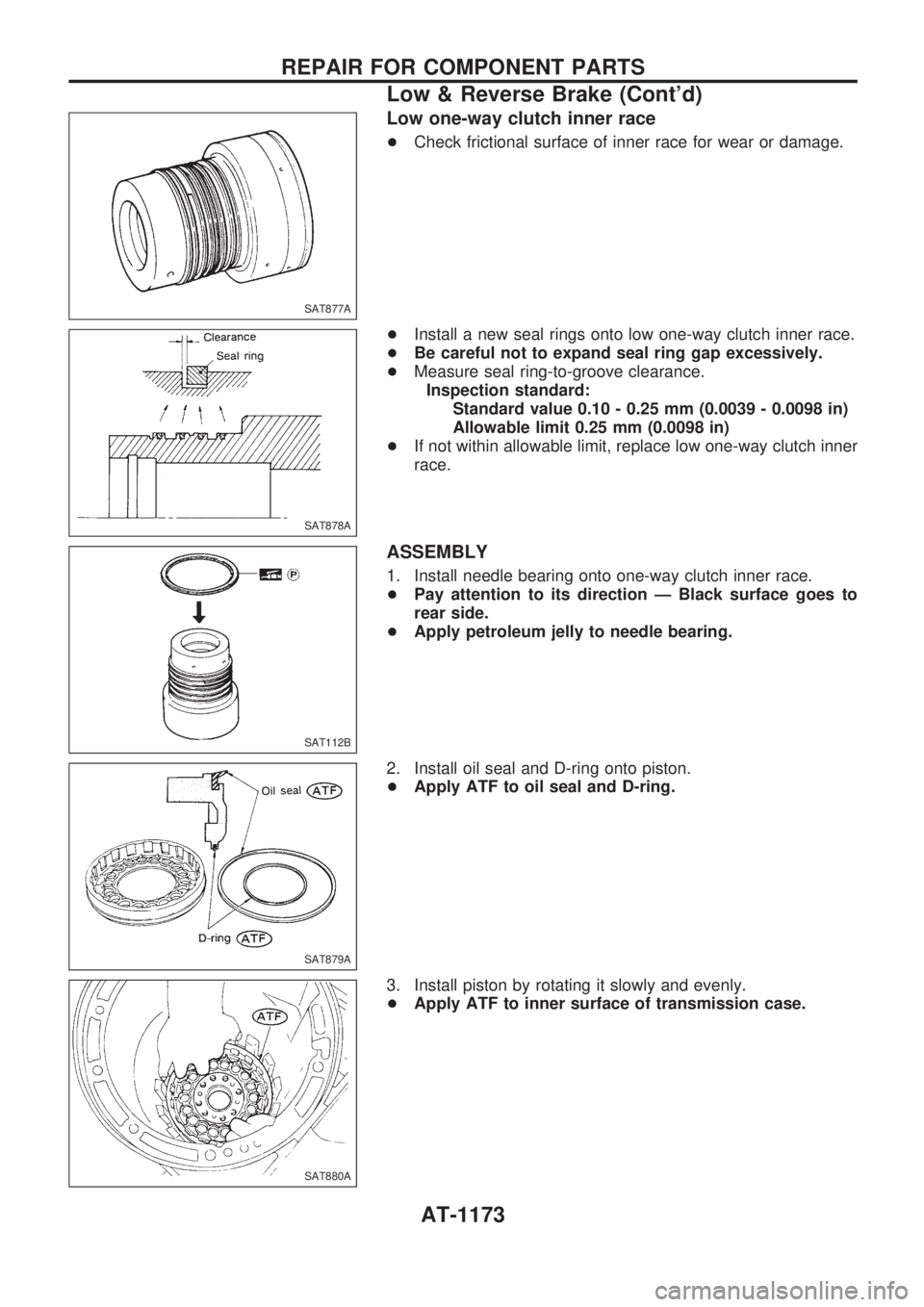

Low one-way clutch inner race

+Check frictional surface of inner race for wear or damage.

+Install a new seal rings onto low one-way clutch inner race.

+Be careful not to expand seal ring gap excessively.

+Measure seal ring-to-groove clearance.

Inspection standard:

Standard value 0.10 - 0.25 mm (0.0039 - 0.0098 in)

Allowable limit 0.25 mm (0.0098 in)

+If not within allowable limit, replace low one-way clutch inner

race.

ASSEMBLY

1. Install needle bearing onto one-way clutch inner race.

+Pay attention to its direction Ð Black surface goes to

rear side.

+Apply petroleum jelly to needle bearing.

2. Install oil seal and D-ring onto piston.

+Apply ATF to oil seal and D-ring.

3. Install piston by rotating it slowly and evenly.

+Apply ATF to inner surface of transmission case.

SAT877A

SAT878A

SAT112B

SAT879A

SAT880A

REPAIR FOR COMPONENT PARTS

Low & Reverse Brake (Cont'd)

AT-1173

Page 176 of 1033

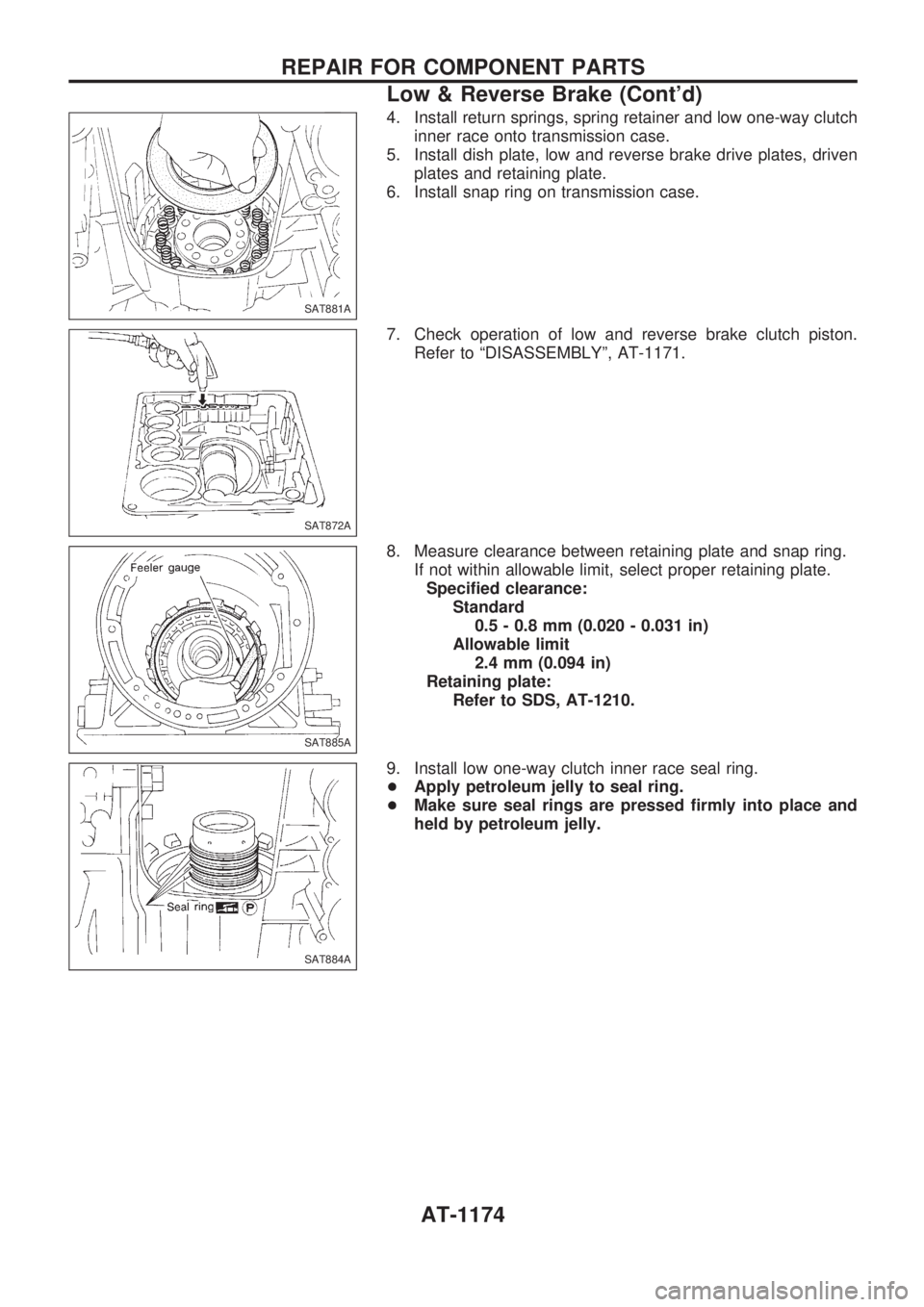

4. Install return springs, spring retainer and low one-way clutch

inner race onto transmission case.

5. Install dish plate, low and reverse brake drive plates, driven

plates and retaining plate.

6. Install snap ring on transmission case.

7. Check operation of low and reverse brake clutch piston.

Refer to ªDISASSEMBLYº, AT-1171.

8. Measure clearance between retaining plate and snap ring.

If not within allowable limit, select proper retaining plate.

Specified clearance:

Standard

0.5 - 0.8 mm (0.020 - 0.031 in)

Allowable limit

2.4 mm (0.094 in)

Retaining plate:

Refer to SDS, AT-1210.

9. Install low one-way clutch inner race seal ring.

+Apply petroleum jelly to seal ring.

+Make sure seal rings are pressed firmly into place and

held by petroleum jelly.

SAT881A

SAT872A

SAT885A

SAT884A

REPAIR FOR COMPONENT PARTS

Low & Reverse Brake (Cont'd)

AT-1174

Page 177 of 1033

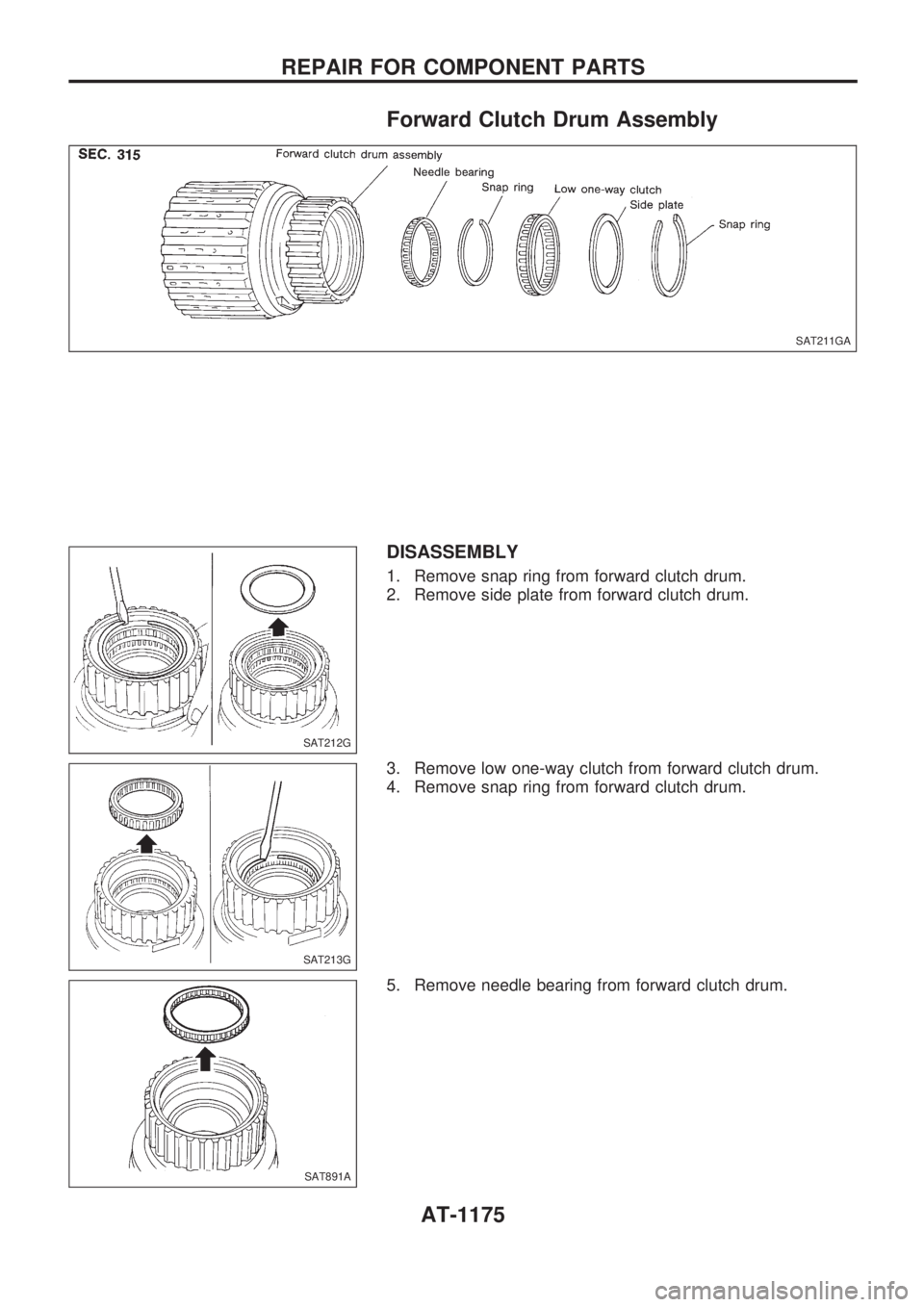

Forward Clutch Drum Assembly

DISASSEMBLY

1. Remove snap ring from forward clutch drum.

2. Remove side plate from forward clutch drum.

3. Remove low one-way clutch from forward clutch drum.

4. Remove snap ring from forward clutch drum.

5. Remove needle bearing from forward clutch drum.

SAT211GA

SAT212G

SAT213G

SAT891A

REPAIR FOR COMPONENT PARTS

AT-1175

Page 178 of 1033

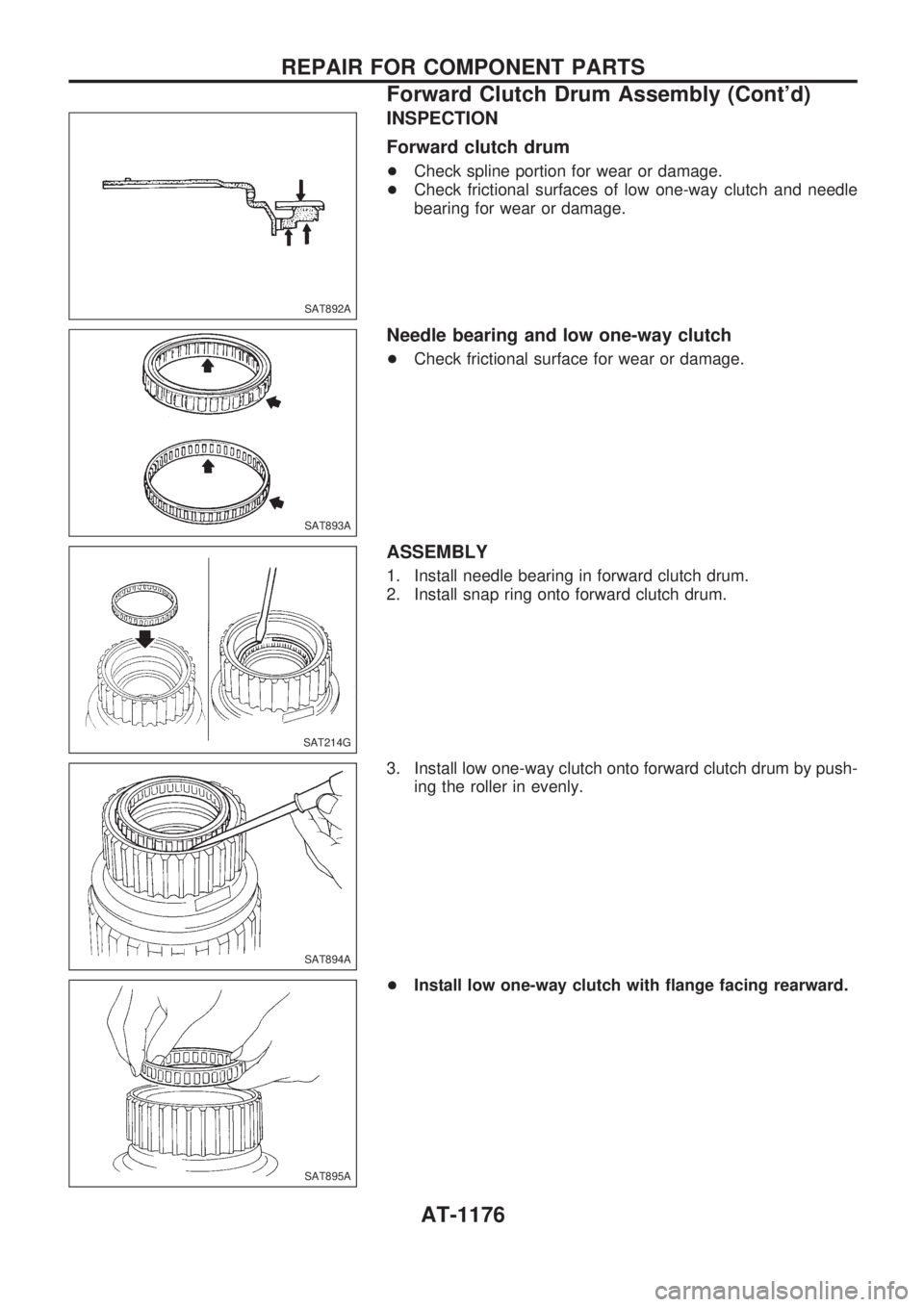

INSPECTION

Forward clutch drum

+Check spline portion for wear or damage.

+Check frictional surfaces of low one-way clutch and needle

bearing for wear or damage.

Needle bearing and low one-way clutch

+Check frictional surface for wear or damage.

ASSEMBLY

1. Install needle bearing in forward clutch drum.

2. Install snap ring onto forward clutch drum.

3. Install low one-way clutch onto forward clutch drum by push-

ing the roller in evenly.

+Install low one-way clutch with flange facing rearward.

SAT892A

SAT893A

SAT214G

SAT894A

SAT895A

REPAIR FOR COMPONENT PARTS

Forward Clutch Drum Assembly (Cont'd)

AT-1176

Page 179 of 1033

4. Install side plate onto forward clutch drum.

5. Install snap ring onto forward clutch drum.

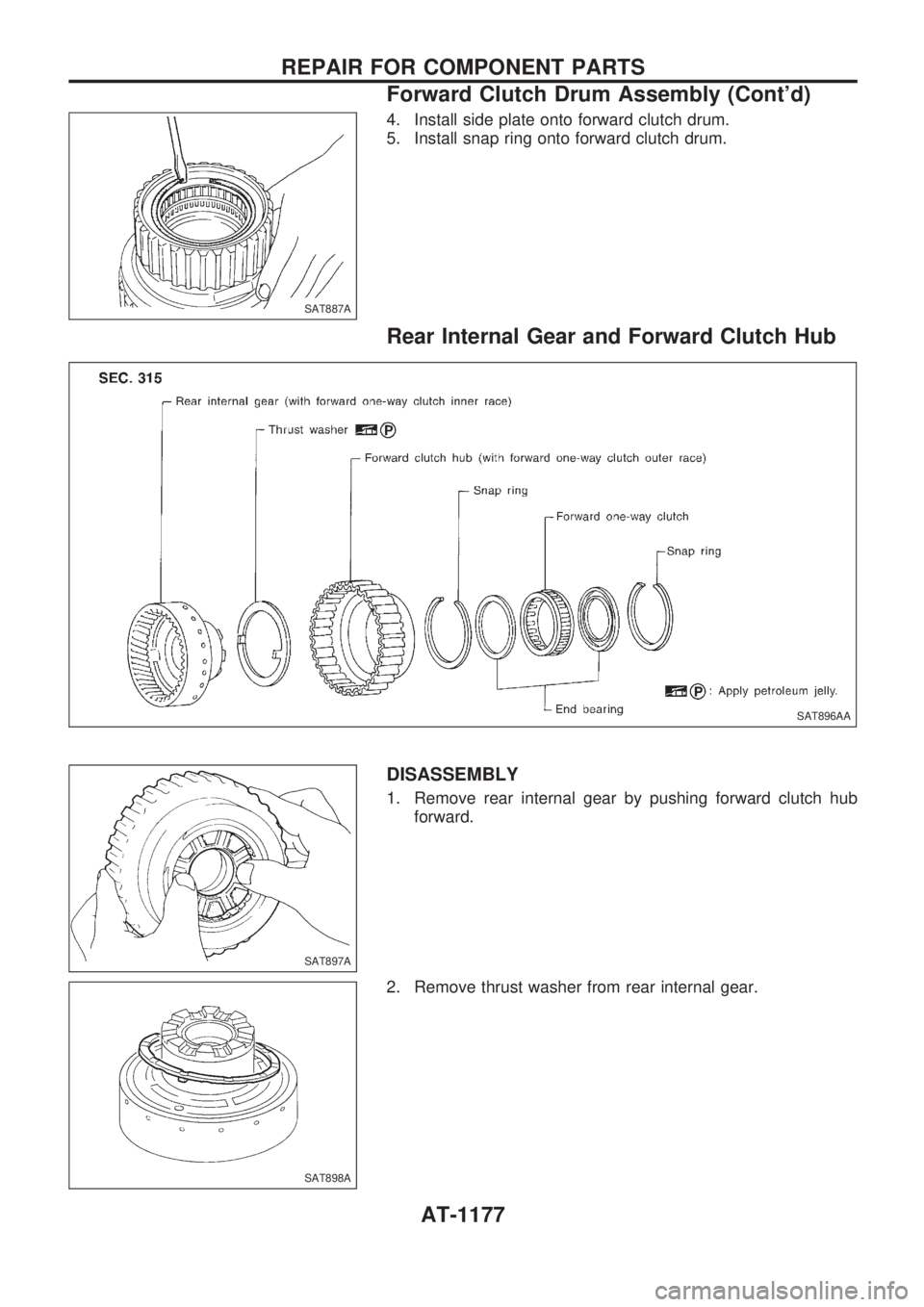

Rear Internal Gear and Forward Clutch Hub

DISASSEMBLY

1. Remove rear internal gear by pushing forward clutch hub

forward.

2. Remove thrust washer from rear internal gear.

SAT887A

SAT896AA

SAT897A

SAT898A

REPAIR FOR COMPONENT PARTS

Forward Clutch Drum Assembly (Cont'd)

AT-1177

Page 180 of 1033

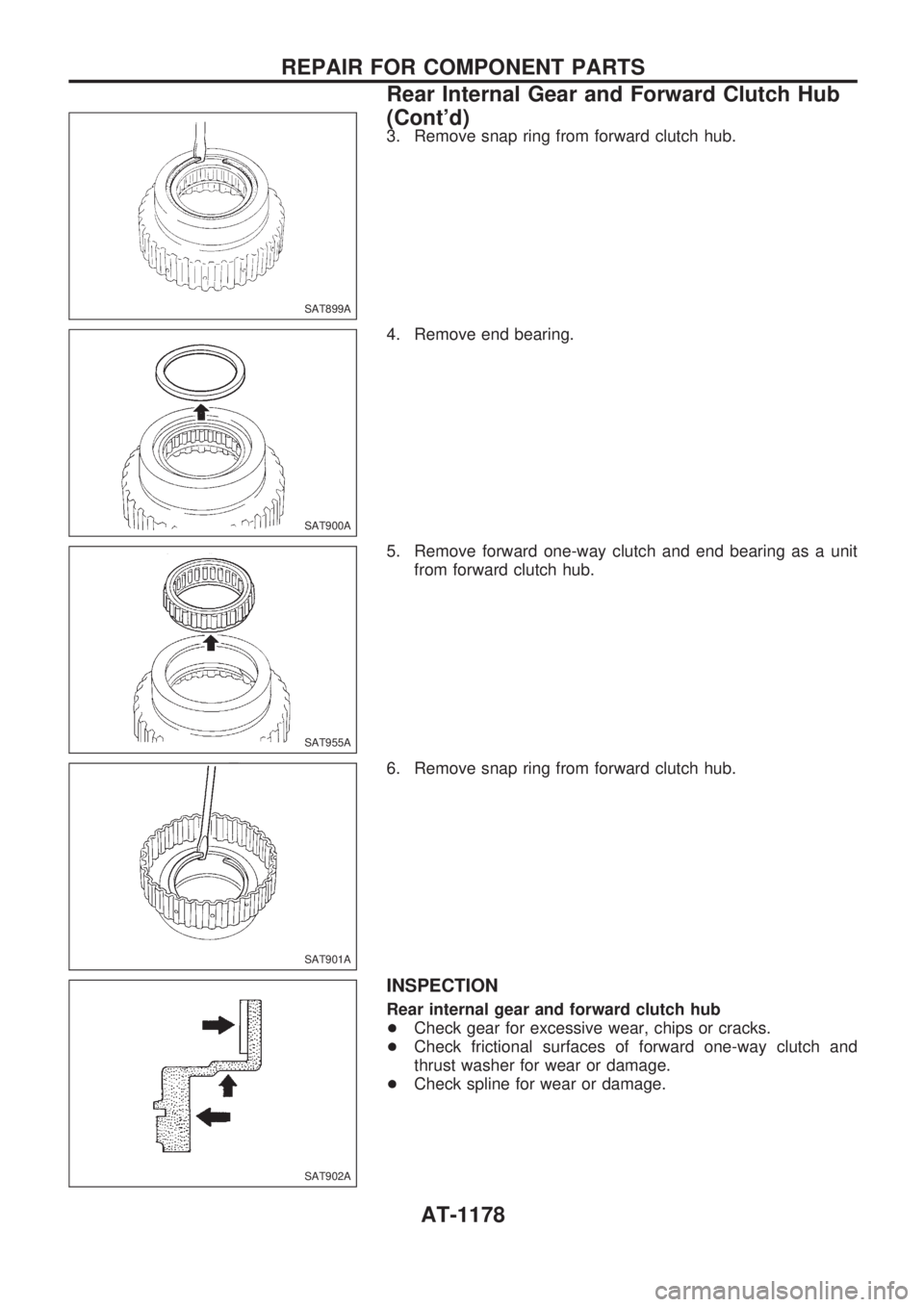

3. Remove snap ring from forward clutch hub.

4. Remove end bearing.

5. Remove forward one-way clutch and end bearing as a unit

from forward clutch hub.

6. Remove snap ring from forward clutch hub.

INSPECTION

Rear internal gear and forward clutch hub

+Check gear for excessive wear, chips or cracks.

+Check frictional surfaces of forward one-way clutch and

thrust washer for wear or damage.

+Check spline for wear or damage.

SAT899A

SAT900A

SAT955A

SAT901A

SAT902A

REPAIR FOR COMPONENT PARTS

Rear Internal Gear and Forward Clutch Hub

(Cont'd)

AT-1178

Trending: tow, cooling, radiator, compression ratio, air suspension, headlamp, heating