NISSAN PATROL 2000 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 781 of 1033

IDLER GEAR END PLAY

+Tighten the holding bolts to the specification.

+Measure the clearance between the gear plate and idler gear

using a feeler gauge.

Unit: mm (in)

Standard Limit

Idler gear (A)

0.06 - 0.12

(0.0024 - 0.0047)0.15 (0.0059)

Idler gear (B)

+If it exceeds the limit, replace the idler gear, shaft, and gear

plate.

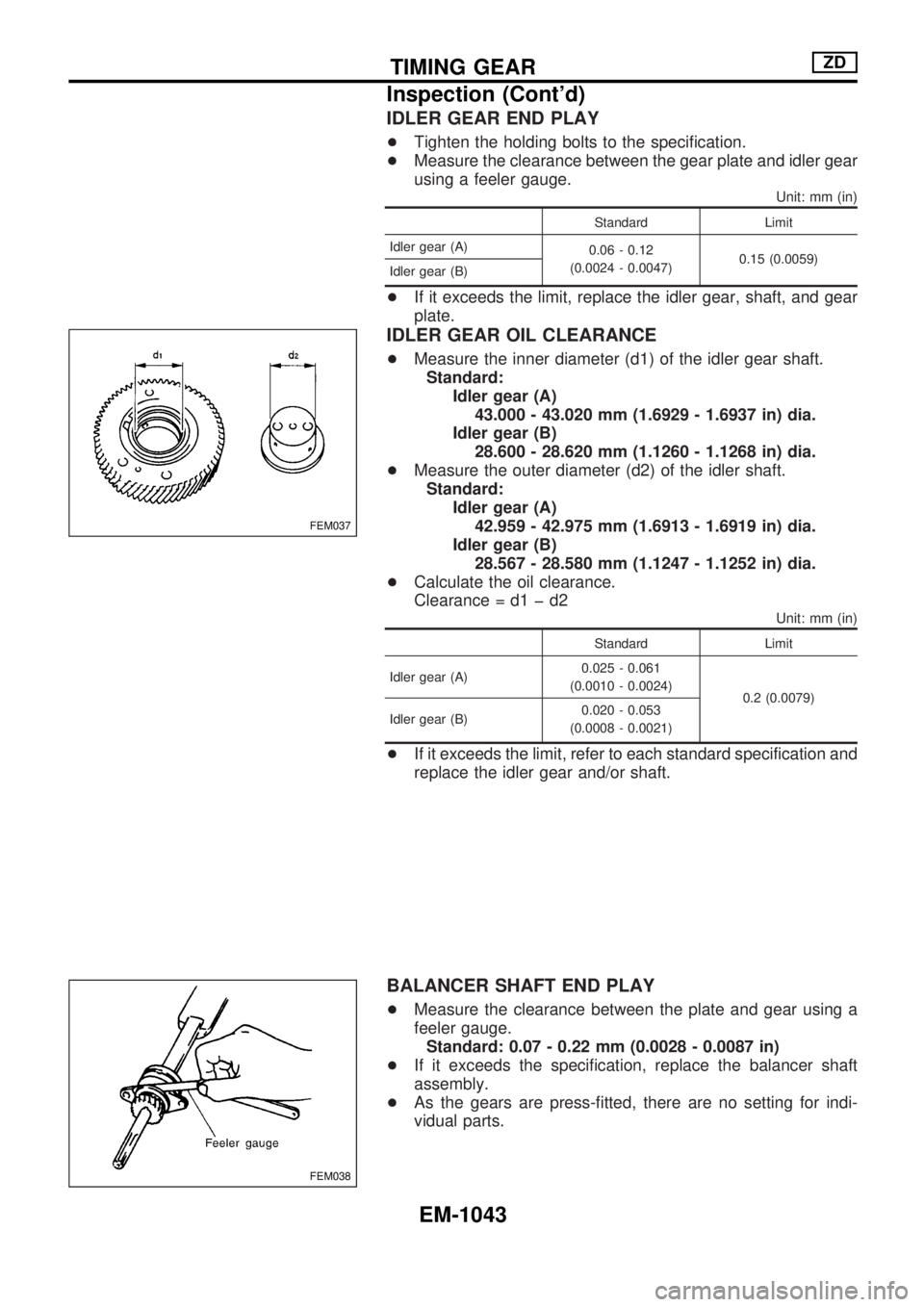

IDLER GEAR OIL CLEARANCE

+Measure the inner diameter (d1) of the idler gear shaft.

Standard:

Idler gear (A)

43.000 - 43.020 mm (1.6929 - 1.6937 in) dia.

Idler gear (B)

28.600 - 28.620 mm (1.1260 - 1.1268 in) dia.

+Measure the outer diameter (d2) of the idler shaft.

Standard:

Idler gear (A)

42.959 - 42.975 mm (1.6913 - 1.6919 in) dia.

Idler gear (B)

28.567 - 28.580 mm (1.1247 - 1.1252 in) dia.

+Calculate the oil clearance.

Clearance = d1 þ d2

Unit: mm (in)

Standard Limit

Idler gear (A)0.025 - 0.061

(0.0010 - 0.0024)

0.2 (0.0079)

Idler gear (B)0.020 - 0.053

(0.0008 - 0.0021)

+If it exceeds the limit, refer to each standard specification and

replace the idler gear and/or shaft.

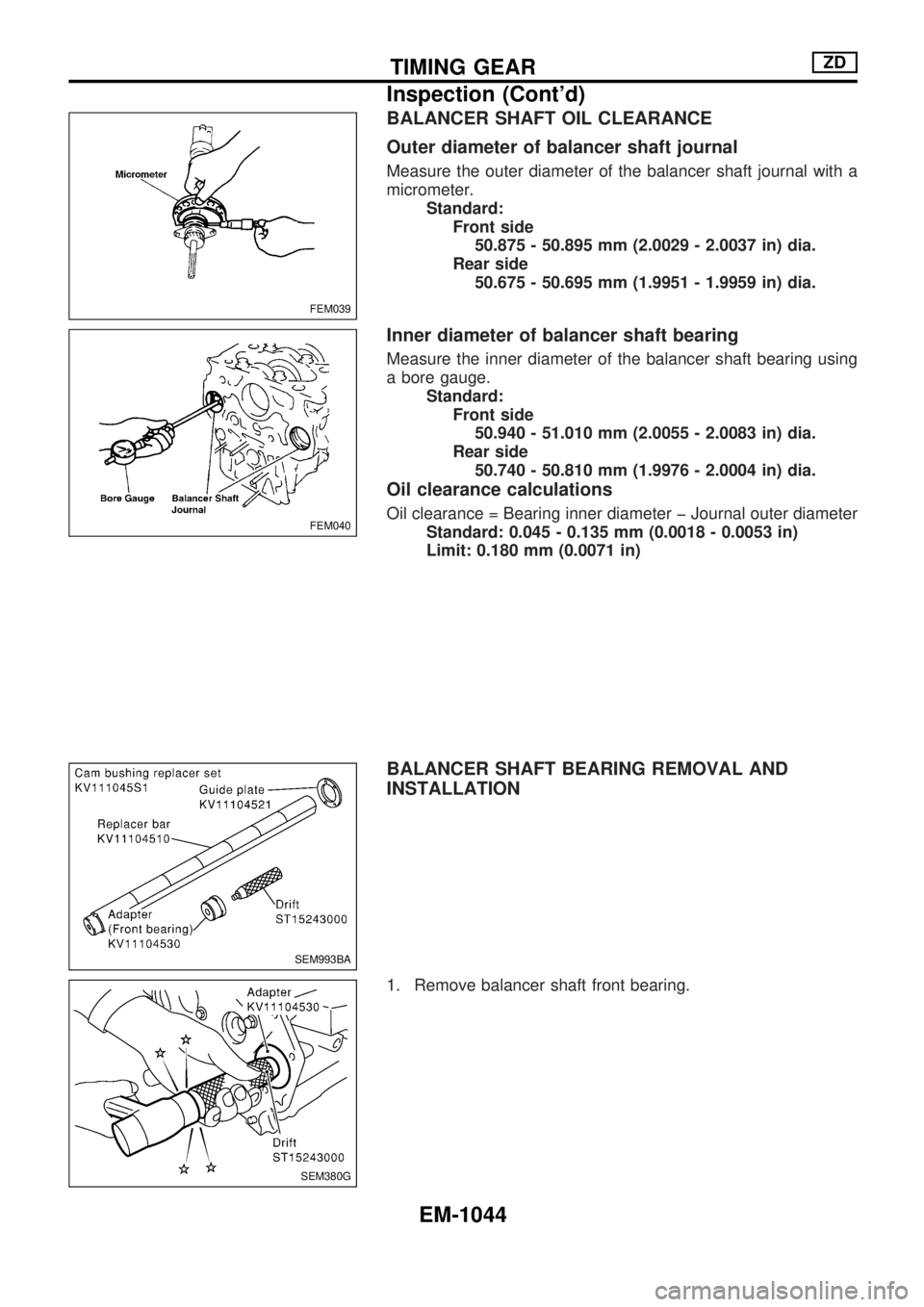

BALANCER SHAFT END PLAY

+Measure the clearance between the plate and gear using a

feeler gauge.

Standard: 0.07 - 0.22 mm (0.0028 - 0.0087 in)

+If it exceeds the specification, replace the balancer shaft

assembly.

+As the gears are press-fitted, there are no setting for indi-

vidual parts.

FEM037

FEM038

TIMING GEARZD

Inspection (Cont'd)

EM-1043

Page 782 of 1033

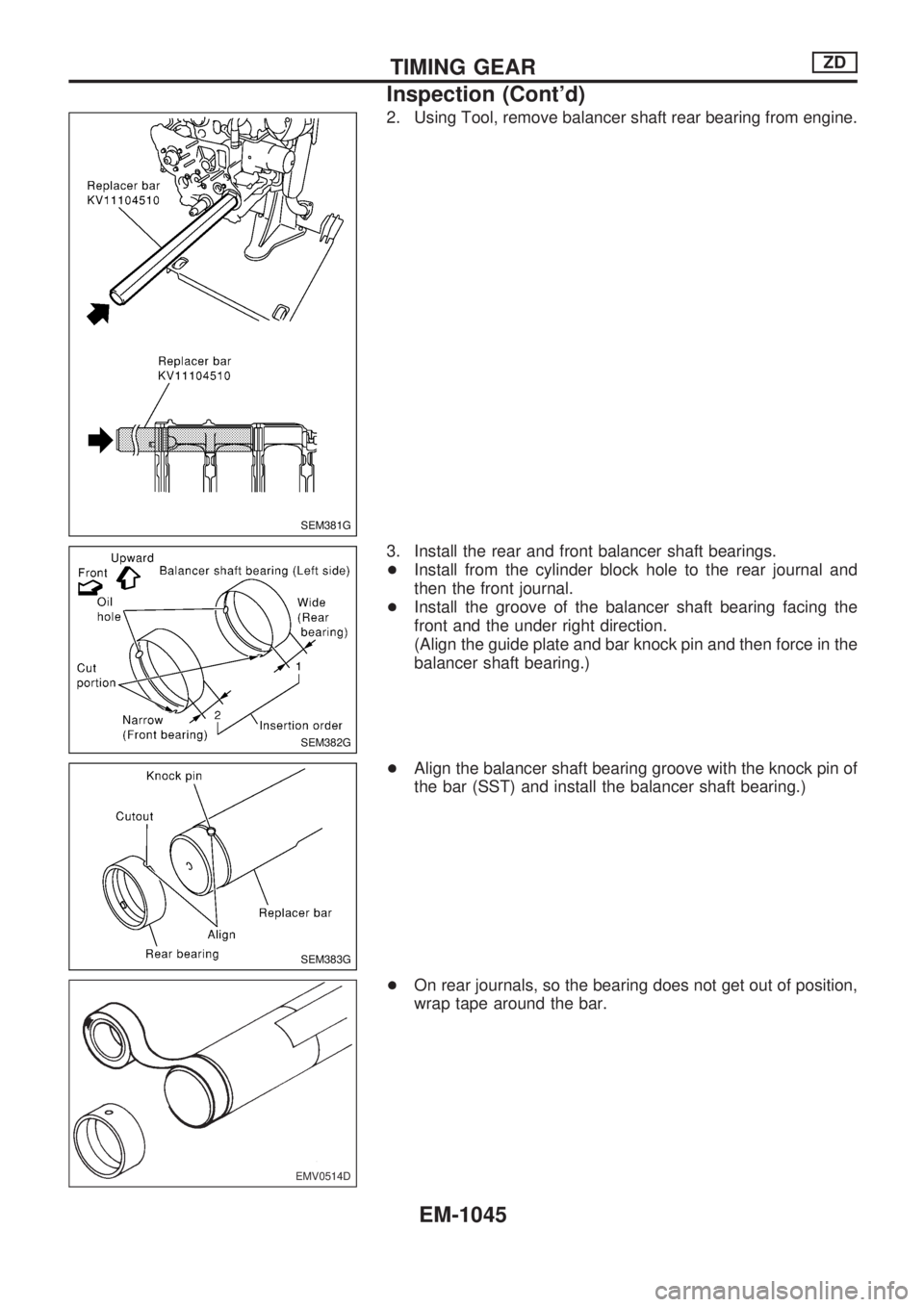

BALANCER SHAFT OIL CLEARANCE

Outer diameter of balancer shaft journal

Measure the outer diameter of the balancer shaft journal with a

micrometer.

Standard:

Front side

50.875 - 50.895 mm (2.0029 - 2.0037 in) dia.

Rear side

50.675 - 50.695 mm (1.9951 - 1.9959 in) dia.

Inner diameter of balancer shaft bearing

Measure the inner diameter of the balancer shaft bearing using

a bore gauge.

Standard:

Front side

50.940 - 51.010 mm (2.0055 - 2.0083 in) dia.

Rear side

50.740 - 50.810 mm (1.9976 - 2.0004 in) dia.

Oil clearance calculations

Oil clearance = Bearing inner diameter þ Journal outer diameter

Standard: 0.045 - 0.135 mm (0.0018 - 0.0053 in)

Limit: 0.180 mm (0.0071 in)

BALANCER SHAFT BEARING REMOVAL AND

INSTALLATION

1. Remove balancer shaft front bearing.

FEM039

FEM040

SEM993BA

SEM380G

TIMING GEARZD

Inspection (Cont'd)

EM-1044

Page 783 of 1033

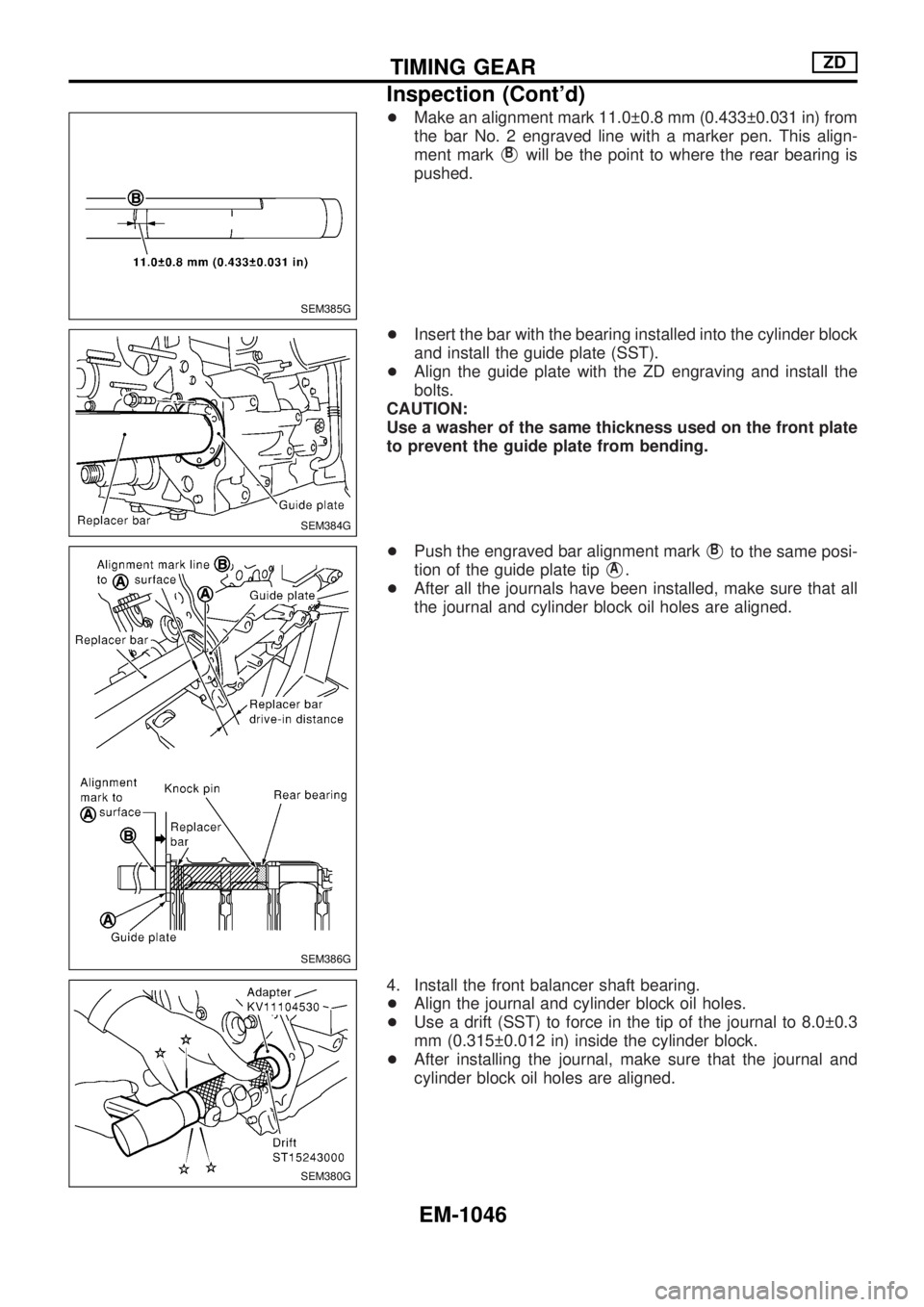

2. Using Tool, remove balancer shaft rear bearing from engine.

3. Install the rear and front balancer shaft bearings.

+Install from the cylinder block hole to the rear journal and

then the front journal.

+Install the groove of the balancer shaft bearing facing the

front and the under right direction.

(Align the guide plate and bar knock pin and then force in the

balancer shaft bearing.)

+Align the balancer shaft bearing groove with the knock pin of

the bar (SST) and install the balancer shaft bearing.)

+On rear journals, so the bearing does not get out of position,

wrap tape around the bar.

SEM381G

SEM382G

SEM383G

EMV0514D

TIMING GEARZD

Inspection (Cont'd)

EM-1045

Page 784 of 1033

+Make an alignment mark 11.0 0.8 mm (0.433 0.031 in) from

the bar No. 2 engraved line with a marker pen. This align-

ment mark

VBwill be the point to where the rear bearing is

pushed.

+Insert the bar with the bearing installed into the cylinder block

and install the guide plate (SST).

+Align the guide plate with the ZD engraving and install the

bolts.

CAUTION:

Use a washer of the same thickness used on the front plate

to prevent the guide plate from bending.

+Push the engraved bar alignment mark

VBto the same posi-

tion of the guide plate tip

VA.

+After all the journals have been installed, make sure that all

the journal and cylinder block oil holes are aligned.

4. Install the front balancer shaft bearing.

+Align the journal and cylinder block oil holes.

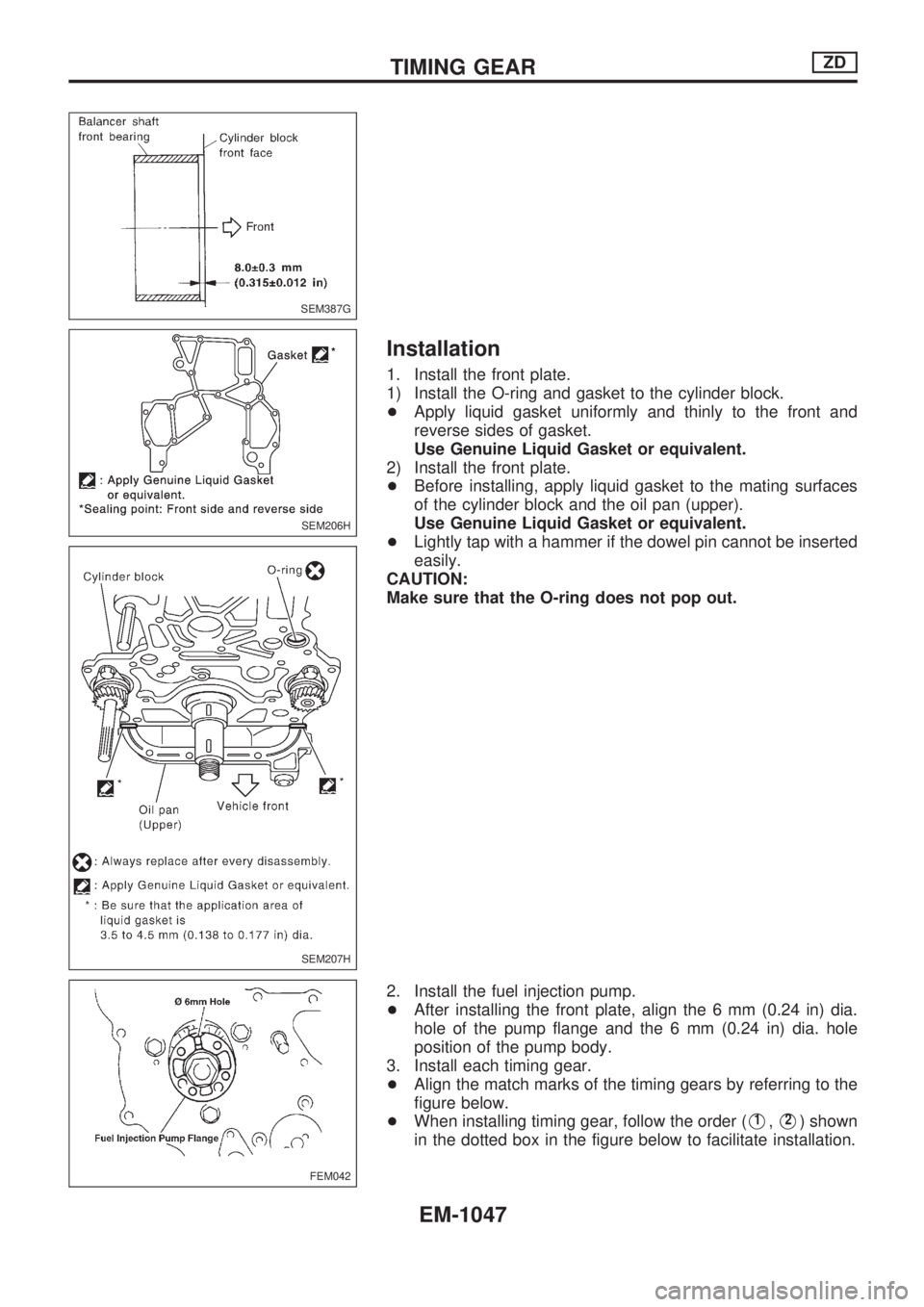

+Use a drift (SST) to force in the tip of the journal to 8.0 0.3

mm (0.315 0.012 in) inside the cylinder block.

+After installing the journal, make sure that the journal and

cylinder block oil holes are aligned.

SEM385G

SEM384G

SEM386G

SEM380G

TIMING GEARZD

Inspection (Cont'd)

EM-1046

Page 785 of 1033

Installation

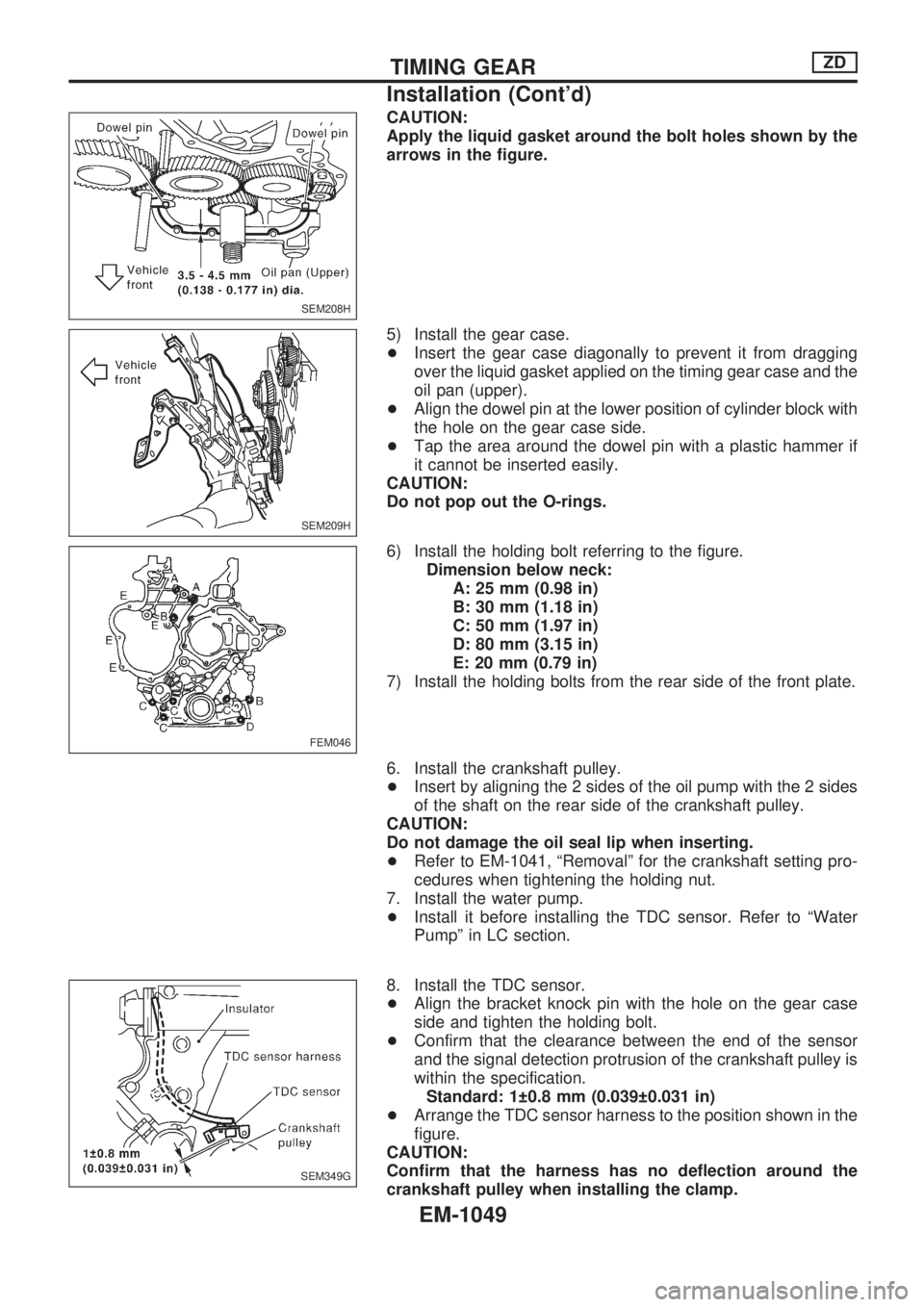

1. Install the front plate.

1) Install the O-ring and gasket to the cylinder block.

+Apply liquid gasket uniformly and thinly to the front and

reverse sides of gasket.

Use Genuine Liquid Gasket or equivalent.

2) Install the front plate.

+Before installing, apply liquid gasket to the mating surfaces

of the cylinder block and the oil pan (upper).

Use Genuine Liquid Gasket or equivalent.

+Lightly tap with a hammer if the dowel pin cannot be inserted

easily.

CAUTION:

Make sure that the O-ring does not pop out.

2. Install the fuel injection pump.

+After installing the front plate, align the 6 mm (0.24 in) dia.

hole of the pump flange and the 6 mm (0.24 in) dia. hole

position of the pump body.

3. Install each timing gear.

+Align the match marks of the timing gears by referring to the

figure below.

+When installing timing gear, follow the order (

V1,V2) shown

in the dotted box in the figure below to facilitate installation.

FEM042

SEM387G

SEM206H

SEM207H

TIMING GEARZD

EM-1047

Page 786 of 1033

![NISSAN PATROL 2000 Electronic Repair Manual 4. Install the front oil seal to the gear case.

+Apply engine oil to the fitting side.

+Evenly insert the front oil seal using a drift [outer dia.: approx.

64 mm (2.52 in)] completely.

CAUTION:

Make s NISSAN PATROL 2000 Electronic Repair Manual 4. Install the front oil seal to the gear case.

+Apply engine oil to the fitting side.

+Evenly insert the front oil seal using a drift [outer dia.: approx.

64 mm (2.52 in)] completely.

CAUTION:

Make s](/img/5/57367/w960_57367-785.png)

4. Install the front oil seal to the gear case.

+Apply engine oil to the fitting side.

+Evenly insert the front oil seal using a drift [outer dia.: approx.

64 mm (2.52 in)] completely.

CAUTION:

Make sure the oil seal does not spill off the end side of the

gear case.

5. Install the gear case.

1) Before installing gear case, remove all traces of liquid gas-

ket from mating surface using a scraper.

2) Align gasket with dowel and install.

3) Install the O-rings to the gear case.

+The O-ring at the top position shown in the figure can be

installed in during cylinder head installation.

4) Apply a continuous bead of liquid gasket to gear case and oil

pan (upper).

+Use Genuine Liquid Gasket or equivalent.

a. Coat of liquid gasket should be maintained within the

specified range as shown in the figure.

b. Attach gear case to cylinder block within 5 minutes after

coating.

c. Wait at least 30 minutes before refilling engine oil or

starting engine.

FEM043

FEM044

SEM353G

FEM045

TIMING GEARZD

Installation (Cont'd)

EM-1048

Page 787 of 1033

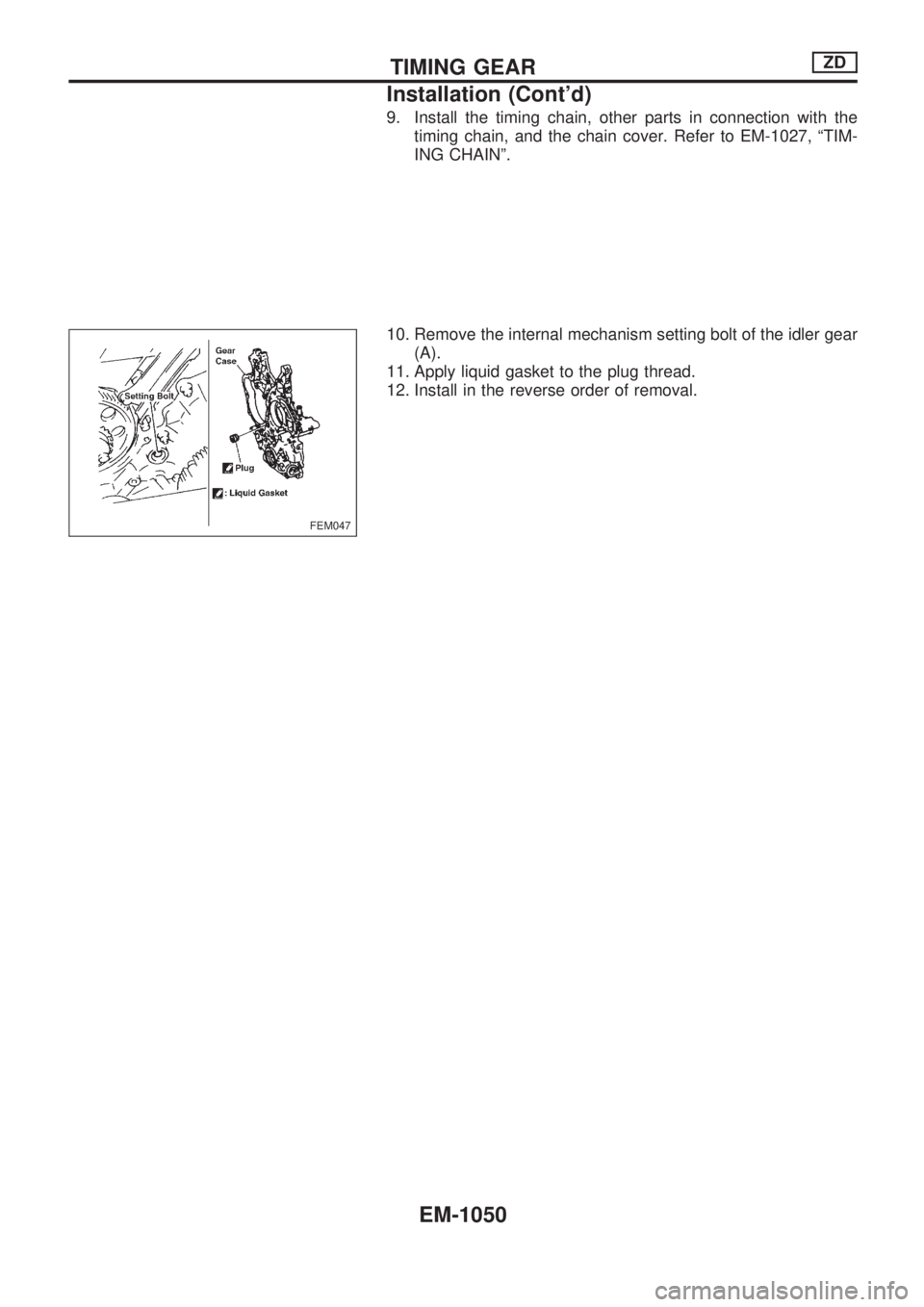

CAUTION:

Apply the liquid gasket around the bolt holes shown by the

arrows in the figure.

5) Install the gear case.

+Insert the gear case diagonally to prevent it from dragging

over the liquid gasket applied on the timing gear case and the

oil pan (upper).

+Align the dowel pin at the lower position of cylinder block with

the hole on the gear case side.

+Tap the area around the dowel pin with a plastic hammer if

it cannot be inserted easily.

CAUTION:

Do not pop out the O-rings.

6) Install the holding bolt referring to the figure.

Dimension below neck:

A: 25 mm (0.98 in)

B: 30 mm (1.18 in)

C: 50 mm (1.97 in)

D: 80 mm (3.15 in)

E: 20 mm (0.79 in)

7) Install the holding bolts from the rear side of the front plate.

6. Install the crankshaft pulley.

+Insert by aligning the 2 sides of the oil pump with the 2 sides

of the shaft on the rear side of the crankshaft pulley.

CAUTION:

Do not damage the oil seal lip when inserting.

+Refer to EM-1041, ªRemovalº for the crankshaft setting pro-

cedures when tightening the holding nut.

7. Install the water pump.

+Install it before installing the TDC sensor. Refer to ªWater

Pumpº in LC section.

8. Install the TDC sensor.

+Align the bracket knock pin with the hole on the gear case

side and tighten the holding bolt.

+Confirm that the clearance between the end of the sensor

and the signal detection protrusion of the crankshaft pulley is

within the specification.

Standard: 1 0.8 mm (0.039 0.031 in)

+Arrange the TDC sensor harness to the position shown in the

figure.

CAUTION:

Confirm that the harness has no deflection around the

crankshaft pulley when installing the clamp.

SEM208H

SEM209H

FEM046

SEM349G

TIMING GEARZD

Installation (Cont'd)

EM-1049

Page 788 of 1033

9. Install the timing chain, other parts in connection with the

timing chain, and the chain cover. Refer to EM-1027, ªTIM-

ING CHAINº.

10. Remove the internal mechanism setting bolt of the idler gear

(A).

11. Apply liquid gasket to the plug thread.

12. Install in the reverse order of removal.

FEM047

TIMING GEARZD

Installation (Cont'd)

EM-1050

Page 789 of 1033

VALVE OIL SEAL

1. Remove timing chain. Refer to EM-1027, ªTIMING CHAINº.

2. Remove injection nozzle assembly. Refer to ªInjection Tube

and Injection Nozzleº in ªBASIC SERVICE PROCEDUREº in

EC section.

3. Remove camshaft. Refer to EM-1031, ªCAMSHAFTº.

4. Remove valve lifters and mark order No. on each lifter.

5. Replace valve oil seal according to the following procedure.

When replacing valve oil seal, set the corresponding piston

at TDC. Failure to do so causes the valve to drop into the

cylinder.

1) Set No. 1 cylinder at TDC.

2) Remove valve springs and valve oil seals for No. 1 and No.

4 cylinders. Valve spring seats should not be removed.

3) Install new valve oil seals for No. 1 and No. 4 cylinders as

illustrated. Reinstall valve springs. (pink paint side toward

cylinder head)

4) Install valve spring retainers on intake valves and valve rota-

tors on exhaust valves, and remount valve assembly.

5) Set No. 2 cylinder at TDC.

6) Replace valve oil seals for No. 2 and No. 3 cylinders accord-

ing to steps 2) and 3).

7) Install valve lifters in original positions.

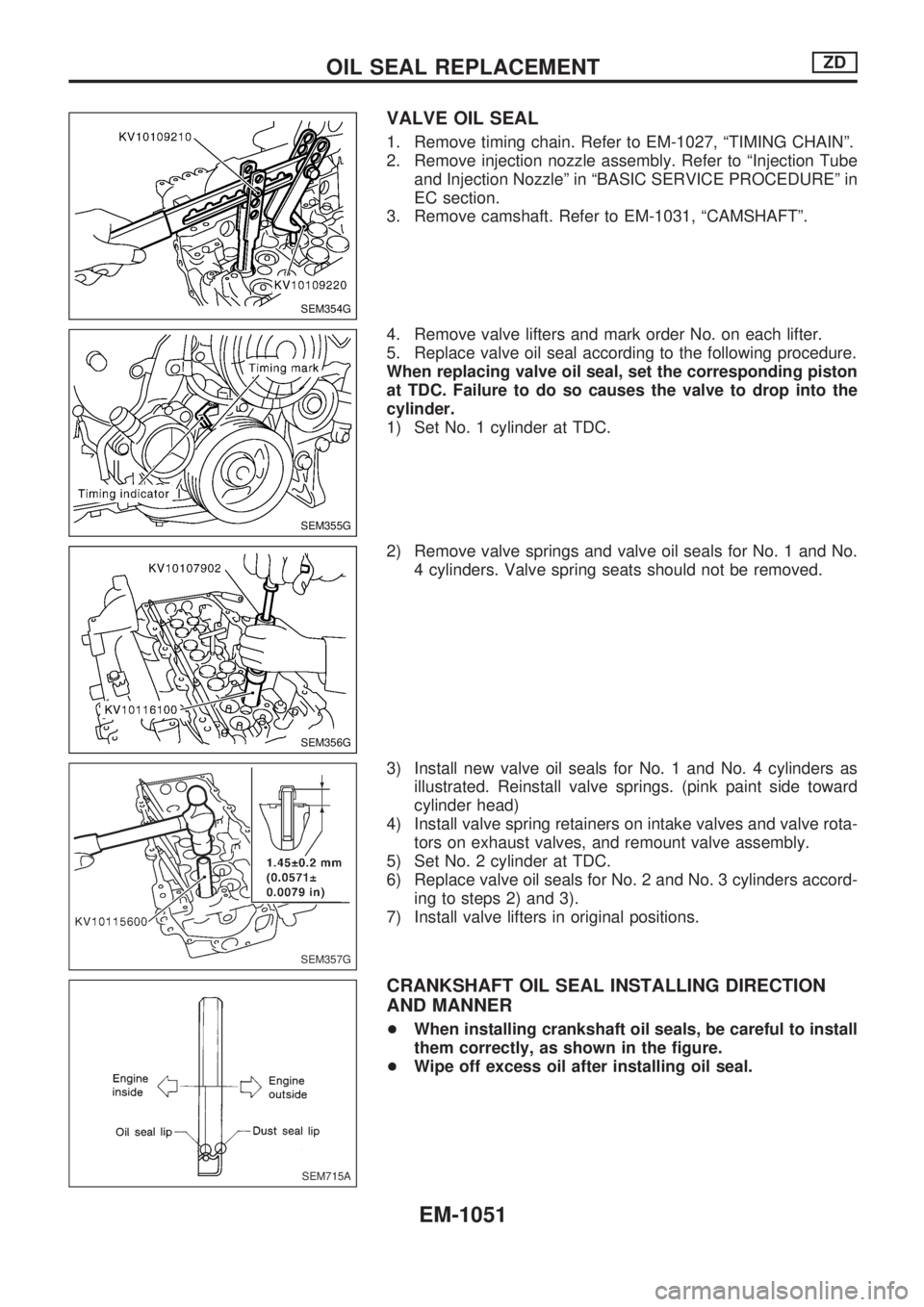

CRANKSHAFT OIL SEAL INSTALLING DIRECTION

AND MANNER

+When installing crankshaft oil seals, be careful to install

them correctly, as shown in the figure.

+Wipe off excess oil after installing oil seal.

SEM354G

SEM355G

SEM356G

SEM357G

SEM715A

OIL SEAL REPLACEMENTZD

EM-1051

Page 790 of 1033

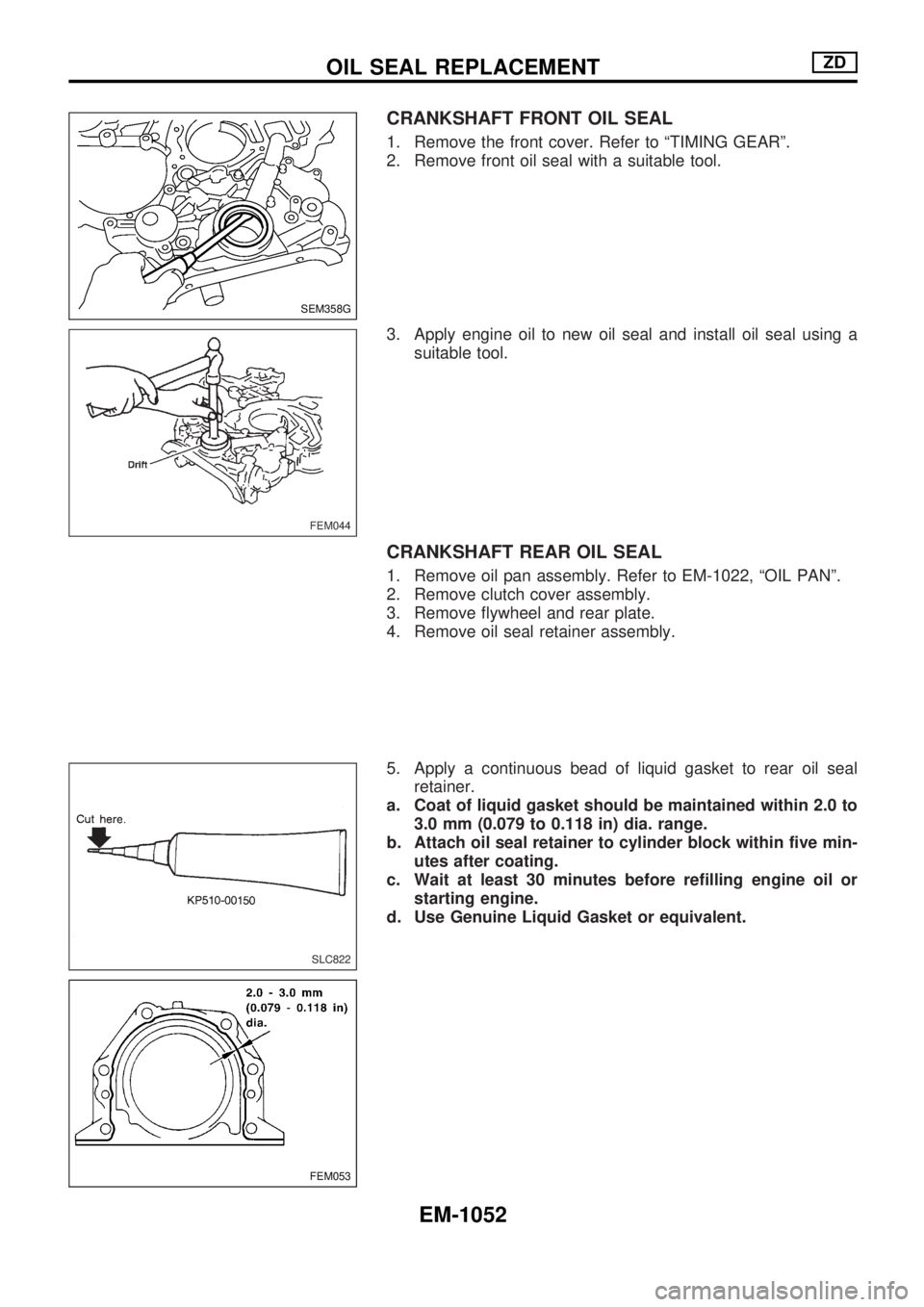

CRANKSHAFT FRONT OIL SEAL

1. Remove the front cover. Refer to ªTIMING GEARº.

2. Remove front oil seal with a suitable tool.

3. Apply engine oil to new oil seal and install oil seal using a

suitable tool.

CRANKSHAFT REAR OIL SEAL

1. Remove oil pan assembly. Refer to EM-1022, ªOIL PANº.

2. Remove clutch cover assembly.

3. Remove flywheel and rear plate.

4. Remove oil seal retainer assembly.

5. Apply a continuous bead of liquid gasket to rear oil seal

retainer.

a. Coat of liquid gasket should be maintained within 2.0 to

3.0 mm (0.079 to 0.118 in) dia. range.

b. Attach oil seal retainer to cylinder block within five min-

utes after coating.

c. Wait at least 30 minutes before refilling engine oil or

starting engine.

d. Use Genuine Liquid Gasket or equivalent.

SEM358G

FEM044

SLC822

FEM053

OIL SEAL REPLACEMENTZD

EM-1052