NISSAN PATROL 2000 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 801 of 1033

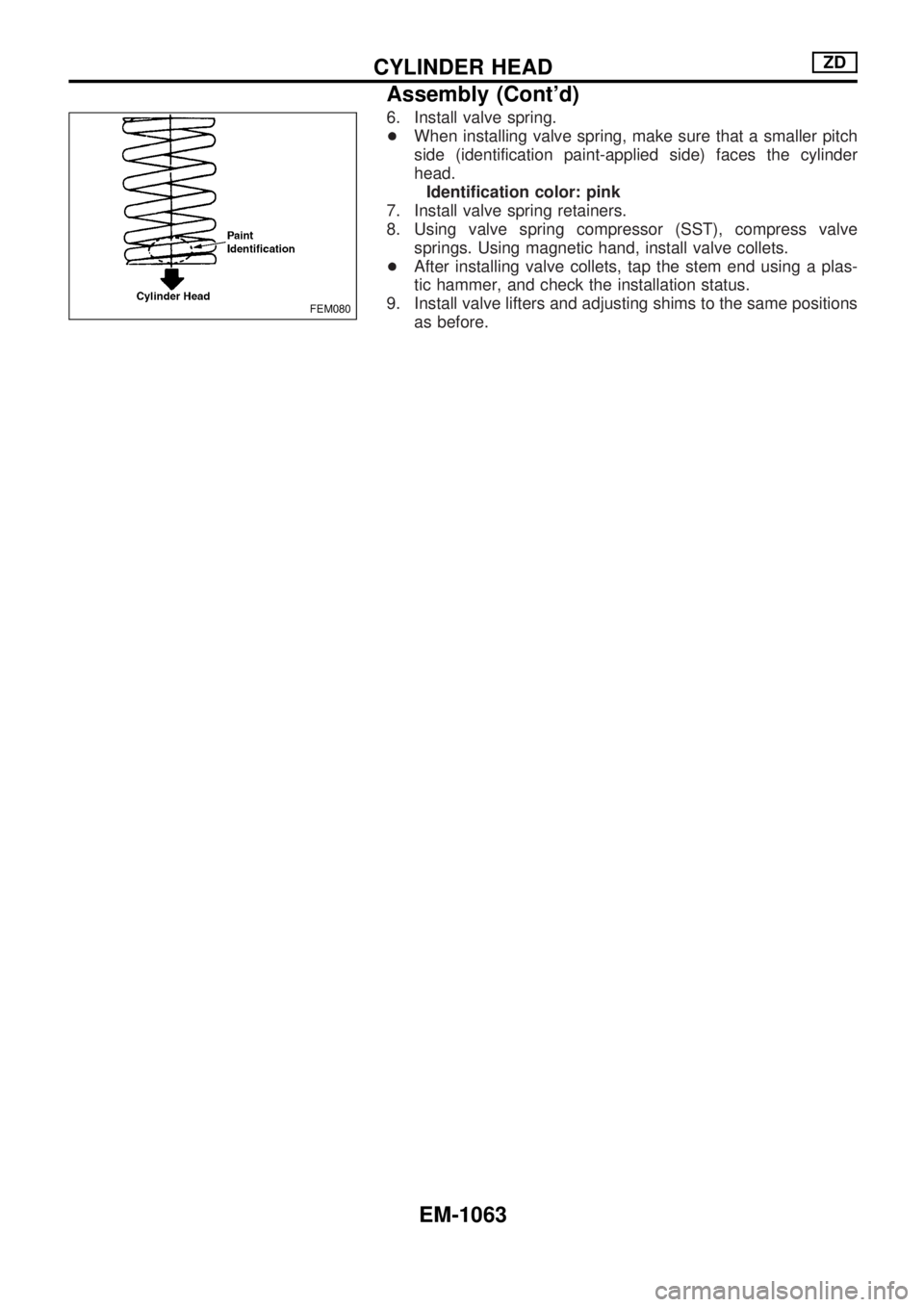

6. Install valve spring.

+When installing valve spring, make sure that a smaller pitch

side (identification paint-applied side) faces the cylinder

head.

Identification color: pink

7. Install valve spring retainers.

8. Using valve spring compressor (SST), compress valve

springs. Using magnetic hand, install valve collets.

+After installing valve collets, tap the stem end using a plas-

tic hammer, and check the installation status.

9. Install valve lifters and adjusting shims to the same positions

as before.

FEM080

CYLINDER HEADZD

Assembly (Cont'd)

EM-1063

Page 802 of 1033

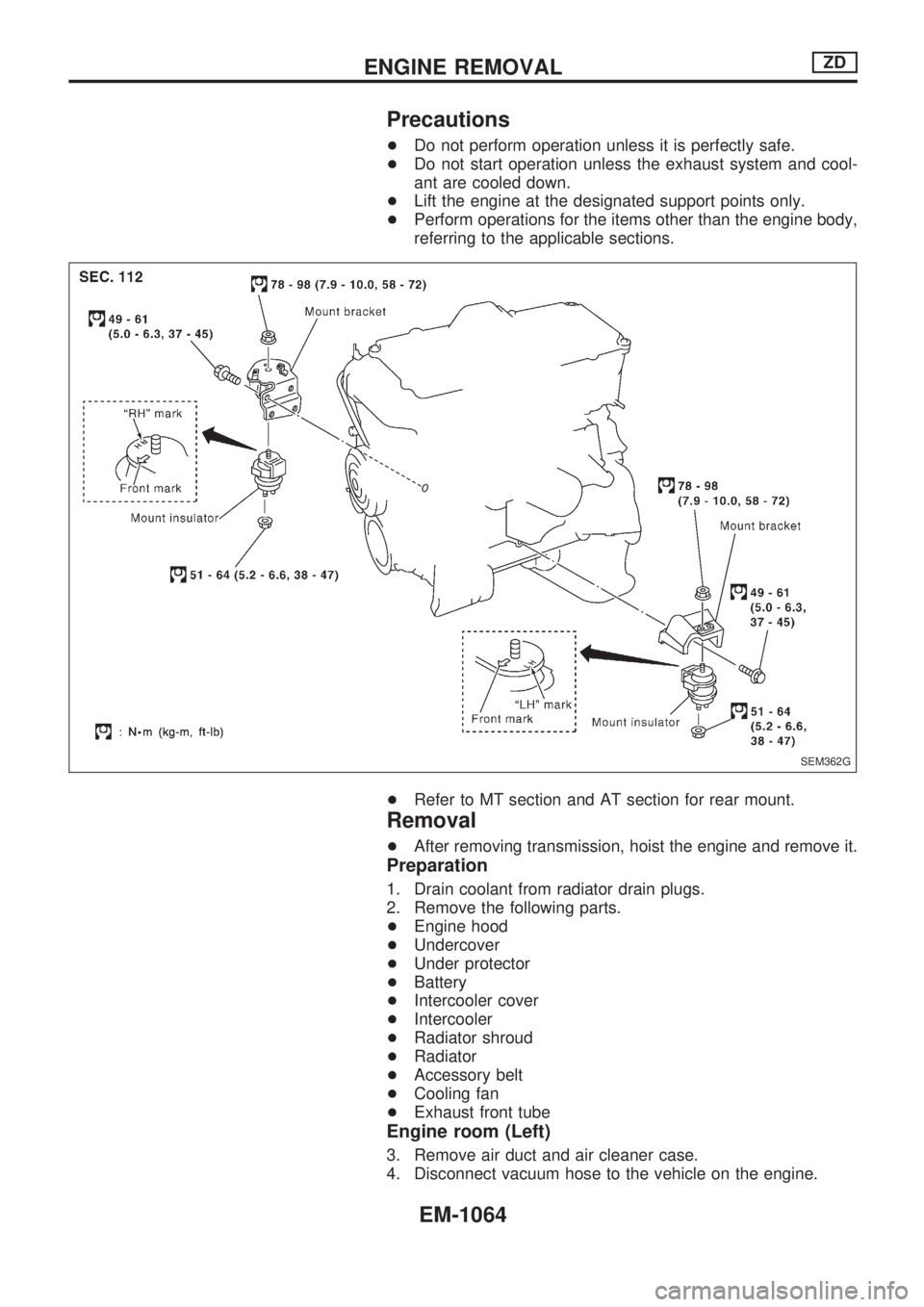

Precautions

+Do not perform operation unless it is perfectly safe.

+Do not start operation unless the exhaust system and cool-

ant are cooled down.

+Lift the engine at the designated support points only.

+Perform operations for the items other than the engine body,

referring to the applicable sections.

+Refer to MT section and AT section for rear mount.

Removal

+After removing transmission, hoist the engine and remove it.

Preparation

1. Drain coolant from radiator drain plugs.

2. Remove the following parts.

+Engine hood

+Undercover

+Under protector

+Battery

+Intercooler cover

+Intercooler

+Radiator shroud

+Radiator

+Accessory belt

+Cooling fan

+Exhaust front tube

Engine room (Left)

3. Remove air duct and air cleaner case.

4. Disconnect vacuum hose to the vehicle on the engine.

SEM362G

ENGINE REMOVALZD

EM-1064

Page 803 of 1033

5. Disconnect harness connectors from alternator and air com-

pressor.

6. Remove alternator.

7. After removing refrigerant, remove pipes of air compressor

and inlet/outlet.

8. Disconnect heating hose, install blank cap to hose to prevent

coolant from leaking.

9. Remove heating pipe.

10. Remove heat insulator.

11. Remove catalytic converter.

Engine room (Right)

12. Remove power steering reservoir tank from bracket, and fix

it to the vehicle with a rope.

CAUTION:

Keep the reservoir tank level when fixing to prevent oil leak.

13. Remove fuel feed and return hoses.

CAUTION:

Install blank caps immediately to avoid fuel leakage.

14. Remove all harness connectors on the engine, and move

harnesses to the side of the vehicle.

Vehicle underfloor

15. Remove starter motor.

16. Detach A/T oil cooler pipes from oil pan. (A/T model)

17. Remove rear propeller shaft.

18. Remove mounting bolts to secure the engine to transmission.

1) Remove torque converter installation bolt. (A/T model)

2) Lift transmission bottom with transmission jack, and remove

rear mount members from the vehicle.

3) Lower transmission with the jack, and remove upper mount-

ing bolts securing the engine to transmission.

4) Lift transmission with the jack, and reinstall rear mount mem-

bers to the vehicle.

5) Position the jack to the front side of transmission.

6) Remove remaining mounting bolts securing the engine to

transmission.

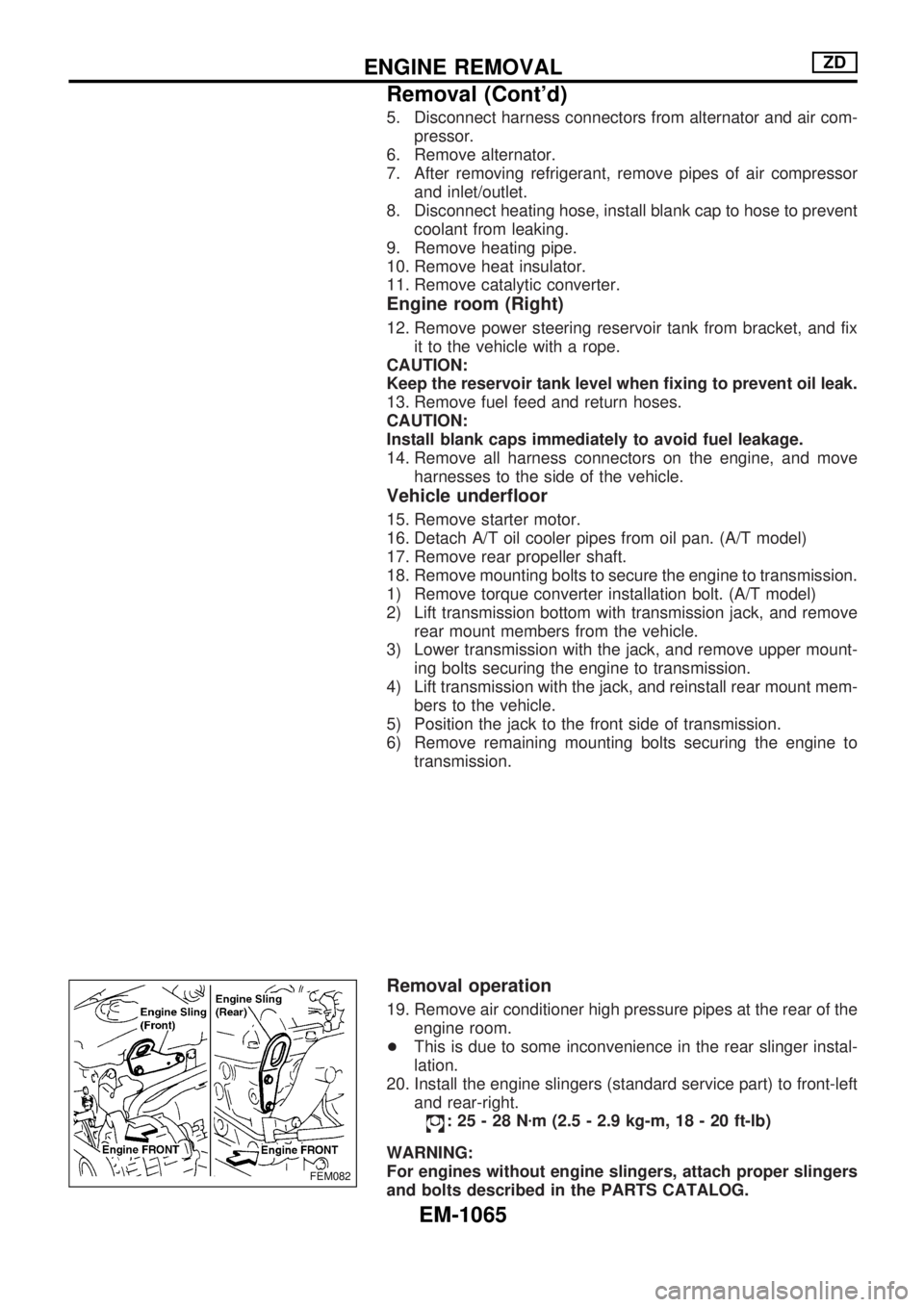

Removal operation

19. Remove air conditioner high pressure pipes at the rear of the

engine room.

+This is due to some inconvenience in the rear slinger instal-

lation.

20. Install the engine slingers (standard service part) to front-left

and rear-right.

:25-28Nzm (2.5 - 2.9 kg-m, 18 - 20 ft-lb)

WARNING:

For engines without engine slingers, attach proper slingers

and bolts described in the PARTS CATALOG.

FEM082

ENGINE REMOVALZD

Removal (Cont'd)

EM-1065

Page 804 of 1033

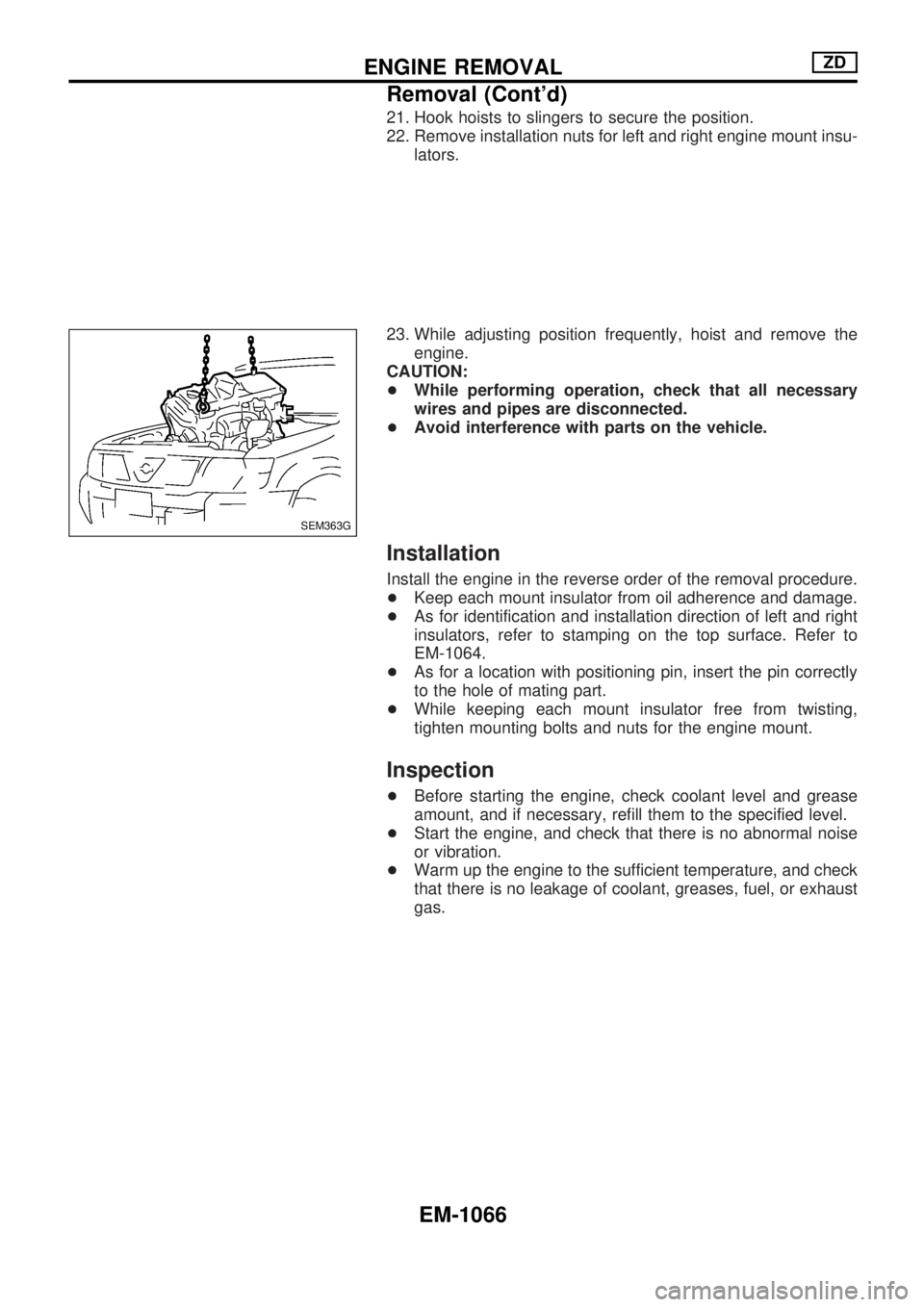

21. Hook hoists to slingers to secure the position.

22. Remove installation nuts for left and right engine mount insu-

lators.

23. While adjusting position frequently, hoist and remove the

engine.

CAUTION:

+While performing operation, check that all necessary

wires and pipes are disconnected.

+Avoid interference with parts on the vehicle.

Installation

Install the engine in the reverse order of the removal procedure.

+Keep each mount insulator from oil adherence and damage.

+As for identification and installation direction of left and right

insulators, refer to stamping on the top surface. Refer to

EM-1064.

+As for a location with positioning pin, insert the pin correctly

to the hole of mating part.

+While keeping each mount insulator free from twisting,

tighten mounting bolts and nuts for the engine mount.

Inspection

+Before starting the engine, check coolant level and grease

amount, and if necessary, refill them to the specified level.

+Start the engine, and check that there is no abnormal noise

or vibration.

+Warm up the engine to the sufficient temperature, and check

that there is no leakage of coolant, greases, fuel, or exhaust

gas.

SEM363G

ENGINE REMOVALZD

Removal (Cont'd)

EM-1066

Page 805 of 1033

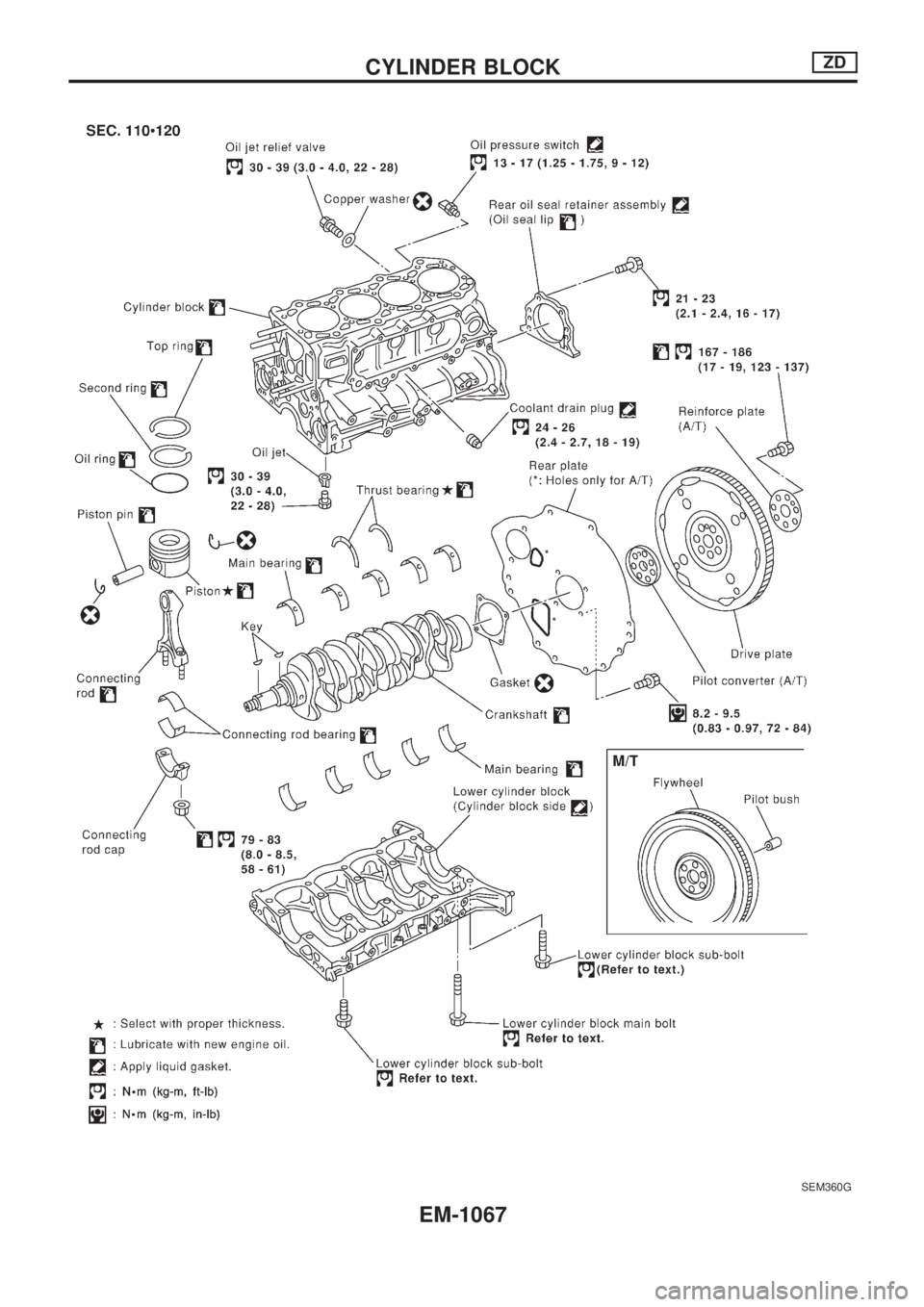

SEM360G

CYLINDER BLOCKZD

EM-1067

Page 806 of 1033

Selection Procedure for Selective Part

Combination

Location Selective part combination Item Method

Cylinder block - pistonPiston and piston assembly

(Part No. is given to a piston

and piston pin as a set.)Piston grade (Piston outer

diameter)Refer to ªSelective combination

chartº.

+Identification grade stamped on each part represents initial

dimension of new part. This grade will not be applied to a

reused part.

+Measure correct dimensions of a reused or modified part,

then refer to ªSelective combination chartº in this manual to

identify the grade.

+Refer to the applicable pages for measurement method for

each part, standards for reuse, and selecting method for

selective part combination.

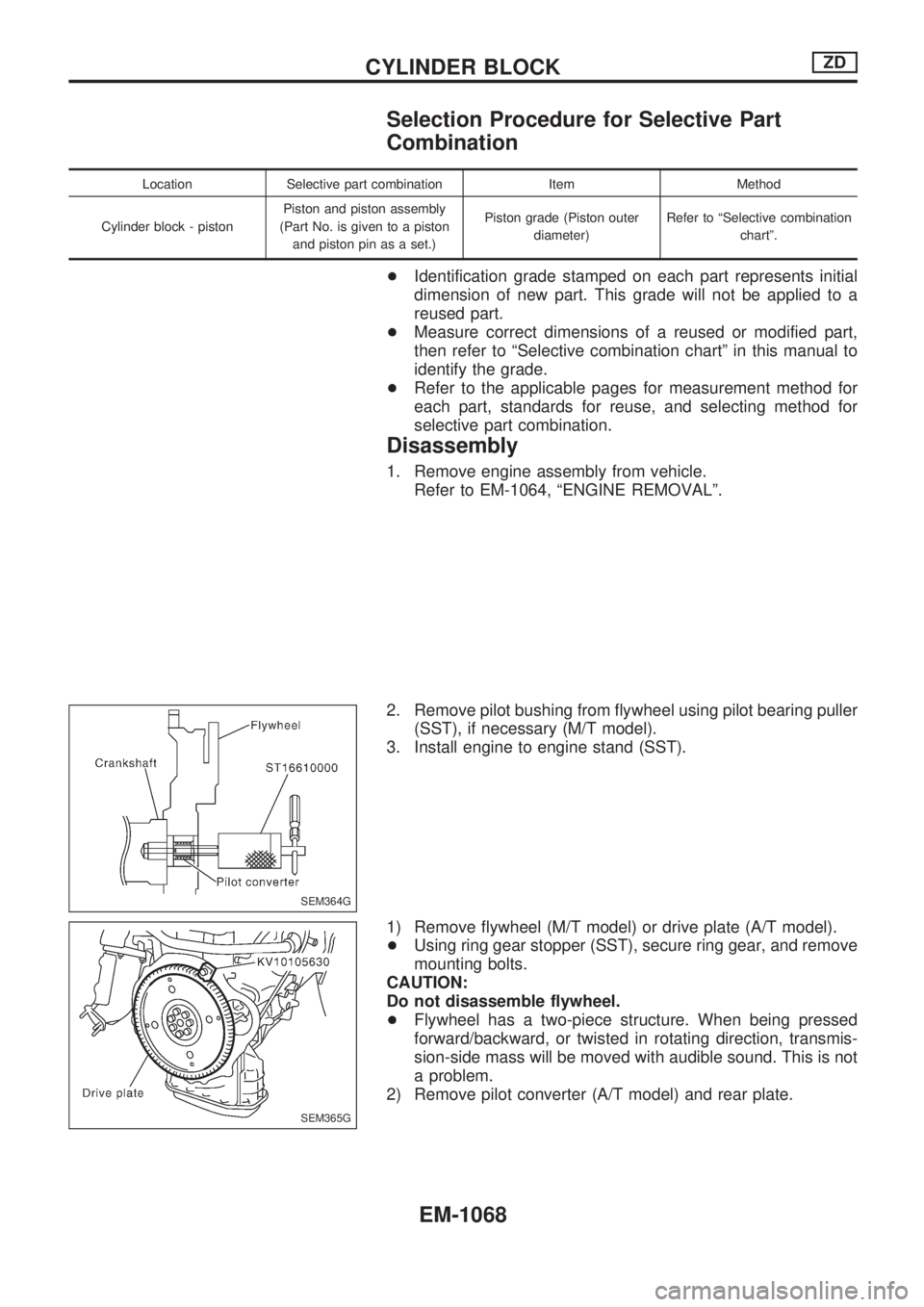

Disassembly

1. Remove engine assembly from vehicle.

Refer to EM-1064, ªENGINE REMOVALº.

2. Remove pilot bushing from flywheel using pilot bearing puller

(SST), if necessary (M/T model).

3. Install engine to engine stand (SST).

1) Remove flywheel (M/T model) or drive plate (A/T model).

+Using ring gear stopper (SST), secure ring gear, and remove

mounting bolts.

CAUTION:

Do not disassemble flywheel.

+Flywheel has a two-piece structure. When being pressed

forward/backward, or twisted in rotating direction, transmis-

sion-side mass will be moved with audible sound. This is not

a problem.

2) Remove pilot converter (A/T model) and rear plate.

SEM364G

SEM365G

CYLINDER BLOCKZD

EM-1068

Page 807 of 1033

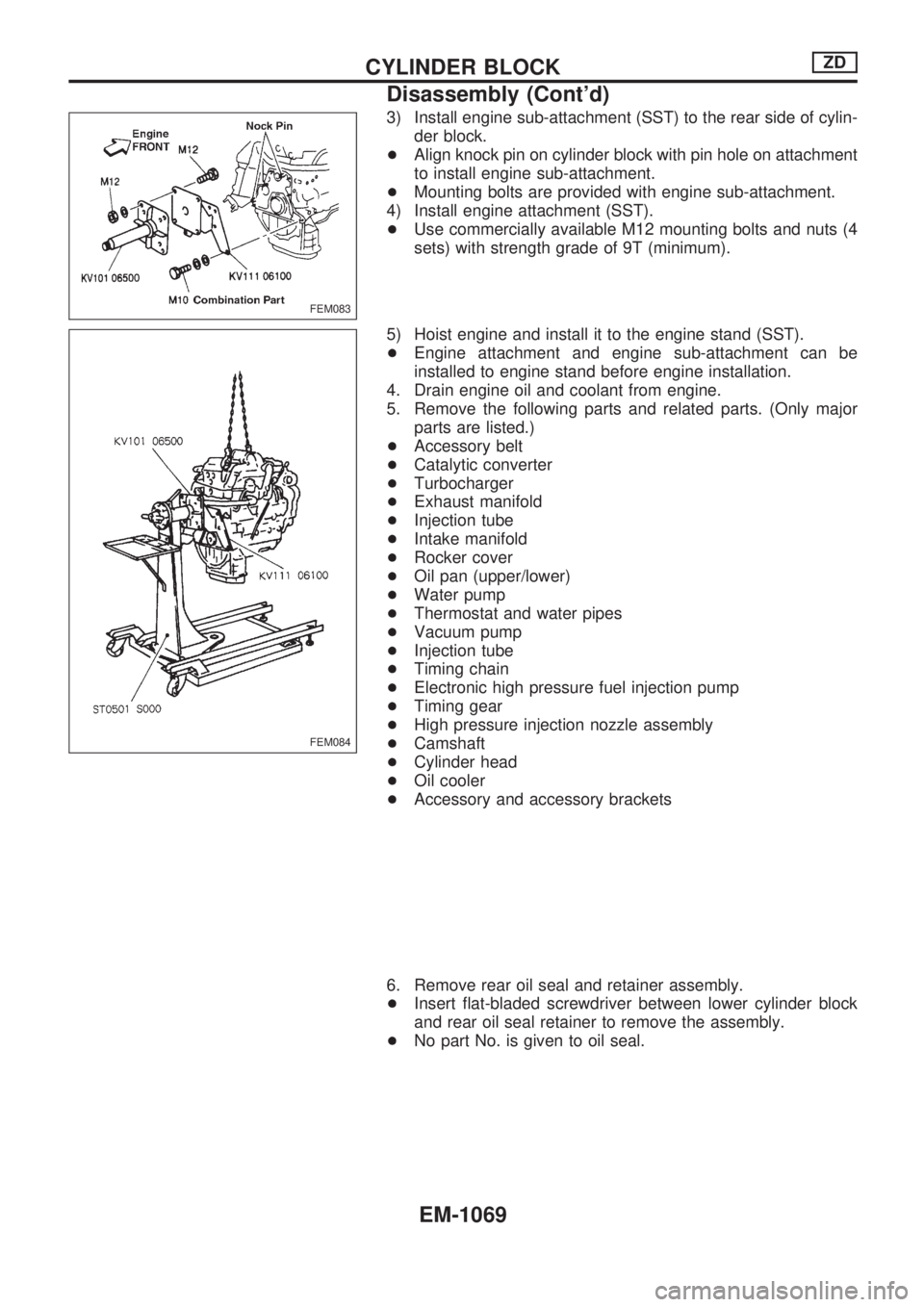

3) Install engine sub-attachment (SST) to the rear side of cylin-

der block.

+Align knock pin on cylinder block with pin hole on attachment

to install engine sub-attachment.

+Mounting bolts are provided with engine sub-attachment.

4) Install engine attachment (SST).

+Use commercially available M12 mounting bolts and nuts (4

sets) with strength grade of 9T (minimum).

5) Hoist engine and install it to the engine stand (SST).

+Engine attachment and engine sub-attachment can be

installed to engine stand before engine installation.

4. Drain engine oil and coolant from engine.

5. Remove the following parts and related parts. (Only major

parts are listed.)

+Accessory belt

+Catalytic converter

+Turbocharger

+Exhaust manifold

+Injection tube

+Intake manifold

+Rocker cover

+Oil pan (upper/lower)

+Water pump

+Thermostat and water pipes

+Vacuum pump

+Injection tube

+Timing chain

+Electronic high pressure fuel injection pump

+Timing gear

+High pressure injection nozzle assembly

+Camshaft

+Cylinder head

+Oil cooler

+Accessory and accessory brackets

6. Remove rear oil seal and retainer assembly.

+Insert flat-bladed screwdriver between lower cylinder block

and rear oil seal retainer to remove the assembly.

+No part No. is given to oil seal.

FEM083

FEM084

CYLINDER BLOCKZD

Disassembly (Cont'd)

EM-1069

Page 808 of 1033

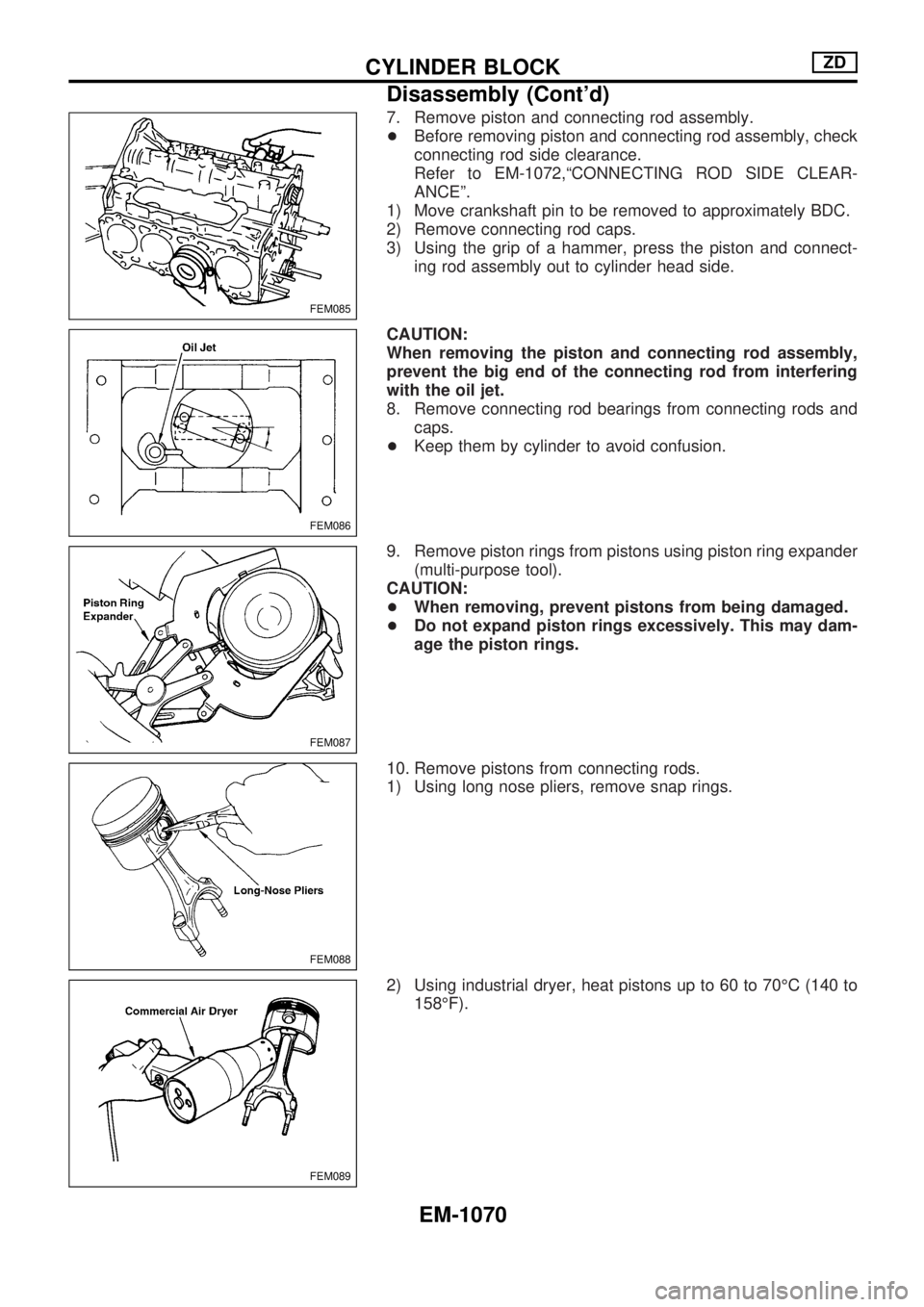

7. Remove piston and connecting rod assembly.

+Before removing piston and connecting rod assembly, check

connecting rod side clearance.

Refer to EM-1072,ªCONNECTING ROD SIDE CLEAR-

ANCEº.

1) Move crankshaft pin to be removed to approximately BDC.

2) Remove connecting rod caps.

3) Using the grip of a hammer, press the piston and connect-

ing rod assembly out to cylinder head side.

CAUTION:

When removing the piston and connecting rod assembly,

prevent the big end of the connecting rod from interfering

with the oil jet.

8. Remove connecting rod bearings from connecting rods and

caps.

+Keep them by cylinder to avoid confusion.

9. Remove piston rings from pistons using piston ring expander

(multi-purpose tool).

CAUTION:

+When removing, prevent pistons from being damaged.

+Do not expand piston rings excessively. This may dam-

age the piston rings.

10. Remove pistons from connecting rods.

1) Using long nose pliers, remove snap rings.

2) Using industrial dryer, heat pistons up to 60 to 70ÉC (140 to

158ÉF).

FEM085

FEM086

FEM087

FEM088

FEM089

CYLINDER BLOCKZD

Disassembly (Cont'd)

EM-1070

Page 809 of 1033

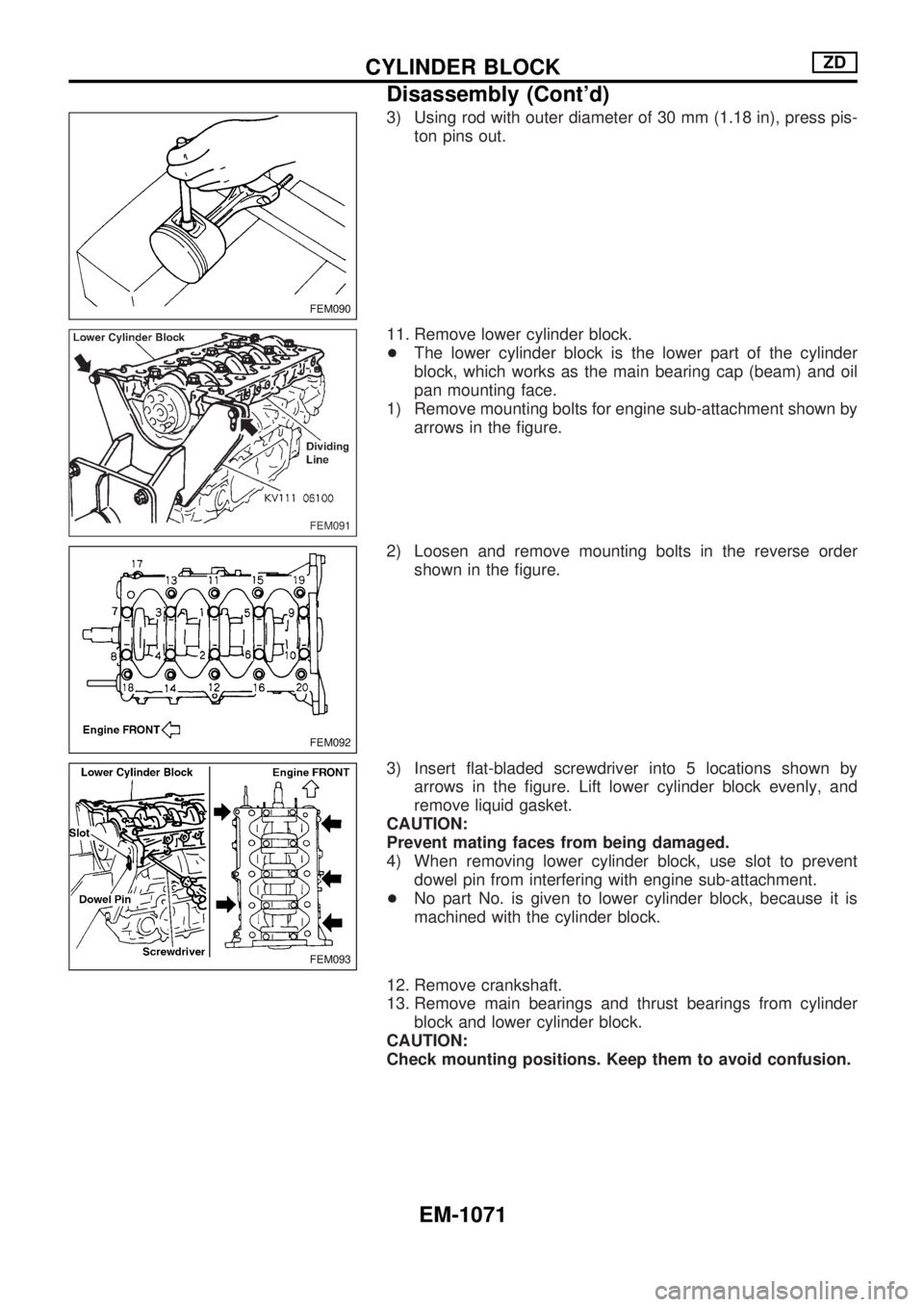

3) Using rod with outer diameter of 30 mm (1.18 in), press pis-

ton pins out.

11. Remove lower cylinder block.

+The lower cylinder block is the lower part of the cylinder

block, which works as the main bearing cap (beam) and oil

pan mounting face.

1) Remove mounting bolts for engine sub-attachment shown by

arrows in the figure.

2) Loosen and remove mounting bolts in the reverse order

shown in the figure.

3) Insert flat-bladed screwdriver into 5 locations shown by

arrows in the figure. Lift lower cylinder block evenly, and

remove liquid gasket.

CAUTION:

Prevent mating faces from being damaged.

4) When removing lower cylinder block, use slot to prevent

dowel pin from interfering with engine sub-attachment.

+No part No. is given to lower cylinder block, because it is

machined with the cylinder block.

12. Remove crankshaft.

13. Remove main bearings and thrust bearings from cylinder

block and lower cylinder block.

CAUTION:

Check mounting positions. Keep them to avoid confusion.

FEM090

FEM091

FEM092

FEM093

CYLINDER BLOCKZD

Disassembly (Cont'd)

EM-1071

Page 810 of 1033

Inspection

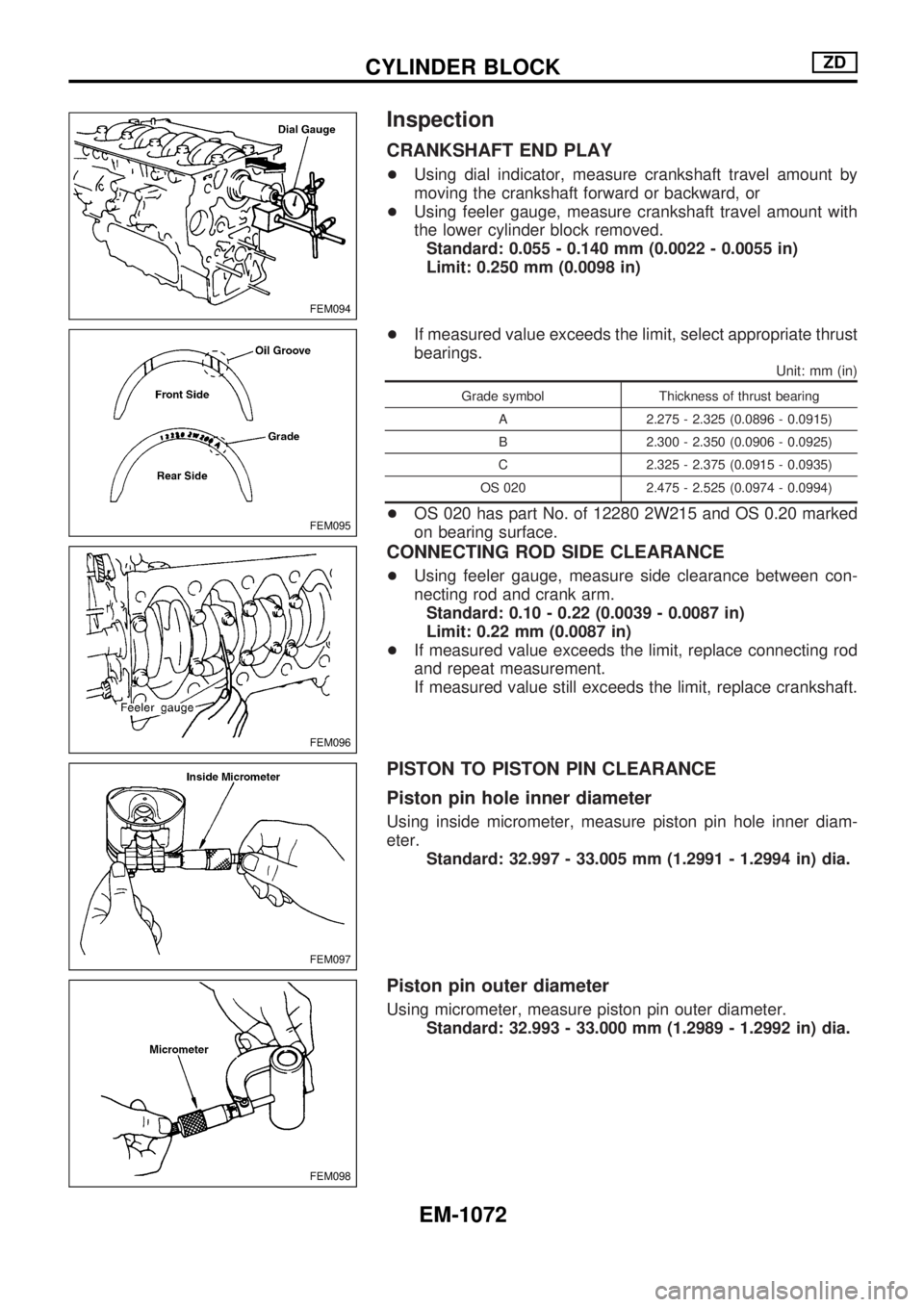

CRANKSHAFT END PLAY

+Using dial indicator, measure crankshaft travel amount by

moving the crankshaft forward or backward, or

+Using feeler gauge, measure crankshaft travel amount with

the lower cylinder block removed.

Standard: 0.055 - 0.140 mm (0.0022 - 0.0055 in)

Limit: 0.250 mm (0.0098 in)

+If measured value exceeds the limit, select appropriate thrust

bearings.

Unit: mm (in)

Grade symbol Thickness of thrust bearing

A 2.275 - 2.325 (0.0896 - 0.0915)

B 2.300 - 2.350 (0.0906 - 0.0925)

C 2.325 - 2.375 (0.0915 - 0.0935)

OS 020 2.475 - 2.525 (0.0974 - 0.0994)

+OS 020 has part No. of 12280 2W215 and OS 0.20 marked

on bearing surface.

CONNECTING ROD SIDE CLEARANCE

+Using feeler gauge, measure side clearance between con-

necting rod and crank arm.

Standard: 0.10 - 0.22 (0.0039 - 0.0087 in)

Limit: 0.22 mm (0.0087 in)

+If measured value exceeds the limit, replace connecting rod

and repeat measurement.

If measured value still exceeds the limit, replace crankshaft.

PISTON TO PISTON PIN CLEARANCE

Piston pin hole inner diameter

Using inside micrometer, measure piston pin hole inner diam-

eter.

Standard: 32.997 - 33.005 mm (1.2991 - 1.2994 in) dia.

Piston pin outer diameter

Using micrometer, measure piston pin outer diameter.

Standard: 32.993 - 33.000 mm (1.2989 - 1.2992 in) dia.

FEM094

FEM095

FEM096

FEM097

FEM098

CYLINDER BLOCKZD

EM-1072