NISSAN PICK-UP 1998 Repair Manual

PICK-UP 1998

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57374/w960_57374-0.png

NISSAN PICK-UP 1998 Repair Manual

Trending: radiator cap, wheel torque, adding oil, relay, fuel cap, AUX, automatic transmission fluid

Page 1131 of 1659

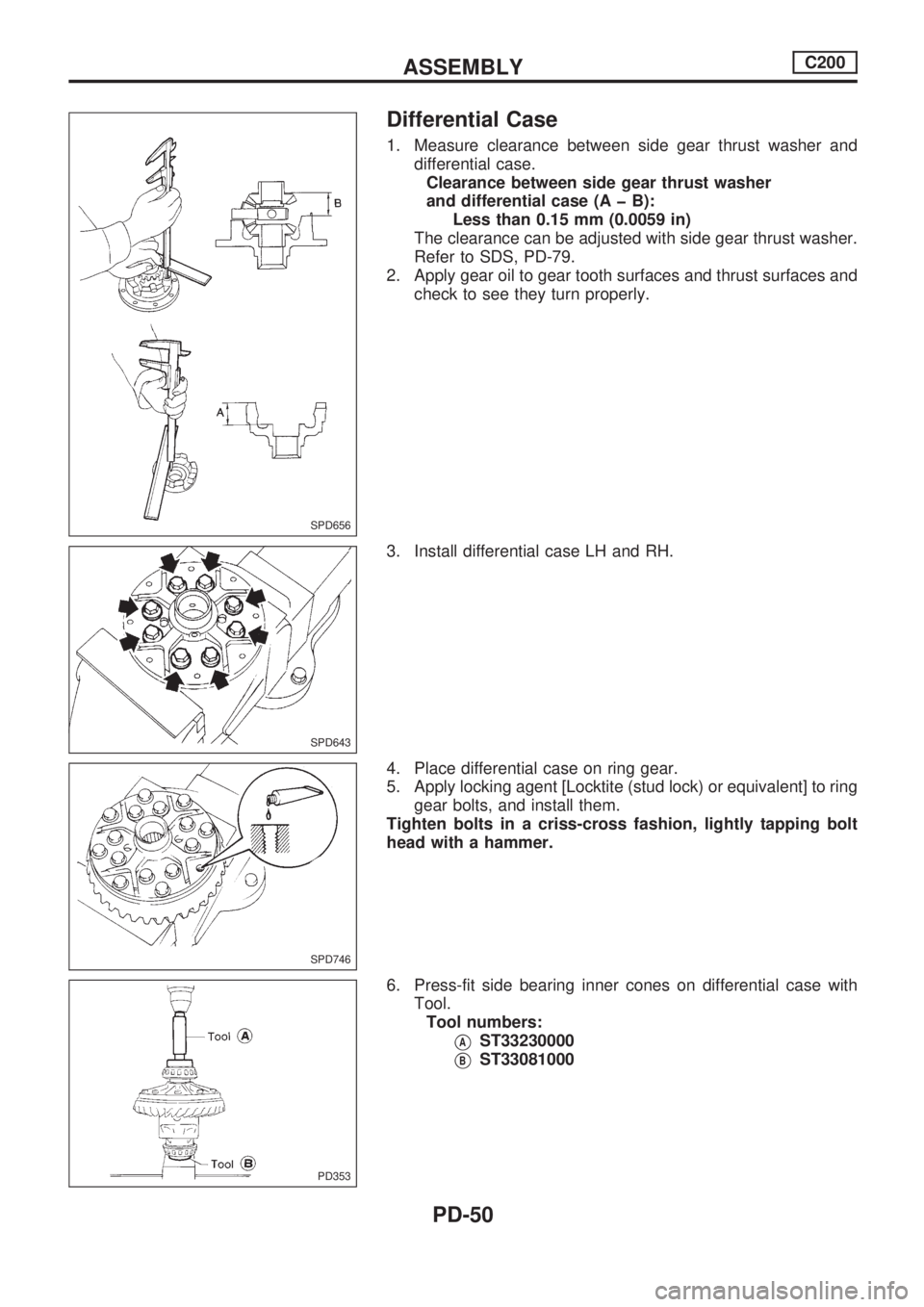

Differential Case

1. Measure clearance between side gear thrust washer and

differential case.

Clearance between side gear thrust washer

and differential case (A þ B):

Less than 0.15 mm (0.0059 in)

The clearance can be adjusted with side gear thrust washer.

Refer to SDS, PD-79.

2. Apply gear oil to gear tooth surfaces and thrust surfaces and

check to see they turn properly.

3. Install differential case LH and RH.

4. Place differential case on ring gear.

5. Apply locking agent [Locktite (stud lock) or equivalent] to ring

gear bolts, and install them.

Tighten bolts in a criss-cross fashion, lightly tapping bolt

head with a hammer.

6. Press-fit side bearing inner cones on differential case with

Tool.

Tool numbers:

VAST33230000

VBST33081000

SPD656

SPD643

SPD746

PD353

ASSEMBLYC200

PD-50

Page 1132 of 1659

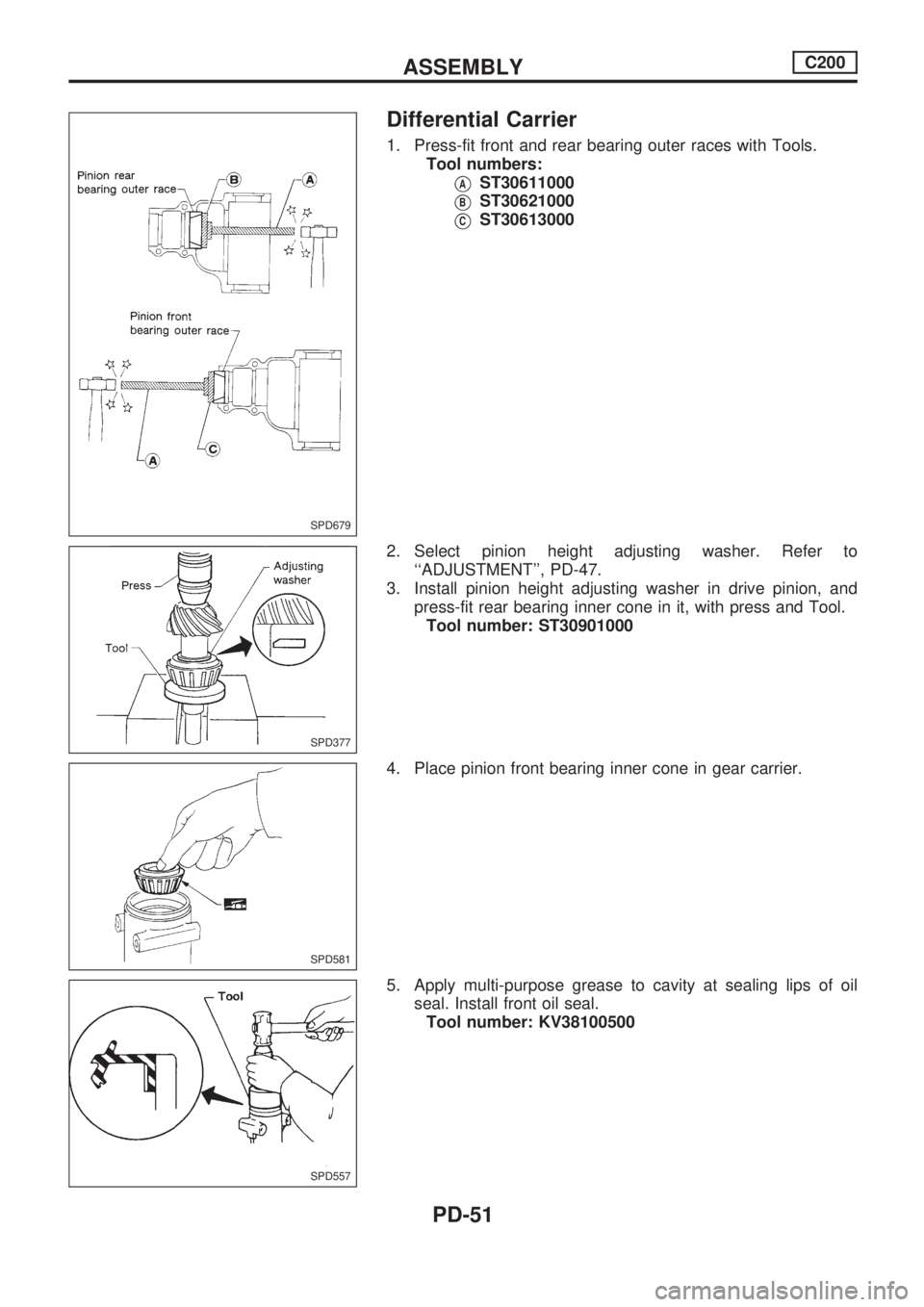

Differential Carrier

1. Press-fit front and rear bearing outer races with Tools.

Tool numbers:

VAST30611000

VBST30621000

VCST30613000

2. Select pinion height adjusting washer. Refer to

``ADJUSTMENT'', PD-47.

3. Install pinion height adjusting washer in drive pinion, and

press-fit rear bearing inner cone in it, with press and Tool.

Tool number: ST30901000

4. Place pinion front bearing inner cone in gear carrier.

5. Apply multi-purpose grease to cavity at sealing lips of oil

seal. Install front oil seal.

Tool number: KV38100500

SPD679

SPD377

SPD581

SPD557

ASSEMBLYC200

PD-51

Page 1133 of 1659

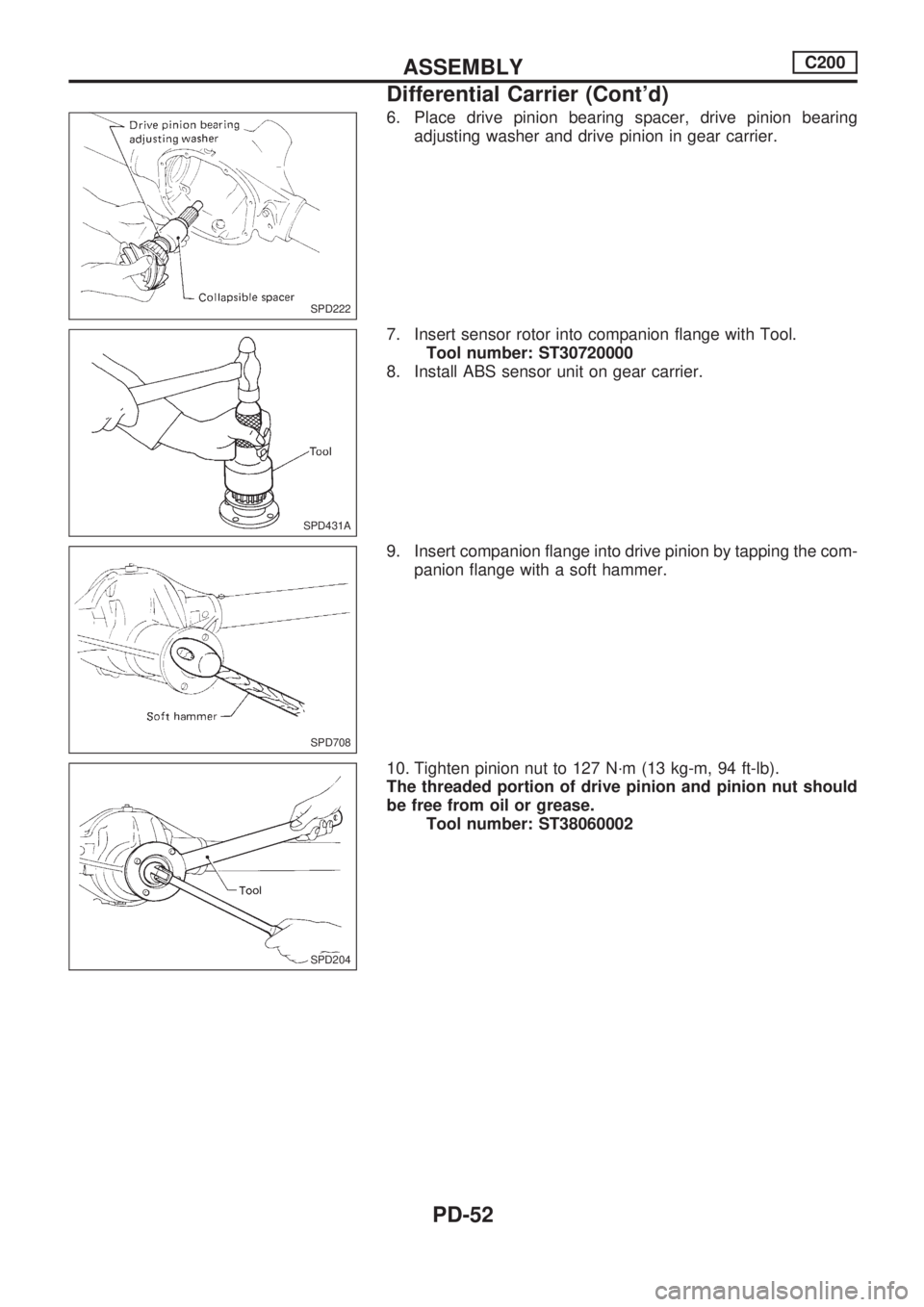

6. Place drive pinion bearing spacer, drive pinion bearing

adjusting washer and drive pinion in gear carrier.

7. Insert sensor rotor into companion flange with Tool.

Tool number: ST30720000

8. Install ABS sensor unit on gear carrier.

9. Insert companion flange into drive pinion by tapping the com-

panion flange with a soft hammer.

10. Tighten pinion nut to 127 N´m (13 kg-m, 94 ft-lb).

The threaded portion of drive pinion and pinion nut should

be free from oil or grease.

Tool number: ST38060002

SPD222

SPD431A

SPD708

SPD204.SPD204

ASSEMBLYC200

Differential Carrier (Cont'd)

PD-52

Page 1134 of 1659

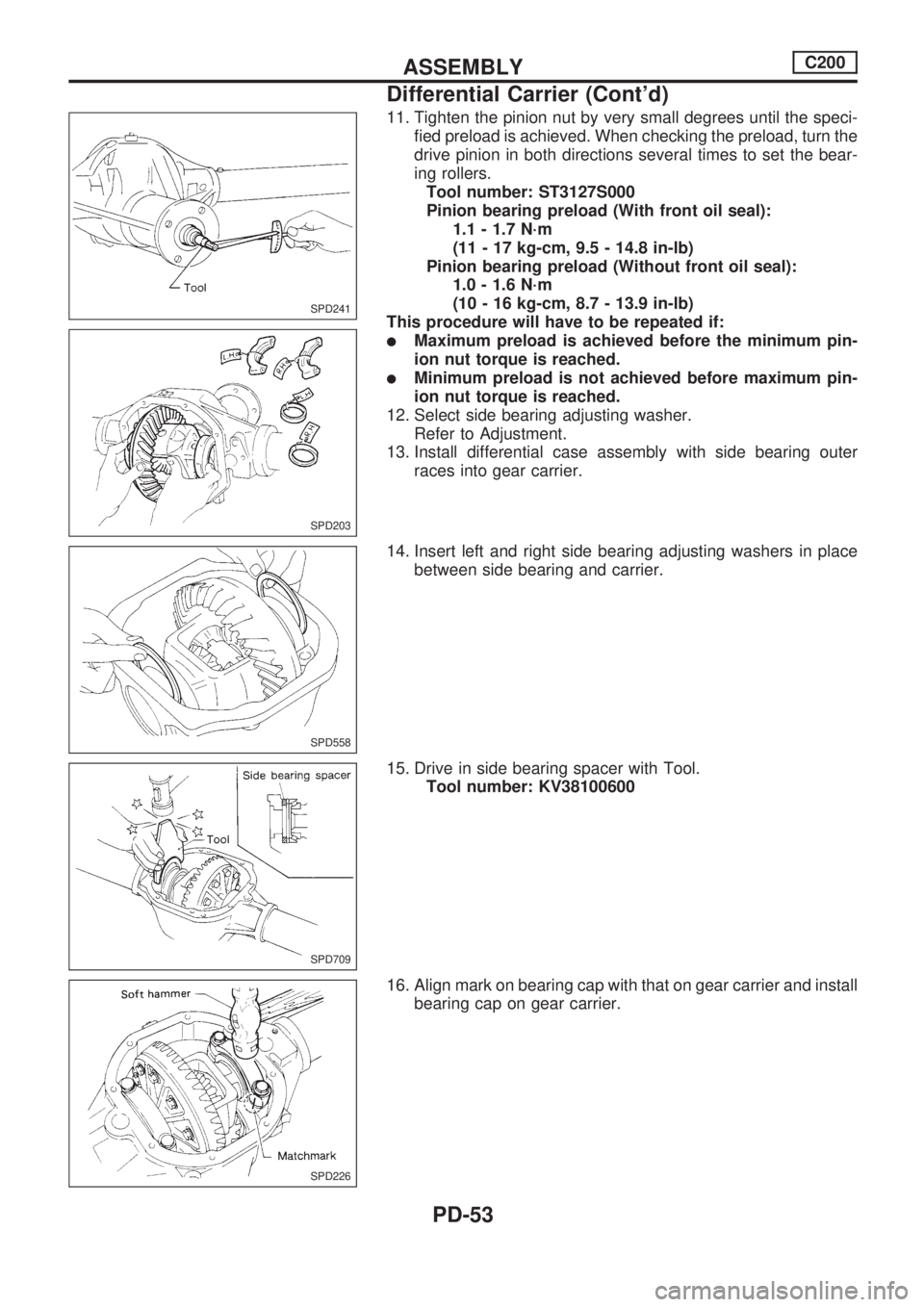

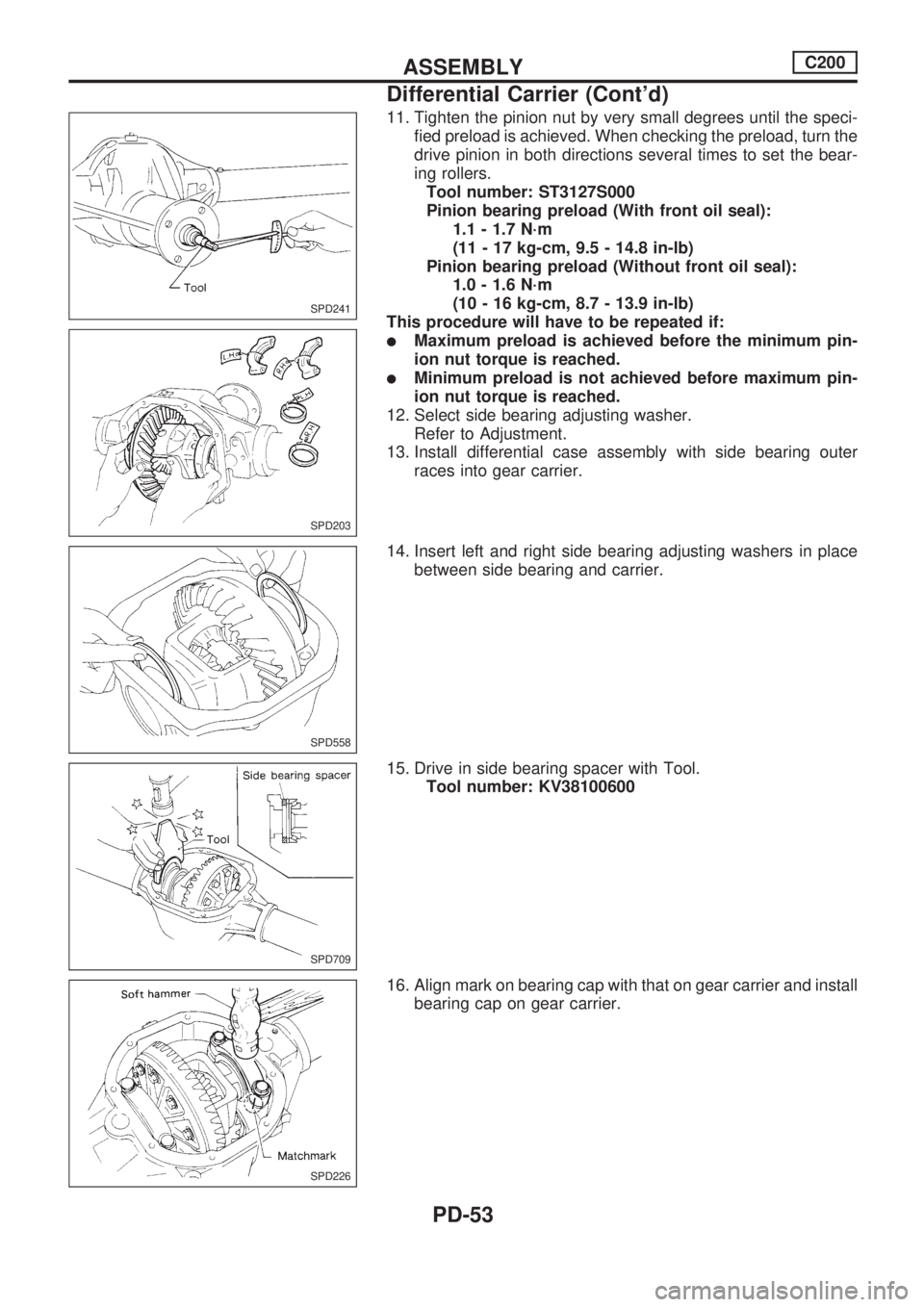

11. Tighten the pinion nut by very small degrees until the speci-

fied preload is achieved. When checking the preload, turn the

drive pinion in both directions several times to set the bear-

ing rollers.

Tool number: ST3127S000

Pinion bearing preload (With front oil seal):

1.1 - 1.7 N´m

(11 - 17 kg-cm, 9.5 - 14.8 in-lb)

Pinion bearing preload (Without front oil seal):

1.0 - 1.6 N´m

(10 - 16 kg-cm, 8.7 - 13.9 in-lb)

This procedure will have to be repeated if:

lMaximum preload is achieved before the minimum pin-

ion nut torque is reached.

lMinimum preload is not achieved before maximum pin-

ion nut torque is reached.

12. Select side bearing adjusting washer.

Refer to Adjustment.

13. Install differential case assembly with side bearing outer

races into gear carrier.

14. Insert left and right side bearing adjusting washers in place

between side bearing and carrier.

15. Drive in side bearing spacer with Tool.

Tool number: KV38100600

16. Align mark on bearing cap with that on gear carrier and install

bearing cap on gear carrier.

SPD241

SPD203

SPD558

SPD709

SPD226

ASSEMBLYC200

Differential Carrier (Cont'd)

PD-53

Page 1135 of 1659

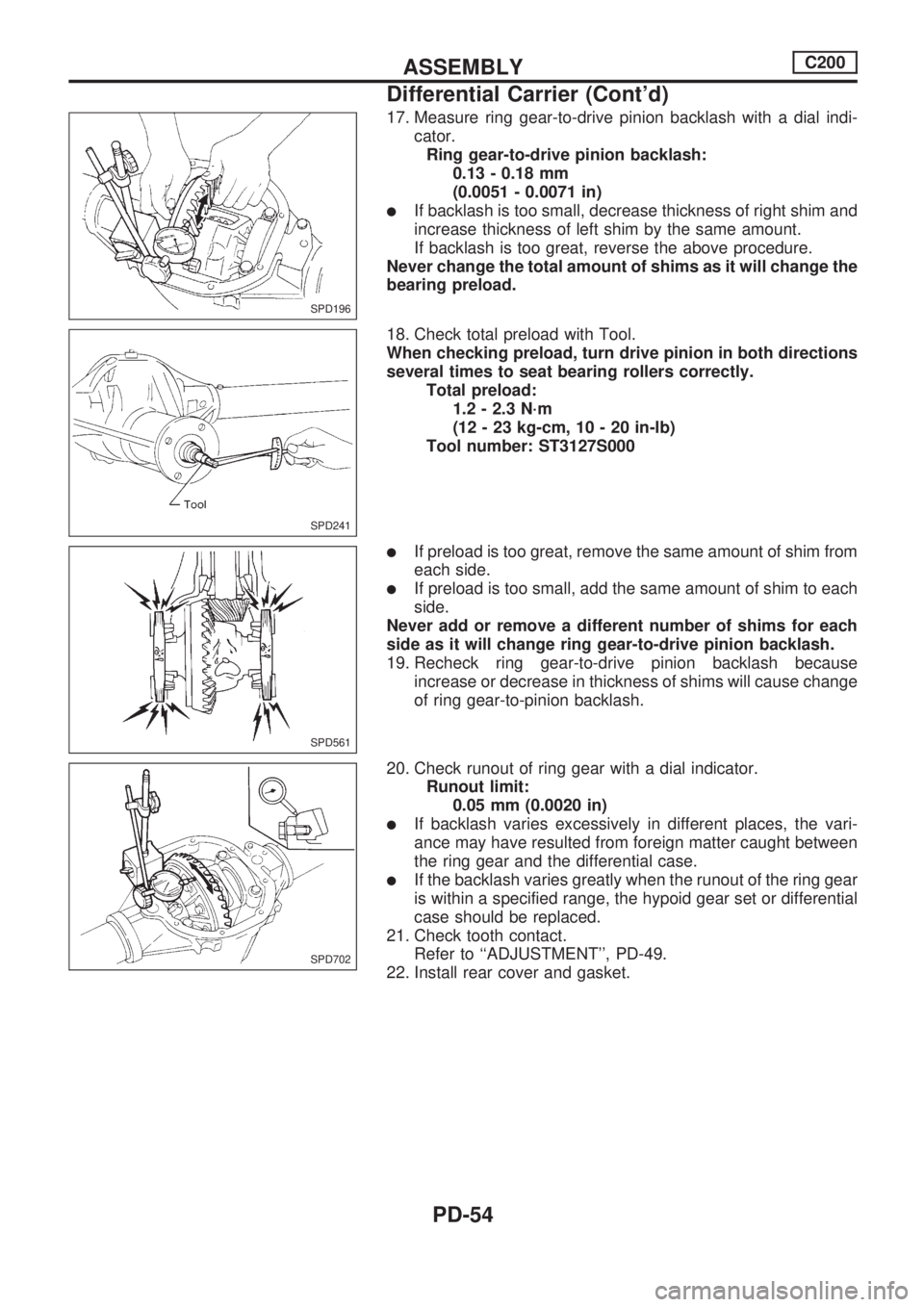

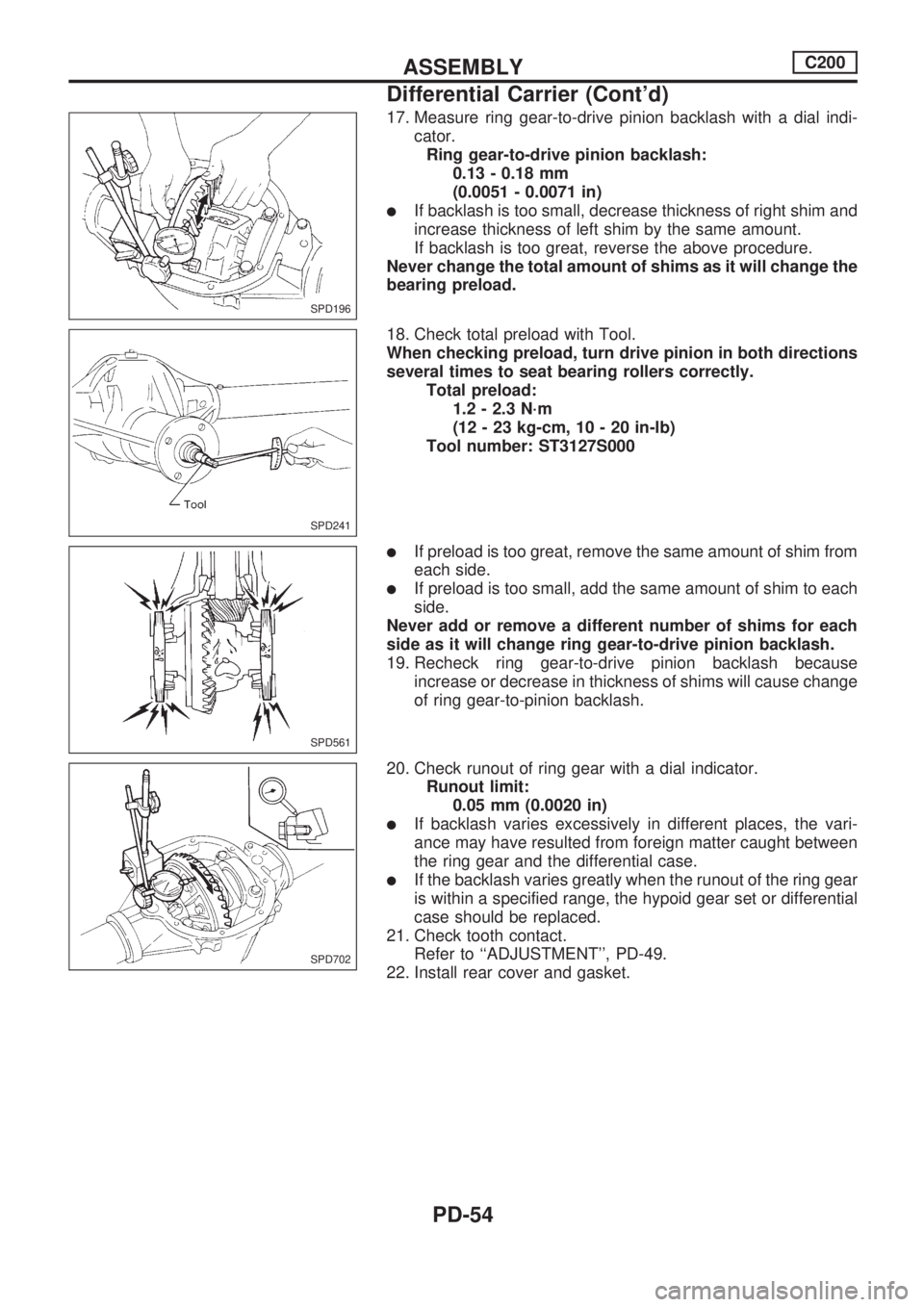

17. Measure ring gear-to-drive pinion backlash with a dial indi-

cator.

Ring gear-to-drive pinion backlash:

0.13 - 0.18 mm

(0.0051 - 0.0071 in)

lIf backlash is too small, decrease thickness of right shim and

increase thickness of left shim by the same amount.

If backlash is too great, reverse the above procedure.

Never change the total amount of shims as it will change the

bearing preload.

18. Check total preload with Tool.

When checking preload, turn drive pinion in both directions

several times to seat bearing rollers correctly.

Total preload:

1.2 - 2.3 N´m

(12 - 23 kg-cm, 10 - 20 in-lb)

Tool number: ST3127S000

lIf preload is too great, remove the same amount of shim from

each side.

lIf preload is too small, add the same amount of shim to each

side.

Never add or remove a different number of shims for each

side as it will change ring gear-to-drive pinion backlash.

19. Recheck ring gear-to-drive pinion backlash because

increase or decrease in thickness of shims will cause change

of ring gear-to-pinion backlash.

20. Check runout of ring gear with a dial indicator.

Runout limit:

0.05 mm (0.0020 in)

lIf backlash varies excessively in different places, the vari-

ance may have resulted from foreign matter caught between

the ring gear and the differential case.

lIf the backlash varies greatly when the runout of the ring gear

is within a specified range, the hypoid gear set or differential

case should be replaced.

21. Check tooth contact.

Refer to ``ADJUSTMENT'', PD-49.

22. Install rear cover and gasket.

SPD196

SPD241

SPD561

SPD702

ASSEMBLYC200

Differential Carrier (Cont'd)

PD-54

Page 1136 of 1659

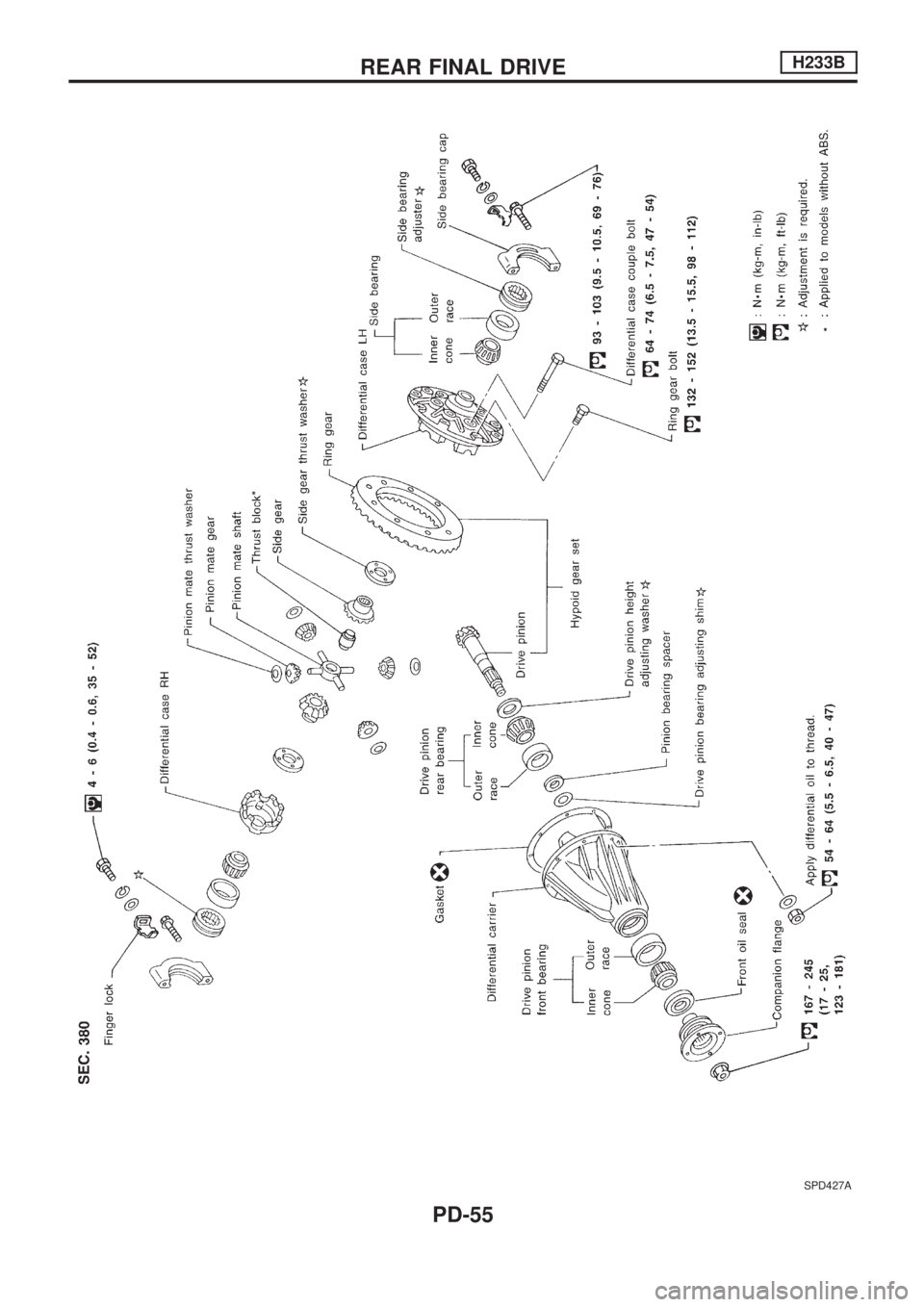

SPD427A

REAR FINAL DRIVEH233B

PD-55

Page 1137 of 1659

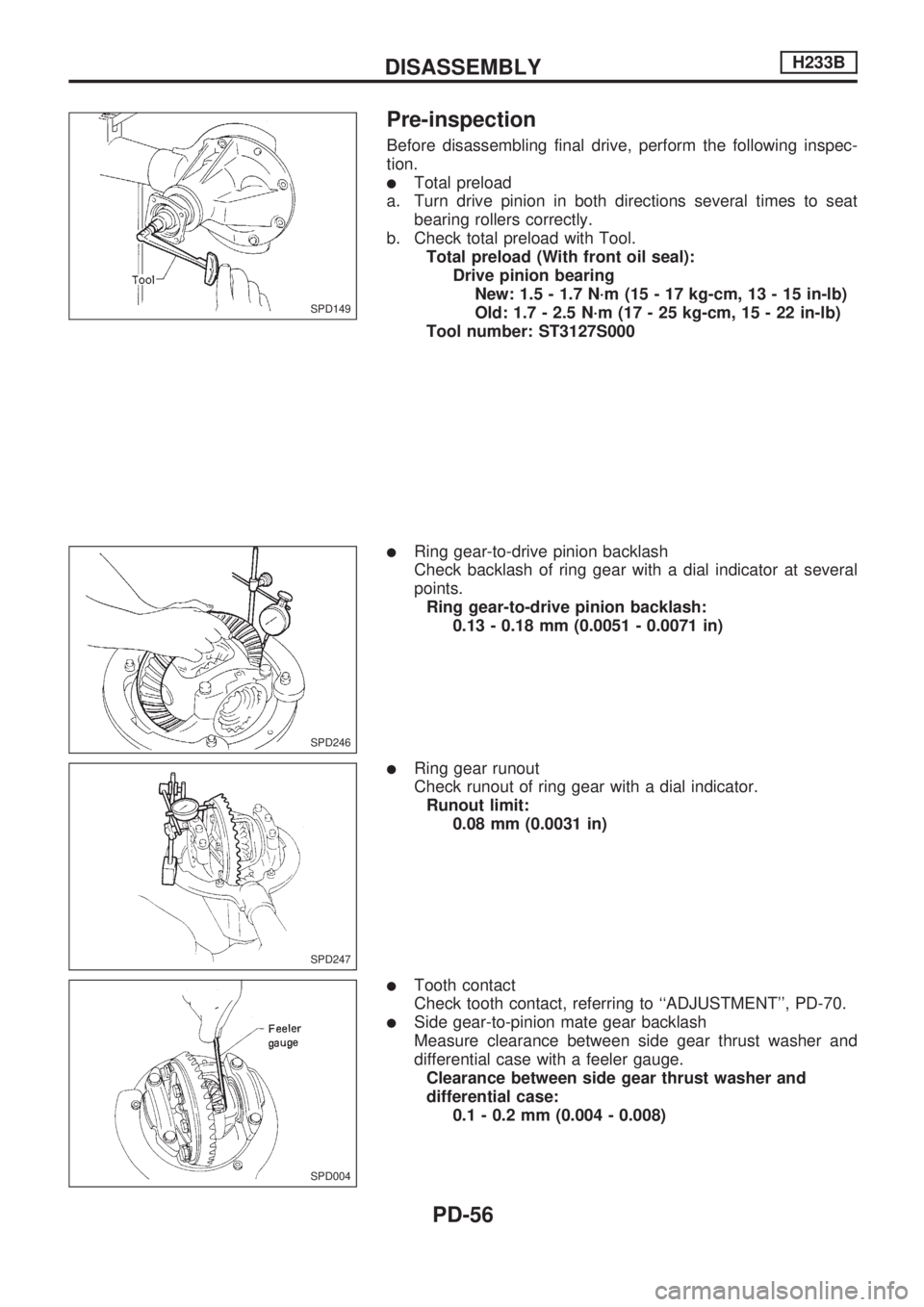

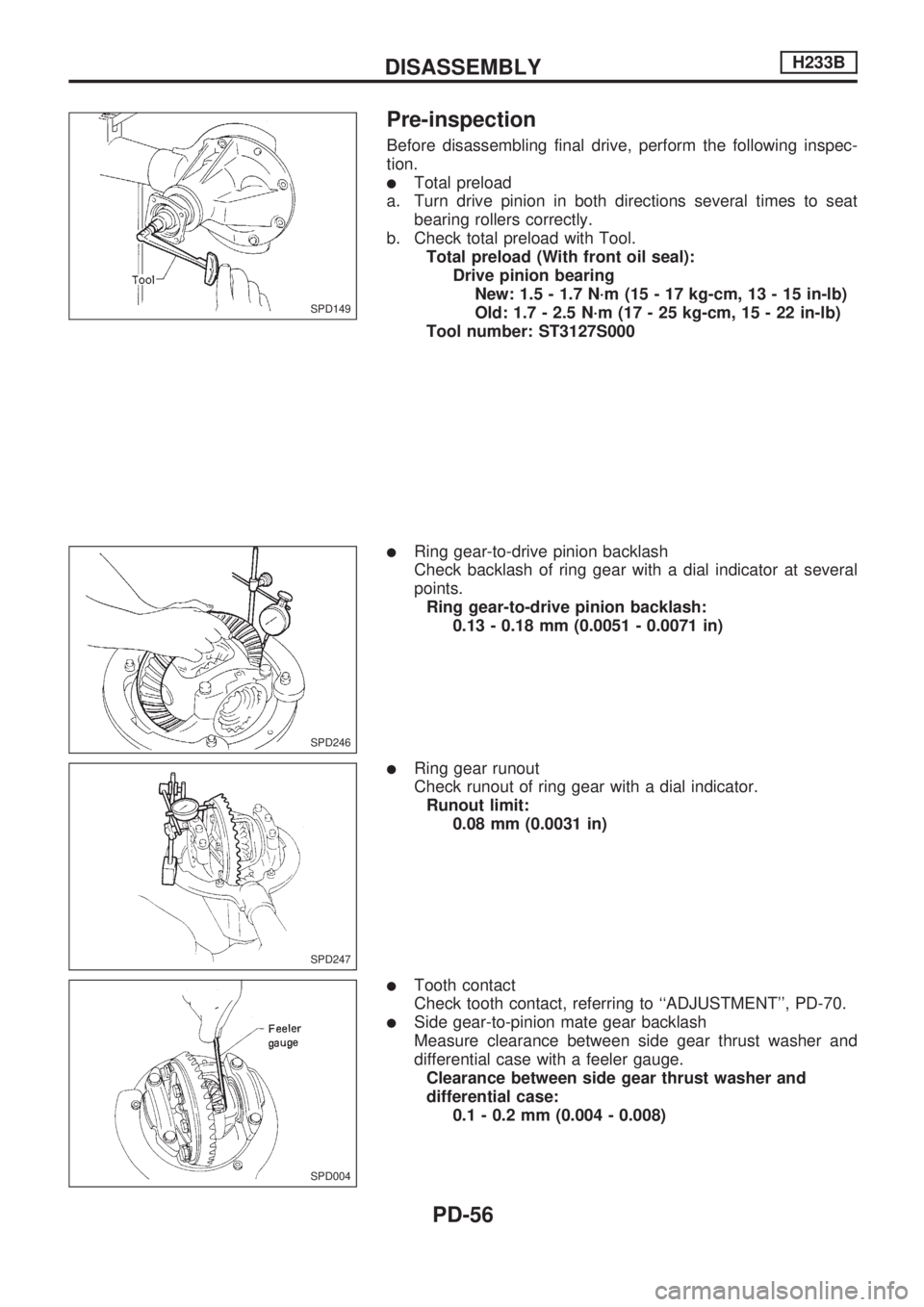

Pre-inspection

Before disassembling final drive, perform the following inspec-

tion.

lTotal preload

a. Turn drive pinion in both directions several times to seat

bearing rollers correctly.

b. Check total preload with Tool.

Total preload (With front oil seal):

Drive pinion bearing

New: 1.5 - 1.7 N´m (15 - 17 kg-cm, 13 - 15 in-lb)

Old: 1.7 - 2.5 N´m (17 - 25 kg-cm, 15 - 22 in-lb)

Tool number: ST3127S000

lRing gear-to-drive pinion backlash

Check backlash of ring gear with a dial indicator at several

points.

Ring gear-to-drive pinion backlash:

0.13 - 0.18 mm (0.0051 - 0.0071 in)

lRing gear runout

Check runout of ring gear with a dial indicator.

Runout limit:

0.08 mm (0.0031 in)

lTooth contact

Check tooth contact, referring to ``ADJUSTMENT'', PD-70.

lSide gear-to-pinion mate gear backlash

Measure clearance between side gear thrust washer and

differential case with a feeler gauge.

Clearance between side gear thrust washer and

differential case:

0.1 - 0.2 mm (0.004 - 0.008)

SPD149

SPD246

SPD247

SPD004

DISASSEMBLYH233B

PD-56

Page 1138 of 1659

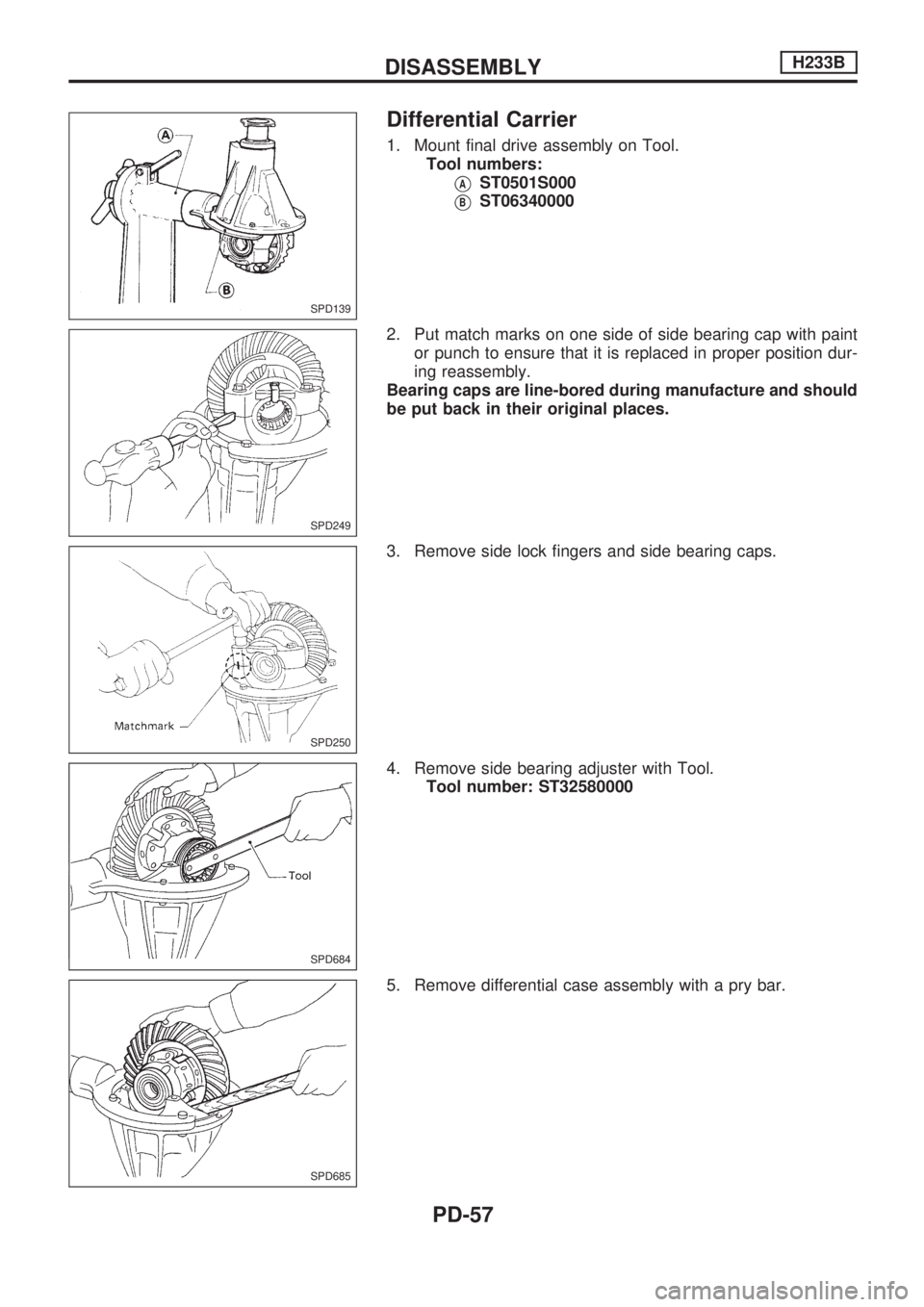

Differential Carrier

1. Mount final drive assembly on Tool.

Tool numbers:

VAST0501S000

VBST06340000

2. Put match marks on one side of side bearing cap with paint

or punch to ensure that it is replaced in proper position dur-

ing reassembly.

Bearing caps are line-bored during manufacture and should

be put back in their original places.

3. Remove side lock fingers and side bearing caps.

4. Remove side bearing adjuster with Tool.

Tool number: ST32580000

5. Remove differential case assembly with a pry bar.

SPD139

SPD249

SPD250

SPD684

SPD685

DISASSEMBLYH233B

PD-57

Page 1139 of 1659

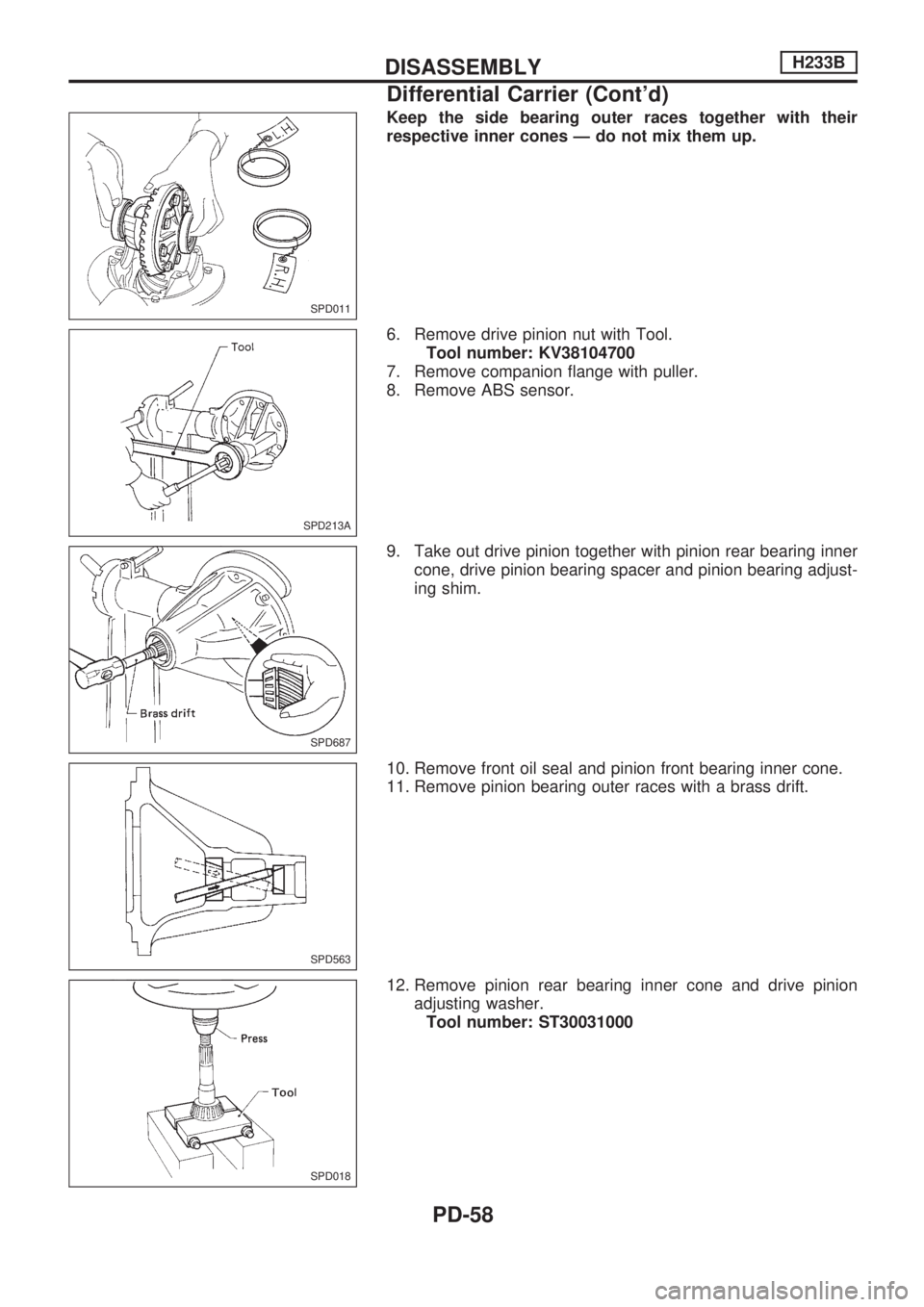

Keep the side bearing outer races together with their

respective inner cones Ð do not mix them up.

6. Remove drive pinion nut with Tool.

Tool number: KV38104700

7. Remove companion flange with puller.

8. Remove ABS sensor.

9. Take out drive pinion together with pinion rear bearing inner

cone, drive pinion bearing spacer and pinion bearing adjust-

ing shim.

10. Remove front oil seal and pinion front bearing inner cone.

11. Remove pinion bearing outer races with a brass drift.

12. Remove pinion rear bearing inner cone and drive pinion

adjusting washer.

Tool number: ST30031000

SPD011

SPD213A

SPD687

SPD563

SPD018

DISASSEMBLYH233B

Differential Carrier (Cont'd)

PD-58

Page 1140 of 1659

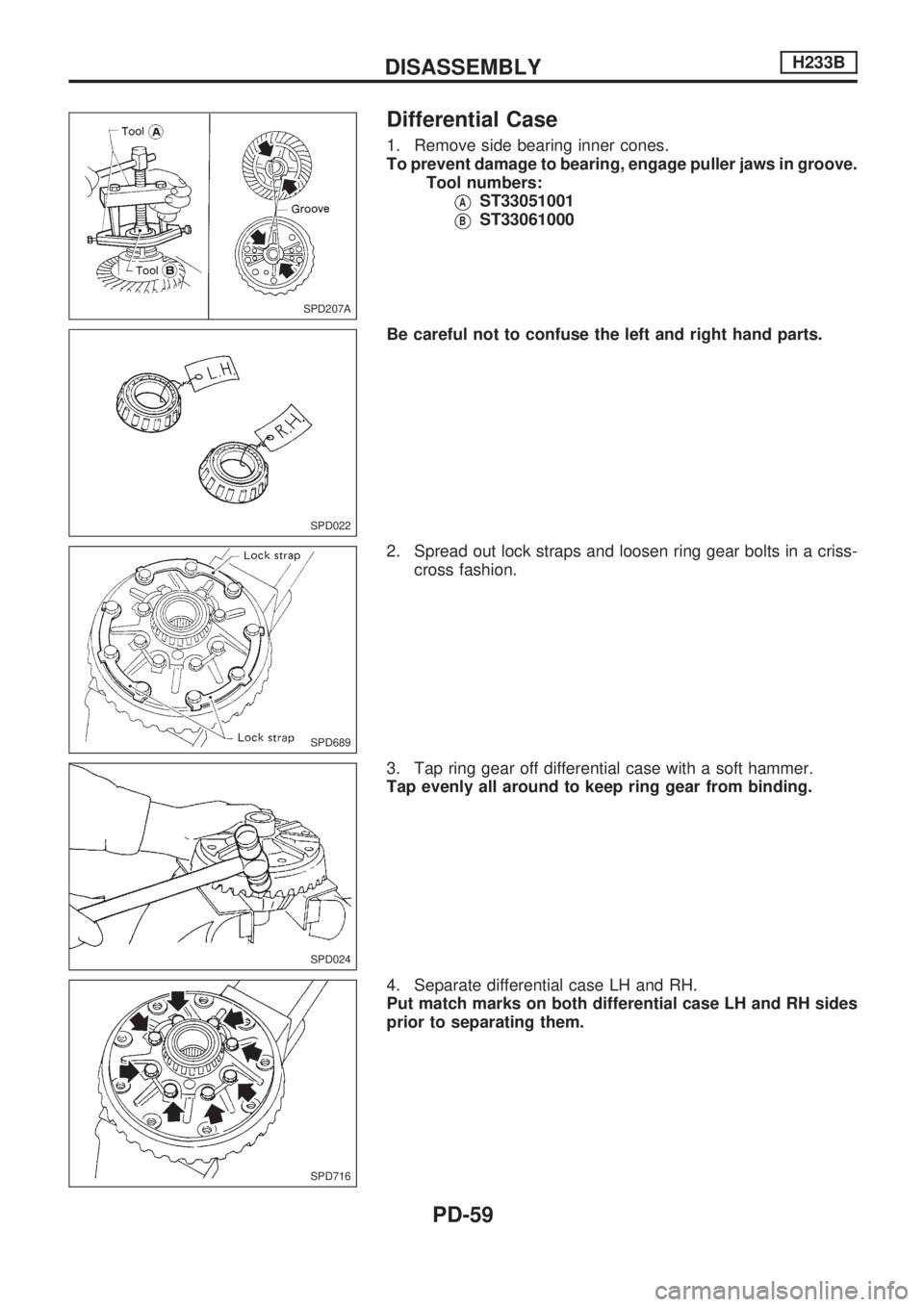

Differential Case

1. Remove side bearing inner cones.

To prevent damage to bearing, engage puller jaws in groove.

Tool numbers:

VAST33051001

VBST33061000

Be careful not to confuse the left and right hand parts.

2. Spread out lock straps and loosen ring gear bolts in a criss-

cross fashion.

3. Tap ring gear off differential case with a soft hammer.

Tap evenly all around to keep ring gear from binding.

4. Separate differential case LH and RH.

Put match marks on both differential case LH and RH sides

prior to separating them.

SPD207A

SPD022

SPD689

SPD024

SPD716

DISASSEMBLYH233B

PD-59

Trending: wiper fluid, height adjustment, sunroof, key, oil reset, fuse box location, fuse box diagram