NISSAN PICK-UP 1998 Repair Manual

PICK-UP 1998

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57374/w960_57374-0.png

NISSAN PICK-UP 1998 Repair Manual

Trending: differential, airbag, fuel filter location, warning light, accelerator, tires, tire size

Page 1091 of 1659

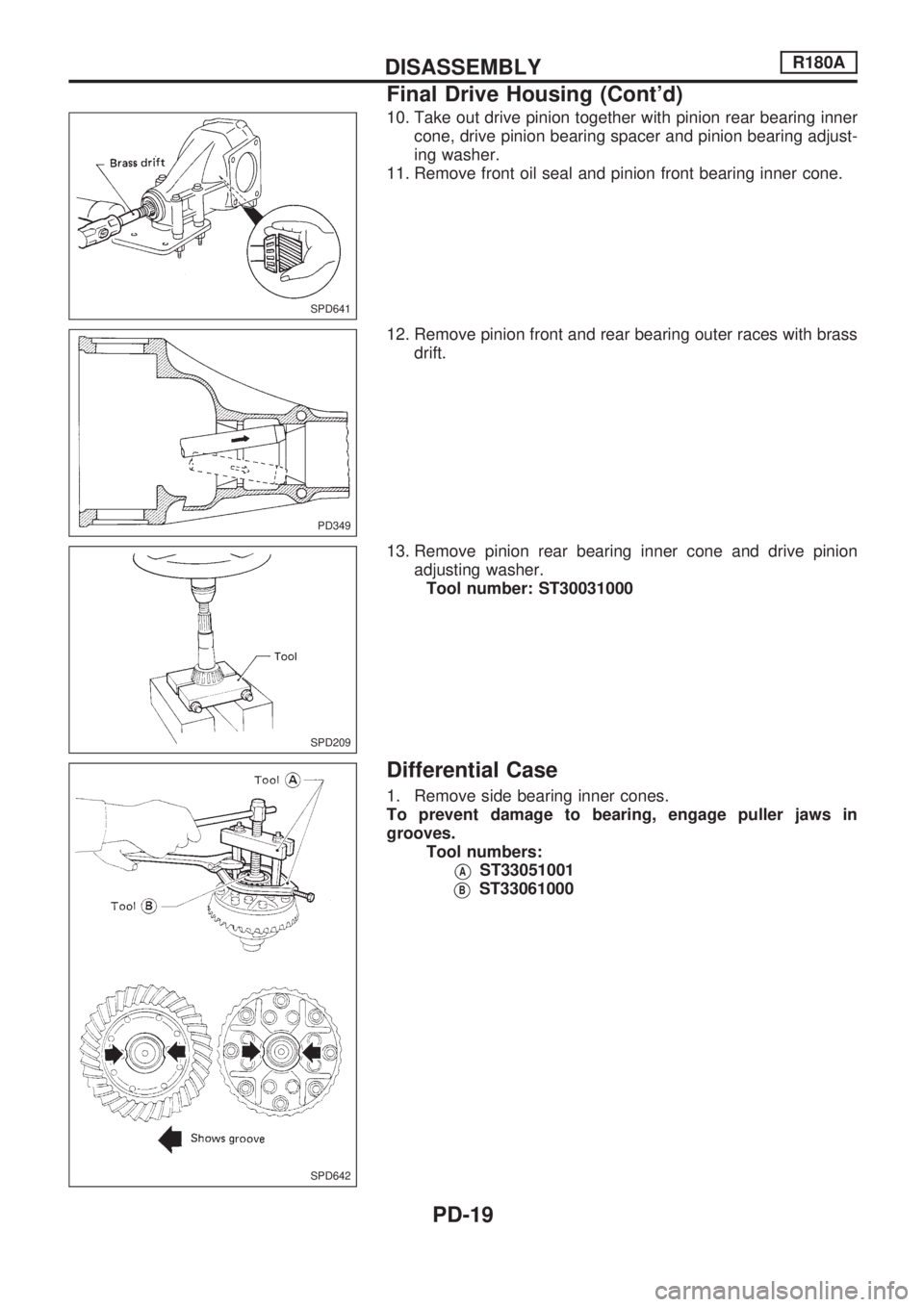

JOURNAL

1. Place matching marks on propeller shaft and flange or yoke.

2. Remove snap ring.

3. Remove pushed out journal bearing by lightly tapping yoke

with a hammer, taking care not to damage journal and yoke

hole.

4. Remove bearing at opposite side in above operation.

Put marks on disassembled parts so that they can be rein-

stalled in their original positions.

Assembly

CENTER BEARING

lWhen installing center bearing, position the ``F'' mark on cen-

ter bearing toward front of vehicle.

lApply a coat of multi-purpose lithium grease containing

molybdenum disulfide to the end face of the center bear-

ing and both sides of the washer.

SPD128

SPD731

SPD732

SPD131

SPD114

PROPELLER SHAFTPropeller shaft

Disassembly (Cont'd)

PD-10

Page 1092 of 1659

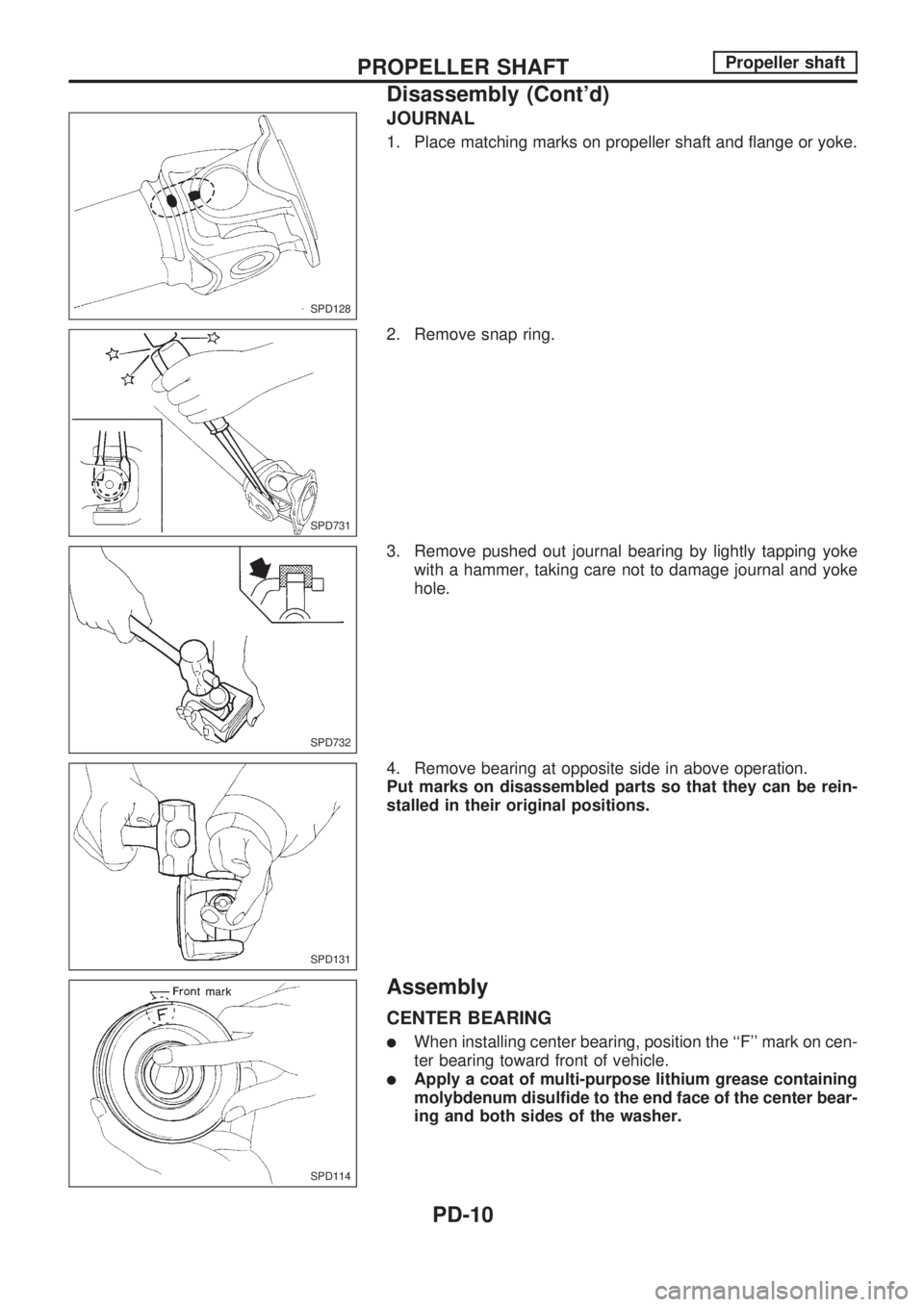

lStake the nut. Always use new one.

lAlign match marks when assembling tubes.

JOURNAL

1. Assemble journal bearing. Apply recommended multi-pur-

pose grease on bearing inner surface.

When assembling, be careful that needle bearing does not

fall down.

2. Select snap ring that will provide specified play in axial direc-

tion of journal, and install them.

Refer to SDS, PD-0.

Select snap rings with a difference in thickness at both

sides within 0.06 mm (0.0024 in).

3. Adjust thrust clearance between bearing and snap ring to

zero by tapping yoke.

4. Check to see that journal moves smoothly and check for axial

play.

Axial play: 0.02 mm (0.0008 in) or less

SPD117

SPD133

SPD134

SPD732

SPD874

PROPELLER SHAFTPropeller shaft

Assembly (Cont'd)

PD-11

Page 1093 of 1659

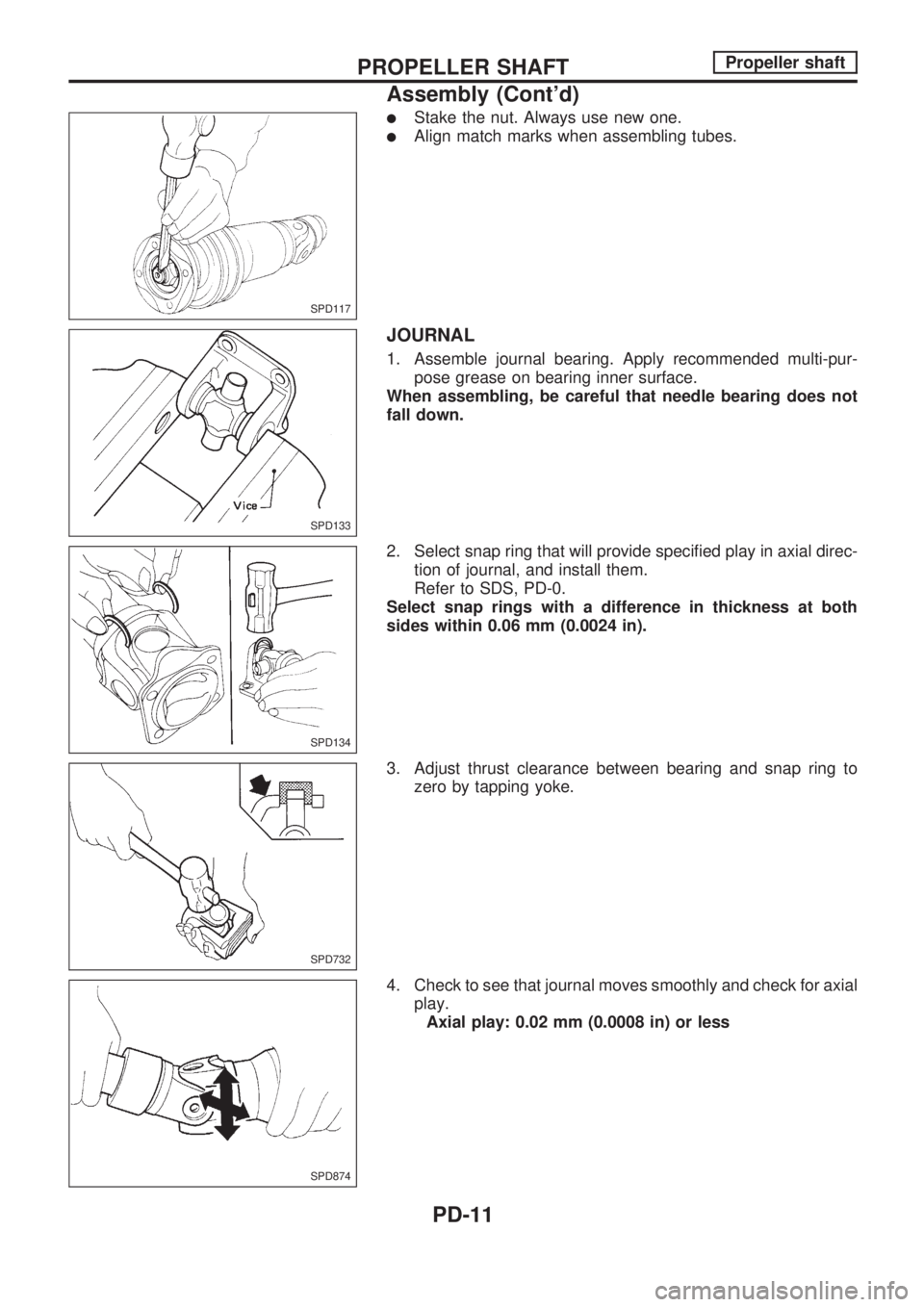

Front Oil Seal Replacement

(Front final drive: Model R180A)

1. Remove front propeller shaft.

2. Loosen drive pinion nut.

3. Remove companion flange using puller.

4. Remove front oil seal.

5. Apply multi-purpose grease to cavity at sealing lips of oil

seal. Press front oil seal into carrier.

Tool number: KV38100500

6. Install companion flange and drive pinion nut.

7. Install propeller shaft.

Front Oil Seal Replacement

(Rear final drive: Model H233B)

CAUTION:

For final drive models using collapsible spacer (C200), bear-

ing preload must be adjusted whenever companion flange is

removed. Therefore, final drive overhaul is required.

1. Remove propeller shaft.

2. Loosen drive pinion nut.

Tool number: KV38104700

3. Remove companion flange.

4. Remove front oil seal.

SPD413A

SPD414A

PD237

SPD737

SPD738

ON-VEHICLE SERVICEFinal drive

PD-12

Page 1094 of 1659

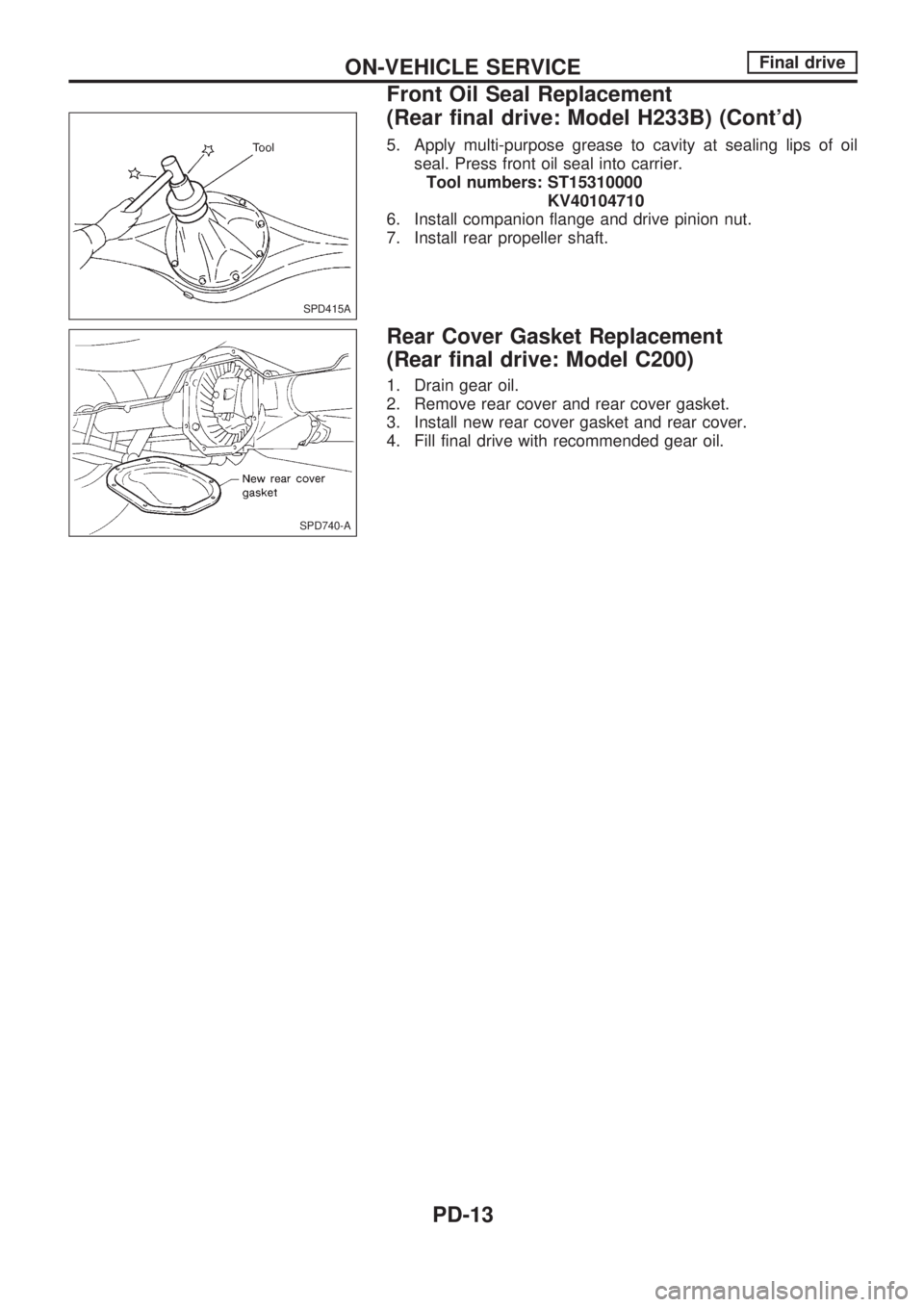

5. Apply multi-purpose grease to cavity at sealing lips of oil

seal. Press front oil seal into carrier.

Tool numbers: ST15310000

KV40104710

6. Install companion flange and drive pinion nut.

7. Install rear propeller shaft.

Rear Cover Gasket Replacement

(Rear final drive: Model C200)

1. Drain gear oil.

2. Remove rear cover and rear cover gasket.

3. Install new rear cover gasket and rear cover.

4. Fill final drive with recommended gear oil.

SPD415A

SPD740-A

ON-VEHICLE SERVICEFinal drive

Front Oil Seal Replacement

(Rear final drive: Model H233B) (Cont'd)

PD-13

Page 1095 of 1659

![NISSAN PICK-UP 1998 Repair Manual Removal

1. Remove front propeller shaft.

2. Remove drive shaft. Refer to FA section [``Drive Shaft,

``FRONT AXLE (4WD)].

3. Remove engine mounting bolts and raise up engine.

4. Remove front final NISSAN PICK-UP 1998 Repair Manual Removal

1. Remove front propeller shaft.

2. Remove drive shaft. Refer to FA section [``Drive Shaft,

``FRONT AXLE (4WD)].

3. Remove engine mounting bolts and raise up engine.

4. Remove front final](/img/5/57374/w960_57374-1094.png)

Removal

1. Remove front propeller shaft.

2. Remove drive shaft. Refer to FA section [``Drive Shaft'',

``FRONT AXLE (4WD)''].

3. Remove engine mounting bolts and raise up engine.

4. Remove front final drive together with differential mounting

member.

Installation

1. Install front final drive assembly together with differential

mounting member.

2. Tighten front final drive securing bolts and nuts by following

the procedure to prevent drive train vibration.

a. Temporarily tighten nut

VA.

b. Temporarily tighten nut

VB.

c. Tighten bolt

VCto the torque of 68 to 87 N´m (6.9 to 8.9 kg-m,

50 to 64 ft-lb).

d. Tighten bolt

VDto the torque of 68 to 87 N´m (6.9 to 8.9 kg-m,

50 to 64 ft-lb).

e. Tighten nut

VAto the torque of 68 to 87 N´m (6.9 to 8.9 kg-m,

50 to 64 ft-lb).

f. Tighten nut

VBto the torque of 68 to 87 N´m (6.9 to 8.9 kg-m,

50 to 64 ft-lb).

g. Tighten nut

VEto the torque of 68 to 87 N´m (6.9 to 8.9 kg-m,

50 to 64 ft-lb).

3. Install drive shaft. Refer to FA section [``Drive Shaft'',

``FRONT AXLE (4WD)''].

4. Install front propeller shaft.

SPD416A

SPD417A

SPD743

REMOVAL AND INSTALLATION (Front final drive)Final drive

PD-14

Page 1096 of 1659

Removal

lRemove propeller shaft.

Plug front end of transfer.

lRemove axle shaft.

Refer to RA section (``REAR AXLE'').

CAUTION:

lBe careful not to damage spline, sleeve yoke and front

oil seal when removing propeller shaft.

lBefore removing the final drive assembly or rear axle

assembly, disconnect the ABS sensor harness connec-

tor from the assembly and move it away from the final

drive/rear axle assembly area. Failure to do so may

result in the sensor wires being damaged and the sen-

sor becoming inoperative.

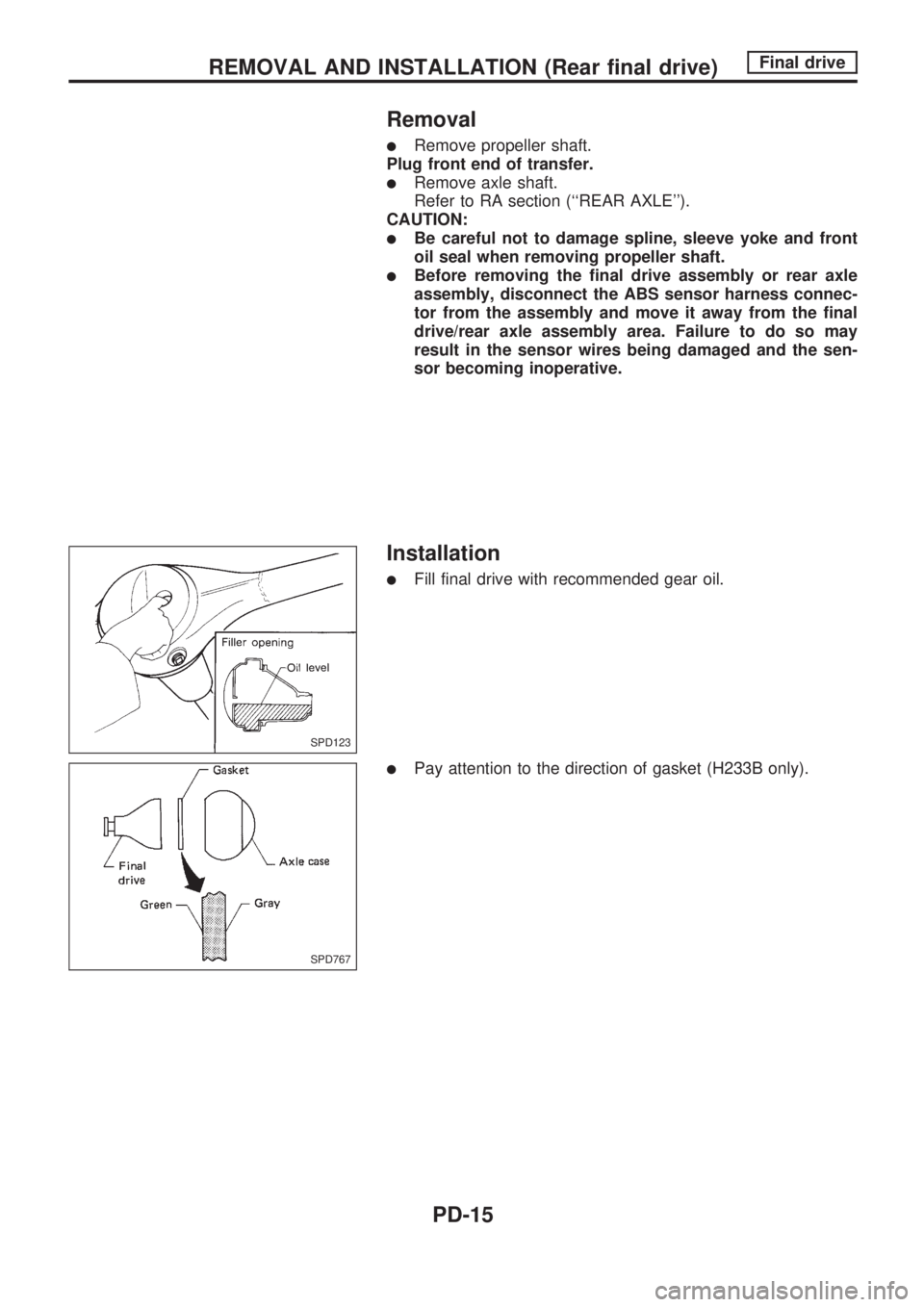

Installation

lFill final drive with recommended gear oil.

lPay attention to the direction of gasket (H233B only).

SPD123

SPD767

REMOVAL AND INSTALLATION (Rear final drive)Final drive

PD-15

Page 1097 of 1659

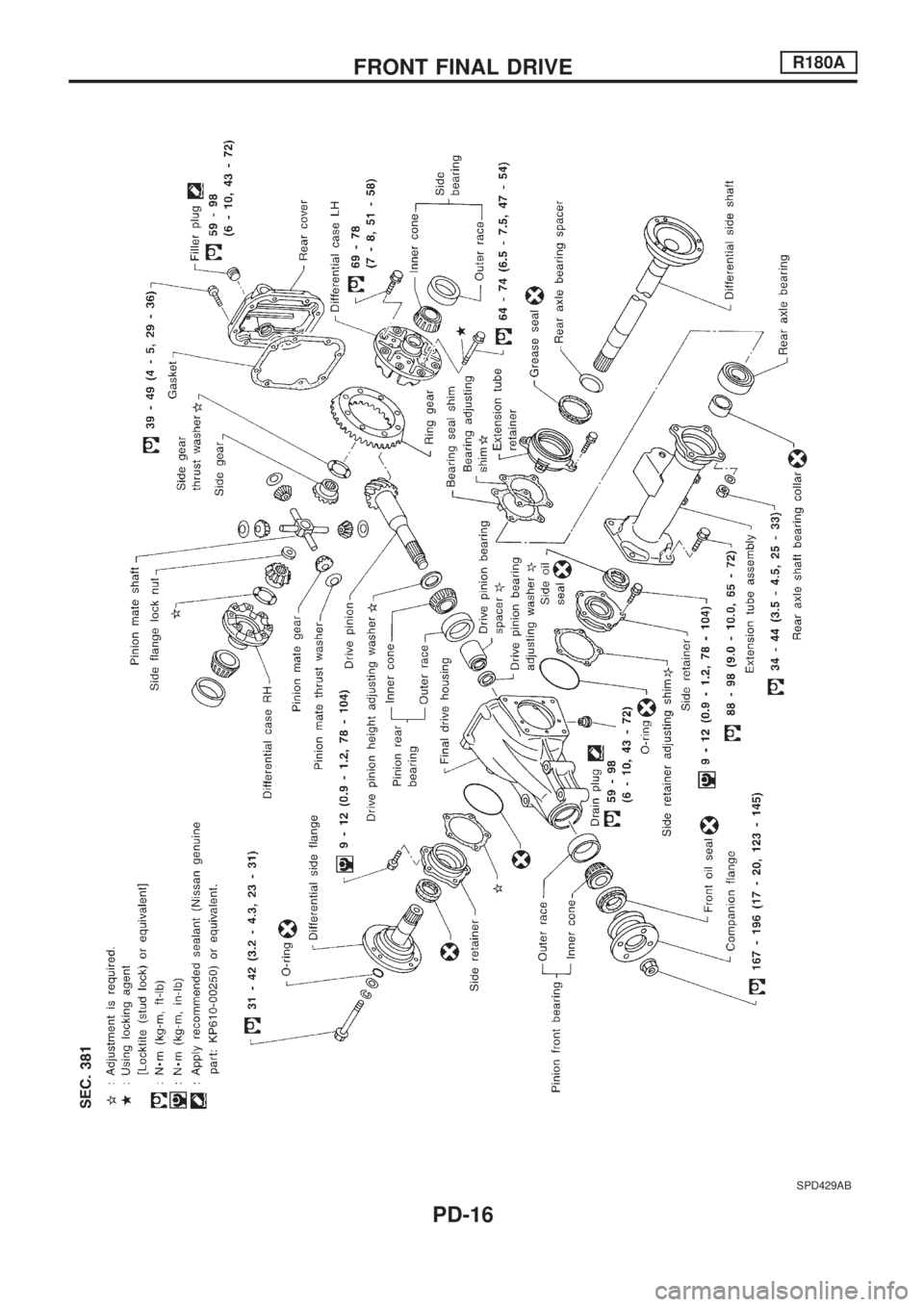

SPD429AB

FRONT FINAL DRIVER180A

PD-16

Page 1098 of 1659

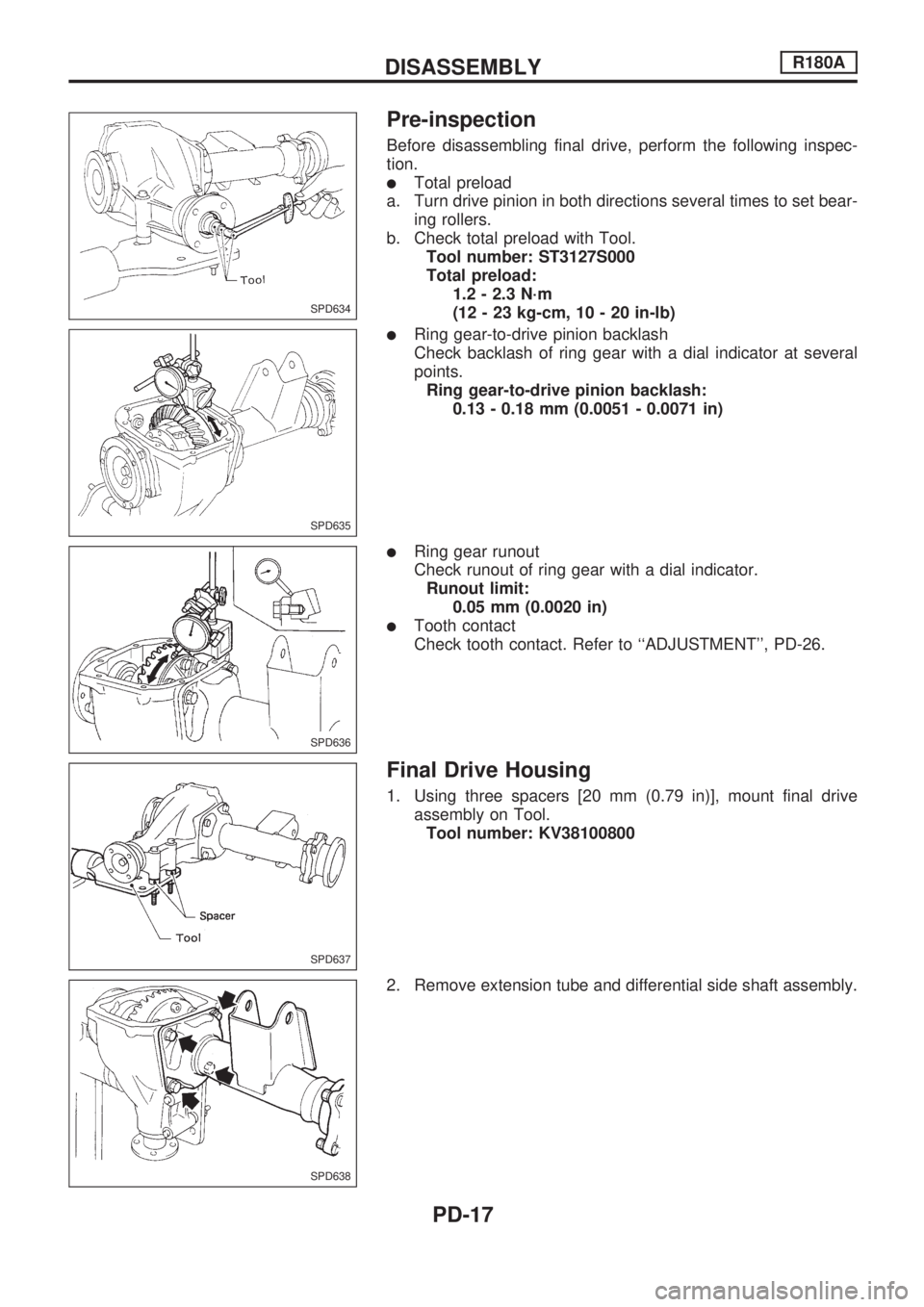

Pre-inspection

Before disassembling final drive, perform the following inspec-

tion.

lTotal preload

a. Turn drive pinion in both directions several times to set bear-

ing rollers.

b. Check total preload with Tool.

Tool number: ST3127S000

Total preload:

1.2 - 2.3 N´m

(12 - 23 kg-cm, 10 - 20 in-lb)

lRing gear-to-drive pinion backlash

Check backlash of ring gear with a dial indicator at several

points.

Ring gear-to-drive pinion backlash:

0.13 - 0.18 mm (0.0051 - 0.0071 in)

lRing gear runout

Check runout of ring gear with a dial indicator.

Runout limit:

0.05 mm (0.0020 in)

lTooth contact

Check tooth contact. Refer to ``ADJUSTMENT'', PD-26.

Final Drive Housing

1. Using three spacers [20 mm (0.79 in)], mount final drive

assembly on Tool.

Tool number: KV38100800

2. Remove extension tube and differential side shaft assembly.

SPD634

SPD635

SPD636

SPD637

SPD638

DISASSEMBLYR180A

PD-17

Page 1099 of 1659

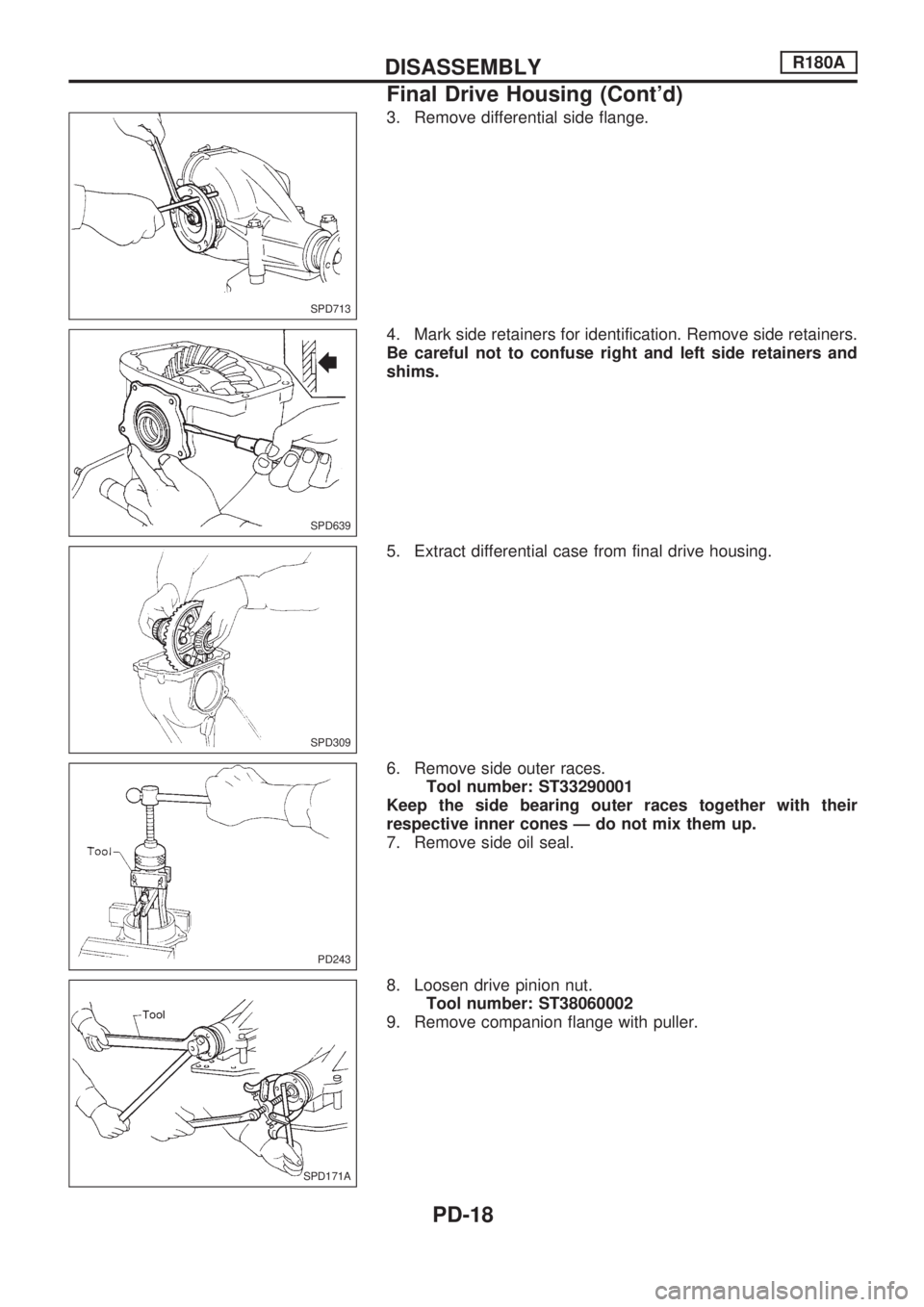

3. Remove differential side flange.

4. Mark side retainers for identification. Remove side retainers.

Be careful not to confuse right and left side retainers and

shims.

5. Extract differential case from final drive housing.

6. Remove side outer races.

Tool number: ST33290001

Keep the side bearing outer races together with their

respective inner cones Ð do not mix them up.

7. Remove side oil seal.

8. Loosen drive pinion nut.

Tool number: ST38060002

9. Remove companion flange with puller.

SPD713

SPD639

SPD309

PD243

SPD171A

DISASSEMBLYR180A

Final Drive Housing (Cont'd)

PD-18

Page 1100 of 1659

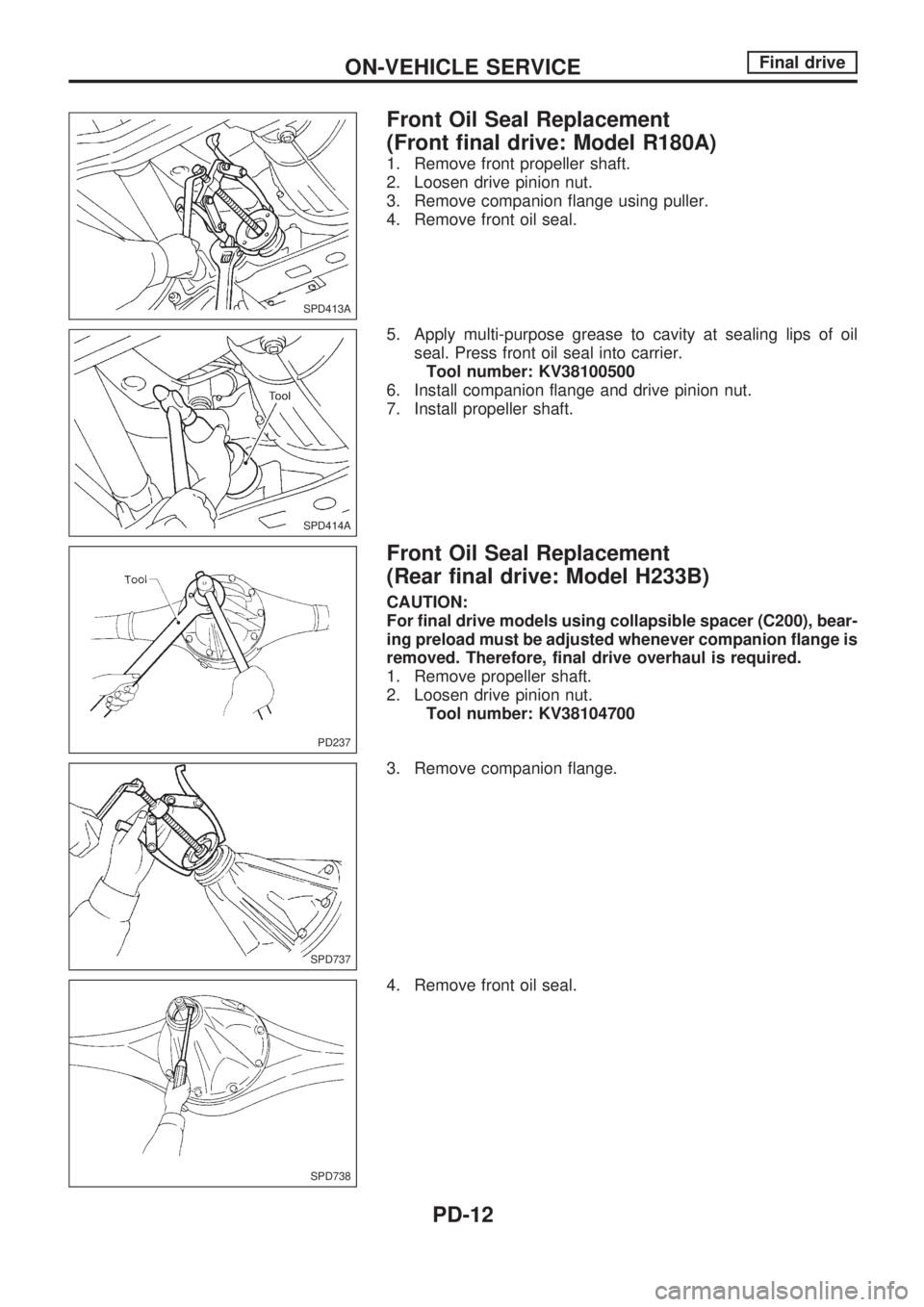

10. Take out drive pinion together with pinion rear bearing inner

cone, drive pinion bearing spacer and pinion bearing adjust-

ing washer.

11. Remove front oil seal and pinion front bearing inner cone.

12. Remove pinion front and rear bearing outer races with brass

drift.

13. Remove pinion rear bearing inner cone and drive pinion

adjusting washer.

Tool number: ST30031000

Differential Case

1. Remove side bearing inner cones.

To prevent damage to bearing, engage puller jaws in

grooves.

Tool numbers:

VAST33051001

VBST33061000

SPD641

PD349

SPD209

SPD642

DISASSEMBLYR180A

Final Drive Housing (Cont'd)

PD-19

Trending: charging, service reset, change time, hood open, lights, OBD port, horn harness

![NISSAN PICK-UP 1998 Repair Manual Removal

1. Remove front propeller shaft.

2. Remove drive shaft. Refer to FA section [``Drive Shaft,

``FRONT AXLE (4WD)].

3. Remove engine mounting bolts and raise up engine.

4. Remove front final NISSAN PICK-UP 1998 Repair Manual Removal

1. Remove front propeller shaft.

2. Remove drive shaft. Refer to FA section [``Drive Shaft,

``FRONT AXLE (4WD)].

3. Remove engine mounting bolts and raise up engine.

4. Remove front final](/img/5/57374/w960_57374-1094.png)