NISSAN PICK-UP 1998 Repair Manual

Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 731 of 1659

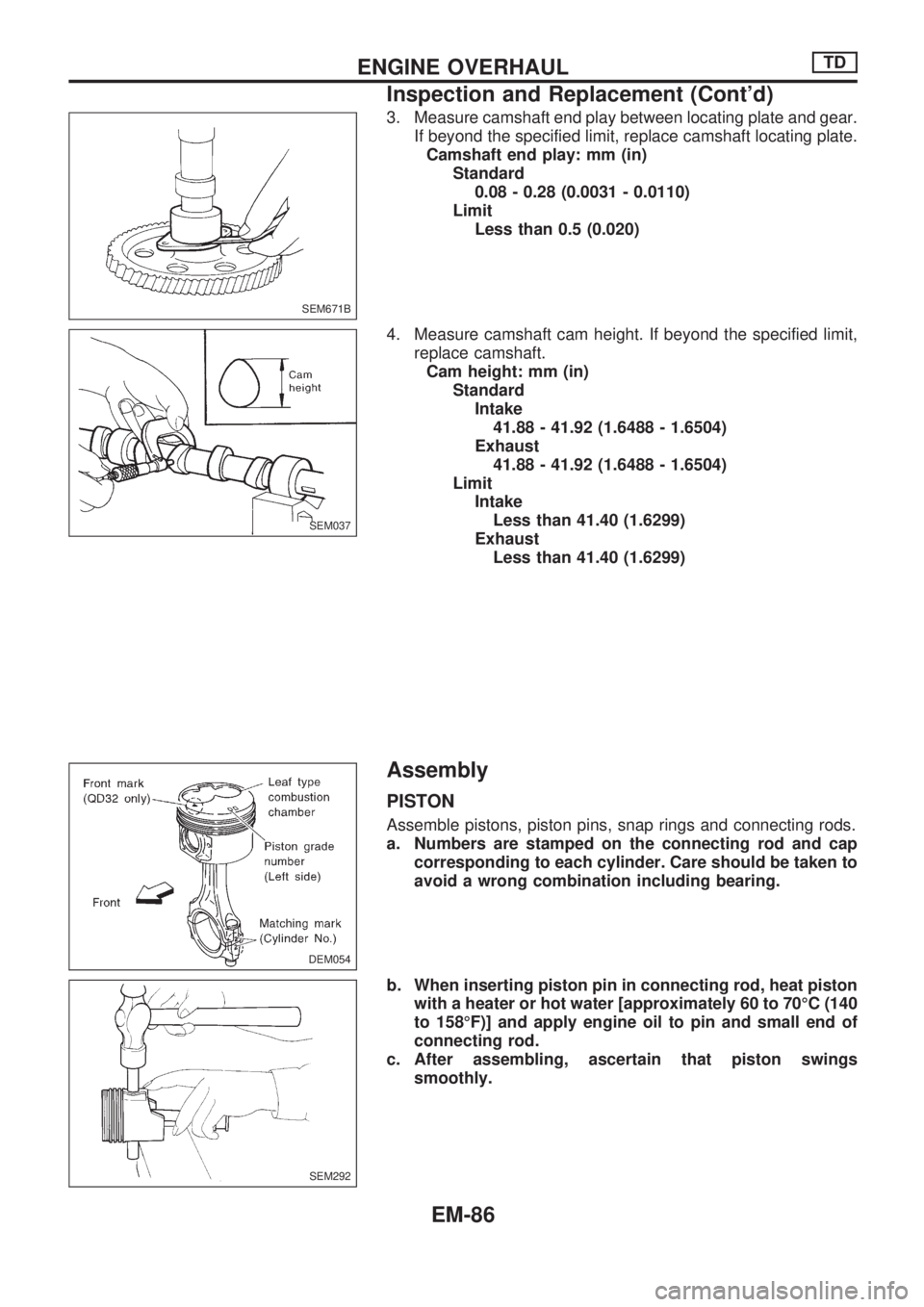

3. Measure camshaft end play between locating plate and gear.

If beyond the specified limit, replace camshaft locating plate.

Camshaft end play: mm (in)

Standard

0.08 - 0.28 (0.0031 - 0.0110)

Limit

Less than 0.5 (0.020)

4. Measure camshaft cam height. If beyond the specified limit,

replace camshaft.

Cam height: mm (in)

Standard

Intake

41.88 - 41.92 (1.6488 - 1.6504)

Exhaust

41.88 - 41.92 (1.6488 - 1.6504)

Limit

Intake

Less than 41.40 (1.6299)

Exhaust

Less than 41.40 (1.6299)

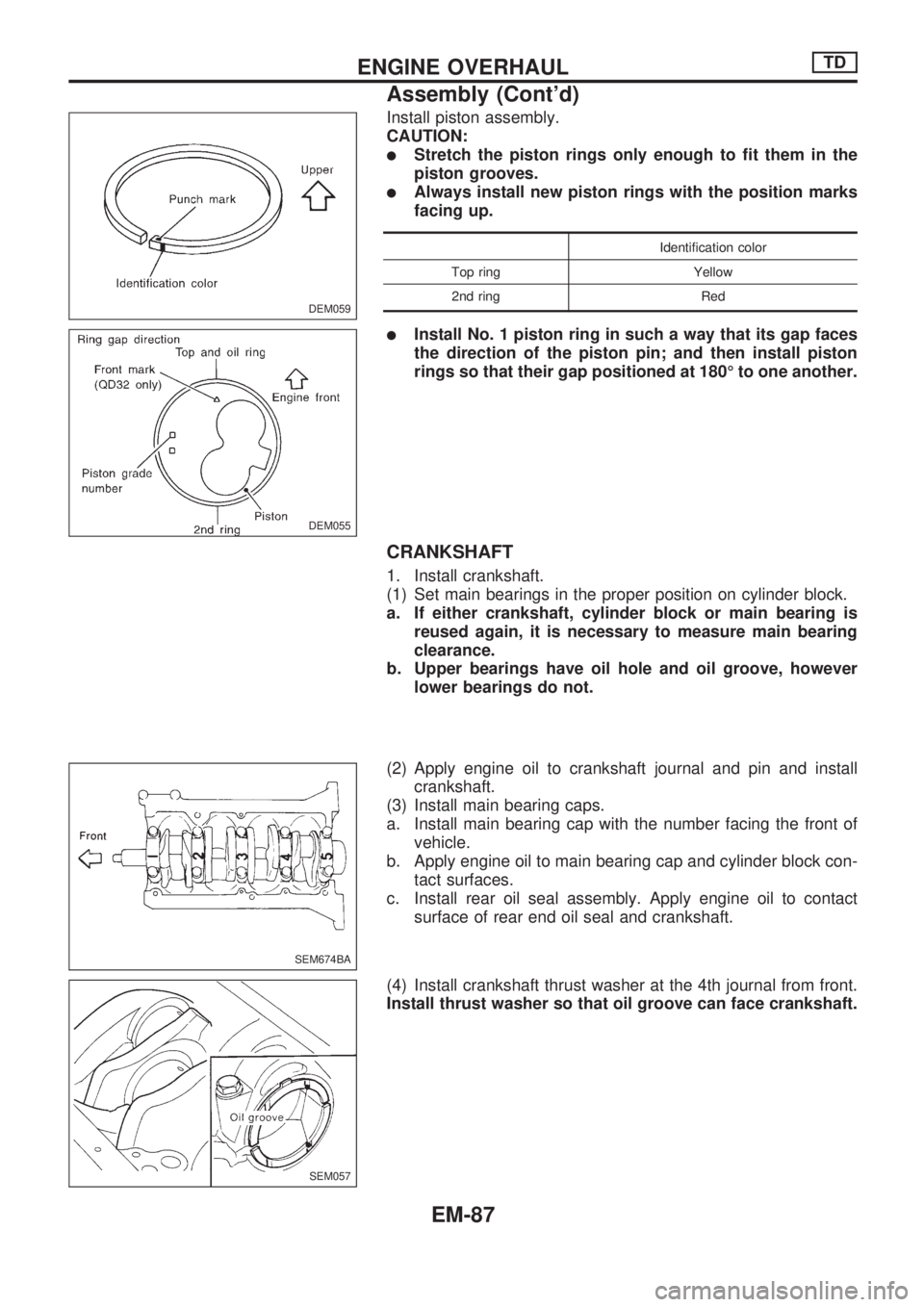

Assembly

PISTON

Assemble pistons, piston pins, snap rings and connecting rods.

a. Numbers are stamped on the connecting rod and cap

corresponding to each cylinder. Care should be taken to

avoid a wrong combination including bearing.

b. When inserting piston pin in connecting rod, heat piston

with a heater or hot water [approximately 60 to 70ÉC (140

to 158ÉF)] and apply engine oil to pin and small end of

connecting rod.

c. After assembling, ascertain that piston swings

smoothly.

SEM671B

SEM037

DEM054

SEM292

ENGINE OVERHAULTD

Inspection and Replacement (Cont'd)

EM-86

Page 732 of 1659

Install piston assembly.

CAUTION:

lStretch the piston rings only enough to fit them in the

piston grooves.

lAlways install new piston rings with the position marks

facing up.

Identification color

Top ring Yellow

2nd ring Red

lInstall No. 1 piston ring in such a way that its gap faces

the direction of the piston pin; and then install piston

rings so that their gap positioned at 180É to one another.

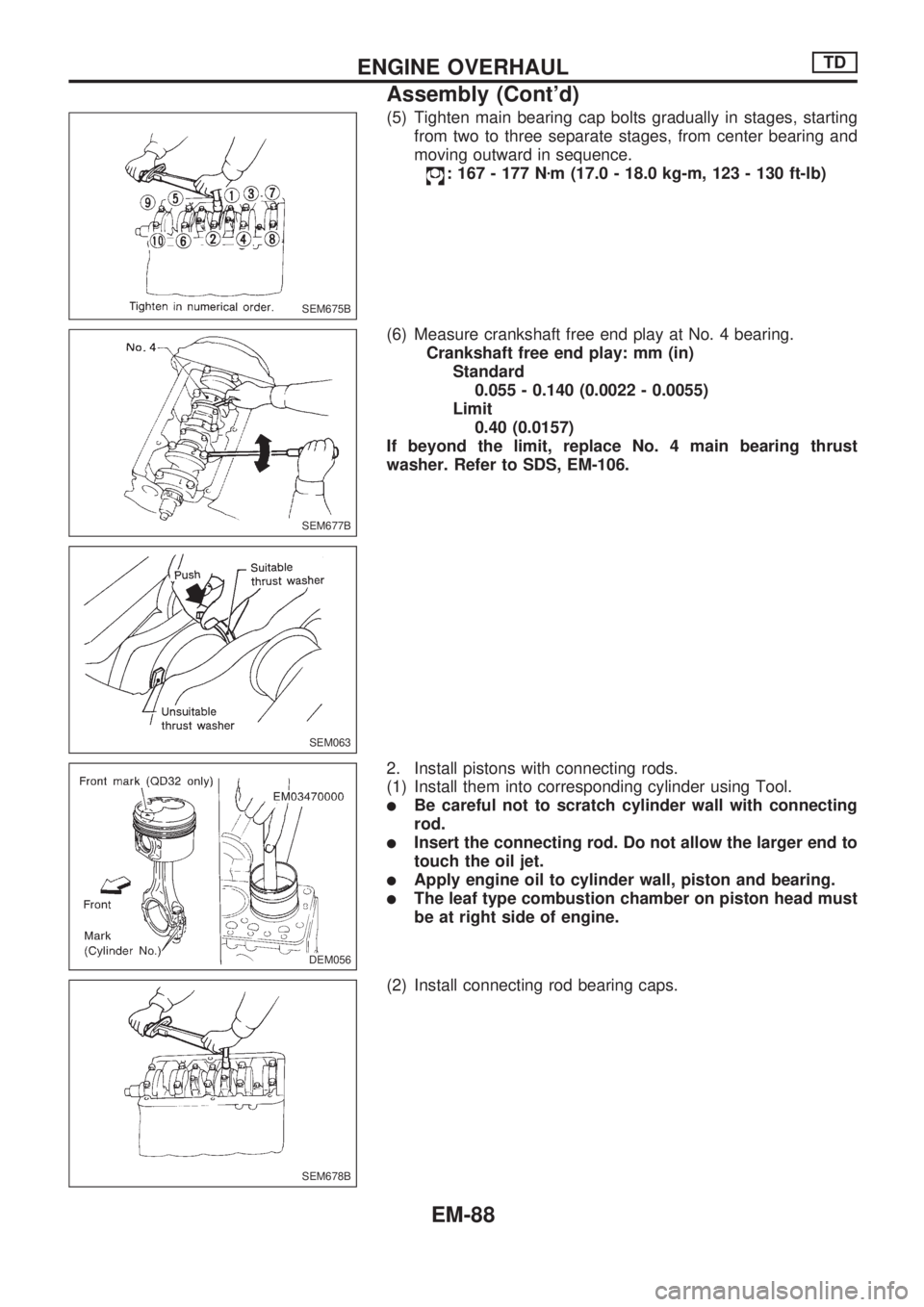

CRANKSHAFT

1. Install crankshaft.

(1) Set main bearings in the proper position on cylinder block.

a. If either crankshaft, cylinder block or main bearing is

reused again, it is necessary to measure main bearing

clearance.

b. Upper bearings have oil hole and oil groove, however

lower bearings do not.

(2) Apply engine oil to crankshaft journal and pin and install

crankshaft.

(3) Install main bearing caps.

a. Install main bearing cap with the number facing the front of

vehicle.

b. Apply engine oil to main bearing cap and cylinder block con-

tact surfaces.

c. Install rear oil seal assembly. Apply engine oil to contact

surface of rear end oil seal and crankshaft.

(4) Install crankshaft thrust washer at the 4th journal from front.

Install thrust washer so that oil groove can face crankshaft.

DEM059

DEM055

SEM674BA

SEM057

ENGINE OVERHAULTD

Assembly (Cont'd)

EM-87

Page 733 of 1659

(5) Tighten main bearing cap bolts gradually in stages, starting

from two to three separate stages, from center bearing and

moving outward in sequence.

: 167 - 177 Nzm (17.0 - 18.0 kg-m, 123 - 130 ft-lb)

(6) Measure crankshaft free end play at No. 4 bearing.

Crankshaft free end play: mm (in)

Standard

0.055 - 0.140 (0.0022 - 0.0055)

Limit

0.40 (0.0157)

If beyond the limit, replace No. 4 main bearing thrust

washer. Refer to SDS, EM-106.

2. Install pistons with connecting rods.

(1) Install them into corresponding cylinder using Tool.

lBe careful not to scratch cylinder wall with connecting

rod.

lInsert the connecting rod. Do not allow the larger end to

touch the oil jet.

lApply engine oil to cylinder wall, piston and bearing.

lThe leaf type combustion chamber on piston head must

be at right side of engine.

(2) Install connecting rod bearing caps.

SEM675B

SEM677B

SEM063

DEM056.DEM056

SEM678B

ENGINE OVERHAULTD

Assembly (Cont'd)

EM-88

Page 734 of 1659

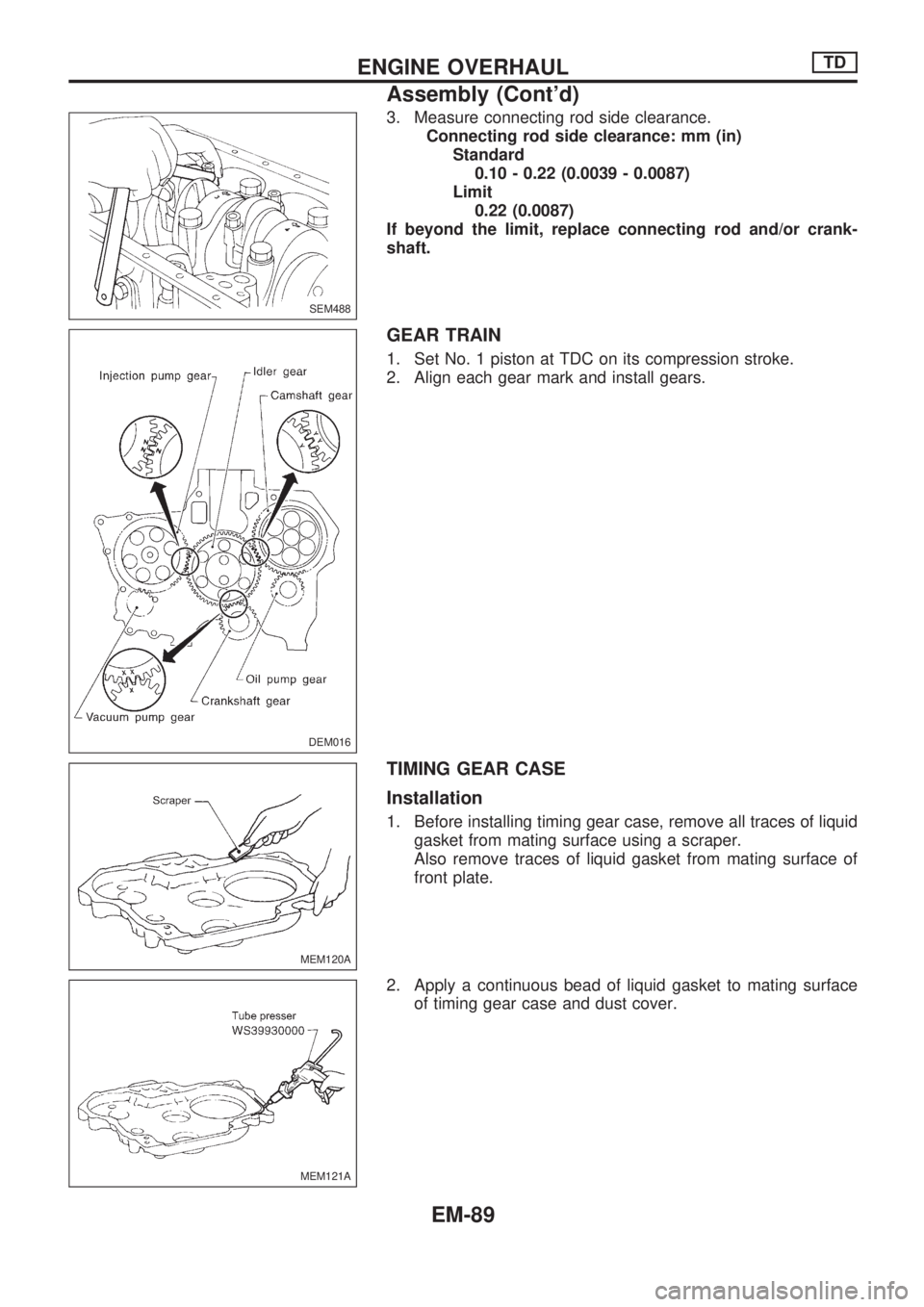

3. Measure connecting rod side clearance.

Connecting rod side clearance: mm (in)

Standard

0.10 - 0.22 (0.0039 - 0.0087)

Limit

0.22 (0.0087)

If beyond the limit, replace connecting rod and/or crank-

shaft.

GEAR TRAIN

1. Set No. 1 piston at TDC on its compression stroke.

2. Align each gear mark and install gears.

TIMING GEAR CASE

Installation

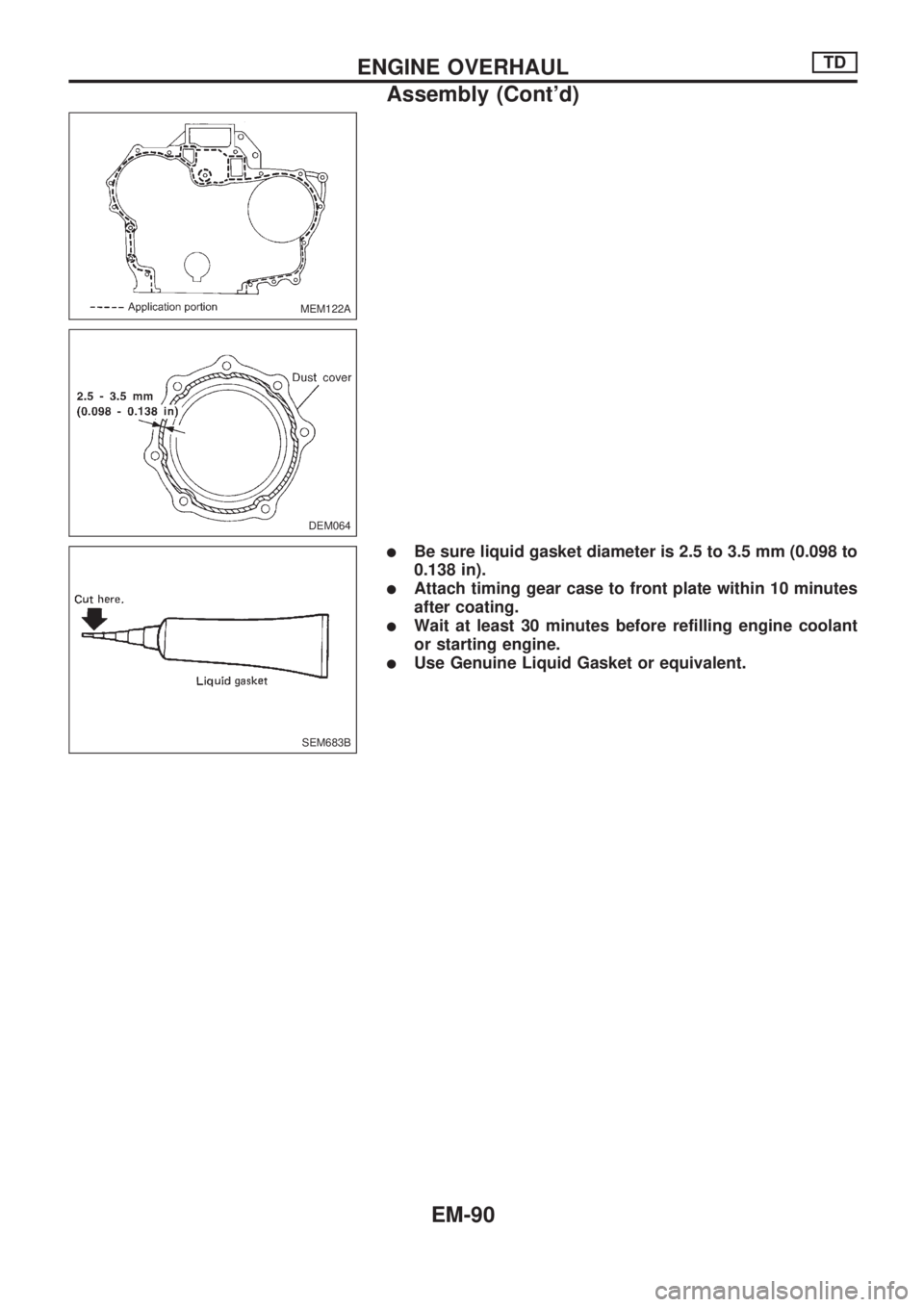

1. Before installing timing gear case, remove all traces of liquid

gasket from mating surface using a scraper.

Also remove traces of liquid gasket from mating surface of

front plate.

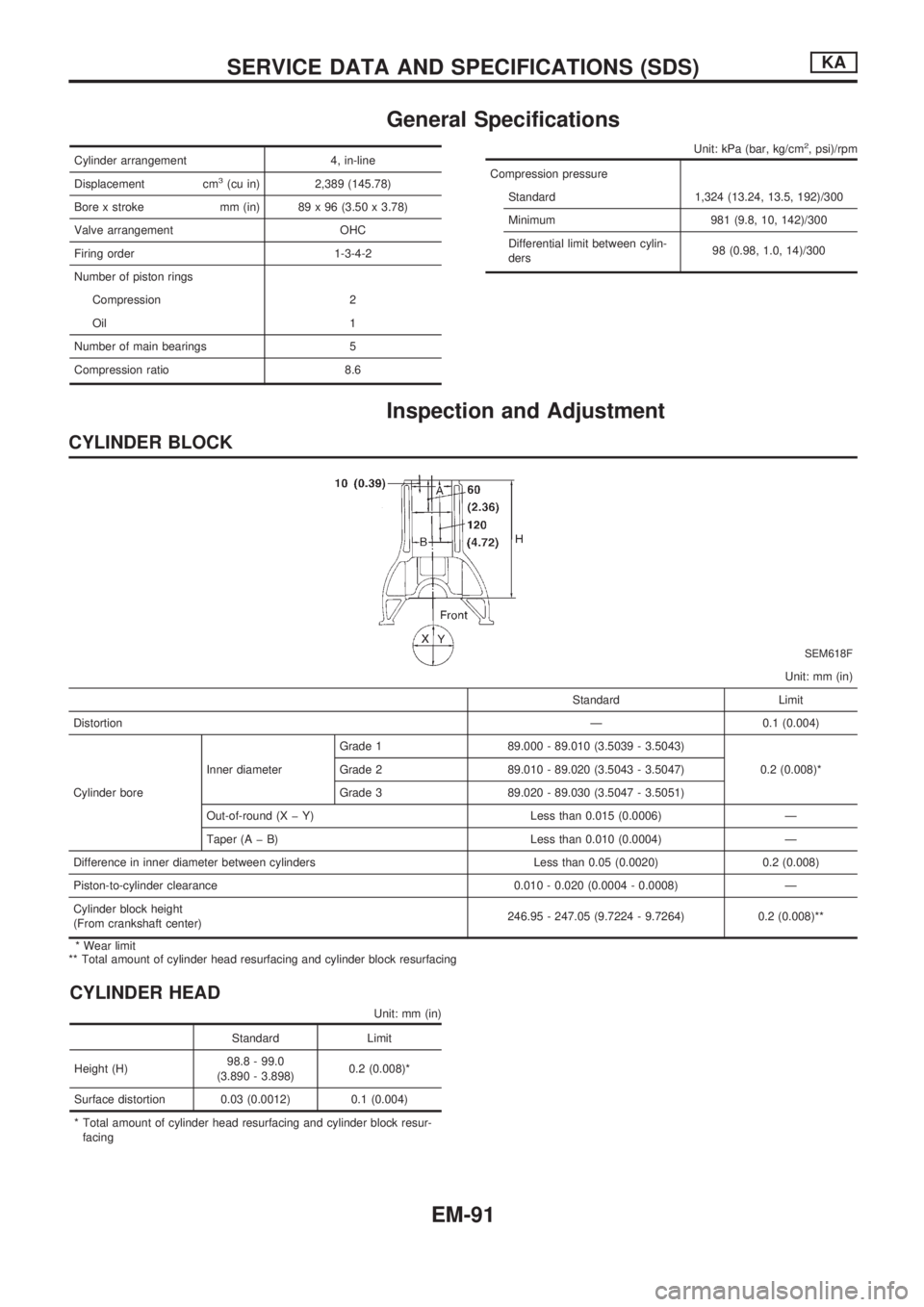

2. Apply a continuous bead of liquid gasket to mating surface

of timing gear case and dust cover.

SEM488

DEM016

MEM120A

MEM121A

ENGINE OVERHAULTD

Assembly (Cont'd)

EM-89

Page 735 of 1659

lBe sure liquid gasket diameter is 2.5 to 3.5 mm (0.098 to

0.138 in).

lAttach timing gear case to front plate within 10 minutes

after coating.

lWait at least 30 minutes before refilling engine coolant

or starting engine.

lUse Genuine Liquid Gasket or equivalent.

MEM122A

DEM064

SEM683B

ENGINE OVERHAULTD

Assembly (Cont'd)

EM-90

Page 736 of 1659

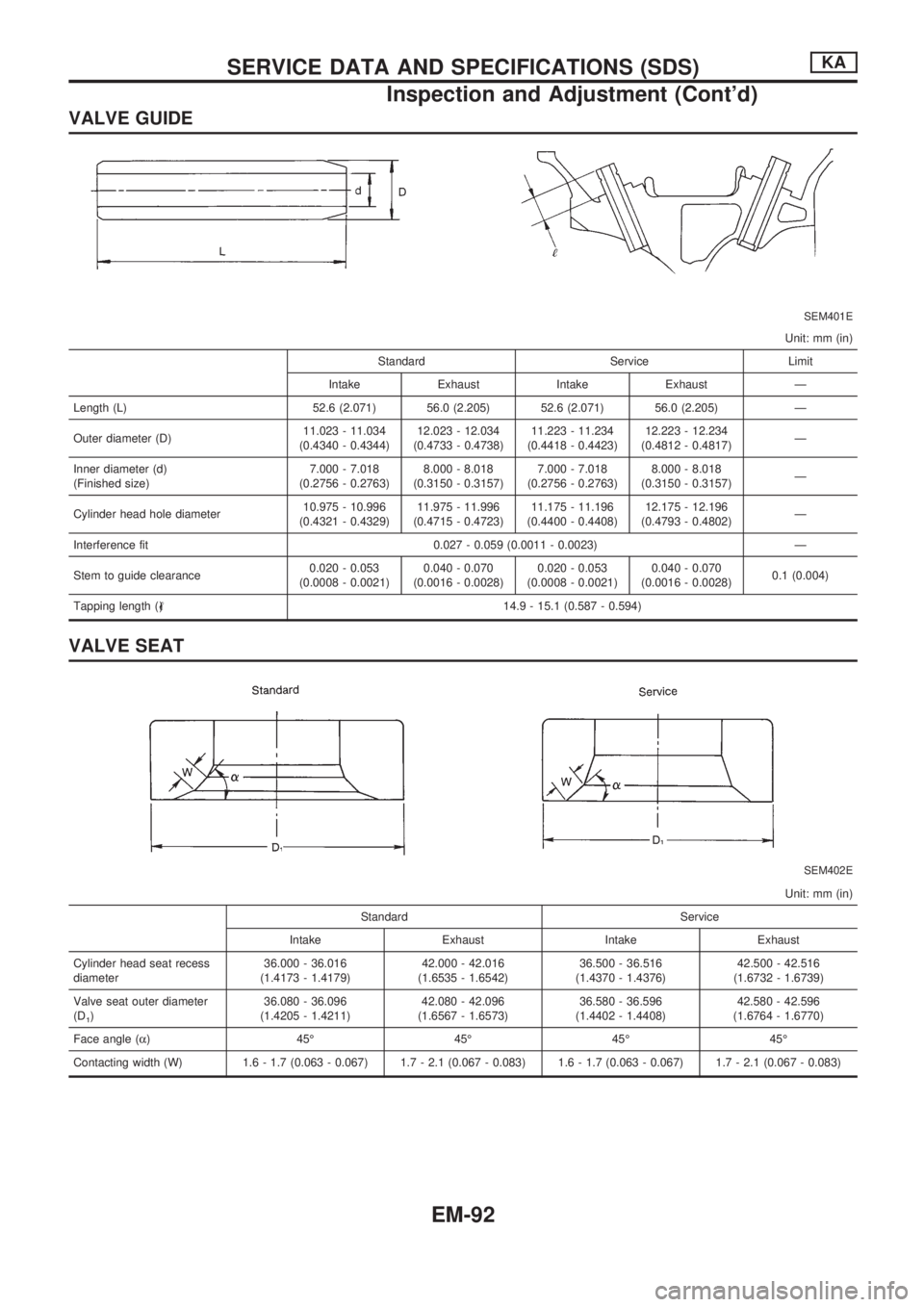

General Specifications

Cylinder arrangement 4, in-line

Displacement cm

3(cu in) 2,389 (145.78)

Bore x stroke mm (in) 89 x 96 (3.50 x 3.78)

Valve arrangement OHC

Firing order 1-3-4-2

Number of piston rings

Compression 2

Oil 1

Number of main bearings 5

Compression ratio 8.6

Unit: kPa (bar, kg/cm2, psi)/rpm

Compression pressure

Standard 1,324 (13.24, 13.5, 192)/300

Minimum 981 (9.8, 10, 142)/300

Differential limit between cylin-

ders98 (0.98, 1.0, 14)/300

Inspection and Adjustment

CYLINDER BLOCK

SEM618F

Unit: mm (in)

Standard Limit

DistortionÐ 0.1 (0.004)

Cylinder boreInner diameterGrade 1 89.000 - 89.010 (3.5039 - 3.5043)

0.2 (0.008)* Grade 2 89.010 - 89.020 (3.5043 - 3.5047)

Grade 3 89.020 - 89.030 (3.5047 - 3.5051)

Out-of-round (X þ Y) Less than 0.015 (0.0006) Ð

Taper (A þ B) Less than 0.010 (0.0004) Ð

Difference in inner diameter between cylinders Less than 0.05 (0.0020) 0.2 (0.008)

Piston-to-cylinder clearance 0.010 - 0.020 (0.0004 - 0.0008) Ð

Cylinder block height

(From crankshaft center)246.95 - 247.05 (9.7224 - 9.7264) 0.2 (0.008)**

* Wear limit

** Total amount of cylinder head resurfacing and cylinder block resurfacing

CYLINDER HEAD

Unit: mm (in)

Standard Limit

Height (H)98.8 - 99.0

(3.890 - 3.898)0.2 (0.008)*

Surface distortion 0.03 (0.0012) 0.1 (0.004)

* Total amount of cylinder head resurfacing and cylinder block resur-

facing

SERVICE DATA AND SPECIFICATIONS (SDS)KA

EM-91

Page 737 of 1659

VALVE GUIDE

SEM401E

Unit: mm (in)

Standard Service Limit

Intake Exhaust Intake Exhaust Ð

Length (L) 52.6 (2.071) 56.0 (2.205) 52.6 (2.071) 56.0 (2.205) Ð

Outer diameter (D)11.023 - 11.034

(0.4340 - 0.4344)12.023 - 12.034

(0.4733 - 0.4738)11.223 - 11.234

(0.4418 - 0.4423)12.223 - 12.234

(0.4812 - 0.4817)Ð

Inner diameter (d)

(Finished size)7.000 - 7.018

(0.2756 - 0.2763)8.000 - 8.018

(0.3150 - 0.3157)7.000 - 7.018

(0.2756 - 0.2763)8.000 - 8.018

(0.3150 - 0.3157)Ð

Cylinder head hole diameter10.975 - 10.996

(0.4321 - 0.4329)11.975 - 11.996

(0.4715 - 0.4723)11.175 - 11.196

(0.4400 - 0.4408)12.175 - 12.196

(0.4793 - 0.4802)Ð

Interference fit 0.027 - 0.059 (0.0011 - 0.0023) Ð

Stem to guide clearance0.020 - 0.053

(0.0008 - 0.0021)0.040 - 0.070

(0.0016 - 0.0028)0.020 - 0.053

(0.0008 - 0.0021)0.040 - 0.070

(0.0016 - 0.0028)0.1 (0.004)

Tapping length (,) 14.9 - 15.1 (0.587 - 0.594)

VALVE SEAT

SEM402E

Unit: mm (in)

Standard Service

Intake Exhaust Intake Exhaust

Cylinder head seat recess

diameter36.000 - 36.016

(1.4173 - 1.4179)42.000 - 42.016

(1.6535 - 1.6542)36.500 - 36.516

(1.4370 - 1.4376)42.500 - 42.516

(1.6732 - 1.6739)

Valve seat outer diameter

(D

1)36.080 - 36.096

(1.4205 - 1.4211)42.080 - 42.096

(1.6567 - 1.6573)36.580 - 36.596

(1.4402 - 1.4408)42.580 - 42.596

(1.6764 - 1.6770)

Face angle (a) 45É 45É 45É 45É

Contacting width (W) 1.6 - 1.7 (0.063 - 0.067) 1.7 - 2.1 (0.067 - 0.083) 1.6 - 1.7 (0.063 - 0.067) 1.7 - 2.1 (0.067 - 0.083)

SERVICE DATA AND SPECIFICATIONS (SDS)KA

Inspection and Adjustment (Cont'd)

EM-92

Page 738 of 1659

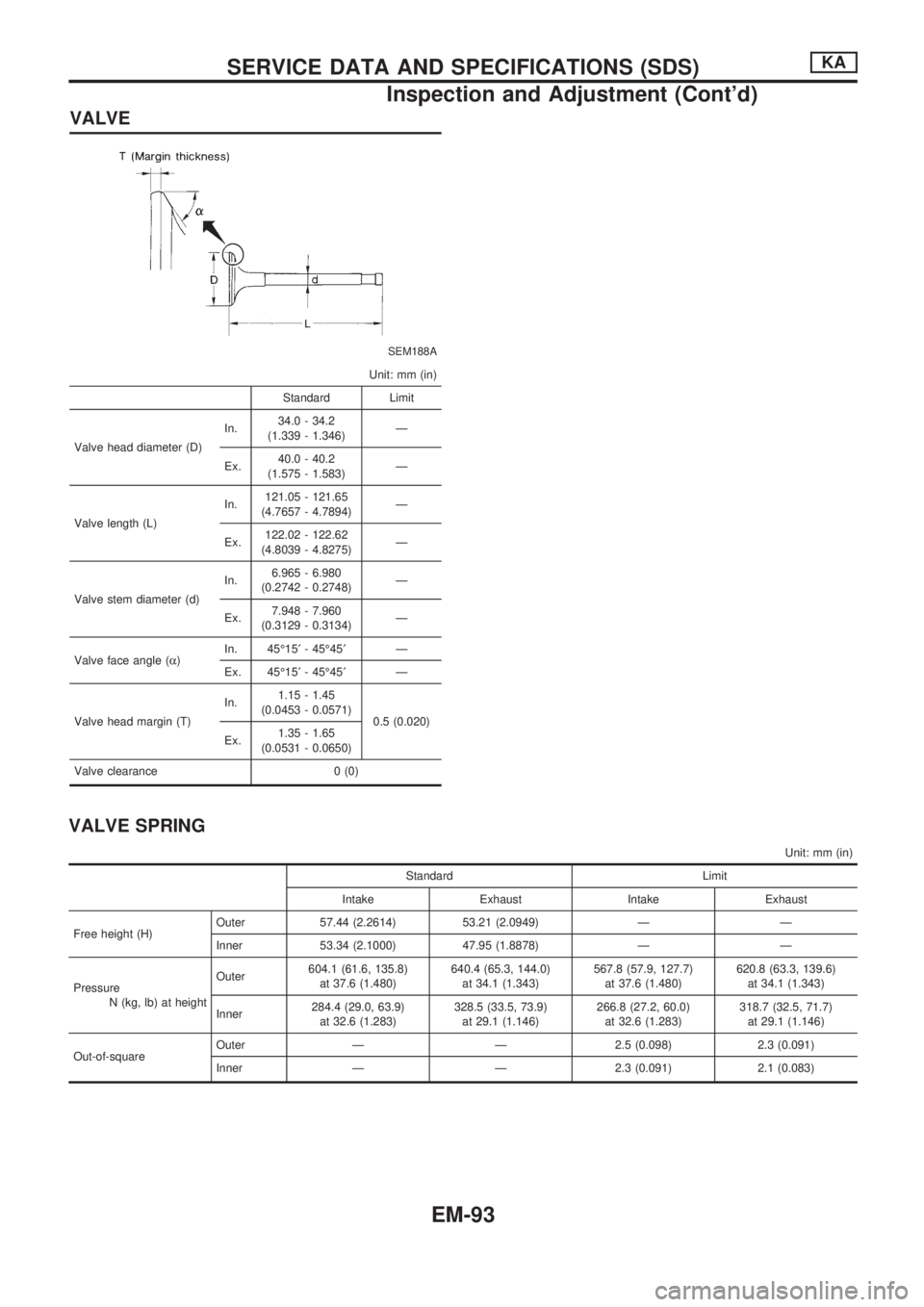

VALVE

SEM188A

Unit: mm (in)

Standard Limit

Valve head diameter (D)In.34.0 - 34.2

(1.339 - 1.346)Ð

Ex.40.0 - 40.2

(1.575 - 1.583)Ð

Valve length (L)In.121.05 - 121.65

(4.7657 - 4.7894)Ð

Ex.122.02 - 122.62

(4.8039 - 4.8275)Ð

Valve stem diameter (d)In.6.965 - 6.980

(0.2742 - 0.2748)Ð

Ex.7.948 - 7.960

(0.3129 - 0.3134)Ð

Valve face angle (a)In. 45É15¢- 45É45¢Ð

Ex. 45É15¢- 45É45¢Ð

Valve head margin (T)In.1.15 - 1.45

(0.0453 - 0.0571)

0.5 (0.020)

Ex.1.35 - 1.65

(0.0531 - 0.0650)

Valve clearance 0 (0)

VALVE SPRING

Unit: mm (in)

Standard Limit

Intake Exhaust Intake Exhaust

Free height (H)Outer 57.44 (2.2614) 53.21 (2.0949) Ð Ð

Inner 53.34 (2.1000) 47.95 (1.8878) Ð Ð

Pressure

N (kg, lb) at heightOuter604.1 (61.6, 135.8)

at 37.6 (1.480)640.4 (65.3, 144.0)

at 34.1 (1.343)567.8 (57.9, 127.7)

at 37.6 (1.480)620.8 (63.3, 139.6)

at 34.1 (1.343)

Inner284.4 (29.0, 63.9)

at 32.6 (1.283)328.5 (33.5, 73.9)

at 29.1 (1.146)266.8 (27.2, 60.0)

at 32.6 (1.283)318.7 (32.5, 71.7)

at 29.1 (1.146)

Out-of-squareOuter Ð Ð 2.5 (0.098) 2.3 (0.091)

Inner Ð Ð 2.3 (0.091) 2.1 (0.083)

SERVICE DATA AND SPECIFICATIONS (SDS)KA

Inspection and Adjustment (Cont'd)

EM-93

Page 739 of 1659

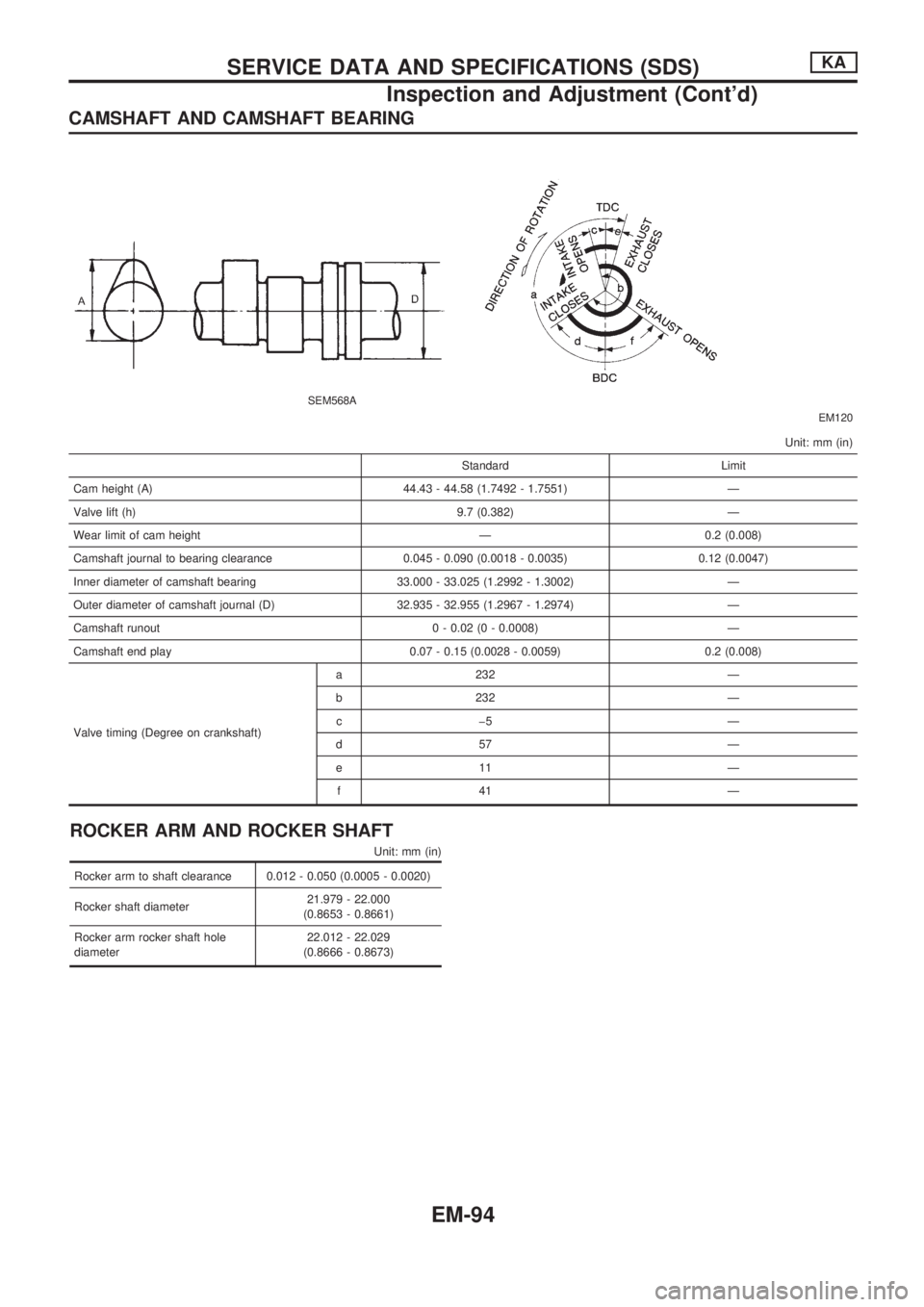

CAMSHAFT AND CAMSHAFT BEARING

SEM568A

EM120

Unit: mm (in)

Standard Limit

Cam height (A) 44.43 - 44.58 (1.7492 - 1.7551) Ð

Valve lift (h) 9.7 (0.382) Ð

Wear limit of cam height Ð 0.2 (0.008)

Camshaft journal to bearing clearance 0.045 - 0.090 (0.0018 - 0.0035) 0.12 (0.0047)

Inner diameter of camshaft bearing 33.000 - 33.025 (1.2992 - 1.3002) Ð

Outer diameter of camshaft journal (D) 32.935 - 32.955 (1.2967 - 1.2974) Ð

Camshaft runout 0 - 0.02 (0 - 0.0008) Ð

Camshaft end play 0.07 - 0.15 (0.0028 - 0.0059) 0.2 (0.008)

Valve timing (Degree on crankshaft)a 232 Ð

b 232 Ð

cþ5 Ð

d57 Ð

e11 Ð

f41 Ð

ROCKER ARM AND ROCKER SHAFT

Unit: mm (in)

Rocker arm to shaft clearance 0.012 - 0.050 (0.0005 - 0.0020)

Rocker shaft diameter21.979 - 22.000

(0.8653 - 0.8661)

Rocker arm rocker shaft hole

diameter22.012 - 22.029

(0.8666 - 0.8673)

SERVICE DATA AND SPECIFICATIONS (SDS)KA

Inspection and Adjustment (Cont'd)

EM-94

Page 740 of 1659

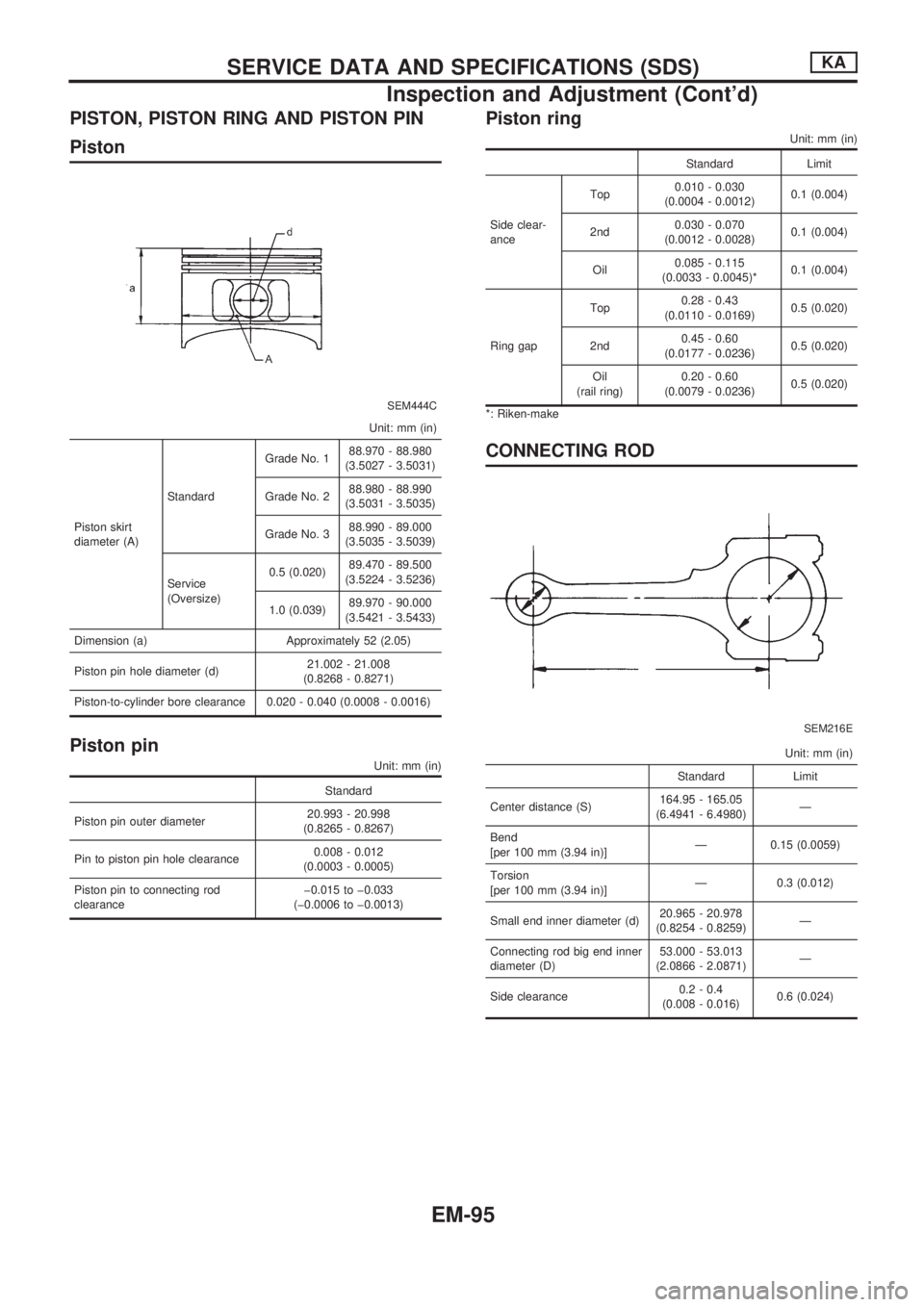

PISTON, PISTON RING AND PISTON PIN

Piston

SEM444C

Unit: mm (in)

Piston skirt

diameter (A)StandardGrade No. 188.970 - 88.980

(3.5027 - 3.5031)

Grade No. 288.980 - 88.990

(3.5031 - 3.5035)

Grade No. 388.990 - 89.000

(3.5035 - 3.5039)

Service

(Oversize)0.5 (0.020)89.470 - 89.500

(3.5224 - 3.5236)

1.0 (0.039)89.970 - 90.000

(3.5421 - 3.5433)

Dimension (a) Approximately 52 (2.05)

Piston pin hole diameter (d)21.002 - 21.008

(0.8268 - 0.8271)

Piston-to-cylinder bore clearance 0.020 - 0.040 (0.0008 - 0.0016)

Piston pin

Unit: mm (in)

Standard

Piston pin outer diameter20.993 - 20.998

(0.8265 - 0.8267)

Pin to piston pin hole clearance0.008 - 0.012

(0.0003 - 0.0005)

Piston pin to connecting rod

clearanceþ0.015 to þ0.033

(þ0.0006 to þ0.0013)

Piston ring

Unit: mm (in)

Standard Limit

Side clear-

anceTop0.010 - 0.030

(0.0004 - 0.0012)0.1 (0.004)

2nd0.030 - 0.070

(0.0012 - 0.0028)0.1 (0.004)

Oil0.085 - 0.115

(0.0033 - 0.0045)*0.1 (0.004)

Ring gapTop0.28 - 0.43

(0.0110 - 0.0169)0.5 (0.020)

2nd0.45 - 0.60

(0.0177 - 0.0236)0.5 (0.020)

Oil

(rail ring)0.20 - 0.60

(0.0079 - 0.0236)0.5 (0.020)

*: Riken-make

CONNECTING ROD

SEM216E

Unit: mm (in)

Standard Limit

Center distance (S)164.95 - 165.05

(6.4941 - 6.4980)Ð

Bend

[per 100 mm (3.94 in)]Ð 0.15 (0.0059)

Torsion

[per 100 mm (3.94 in)]Ð 0.3 (0.012)

Small end inner diameter (d)20.965 - 20.978

(0.8254 - 0.8259)Ð

Connecting rod big end inner

diameter (D)53.000 - 53.013

(2.0866 - 2.0871)Ð

Side clearance0.2 - 0.4

(0.008 - 0.016)0.6 (0.024)

SERVICE DATA AND SPECIFICATIONS (SDS)KA

Inspection and Adjustment (Cont'd)

EM-95