NISSAN PICK-UP 1998 Repair Manual

Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 781 of 1659

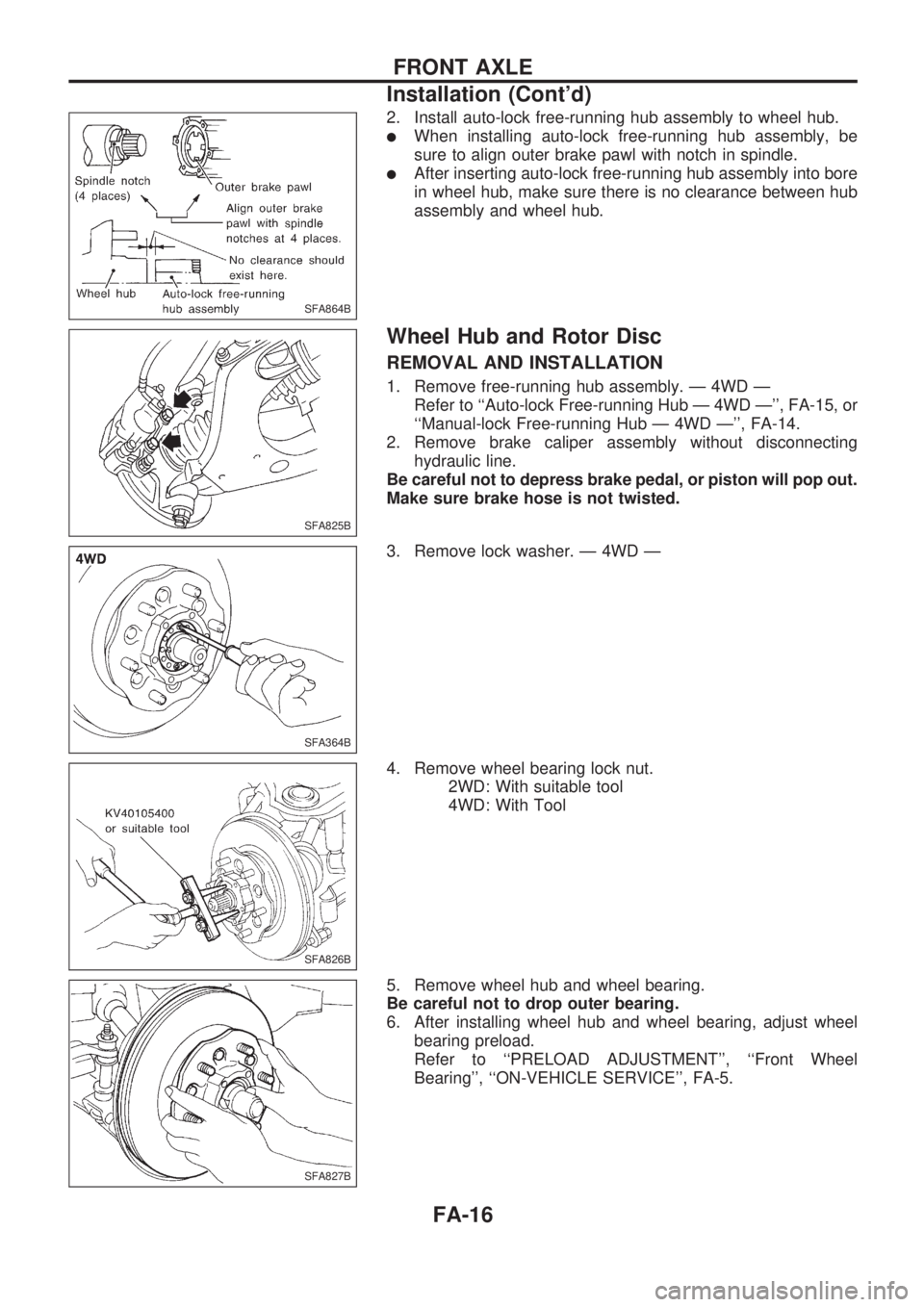

2. Install auto-lock free-running hub assembly to wheel hub.

lWhen installing auto-lock free-running hub assembly, be

sure to align outer brake pawl with notch in spindle.

lAfter inserting auto-lock free-running hub assembly into bore

in wheel hub, make sure there is no clearance between hub

assembly and wheel hub.

Wheel Hub and Rotor Disc

REMOVAL AND INSTALLATION

1. Remove free-running hub assembly. Ð 4WD Ð

Refer to ``Auto-lock Free-running Hub Ð 4WD Ð'', FA-15, or

``Manual-lock Free-running Hub Ð 4WD Ð'', FA-14.

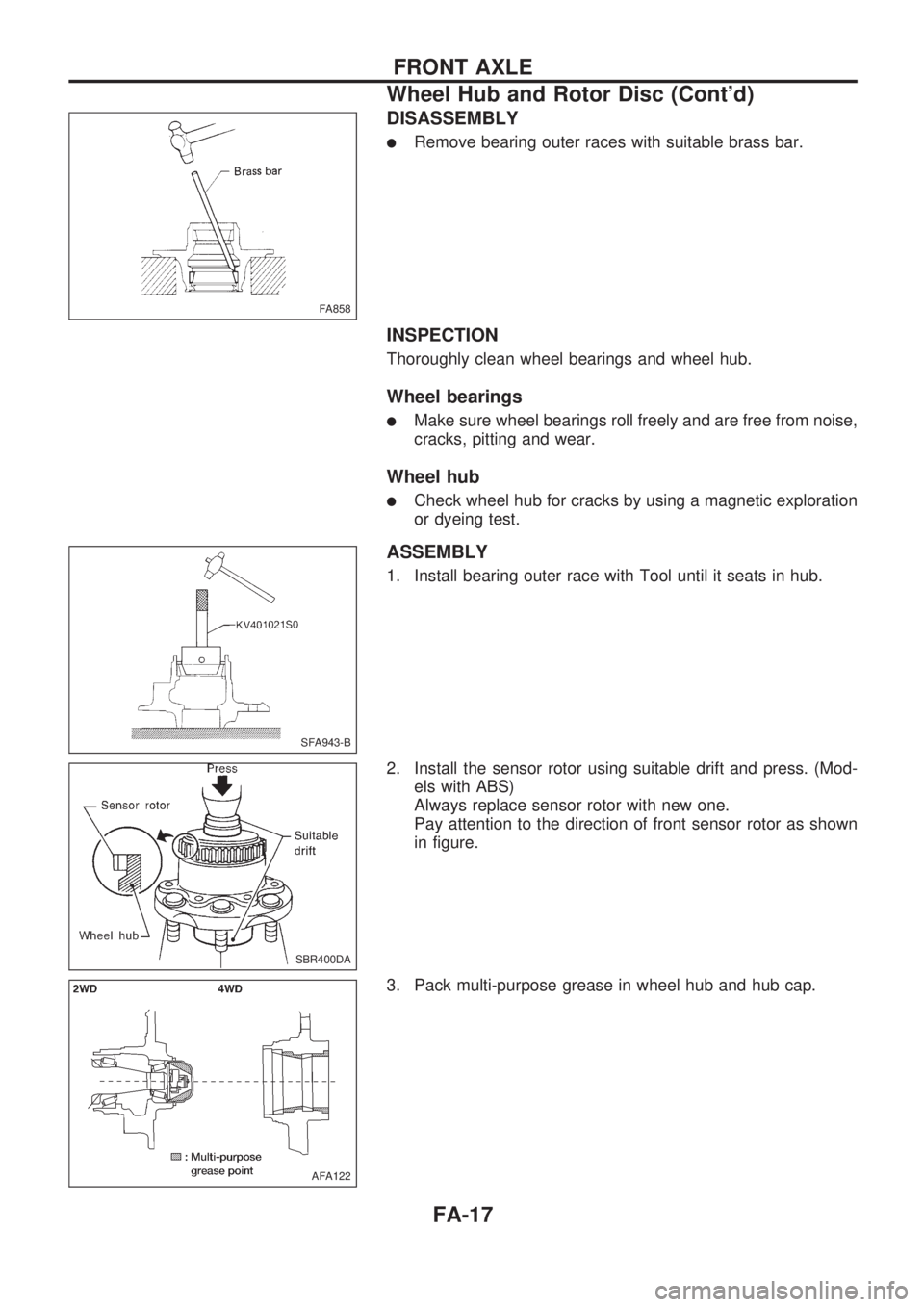

2. Remove brake caliper assembly without disconnecting

hydraulic line.

Be careful not to depress brake pedal, or piston will pop out.

Make sure brake hose is not twisted.

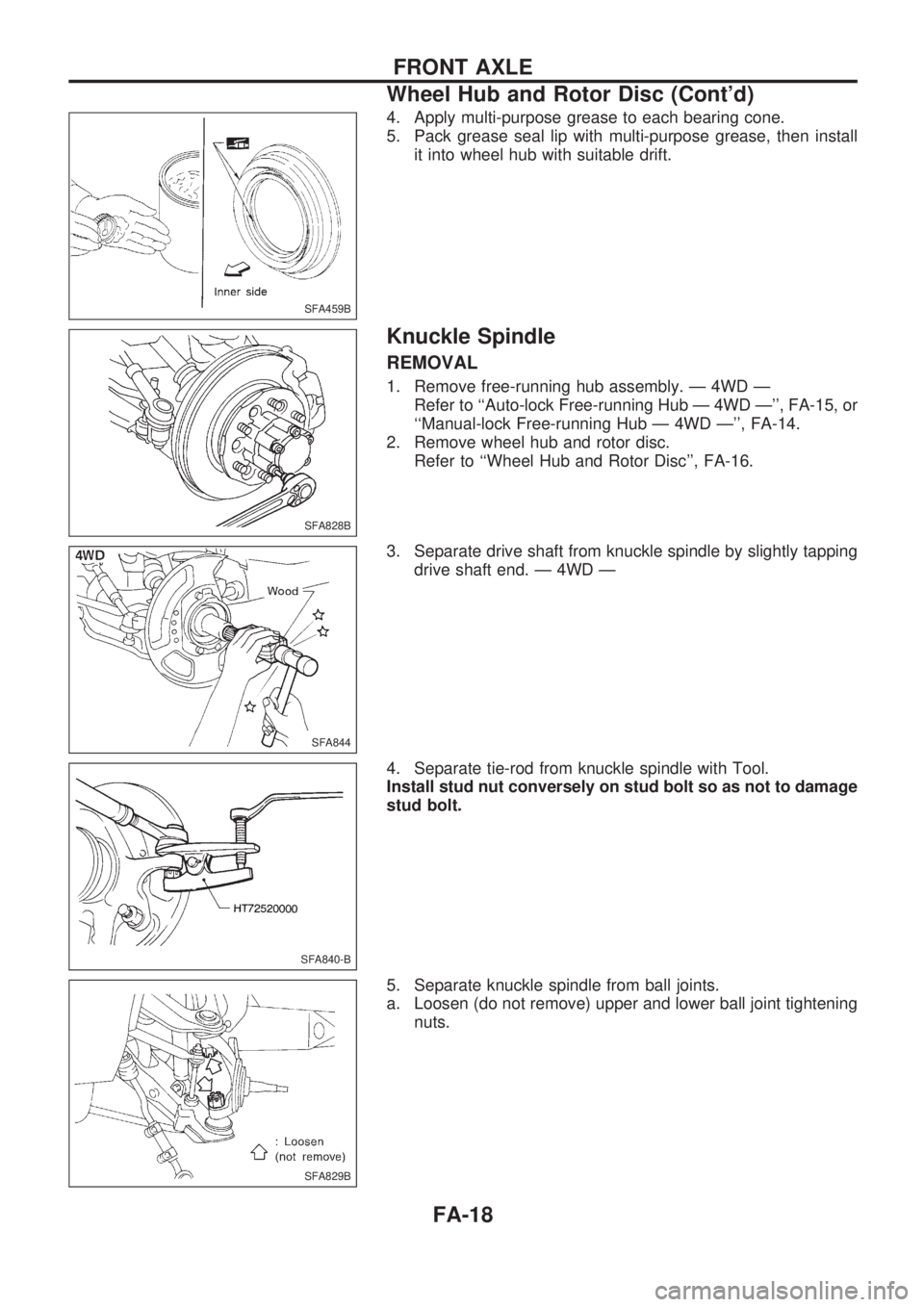

3. Remove lock washer. Ð 4WD Ð

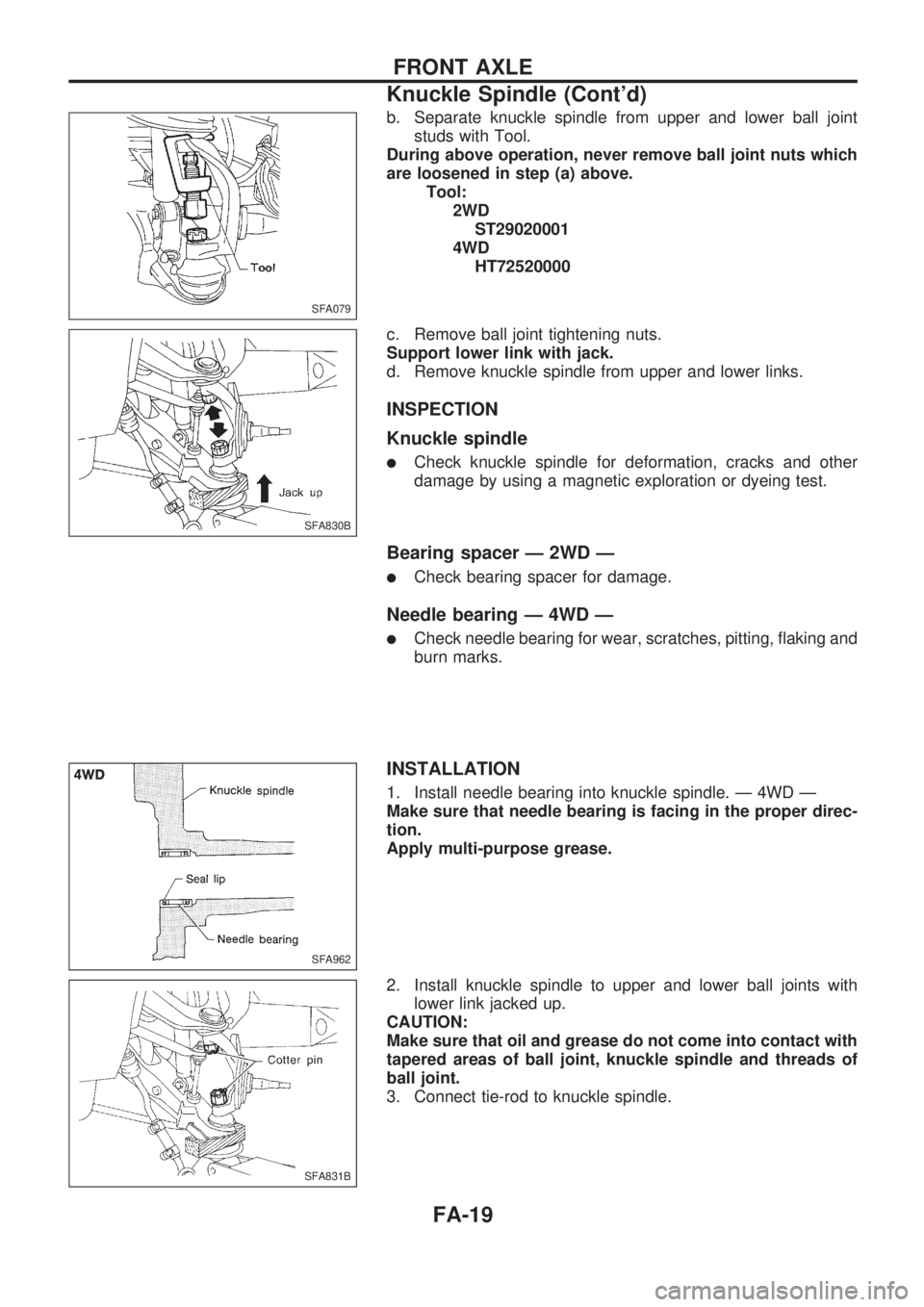

4. Remove wheel bearing lock nut.

2WD: With suitable tool

4WD: With Tool

5. Remove wheel hub and wheel bearing.

Be careful not to drop outer bearing.

6. After installing wheel hub and wheel bearing, adjust wheel

bearing preload.

Refer to ``PRELOAD ADJUSTMENT'', ``Front Wheel

Bearing'', ``ON-VEHICLE SERVICE'', FA-5.

SFA864B

SFA825B

SFA364B

SFA826B

SFA827B

FRONT AXLE

Installation (Cont'd)

FA-16

Page 782 of 1659

DISASSEMBLY

lRemove bearing outer races with suitable brass bar.

INSPECTION

Thoroughly clean wheel bearings and wheel hub.

Wheel bearings

lMake sure wheel bearings roll freely and are free from noise,

cracks, pitting and wear.

Wheel hub

lCheck wheel hub for cracks by using a magnetic exploration

or dyeing test.

ASSEMBLY

1. Install bearing outer race with Tool until it seats in hub.

2. Install the sensor rotor using suitable drift and press. (Mod-

els with ABS)

Always replace sensor rotor with new one.

Pay attention to the direction of front sensor rotor as shown

in figure.

3. Pack multi-purpose grease in wheel hub and hub cap.

FA858

SFA943-B

SBR400DA

AFA122

FRONT AXLE

Wheel Hub and Rotor Disc (Cont'd)

FA-17

Page 783 of 1659

4. Apply multi-purpose grease to each bearing cone.

5. Pack grease seal lip with multi-purpose grease, then install

it into wheel hub with suitable drift.

Knuckle Spindle

REMOVAL

1. Remove free-running hub assembly. Ð 4WD Ð

Refer to ``Auto-lock Free-running Hub Ð 4WD Ð'', FA-15, or

``Manual-lock Free-running Hub Ð 4WD Ð'', FA-14.

2. Remove wheel hub and rotor disc.

Refer to ``Wheel Hub and Rotor Disc'', FA-16.

3. Separate drive shaft from knuckle spindle by slightly tapping

drive shaft end. Ð 4WD Ð

4. Separate tie-rod from knuckle spindle with Tool.

Install stud nut conversely on stud bolt so as not to damage

stud bolt.

5. Separate knuckle spindle from ball joints.

a. Loosen (do not remove) upper and lower ball joint tightening

nuts.

SFA459B

SFA828B

SFA844

SFA840-B

SFA829B

FRONT AXLE

Wheel Hub and Rotor Disc (Cont'd)

FA-18

Page 784 of 1659

b. Separate knuckle spindle from upper and lower ball joint

studs with Tool.

During above operation, never remove ball joint nuts which

are loosened in step (a) above.

Tool:

2WD

ST29020001

4WD

HT72520000

c. Remove ball joint tightening nuts.

Support lower link with jack.

d. Remove knuckle spindle from upper and lower links.

INSPECTION

Knuckle spindle

lCheck knuckle spindle for deformation, cracks and other

damage by using a magnetic exploration or dyeing test.

Bearing spacer Ð 2WD Ð

lCheck bearing spacer for damage.

Needle bearing Ð 4WD Ð

lCheck needle bearing for wear, scratches, pitting, flaking and

burn marks.

INSTALLATION

1. Install needle bearing into knuckle spindle. Ð 4WD Ð

Make sure that needle bearing is facing in the proper direc-

tion.

Apply multi-purpose grease.

2. Install knuckle spindle to upper and lower ball joints with

lower link jacked up.

CAUTION:

Make sure that oil and grease do not come into contact with

tapered areas of ball joint, knuckle spindle and threads of

ball joint.

3. Connect tie-rod to knuckle spindle.

SFA079

SFA830B

SFA962

SFA831B

FRONT AXLE

Knuckle Spindle (Cont'd)

FA-19

Page 785 of 1659

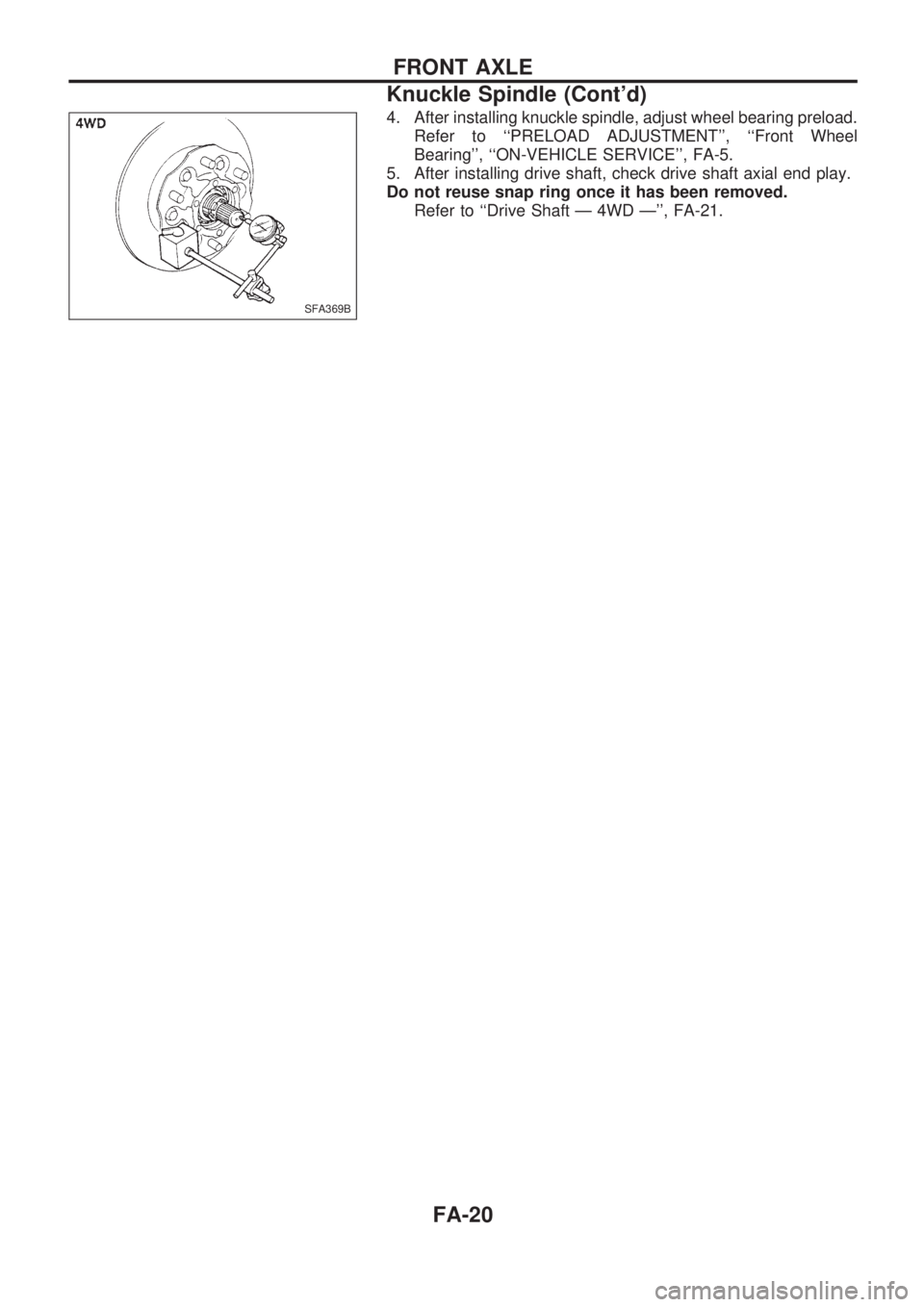

4. After installing knuckle spindle, adjust wheel bearing preload.

Refer to ``PRELOAD ADJUSTMENT'', ``Front Wheel

Bearing'', ``ON-VEHICLE SERVICE'', FA-5.

5. After installing drive shaft, check drive shaft axial end play.

Do not reuse snap ring once it has been removed.

Refer to ``Drive Shaft Ð 4WD Ð'', FA-21.

SFA369B

FRONT AXLE

Knuckle Spindle (Cont'd)

FA-20

Page 786 of 1659

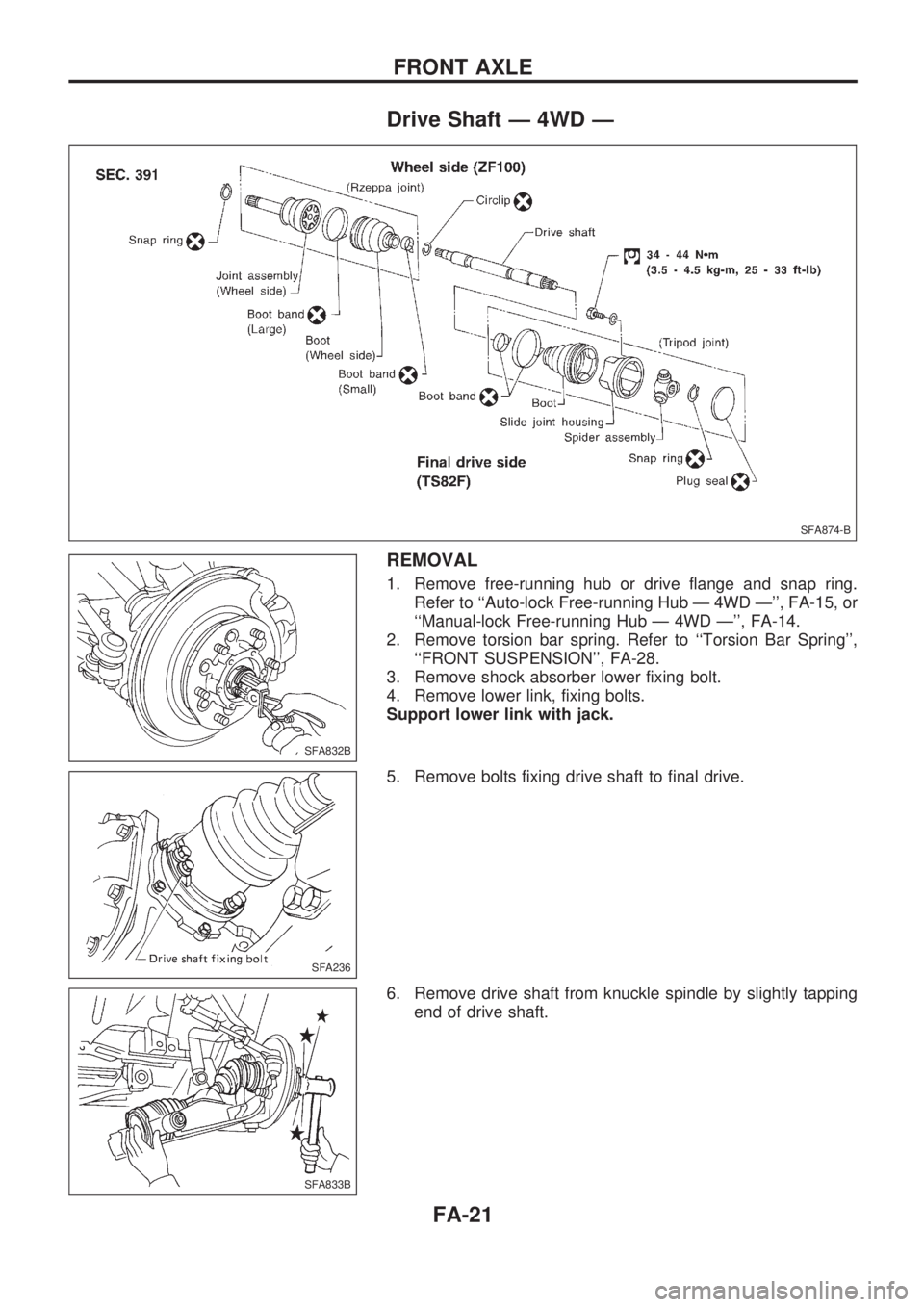

Drive Shaft Ð 4WD Ð

REMOVAL

1. Remove free-running hub or drive flange and snap ring.

Refer to ``Auto-lock Free-running Hub Ð 4WD Ð'', FA-15, or

``Manual-lock Free-running Hub Ð 4WD Ð'', FA-14.

2. Remove torsion bar spring. Refer to ``Torsion Bar Spring'',

``FRONT SUSPENSION'', FA-28.

3. Remove shock absorber lower fixing bolt.

4. Remove lower link, fixing bolts.

Support lower link with jack.

5. Remove bolts fixing drive shaft to final drive.

6. Remove drive shaft from knuckle spindle by slightly tapping

end of drive shaft.

SFA874-B

SFA832B

SFA236

SFA833B

FRONT AXLE

FA-21

Page 787 of 1659

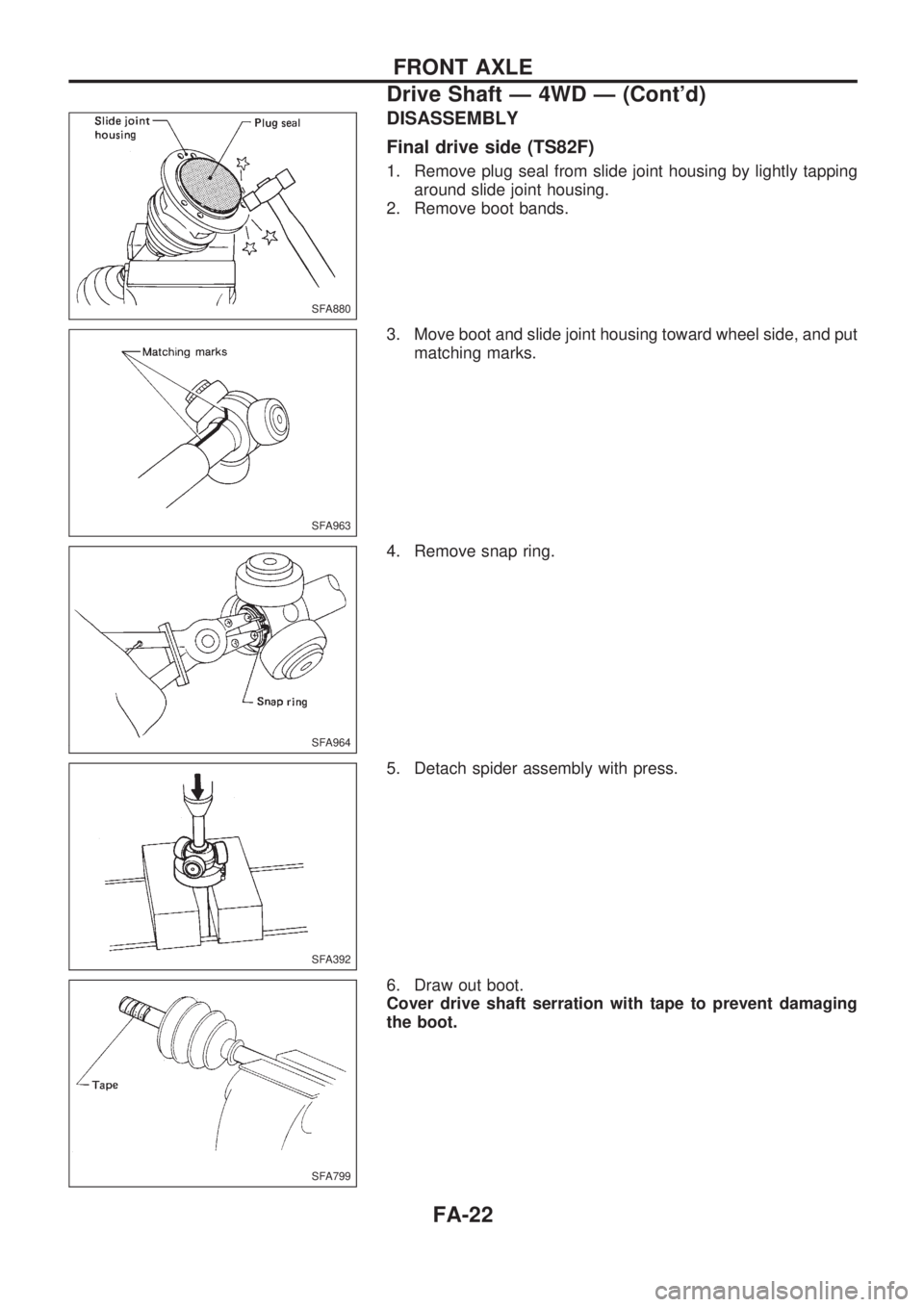

DISASSEMBLY

Final drive side (TS82F)

1. Remove plug seal from slide joint housing by lightly tapping

around slide joint housing.

2. Remove boot bands.

3. Move boot and slide joint housing toward wheel side, and put

matching marks.

4. Remove snap ring.

5. Detach spider assembly with press.

6. Draw out boot.

Cover drive shaft serration with tape to prevent damaging

the boot.

SFA880

SFA963

SFA964

SFA392

SFA799

FRONT AXLE

Drive Shaft Ð 4WD Ð (Cont'd)

FA-22

Page 788 of 1659

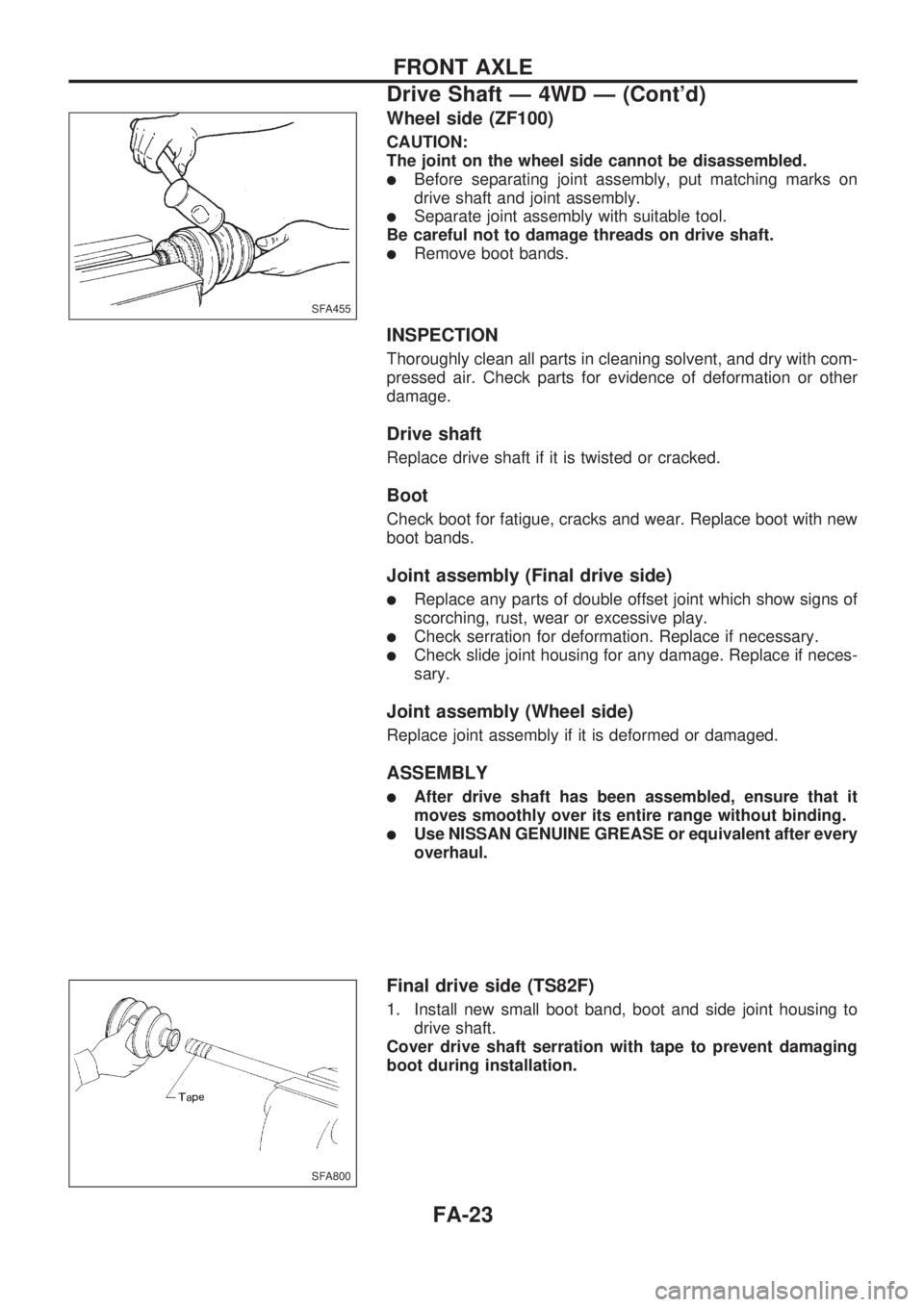

Wheel side (ZF100)

CAUTION:

The joint on the wheel side cannot be disassembled.

lBefore separating joint assembly, put matching marks on

drive shaft and joint assembly.

lSeparate joint assembly with suitable tool.

Be careful not to damage threads on drive shaft.

lRemove boot bands.

INSPECTION

Thoroughly clean all parts in cleaning solvent, and dry with com-

pressed air. Check parts for evidence of deformation or other

damage.

Drive shaft

Replace drive shaft if it is twisted or cracked.

Boot

Check boot for fatigue, cracks and wear. Replace boot with new

boot bands.

Joint assembly (Final drive side)

lReplace any parts of double offset joint which show signs of

scorching, rust, wear or excessive play.

lCheck serration for deformation. Replace if necessary.

lCheck slide joint housing for any damage. Replace if neces-

sary.

Joint assembly (Wheel side)

Replace joint assembly if it is deformed or damaged.

ASSEMBLY

lAfter drive shaft has been assembled, ensure that it

moves smoothly over its entire range without binding.

lUse NISSAN GENUINE GREASE or equivalent after every

overhaul.

Final drive side (TS82F)

1. Install new small boot band, boot and side joint housing to

drive shaft.

Cover drive shaft serration with tape to prevent damaging

boot during installation.

SFA455

SFA800

FRONT AXLE

Drive Shaft Ð 4WD Ð (Cont'd)

FA-23

Page 789 of 1659

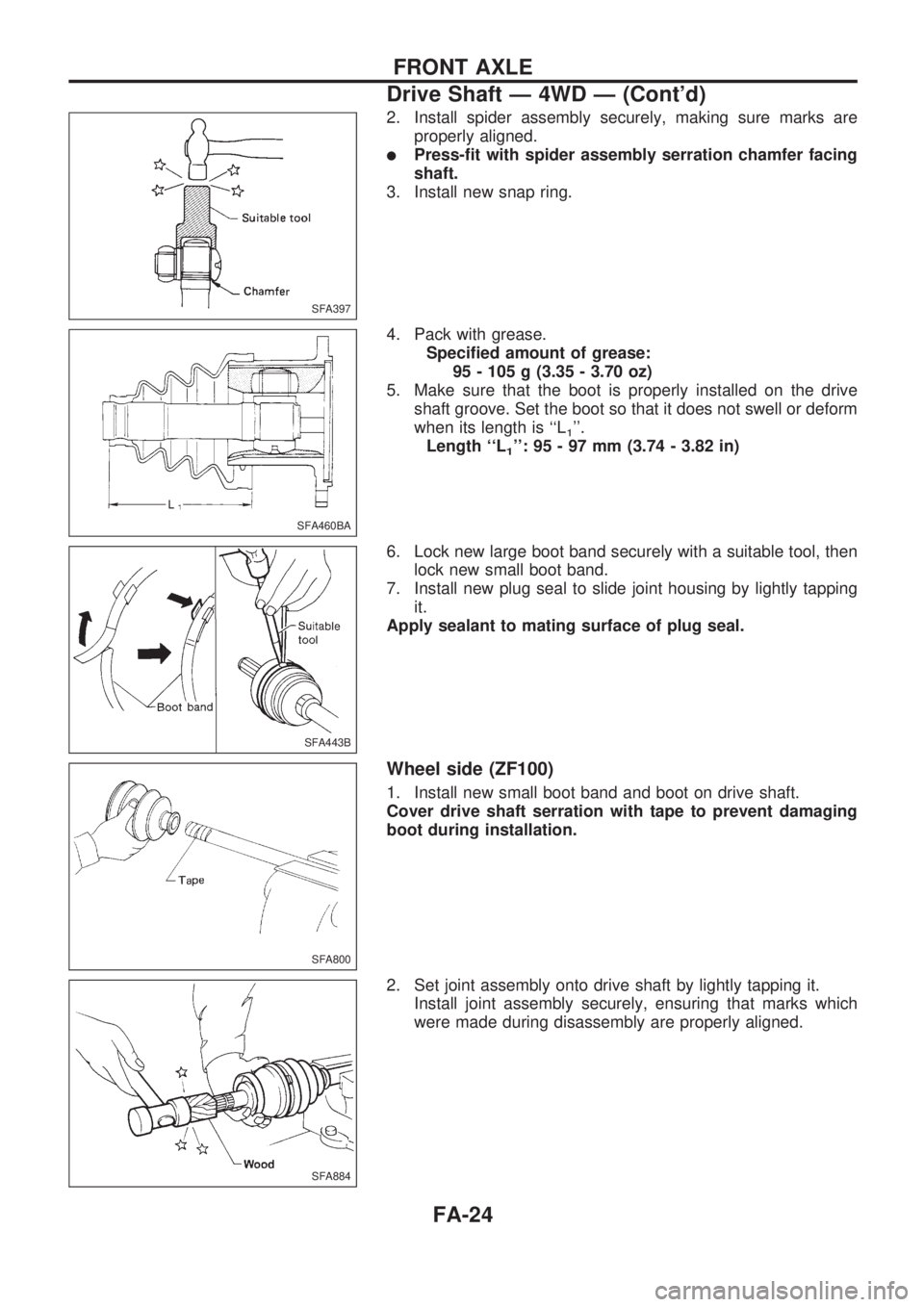

2. Install spider assembly securely, making sure marks are

properly aligned.

lPress-fit with spider assembly serration chamfer facing

shaft.

3. Install new snap ring.

4. Pack with grease.

Specified amount of grease:

95 - 105 g (3.35 - 3.70 oz)

5. Make sure that the boot is properly installed on the drive

shaft groove. Set the boot so that it does not swell or deform

when its length is ``L

1''.

Length ``L

1'': 95 - 97 mm (3.74 - 3.82 in)

6. Lock new large boot band securely with a suitable tool, then

lock new small boot band.

7. Install new plug seal to slide joint housing by lightly tapping

it.

Apply sealant to mating surface of plug seal.

Wheel side (ZF100)

1. Install new small boot band and boot on drive shaft.

Cover drive shaft serration with tape to prevent damaging

boot during installation.

2. Set joint assembly onto drive shaft by lightly tapping it.

Install joint assembly securely, ensuring that marks which

were made during disassembly are properly aligned.

SFA397

SFA460BA

SFA443B

SFA800

SFA884

FRONT AXLE

Drive Shaft Ð 4WD Ð (Cont'd)

FA-24

Page 790 of 1659

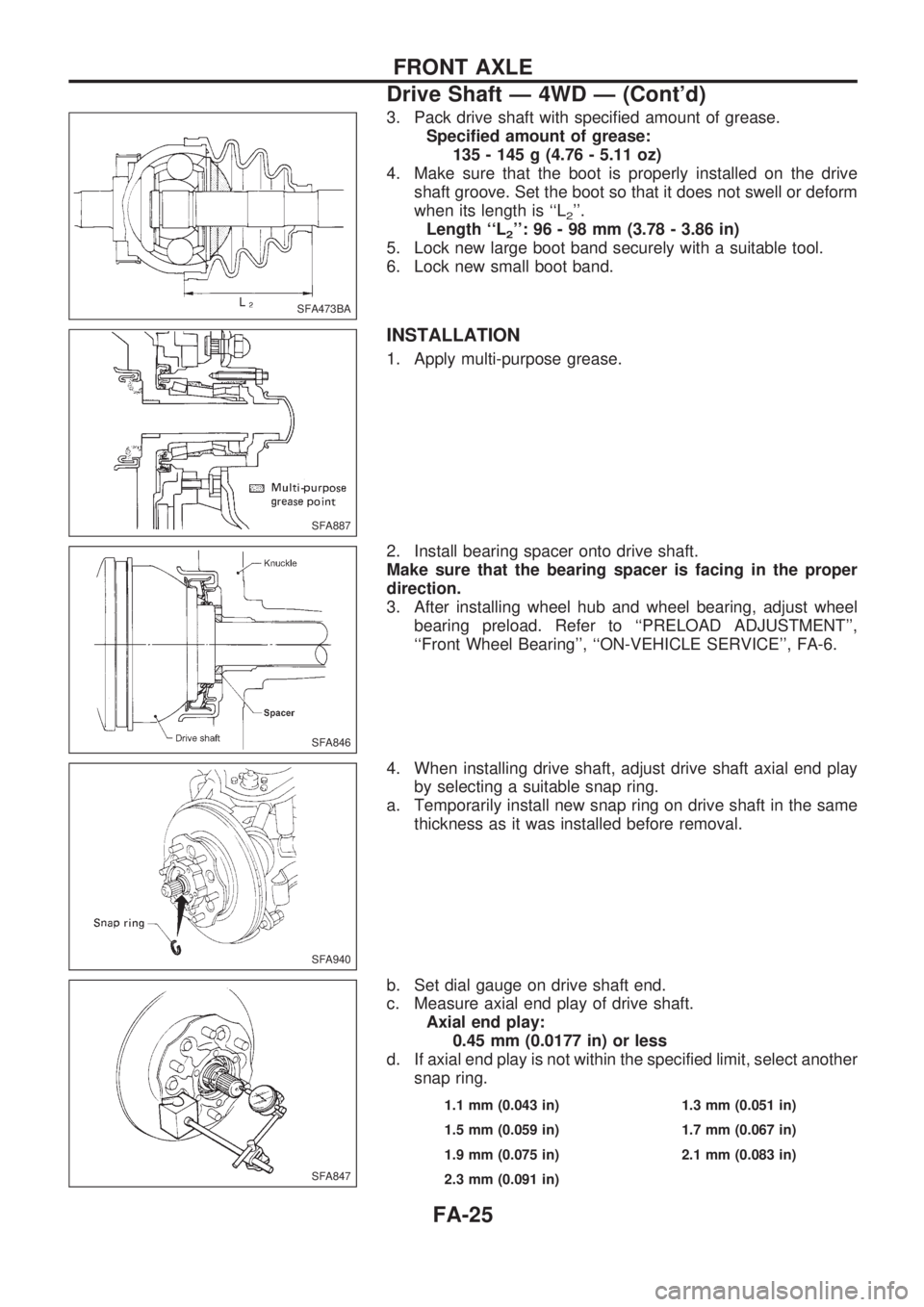

3. Pack drive shaft with specified amount of grease.

Specified amount of grease:

135 - 145 g (4.76 - 5.11 oz)

4. Make sure that the boot is properly installed on the drive

shaft groove. Set the boot so that it does not swell or deform

when its length is ``L

2''.

Length ``L

2'': 96 - 98 mm (3.78 - 3.86 in)

5. Lock new large boot band securely with a suitable tool.

6. Lock new small boot band.

INSTALLATION

1. Apply multi-purpose grease.

2. Install bearing spacer onto drive shaft.

Make sure that the bearing spacer is facing in the proper

direction.

3. After installing wheel hub and wheel bearing, adjust wheel

bearing preload. Refer to ``PRELOAD ADJUSTMENT'',

``Front Wheel Bearing'', ``ON-VEHICLE SERVICE'', FA-6.

4. When installing drive shaft, adjust drive shaft axial end play

by selecting a suitable snap ring.

a. Temporarily install new snap ring on drive shaft in the same

thickness as it was installed before removal.

b. Set dial gauge on drive shaft end.

c. Measure axial end play of drive shaft.

Axial end play:

0.45 mm (0.0177 in) or less

d. If axial end play is not within the specified limit, select another

snap ring.

1.1 mm (0.043 in) 1.3 mm (0.051 in)

1.5 mm (0.059 in) 1.7 mm (0.067 in)

1.9 mm (0.075 in) 2.1 mm (0.083 in)

2.3 mm (0.091 in)

SFA473BA

SFA887

SFA846

SFA940

SFA847

FRONT AXLE

Drive Shaft Ð 4WD Ð (Cont'd)

FA-25