NISSAN PICK-UP 1998 Repair Manual

Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 801 of 1659

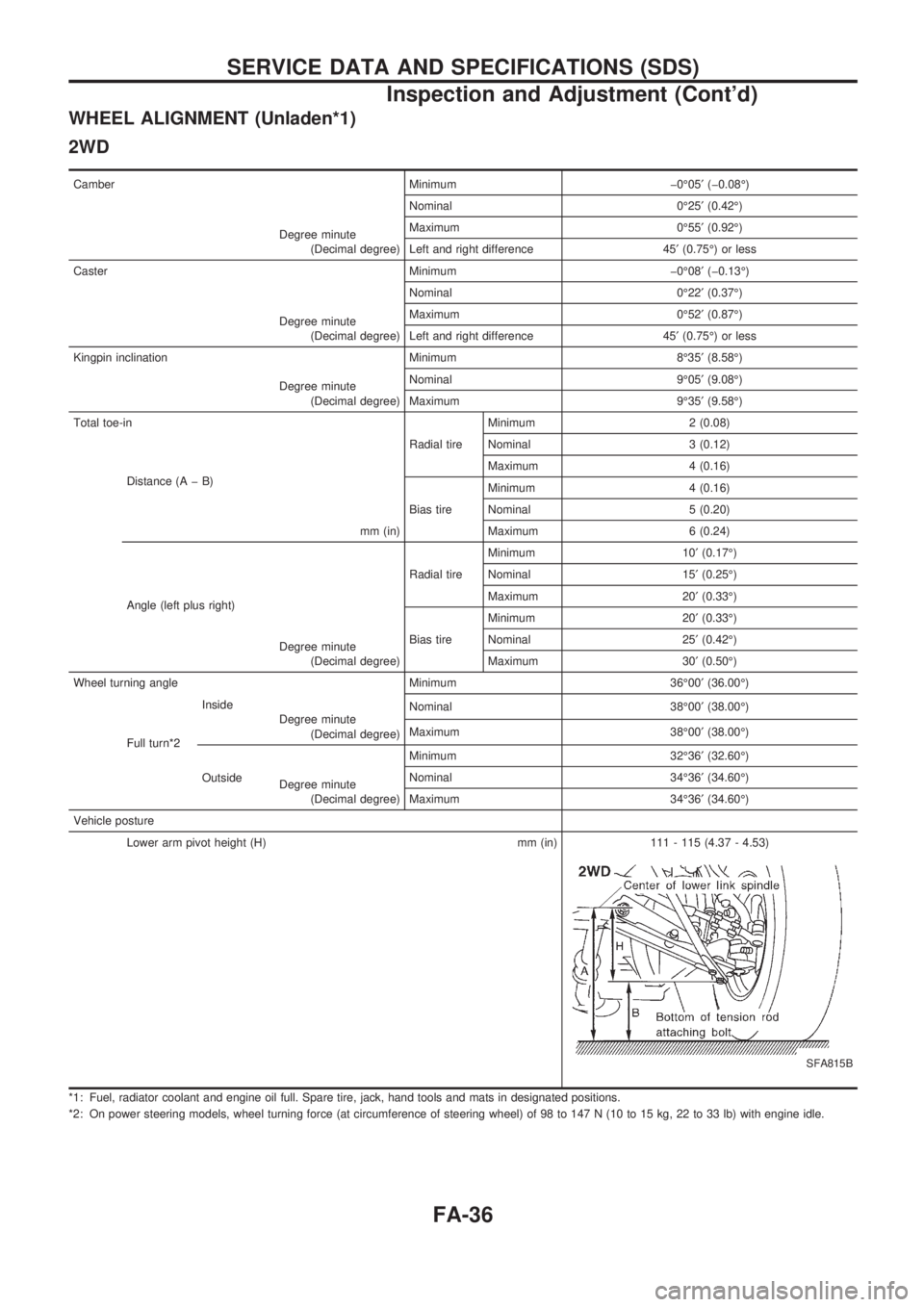

WHEEL ALIGNMENT (Unladen*1)

2WD

Camber Minimum þ0É05¢(þ0.08É)

Degree minute

(Decimal degree)Nominal 0É25¢(0.42É)

Maximum 0É55¢(0.92É)

Left and right difference 45¢(0.75É) or less

Caster Minimum þ0É08¢(þ0.13É)

Degree minute

(Decimal degree)Nominal 0É22¢(0.37É)

Maximum 0É52¢(0.87É)

Left and right difference 45¢(0.75É) or less

Kingpin inclination Minimum 8É35¢(8.58É)

Degree minute

(Decimal degree)Nominal 9É05¢(9.08É)

Maximum 9É35¢(9.58É)

Total toe-in

Radial tireMinimum 2 (0.08)

Distance (A þ B)

mm (in)Nominal 3 (0.12)

Maximum 4 (0.16)

Bias tireMinimum 4 (0.16)

Nominal 5 (0.20)

Maximum 6 (0.24)

Angle (left plus right)

Degree minute

(Decimal degree)Radial tireMinimum 10¢(0.17É)

Nominal 15¢(0.25É)

Maximum 20¢(0.33É)

Bias tireMinimum 20¢(0.33É)

Nominal 25¢(0.42É)

Maximum 30¢(0.50É)

Wheel turning angle Minimum 36É00¢(36.00É)

Full turn*2Inside

Degree minute

(Decimal degree)Nominal 38É00¢(38.00É)

Maximum 38É00¢(38.00É)

OutsideMinimum 32É36¢(32.60É)

Degree minute

(Decimal degree)Nominal 34É36¢(34.60É)

Maximum 34É36¢(34.60É)

Vehicle posture

Lower arm pivot height (H) mm (in) 111 - 115 (4.37 - 4.53)

SFA815B

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

*2: On power steering models, wheel turning force (at circumference of steering wheel) of 98 to 147 N (10 to 15 kg, 22 to 33 lb) with engine idle.

SERVICE DATA AND SPECIFICATIONS (SDS)

Inspection and Adjustment (Cont'd)

FA-36

Page 802 of 1659

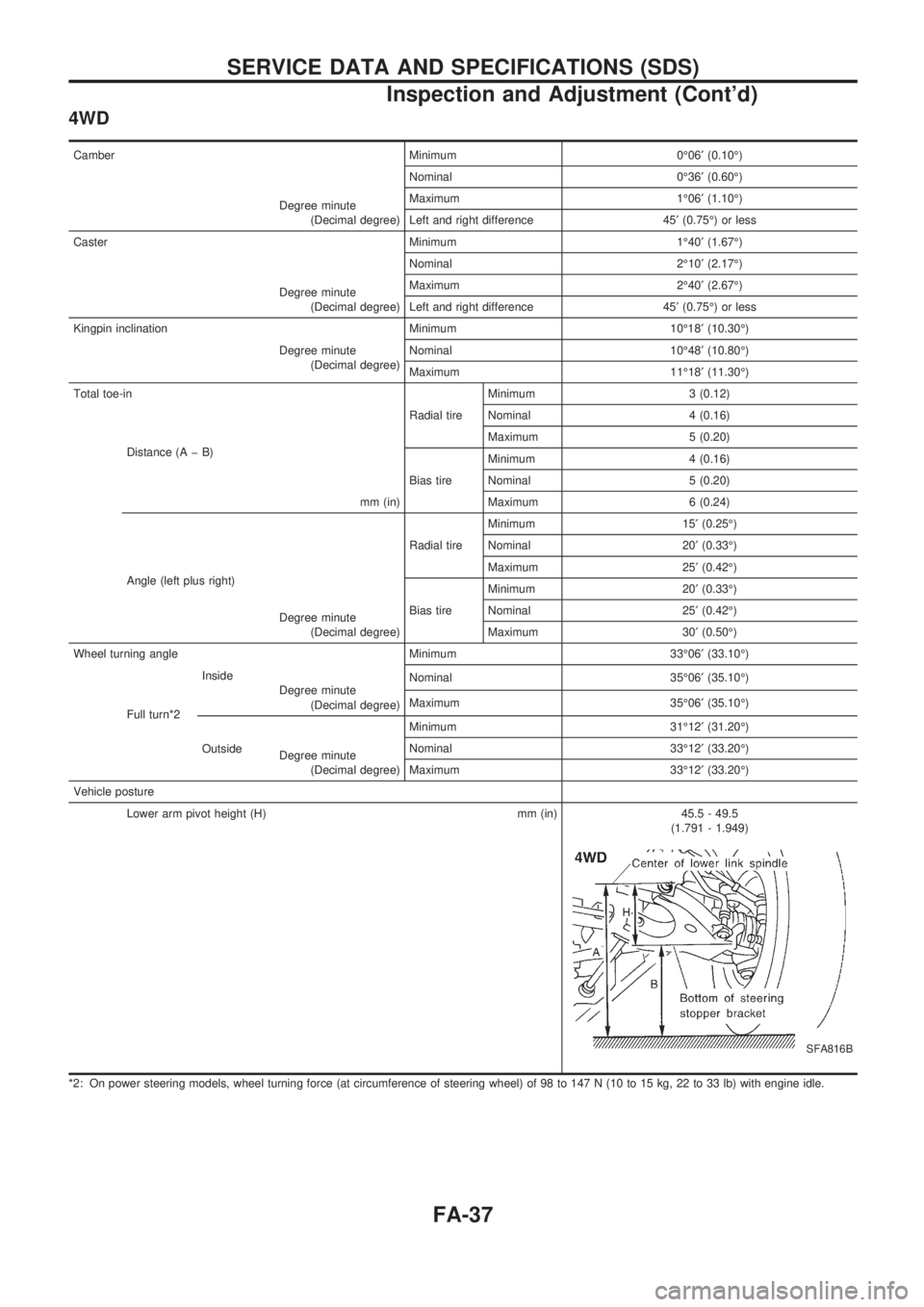

4WD

Camber Minimum 0É06¢(0.10É)

Degree minute

(Decimal degree)Nominal 0É36¢(0.60É)

Maximum 1É06¢(1.10É)

Left and right difference 45¢(0.75É) or less

Caster Minimum 1É40¢(1.67É)

Degree minute

(Decimal degree)Nominal 2É10¢(2.17É)

Maximum 2É40¢(2.67É)

Left and right difference 45¢(0.75É) or less

Kingpin inclination Minimum 10É18¢(10.30É)

Degree minute

(Decimal degree)Nominal 10É48¢(10.80É)

Maximum 11É18¢(11.30É)

Total toe-in

Radial tireMinimum 3 (0.12)

Distance (A þ B)

mm (in)Nominal 4 (0.16)

Maximum 5 (0.20)

Bias tireMinimum 4 (0.16)

Nominal 5 (0.20)

Maximum 6 (0.24)

Angle (left plus right)

Degree minute

(Decimal degree)Radial tireMinimum 15¢(0.25É)

Nominal 20¢(0.33É)

Maximum 25¢(0.42É)

Bias tireMinimum 20¢(0.33É)

Nominal 25¢(0.42É)

Maximum 30¢(0.50É)

Wheel turning angle Minimum 33É06¢(33.10É)

Full turn*2Inside

Degree minute

(Decimal degree)Nominal 35É06¢(35.10É)

Maximum 35É06¢(35.10É)

OutsideMinimum 31É12¢(31.20É)

Degree minute

(Decimal degree)Nominal 33É12¢(33.20É)

Maximum 33É12¢(33.20É)

Vehicle posture

Lower arm pivot height (H) mm (in) 45.5 - 49.5

(1.791 - 1.949)

SFA816B

*2: On power steering models, wheel turning force (at circumference of steering wheel) of 98 to 147 N (10 to 15 kg, 22 to 33 lb) with engine idle.

SERVICE DATA AND SPECIFICATIONS (SDS)

Inspection and Adjustment (Cont'd)

FA-37

Page 803 of 1659

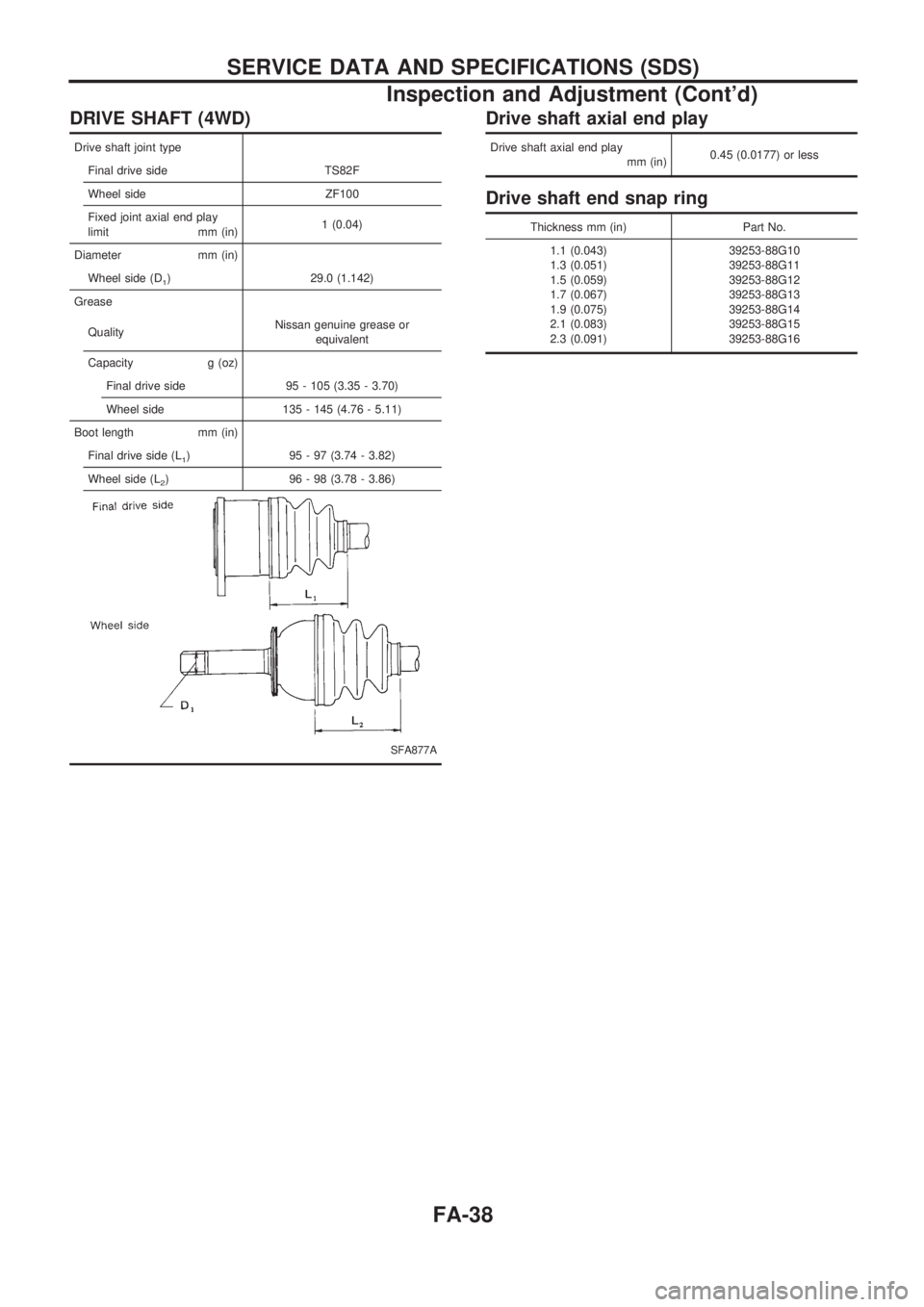

DRIVE SHAFT (4WD)

Drive shaft joint type

Final drive side TS82F

Wheel side ZF100

Fixed joint axial end play

limit mm (in)1 (0.04)

Diameter mm (in)

Wheel side (D

1) 29.0 (1.142)

Grease

QualityNissan genuine grease or

equivalent

Capacity g (oz)

Final drive side 95 - 105 (3.35 - 3.70)

Wheel side 135 - 145 (4.76 - 5.11)

Boot length mm (in)

Final drive side (L

1) 95 - 97 (3.74 - 3.82)

Wheel side (L

2) 96 - 98 (3.78 - 3.86)

SFA877A

Drive shaft axial end play

Drive shaft axial end play

mm (in)0.45 (0.0177) or less

Drive shaft end snap ring

Thickness mm (in) Part No.

1.1 (0.043)

1.3 (0.051)

1.5 (0.059)

1.7 (0.067)

1.9 (0.075)

2.1 (0.083)

2.3 (0.091)39253-88G10

39253-88G11

39253-88G12

39253-88G13

39253-88G14

39253-88G15

39253-88G16

SERVICE DATA AND SPECIFICATIONS (SDS)

Inspection and Adjustment (Cont'd)

FA-38

Page 804 of 1659

GENERAL INFORMATION

SECTION

GI

CONTENTS

PRECAUTIONS......................................................... 1

Precautions for Supplemental Restraint

System (SRS) ``AIR BAG'' (4WD models)............. 1

Precautions for Supplemental Restraint

System (SRS) ``AIR BAG'' (2WD models)............. 1

Precautions for NATS ............................................ 2

General Precautions .............................................. 2

Precautions for Multiport Fuel Injection System

or ECCS Engine .................................................... 4

Precautions for Three Way Catalyst

(If so equipped) ...................................................... 4

Precautions for Engine Oils ................................... 4

Precautions for Fuel............................................... 5

Precautions for Air Conditioning ............................ 6

HOW TO USE THIS MANUAL.................................. 7

HOW TO READ WIRING DIAGRAMS...................... 9

Sample/Wiring Diagram - EXAMPL - .................... 9

Description ........................................................... 11

HOW TO CHECK TERMINAL................................. 18

How to Probe Connectors ................................... 18

How to Check Enlarged Contact Spring of

Terminal ............................................................... 19

Waterproof Connector Inspection ........................ 20

Terminal Lock Inspection ..................................... 20

HOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT......................... 21

Work Flow ............................................................ 21HOW TO PERFORM EFFICIENT DIAGNOSIS...... 22

Incident Simulation Tests..................................... 22

Circuit Inspection ................................................. 25

HOW TO FOLLOW FLOW CHART IN

TROUBLE DIAGNOSES......................................... 31

How to Follow This Flow Chart ........................... 32

CONSULT CHECKING SYSTEM............................ 34

Function and System Application ........................ 34

Lithium Battery Replacement............................... 34

Checking Equipment ............................................ 35

Loading Procedure............................................... 36

CONSULT Data Link Connector (DLC) Circuit ... 36

IDENTIFICATION INFORMATION.......................... 37

Model Variation .................................................... 37

Identification Number ........................................... 40

Dimensions .......................................................... 44

Wheels and Tires ................................................. 46

LIFTING POINTS AND TOW TRUCK TOWING..... 47

Pantograph Jack .................................................. 47

Screw Jack........................................................... 48

Garage Jack and Safety Stand ........................... 49

2-pole Lift ............................................................. 50

Tow Truck Towing ............................................... 51

Towing Point ........................................................ 53

TIGHTENING TORQUE OF STANDARD BOLTS.. 54

SAE J1930 TERMINOLOGY LIST.......................... 55

SAE J1930 Terminology List ............................... 55

GI

Page 805 of 1659

Observe the following precautions to ensure safe and

proper servicing. These precautions are not described in

each individual section.

Precautions for Supplemental Restraint

System (SRS) ``AIR BAG'' (4WD models)

The Supplemental Restraint System ``AIR BAG'', used along with

a seat belt, helps to reduce the risk or severity of injury to the

driver in a frontal collision. The Supplemental Restraint System

consists of an air bag module (located in the center of the steer-

ing wheel), a diagnosis sensor unit, warning lamp, wiring harness

and spiral cable. Information necessary to service the system

safely is included in theRS sectionof this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could

increase the risk of personal injury or death in the event

of a collision which would result in air bag inflation, all

maintenance must be performed by an authorized

NISSAN dealer.

lImproper maintenance, including incorrect removal and

installation of the SRS, can lead to personal injury

caused by unintentional activation of the system.

lDo not use electrical test equipment on any circuit

related to the SRS unless instructed to in this Service

Manual. SRS wiring harnesses are covered with yellow

insulation either just before the harness connectors or

for the complete harness, for easy identification.

Precautions for Supplemental Restraint

System (SRS) ``AIR BAG'' (2WD models)

The Supplemental Restraint System ``AIR BAG'', used along with

a seat belt, helps to reduce the risk or severity of injury to the

driver in a frontal collision. The Supplemental Restraint System

consists of an air bag module (located in the center of the steer-

ing wheel), a diagnosis sensor unit, warning lamp and spiral

cable. Information necessary to service the system safely is

included in theRS sectionof this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could

increase the risk of personal injury or death in the event

of a collision which would result in air bag inflation, all

maintenance must be performed by an authorized

NISSAN dealer.

lImproper maintenance, including incorrect removal and

installation of the SRS, can lead to personal injury

caused by unintentional activation of the system.

lDo not use electrical test equipment on any circuit

related to the SRS.

SGI646

PRECAUTIONS

GI-1

Page 806 of 1659

Precautions for NATS

NATS (Nissan Anti-Theft System)

NATS will immobilize the engine if someone tries to start it with-

out the registered key of NATS.

All of the originally supplied ignition key IDs have been NATS

registered.

The NATS security indicator is located on the instrument panel.

The indicator blinks when the ignition switch is in ``OFF'' or

``ACC'' position. Therefore, NATS warns outsiders that the

vehicle is equipped with the anti-theft system.

lGasoline engine:

When NATS detects trouble, the malfunction indicator lamp

(MIL) blinks.

This blinking indicates that the anti-theft is not functioning, so

prompt service is required.

lDiesel engine:

When NATS detects trouble while engine is running or igni-

tion switch in ``ON'' position, the NATS security indicator

comes on.

This indicates that the anti-theft is not functioning, so prompt

service is required.

lWhen servicing NATS (trouble diagnoses, system initialisa-

tion and additional registration of other NATS ignition key

IDs), CONSULT hardware and CONSULT NATS software is

necessary.

Regarding the procedures of NATS initialisation and NATS

ignition key ID registration, refer to CONSULT operation

manual, NATS.

Therefore, CONSULT NATS software (program card and

operation manual) must be kept strictly confidential to main-

tain the integrity of the anti-theft function.

lWhen servicing NATS (trouble diagnoses, system initialisa-

tion and additional registration of other NATS ignition key

IDs), it may be necessary to re-register original key identifi-

cation. Therefore, be sure to receive all keys from vehicle

owner.

A maximum of four key IDs can be registered into NATS.

General Precautions

lDo not operate the engine for an extended period of time

without proper exhaust ventilation.

Keep the work area well ventilated and free of any inflam-

mable materials. Special care should be taken when han-

dling any inflammable or poisonous materials, such as

gasoline, refrigerant gas, etc. When working in a pit or other

enclosed area, be sure to properly ventilate the area before

working with hazardous materials.

Do not smoke while working on the vehicle.

SGI916

SGI285

PRECAUTIONS

GI-2

Page 807 of 1659

lBefore jacking up the vehicle, apply wheel chocks or other

tire blocks to the wheels to prevent the vehicle from moving.

After jacking up the vehicle, support the vehicle weight with

safety stands at the points designated for proper lifting before

working on the vehicle.

These operations should be done on a level surface.

lWhen removing a heavy component such as the engine or

transaxle/transmission, be careful not to lose your balance

and drop them. Also, do not allow them to strike adjacent

parts, especially the brake tubes and master cylinder.

lBefore starting repairs which do not require battery power:

Turn off ignition switch.

Disconnect the negative battery terminal.

lTo prevent serious burns:

Avoid contact with hot metal parts.

Do not remove the radiator cap when the engine is hot.

lBefore servicing the vehicle:

Protect fenders, upholstery and carpeting with appropriate

covers.

Take caution that keys, buckles or buttons do not scratch

paint.

lClean all disassembled parts in the designated liquid or sol-

vent prior to inspection or assembly.

lReplace oil seals, gaskets, packings, O-rings, locking

washers, cotter pins, self-locking nuts, etc. with new ones.

lReplace inner and outer races of tapered roller bearings and

needle bearings as a set.

lArrange the disassembled parts in accordance with their

assembled locations and sequence.

lDo not touch the terminals of electrical components which

use microcomputers (such as ECMs).

Static electricity may damage internal electronic compo-

nents.

SGI231

SEF289H

SGI233

SGI234

PRECAUTIONS

General Precautions (Cont'd)

GI-3

Page 808 of 1659

lAfter disconnecting vacuum or air hoses, attach a tag to

indicate the proper connection.

lUse only the fluids and lubricants specified in this manual.

lUse approved bonding agent, sealants or their equivalents

when required.

lUse tools and recommended special tools where specified

for safe and efficient service repairs.

lWhen repairing the fuel, oil, water, vacuum or exhaust

systems, check all affected lines for leaks.

lDispose of drained oil or the solvent used for cleaning parts

in an appropriate manner.

WARNING:

To prevent ECM from storing the diagnostic trouble codes,

do not carelessly disconnect the harness connectors which

are related to the ECCS system and TCM (Transmission

Control Module) system. The connectors should be discon-

nected only when working according to the WORK FLOW of

TROUBLE DIAGNOSES in EC section.

Precautions for Multiport Fuel Injection

System or ECCS Engine

lBefore connecting or disconnecting any harness connector

for the multiport fuel injection system or ECM (Engine Con-

trol Module):

Turn ignition switch to ``OFF'' position.

Disconnect negative battery terminal.

Otherwise, there may be damage to ECM.

lBefore disconnecting pressurized fuel line from fuel pump to

injectors, be sure to release fuel pressure.

lBe careful not to jar components such as ECM and mass air

flow sensor.

Precautions for Three Way Catalyst

(If so equipped)

If a large amount of unburned fuel flows into the catalyst, the

catalyst temperature will be excessively high. To prevent this,

follow the instructions below:

lUse unleaded gasoline only. Leaded gasoline will seriously

damage the three way catalyst.

lWhen checking for ignition spark or measuring engine

compression, make tests quickly and only when necessary.

lDo not run engine when the fuel tank level is low, otherwise

the engine may misfire causing damage to the catalyst.

Do not place the vehicle on flammable material. Keep flammable

material off the exhaust pipe and the three way catalyst.

Precautions for Engine Oils

Prolonged and repeated contact with used engine oil may cause

skin cancer. Try to avoid direct skin contact with used oil.

SGI787

PRECAUTIONS

General Precautions (Cont'd)

GI-4

Page 809 of 1659

If skin contact is made, wash thoroughly with soap or hand

cleaner as soon as possible.

HEALTH PROTECTION PRECAUTIONS

lAvoid prolonged and repeated contact with oils, particularly

used engine oils.

lWear protective clothing, including impervious gloves where

practicable.

lDo not put oily rags in pockets.

lAvoid contaminating clothes, particularly underpants, with oil.

lHeavily soiled clothing and oil-impregnated footwear should

not be worn. Overalls must be cleaned regularly.

lFirst Aid treatment should be obtained immediately for open

cuts and wounds.

lUse barrier creams, applying them before each work period,

to help the removal of oil from the skin.

lWash with soap and water to ensure all oil is removed (skin

cleansers and nail brushes will help). Preparations contain-

ing lanolin replace the natural skin oils which have been

removed.

lDo not use gasoline, kerosine, diesel fuel, gas oil, thinners

or solvents for cleaning skin.

lIf skin disorders develop, obtain medical advice without

delay.

lWhere practicable, degrease components prior to handling.

lWhere there is a risk of eye contact, eye protection should

be worn, for example, chemical goggles or face shields; in

addition an eye wash facility should be provided.

ENVIRONMENTAL PROTECTION PRECAUTIONS

Burning used engine oil in small space heaters or boilers can be

recommended only for units of approved design. The heating

system must meet the requirements of HM Inspectorate of Pol-

lution for small burners of less than 0.4 MW. If in doubt check

with the appropriate local authority and/or manufacturer of the

approved appliance.

Dispose of used oil and used oil filters through authorized waste

disposal contractors to licensed waste disposal sites, or to the

waste oil reclamation trade. If in doubt, contact the local author-

ity for advice on disposal facilities.

It is illegal to pour used oil on to the ground, down sewers or

drains, or into water courses.

The regulations concerning the pollution of the environment

will vary from country to country.

Precautions for Fuel

GASOLINE ENGINE:

Three way catalyst equipped models ... unleaded gasoline of at

least 91 octane (RON)

CAUTION:

Do not use leaded gasoline. Using leaded gasoline will dam-

age the three way catalyst.

Except for the above models ... unleaded or leaded gasoline of

above 88 octane (RON)

Use unleaded fuel if instructed on the fuel filler lid.

PRECAUTIONS

Precautions for Engine Oils (Cont'd)

GI-5

Page 810 of 1659

DIESEL ENGINE*:

For Europe: diesel fuel of above 50 cetane

* If two types of diesel fuel are available, use summer or win-

ter fuel properly according to the following temperature con-

ditions.

lAbove þ7ÉC (20ÉF) ... Summer type diesel fuel.

lBelow þ7ÉC (20ÉF) ... Winter type diesel fuel.

CAUTION:

lDo not use home heating oil, gasoline, or other alternate

fuels in your diesel engine. The use of those can cause

engine damage.

lDo not use summer fuel at temperature below þ7ÉC

(20ÉF). The cold temperature will cause wax to form in

the fuel. As a result, it may prevent the engine from run-

ning smoothly.

lDo not add gasoline or other alternate fuels to diesel

fuel.

Precautions for Air Conditioning

Use an approved refrigerant recovery unit any time the air con-

ditioning system must be discharged. Refer to HA section

(``HFC-134a (R-134a) Service Procedure'', ``SERVICE PRO-

CEDURES'') for specific instructions.

PRECAUTIONS

Precautions for Fuel (Cont'd)

GI-6