NISSAN PICK-UP 1998 Repair Manual

Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 821 of 1659

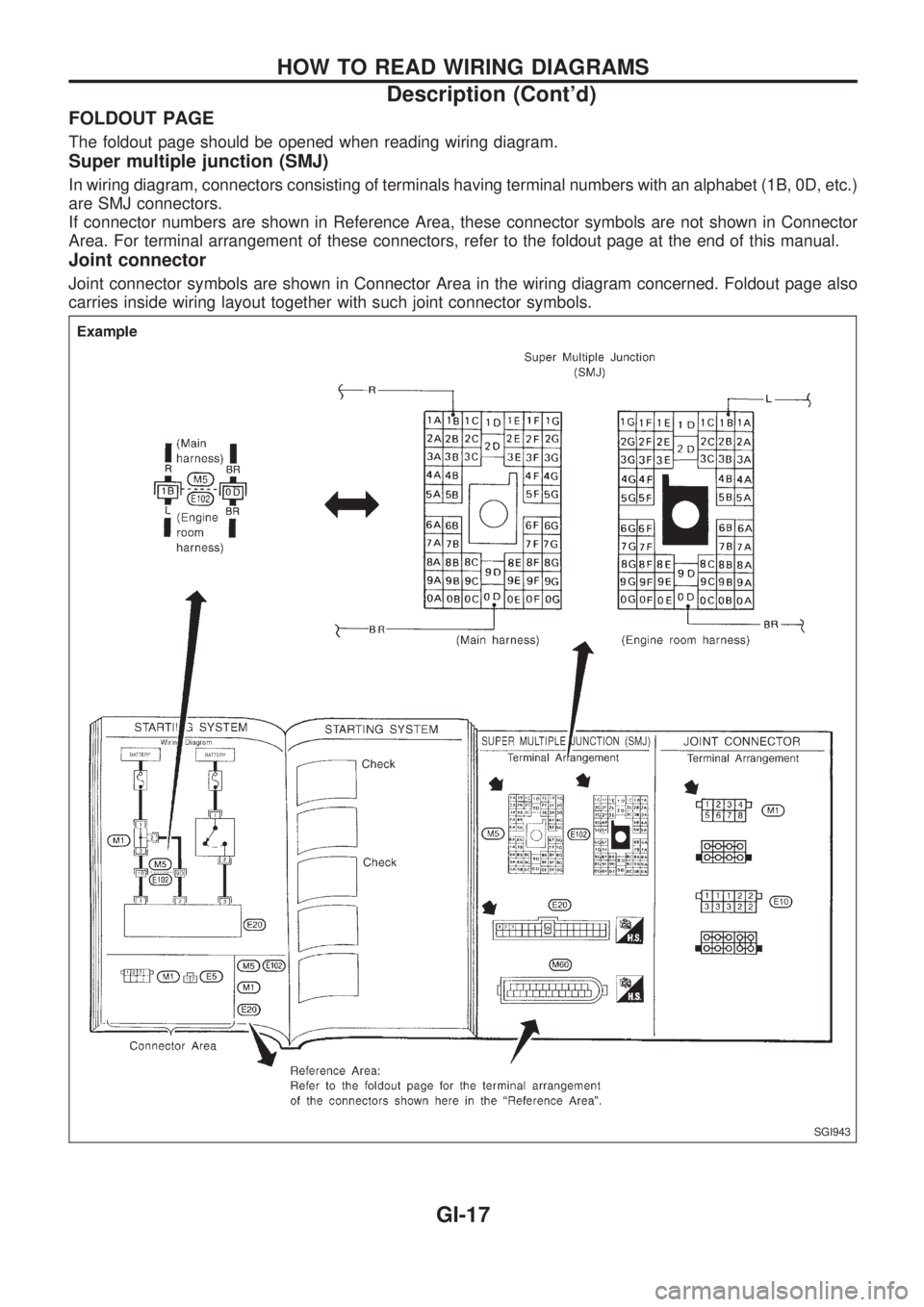

FOLDOUT PAGE

The foldout page should be opened when reading wiring diagram.

Super multiple junction (SMJ)

In wiring diagram, connectors consisting of terminals having terminal numbers with an alphabet (1B, 0D, etc.)

are SMJ connectors.

If connector numbers are shown in Reference Area, these connector symbols are not shown in Connector

Area. For terminal arrangement of these connectors, refer to the foldout page at the end of this manual.

Joint connector

Joint connector symbols are shown in Connector Area in the wiring diagram concerned. Foldout page also

carries inside wiring layout together with such joint connector symbols.

SGI943

HOW TO READ WIRING DIAGRAMS

Description (Cont'd)

GI-17

Page 822 of 1659

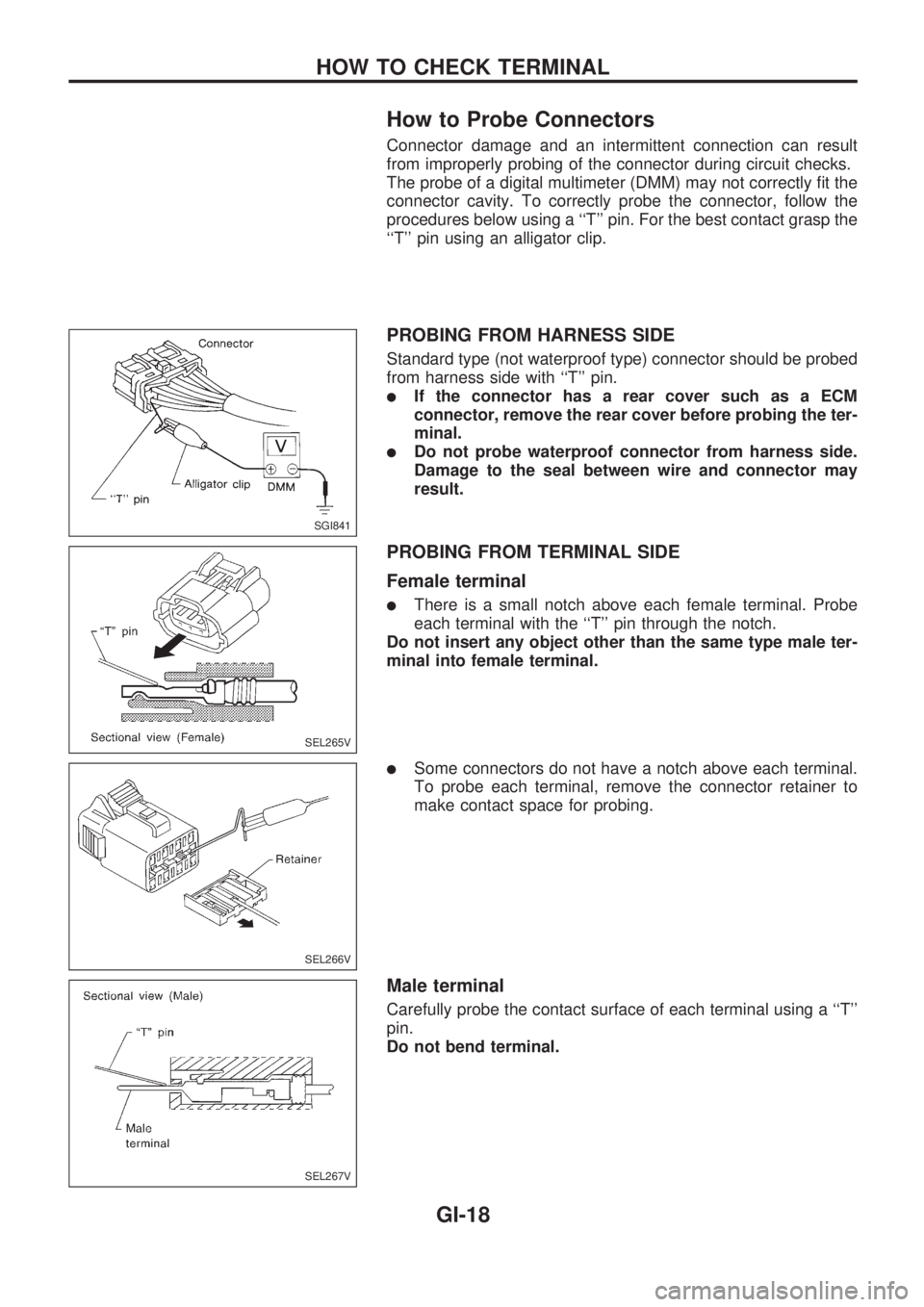

How to Probe Connectors

Connector damage and an intermittent connection can result

from improperly probing of the connector during circuit checks.

The probe of a digital multimeter (DMM) may not correctly fit the

connector cavity. To correctly probe the connector, follow the

procedures below using a ``T'' pin. For the best contact grasp the

``T'' pin using an alligator clip.

PROBING FROM HARNESS SIDE

Standard type (not waterproof type) connector should be probed

from harness side with ``T'' pin.

lIf the connector has a rear cover such as a ECM

connector, remove the rear cover before probing the ter-

minal.

lDo not probe waterproof connector from harness side.

Damage to the seal between wire and connector may

result.

PROBING FROM TERMINAL SIDE

Female terminal

lThere is a small notch above each female terminal. Probe

each terminal with the ``T'' pin through the notch.

Do not insert any object other than the same type male ter-

minal into female terminal.

lSome connectors do not have a notch above each terminal.

To probe each terminal, remove the connector retainer to

make contact space for probing.

Male terminal

Carefully probe the contact surface of each terminal using a ``T''

pin.

Do not bend terminal.

SGI841

SEL265V

SEL266V

SEL267V

HOW TO CHECK TERMINAL

GI-18

Page 823 of 1659

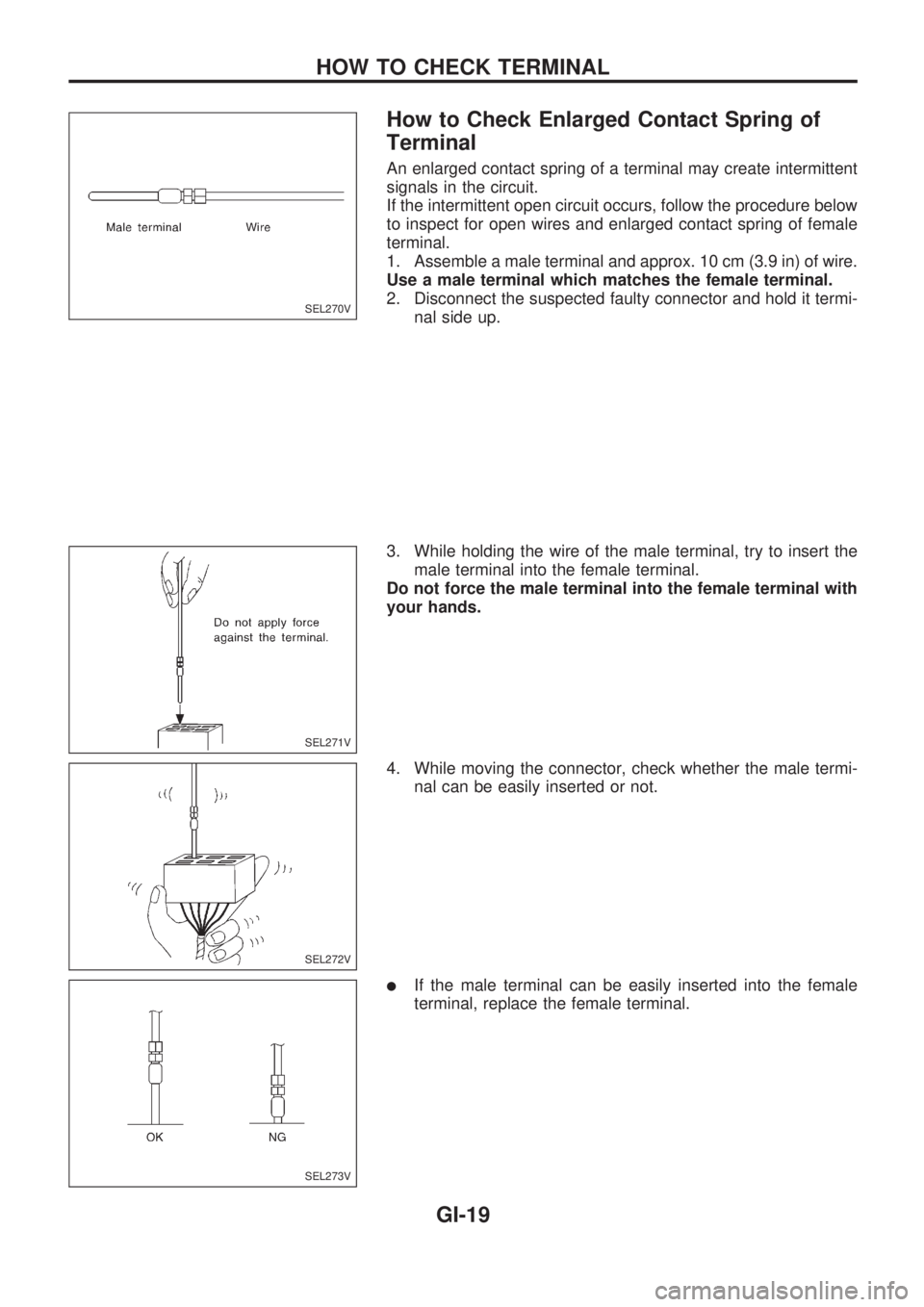

How to Check Enlarged Contact Spring of

Terminal

An enlarged contact spring of a terminal may create intermittent

signals in the circuit.

If the intermittent open circuit occurs, follow the procedure below

to inspect for open wires and enlarged contact spring of female

terminal.

1. Assemble a male terminal and approx. 10 cm (3.9 in) of wire.

Use a male terminal which matches the female terminal.

2. Disconnect the suspected faulty connector and hold it termi-

nal side up.

3. While holding the wire of the male terminal, try to insert the

male terminal into the female terminal.

Do not force the male terminal into the female terminal with

your hands.

4. While moving the connector, check whether the male termi-

nal can be easily inserted or not.

lIf the male terminal can be easily inserted into the female

terminal, replace the female terminal.

SEL270V

SEL271V

SEL272V

SEL273V

HOW TO CHECK TERMINAL

GI-19

Page 824 of 1659

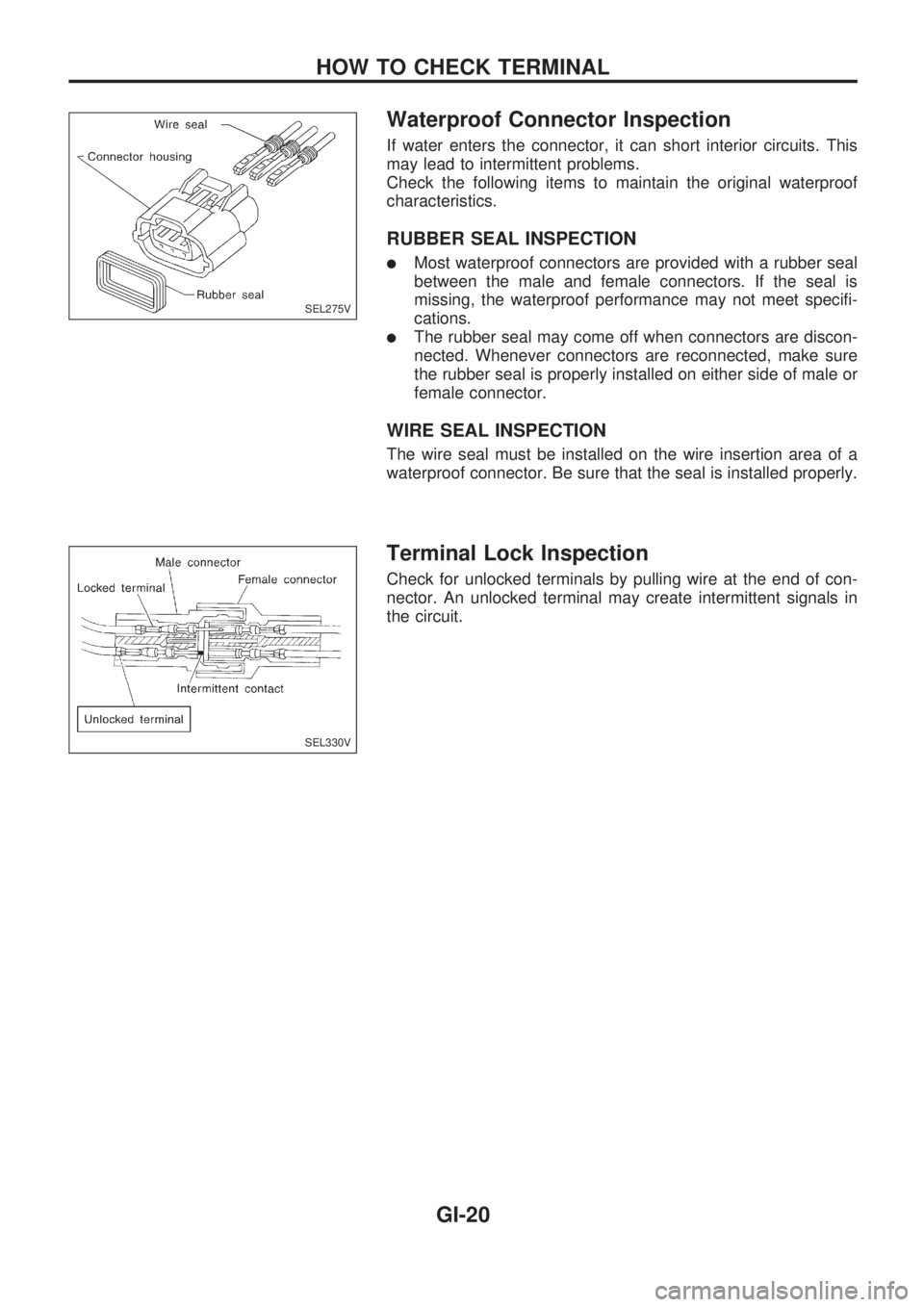

Waterproof Connector Inspection

If water enters the connector, it can short interior circuits. This

may lead to intermittent problems.

Check the following items to maintain the original waterproof

characteristics.

RUBBER SEAL INSPECTION

lMost waterproof connectors are provided with a rubber seal

between the male and female connectors. If the seal is

missing, the waterproof performance may not meet specifi-

cations.

lThe rubber seal may come off when connectors are discon-

nected. Whenever connectors are reconnected, make sure

the rubber seal is properly installed on either side of male or

female connector.

WIRE SEAL INSPECTION

The wire seal must be installed on the wire insertion area of a

waterproof connector. Be sure that the seal is installed properly.

Terminal Lock Inspection

Check for unlocked terminals by pulling wire at the end of con-

nector. An unlocked terminal may create intermittent signals in

the circuit.

SEL275V

SEL330V

HOW TO CHECK TERMINAL

GI-20

Page 825 of 1659

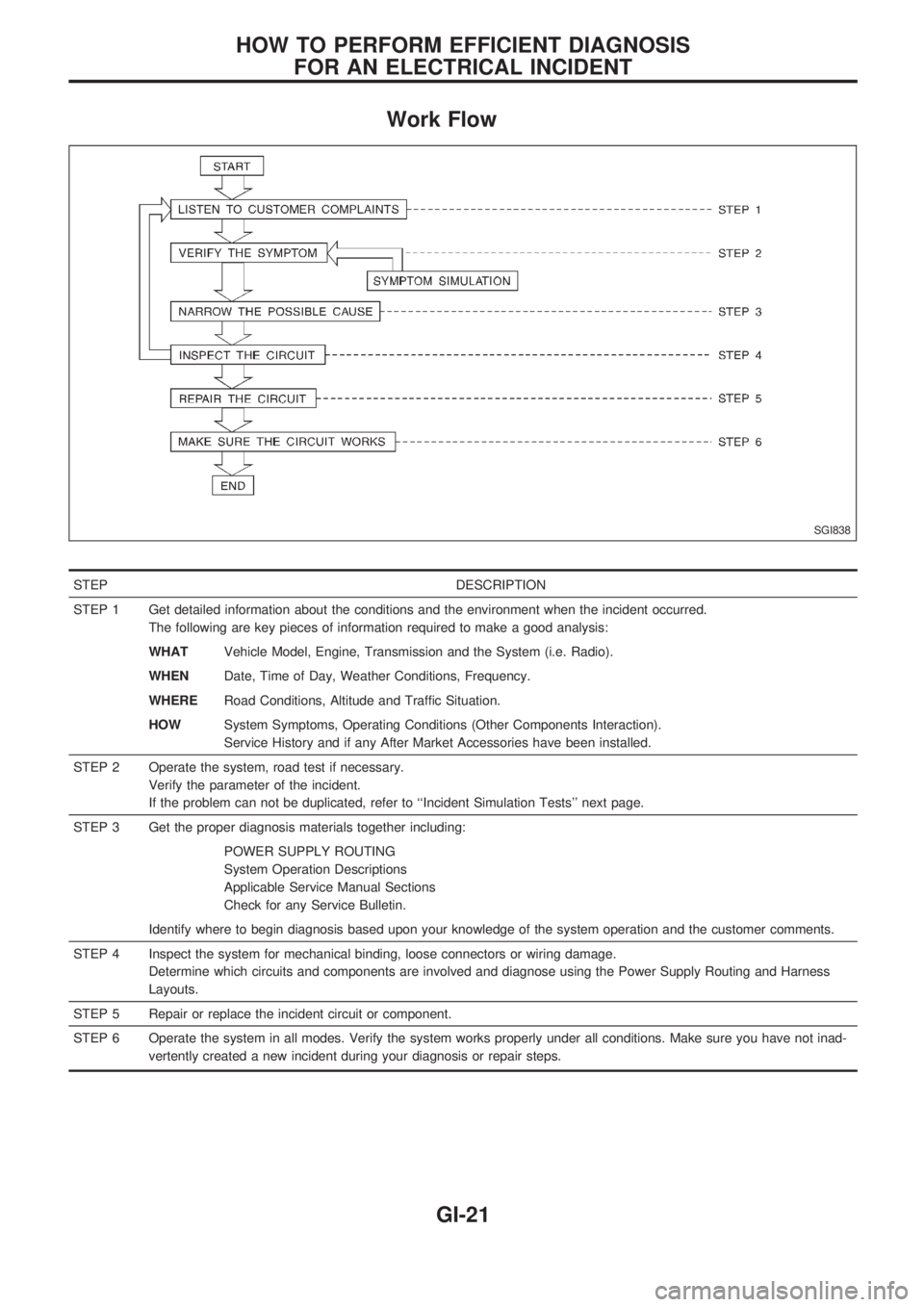

Work Flow

STEP DESCRIPTION

STEP 1 Get detailed information about the conditions and the environment when the incident occurred.

The following are key pieces of information required to make a good analysis:

WHATVehicle Model, Engine, Transmission and the System (i.e. Radio).

WHENDate, Time of Day, Weather Conditions, Frequency.

WHERERoad Conditions, Altitude and Traffic Situation.

HOWSystem Symptoms, Operating Conditions (Other Components Interaction).

Service History and if any After Market Accessories have been installed.

STEP 2 Operate the system, road test if necessary.

Verify the parameter of the incident.

If the problem can not be duplicated, refer to ``Incident Simulation Tests'' next page.

STEP 3 Get the proper diagnosis materials together including:

POWER SUPPLY ROUTING

System Operation Descriptions

Applicable Service Manual Sections

Check for any Service Bulletin.

Identify where to begin diagnosis based upon your knowledge of the system operation and the customer comments.

STEP 4 Inspect the system for mechanical binding, loose connectors or wiring damage.

Determine which circuits and components are involved and diagnose using the Power Supply Routing and Harness

Layouts.

STEP 5 Repair or replace the incident circuit or component.

STEP 6 Operate the system in all modes. Verify the system works properly under all conditions. Make sure you have not inad-

vertently created a new incident during your diagnosis or repair steps.

SGI838

HOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT

GI-21

Page 826 of 1659

Incident Simulation Tests

INTRODUCTION

Sometimes the symptom is not present when the vehicle is brought in for service. If possible, re-create the

conditions present at the time of the incident. Doing so may help avoid a No Trouble Found Diagnosis. The

following section illustrates ways to simulate the conditions/environment under which the owner experiences

an electrical incident.

The section is broken into the six following topics:

lVehicle vibration

lHeat sensitive

lFreezing

lWater intrusion

lElectrical load

lCold or hot start up

Get a thorough description of the incident from the customer. It is important for simulating the conditions of

the problem.

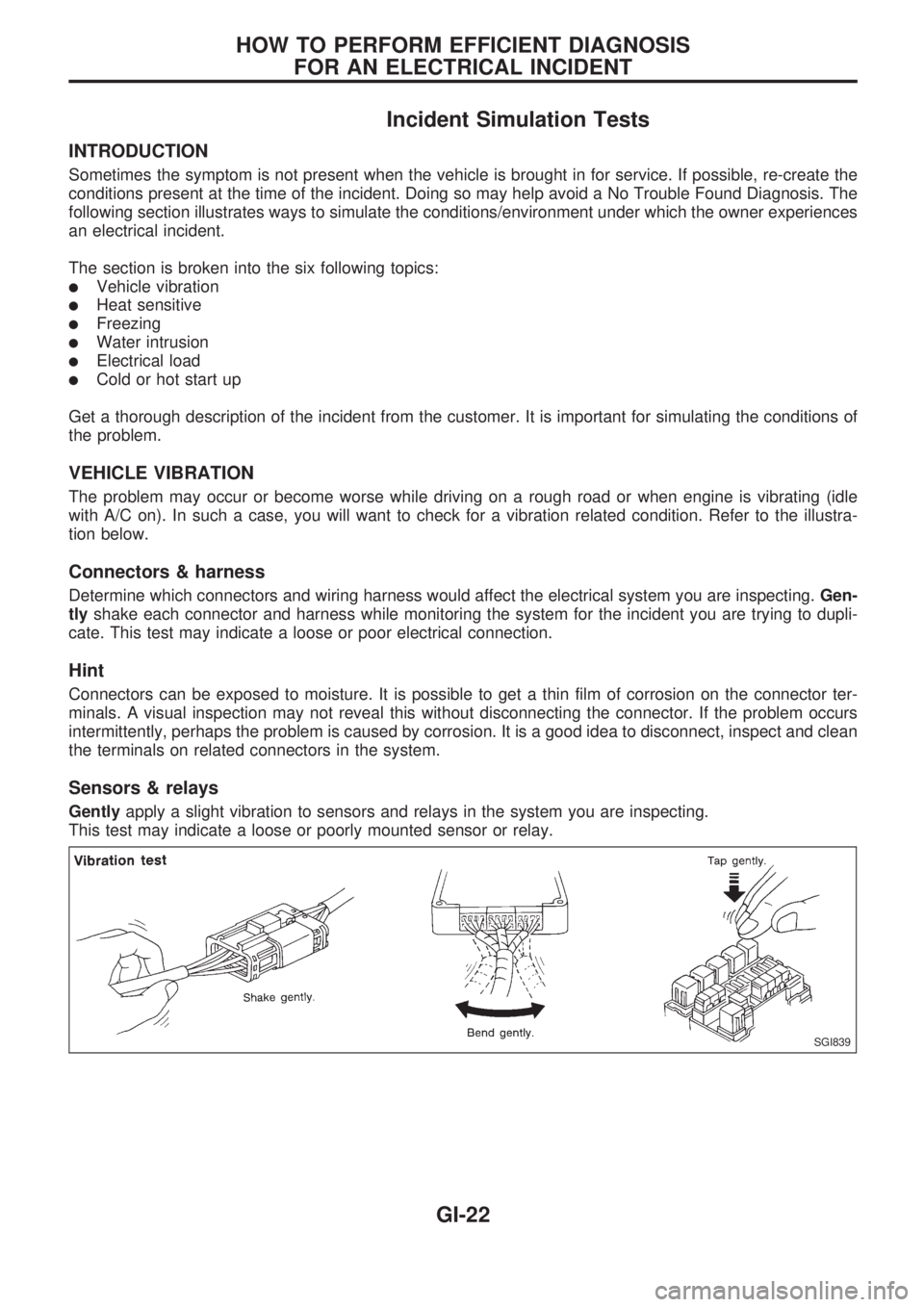

VEHICLE VIBRATION

The problem may occur or become worse while driving on a rough road or when engine is vibrating (idle

with A/C on). In such a case, you will want to check for a vibration related condition. Refer to the illustra-

tion below.

Connectors & harness

Determine which connectors and wiring harness would affect the electrical system you are inspecting.Gen-

tlyshake each connector and harness while monitoring the system for the incident you are trying to dupli-

cate. This test may indicate a loose or poor electrical connection.

Hint

Connectors can be exposed to moisture. It is possible to get a thin film of corrosion on the connector ter-

minals. A visual inspection may not reveal this without disconnecting the connector. If the problem occurs

intermittently, perhaps the problem is caused by corrosion. It is a good idea to disconnect, inspect and clean

the terminals on related connectors in the system.

Sensors & relays

Gentlyapply a slight vibration to sensors and relays in the system you are inspecting.

This test may indicate a loose or poorly mounted sensor or relay.

SGI839

HOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT

GI-22

Page 827 of 1659

Engine compartment

There are several reasons a vehicle or engine vibration could

cause an electrical complaint. Some of the things to check for

are:

lConnectors not fully seated.

lWiring harness not long enough and is being stressed due

to engine vibrations or rocking.

lWires laying across brackets or moving components.

lLoose, dirty or corroded ground wires.

lWires routed too close to hot components.

To inspect components under the hood, start by verifying the

integrity of ground connections. (Refer to GROUND INSPEC-

TION described later.) First check that the system is properly

grounded. Then check for loose connection bygently shaking

the wiring or components as previously explained. Using the

wiring diagrams inspect the wiring for continuity.

Behind the instrument panel

An improperly routed or improperly clamped harness can

become pinched during accessory installation. Vehicle vibration

can aggravate a harness which is routed along a bracket or near

a screw.

Under seating areas

An unclamped or loose harness can cause wiring to be pinched

by seat components (such as slide guides) during vehicle vibra-

tion. If the wiring runs under seating areas, inspect wire routing

for possible damage or pinching.

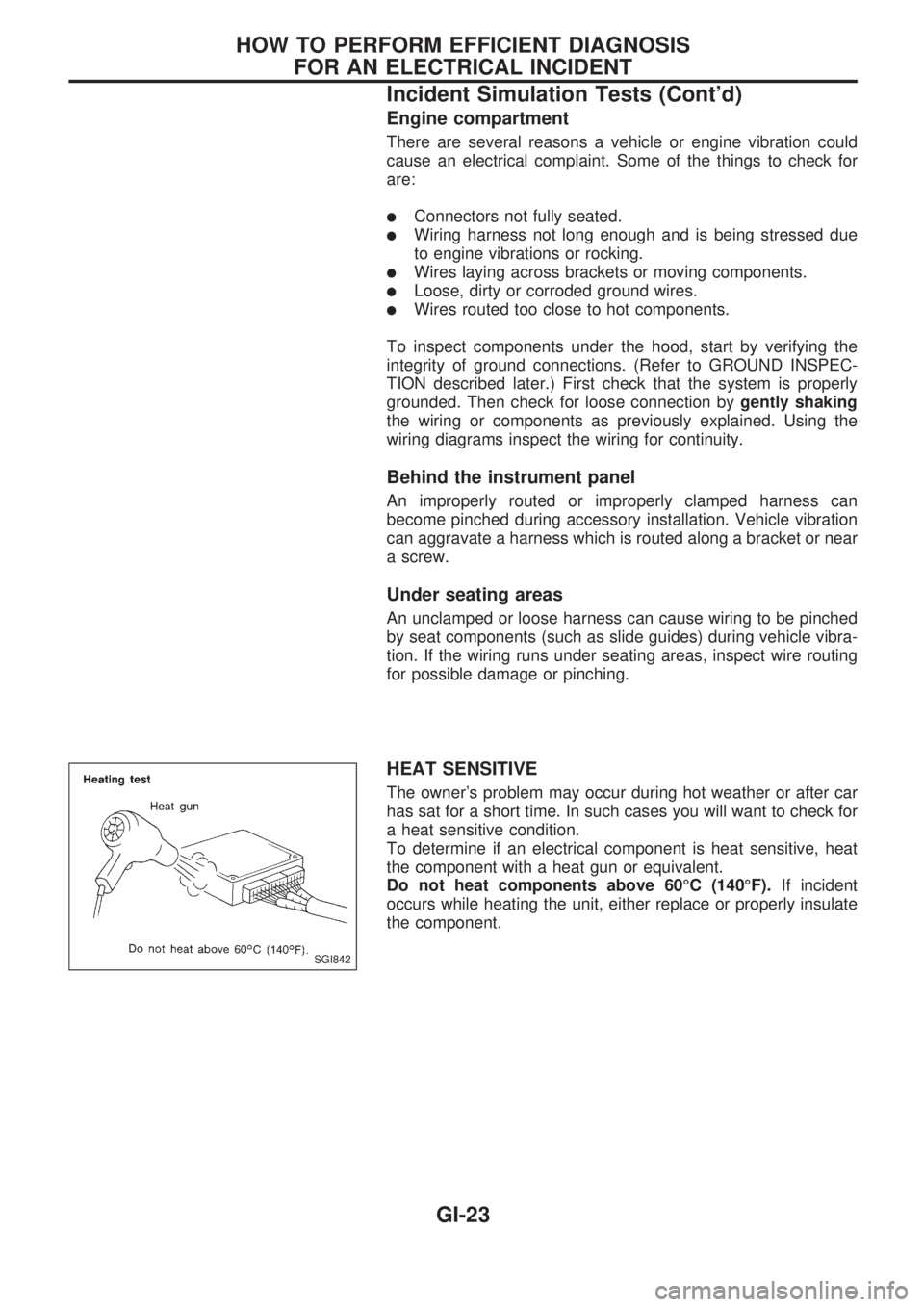

HEAT SENSITIVE

The owner's problem may occur during hot weather or after car

has sat for a short time. In such cases you will want to check for

a heat sensitive condition.

To determine if an electrical component is heat sensitive, heat

the component with a heat gun or equivalent.

Do not heat components above 60ÉC (140ÉF).If incident

occurs while heating the unit, either replace or properly insulate

the component.

SGI842

HOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT

Incident Simulation Tests (Cont'd)

GI-23

Page 828 of 1659

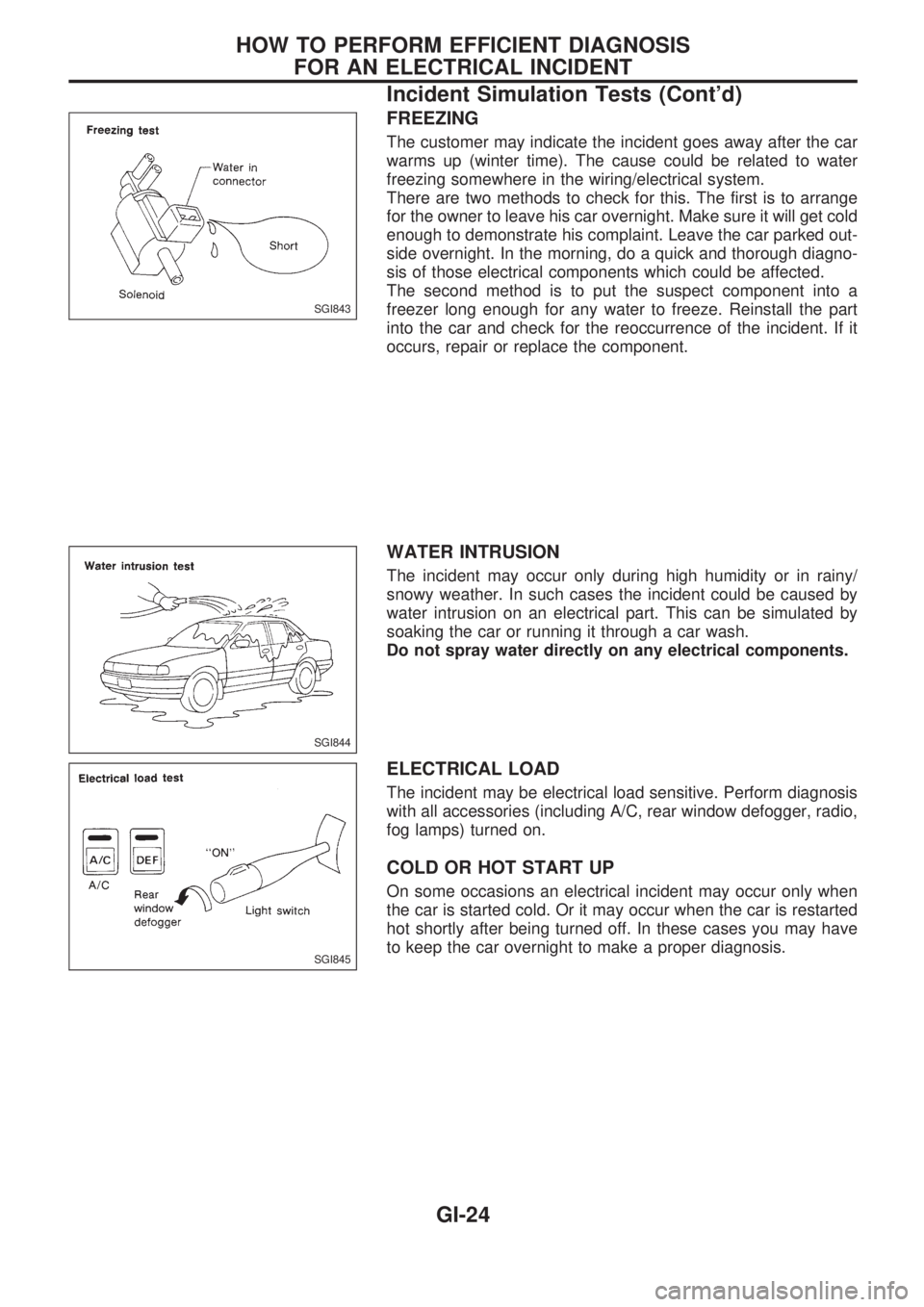

FREEZING

The customer may indicate the incident goes away after the car

warms up (winter time). The cause could be related to water

freezing somewhere in the wiring/electrical system.

There are two methods to check for this. The first is to arrange

for the owner to leave his car overnight. Make sure it will get cold

enough to demonstrate his complaint. Leave the car parked out-

side overnight. In the morning, do a quick and thorough diagno-

sis of those electrical components which could be affected.

The second method is to put the suspect component into a

freezer long enough for any water to freeze. Reinstall the part

into the car and check for the reoccurrence of the incident. If it

occurs, repair or replace the component.

WATER INTRUSION

The incident may occur only during high humidity or in rainy/

snowy weather. In such cases the incident could be caused by

water intrusion on an electrical part. This can be simulated by

soaking the car or running it through a car wash.

Do not spray water directly on any electrical components.

ELECTRICAL LOAD

The incident may be electrical load sensitive. Perform diagnosis

with all accessories (including A/C, rear window defogger, radio,

fog lamps) turned on.

COLD OR HOT START UP

On some occasions an electrical incident may occur only when

the car is started cold. Or it may occur when the car is restarted

hot shortly after being turned off. In these cases you may have

to keep the car overnight to make a proper diagnosis.

SGI843

SGI844

SGI845

HOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT

Incident Simulation Tests (Cont'd)

GI-24

Page 829 of 1659

Circuit Inspection

INTRODUCTION

In general, testing electrical circuits is an easy task if it is approached in a logical and organized method.

Before beginning it is important to have all available information on the system to be tested. Also, get a

thorough understanding of system operation. Then you will be able to use the appropriate equipment and

follow the correct test procedure.

You may have to simulate vehicle vibrations while testing electrical components.Gently shakethe wiring

harness or electrical component to do this.

OPEN A circuit is open when there is no continuity through a section of the circuit.

SHORT There are two types of shorts.

lSHORT CIRCUITWhen a circuit contacts another circuit and causes the

normal resistance to change.

lSHORT TO GROUNDWhen a circuit contacts a ground source and grounds the

circuit.

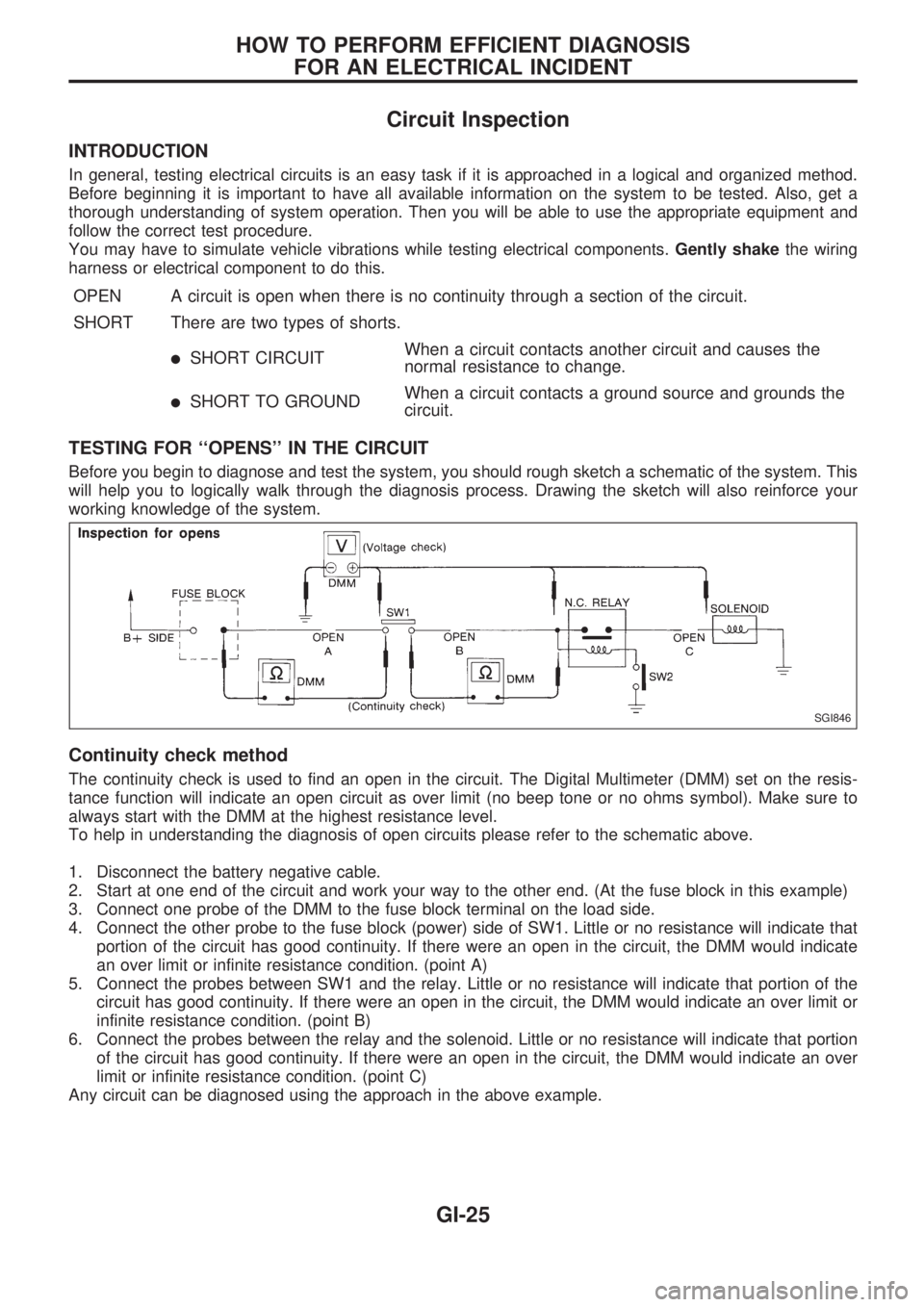

TESTING FOR ``OPENS'' IN THE CIRCUIT

Before you begin to diagnose and test the system, you should rough sketch a schematic of the system. This

will help you to logically walk through the diagnosis process. Drawing the sketch will also reinforce your

working knowledge of the system.

Continuity check method

The continuity check is used to find an open in the circuit. The Digital Multimeter (DMM) set on the resis-

tance function will indicate an open circuit as over limit (no beep tone or no ohms symbol). Make sure to

always start with the DMM at the highest resistance level.

To help in understanding the diagnosis of open circuits please refer to the schematic above.

1. Disconnect the battery negative cable.

2. Start at one end of the circuit and work your way to the other end. (At the fuse block in this example)

3. Connect one probe of the DMM to the fuse block terminal on the load side.

4. Connect the other probe to the fuse block (power) side of SW1. Little or no resistance will indicate that

portion of the circuit has good continuity. If there were an open in the circuit, the DMM would indicate

an over limit or infinite resistance condition. (point A)

5. Connect the probes between SW1 and the relay. Little or no resistance will indicate that portion of the

circuit has good continuity. If there were an open in the circuit, the DMM would indicate an over limit or

infinite resistance condition. (point B)

6. Connect the probes between the relay and the solenoid. Little or no resistance will indicate that portion

of the circuit has good continuity. If there were an open in the circuit, the DMM would indicate an over

limit or infinite resistance condition. (point C)

Any circuit can be diagnosed using the approach in the above example.

SGI846

HOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT

GI-25

Page 830 of 1659

Voltage check method

To help in understanding the diagnosis of open circuits please refer to the previous schematic.

In any powered circuit, an open can be found by methodically checking the system for the presence of volt-

age. This is done by switching the DMM to the voltage function.

1. Connect one probe of the DMM to a known good ground.

2. Begin probing at one end of the circuit and work your way to the other end.

3. With SW1 open, probe at SW1 to check for voltage.

voltage; open is further down the circuit than SW1.

no voltage; open is between fuse block and SW1 (point A).

4. Close SW1 and probe at relay.

voltage; open is further down the circuit than the relay.

no voltage; open is between SW1 and relay (point B).

5. Close the relay and probe at the solenoid.

voltage; open is further down the circuit than the solenoid.

no voltage; open is between relay and solenoid (point C).

Any powered circuit can be diagnosed using the approach in the above example.

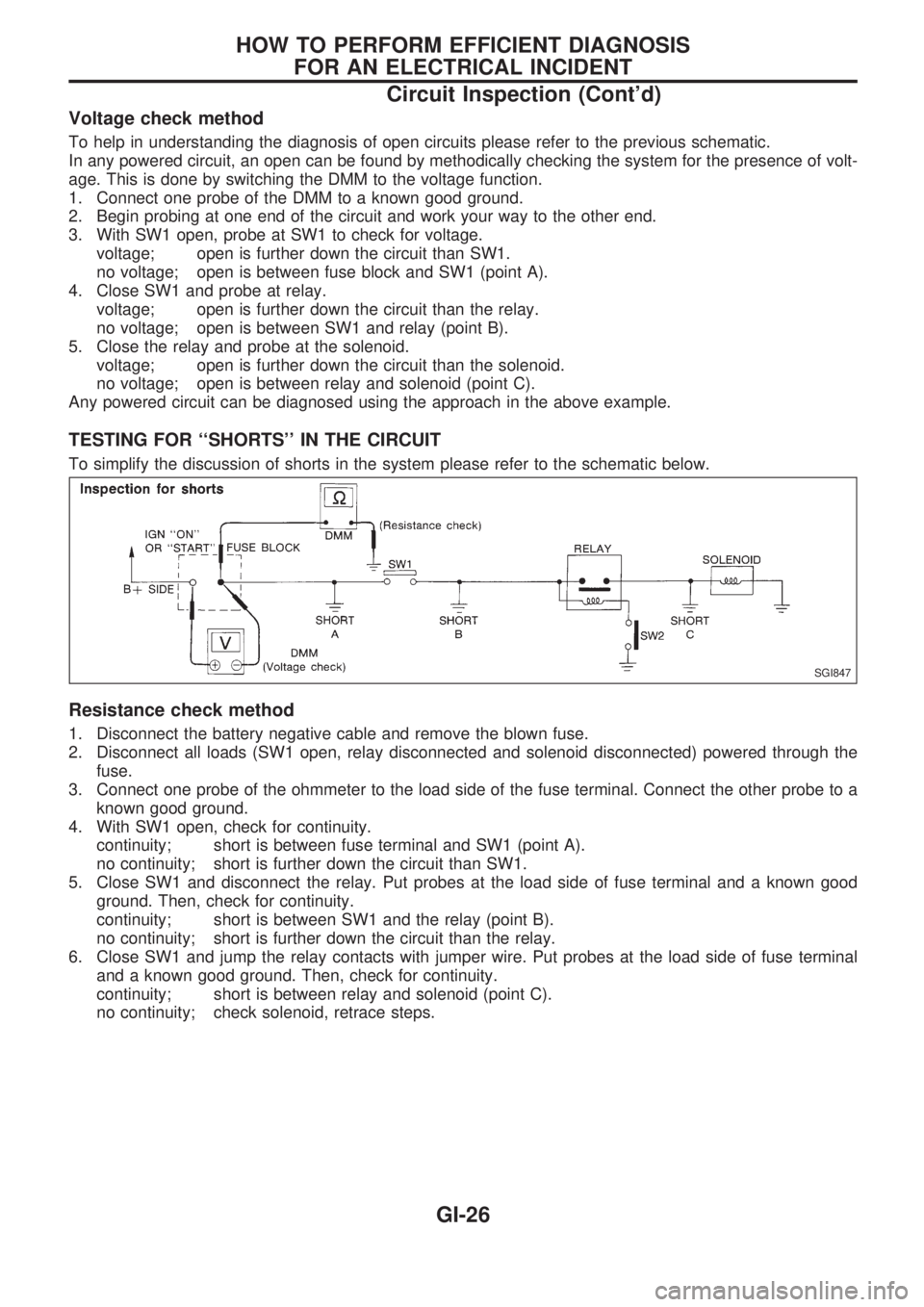

TESTING FOR ``SHORTS'' IN THE CIRCUIT

To simplify the discussion of shorts in the system please refer to the schematic below.

Resistance check method

1. Disconnect the battery negative cable and remove the blown fuse.

2. Disconnect all loads (SW1 open, relay disconnected and solenoid disconnected) powered through the

fuse.

3. Connect one probe of the ohmmeter to the load side of the fuse terminal. Connect the other probe to a

known good ground.

4. With SW1 open, check for continuity.

continuity; short is between fuse terminal and SW1 (point A).

no continuity; short is further down the circuit than SW1.

5. Close SW1 and disconnect the relay. Put probes at the load side of fuse terminal and a known good

ground. Then, check for continuity.

continuity; short is between SW1 and the relay (point B).

no continuity; short is further down the circuit than the relay.

6. Close SW1 and jump the relay contacts with jumper wire. Put probes at the load side of fuse terminal

and a known good ground. Then, check for continuity.

continuity; short is between relay and solenoid (point C).

no continuity; check solenoid, retrace steps.

SGI847

HOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT

Circuit Inspection (Cont'd)

GI-26