NISSAN PICK-UP 1998 Repair Manual

Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 791 of 1659

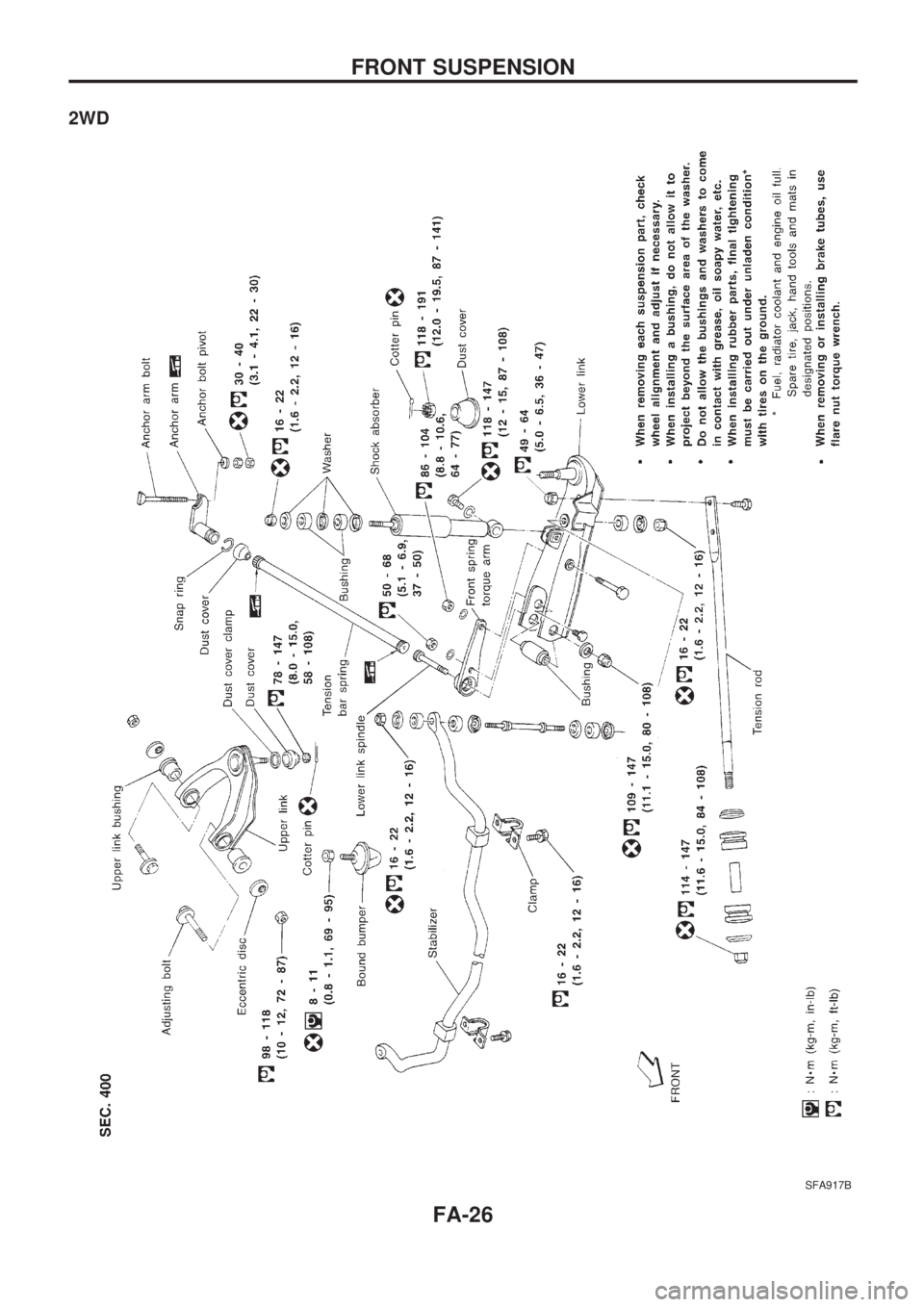

2WD

SFA917B

FRONT SUSPENSION

FA-26

Page 792 of 1659

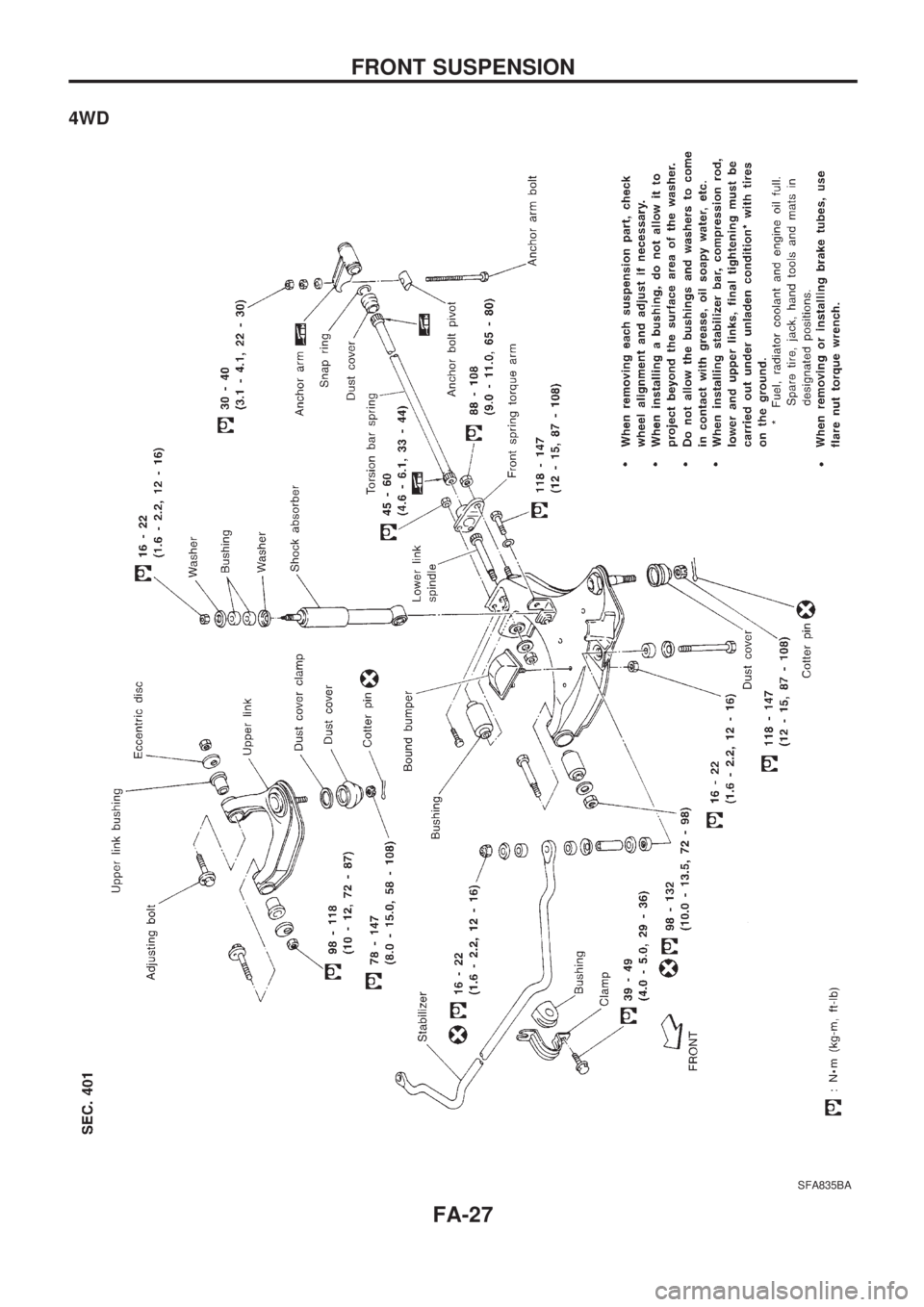

4WD

SFA835BA

FRONT SUSPENSION

FA-27

Page 793 of 1659

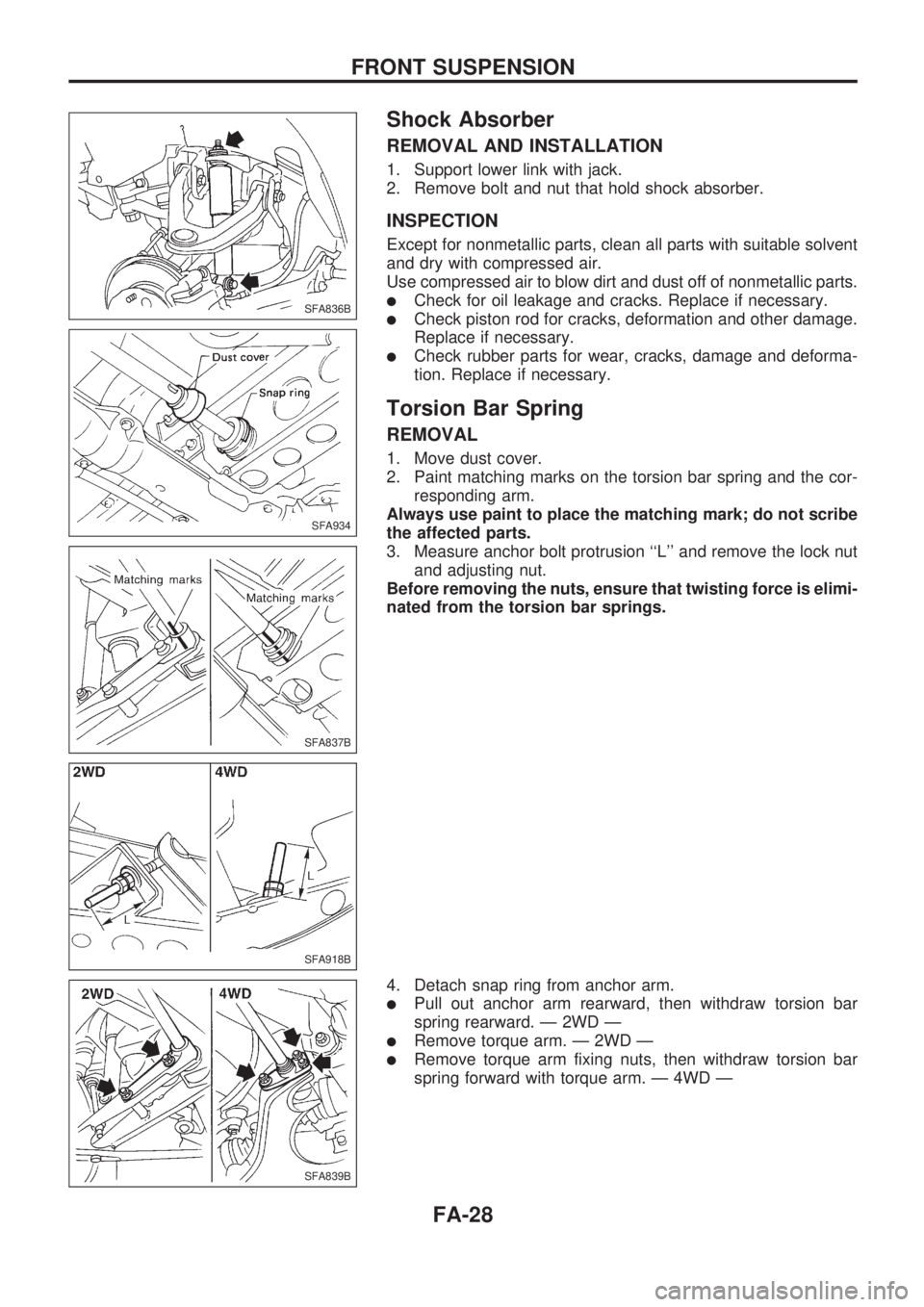

Shock Absorber

REMOVAL AND INSTALLATION

1. Support lower link with jack.

2. Remove bolt and nut that hold shock absorber.

INSPECTION

Except for nonmetallic parts, clean all parts with suitable solvent

and dry with compressed air.

Use compressed air to blow dirt and dust off of nonmetallic parts.

lCheck for oil leakage and cracks. Replace if necessary.

lCheck piston rod for cracks, deformation and other damage.

Replace if necessary.

lCheck rubber parts for wear, cracks, damage and deforma-

tion. Replace if necessary.

Torsion Bar Spring

REMOVAL

1. Move dust cover.

2. Paint matching marks on the torsion bar spring and the cor-

responding arm.

Always use paint to place the matching mark; do not scribe

the affected parts.

3. Measure anchor bolt protrusion ``L'' and remove the lock nut

and adjusting nut.

Before removing the nuts, ensure that twisting force is elimi-

nated from the torsion bar springs.

4. Detach snap ring from anchor arm.

lPull out anchor arm rearward, then withdraw torsion bar

spring rearward. Ð 2WD Ð

lRemove torque arm. Ð 2WD Ð

lRemove torque arm fixing nuts, then withdraw torsion bar

spring forward with torque arm. Ð 4WD Ð

SFA836B

SFA934

SFA837B

SFA918B

SFA839B

FRONT SUSPENSION

FA-28

Page 794 of 1659

INSPECTION

lCheck torsion bar spring for wear, twist, bend and other

damage.

lCheck serrations of each part for cracks, wear, twist and

other damage.

lCheck dust cover for cracks.

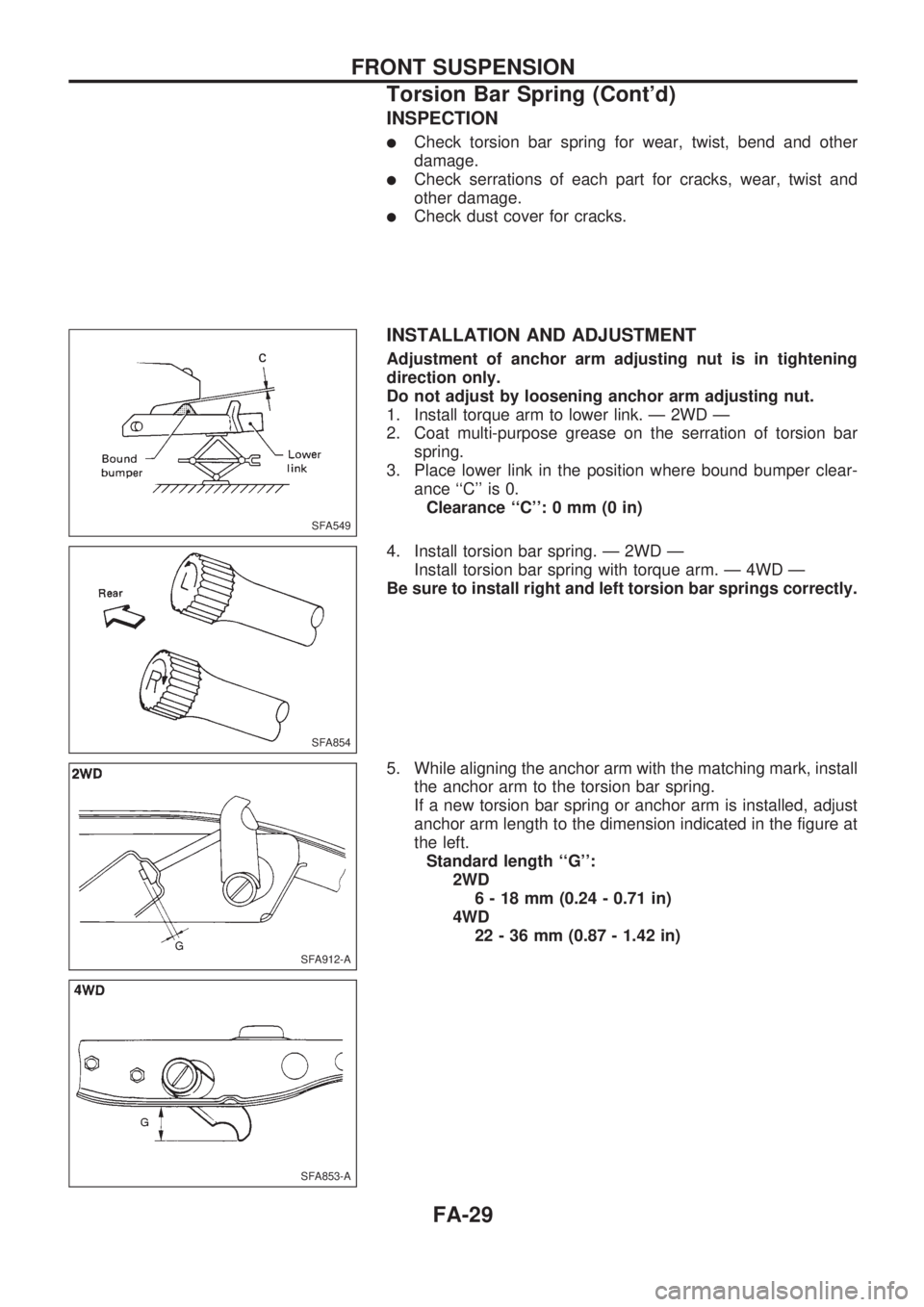

INSTALLATION AND ADJUSTMENT

Adjustment of anchor arm adjusting nut is in tightening

direction only.

Do not adjust by loosening anchor arm adjusting nut.

1. Install torque arm to lower link. Ð 2WD Ð

2. Coat multi-purpose grease on the serration of torsion bar

spring.

3. Place lower link in the position where bound bumper clear-

ance ``C'' is 0.

Clearance ``C'': 0 mm (0 in)

4. Install torsion bar spring. Ð 2WD Ð

Install torsion bar spring with torque arm. Ð 4WD Ð

Be sure to install right and left torsion bar springs correctly.

5. While aligning the anchor arm with the matching mark, install

the anchor arm to the torsion bar spring.

If a new torsion bar spring or anchor arm is installed, adjust

anchor arm length to the dimension indicated in the figure at

the left.

Standard length ``G'':

2WD

6 - 18 mm (0.24 - 0.71 in)

4WD

22 - 36 mm (0.87 - 1.42 in)

SFA549

SFA854

SFA912-A

SFA853-A

FRONT SUSPENSION

Torsion Bar Spring (Cont'd)

FA-29

Page 795 of 1659

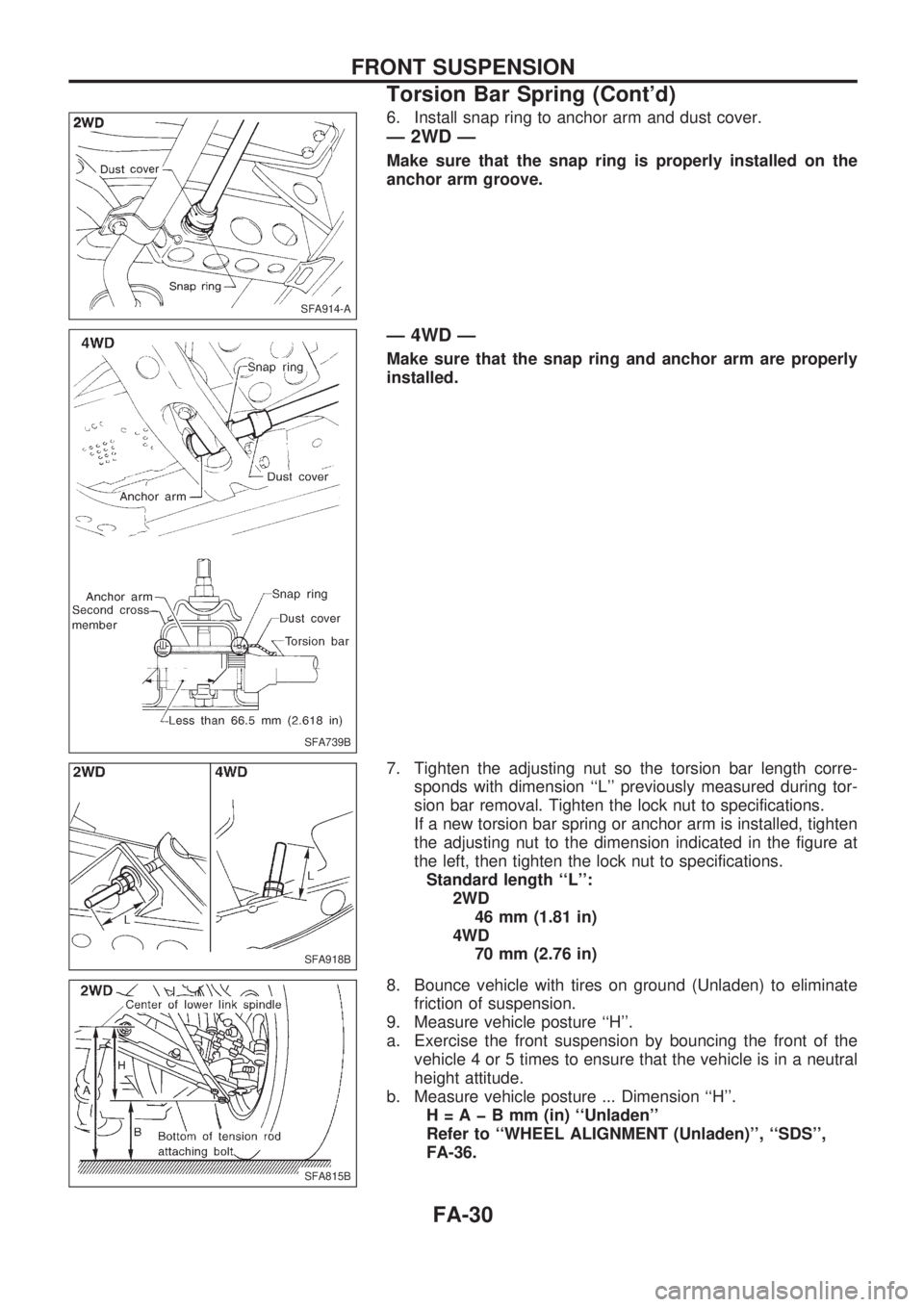

6. Install snap ring to anchor arm and dust cover.

Ð 2WD Ð

Make sure that the snap ring is properly installed on the

anchor arm groove.

Ð 4WD Ð

Make sure that the snap ring and anchor arm are properly

installed.

7. Tighten the adjusting nut so the torsion bar length corre-

sponds with dimension ``L'' previously measured during tor-

sion bar removal. Tighten the lock nut to specifications.

If a new torsion bar spring or anchor arm is installed, tighten

the adjusting nut to the dimension indicated in the figure at

the left, then tighten the lock nut to specifications.

Standard length ``L'':

2WD

46 mm (1.81 in)

4WD

70 mm (2.76 in)

8. Bounce vehicle with tires on ground (Unladen) to eliminate

friction of suspension.

9. Measure vehicle posture ``H''.

a. Exercise the front suspension by bouncing the front of the

vehicle 4 or 5 times to ensure that the vehicle is in a neutral

height attitude.

b. Measure vehicle posture ... Dimension ``H''.

H=AþBmm(in) ``Unladen''

Refer to ``WHEEL ALIGNMENT (Unladen)'', ``SDS'',

FA-36.

SFA914-A

SFA739B

SFA918B

SFA815B

FRONT SUSPENSION

Torsion Bar Spring (Cont'd)

FA-30

Page 796 of 1659

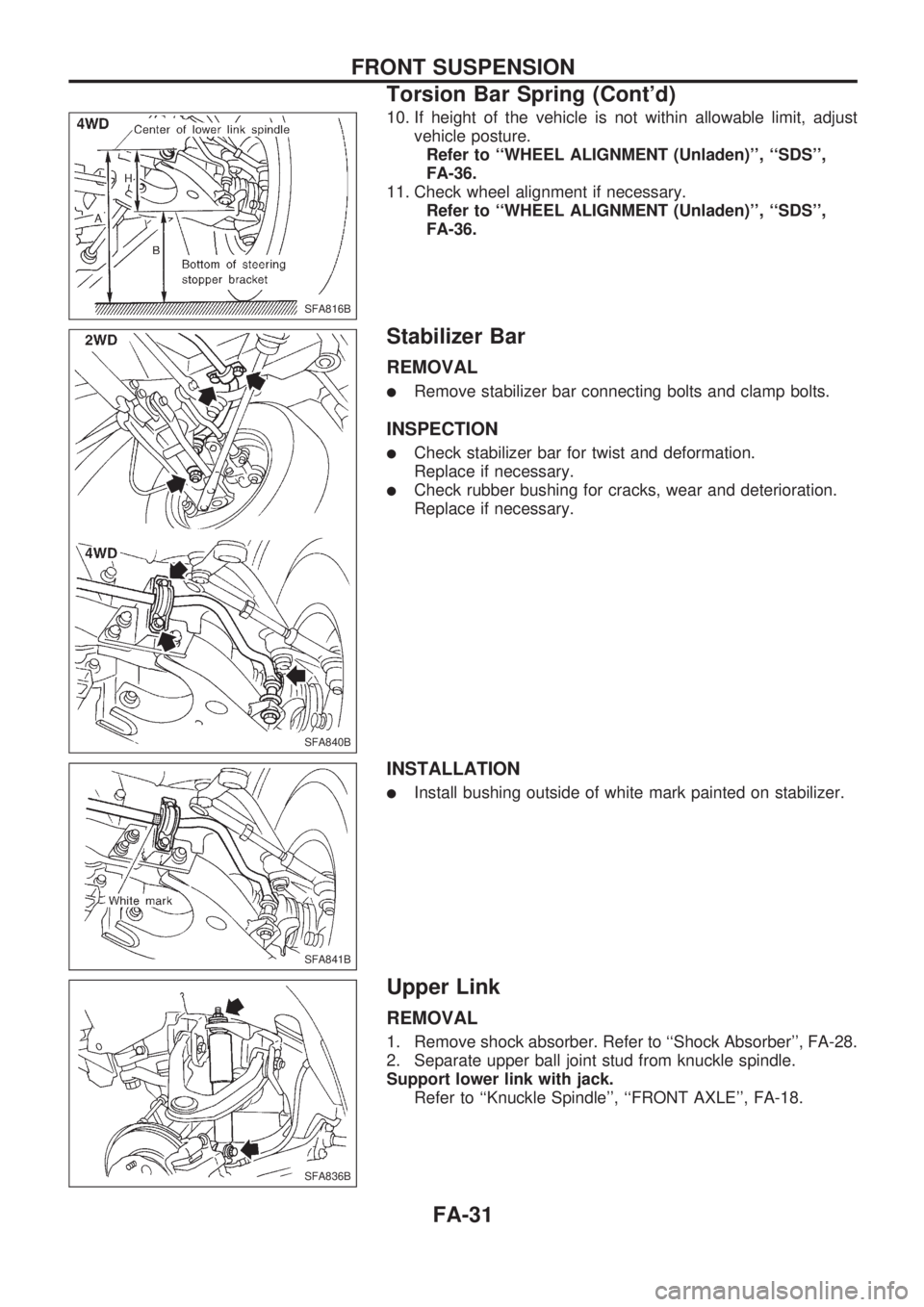

10. If height of the vehicle is not within allowable limit, adjust

vehicle posture.

Refer to ``WHEEL ALIGNMENT (Unladen)'', ``SDS'',

FA-36.

11. Check wheel alignment if necessary.

Refer to ``WHEEL ALIGNMENT (Unladen)'', ``SDS'',

FA-36.

Stabilizer Bar

REMOVAL

lRemove stabilizer bar connecting bolts and clamp bolts.

INSPECTION

lCheck stabilizer bar for twist and deformation.

Replace if necessary.

lCheck rubber bushing for cracks, wear and deterioration.

Replace if necessary.

INSTALLATION

lInstall bushing outside of white mark painted on stabilizer.

Upper Link

REMOVAL

1. Remove shock absorber. Refer to ``Shock Absorber'', FA-28.

2. Separate upper ball joint stud from knuckle spindle.

Support lower link with jack.

Refer to ``Knuckle Spindle'', ``FRONT AXLE'', FA-18.

SFA816B

SFA840B

SFA841B

SFA836B

FRONT SUSPENSION

Torsion Bar Spring (Cont'd)

FA-31

Page 797 of 1659

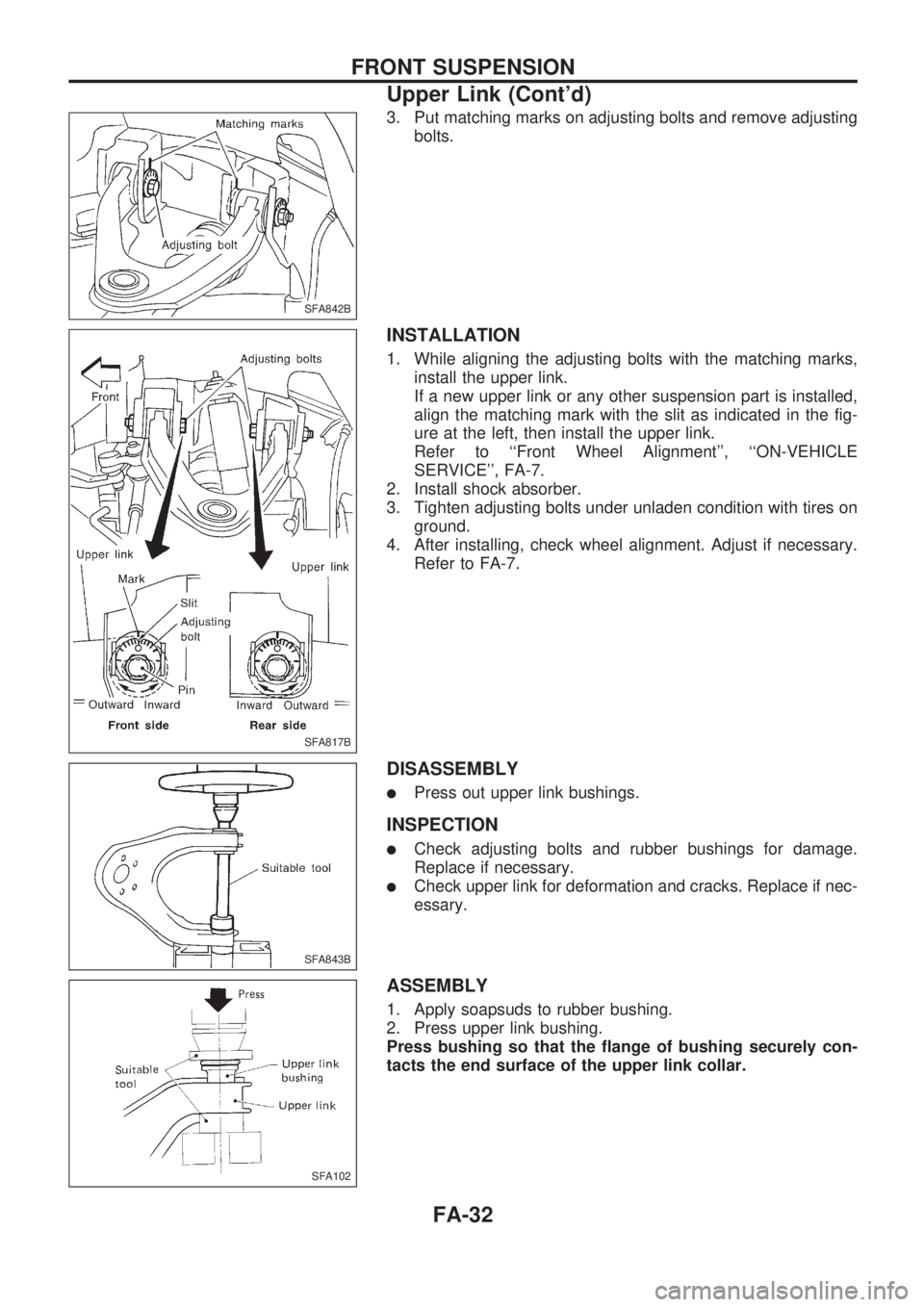

3. Put matching marks on adjusting bolts and remove adjusting

bolts.

INSTALLATION

1. While aligning the adjusting bolts with the matching marks,

install the upper link.

If a new upper link or any other suspension part is installed,

align the matching mark with the slit as indicated in the fig-

ure at the left, then install the upper link.

Refer to ``Front Wheel Alignment'', ``ON-VEHICLE

SERVICE'', FA-7.

2. Install shock absorber.

3. Tighten adjusting bolts under unladen condition with tires on

ground.

4. After installing, check wheel alignment. Adjust if necessary.

Refer to FA-7.

DISASSEMBLY

lPress out upper link bushings.

INSPECTION

lCheck adjusting bolts and rubber bushings for damage.

Replace if necessary.

lCheck upper link for deformation and cracks. Replace if nec-

essary.

ASSEMBLY

1. Apply soapsuds to rubber bushing.

2. Press upper link bushing.

Press bushing so that the flange of bushing securely con-

tacts the end surface of the upper link collar.

SFA842B

SFA817B

SFA843B

SFA102

FRONT SUSPENSION

Upper Link (Cont'd)

FA-32

Page 798 of 1659

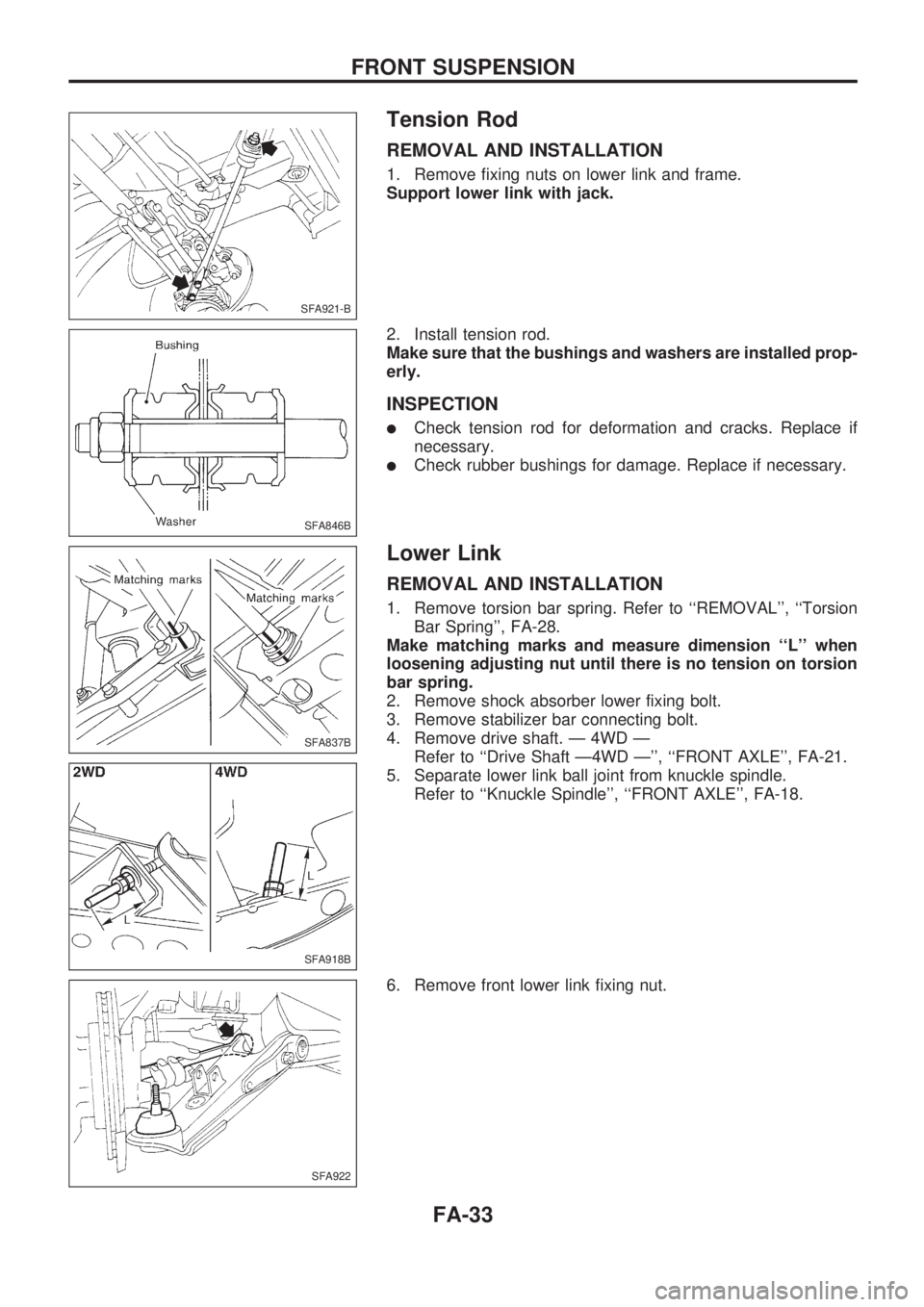

Tension Rod

REMOVAL AND INSTALLATION

1. Remove fixing nuts on lower link and frame.

Support lower link with jack.

2. Install tension rod.

Make sure that the bushings and washers are installed prop-

erly.

INSPECTION

lCheck tension rod for deformation and cracks. Replace if

necessary.

lCheck rubber bushings for damage. Replace if necessary.

Lower Link

REMOVAL AND INSTALLATION

1. Remove torsion bar spring. Refer to ``REMOVAL'', ``Torsion

Bar Spring'', FA-28.

Make matching marks and measure dimension ``L'' when

loosening adjusting nut until there is no tension on torsion

bar spring.

2. Remove shock absorber lower fixing bolt.

3. Remove stabilizer bar connecting bolt.

4. Remove drive shaft. Ð 4WD Ð

Refer to ``Drive Shaft Ð4WD Ð'', ``FRONT AXLE'', FA-21.

5. Separate lower link ball joint from knuckle spindle.

Refer to ``Knuckle Spindle'', ``FRONT AXLE'', FA-18.

6. Remove front lower link fixing nut.

SFA921-B

SFA846B

SFA837B

SFA918B

SFA922

FRONT SUSPENSION

FA-33

Page 799 of 1659

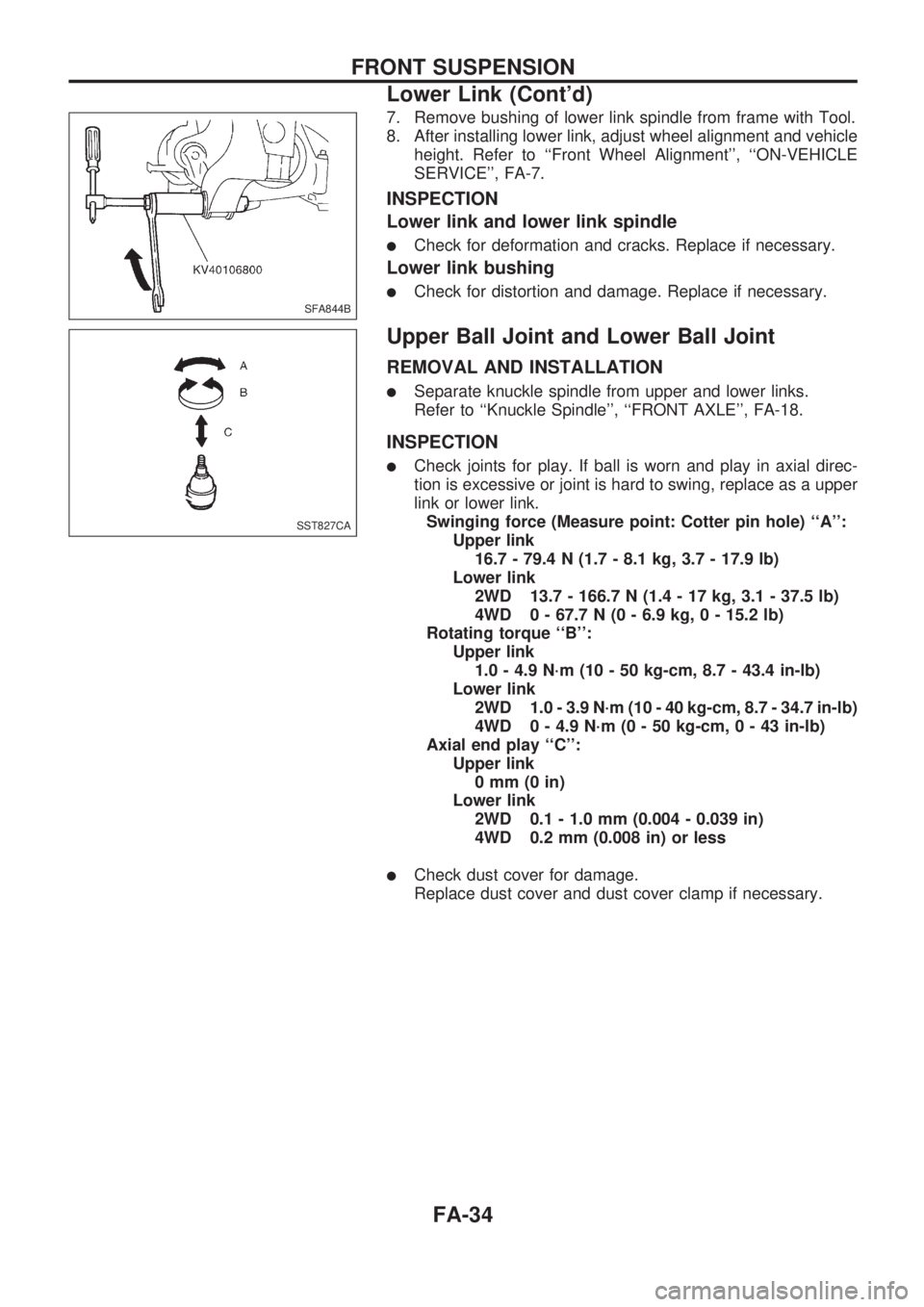

7. Remove bushing of lower link spindle from frame with Tool.

8. After installing lower link, adjust wheel alignment and vehicle

height. Refer to ``Front Wheel Alignment'', ``ON-VEHICLE

SERVICE'', FA-7.

INSPECTION

Lower link and lower link spindle

lCheck for deformation and cracks. Replace if necessary.

Lower link bushing

lCheck for distortion and damage. Replace if necessary.

Upper Ball Joint and Lower Ball Joint

REMOVAL AND INSTALLATION

lSeparate knuckle spindle from upper and lower links.

Refer to ``Knuckle Spindle'', ``FRONT AXLE'', FA-18.

INSPECTION

lCheck joints for play. If ball is worn and play in axial direc-

tion is excessive or joint is hard to swing, replace as a upper

link or lower link.

Swinging force (Measure point: Cotter pin hole) ``A'':

Upper link

16.7 - 79.4 N (1.7 - 8.1 kg, 3.7 - 17.9 lb)

Lower link

2WD 13.7 - 166.7 N (1.4 - 17 kg, 3.1 - 37.5 lb)

4WD 0 - 67.7 N (0 - 6.9 kg, 0 - 15.2 lb)

Rotating torque ``B'':

Upper link

1.0 - 4.9 N´m (10 - 50 kg-cm, 8.7 - 43.4 in-lb)

Lower link

2WD 1.0 - 3.9 N´m (10 - 40 kg-cm, 8.7 - 34.7 in-lb)

4WD 0 - 4.9 N´m (0 - 50 kg-cm,0-43in-lb)

Axial end play ``C'':

Upper link

0mm(0in)

Lower link

2WD 0.1 - 1.0 mm (0.004 - 0.039 in)

4WD 0.2 mm (0.008 in) or less

lCheck dust cover for damage.

Replace dust cover and dust cover clamp if necessary.

SFA844B

SST827CA

FRONT SUSPENSION

Lower Link (Cont'd)

FA-34

Page 800 of 1659

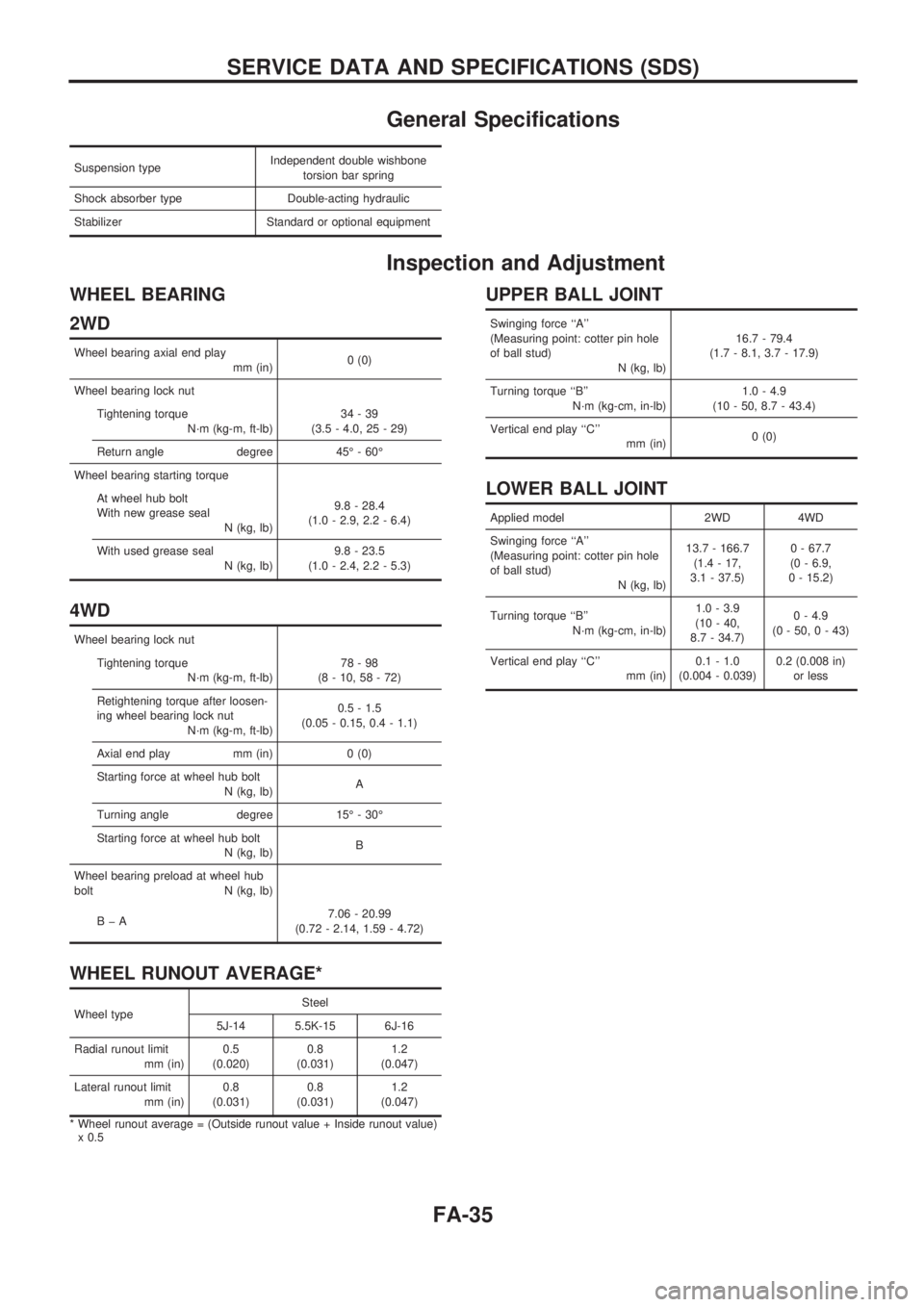

General Specifications

Suspension typeIndependent double wishbone

torsion bar spring

Shock absorber type Double-acting hydraulic

Stabilizer Standard or optional equipment

Inspection and Adjustment

WHEEL BEARING

2WD

Wheel bearing axial end play

mm (in)0 (0)

Wheel bearing lock nut

Tightening torque

N´m (kg-m, ft-lb)34-39

(3.5 - 4.0, 25 - 29)

Return angle degree 45É - 60É

Wheel bearing starting torque

At wheel hub bolt

With new grease seal

N (kg, lb)9.8 - 28.4

(1.0 - 2.9, 2.2 - 6.4)

With used grease seal

N (kg, lb)9.8 - 23.5

(1.0 - 2.4, 2.2 - 5.3)

4WD

Wheel bearing lock nut

Tightening torque

N´m (kg-m, ft-lb)78-98

(8 - 10, 58 - 72)

Retightening torque after loosen-

ing wheel bearing lock nut

N´m (kg-m, ft-lb)0.5 - 1.5

(0.05 - 0.15, 0.4 - 1.1)

Axial end play mm (in) 0 (0)

Starting force at wheel hub bolt

N (kg, lb)A

Turning angle degree 15É - 30É

Starting force at wheel hub bolt

N (kg, lb)B

Wheel bearing preload at wheel hub

bolt N (kg, lb)

BþA7.06 - 20.99

(0.72 - 2.14, 1.59 - 4.72)

WHEEL RUNOUT AVERAGE*

Wheel typeSteel

5J-14 5.5K-15 6J-16

Radial runout limit

mm (in)0.5

(0.020)0.8

(0.031)1.2

(0.047)

Lateral runout limit

mm (in)0.8

(0.031)0.8

(0.031)1.2

(0.047)

* Wheel runout average = (Outside runout value + Inside runout value)

x 0.5

UPPER BALL JOINT

Swinging force ``A''

(Measuring point: cotter pin hole

of ball stud)

N (kg, lb)16.7 - 79.4

(1.7 - 8.1, 3.7 - 17.9)

Turning torque ``B''

N´m (kg-cm, in-lb)1.0 - 4.9

(10 - 50, 8.7 - 43.4)

Vertical end play ``C''

mm (in)0 (0)

LOWER BALL JOINT

Applied model 2WD 4WD

Swinging force ``A''

(Measuring point: cotter pin hole

of ball stud)

N (kg, lb)13.7 - 166.7

(1.4 - 17,

3.1 - 37.5)0 - 67.7

(0 - 6.9,

0 - 15.2)

Turning torque ``B''

N´m (kg-cm, in-lb)1.0 - 3.9

(10 - 40,

8.7 - 34.7)0 - 4.9

(0 - 50, 0 - 43)

Vertical end play ``C''

mm (in)0.1 - 1.0

(0.004 - 0.039)0.2 (0.008 in)

or less

SERVICE DATA AND SPECIFICATIONS (SDS)

FA-35