NISSAN PICK-UP 1999 Repair Manual

Manufacturer: NISSAN, Model Year: 1999, Model line: PICK-UP, Model: NISSAN PICK-UP 1999Pages: 666, PDF Size: 16.21 MB

Page 191 of 666

HEL764A

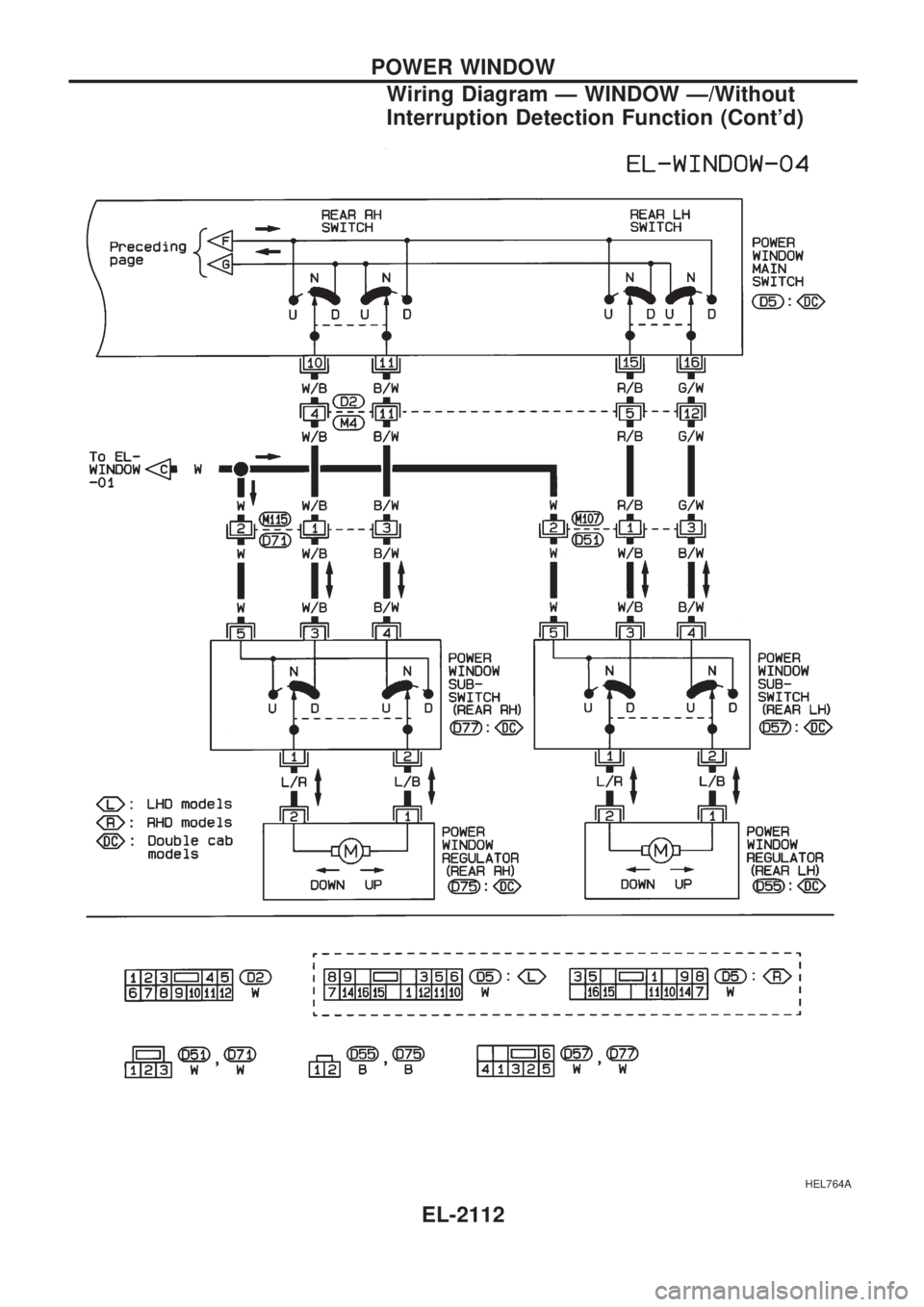

POWER WINDOW

Wiring Diagram Ð WINDOW Ð/Without

Interruption Detection Function (Cont'd)

EL-2112

Page 192 of 666

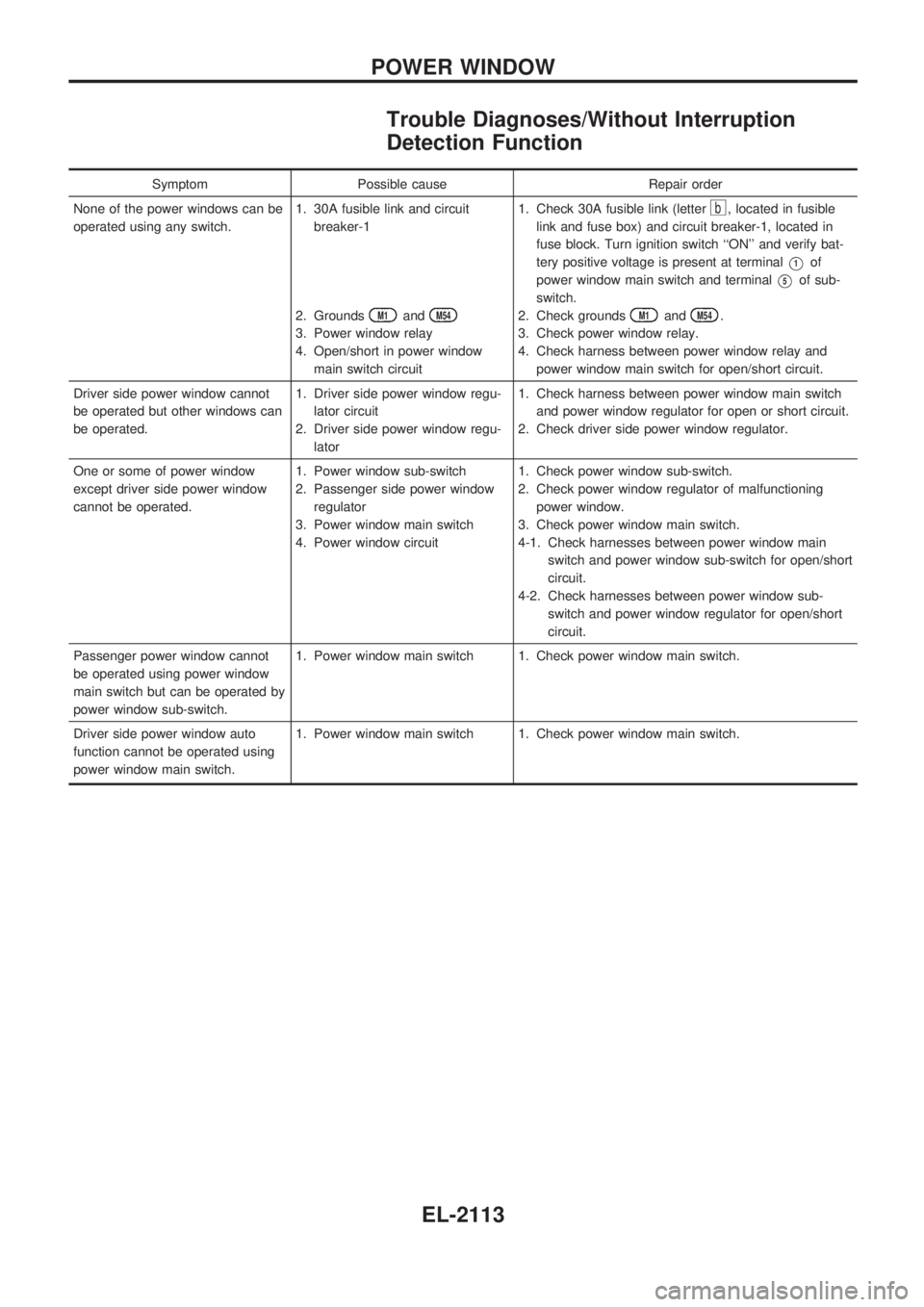

Trouble Diagnoses/Without Interruption

Detection Function

Symptom Possible cause Repair order

None of the power windows can be

operated using any switch.1. 30A fusible link and circuit

breaker-1

2. Grounds

M1andM54

3. Power window relay

4. Open/short in power window

main switch circuit1. Check 30A fusible link (letter

b, located in fusible

link and fuse box) and circuit breaker-1, located in

fuse block. Turn ignition switch ``ON'' and verify bat-

tery positive voltage is present at terminal

V1of

power window main switch and terminal

V5of sub-

switch.

2. Check grounds

M1andM54.

3. Check power window relay.

4. Check harness between power window relay and

power window main switch for open/short circuit.

Driver side power window cannot

be operated but other windows can

be operated.1. Driver side power window regu-

lator circuit

2. Driver side power window regu-

lator1. Check harness between power window main switch

and power window regulator for open or short circuit.

2. Check driver side power window regulator.

One or some of power window

except driver side power window

cannot be operated.1. Power window sub-switch

2. Passenger side power window

regulator

3. Power window main switch

4. Power window circuit1. Check power window sub-switch.

2. Check power window regulator of malfunctioning

power window.

3. Check power window main switch.

4-1. Check harnesses between power window main

switch and power window sub-switch for open/short

circuit.

4-2. Check harnesses between power window sub-

switch and power window regulator for open/short

circuit.

Passenger power window cannot

be operated using power window

main switch but can be operated by

power window sub-switch.1. Power window main switch 1. Check power window main switch.

Driver side power window auto

function cannot be operated using

power window main switch.1. Power window main switch 1. Check power window main switch.

POWER WINDOW

EL-2113

Page 193 of 666

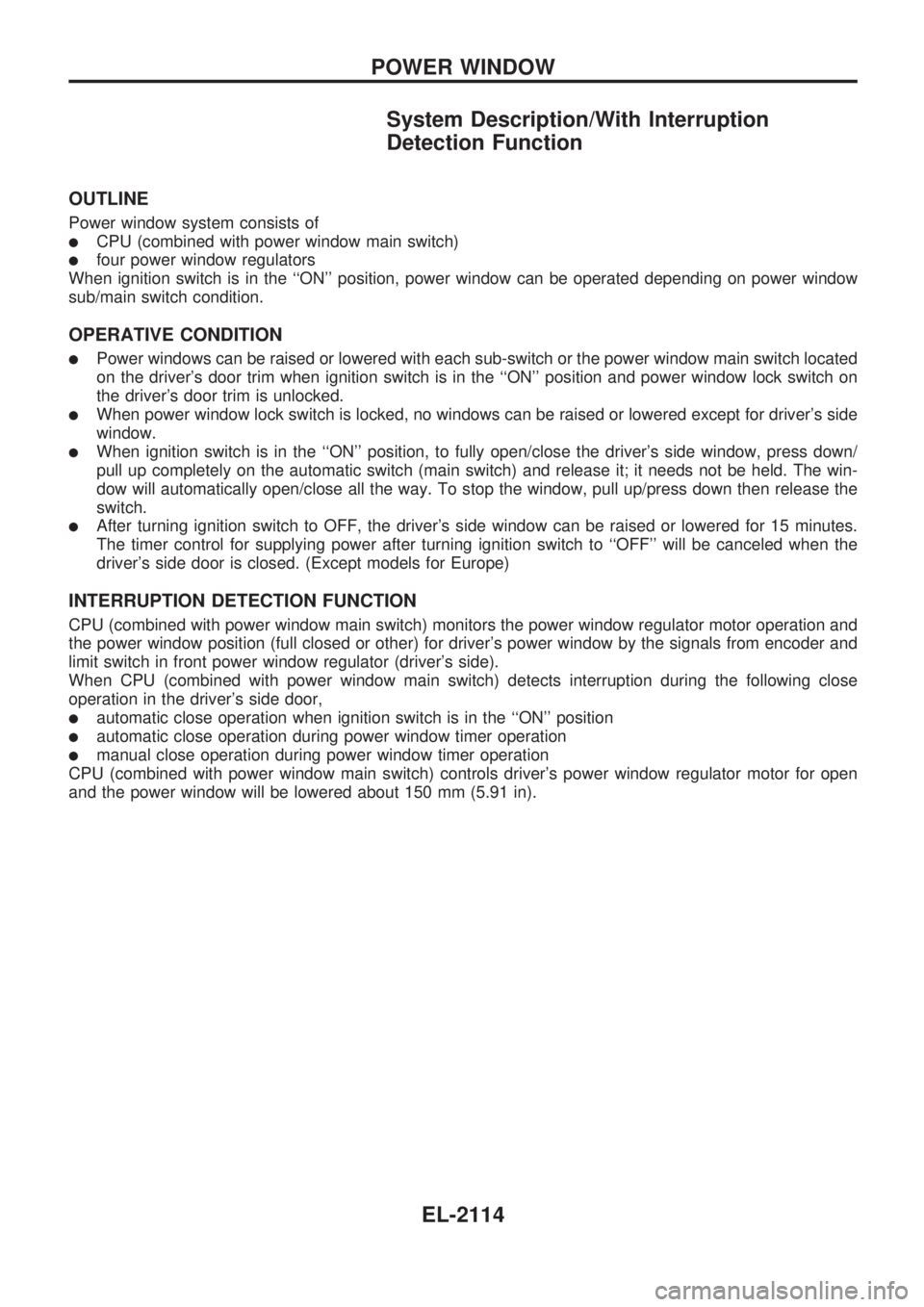

System Description/With Interruption

Detection Function

OUTLINE

Power window system consists of

lCPU (combined with power window main switch)

lfour power window regulators

When ignition switch is in the ``ON'' position, power window can be operated depending on power window

sub/main switch condition.

OPERATIVE CONDITION

lPower windows can be raised or lowered with each sub-switch or the power window main switch located

on the driver's door trim when ignition switch is in the ``ON'' position and power window lock switch on

the driver's door trim is unlocked.

lWhen power window lock switch is locked, no windows can be raised or lowered except for driver's side

window.

lWhen ignition switch is in the ``ON'' position, to fully open/close the driver's side window, press down/

pull up completely on the automatic switch (main switch) and release it; it needs not be held. The win-

dow will automatically open/close all the way. To stop the window, pull up/press down then release the

switch.

lAfter turning ignition switch to OFF, the driver's side window can be raised or lowered for 15 minutes.

The timer control for supplying power after turning ignition switch to ``OFF'' will be canceled when the

driver's side door is closed. (Except models for Europe)

INTERRUPTION DETECTION FUNCTION

CPU (combined with power window main switch) monitors the power window regulator motor operation and

the power window position (full closed or other) for driver's power window by the signals from encoder and

limit switch in front power window regulator (driver's side).

When CPU (combined with power window main switch) detects interruption during the following close

operation in the driver's side door,

lautomatic close operation when ignition switch is in the ``ON'' position

lautomatic close operation during power window timer operation

lmanual close operation during power window timer operation

CPU (combined with power window main switch) controls driver's power window regulator motor for open

and the power window will be lowered about 150 mm (5.91 in).

POWER WINDOW

EL-2114

Page 194 of 666

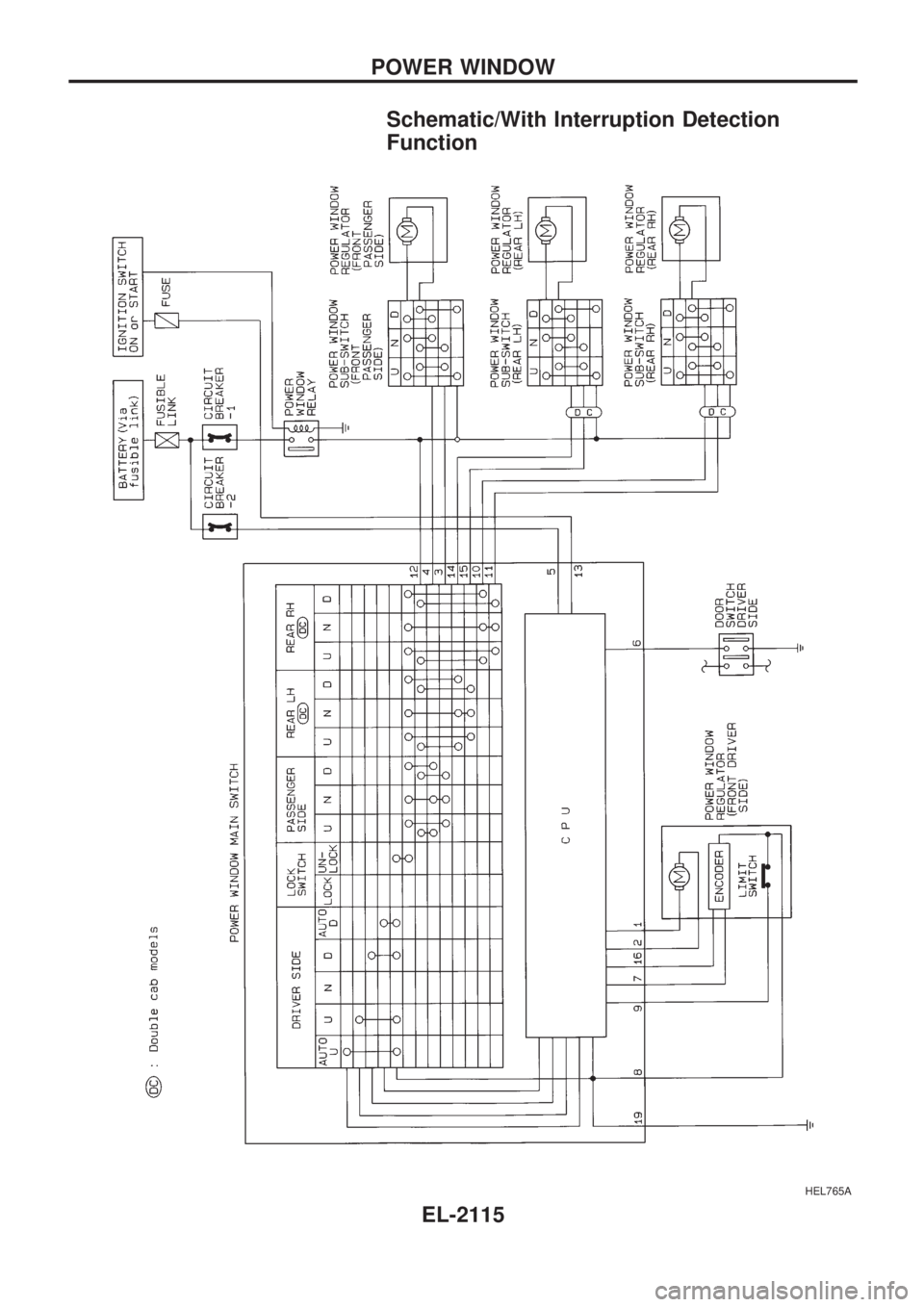

Schematic/With Interruption Detection

Function

HEL765A

POWER WINDOW

EL-2115

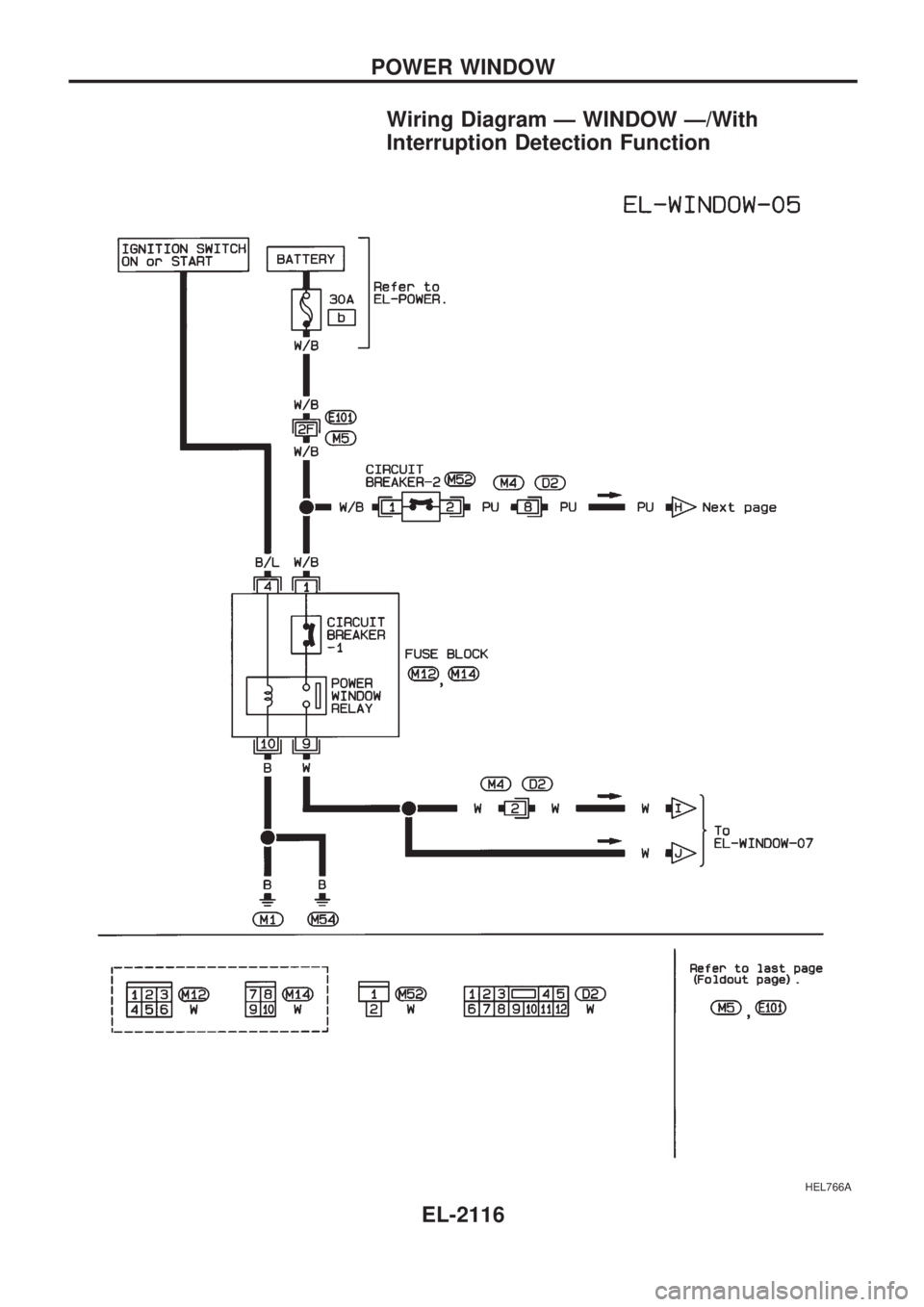

Page 195 of 666

Wiring Diagram Ð WINDOW Ð/With

Interruption Detection Function

HEL766A

POWER WINDOW

EL-2116

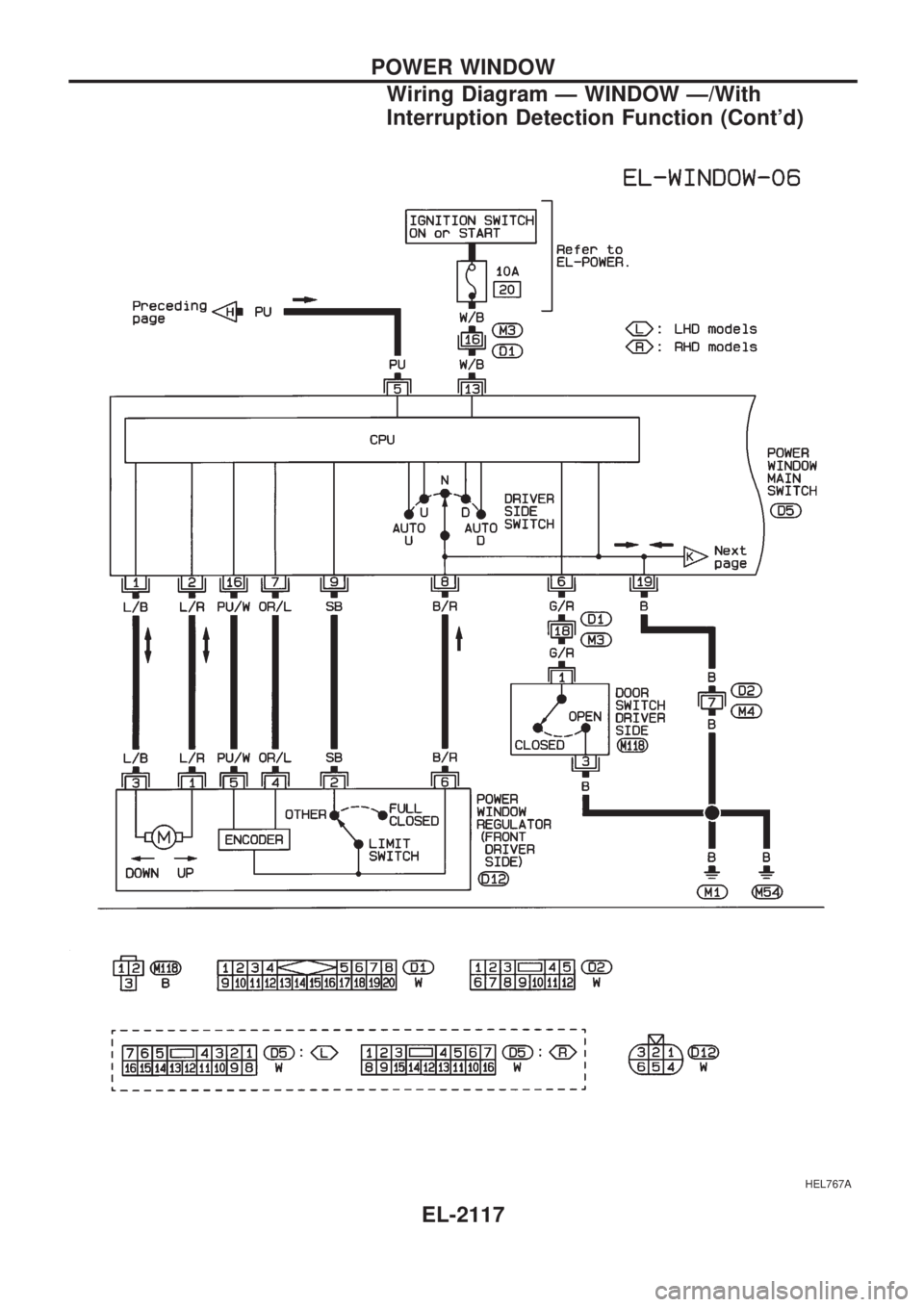

Page 196 of 666

HEL767A

POWER WINDOW

Wiring Diagram Ð WINDOW Ð/With

Interruption Detection Function (Cont'd)

EL-2117

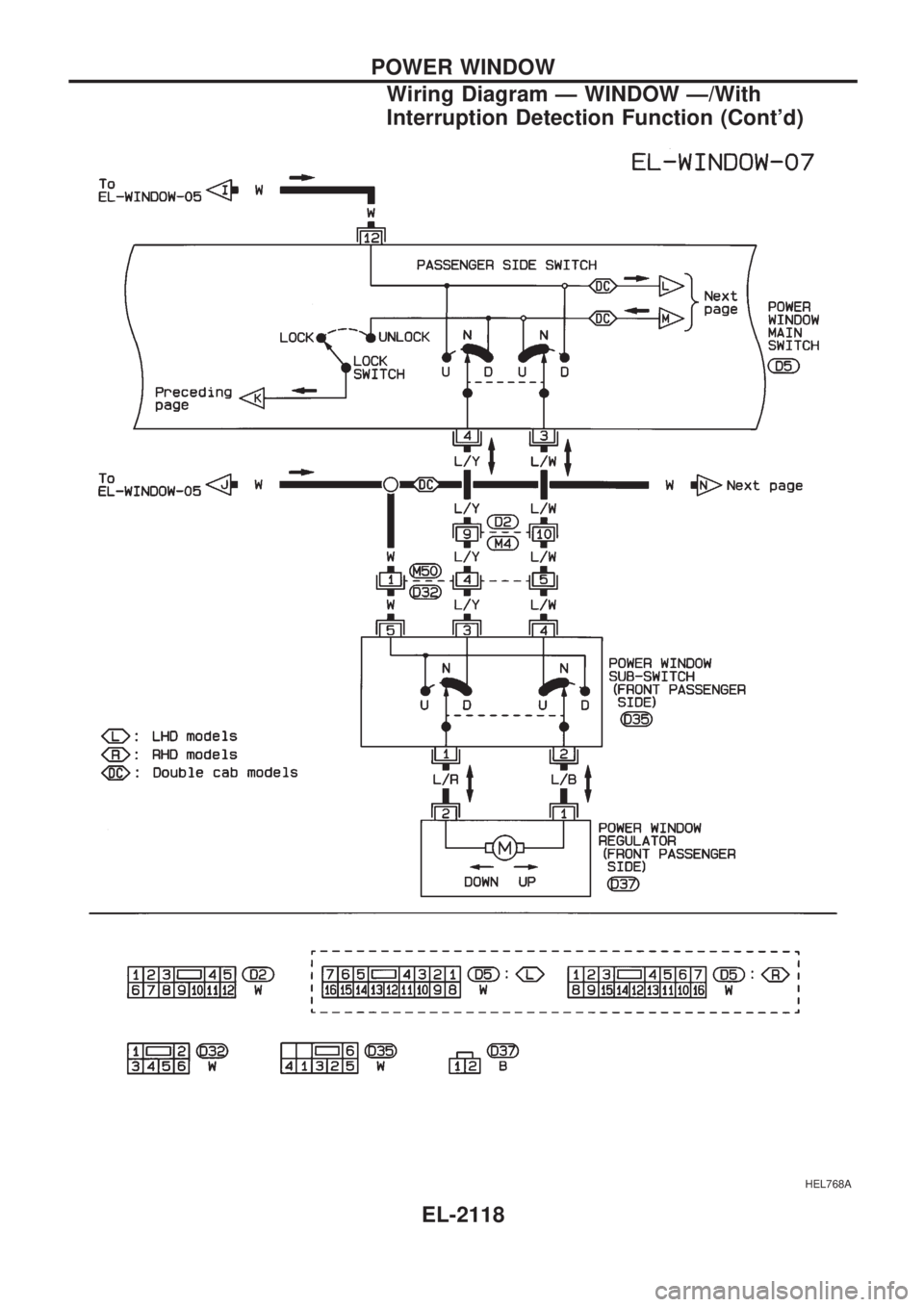

Page 197 of 666

HEL768A

POWER WINDOW

Wiring Diagram Ð WINDOW Ð/With

Interruption Detection Function (Cont'd)

EL-2118

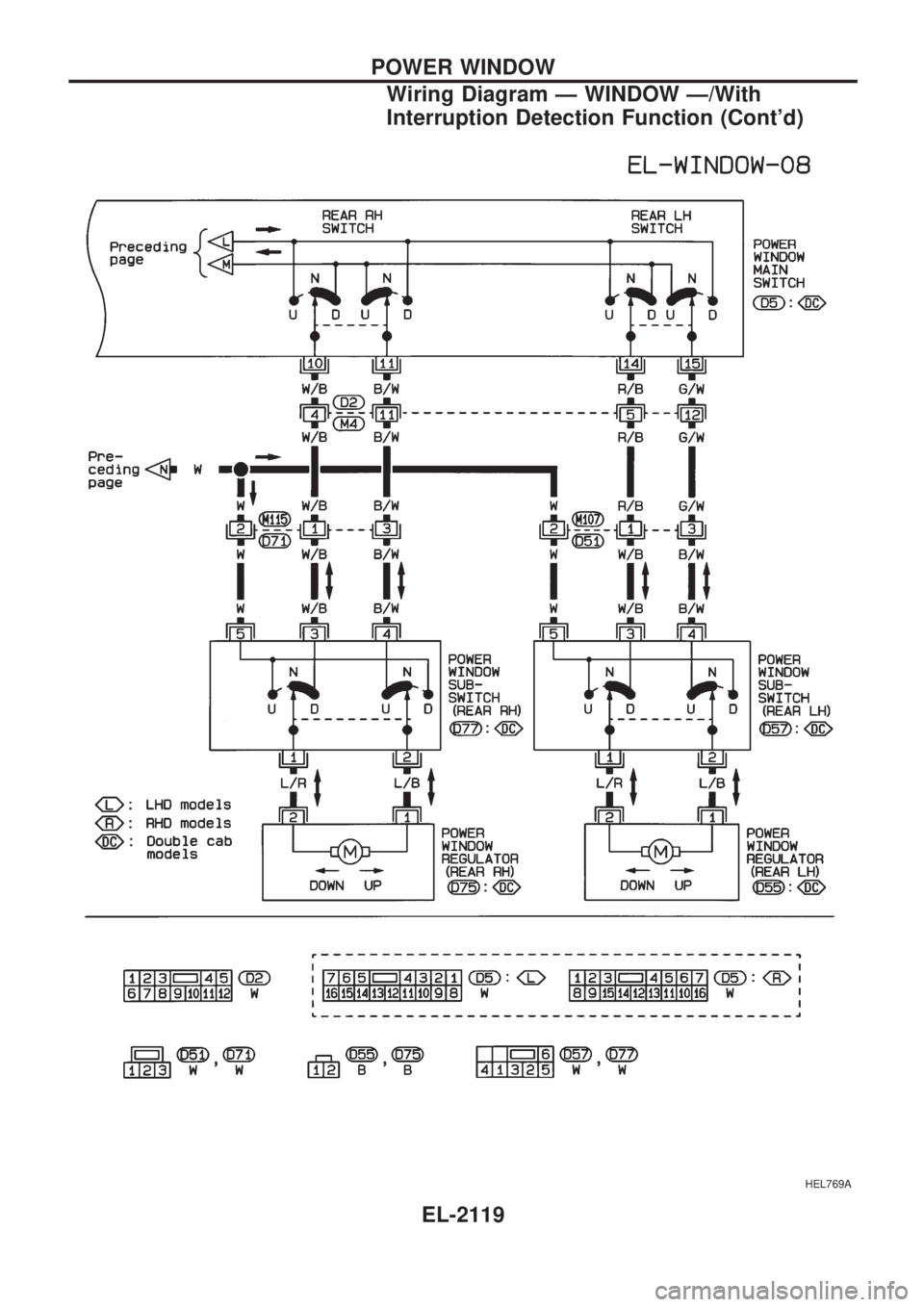

Page 198 of 666

HEL769A

POWER WINDOW

Wiring Diagram Ð WINDOW Ð/With

Interruption Detection Function (Cont'd)

EL-2119

Page 199 of 666

Trouble Diagnoses/With Interruption

Detection Function

Symptom Possible cause Repair order

None of the power windows can be

operated using any switch.1. 10A fuse, 30A fusible link

2. Ground circuit

3. Power window main switch1. Check 10A fuse [No.

20, located in fuse block (J/B)],

30A fusible link (letter

b, located in fuse and fusible

link box).

2. Check ground circuit of power window main switch

terminal

V19.

3. Check power window main switch.

Driver side power window cannot

be operated but other windows can

be operated.1. Driver side power window regu-

lator circuit

2. Driver side power window regu-

lator

3.

M52circuit breaker-2

4.

M52circuit breaker-2 circuit

5. Power window main switch cir-

cuit1. Check harness between power window main switch

and driver side power window regulator for open or

short circuit.

2. Check driver side power window regulator.

3. Check

M52circuit breaker-2.

4. Check harness between

M52circuit breaker-2 and

30A fusible link (letter

b, located in fuse and fusible

link box).

5-1. Check harness between power window main

switch terminal

V13and 10A fuse [No.20, located

in fuse block (J/B)].

5-2. Check harness between power window main

switch terminal

V5andM52circuit breaker.

One or more power windows

except driver's side window cannot

be operated.1. Power window sub-switches

2. Power window regulators

3. Power window main switch

4. Power window circuit1. Check power window sub-switch.

2. Check power window regulator.

3. Check power window main switch.

4-1. Check harnesses between power window main

switch and power window sub-switch for open/

short circuit.

4-2. Check harnesses between power window sub-

switch and power window regulator for open/

short circuit.

Power windows except driver's side

window cannot be operated using

power window main switch but can

be operated by power window sub-

switch.1. Power window main switch 1. Check power window main switch.

Driver side power window auto-

matic operation does not function

properly.1. Power window main switch

2. Encoder and limit switch1. Check power window main switch.

2. Check encoder and limit switch. (EL-2121)

Timer control for supplying power

after turning ignition switch to

``OFF'' does not operate properly.

(Except models for Europe)1. Driver side door switch circuit

2. Driver side door switch

3. Ignition switch ON signal circuit

4. Power window main switch1. Check harness between driver side door switch and

power window main switch.

2. Check driver side door switch.

3. Check ignition switch ON signal circuit to power win-

dow main switch.

4. Check power window main switch.

POWER WINDOW

EL-2120

Page 200 of 666

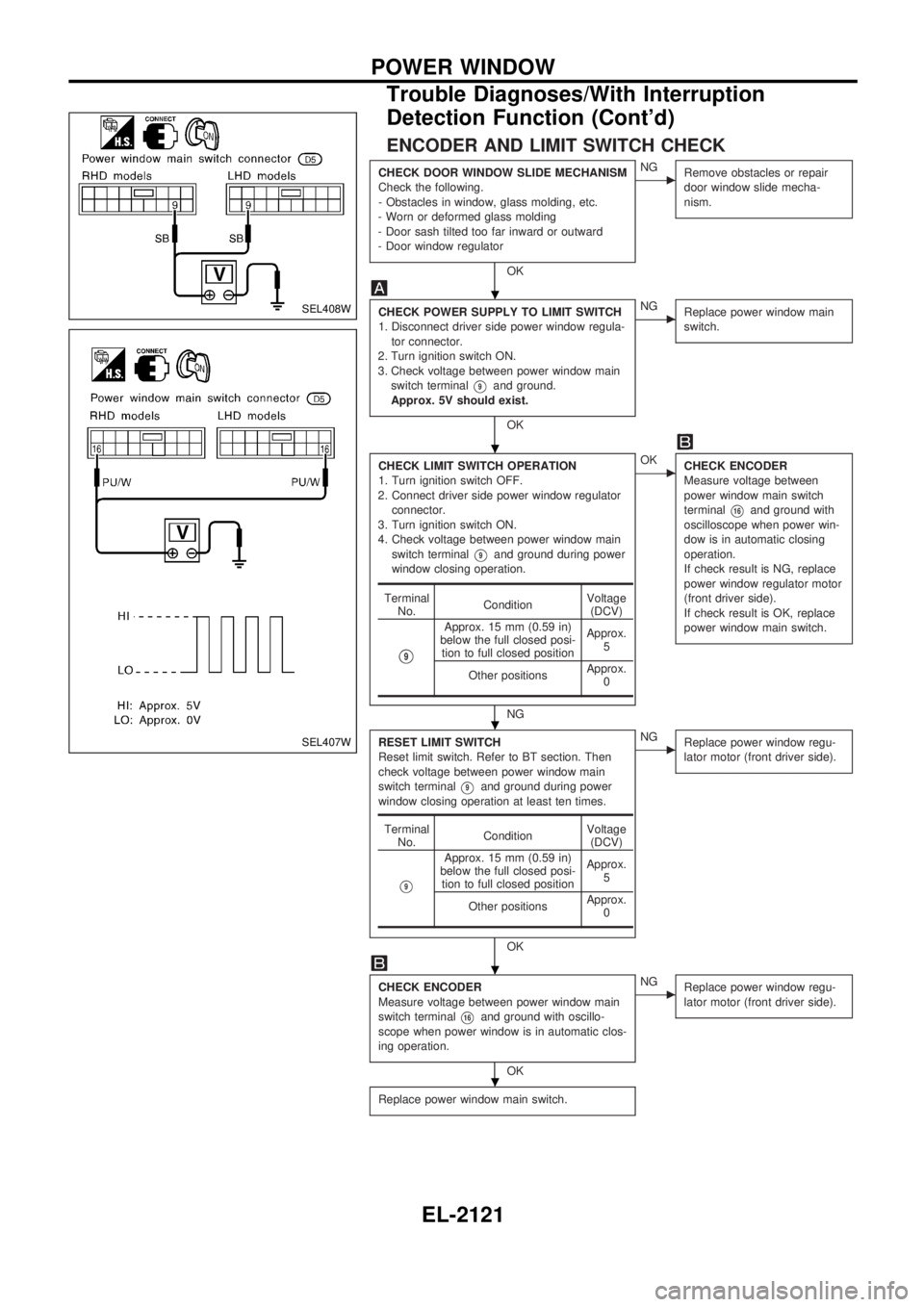

ENCODER AND LIMIT SWITCH CHECK

CHECK DOOR WINDOW SLIDE MECHANISM

Check the following.

- Obstacles in window, glass molding, etc.

- Worn or deformed glass molding

- Door sash tilted too far inward or outward

- Door window regulator

OK

cNG

Remove obstacles or repair

door window slide mecha-

nism.

CHECK POWER SUPPLY TO LIMIT SWITCH

1. Disconnect driver side power window regula-

tor connector.

2. Turn ignition switch ON.

3. Check voltage between power window main

switch terminal

V9and ground.

Approx. 5V should exist.

OK

cNG

Replace power window main

switch.

CHECK LIMIT SWITCH OPERATION

1. Turn ignition switch OFF.

2. Connect driver side power window regulator

connector.

3. Turn ignition switch ON.

4. Check voltage between power window main

switch terminal

V9and ground during power

window closing operation.

NG

cOK

CHECK ENCODER

Measure voltage between

power window main switch

terminal

V16and ground with

oscilloscope when power win-

dow is in automatic closing

operation.

If check result is NG, replace

power window regulator motor

(front driver side).

If check result is OK, replace

power window main switch.

RESET LIMIT SWITCH

Reset limit switch. Refer to BT section. Then

check voltage between power window main

switch terminal

V9and ground during power

window closing operation at least ten times.

OK

cNG

Replace power window regu-

lator motor (front driver side).

CHECK ENCODER

Measure voltage between power window main

switch terminal

V16and ground with oscillo-

scope when power window is in automatic clos-

ing operation.

OK

cNG

Replace power window regu-

lator motor (front driver side).

Replace power window main switch.

Terminal

No.ConditionVoltage

(DCV)

V9

Approx. 15 mm (0.59 in)

below the full closed posi-

tion to full closed positionApprox.

5

Other positionsApprox.

0

Terminal

No.ConditionVoltage

(DCV)

V9

Approx. 15 mm (0.59 in)

below the full closed posi-

tion to full closed positionApprox.

5

Other positionsApprox.

0

SEL408W

SEL407W

.

.

.

.

.

POWER WINDOW

Trouble Diagnoses/With Interruption

Detection Function (Cont'd)

EL-2121