NISSAN PICK-UP 2001 Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: PICK-UP, Model: NISSAN PICK-UP 2001Pages: 1306, PDF Size: 31.7 MB

Page 1001 of 1306

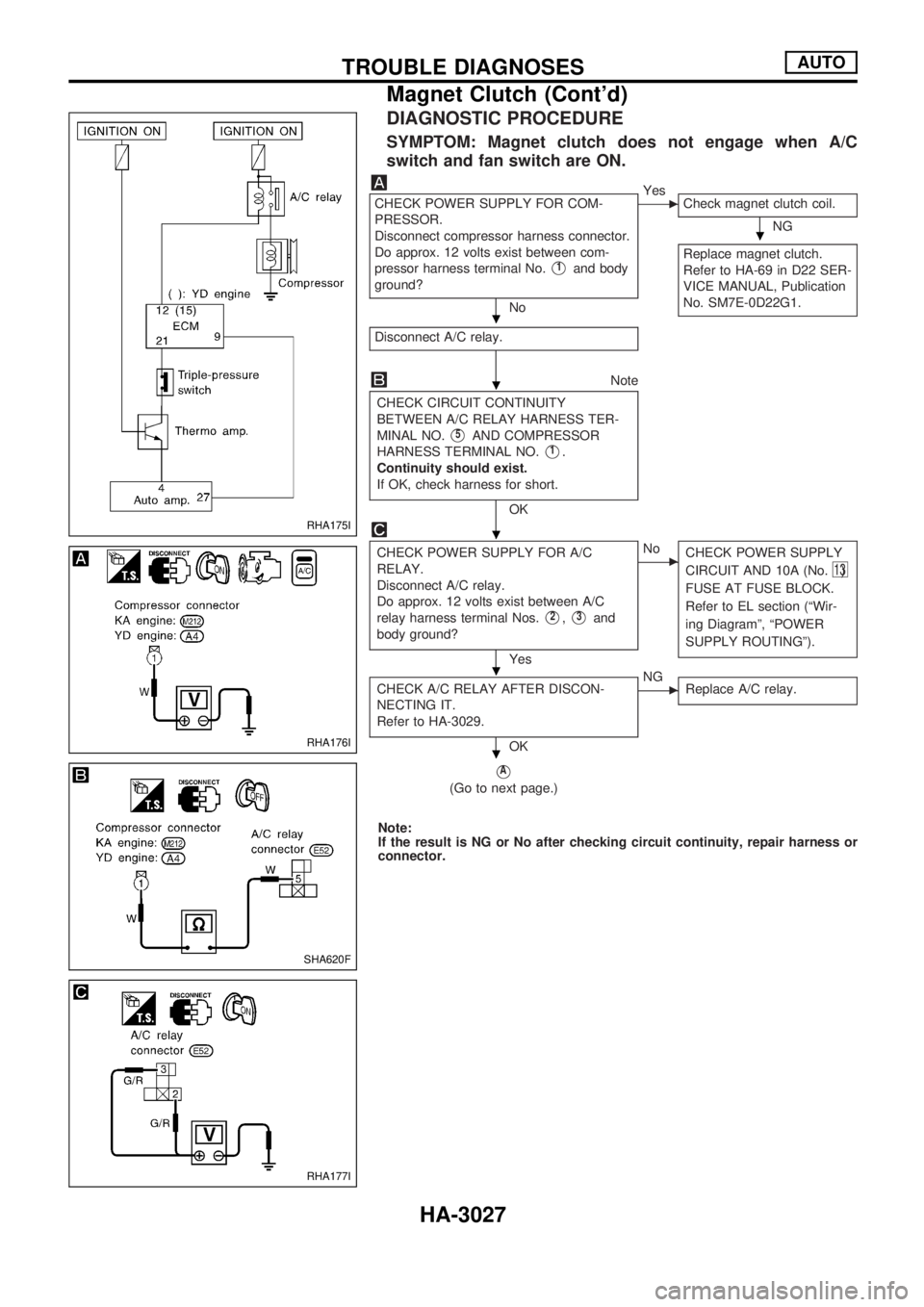

DIAGNOSTIC PROCEDURE

SYMPTOM: Magnet clutch does not engage when A/C

switch and fan switch are ON.

CHECK POWER SUPPLY FOR COM-

PRESSOR.

Disconnect compressor harness connector.

Do approx. 12 volts exist between com-

pressor harness terminal No.

V1and body

ground?

No

cYes

Check magnet clutch coil.

NG

Replace magnet clutch.

Refer to HA-69 in D22 SER-

VICE MANUAL, Publication

No. SM7E-0D22G1.

Disconnect A/C relay.

Note

CHECK CIRCUIT CONTINUITY

BETWEEN A/C RELAY HARNESS TER-

MINAL NO.

V5AND COMPRESSOR

HARNESS TERMINAL NO.

V1.

Continuity should exist.

If OK, check harness for short.

OK

CHECK POWER SUPPLY FOR A/C

RELAY.

Disconnect A/C relay.

Do approx. 12 volts exist between A/C

relay harness terminal Nos.

V2,V3and

body ground?

Yes

cNo

CHECK POWER SUPPLY

CIRCUIT AND 10A (No.

13)

FUSE AT FUSE BLOCK.

Refer to EL section (ªWir-

ing Diagramº, ªPOWER

SUPPLY ROUTINGº).

CHECK A/C RELAY AFTER DISCON-

NECTING IT.

Refer to HA-3029.

OK

cNG

Replace A/C relay.

VA

(Go to next page.)

Note:

If the result is NG or No after checking circuit continuity, repair harness or

connector.

RHA175I

RHA176I

SHA620F

RHA177I

.

.

.

.

.

.

TROUBLE DIAGNOSESAUTO

Magnet Clutch (Cont'd)

HA-3027

Page 1002 of 1306

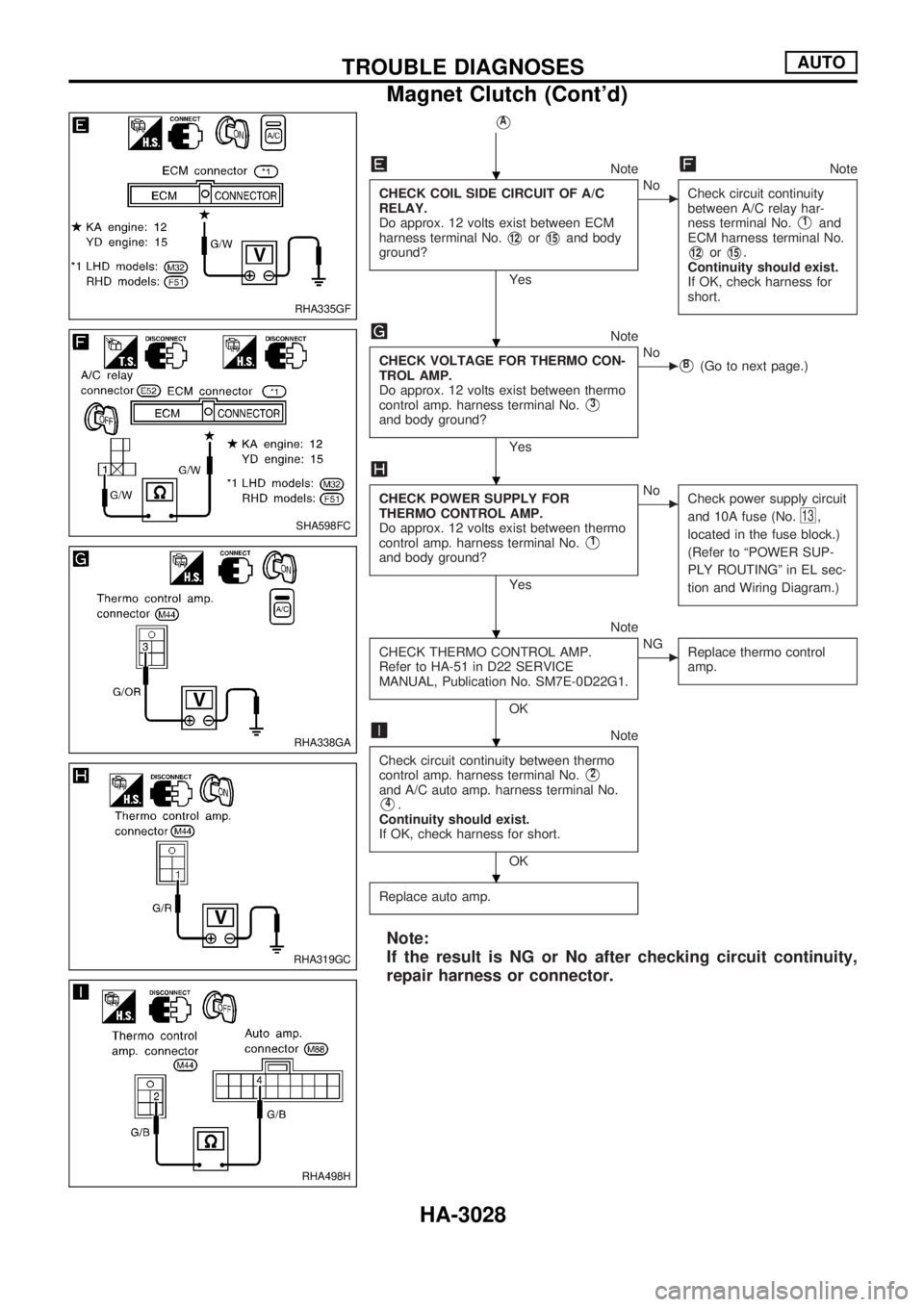

VA

NoteNote

CHECK COIL SIDE CIRCUIT OF A/C

RELAY.

Do approx. 12 volts exist between ECM

harness terminal No.

V12orV15and body

ground?

Yes

cNo

Check circuit continuity

between A/C relay har-

ness terminal No.

V1and

ECM harness terminal No.

V12orV15.

Continuity should exist.

If OK, check harness for

short.

Note

CHECK VOLTAGE FOR THERMO CON-

TROL AMP.

Do approx. 12 volts exist between thermo

control amp. harness terminal No.

V3

and body ground?

Yes

cNoVB(Go to next page.)

CHECK POWER SUPPLY FOR

THERMO CONTROL AMP.

Do approx. 12 volts exist between thermo

control amp. harness terminal No.

V1

and body ground?

Yes

cNo

Check power supply circuit

and 10A fuse (No.

13,

located in the fuse block.)

(Refer to ªPOWER SUP-

PLY ROUTINGº in EL sec-

tion and Wiring Diagram.)

Note

CHECK THERMO CONTROL AMP.

Refer to HA-51 in D22 SERVICE

MANUAL, Publication No. SM7E-0D22G1.

OK

cNG

Replace thermo control

amp.

Note

Check circuit continuity between thermo

control amp. harness terminal No.

V2

and A/C auto amp. harness terminal No.

V4.

Continuity should exist.

If OK, check harness for short.

OK

Replace auto amp.

Note:

If the result is NG or No after checking circuit continuity,

repair harness or connector.

RHA335GF

SHA598FC

RHA338GA

RHA319GC

RHA498H

.

.

.

.

.

.

TROUBLE DIAGNOSESAUTO

Magnet Clutch (Cont'd)

HA-3028

Page 1003 of 1306

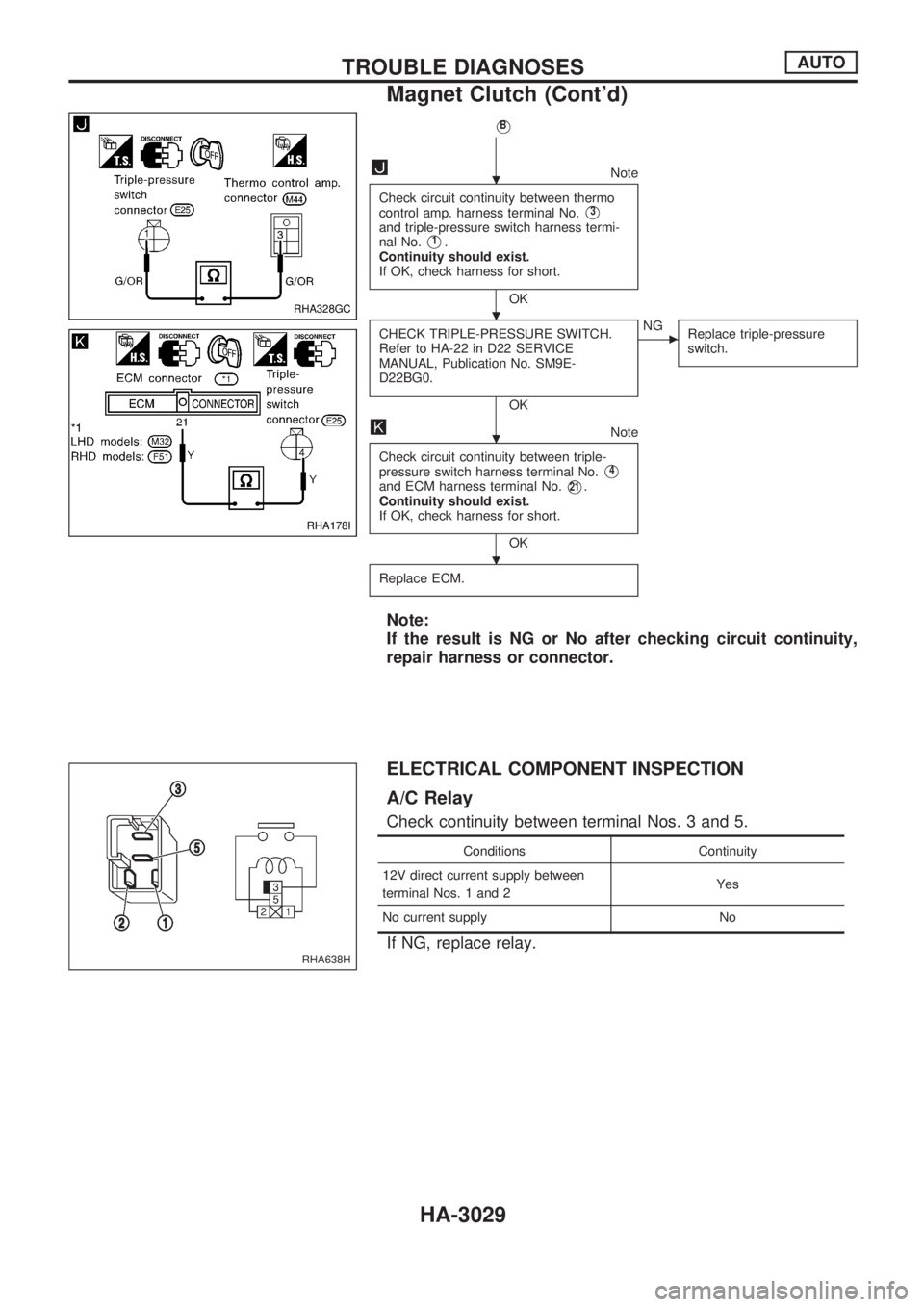

VB

Note

Check circuit continuity between thermo

control amp. harness terminal No.

V3

and triple-pressure switch harness termi-

nal No.

V1.

Continuity should exist.

If OK, check harness for short.

OK

CHECK TRIPLE-PRESSURE SWITCH.

Refer to HA-22 in D22 SERVICE

MANUAL, Publication No. SM9E-

D22BG0.

OK

cNG

Replace triple-pressure

switch.

Note

Check circuit continuity between triple-

pressure switch harness terminal No.

V4

and ECM harness terminal No.V21.

Continuity should exist.

If OK, check harness for short.

OK

Replace ECM.

Note:

If the result is NG or No after checking circuit continuity,

repair harness or connector.

ELECTRICAL COMPONENT INSPECTION

A/C Relay

Check continuity between terminal Nos. 3 and 5.

Conditions Continuity

12V direct current supply between

terminal Nos. 1 and 2Yes

No current supply No

If NG, replace relay.

RHA328GC

RHA178I

RHA638H

.

. .

.

.

TROUBLE DIAGNOSESAUTO

Magnet Clutch (Cont'd)

HA-3029

Page 1004 of 1306

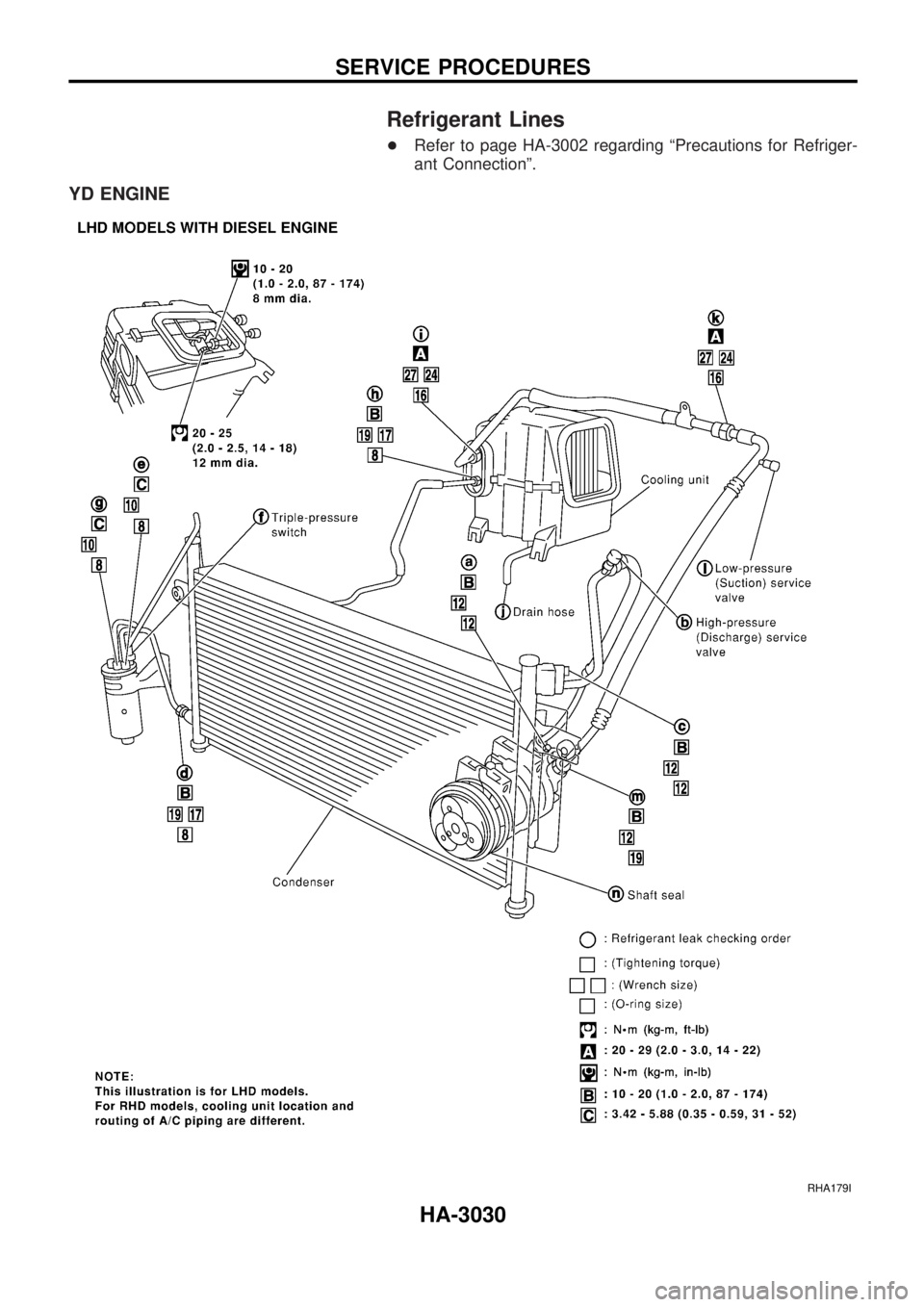

Refrigerant Lines

+Refer to page HA-3002 regarding ªPrecautions for Refriger-

ant Connectionº.

YD ENGINE

RHA179I

SERVICE PROCEDURES

HA-3030

Page 1005 of 1306

Checking Refrigerant Leaks

CHECKING PROCEDURE

To prevent inaccurate or false readings, make sure there is

no refrigerant vapor or tobacco smoke in the vicinity of the

vehicle. Perform the leak test in calm area (low air/wind

movement) so that the leaking refrigerant is not dispersed.

1. Turn engine off.

2. Connect a suitable A/C manifold gauge set to the A/C ser-

vice ports.

3. Check if the A/C refrigerant pressure is at least 345 kPa

(3.452 bar, 3.52 kg/cm

2, 50 psi) above 16ÉC (61ÉF). If less

than specification, evacuate and recharge the system with

the specified amount of refrigerant.

NOTE: At temperatures below 16ÉC (61ÉF), leaks may not be

detected since the system may not reach 345 kPa

(3.452 bar, 3.52 kg/cm

2, 50 psi).

4. Conduct the leak test from the high side to the low side at

points

jathroughjn. Refer to HA-3030.

Perform a leak check for the following areas carefully. Clean

the component to be checked and move the leak detector

probe completely around the connection/component.

+Compressor

Check the fitting of high and low pressure hoses, relief valve

and shaft seal.

+Liquid tank

Check the pressure switch, tube fitting, weld seams and the

fusible plug mounts.

+Service valves

Check all around the service valves. Ensure service valve

caps are secured on the service valves (to prevent leaks).

NOTE: After removing A/C manifold gauge set from service

valves, wipe any residue from valves to prevent any

false readings by leak detector.

+Cooling unit (Evaporator)

Turn blower fan on ªHighº for at least 15 seconds to dissipate

any refrigerant trace in the cooling unit. Insert the leak detec-

tor probe into the drain hose immediately after stopping the

engine. (Keep the probe inserted for at least ten seconds.)

5. If a leak detector detects a leak, verify at least once by

blowing compressed air into area of suspected leak, then

repeat check.

6. Do not stop when one leak is found. Continue to check for

additional leaks at all system components.

7. Start engine.

8. Set the heater A/C control as follows:

a. A/C switch ON

b. Face mode

c. Recirculation switch ON

d. Max cold temperature

e. Fan speed high

9. Run engine at 1,500 rpm for at least 2 minutes.

10. Turn engine off and perform leak check again following steps

4 through 6 above.

SERVICE PROCEDURESMANUAL AND AUTO

HA-3031

Page 1006 of 1306

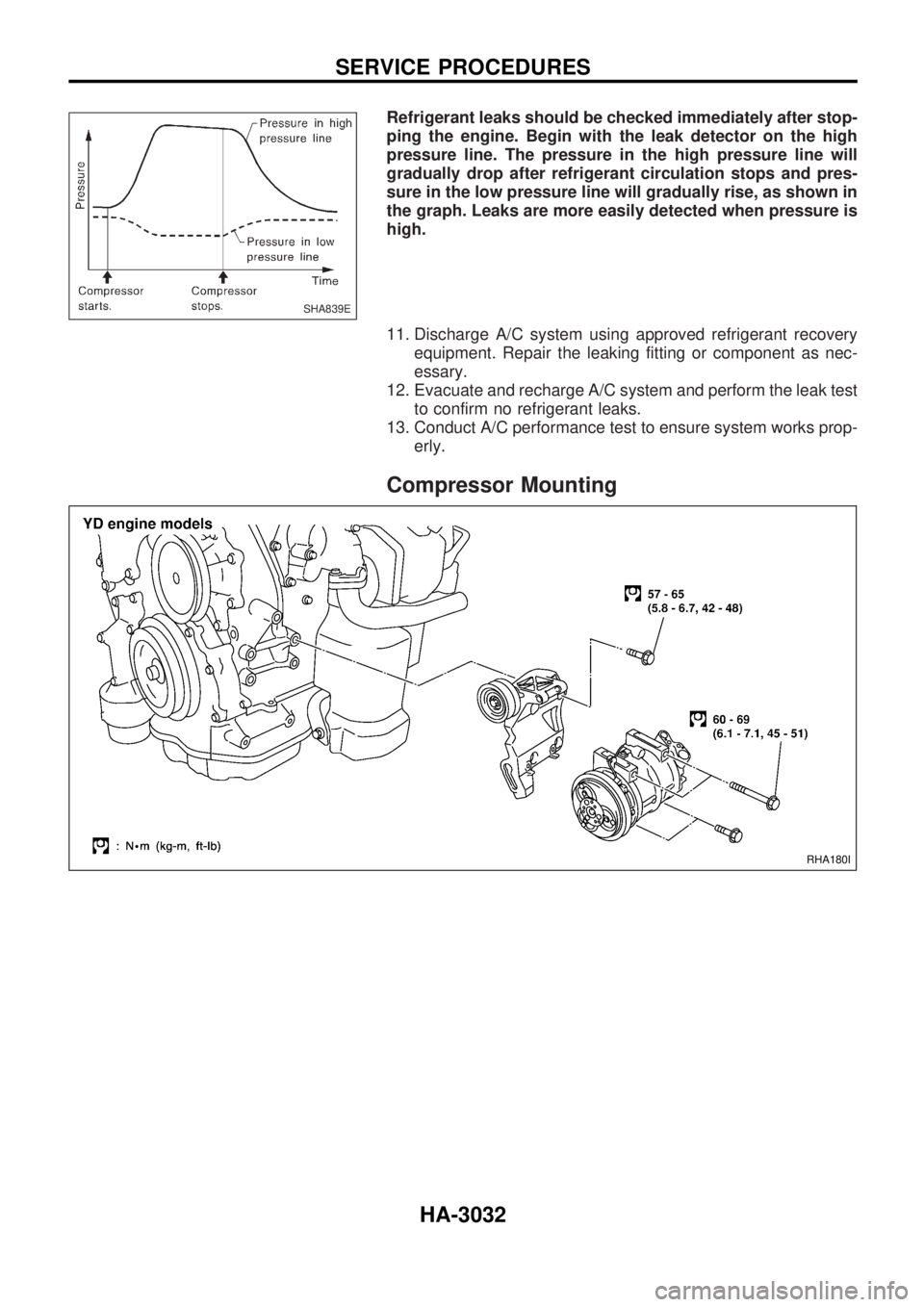

Refrigerant leaks should be checked immediately after stop-

ping the engine. Begin with the leak detector on the high

pressure line. The pressure in the high pressure line will

gradually drop after refrigerant circulation stops and pres-

sure in the low pressure line will gradually rise, as shown in

the graph. Leaks are more easily detected when pressure is

high.

11. Discharge A/C system using approved refrigerant recovery

equipment. Repair the leaking fitting or component as nec-

essary.

12. Evacuate and recharge A/C system and perform the leak test

to confirm no refrigerant leaks.

13. Conduct A/C performance test to ensure system works prop-

erly.

Compressor Mounting

SHA839E

RHA180I

SERVICE PROCEDURES

HA-3032

Page 1007 of 1306

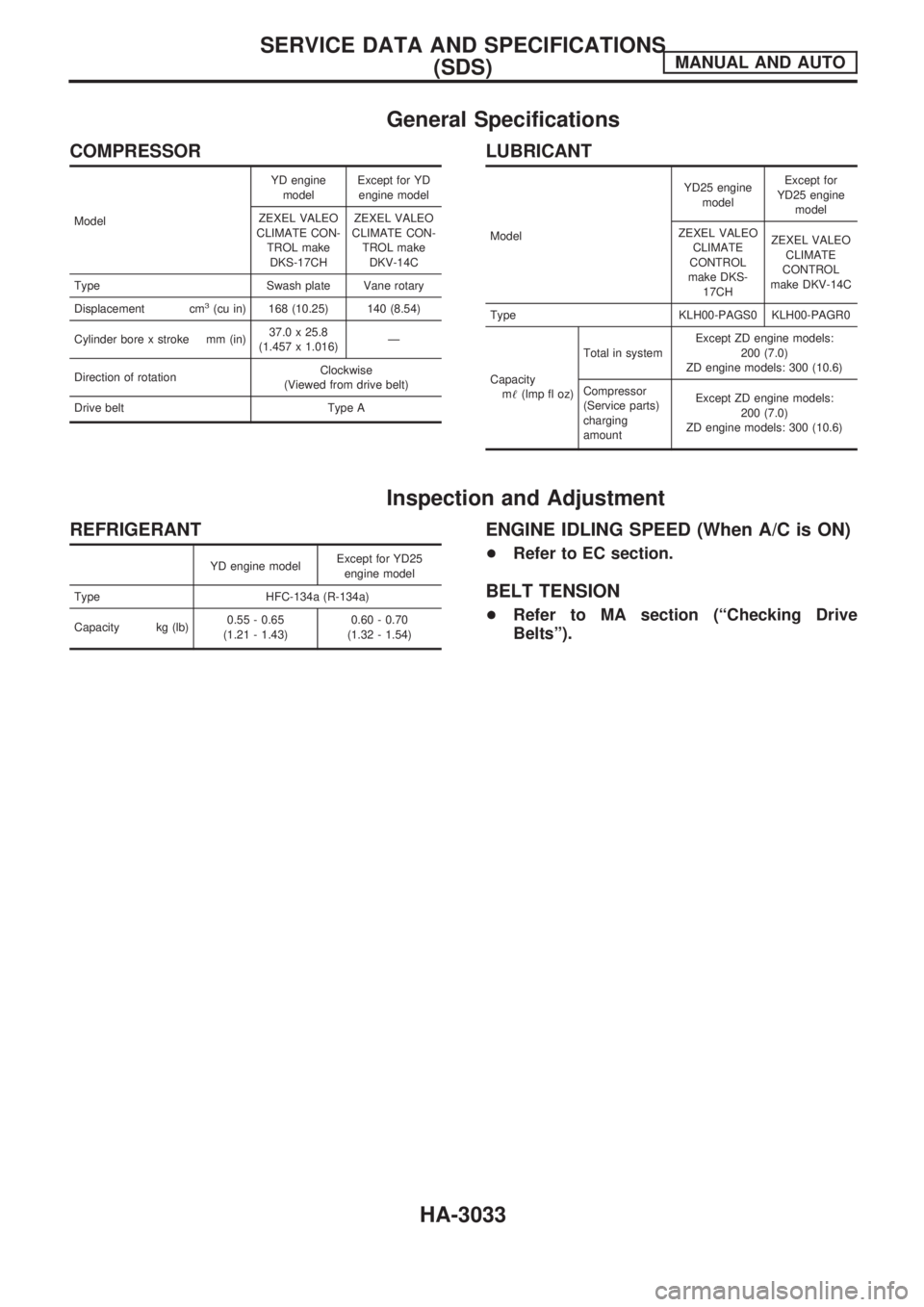

General Specifications

COMPRESSOR

ModelYD engine

modelExcept for YD

engine model

ZEXEL VALEO

CLIMATE CON-

TROL make

DKS-17CHZEXEL VALEO

CLIMATE CON-

TROL make

DKV-14C

Type Swash plate Vane rotary

Displacement cm

3(cu in) 168 (10.25) 140 (8.54)

Cylinder bore x stroke mm (in)37.0 x 25.8

(1.457 x 1.016)Ð

Direction of rotationClockwise

(Viewed from drive belt)

Drive belt Type A

LUBRICANT

ModelYD25 engine

modelExcept for

YD25 engine

model

ZEXEL VALEO

CLIMATE

CONTROL

make DKS-

17CHZEXEL VALEO

CLIMATE

CONTROL

make DKV-14C

Type KLH00-PAGS0 KLH00-PAGR0

Capacity

m!(lmp fl oz)Total in systemExcept ZD engine models:

200 (7.0)

ZD engine models: 300 (10.6)

Compressor

(Service parts)

charging

amountExcept ZD engine models:

200 (7.0)

ZD engine models: 300 (10.6)

Inspection and Adjustment

REFRIGERANT

YD engine modelExcept for YD25

engine model

Type HFC-134a (R-134a)

Capacity kg (lb)0.55 - 0.65

(1.21 - 1.43)0.60 - 0.70

(1.32 - 1.54)

ENGINE IDLING SPEED (When A/C is ON)

+Refer to EC section.

BELT TENSION

+Refer to MA section (ªChecking Drive

Beltsº).

SERVICE DATA AND SPECIFICATIONS

(SDS)MANUAL AND AUTO

HA-3033

Page 1008 of 1306

GENERAL INFORMATION

SECTION

GI

MODIFICATION NOTICE:

+YD25DDTi engine has been adopted.

+KA24E engine has been replaced with KA24DE engine.

+The appearance design has been changed.

CONTENTS

CONSULT-II CHECKING SYSTEM..................... 3002

Function and System Application .................... 3002

Nickel Metal Hydride Battery Replacement ..... 3002

Checking Equipment ........................................ 3003

CONSULT-II Data Link Connector (DLC)

Circuit ............................................................... 3003IDENTIFICATION INFORMATION...................... 3004

Model Variation ................................................ 3004

Identification Number ....................................... 3005

Wheels and Tires ............................................. 3007

Dimensions ...................................................... 3007

This modification has been included in production starting with the following vehicle identification numbers

(Chassis number):

JN1APGD22U0050001

JN1BPGD22U0030001

JN1APUD22U0030001

JN1BPUD22U0070001

JN1CPUD22U0070001

JN1ADGD22U0020001

JN1BDGD22U0030001

JN1BDUD22U0030001

JN1CDUD22U0030001

JN1CPGD22U0040001

JN1CPGD22U0740101

JN1CDUD22U0740101

JN1CPUD22U0765101

GI

Page 1009 of 1306

Function and System Application

Diagnostic test

modeFunction ENGINE A/T ABS AIR BAG

Work supportThis mode enables a technician to

adjust some devices faster and more

accurate by following the indications

on CONSULT-II.xxÐÐ

Self-diagnostic

resultsSelf-diagnostic results can be read

and erased quickly.xxxx

Trouble diagnos-

tic recordCurrent self-diagnostic results and all

trouble diagnostic records previously

stored can be read.ÐÐÐ x

ECU discrimi-

nated No.Classification number of a replace-

ment ECU can be read to prevent an

incorrect ECU from being installed.ÐÐÐ x

Data monitorInput/Output data in the ECU (ECM)

can be read.xxxÐ

DTC work sup-

portThis mode enables a technician to

set operating conditions to confirm

self-diagnosis status/results.ÐxÐÐ

Active testDiagnostic Test Mode in which CON-

SULT-II drives some actuators apart

from the ECMs and also shifts some

parameters in a specified range.xÐxÐ

ECU (ECM) part

numberECU (ECM) part number can be

read.xxxÐ

x: Applicable

Nickel Metal Hydride Battery Replacement

CONSULT-II contains a nickel metal hydride battery. When replacing the battery obey the following:

WARNING:

Replace the nickel metal hydride battery with Genuine CONSULT-II battery only. Use of another bat-

tery may present a risk of fire or explosion. The battery may present a fire or chemical burn hazard

if mistreated. Do not recharge, disassemble of dispose of in fire.

Keep the battery out of reach of children and discard used battery conforming to the local regula-

tions.

CONSULT-II CHECKING SYSTEM

GI-3002

Page 1010 of 1306

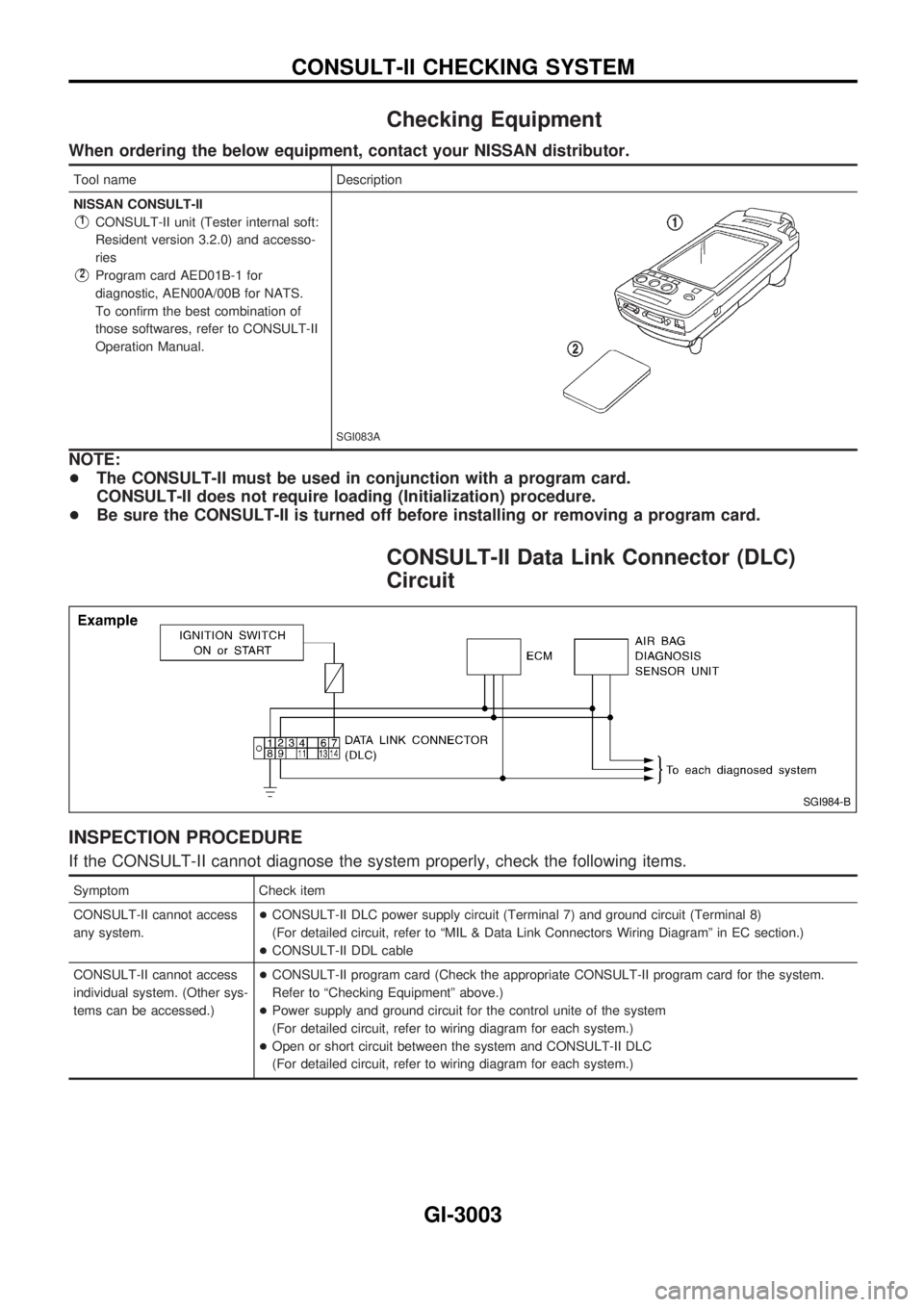

Checking Equipment

When ordering the below equipment, contact your NISSAN distributor.

Tool name Description

NISSAN CONSULT-II

V1CONSULT-II unit (Tester internal soft:

Resident version 3.2.0) and accesso-

ries

V2Program card AED01B-1 for

diagnostic, AEN00A/00B for NATS.

To confirm the best combination of

those softwares, refer to CONSULT-II

Operation Manual.

SGI083A

NOTE:

+The CONSULT-II must be used in conjunction with a program card.

CONSULT-II does not require loading (Initialization) procedure.

+Be sure the CONSULT-II is turned off before installing or removing a program card.

CONSULT-II Data Link Connector (DLC)

Circuit

INSPECTION PROCEDURE

If the CONSULT-II cannot diagnose the system properly, check the following items.

Symptom Check item

CONSULT-II cannot access

any system.+CONSULT-II DLC power supply circuit (Terminal 7) and ground circuit (Terminal 8)

(For detailed circuit, refer to ªMIL & Data Link Connectors Wiring Diagramº in EC section.)

+CONSULT-II DDL cable

CONSULT-II cannot access

individual system. (Other sys-

tems can be accessed.)+CONSULT-II program card (Check the appropriate CONSULT-II program card for the system.

Refer to ªChecking Equipmentº above.)

+Power supply and ground circuit for the control unite of the system

(For detailed circuit, refer to wiring diagram for each system.)

+Open or short circuit between the system and CONSULT-II DLC

(For detailed circuit, refer to wiring diagram for each system.)

SGI984-B

CONSULT-II CHECKING SYSTEM

GI-3003