NISSAN PRIMERA 1999 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 1571 of 2267

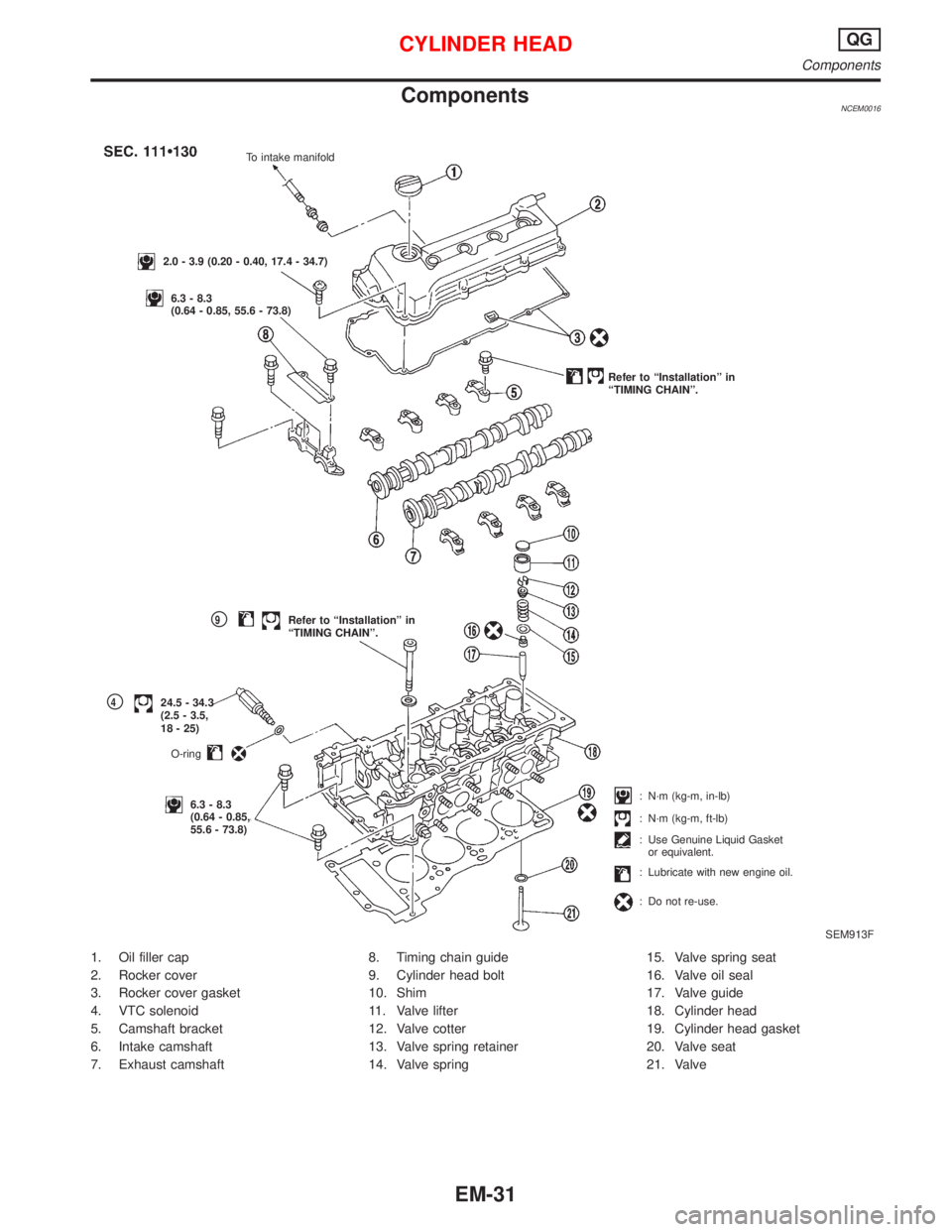

ComponentsNCEM0016

1. Oil filler cap

2. Rocker cover

3. Rocker cover gasket

4. VTC solenoid

5. Camshaft bracket

6. Intake camshaft

7. Exhaust camshaft8. Timing chain guide

9. Cylinder head bolt

10. Shim

11. Valve lifter

12. Valve cotter

13. Valve spring retainer

14. Valve spring15. Valve spring seat

16. Valve oil seal

17. Valve guide

18. Cylinder head

19. Cylinder head gasket

20. Valve seat

21. Valve

SEM913F To intake manifold

2.0 - 3.9 (0.20 - 0.40, 17.4 - 34.7)

6.3 - 8.3

(0.64 - 0.85, 55.6 - 73.8)

Refer to ªInstallationº in

ªTIMING CHAINº.

p9Refer to ªInstallationº in

ªTIMING CHAINº.

p424.5 - 34.3

(2.5 - 3.5,

18 - 25)

O-ring

6.3 - 8.3

(0.64 - 0.85,

55.6 - 73.8): N´m (kg-m, in-lb)

: N´m (kg-m, ft-lb)

: Use Genuine Liquid Gasket

or equivalent.

: Lubricate with new engine oil.

: Do not re-use.

CYLINDER HEADQG

Components

EM-31

Page 1572 of 2267

CAUTION:

IWhen installing camshaft and oil seal, lubricate contacting

surfaces with new engine oil.

IWhen tightening cylinder head bolts, camshaft sprocket

bolts and camshaft bracket bolts, lubricate bolt threads

and seat surfaces with new engine oil.

IAttach tags to valve lifters so as not to mix them up.

RemovalNCEM00171. Drain engine coolant from radiator and cylinder block.

Be careful not to spill coolant on drive belts.

2. Release fuel pressure.

Refer to EC section (ªFuel Pressure Releaseº, ªBASIC SER-

VICE PROCEDUREº).

3. Remove air duct to intake manifold collector.

4. Remove front undercovers.

5. Remove front exhaust tube.

6. Remove vacuum hoses, fuel hoses, water hoses, wires,

harness, connectors and so on.

7. Remove ignition coils.

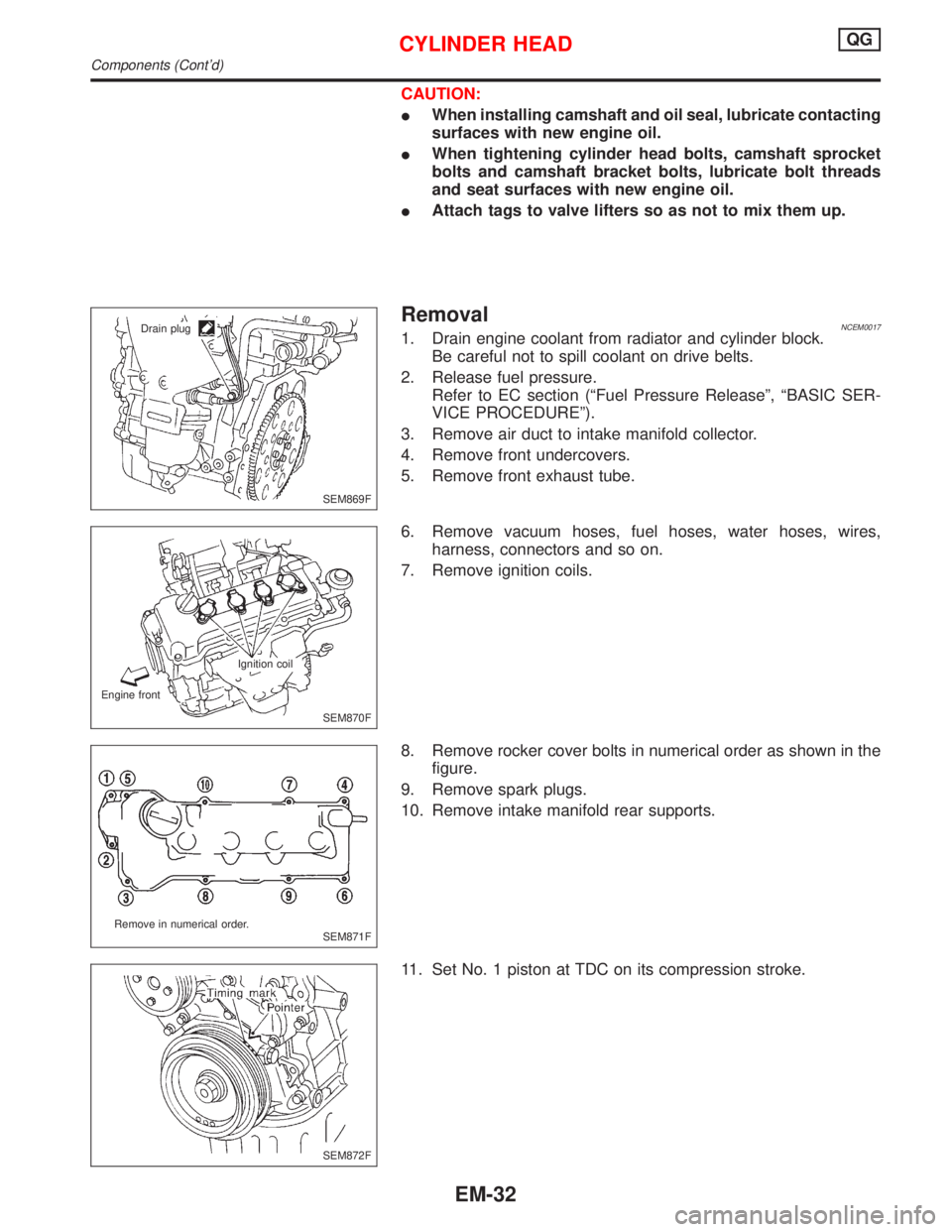

8. Remove rocker cover bolts in numerical order as shown in the

figure.

9. Remove spark plugs.

10. Remove intake manifold rear supports.

11. Set No. 1 piston at TDC on its compression stroke.

SEM869F Drain plug

SEM870F Ignition coil

Engine front

SEM871F Remove in numerical order.

SEM872F

CYLINDER HEADQG

Components (Cont'd)

EM-32

Page 1573 of 2267

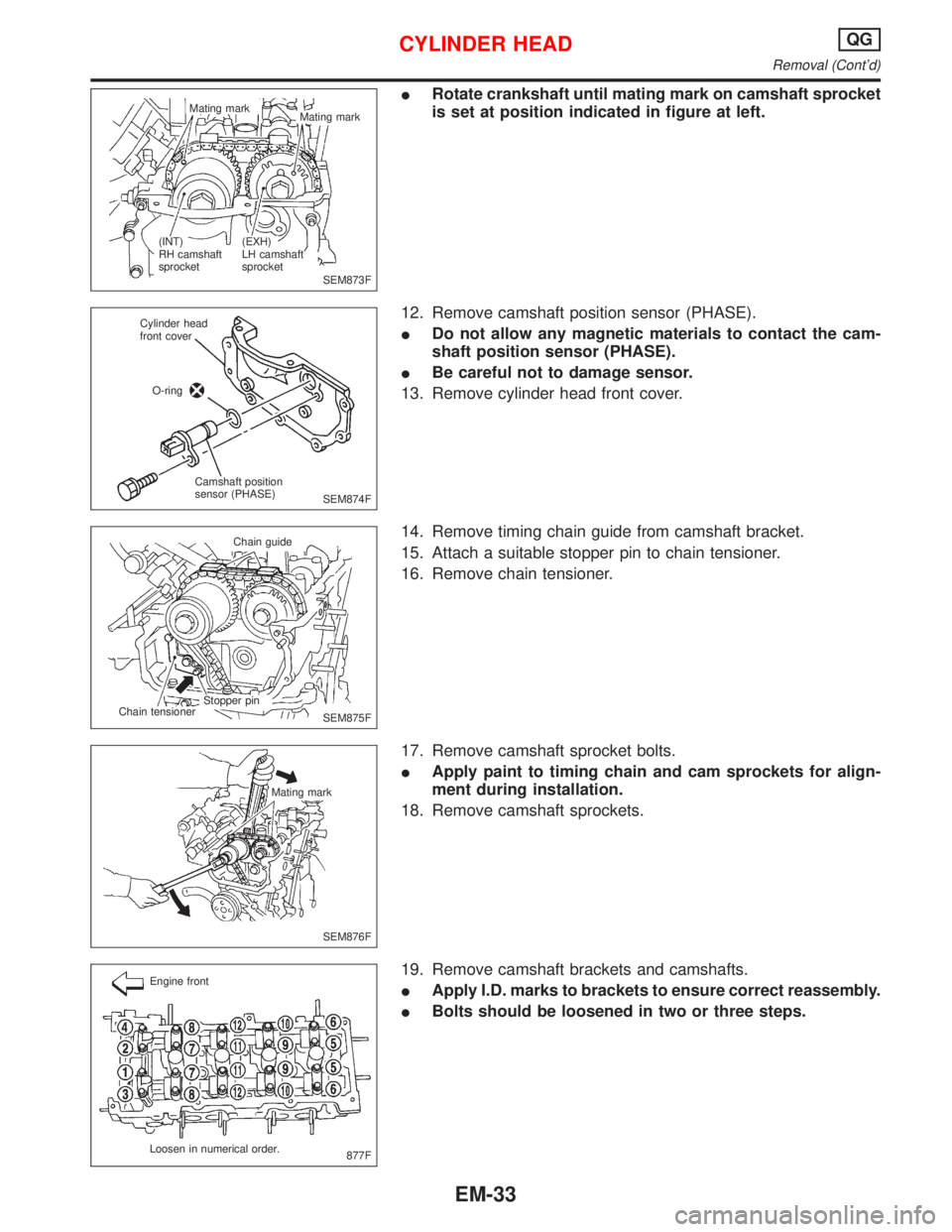

IRotate crankshaft until mating mark on camshaft sprocket

is set at position indicated in figure at left.

12. Remove camshaft position sensor (PHASE).

IDo not allow any magnetic materials to contact the cam-

shaft position sensor (PHASE).

IBe careful not to damage sensor.

13. Remove cylinder head front cover.

14. Remove timing chain guide from camshaft bracket.

15. Attach a suitable stopper pin to chain tensioner.

16. Remove chain tensioner.

17. Remove camshaft sprocket bolts.

IApply paint to timing chain and cam sprockets for align-

ment during installation.

18. Remove camshaft sprockets.

19. Remove camshaft brackets and camshafts.

IApply I.D. marks to brackets to ensure correct reassembly.

IBolts should be loosened in two or three steps.

SEM873F Mating mark

Mating mark

(EXH)

LH camshaft

sprocket (INT)

RH camshaft

sprocket

SEM874F Cylinder head

front cover

O-ring

Camshaft position

sensor (PHASE)

SEM875F Chain guide

Stopper pin

Chain tensioner

SEM876F Mating mark

877F Engine front

Loosen in numerical order.

CYLINDER HEADQG

Removal (Cont'd)

EM-33

Page 1574 of 2267

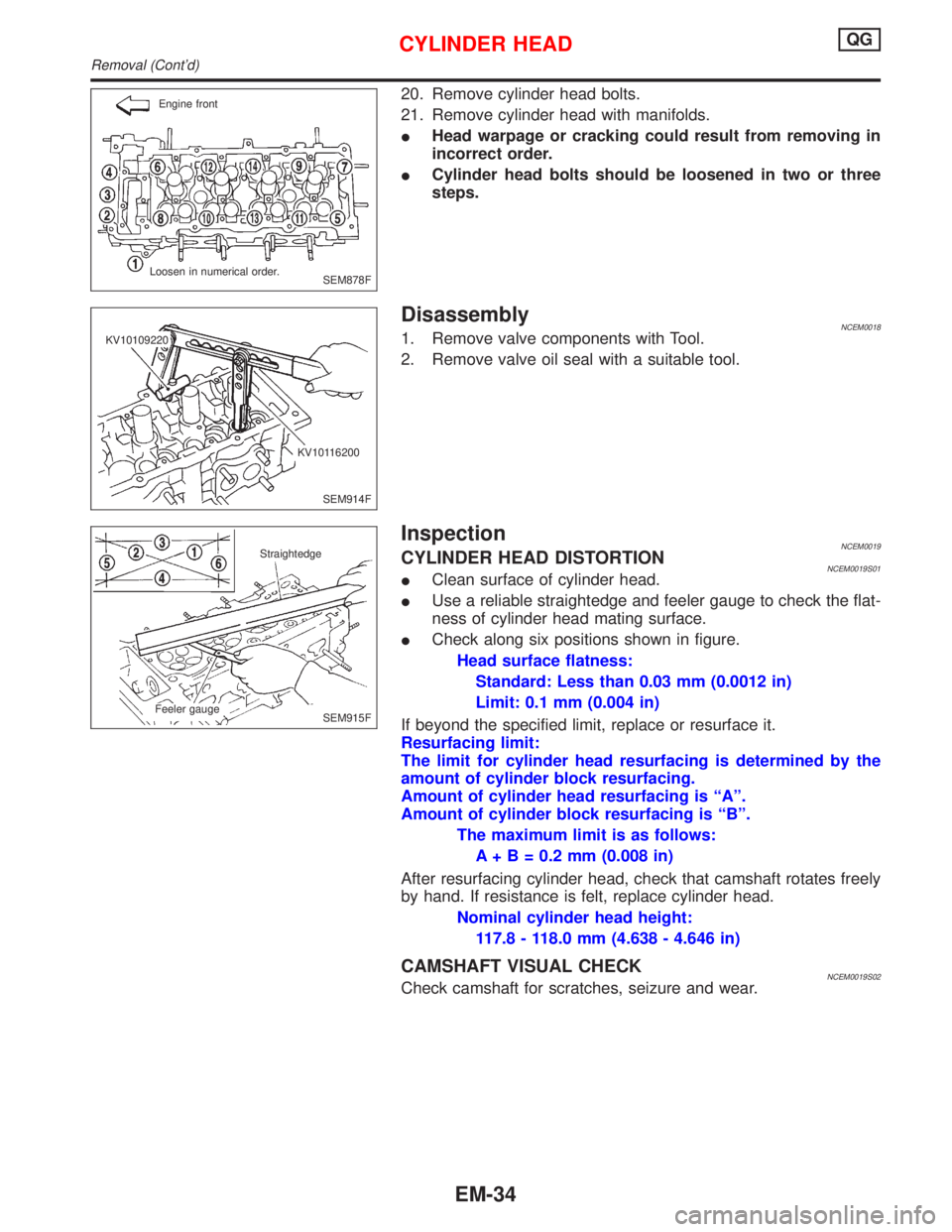

20. Remove cylinder head bolts.

21. Remove cylinder head with manifolds.

IHead warpage or cracking could result from removing in

incorrect order.

ICylinder head bolts should be loosened in two or three

steps.

DisassemblyNCEM00181. Remove valve components with Tool.

2. Remove valve oil seal with a suitable tool.

InspectionNCEM0019CYLINDER HEAD DISTORTIONNCEM0019S01IClean surface of cylinder head.

IUse a reliable straightedge and feeler gauge to check the flat-

ness of cylinder head mating surface.

ICheck along six positions shown in figure.

Head surface flatness:

Standard: Less than 0.03 mm (0.0012 in)

Limit: 0.1 mm (0.004 in)

If beyond the specified limit, replace or resurface it.

Resurfacing limit:

The limit for cylinder head resurfacing is determined by the

amount of cylinder block resurfacing.

Amount of cylinder head resurfacing is ªAº.

Amount of cylinder block resurfacing is ªBº.

The maximum limit is as follows:

A + B = 0.2 mm (0.008 in)

After resurfacing cylinder head, check that camshaft rotates freely

by hand. If resistance is felt, replace cylinder head.

Nominal cylinder head height:

117.8 - 118.0 mm (4.638 - 4.646 in)

CAMSHAFT VISUAL CHECKNCEM0019S02Check camshaft for scratches, seizure and wear.

SEM878F Loosen in numerical order.Engine front

SEM914F KV10109220

KV10116200

SEM915F Straightedge

Feeler gauge

CYLINDER HEADQG

Removal (Cont'd)

EM-34

Page 1575 of 2267

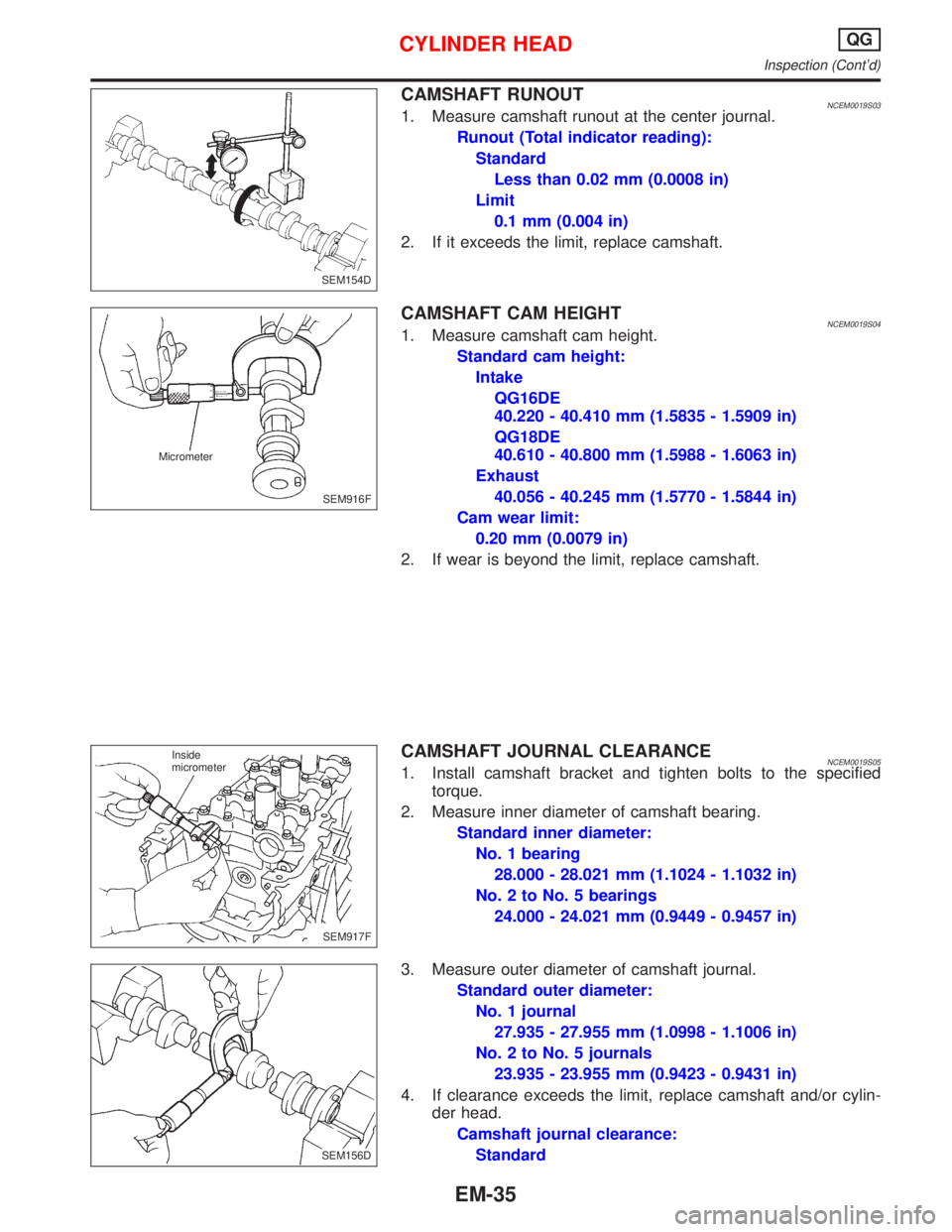

CAMSHAFT RUNOUTNCEM0019S031. Measure camshaft runout at the center journal.

Runout (Total indicator reading):

Standard

Less than 0.02 mm (0.0008 in)

Limit

0.1 mm (0.004 in)

2. If it exceeds the limit, replace camshaft.

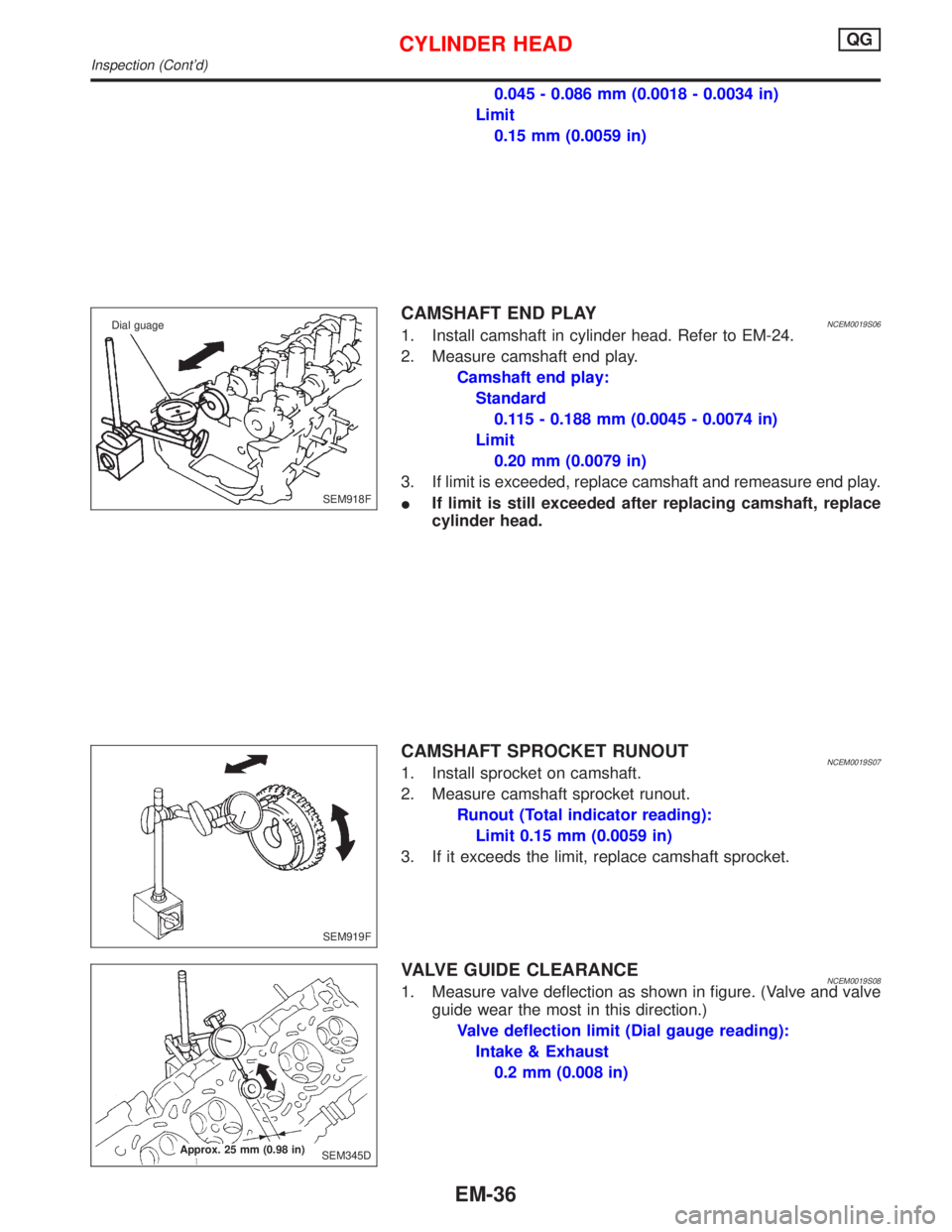

CAMSHAFT CAM HEIGHTNCEM0019S041. Measure camshaft cam height.

Standard cam height:

Intake

QG16DE

40.220 - 40.410 mm (1.5835 - 1.5909 in)

QG18DE

40.610 - 40.800 mm (1.5988 - 1.6063 in)

Exhaust

40.056 - 40.245 mm (1.5770 - 1.5844 in)

Cam wear limit:

0.20 mm (0.0079 in)

2. If wear is beyond the limit, replace camshaft.

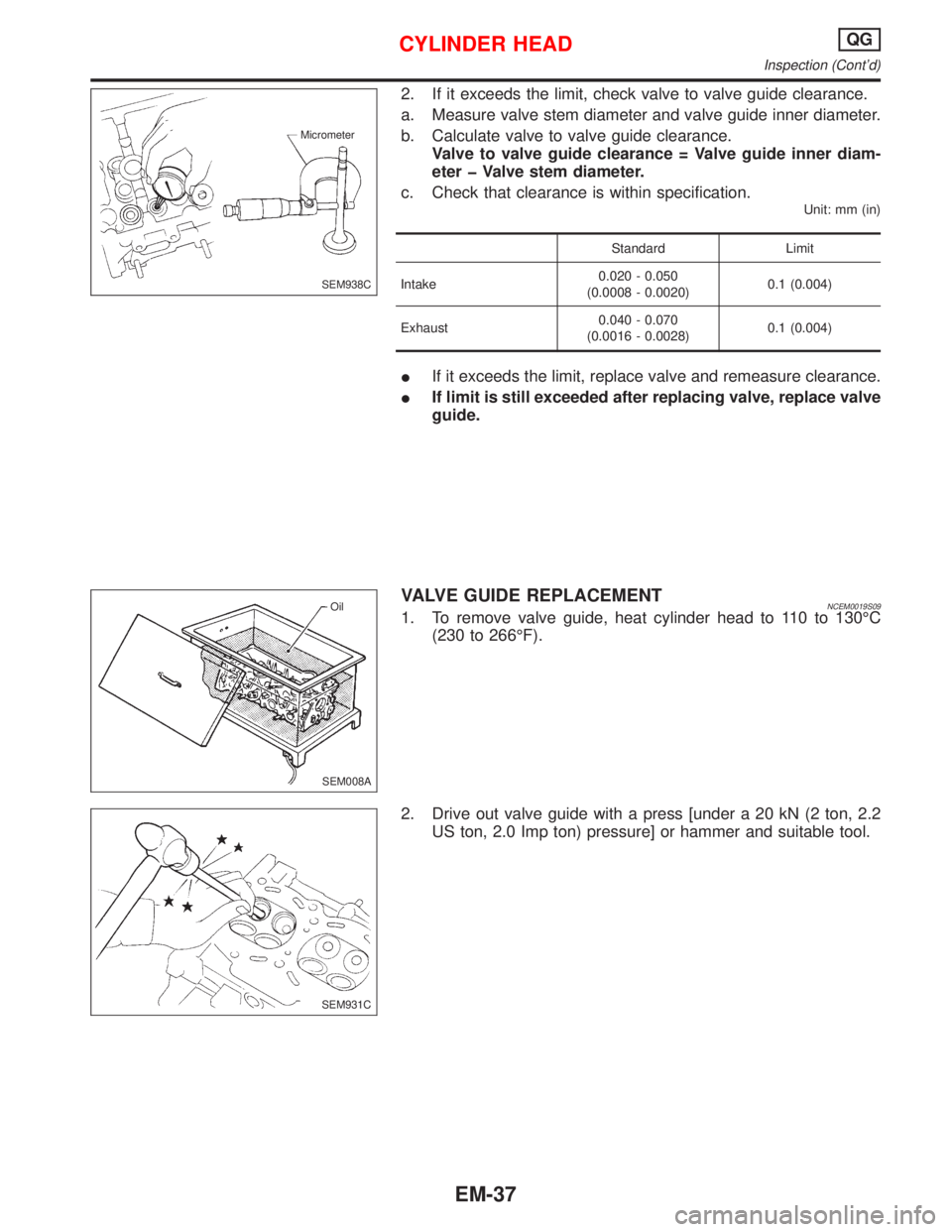

CAMSHAFT JOURNAL CLEARANCENCEM0019S051. Install camshaft bracket and tighten bolts to the specified

torque.

2. Measure inner diameter of camshaft bearing.

Standard inner diameter:

No. 1 bearing

28.000 - 28.021 mm (1.1024 - 1.1032 in)

No. 2 to No. 5 bearings

24.000 - 24.021 mm (0.9449 - 0.9457 in)

3. Measure outer diameter of camshaft journal.

Standard outer diameter:

No. 1 journal

27.935 - 27.955 mm (1.0998 - 1.1006 in)

No. 2 to No. 5 journals

23.935 - 23.955 mm (0.9423 - 0.9431 in)

4. If clearance exceeds the limit, replace camshaft and/or cylin-

der head.

Camshaft journal clearance:

Standard

SEM154D

SEM916F Micrometer

SEM917F Inside

micrometer

SEM156D

CYLINDER HEADQG

Inspection (Cont'd)

EM-35

Page 1576 of 2267

0.045 - 0.086 mm (0.0018 - 0.0034 in)

Limit

0.15 mm (0.0059 in)

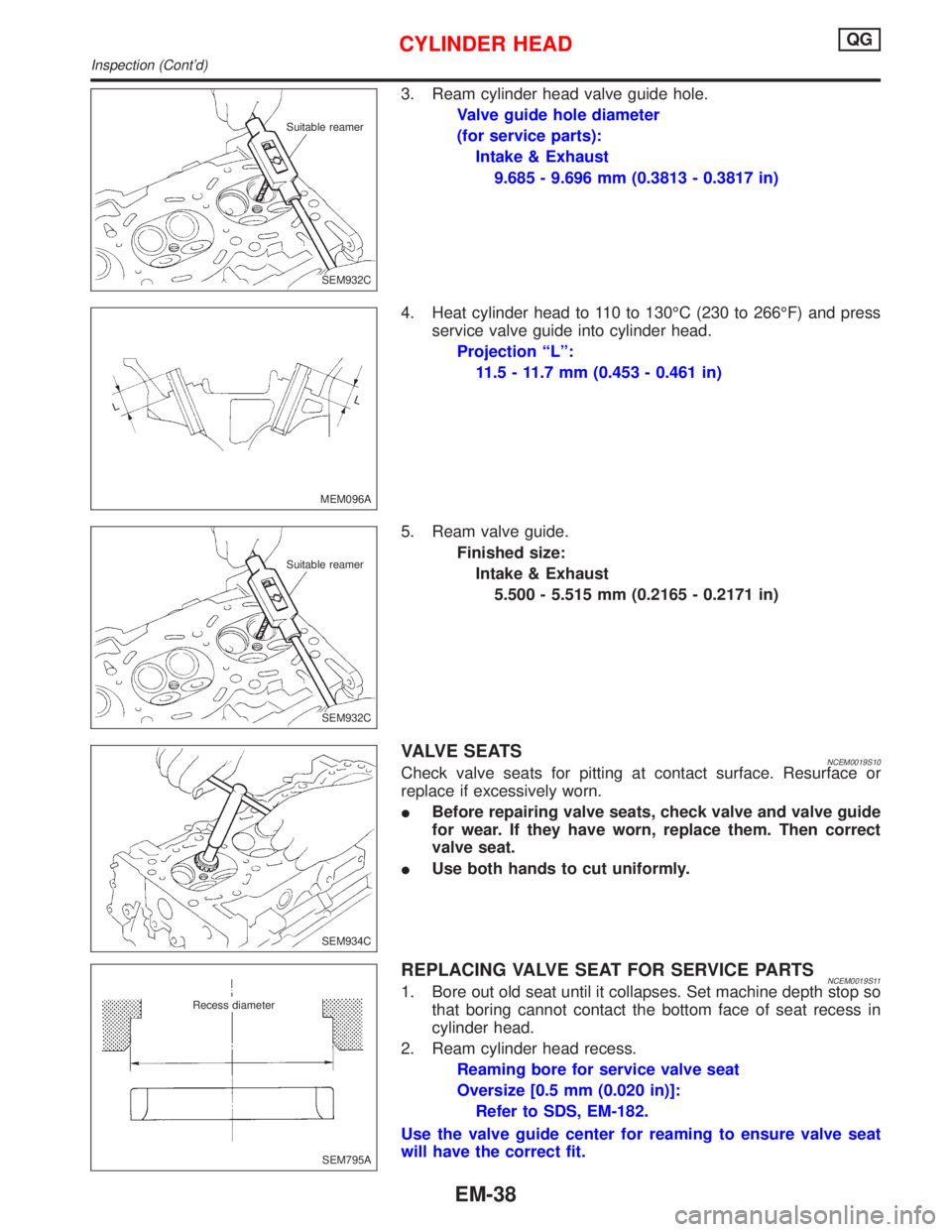

CAMSHAFT END PLAYNCEM0019S061. Install camshaft in cylinder head. Refer to EM-24.

2. Measure camshaft end play.

Camshaft end play:

Standard

0.115 - 0.188 mm (0.0045 - 0.0074 in)

Limit

0.20 mm (0.0079 in)

3. If limit is exceeded, replace camshaft and remeasure end play.

IIf limit is still exceeded after replacing camshaft, replace

cylinder head.

CAMSHAFT SPROCKET RUNOUTNCEM0019S071. Install sprocket on camshaft.

2. Measure camshaft sprocket runout.

Runout (Total indicator reading):

Limit 0.15 mm (0.0059 in)

3. If it exceeds the limit, replace camshaft sprocket.

VALVE GUIDE CLEARANCENCEM0019S081. Measure valve deflection as shown in figure. (Valve and valve

guide wear the most in this direction.)

Valve deflection limit (Dial gauge reading):

Intake & Exhaust

0.2 mm (0.008 in)

SEM918F Dial guage

SEM919F

SEM345D Approx. 25 mm (0.98 in)

CYLINDER HEADQG

Inspection (Cont'd)

EM-36

Page 1577 of 2267

2. If it exceeds the limit, check valve to valve guide clearance.

a. Measure valve stem diameter and valve guide inner diameter.

b. Calculate valve to valve guide clearance.

Valve to valve guide clearance = Valve guide inner diam-

eter þ Valve stem diameter.

c. Check that clearance is within specification.

Unit: mm (in)

Standard Limit

Intake0.020 - 0.050

(0.0008 - 0.0020)0.1 (0.004)

Exhaust0.040 - 0.070

(0.0016 - 0.0028)0.1 (0.004)

IIf it exceeds the limit, replace valve and remeasure clearance.

IIf limit is still exceeded after replacing valve, replace valve

guide.

VALVE GUIDE REPLACEMENTNCEM0019S091. To remove valve guide, heat cylinder head to 110 to 130ÉC

(230 to 266ÉF).

2. Drive out valve guide with a press [under a 20 kN (2 ton, 2.2

US ton, 2.0 Imp ton) pressure] or hammer and suitable tool.

SEM938C Micrometer

SEM008AOil

SEM931C

CYLINDER HEADQG

Inspection (Cont'd)

EM-37

Page 1578 of 2267

3. Ream cylinder head valve guide hole.

Valve guide hole diameter

(for service parts):

Intake & Exhaust

9.685 - 9.696 mm (0.3813 - 0.3817 in)

4. Heat cylinder head to 110 to 130ÉC (230 to 266ÉF) and press

service valve guide into cylinder head.

Projection ªLº:

11.5 - 11.7 mm (0.453 - 0.461 in)

5. Ream valve guide.

Finished size:

Intake & Exhaust

5.500 - 5.515 mm (0.2165 - 0.2171 in)

VALVE SEATSNCEM0019S10Check valve seats for pitting at contact surface. Resurface or

replace if excessively worn.

IBefore repairing valve seats, check valve and valve guide

for wear. If they have worn, replace them. Then correct

valve seat.

IUse both hands to cut uniformly.

REPLACING VALVE SEAT FOR SERVICE PARTSNCEM0019S111. Bore out old seat until it collapses. Set machine depth stop so

that boring cannot contact the bottom face of seat recess in

cylinder head.

2. Ream cylinder head recess.

Reaming bore for service valve seat

Oversize [0.5 mm (0.020 in)]:

Refer to SDS, EM-182.

Use the valve guide center for reaming to ensure valve seat

will have the correct fit.

SEM932C Suitable reamer

MEM096A

SEM932C Suitable reamer

SEM934C

SEM795A

.Recess diameter

CYLINDER HEADQG

Inspection (Cont'd)

EM-38

Page 1579 of 2267

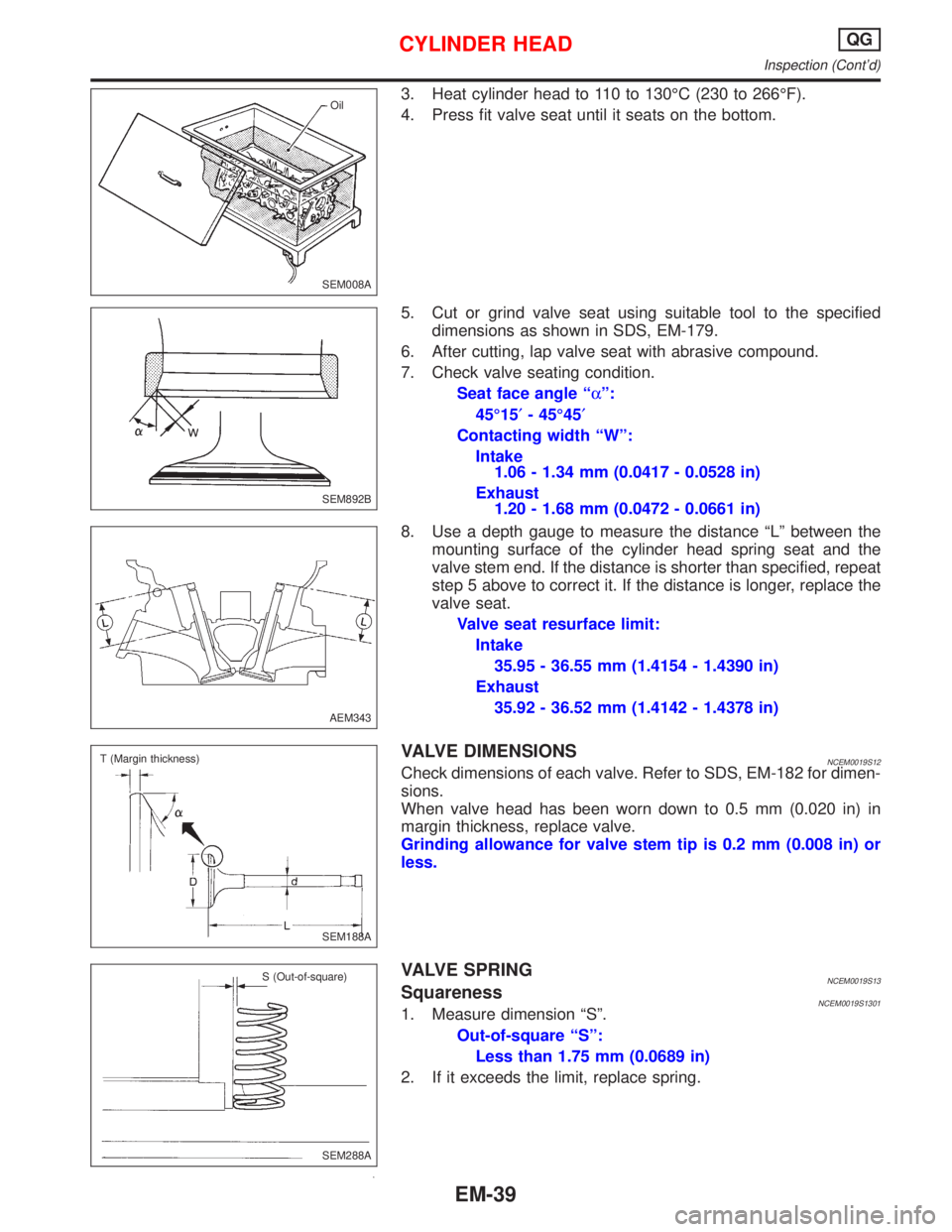

3. Heat cylinder head to 110 to 130ÉC (230 to 266ÉF).

4. Press fit valve seat until it seats on the bottom.

5. Cut or grind valve seat using suitable tool to the specified

dimensions as shown in SDS, EM-179.

6. After cutting, lap valve seat with abrasive compound.

7. Check valve seating condition.

Seat face angle ªaº:

45É15¢- 45É45¢

Contacting width ªWº:

Intake

1.06 - 1.34 mm (0.0417 - 0.0528 in)

Exhaust

1.20 - 1.68 mm (0.0472 - 0.0661 in)

8. Use a depth gauge to measure the distance ªLº between the

mounting surface of the cylinder head spring seat and the

valve stem end. If the distance is shorter than specified, repeat

step 5 above to correct it. If the distance is longer, replace the

valve seat.

Valve seat resurface limit:

Intake

35.95 - 36.55 mm (1.4154 - 1.4390 in)

Exhaust

35.92 - 36.52 mm (1.4142 - 1.4378 in)

VALVE DIMENSIONSNCEM0019S12Check dimensions of each valve. Refer to SDS, EM-182 for dimen-

sions.

When valve head has been worn down to 0.5 mm (0.020 in) in

margin thickness, replace valve.

Grinding allowance for valve stem tip is 0.2 mm (0.008 in) or

less.

VALVE SPRINGNCEM0019S13SquarenessNCEM0019S13011. Measure dimension ªSº.

Out-of-square ªSº:

Less than 1.75 mm (0.0689 in)

2. If it exceeds the limit, replace spring.

SEM008AOil

SEM892B

AEM343

SEM188A T (Margin thickness)

SEM288A S (Out-of-square)

CYLINDER HEADQG

Inspection (Cont'd)

EM-39

Page 1580 of 2267

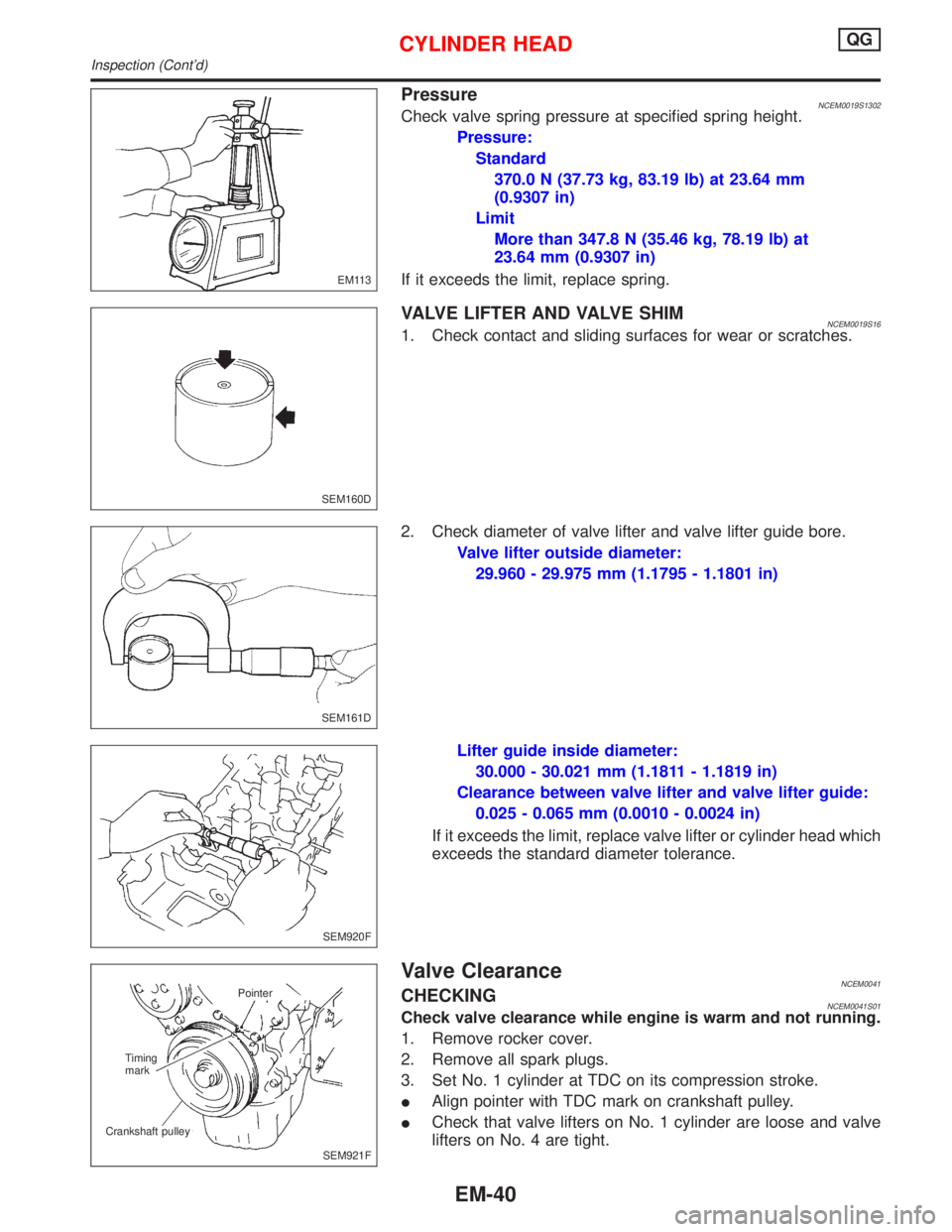

PressureNCEM0019S1302Check valve spring pressure at specified spring height.

Pressure:

Standard

370.0 N (37.73 kg, 83.19 lb) at 23.64 mm

(0.9307 in)

Limit

More than 347.8 N (35.46 kg, 78.19 lb) at

23.64 mm (0.9307 in)

If it exceeds the limit, replace spring.

VALVE LIFTER AND VALVE SHIMNCEM0019S161. Check contact and sliding surfaces for wear or scratches.

2. Check diameter of valve lifter and valve lifter guide bore.

Valve lifter outside diameter:

29.960 - 29.975 mm (1.1795 - 1.1801 in)

Lifter guide inside diameter:

30.000 - 30.021 mm (1.1811 - 1.1819 in)

Clearance between valve lifter and valve lifter guide:

0.025 - 0.065 mm (0.0010 - 0.0024 in)

If it exceeds the limit, replace valve lifter or cylinder head which

exceeds the standard diameter tolerance.

Valve ClearanceNCEM0041CHECKINGNCEM0041S01Check valve clearance while engine is warm and not running.

1. Remove rocker cover.

2. Remove all spark plugs.

3. Set No. 1 cylinder at TDC on its compression stroke.

IAlign pointer with TDC mark on crankshaft pulley.

ICheck that valve lifters on No. 1 cylinder are loose and valve

lifters on No. 4 are tight.

EM113

SEM160D

SEM161D

SEM920F

SEM921F Pointer

Timing

mark

Crankshaft pulley

CYLINDER HEADQG

Inspection (Cont'd)

EM-40