NISSAN PRIMERA 1999 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 1541 of 2267

ENGINE MECHANICAL

SECTION

EM

CONTENTS

PRECAUTIONS...............................................................5

Parts Requiring Angular Tightening .............................5

Liquid Gasket Application Procedure ..........................5

PREPARATION................................................................6

Special Service Tools ..................................................6

Commercial Service Tools .........................................10

QG

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING................................................... 11

NVH Troubleshooting - Engine Noise ....................... 11

OUTER COMPONENT PARTS.....................................13

Removal and Installation ...........................................13

MEASUREMENT OF COMPRESSION PRESSURE....16

OIL PAN.........................................................................17

Components...............................................................17

Removal .....................................................................17

Installation ..................................................................18

TIMING CHAIN..............................................................19

Components...............................................................19

Removal .....................................................................20

Inspection...................................................................24

Installation ..................................................................24

OIL SEAL.......................................................................29

Replacement ..............................................................29

VALVE OIL SEAL.....................................................29

FRONT OIL SEAL....................................................29

REAR OIL SEAL......................................................30

CYLINDER HEAD..........................................................31

Components...............................................................31

Removal .....................................................................32

Disassembly...............................................................34

Inspection...................................................................34

CYLINDER HEAD DISTORTION...............................34

CAMSHAFT VISUAL CHECK....................................34

CAMSHAFT RUNOUT..............................................35

CAMSHAFT CAM HEIGHT.......................................35

CAMSHAFT JOURNAL CLEARANCE........................35

CAMSHAFT END PLAY............................................36

CAMSHAFT SPROCKET RUNOUT...........................36

VALVE GUIDE CLEARANCE....................................36

VALVE GUIDE REPLACEMENT................................37

VALVE SEATS.........................................................38

REPLACING VALVE SEAT FOR SERVICE PARTS.....38

VALVE DIMENSIONS...............................................39

VALVE SPRING.......................................................39

VALVE LIFTER AND VALVE SHIM.............................40

Valve Clearance.........................................................40

CHECKING.............................................................40

ADJUSTING............................................................41

Assembly ...................................................................43

Installation ..................................................................43

ENGINE REMOVAL.......................................................48

Removal and Installation ...........................................48

REMOVAL...............................................................49

INSTALLATION........................................................51

CYLINDER BLOCK.......................................................52

Components...............................................................52

Removal and Installation ...........................................53

Disassembly...............................................................53

PISTON AND CRANKSHAFT....................................53

Inspection...................................................................54

PISTON AND PISTON PIN CLEARANCE...................54

PISTON RING SIDE CLEARANCE............................54

PISTON RING END GAP..........................................54

CONNECTING ROD BEND AND TORSION...............55

CYLINDER BLOCK DISTORTION AND WEAR...........55

PISTON-TO-BORE CLEARANCE..............................56

CRANKSHAFT.........................................................57

BEARING CLEARANCE...........................................57

CONNECTING ROD BUSHING CLEARANCE

(Small end)

..............................................................59

REPLACEMENT OF CONNECTING ROD

BUSHING (Small end)

..............................................60

FLYWHEEL/DRIVE PLATE RUNOUT.........................60

EM

Page 1542 of 2267

Assembly ...................................................................60

PISTON..................................................................60

CRANKSHAFT.........................................................61

SR20DE

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING........................................64

NVH Troubleshooting - Engine Noise .......................65

OUTER COMPONENT PARTS.....................................66

COMPRESSION PRESSURE........................................69

Measurement of Compression Pressure ...................69

OIL PAN.........................................................................70

Removal .....................................................................70

Installation ..................................................................73

TIMING CHAIN..............................................................75

Components...............................................................75

Removal .....................................................................76

Inspection...................................................................79

Installation ..................................................................79

OIL SEAL REPLACEMENT..........................................84

VALVE OIL SEAL.....................................................84

FRONT OIL SEAL....................................................84

REAR OIL SEAL......................................................85

CYLINDER HEAD..........................................................86

Components...............................................................86

Removal .....................................................................87

Disassembly...............................................................89

Inspection...................................................................91

CYLINDER HEAD DISTORTION...............................91

CAMSHAFT VISUAL CHECK....................................91

CAMSHAFT RUNOUT..............................................92

CAMSHAFT CAM HEIGHT.......................................92

CAMSHAFT JOURNAL CLEARANCE........................92

CAMSHAFT END PLAY............................................93

CAMSHAFT SPROCKET RUNOUT...........................93

VALVE GUIDE CLEARANCE....................................93

VALVE GUIDE REPLACEMENT................................94

VALVE SEATS.........................................................95

REPLACING VALVE SEAT FOR SERVICE PARTS.....95

VALVE DIMENSIONS...............................................95

VALVE SPRING.......................................................96

HYDRAULIC LASH ADJUSTER................................96

ROCKER ARM, SHIM AND ROCKER ARM GUIDE.....97

Assembly ...................................................................97

Installation ..................................................................99

ENGINE REMOVAL.....................................................106

Components.............................................................106

Removal ...................................................................107

Installation ................................................................108

CYLINDER BLOCK.....................................................109

Components.............................................................109

Disassembly............................................................. 110

PISTON AND CRANKSHAFT.................................. 110Inspection................................................................. 110

PISTON AND PISTON PIN CLEARANCE................. 110

PISTON RING SIDE CLEARANCE.......................... 111

PISTON RING END GAP........................................ 111

CONNECTING ROD BEND AND TORSION............. 111

CYLINDER BLOCK DISTORTION AND WEAR......... 112

PISTON-TO-BORE CLEARANCE............................ 112

CRANKSHAFT....................................................... 113

BEARING CLEARANCE......................................... 114

CONNECTING ROD BUSHING CLEARANCE

(Small end)

............................................................ 116

REPLACEMENT OF CONNECTING ROD

BUSHING (Small end)

............................................ 117

REPLACEMENT OF PILOT BUSHING (M/T) OR

PILOT CONVERTER (CVT)

.................................... 117

FLYWHEEL/DRIVE PLATE RUNOUT....................... 117

Assembly ................................................................. 117

PISTON................................................................ 117

CRANKSHAFT....................................................... 118

CD20T

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................121

NVH Troubleshooting Chart - Engine Noise ...........122

OUTER COMPONENT PARTS...................................123

COMPRESSION PRESSURE......................................126

OIL PAN.......................................................................129

Removal ...................................................................129

Installation ................................................................129

TIMING BELT...............................................................131

Camshaft Timing Belt ..............................................131

REMOVAL.............................................................131

Inspection.................................................................133

Installation ................................................................134

Injection Pump Timing Belt ......................................135

REMOVAL.............................................................135

INSTALLATION......................................................136

OIL SEAL REPLACEMENT........................................138

VALVE OIL SEAL...................................................138

CAMSHAFT AND CRANKSHAFT OIL SEAL

INSTALLING DIRECTION AND MANNER

................138

CAMSHAFT OIL SEALS.........................................138

CRANKSHAFT FRONT OIL SEAL...........................139

CRANKSHAFT REAR OIL SEAL.............................139

CYLINDER HEAD........................................................140

Components.............................................................140

Removal ...................................................................141

Disassembly.............................................................141

Inspection.................................................................142

CYLINDER HEAD DISTORTION.............................142

VALVE GUIDE CLEARANCE..................................142

VALVE GUIDE REPLACEMENT..............................142

VALVE SEATS.......................................................143

VALVE SEAT REPLACEMENT................................143

CONTENTS(Cont'd)

EM-2

Page 1543 of 2267

VALVE DIMENSIONS.............................................144

VALVE SPRING SQUARENESS..............................145

VALVE SPRING PRESSURE LOAD........................145

VALVE LIFTER......................................................145

COMBUSTION CHAMBER REPLACEMENT............146

CAMSHAFT VISUAL CHECK..................................147

CAMSHAFT END PLAY..........................................147

CAMSHAFT RUNOUT............................................147

CAMSHAFT CAM HEIGHT.....................................147

CAMSHAFT JOURNAL CLEARANCE......................147

Valve clearance .......................................................148

Checking ..................................................................148

Adjusting ..................................................................149

Assembly .................................................................151

Installation ................................................................151

TURBOCHARGER.......................................................156

Removal ...................................................................156

Disassembly.............................................................157

Inspection.................................................................158

OIL AND WATER TUBES........................................158

ROTOR SHAFT.....................................................158

TURBINE WHEEL..................................................159

COMPRESSOR WHEEL.........................................159

WASTEGATE VALVE..............................................160

WASTEGATE VALVE ACTUATOR...........................160

Assembly .................................................................160

Installation ................................................................160

ENGINE REMOVAL.....................................................162

CYLINDER BLOCK.....................................................166

Components.............................................................166

Preparation ..............................................................167

Disassembly.............................................................167

PISTON AND CRANKSHAFT..................................167

Inspection.................................................................168

PISTON AND PISTON PIN CLEARANCE.................168

PISTON RING SIDE CLEARANCE..........................168

PISTON RING END GAP........................................169

MAIN BEARING CLEARANCE................................169

CONNECTING ROD BEARING CLEARANCE (Big

end)

......................................................................170

CONNECTING ROD AND PISTON PIN

CLEARANCE (Small end)

.......................................171

CONNECTING ROD BEND AND TORSION.............172

CRANKSHAFT.......................................................172

CYLINDER BLOCK DISTORTION...........................173

CYLINDER BORE..................................................173

PISTON-TO-BORE CLEARANCE............................174

Assembly .................................................................175

PISTON................................................................175

CRANKSHAFT.......................................................175

PISTON WITH CONNECTING ROD........................176

FLYWHEEL RUNOUT.............................................177QG

SERVICE DATA AND SPECIFICATIONS (SDS)........178

General Specifications .............................................178

Compression Pressure ............................................178

Cylinder Head ..........................................................178

Valve ........................................................................179

VA LV E...................................................................179

VALVE SPRING.....................................................179

VALVE LIFTER......................................................179

VALVE CLEARANCE..............................................179

VALVE GUIDE.......................................................180

AVAILABLE SHIMS................................................180

VA LV E S E AT.........................................................182

VALVE SEAT RESURFACE LIMIT...........................183

Camshaft and Camshaft Bearing ............................183

Cylinder Block ..........................................................184

Piston, Piston Ring and Piston Pin .........................185

PISTON................................................................185

PISTON RING.......................................................185

PISTON PIN..........................................................185

Connecting Rod .......................................................186

Crankshaft................................................................186

Main Bearing............................................................186

STANDARD...........................................................186

UNDERSIZE..........................................................186

Connecting Rod Bearing .........................................187

STANDARD SIZE...................................................187

UNDERSIZE..........................................................187

Bearing Clearance ...................................................187

Miscellaneous Components.....................................187

SR20DE

SERVICE DATA AND SPECIFICATIONS (SDS)........188

General Specifications .............................................188

Inspection and Adjustment ......................................188

COMPRESSION PRESSURE.................................188

CYLINDER HEAD..................................................188

VA LV E...................................................................189

CAMSHAFT AND CAMSHAFT BEARING.................192

CYLINDER BLOCK................................................192

PISTON, PISTON RING AND PISTON PIN..............193

CONNECTING ROD...............................................193

CRANKSHAFT.......................................................194

AVAILABLE MAIN BEARING...................................194

AVAILABLE CONNECTING ROD BEARING.............195

MISCELLANEOUS COMPONENTS.........................195

CD20T

SERVICE DATA AND SPECIFICATIONS (SDS)........196

General Specifications .............................................196

Inspection and Adjustment ......................................196

COMPRESSION PRESSURE.................................196

CYLINDER HEAD..................................................196

CONTENTS(Cont'd)

EM-3

Page 1544 of 2267

CAMSHAFT AND CAMSHAFT BEARING.................196

VA LV E...................................................................197

VALVE LIFTER......................................................198

AVAILABLE SHIMS................................................198

VALVE CLEARANCE..............................................198

CYLINDER BLOCK................................................199

PISTON, PISTON RING AND PISTON PIN..............199

CONNECTING ROD...............................................200

CRANKSHAFT.......................................................200

AVAILABLE MAIN BEARINGS.................................200

TURBOCHARGER.................................................201

MISCELLANEOUS COMPONENTS.........................201

CONTENTS(Cont'd)

EM-4

Page 1545 of 2267

Parts Requiring Angular Tightening

ISome important engine parts are tightened using an angular-

tightening method rather than a torque setting method.

IIf these parts are tightened using a torque setting method,

dispersal of the tightening force (axial bolt force) will be two or

three times that of the dispersal produced by using the correct

angular-tightening method.

IAlthough the torque setting values (described in this manual)

are equivalent to those used when bolts and nuts are tightened

with an angular-tightening method, they should be used for

reference only.

ITo assure the satisfactory maintenance of the engine, bolts

and nuts must be tightened using an angular-tightening

method.

IBefore tightening the bolts and nuts, ensure that the thread

and seating surfaces are clean and then coated with engine oil.

IThe bolts and nuts which require the angular-tightening

method are as follows:

(1) Cylinder head bolts ..... SR, CD, QG

(2) Main bearing cap bolts ..... SR

(3) Connecting rod cap nuts ..... SR, QG

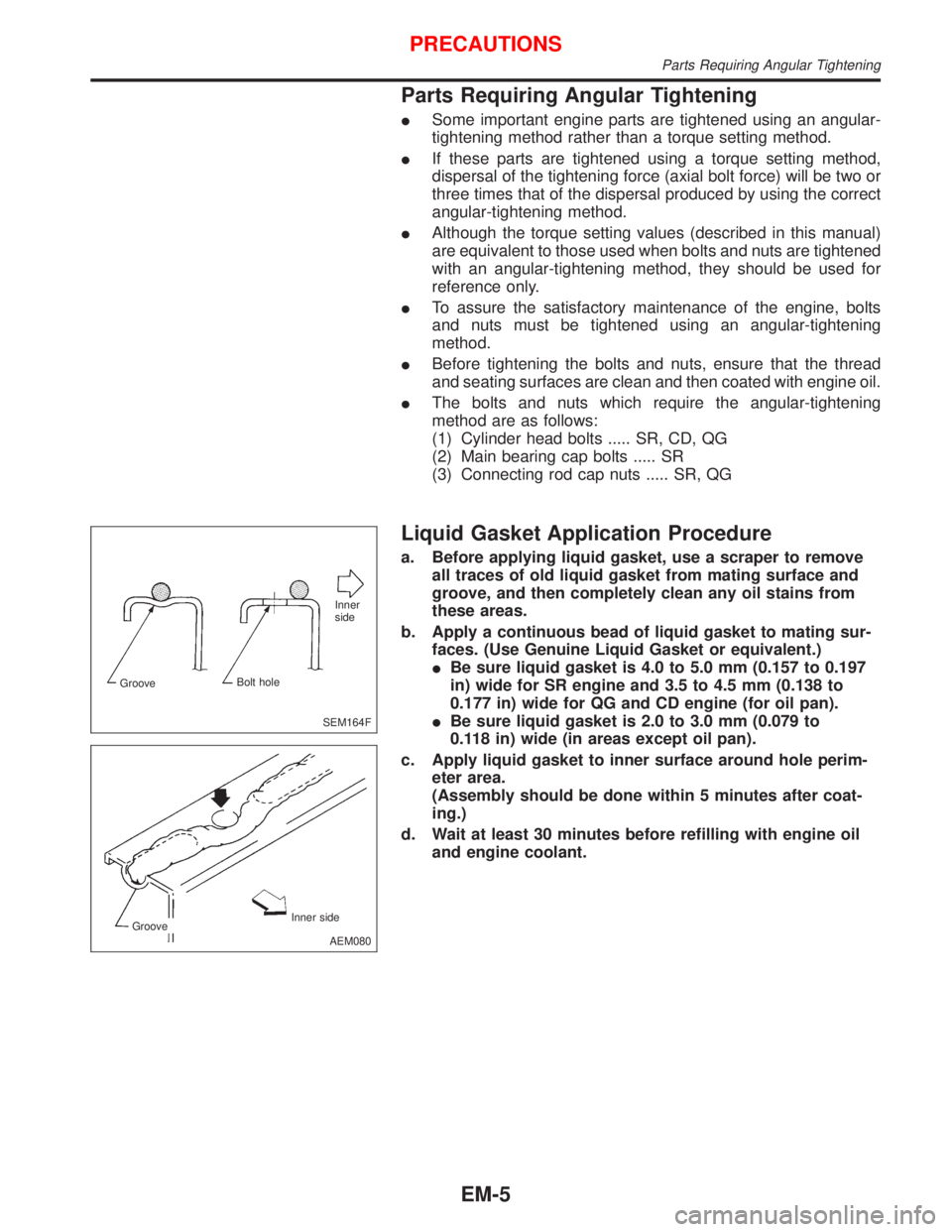

Liquid Gasket Application Procedure

a. Before applying liquid gasket, use a scraper to remove

all traces of old liquid gasket from mating surface and

groove, and then completely clean any oil stains from

these areas.

b. Apply a continuous bead of liquid gasket to mating sur-

faces. (Use Genuine Liquid Gasket or equivalent.)

IBe sure liquid gasket is 4.0 to 5.0 mm (0.157 to 0.197

in) wide for SR engine and 3.5 to 4.5 mm (0.138 to

0.177 in) wide for QG and CD engine (for oil pan).

IBe sure liquid gasket is 2.0 to 3.0 mm (0.079 to

0.118 in) wide (in areas except oil pan).

c. Apply liquid gasket to inner surface around hole perim-

eter area.

(Assembly should be done within 5 minutes after coat-

ing.)

d. Wait at least 30 minutes before refilling with engine oil

and engine coolant.

SEM164FInner

side

GrooveBolt hole

AEM080 Inner side

Groove

PRECAUTIONS

Parts Requiring Angular Tightening

EM-5

Page 1546 of 2267

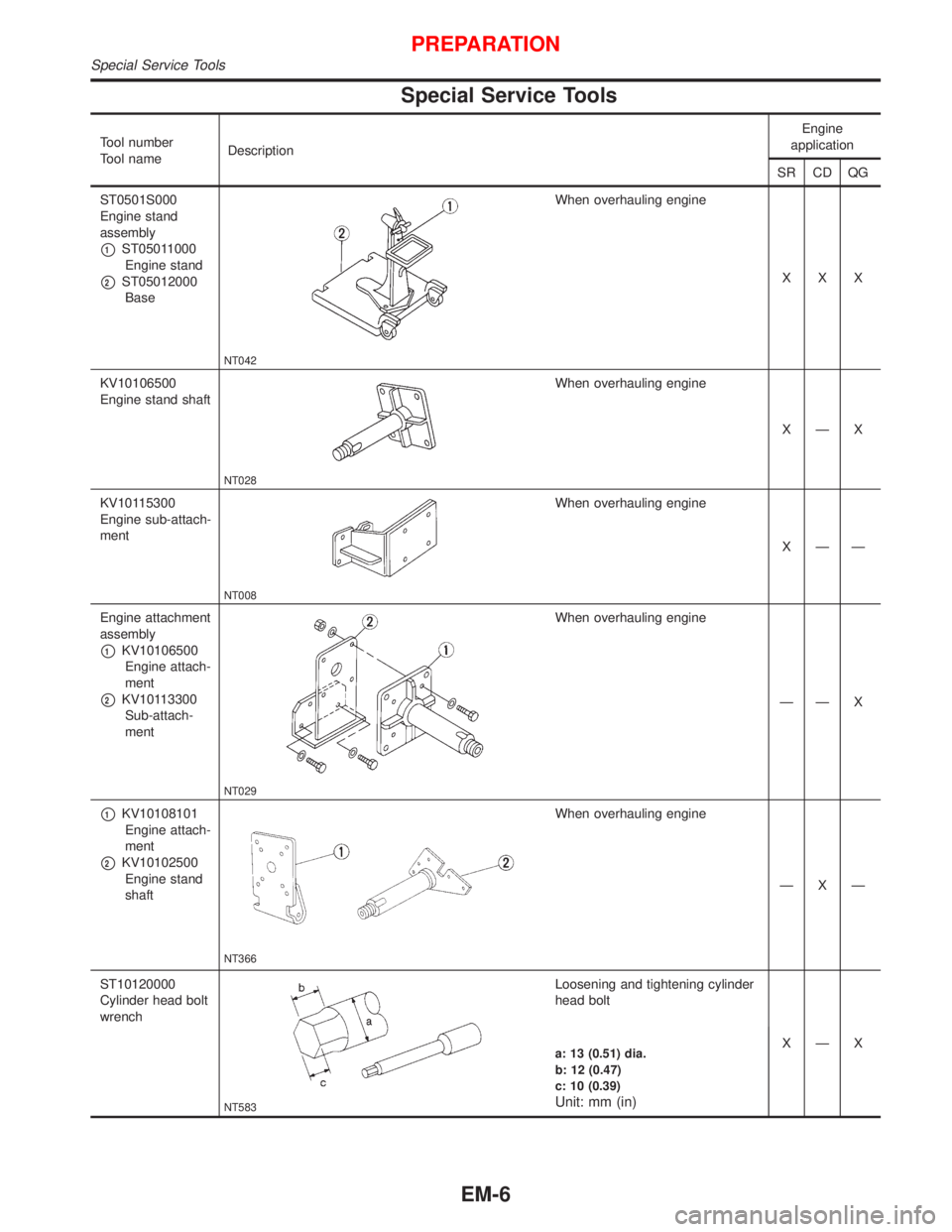

Special Service Tools

Tool number

Tool nameDescriptionEngine

application

SR CD QG

ST0501S000

Engine stand

assembly

p1ST05011000

Engine stand

p2ST05012000

Base

NT042

When overhauling engine

XXX

KV10106500

Engine stand shaft

NT028

When overhauling engine

XÐX

KV10115300

Engine sub-attach-

ment

NT008

When overhauling engine

XÐÐ

Engine attachment

assembly

p1KV10106500

Engine attach-

ment

p2KV10113300

Sub-attach-

ment

NT029

When overhauling engine

ÐÐ X

p1KV10108101

Engine attach-

ment

p2KV10102500

Engine stand

shaft

NT366

When overhauling engine

ÐXÐ

ST10120000

Cylinder head bolt

wrench

NT583

Loosening and tightening cylinder

head bolt

XÐX

a: 13 (0.51) dia.

b: 12 (0.47)

c: 10 (0.39)

Unit: mm (in)

PREPARATION

Special Service Tools

EM-6

Page 1547 of 2267

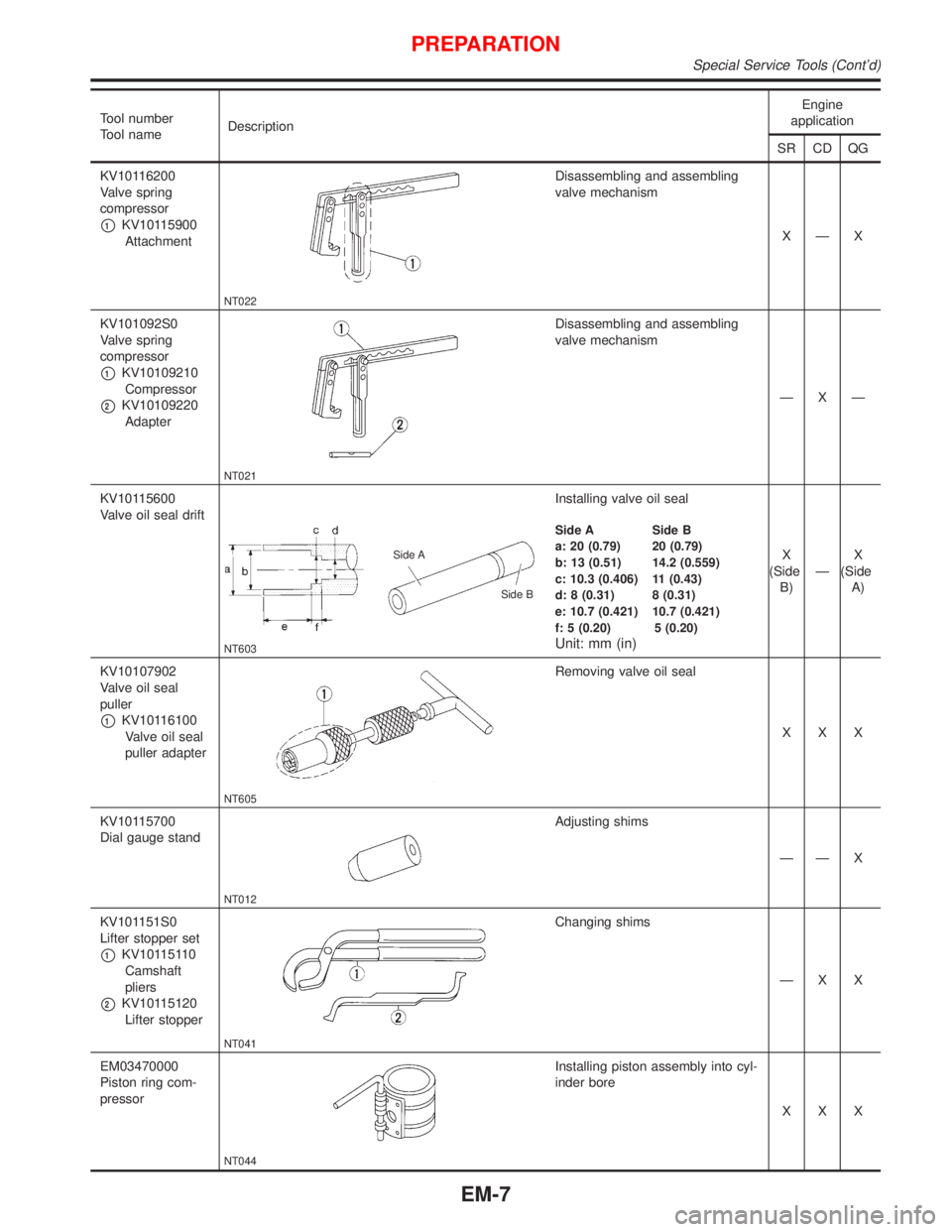

Tool number

Tool nameDescriptionEngine

application

SR CD QG

KV10116200

Valve spring

compressor

p1KV10115900

Attachment

NT022

Disassembling and assembling

valve mechanism

XÐX

KV101092S0

Valve spring

compressor

p1KV10109210

Compressor

p2KV10109220

Adapter

NT021

Disassembling and assembling

valve mechanism

ÐXÐ

KV10115600

Valve oil seal drift

NT603Side A

Side B

Installing valve oil seal

X

(Side

B)ÐX

(Side

A)

Side A Side B

a: 20 (0.79) 20 (0.79)

b: 13 (0.51) 14.2 (0.559)

c: 10.3 (0.406) 11 (0.43)

d: 8 (0.31) 8 (0.31)

e: 10.7 (0.421) 10.7 (0.421)

f: 5 (0.20) 5 (0.20)

Unit: mm (in)

KV10107902

Valve oil seal

puller

p1KV10116100

Valve oil seal

puller adapter

NT605

Removing valve oil seal

XXX

KV10115700

Dial gauge stand

NT012

Adjusting shims

ÐÐ X

KV101151S0

Lifter stopper set

p1KV10115110

Camshaft

pliers

p2KV10115120

Lifter stopper

NT041

Changing shims

ÐX X

EM03470000

Piston ring com-

pressor

NT044

Installing piston assembly into cyl-

inder bore

XXX

PREPARATION

Special Service Tools (Cont'd)

EM-7

Page 1548 of 2267

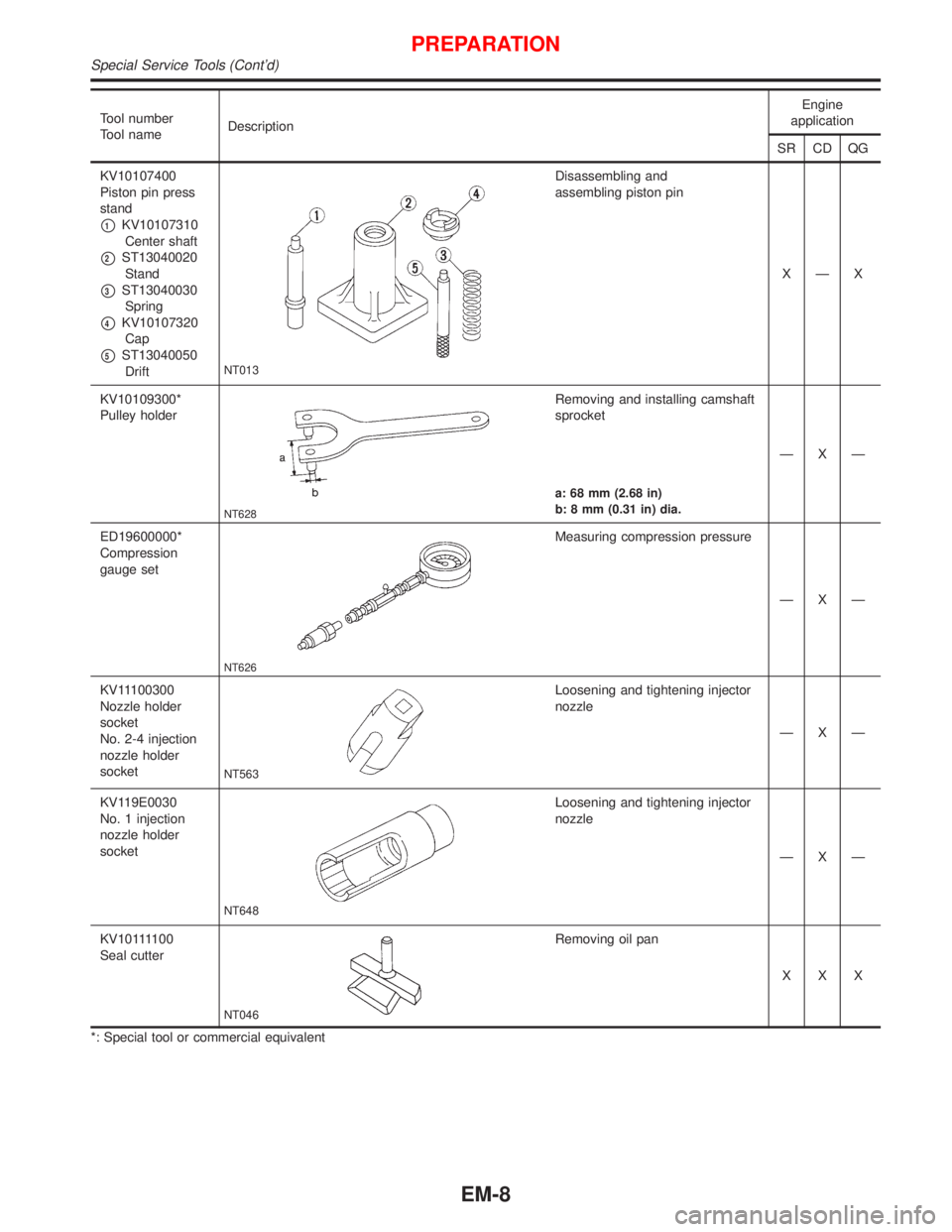

Tool number

Tool nameDescriptionEngine

application

SR CD QG

KV10107400

Piston pin press

stand

p1KV10107310

Center shaft

p2ST13040020

Stand

p3ST13040030

Spring

p4KV10107320

Cap

p5ST13040050

DriftNT013

Disassembling and

assembling piston pin

XÐX

KV10109300*

Pulley holder

NT628

Removing and installing camshaft

sprocket

ÐXÐ

a: 68 mm (2.68 in)

b: 8 mm (0.31 in) dia.

ED19600000*

Compression

gauge set

NT626

Measuring compression pressure

ÐXÐ

KV11100300

Nozzle holder

socket

No. 2-4 injection

nozzle holder

socket

NT563

Loosening and tightening injector

nozzle

ÐXÐ

KV119E0030

No. 1 injection

nozzle holder

socket

NT648

Loosening and tightening injector

nozzle

ÐXÐ

KV101111 0 0

Seal cutter

NT046

Removing oil pan

XXX

*: Special tool or commercial equivalent

PREPARATION

Special Service Tools (Cont'd)

EM-8

Page 1549 of 2267

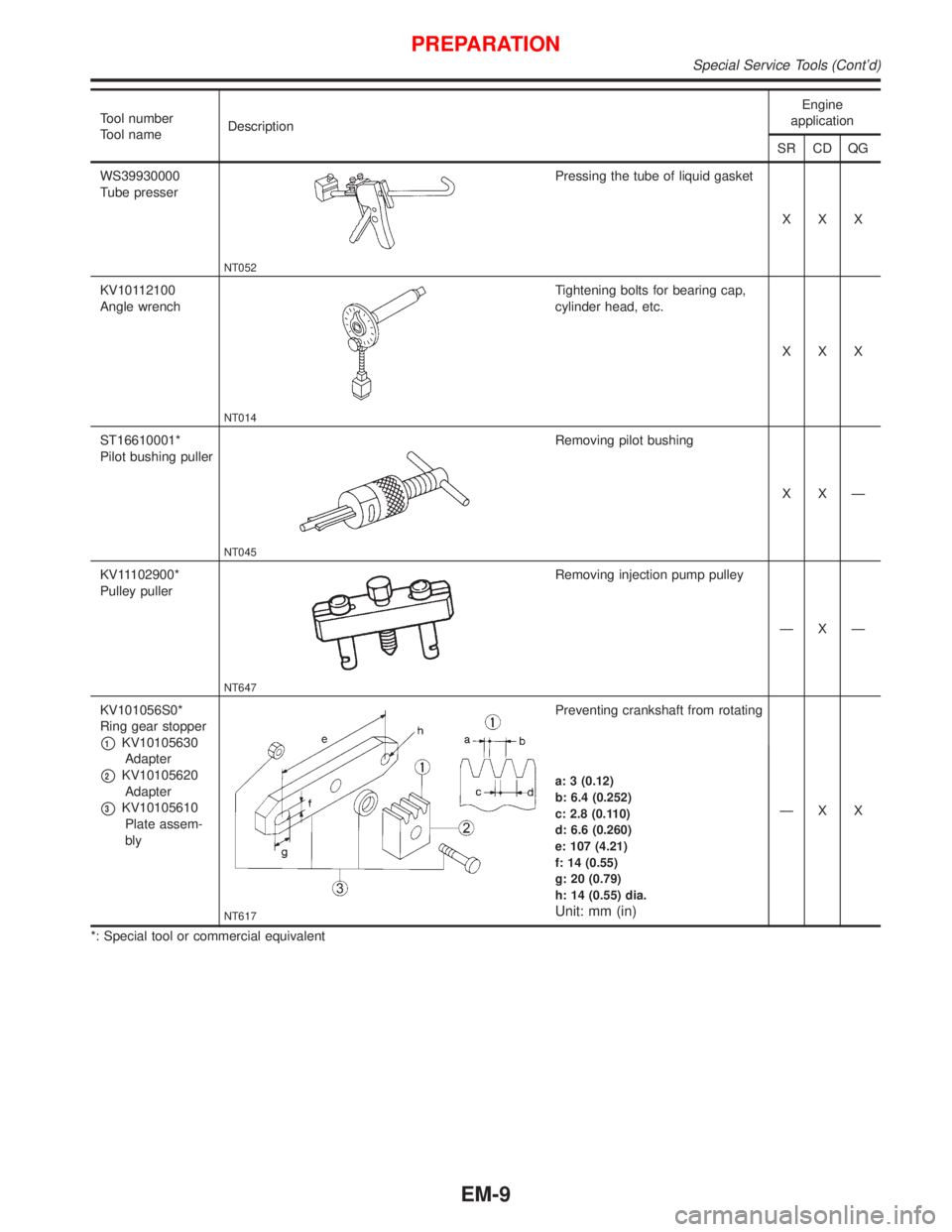

Tool number

Tool nameDescriptionEngine

application

SR CD QG

WS39930000

Tube presser

NT052

Pressing the tube of liquid gasket

XXX

KV10112100

Angle wrench

NT014

Tightening bolts for bearing cap,

cylinder head, etc.

XXX

ST16610001*

Pilot bushing puller

NT045

Removing pilot bushing

XXÐ

KV11102900*

Pulley puller

NT647

Removing injection pump pulley

ÐXÐ

KV101056S0*

Ring gear stopper

p1KV10105630

Adapter

p2KV10105620

Adapter

p3KV10105610

Plate assem-

bly

NT617

Preventing crankshaft from rotating

ÐX X

a: 3 (0.12)

b: 6.4 (0.252)

c: 2.8 (0.110)

d: 6.6 (0.260)

e: 107 (4.21)

f: 14 (0.55)

g: 20 (0.79)

h: 14 (0.55) dia.

Unit: mm (in)

*: Special tool or commercial equivalent

PREPARATION

Special Service Tools (Cont'd)

EM-9

Page 1550 of 2267

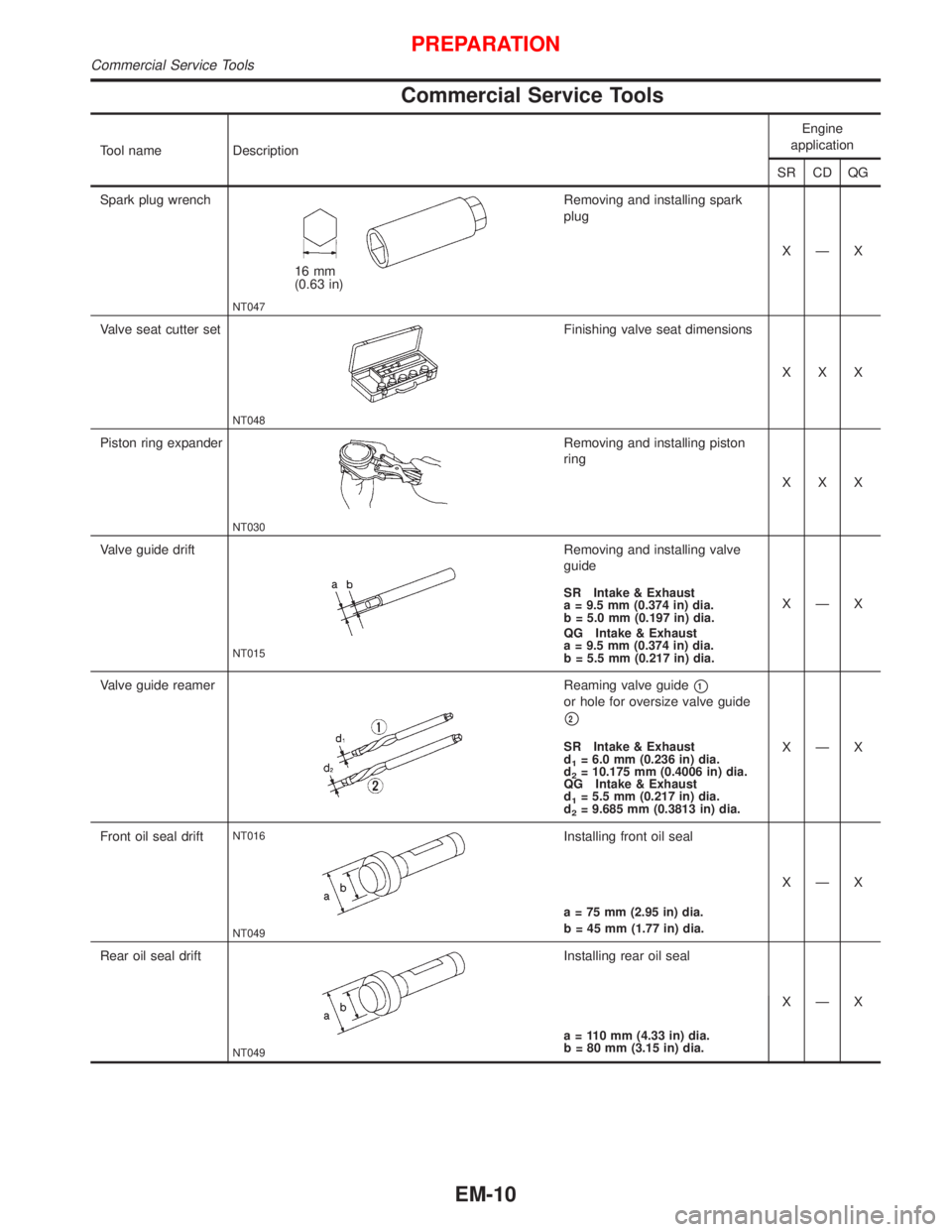

Commercial Service Tools

Tool name DescriptionEngine

application

SR CD QG

Spark plug wrench

NT047

16 mm

(0.63 in)Removing and installing spark

plug

XÐX

Valve seat cutter set

NT048

Finishing valve seat dimensions

XXX

Piston ring expander

NT030

Removing and installing piston

ring

XXX

Valve guide drift

NT015

Removing and installing valve

guide

XÐX

SR Intake & Exhaust

a = 9.5 mm (0.374 in) dia.

b = 5.0 mm (0.197 in) dia.

QG Intake & Exhaust

a = 9.5 mm (0.374 in) dia.

b = 5.5 mm (0.217 in) dia.

Valve guide reamer

NT016

Reaming valve guidep1

or hole for oversize valve guide

p2

XÐXSR Intake & Exhaust

d1= 6.0 mm (0.236 in) dia.

d2= 10.175 mm (0.4006 in) dia.

QG Intake & Exhaust

d

1= 5.5 mm (0.217 in) dia.

d2= 9.685 mm (0.3813 in) dia.

Front oil seal drift

NT049

Installing front oil seal

XÐX

a = 75 mm (2.95 in) dia.

b = 45 mm (1.77 in) dia.

Rear oil seal drift

NT049

Installing rear oil seal

XÐX

a = 110 mm (4.33 in) dia.

b = 80 mm (3.15 in) dia.

PREPARATION

Commercial Service Tools

EM-10