NISSAN PRIMERA 1999 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 1601 of 2267

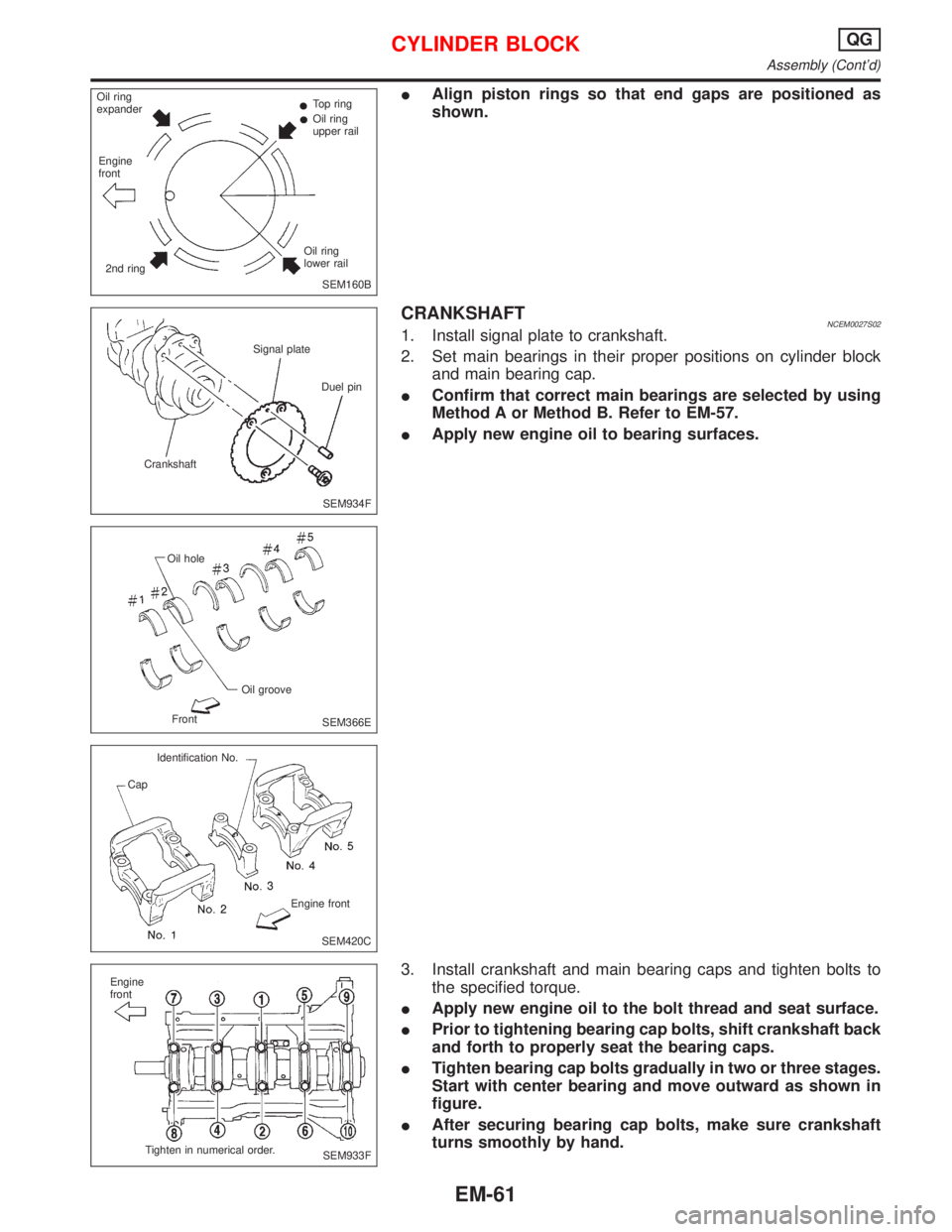

IAlign piston rings so that end gaps are positioned as

shown.

CRANKSHAFTNCEM0027S021. Install signal plate to crankshaft.

2. Set main bearings in their proper positions on cylinder block

and main bearing cap.

IConfirm that correct main bearings are selected by using

Method A or Method B. Refer to EM-57.

IApply new engine oil to bearing surfaces.

3. Install crankshaft and main bearing caps and tighten bolts to

the specified torque.

IApply new engine oil to the bolt thread and seat surface.

IPrior to tightening bearing cap bolts, shift crankshaft back

and forth to properly seat the bearing caps.

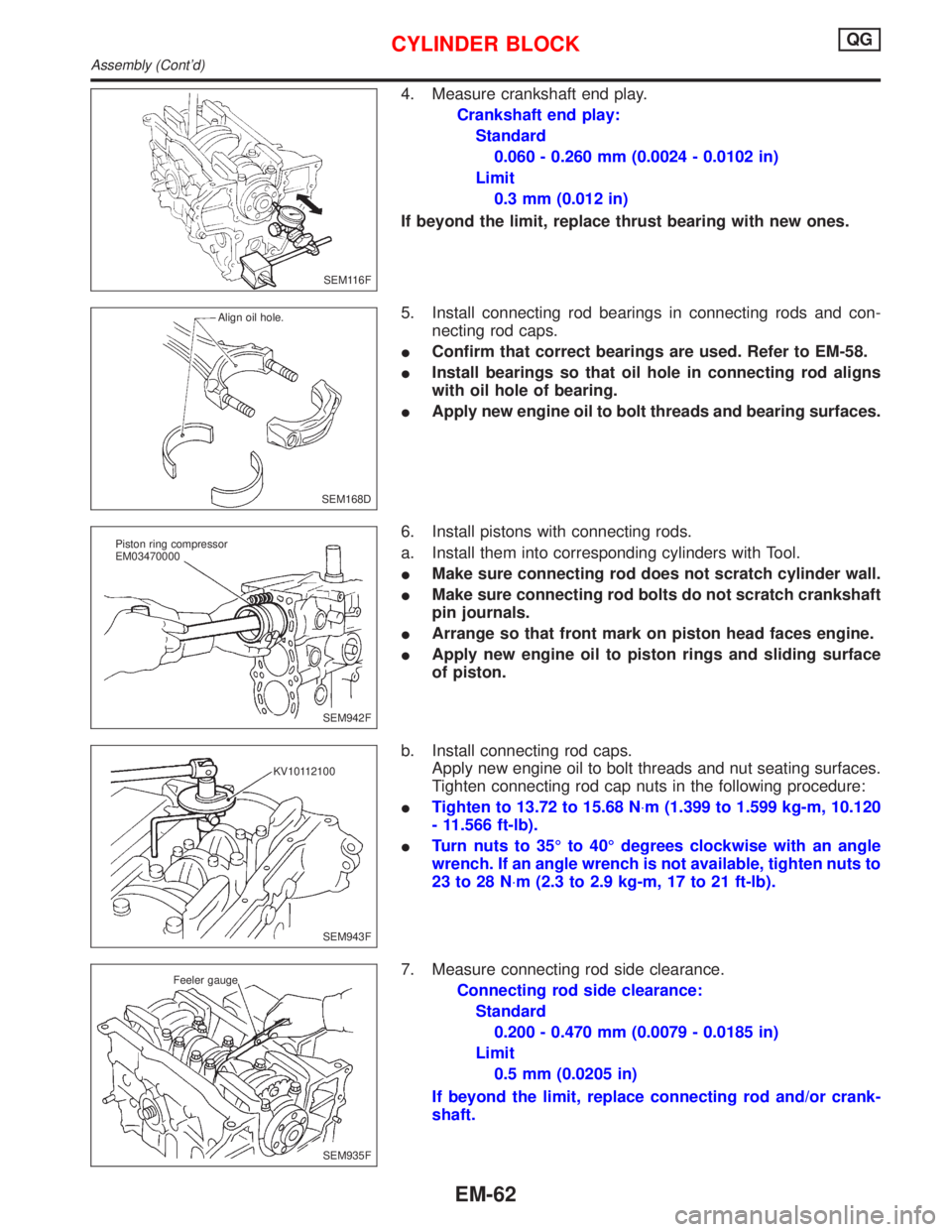

ITighten bearing cap bolts gradually in two or three stages.

Start with center bearing and move outward as shown in

figure.

IAfter securing bearing cap bolts, make sure crankshaft

turns smoothly by hand.

SEM160B Oil ring

expanderTop ring

Oil ring

upper rail

Oil ring

lower rail

2nd ring Engine

front

SEM934F CrankshaftSignal plate

Duel pin

SEM366E Oil hole

Oil groove

Front

SEM420C Identification No.

Cap

Engine front

SEM933F Engine

front

Tighten in numerical order.

CYLINDER BLOCKQG

Assembly (Cont'd)

EM-61

Page 1602 of 2267

4. Measure crankshaft end play.

Crankshaft end play:

Standard

0.060 - 0.260 mm (0.0024 - 0.0102 in)

Limit

0.3 mm (0.012 in)

If beyond the limit, replace thrust bearing with new ones.

5. Install connecting rod bearings in connecting rods and con-

necting rod caps.

IConfirm that correct bearings are used. Refer to EM-58.

IInstall bearings so that oil hole in connecting rod aligns

with oil hole of bearing.

IApply new engine oil to bolt threads and bearing surfaces.

6. Install pistons with connecting rods.

a. Install them into corresponding cylinders with Tool.

IMake sure connecting rod does not scratch cylinder wall.

IMake sure connecting rod bolts do not scratch crankshaft

pin journals.

IArrange so that front mark on piston head faces engine.

IApply new engine oil to piston rings and sliding surface

of piston.

b. Install connecting rod caps.

Apply new engine oil to bolt threads and nut seating surfaces.

Tighten connecting rod cap nuts in the following procedure:

ITighten to 13.72 to 15.68 N×m (1.399 to 1.599 kg-m, 10.120

- 11.566 ft-lb).

ITurn nuts to 35É to 40É degrees clockwise with an angle

wrench. If an angle wrench is not available, tighten nuts to

23 to 28 N×m (2.3 to 2.9 kg-m, 17 to 21 ft-lb).

7. Measure connecting rod side clearance.

Connecting rod side clearance:

Standard

0.200 - 0.470 mm (0.0079 - 0.0185 in)

Limit

0.5 mm (0.0205 in)

If beyond the limit, replace connecting rod and/or crank-

shaft.

SEM116F

SEM168D Align oil hole.

SEM942F Piston ring compressor

EM03470000

SEM943F KV10112100

SEM935F Feeler gauge

CYLINDER BLOCKQG

Assembly (Cont'd)

EM-62

Page 1603 of 2267

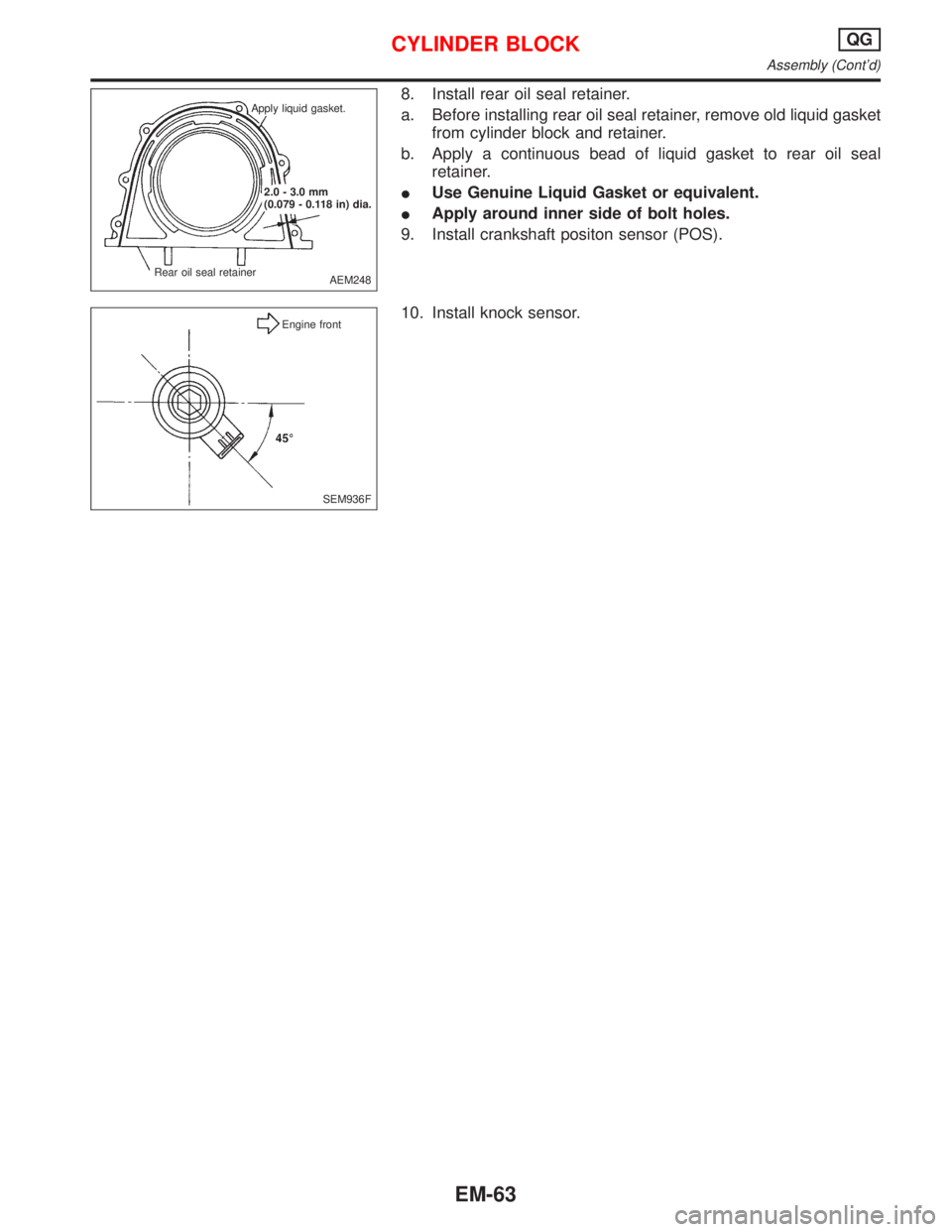

8. Install rear oil seal retainer.

a. Before installing rear oil seal retainer, remove old liquid gasket

from cylinder block and retainer.

b. Apply a continuous bead of liquid gasket to rear oil seal

retainer.

IUse Genuine Liquid Gasket or equivalent.

IApply around inner side of bolt holes.

9. Install crankshaft positon sensor (POS).

10. Install knock sensor.

AEM248 Apply liquid gasket.

.2.0 - 3.0 mm

(0.079 - 0.118 in) dia.

Rear oil seal retainer

SEM936F Engine front

CYLINDER BLOCKQG

Assembly (Cont'd)

EM-63

Page 1604 of 2267

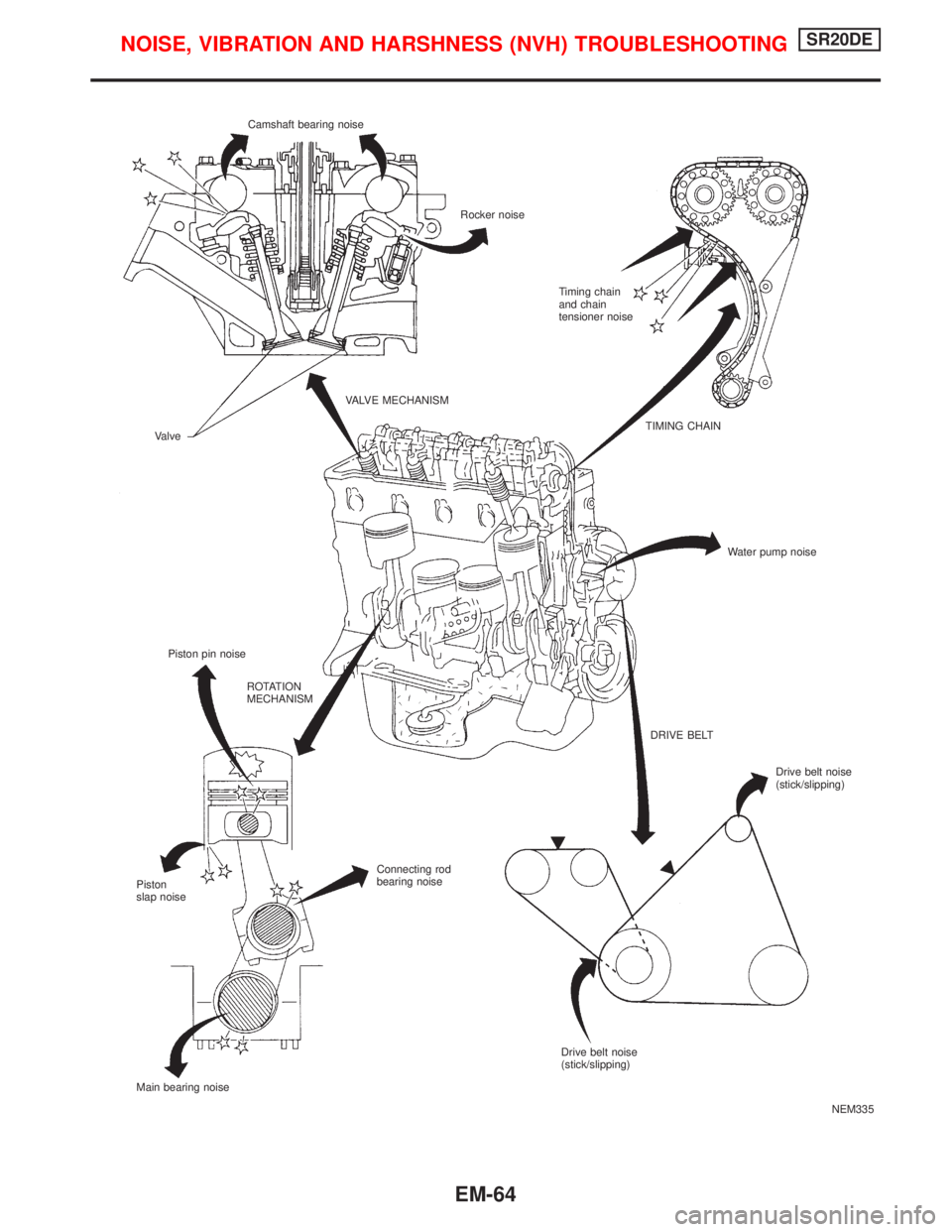

NEM335 Camshaft bearing noise

Rocker noise

Timing chain

and chain

tensioner noise

VALVE MECHANISM

Valve

Piston pin noiseTIMING CHAIN

Water pump noise

ROTATION

MECHANISM

DRIVE BELT

Connecting rod

bearing noise

Piston

slap noise

Main bearing noiseDrive belt noise

(stick/slipping)

Drive belt noise

(stick/slipping)

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGSR20DE

EM-64

Page 1605 of 2267

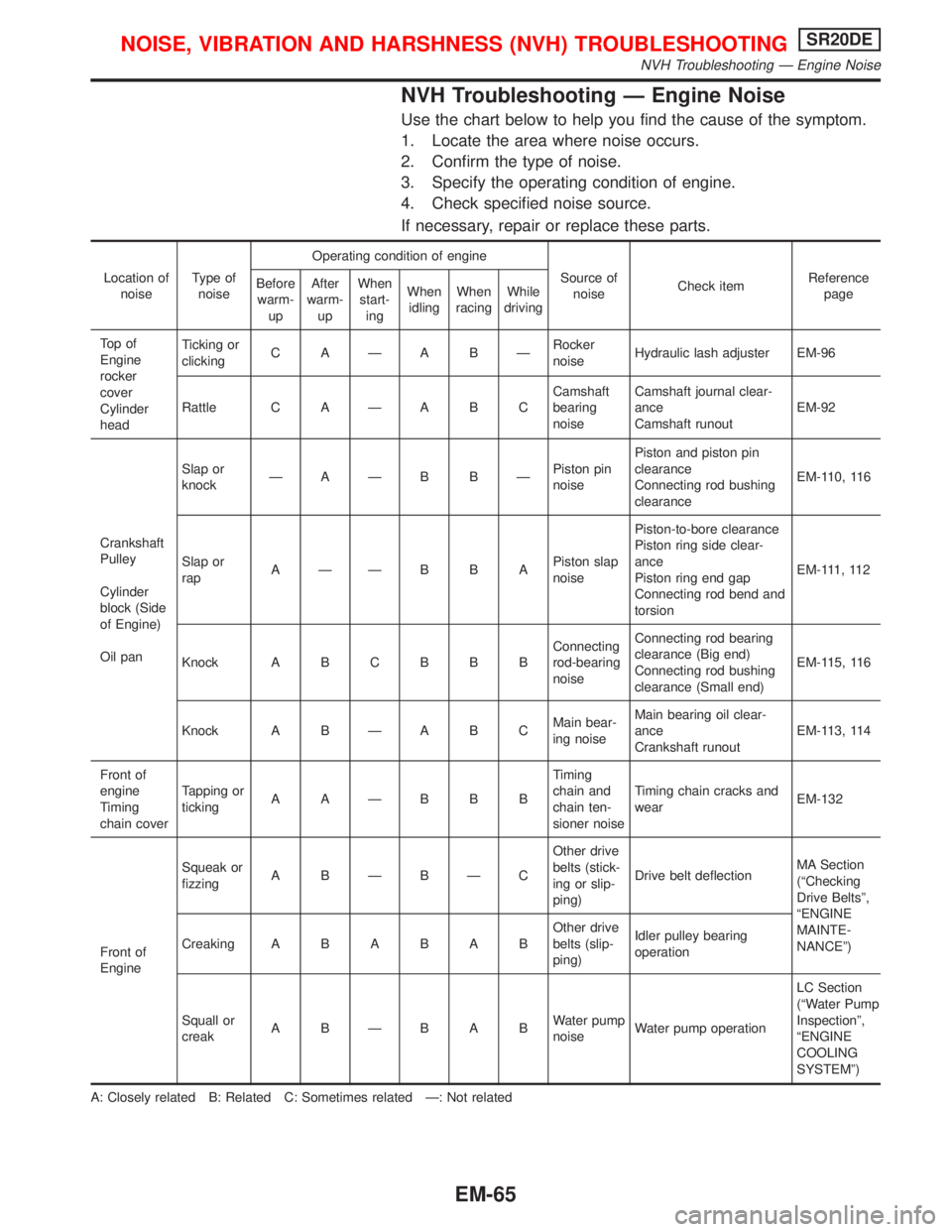

NVH Troubleshooting Ð Engine Noise

Use the chart below to help you find the cause of the symptom.

1. Locate the area where noise occurs.

2. Confirm the type of noise.

3. Specify the operating condition of engine.

4. Check specified noise source.

If necessary, repair or replace these parts.

Location of

noiseType of

noiseOperating condition of engine

Source of

noiseCheck itemReference

page Before

warm-

upAfter

warm-

upWhen

start-

ingWhen

idlingWhen

racingWhile

driving

To p o f

Engine

rocker

cover

Cylinder

headTicking or

clickingC AÐA BÐRocker

noiseHydraulic lash adjuster EM-96

Rattle C A Ð A B CCamshaft

bearing

noiseCamshaft journal clear-

ance

Camshaft runoutEM-92

Crankshaft

Pulley

Cylinder

block (Side

of Engine)

Oil panSlap or

knockÐAÐB BÐPiston pin

noisePiston and piston pin

clearance

Connecting rod bushing

clearanceEM-110, 116

Slap or

rapAÐÐB B APiston slap

noisePiston-to-bore clearance

Piston ring side clear-

ance

Piston ring end gap

Connecting rod bend and

torsionEM-111, 112

Knock A B C B B BConnecting

rod-bearing

noiseConnecting rod bearing

clearance (Big end)

Connecting rod bushing

clearance (Small end)EM-115, 116

Knock A B Ð A B CMain bear-

ing noiseMain bearing oil clear-

ance

Crankshaft runoutEM-113, 114

Front of

engine

Timing

chain coverTapping or

tickingAAÐBBBTiming

chain and

chain ten-

sioner noiseTiming chain cracks and

wearEM-132

Front of

EngineSqueak or

fizzingA BÐBÐCOther drive

belts (stick-

ing or slip-

ping)Drive belt deflectionMA Section

(ªChecking

Drive Beltsº,

ªENGINE

MAINTE-

NANCEº) CreakingABABABOther drive

belts (slip-

ping)Idler pulley bearing

operation

Squall or

creakABÐBABWater pump

noiseWater pump operationLC Section

(ªWater Pump

Inspectionº,

ªENGINE

COOLING

SYSTEMº)

A: Closely related B: Related C: Sometimes related Ð: Not related

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGSR20DE

NVH Troubleshooting Ð Engine Noise

EM-65

Page 1606 of 2267

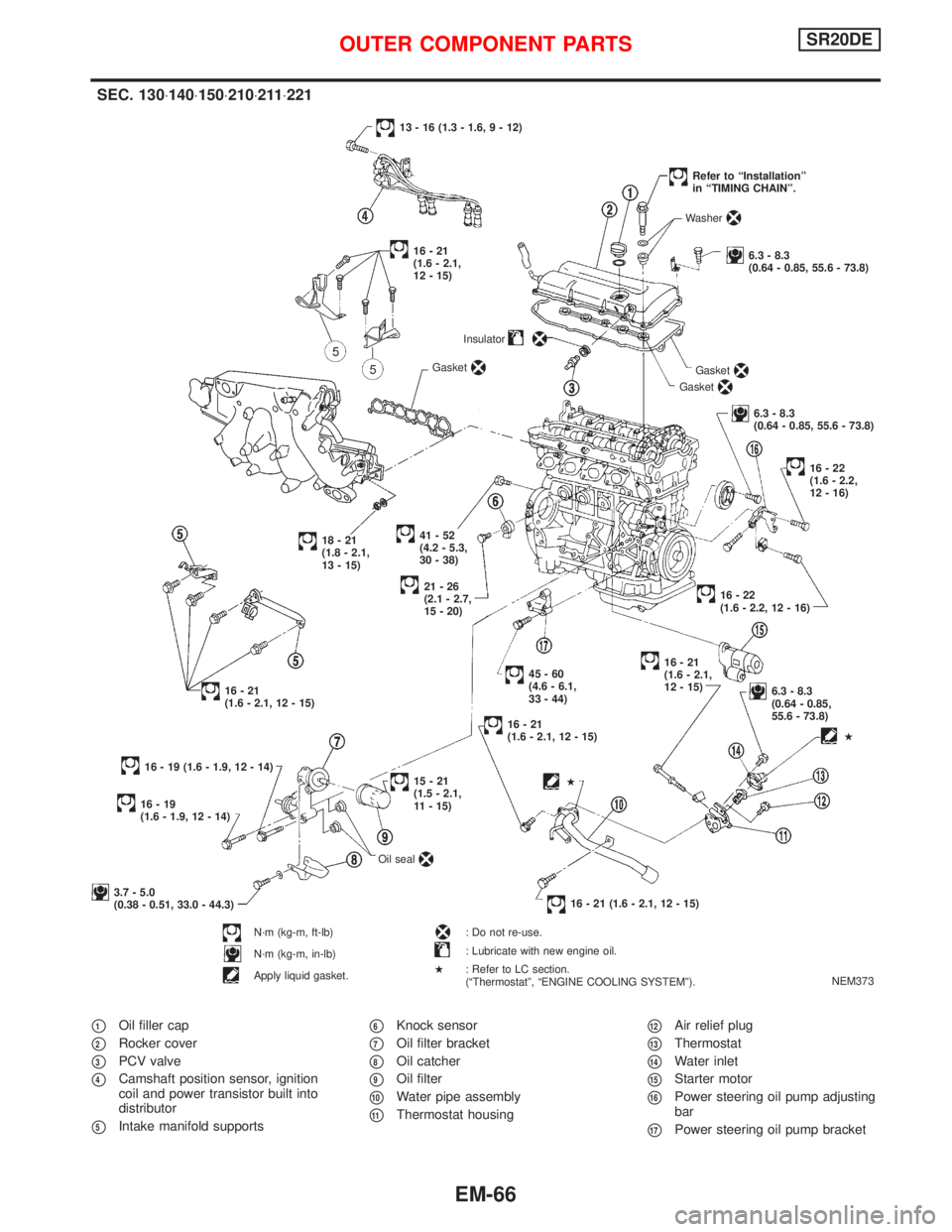

p1Oil filler cap

p2Rocker cover

p3PCV valve

p4Camshaft position sensor, ignition

coil and power transistor built into

distributor

p5Intake manifold supports

p6Knock sensor

p7Oil filter bracket

p8Oil catcher

p9Oil filter

p10Water pipe assembly

p11Thermostat housing

p12Air relief plug

p13Thermostat

p14Water inlet

p15Starter motor

p16Power steering oil pump adjusting

bar

p17Power steering oil pump bracket

NEM373

SEC. 130×140×150×210×211×221

.41-52

(4.2 - 5.3,

30 - 38)Insulator

21-26

(2.1 - 2.7,

15 - 20)

18-21

(1.8 - 2.1,

13 - 15)

16-21

(1.6 - 2.1, 12 - 15)

45-60

(4.6 - 6.1,

33 - 44)

16-21

(1.6 - 2.1, 12 - 15)

16 - 19 (1.6 - 1.9, 12 - 14)Gasket

13 - 16 (1.3 - 1.6, 9 - 12)

Gasket

Gasket

Washer

6.3 - 8.3

(0.64 - 0.85, 55.6 - 73.8)

Refer to ªInstallationº

in ªTIMING CHAINº.

6.3 - 8.3

(0.64 - 0.85, 55.6 - 73.8)

16-22

(1.6 - 2.2,

12 - 16)

.16-22

(1.6 - 2.2, 12 - 16)

16-21

(1.6 - 2.1,

12 - 15)

6.3 - 8.3

(0.64 - 0.85,

55.6 - 73.8)

16 - 21 (1.6 - 2.1, 12 - 15)

16-19

(1.6 - 1.9, 12 - 14)

15-21

(1.5 - 2.1,

11 - 15)

3.7 - 5.0

(0.38 - 0.51, 33.0 - 44.3)

N´m (kg-m, ft-lb)

N´m (kg-m, in-lb)

Apply liquid gasket.Oil seal

: Do not re-use.

: Lubricate with new engine oil.

: Refer to LC section.

(ªThermostatº, ªENGINE COOLING SYSTEMº).

H

H

H

16-21

(1.6 - 2.1,

12 - 15)

OUTER COMPONENT PARTSSR20DE

EM-66

Page 1607 of 2267

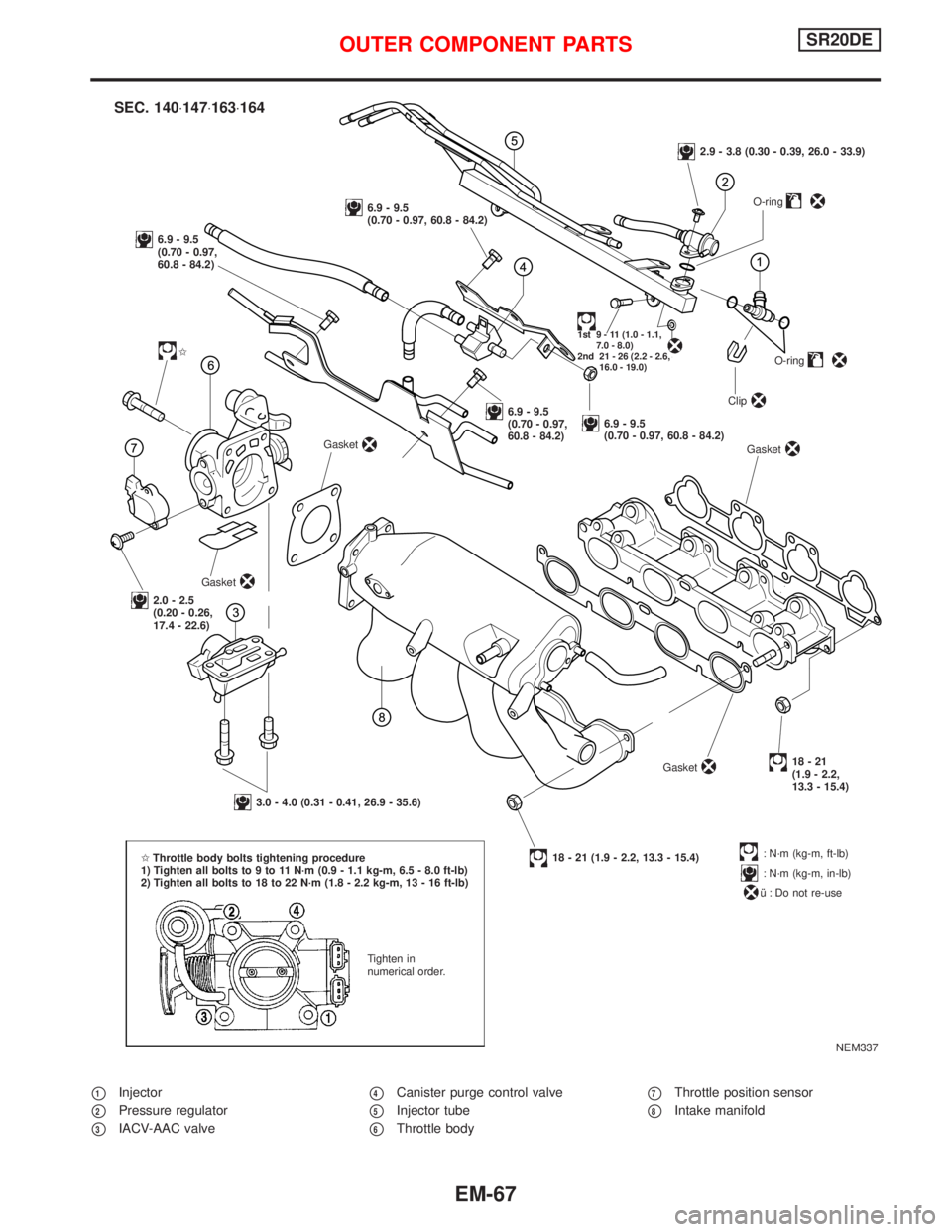

p1Injector

p2Pressure regulator

p3IACV-AAC valve

p4Canister purge control valve

p5Injector tube

p6Throttle body

p7Throttle position sensor

p8Intake manifold

NEM337

.

SEC. 140×147×163×164

6.9 - 9.5

(0.70 - 0.97,

60.8 - 84.2)

6.9 - 9.5

(0.70 - 0.97, 60.8 - 84.2)

2.9 - 3.8 (0.30 - 0.39, 26.0 - 33.9)

O-ring

1st 9 - 11 (1.0 - 1.1,

7.0 - 8.0)

2nd 21 - 26 (2.2 - 2.6,

16.0 - 19.0)

I

Gasket

6.9 - 9.5

(0.70 - 0.97,

60.8 - 84.2)6.9 - 9.5

(0.70 - 0.97, 60.8 - 84.2)O-ring

Clip

Gasket

2.0 - 2.5

(0.20 - 0.26,

17.4 - 22.6)Gasket

3.0 - 4.0 (0.31 - 0.41, 26.9 - 35.6)

18 - 21 (1.9 - 2.2, 13.3 - 15.4)Gasket

18-21

(1.9 - 2.2,

13.3 - 15.4)

: N´m (kg-m, ft-lb)

: N´m (kg-m, in-lb)

î : Do not re-use IThrottle body bolts tightening procedure

1) Tighten all bolts to 9 to 11 N´m (0.9 - 1.1 kg-m, 6.5 - 8.0 ft-lb)

2) Tighten all bolts to 18 to 22 N´m (1.8 - 2.2 kg-m, 13 - 16 ft-lb)

Tighten in

numerical order.

OUTER COMPONENT PARTSSR20DE

EM-67

Page 1608 of 2267

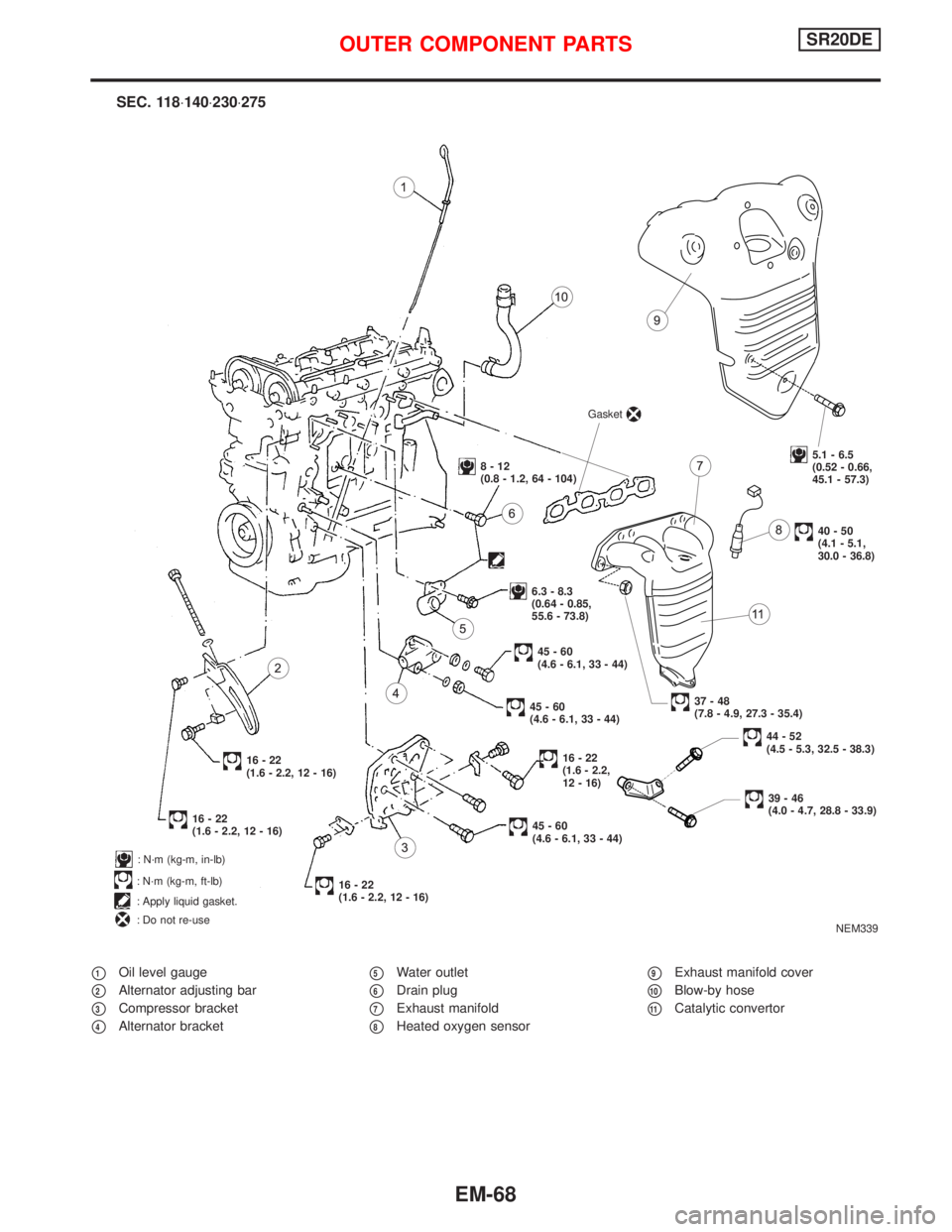

p1Oil level gauge

p2Alternator adjusting bar

p3Compressor bracket

p4Alternator bracket

p5Water outlet

p6Drain plug

p7Exhaust manifold

p8Heated oxygen sensor

p9Exhaust manifold cover

p10Blow-by hose

p11Catalytic convertor

NEM339

: N´m (kg-m, in-lb)

: N´m (kg-m, ft-lb)

: Apply liquid gasket.

: Do not re-use

SEC. 118×140×230×275

Gasket

5.1 - 6.5

(0.52 - 0.66,

45.1 - 57.3)

40-50

(4.1 - 5.1,

30.0 - 36.8)

8-12

(0.8 - 1.2, 64 - 104)

6.3 - 8.3

(0.64 - 0.85,

55.6 - 73.8)

37-48

(7.8 - 4.9, 27.3 - 35.4)

45-60

(4.6 - 6.1, 33 - 44)

45-60

(4.6 - 6.1, 33 - 44)

16-22

(1.6 - 2.2, 12 - 16)

16-22

(1.6 - 2.2, 12 - 16)

16-22

(1.6 - 2.2,

12 - 16)

45-60

(4.6 - 6.1, 33 - 44)

16-22

(1.6 - 2.2, 12 - 16)

44-52

(4.5 - 5.3, 32.5 - 38.3)

39-46

(4.0 - 4.7, 28.8 - 33.9)

OUTER COMPONENT PARTSSR20DE

EM-68

Page 1609 of 2267

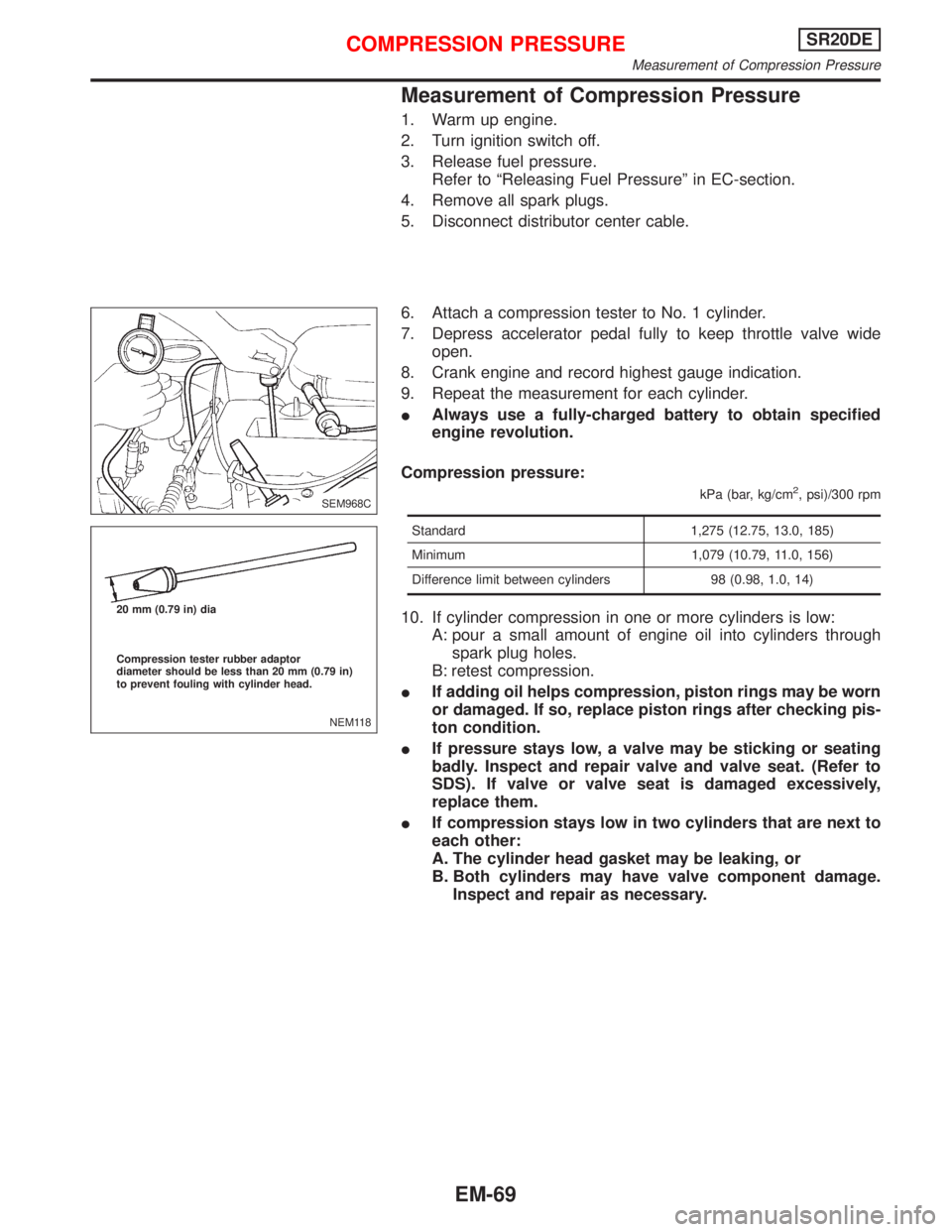

Measurement of Compression Pressure

1. Warm up engine.

2. Turn ignition switch off.

3. Release fuel pressure.

Refer to ªReleasing Fuel Pressureº in EC-section.

4. Remove all spark plugs.

5. Disconnect distributor center cable.

6. Attach a compression tester to No. 1 cylinder.

7. Depress accelerator pedal fully to keep throttle valve wide

open.

8. Crank engine and record highest gauge indication.

9. Repeat the measurement for each cylinder.

IAlways use a fully-charged battery to obtain specified

engine revolution.

Compression pressure:

kPa (bar, kg/cm2, psi)/300 rpm

Standard 1,275 (12.75, 13.0, 185)

Minimum 1,079 (10.79, 11.0, 156)

Difference limit between cylinders 98 (0.98, 1.0, 14)

10. If cylinder compression in one or more cylinders is low:

A: pour a small amount of engine oil into cylinders through

spark plug holes.

B: retest compression.

IIf adding oil helps compression, piston rings may be worn

or damaged. If so, replace piston rings after checking pis-

ton condition.

IIf pressure stays low, a valve may be sticking or seating

badly. Inspect and repair valve and valve seat. (Refer to

SDS). If valve or valve seat is damaged excessively,

replace them.

IIf compression stays low in two cylinders that are next to

each other:

A. The cylinder head gasket may be leaking, or

B. Both cylinders may have valve component damage.

Inspect and repair as necessary.

SEM968C

NEM118 20 mm (0.79 in) dia

Compression tester rubber adaptor

diameter should be less than 20 mm (0.79 in)

to prevent fouling with cylinder head.

COMPRESSION PRESSURESR20DE

Measurement of Compression Pressure

EM-69

Page 1610 of 2267

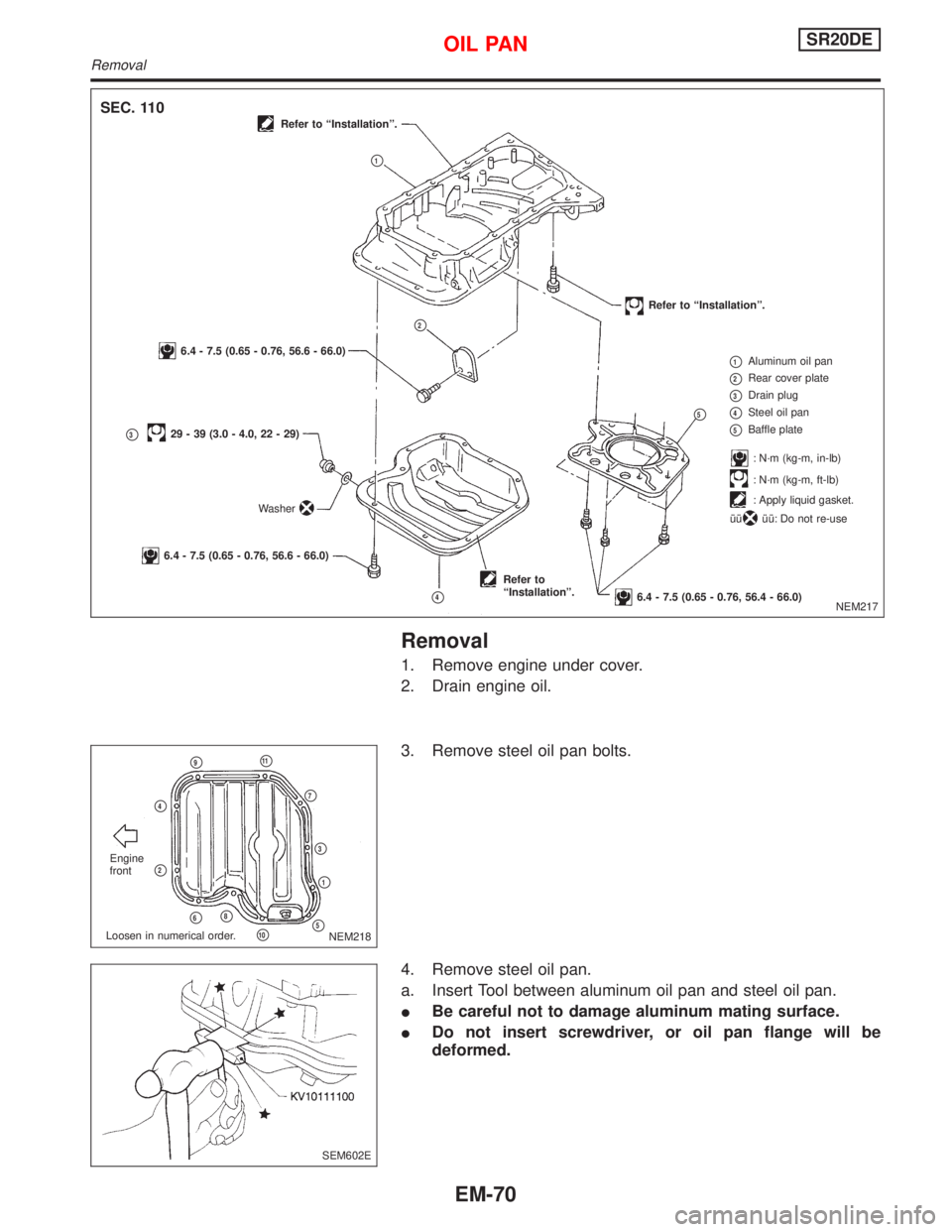

Removal

1. Remove engine under cover.

2. Drain engine oil.

3. Remove steel oil pan bolts.

4. Remove steel oil pan.

a. Insert Tool between aluminum oil pan and steel oil pan.

IBe careful not to damage aluminum mating surface.

IDo not insert screwdriver, or oil pan flange will be

deformed.

NEM217

SEC. 110Refer to ªInstallationº.

Refer to ªInstallationº.

6.4 - 7.5 (0.65 - 0.76, 56.6 - 66.0)

p329 - 39 (3.0 - 4.0, 22 - 29)

6.4 - 7.5 (0.65 - 0.76, 56.6 - 66.0)

Refer to

ªInstallationº.

6.4 - 7.5 (0.65 - 0.76, 56.4 - 66.0)

p1Aluminum oil pan

p2Rear cover plate

p3Drain plug

p4Steel oil pan

p5Baffle plate

: N´m (kg-m, in-lb)

: N´m (kg-m, ft-lb)

: Apply liquid gasket.

îî

îî: Do not re-use

p1

p2

Washer

p4

p5

NEM218 Engine

front

p9p11

p7

p3

p1

p5p10

p8p6

p2

p4

Loosen in numerical order.

SEM602E

OIL PANSR20DE

Removal

EM-70