NISSAN PRIMERA 1999 Electronic Repair Manual

PRIMERA 1999

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57377/w960_57377-0.png

NISSAN PRIMERA 1999 Electronic Repair Manual

Trending: suspension, airbag, engine overheat, adding oil, change time, service schedule, fuse box

Page 1611 of 2267

b. Slide Tool by tapping on the side of the Tool with a hammer.

c. Remove steel oil pan.

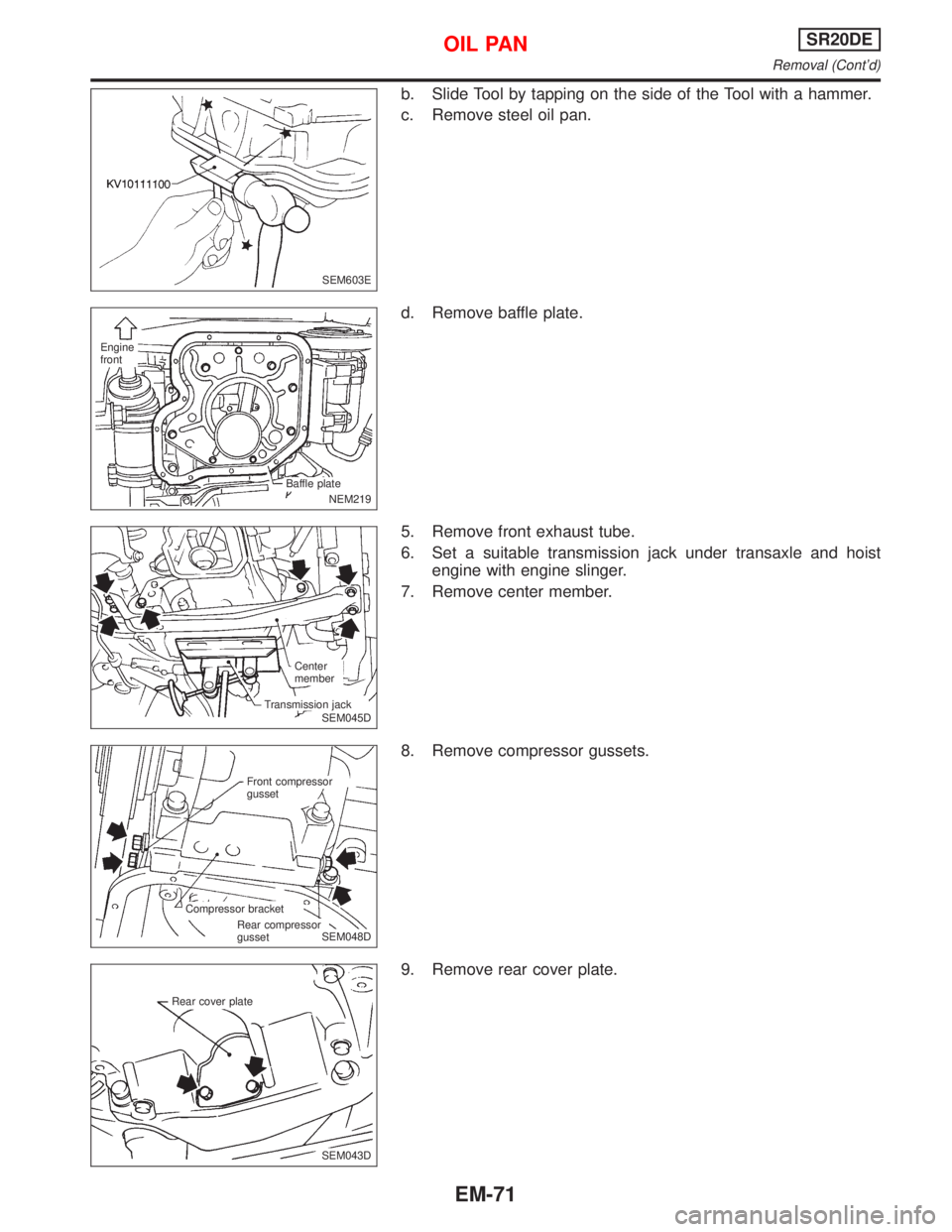

d. Remove baffle plate.

5. Remove front exhaust tube.

6. Set a suitable transmission jack under transaxle and hoist

engine with engine slinger.

7. Remove center member.

8. Remove compressor gussets.

9. Remove rear cover plate.

SEM603E

NEM219

.Engine

front

.Baffle plate

SEM045D Center

member

Transmission jack

.SEM048D Front compressor

gusset

Compressor bracket

Rear compressor

gusset

SEM043D Rear cover plate

OIL PANSR20DE

Removal (Cont'd)

EM-71

Page 1612 of 2267

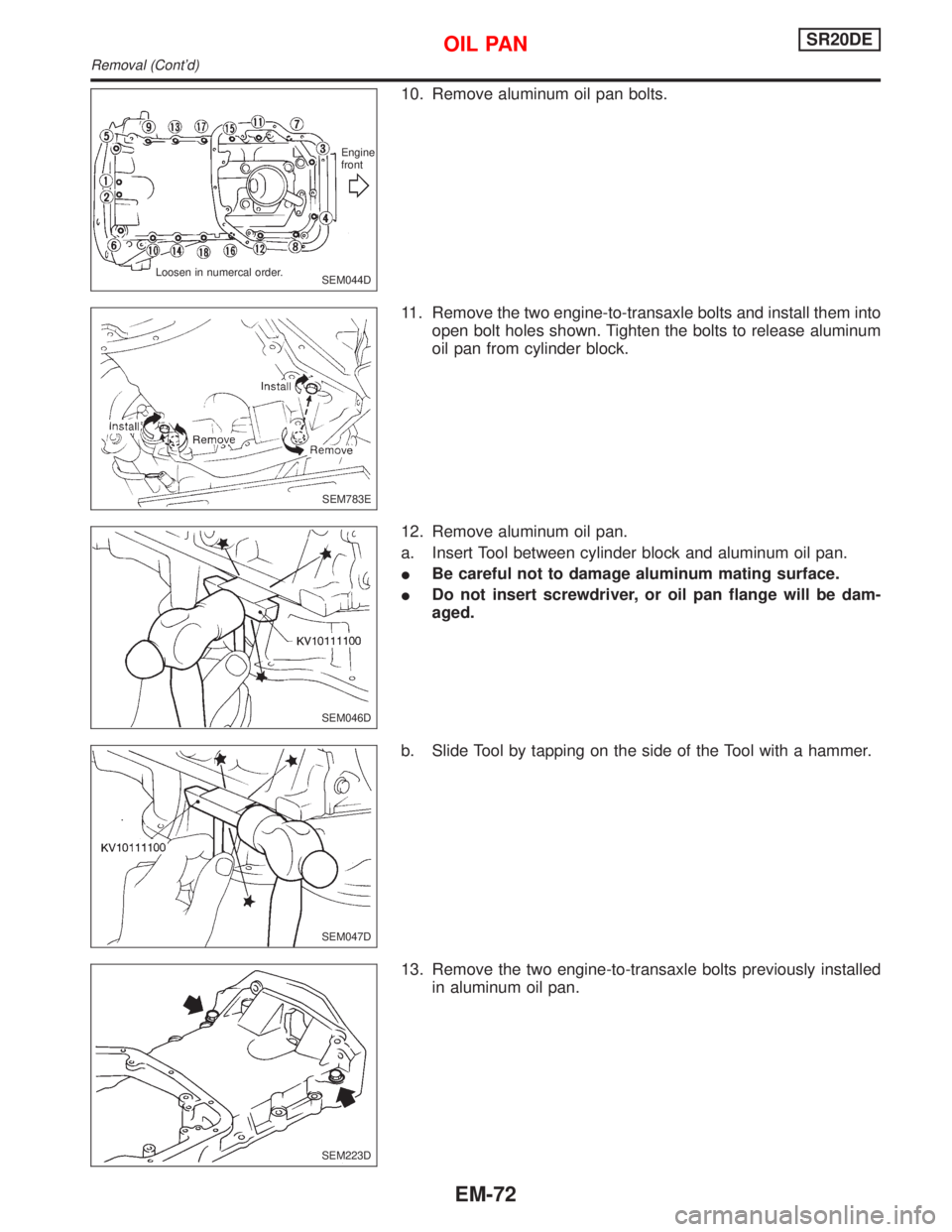

10. Remove aluminum oil pan bolts.

11. Remove the two engine-to-transaxle bolts and install them into

open bolt holes shown. Tighten the bolts to release aluminum

oil pan from cylinder block.

12. Remove aluminum oil pan.

a. Insert Tool between cylinder block and aluminum oil pan.

IBe careful not to damage aluminum mating surface.

IDo not insert screwdriver, or oil pan flange will be dam-

aged.

b. Slide Tool by tapping on the side of the Tool with a hammer.

13. Remove the two engine-to-transaxle bolts previously installed

in aluminum oil pan.

SEM044DEngine

front

Loosen in numercal order.

SEM783E

SEM046D

SEM047D

SEM223D

OIL PANSR20DE

Removal (Cont'd)

EM-72

Page 1613 of 2267

Installation

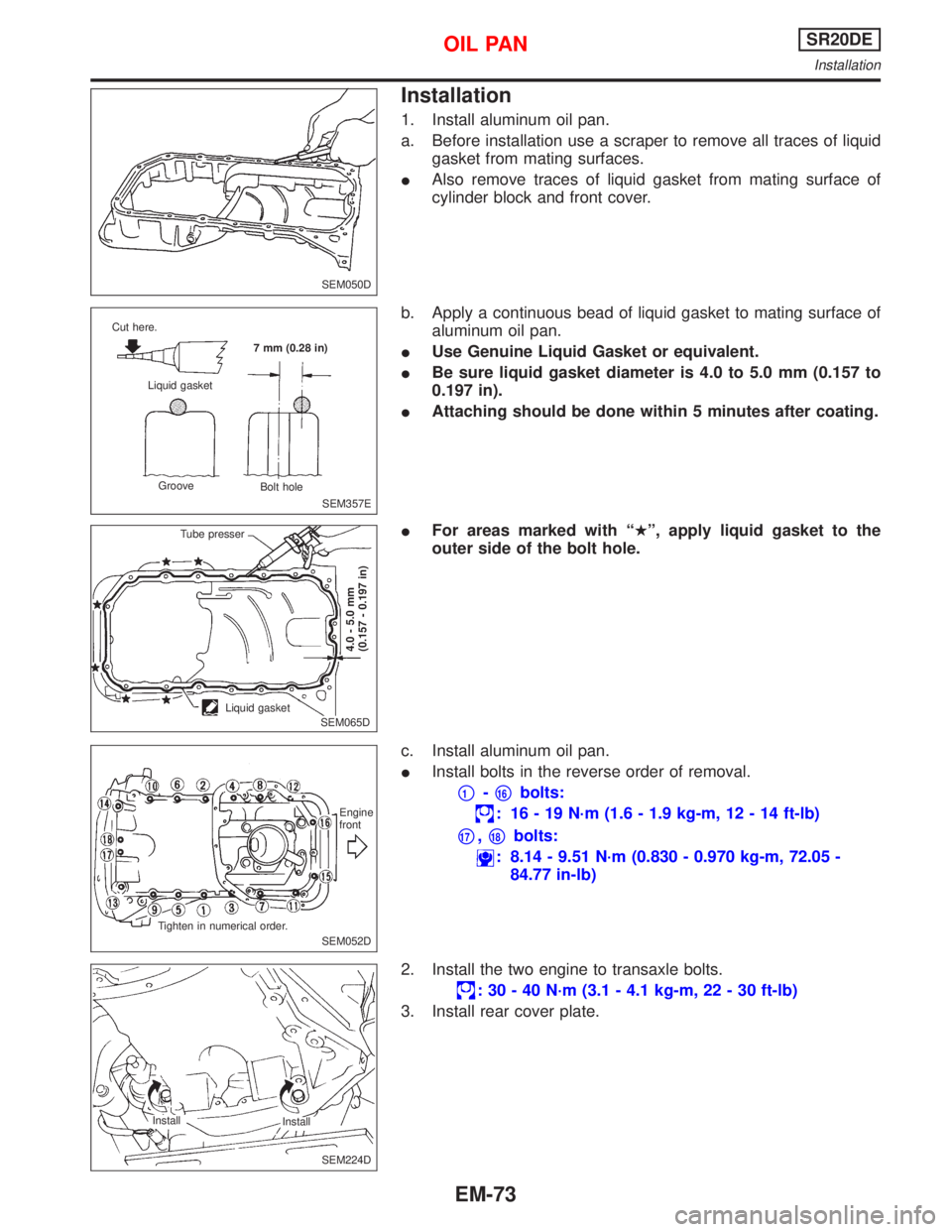

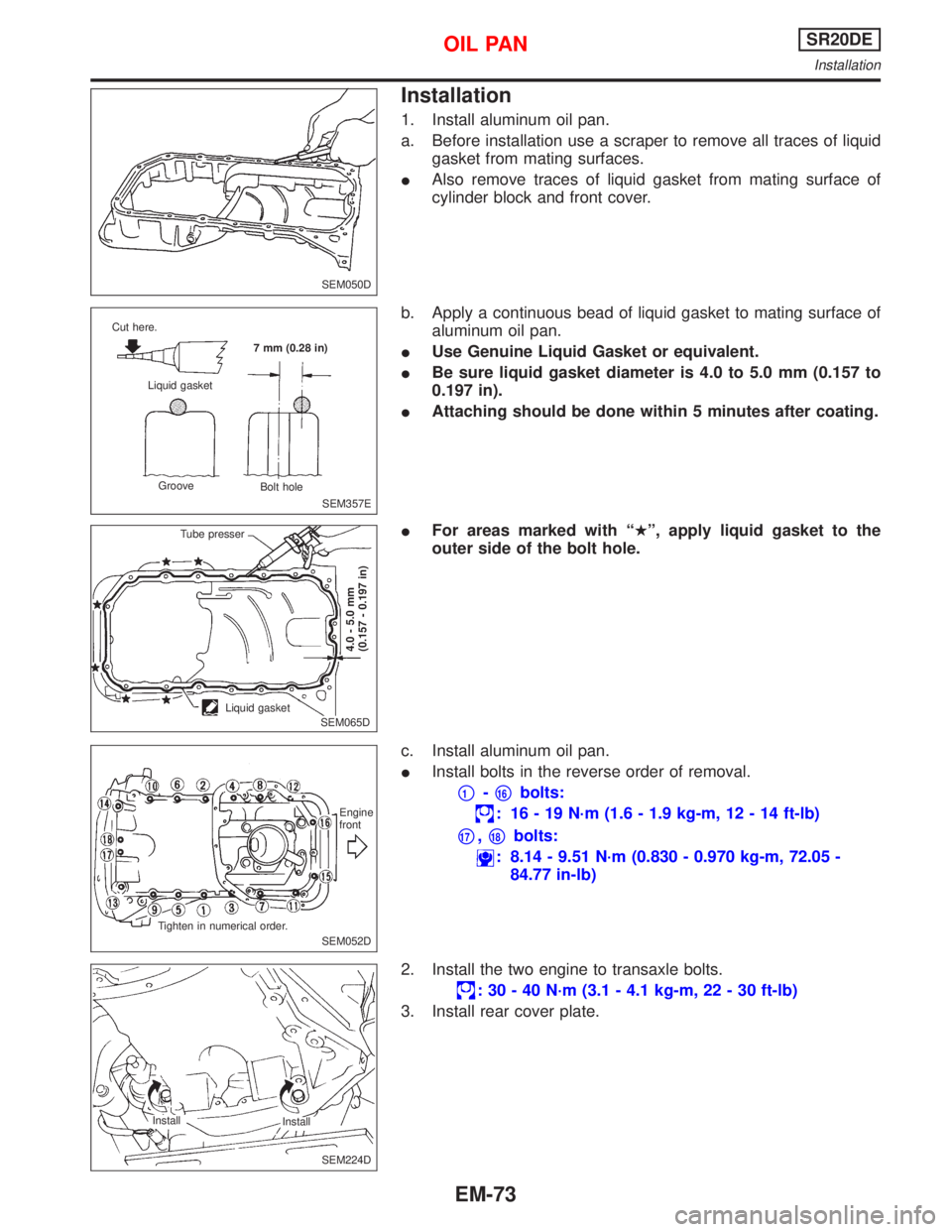

1. Install aluminum oil pan.

a. Before installation use a scraper to remove all traces of liquid

gasket from mating surfaces.

IAlso remove traces of liquid gasket from mating surface of

cylinder block and front cover.

b. Apply a continuous bead of liquid gasket to mating surface of

aluminum oil pan.

IUse Genuine Liquid Gasket or equivalent.

IBe sure liquid gasket diameter is 4.0 to 5.0 mm (0.157 to

0.197 in).

IAttaching should be done within 5 minutes after coating.

IFor areas marked with ªHº, apply liquid gasket to the

outer side of the bolt hole.

c. Install aluminum oil pan.

IInstall bolts in the reverse order of removal.

p1-p16bolts:

: 16 - 19 N´m (1.6 - 1.9 kg-m, 12 - 14 ft-lb)

p17,p18bolts:

: 8.14 - 9.51 N´m (0.830 - 0.970 kg-m, 72.05 -

84.77 in-lb)

2. Install the two engine to transaxle bolts.

: 30 - 40 N´m (3.1 - 4.1 kg-m, 22 - 30 ft-lb)

3. Install rear cover plate.

SEM050D

SEM357E Cut here.

Liquid gasket

Groove

Bolt hole 7 mm (0.28 in)

.SEM065D Tube presserLiquid gasket

4.0 - 5.0 mm

(0.157 - 0.197 in)

SEM052DEngine

front

Tighten in numerical order.

SEM224D Install

Install

OIL PANSR20DE

Installation

EM-73

Page 1614 of 2267

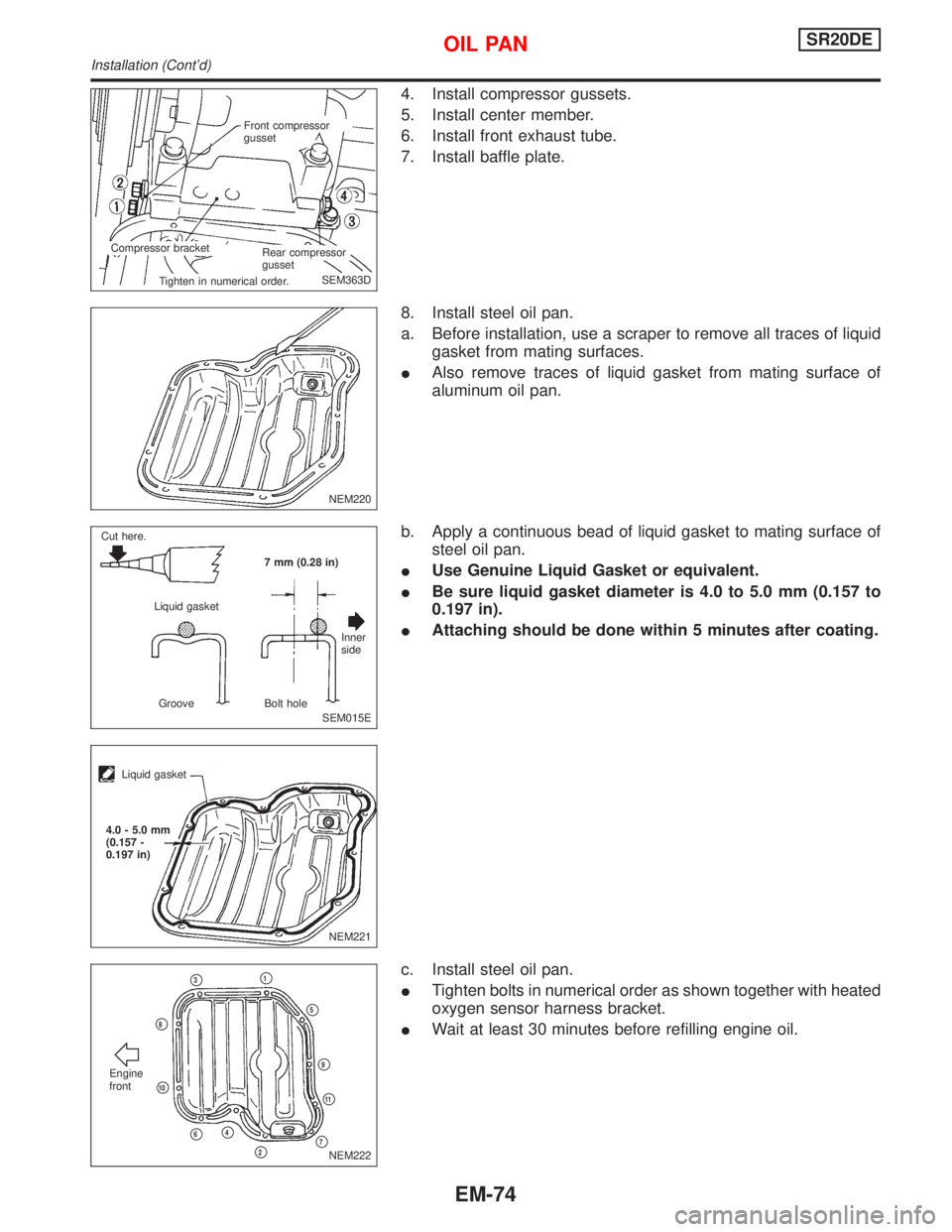

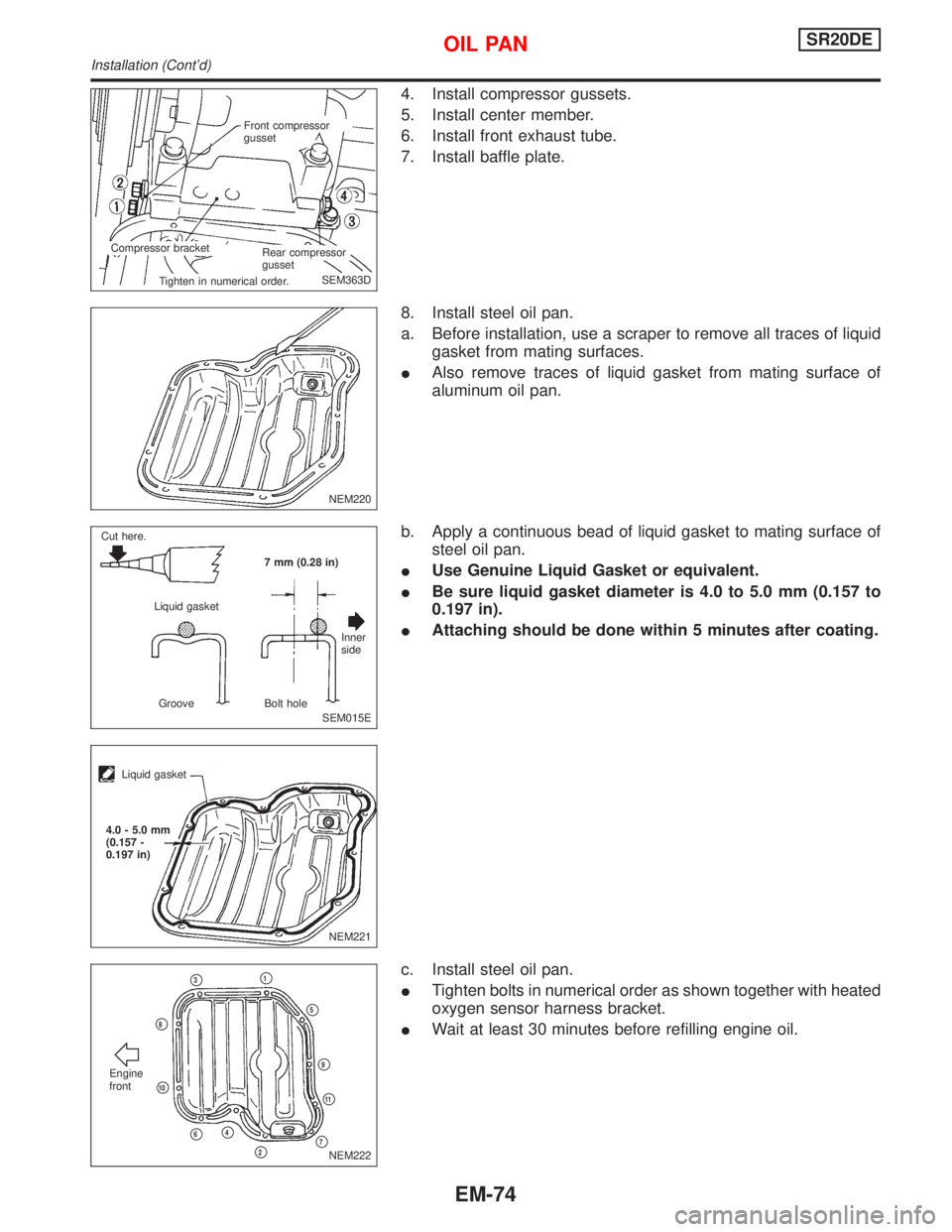

4. Install compressor gussets.

5. Install center member.

6. Install front exhaust tube.

7. Install baffle plate.

8. Install steel oil pan.

a. Before installation, use a scraper to remove all traces of liquid

gasket from mating surfaces.

IAlso remove traces of liquid gasket from mating surface of

aluminum oil pan.

b. Apply a continuous bead of liquid gasket to mating surface of

steel oil pan.

IUse Genuine Liquid Gasket or equivalent.

IBe sure liquid gasket diameter is 4.0 to 5.0 mm (0.157 to

0.197 in).

IAttaching should be done within 5 minutes after coating.

c. Install steel oil pan.

ITighten bolts in numerical order as shown together with heated

oxygen sensor harness bracket.

IWait at least 30 minutes before refilling engine oil.

SEM363D Front compressor

gusset

Compressor bracket

Rear compressor

gusset

Tighten in numerical order.

NEM220

SEM015E Cut here.

Liquid gasket7 mm (0.28 in)

Inner

side

Groove Bolt hole

NEM221

Liquid gasket

4.0 - 5.0 mm

(0.157 -

0.197 in)

NEM222p7

Engine

front

p3p1

p5

p9

p11

p2

p4p6

p10

p8

OIL PANSR20DE

Installation (Cont'd)

EM-74

Page 1615 of 2267

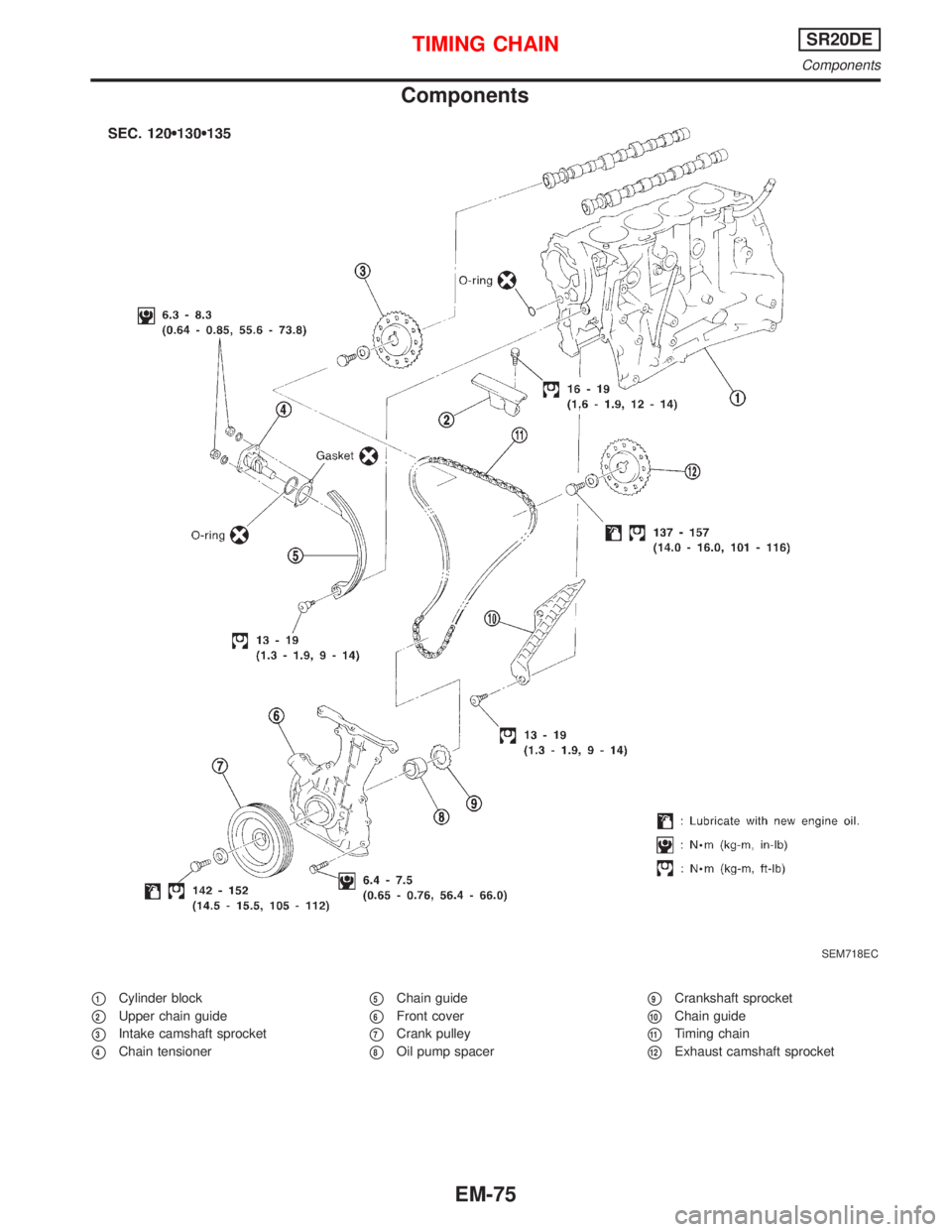

Components

p1Cylinder block

p2Upper chain guide

p3Intake camshaft sprocket

p4Chain tensioner

p5Chain guide

p6Front cover

p7Crank pulley

p8Oil pump spacer

p9Crankshaft sprocket

p10Chain guide

p11Timing chain

p12Exhaust camshaft sprocket

SEM718EC

TIMING CHAINSR20DE

Components

EM-75

Page 1616 of 2267

CAUTION:

IAfter removing timing chain, do not turn crankshaft and

camshaft separately, or valves will strike piston heads.

IWhen installing chain tensioner, oil seals, or other sliding

parts, lubricate contacting surfaces with new engine oil.

IApply new engine oil to bolt threads and seat surfaces

when installing camshaft sprocket and crankshaft pulley.

RemovalNLEM01261. Remove engine under cover.

2. Remove front RH wheel and engine side cover.

3. Drain coolant by removing cylinder block drain plug and lower

radiator hose. Refer to MA-29, ªChanging Engine Coolantº.

4. Remove drive belts and water pump pulley.

5. Disconnect the following parts:

IVacuum hoses

IWires

IHarness

IConnectors

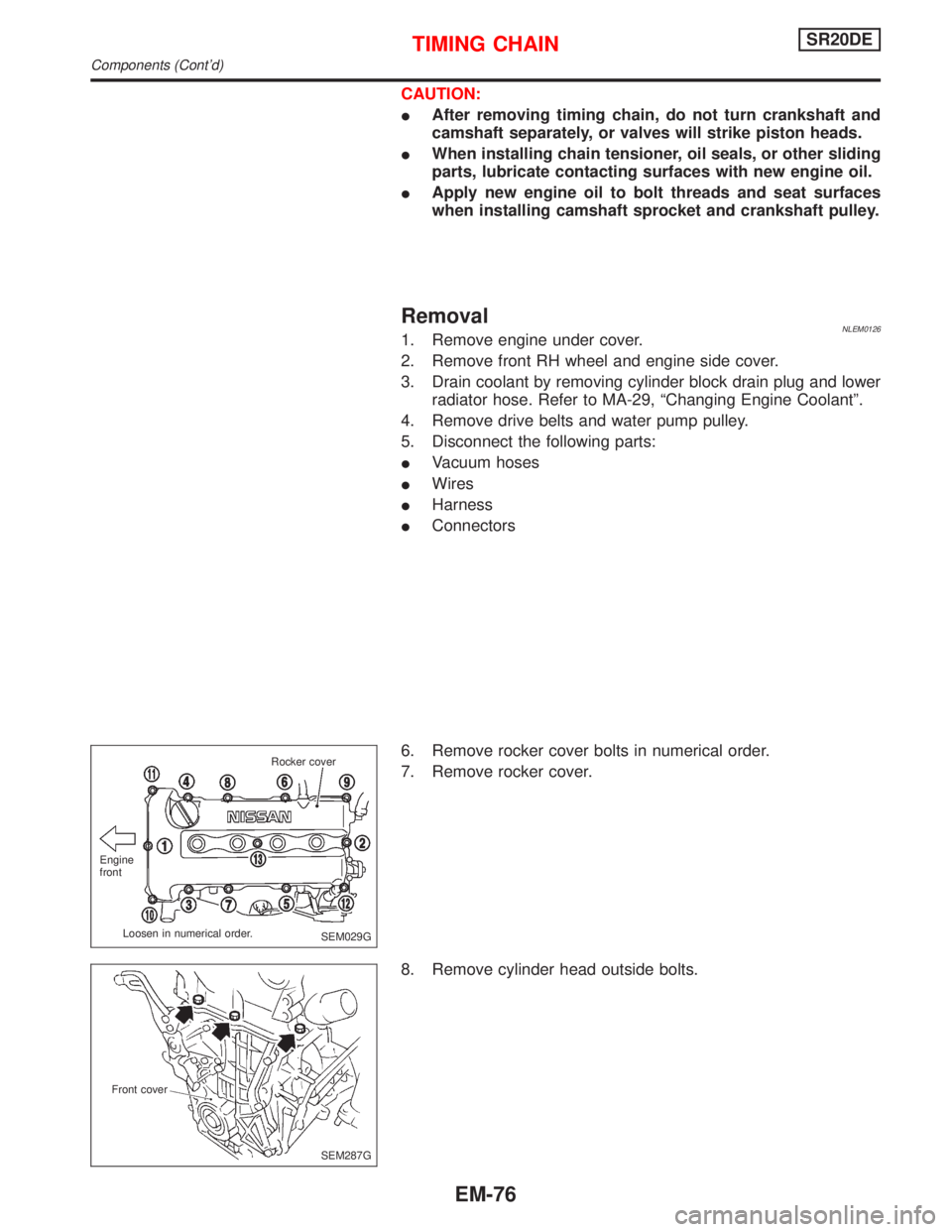

6. Remove rocker cover bolts in numerical order.

7. Remove rocker cover.

8. Remove cylinder head outside bolts.

SEM029G Engine

front

Loosen in numerical order.Rocker cover

SEM287G Front cover

TIMING CHAINSR20DE

Components (Cont'd)

EM-76

Page 1617 of 2267

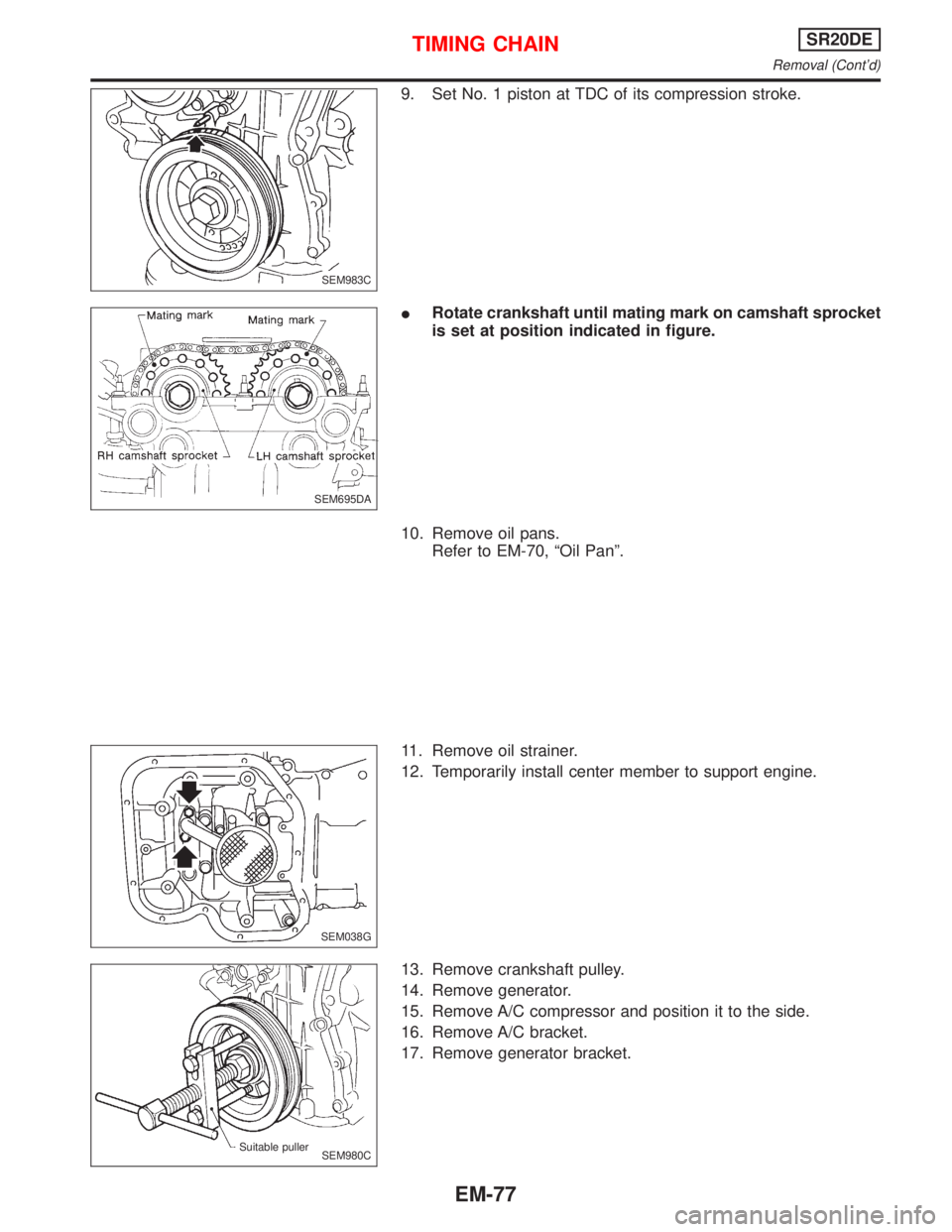

9. Set No. 1 piston at TDC of its compression stroke.

IRotate crankshaft until mating mark on camshaft sprocket

is set at position indicated in figure.

10. Remove oil pans.

Refer to EM-70, ªOil Panº.

11. Remove oil strainer.

12. Temporarily install center member to support engine.

13. Remove crankshaft pulley.

14. Remove generator.

15. Remove A/C compressor and position it to the side.

16. Remove A/C bracket.

17. Remove generator bracket.

SEM983C

SEM695DA

SEM038G

SEM980C Suitable puller

TIMING CHAINSR20DE

Removal (Cont'd)

EM-77

Page 1618 of 2267

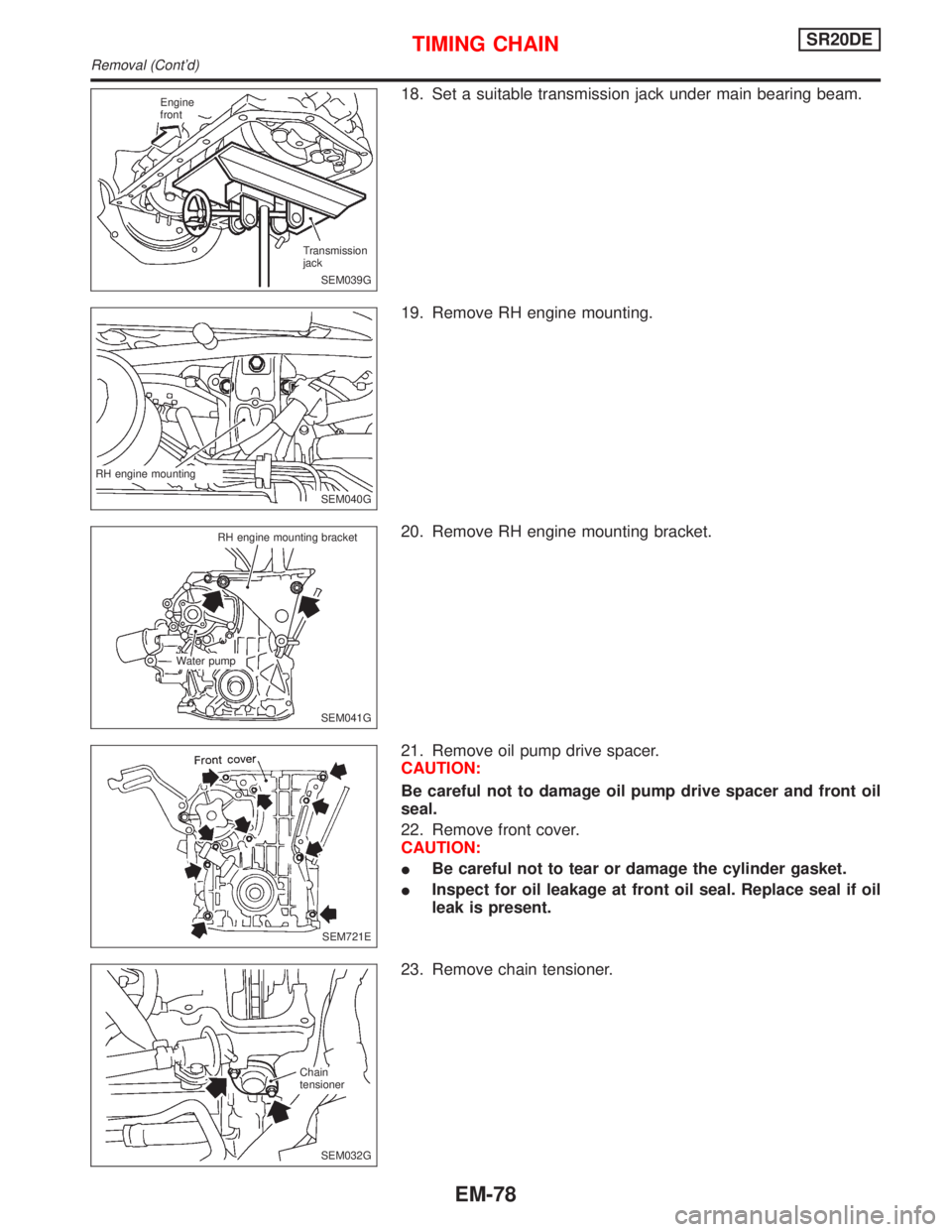

18. Set a suitable transmission jack under main bearing beam.

19. Remove RH engine mounting.

20. Remove RH engine mounting bracket.

21. Remove oil pump drive spacer.

CAUTION:

Be careful not to damage oil pump drive spacer and front oil

seal.

22. Remove front cover.

CAUTION:

IBe careful not to tear or damage the cylinder gasket.

IInspect for oil leakage at front oil seal. Replace seal if oil

leak is present.

23. Remove chain tensioner.

SEM039G Engine

front

Transmission

jack

SEM040G RH engine mounting

SEM041G RH engine mounting bracket

Water pump

SEM721E

.SEM032G Chain

tensioner

TIMING CHAINSR20DE

Removal (Cont'd)

EM-78

Page 1619 of 2267

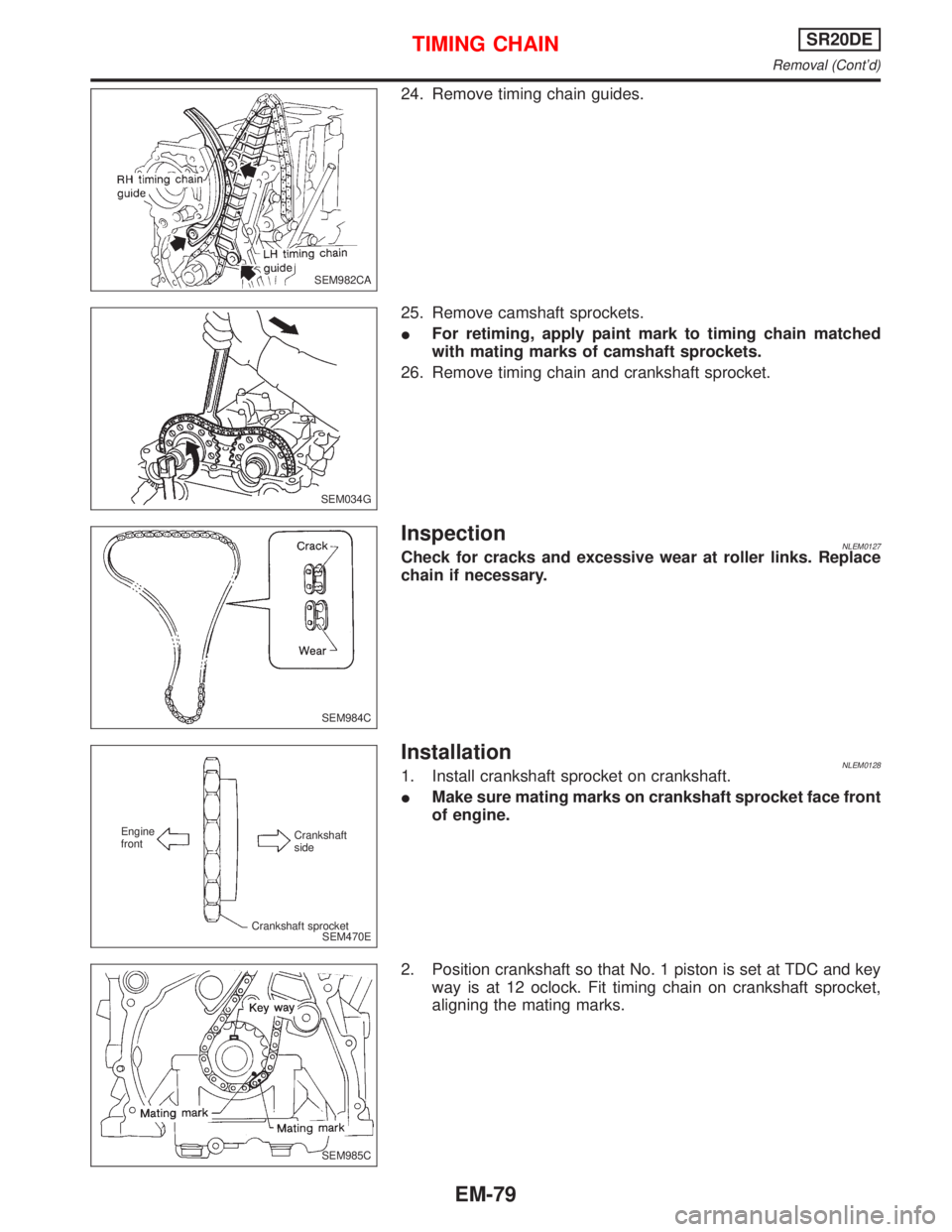

24. Remove timing chain guides.

25. Remove camshaft sprockets.

IFor retiming, apply paint mark to timing chain matched

with mating marks of camshaft sprockets.

26. Remove timing chain and crankshaft sprocket.

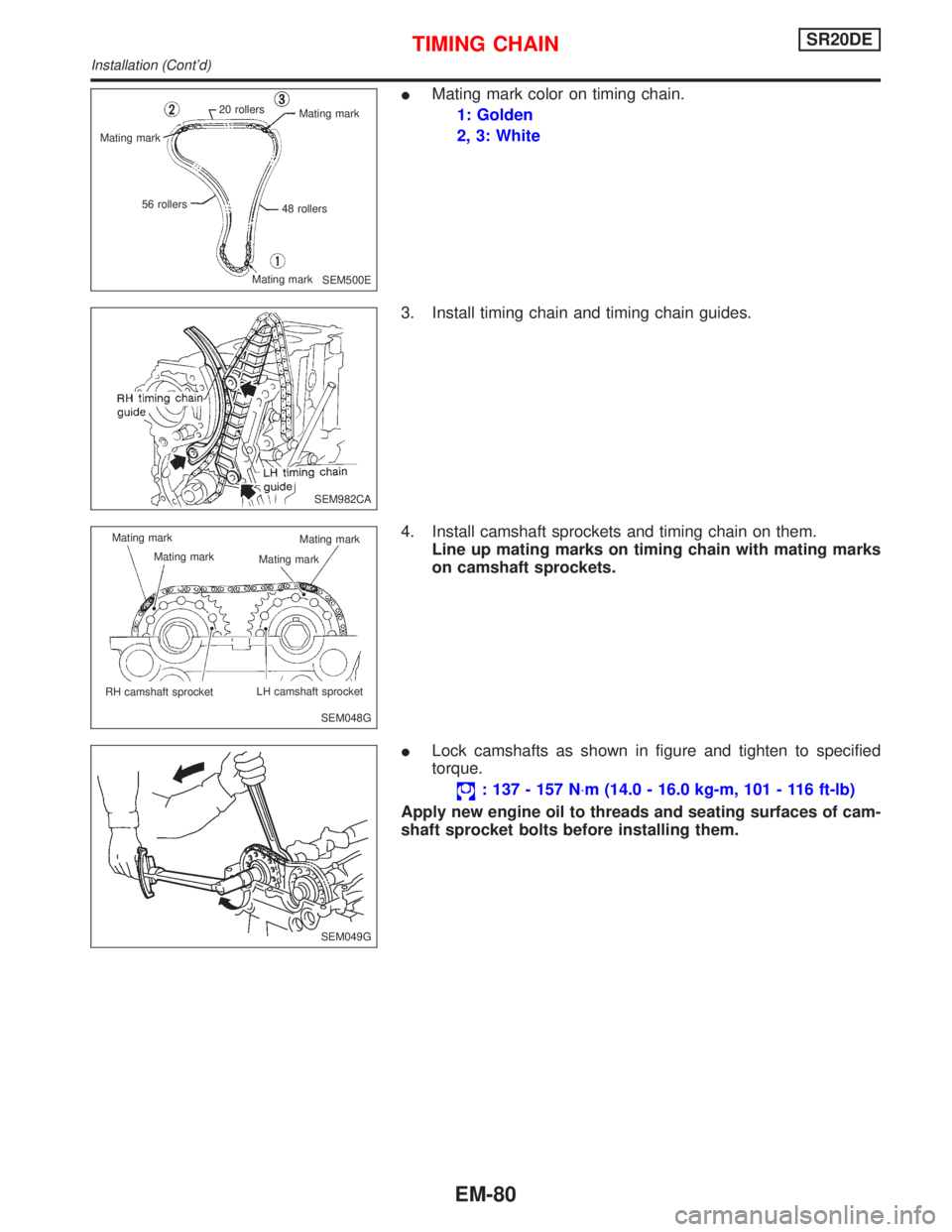

InspectionNLEM0127Check for cracks and excessive wear at roller links. Replace

chain if necessary.

InstallationNLEM01281. Install crankshaft sprocket on crankshaft.

IMake sure mating marks on crankshaft sprocket face front

of engine.

2. Position crankshaft so that No. 1 piston is set at TDC and key

way is at 12 oclock. Fit timing chain on crankshaft sprocket,

aligning the mating marks.

SEM982CA

SEM034G

SEM984C

SEM470E Engine

frontCrankshaft

side

Crankshaft sprocket

SEM985C

TIMING CHAINSR20DE

Removal (Cont'd)

EM-79

Page 1620 of 2267

IMating mark color on timing chain.

1: Golden

2, 3: White

3. Install timing chain and timing chain guides.

4. Install camshaft sprockets and timing chain on them.

Line up mating marks on timing chain with mating marks

on camshaft sprockets.

ILock camshafts as shown in figure and tighten to specified

torque.

: 137 - 157 N×m (14.0 - 16.0 kg-m, 101 - 116 ft-lb)

Apply new engine oil to threads and seating surfaces of cam-

shaft sprocket bolts before installing them.

SEM500E 20 rollers

Mating mark

48 rollers

Mating mark 56 rollers Mating mark

SEM982CA

SEM048G Mating mark

Mating mark

.RH camshaft sprocket.LH camshaft sprocket Mating mark

Mating mark

SEM049G

TIMING CHAINSR20DE

Installation (Cont'd)

EM-80

Trending: dead battery, brake light, maintenance schedule, catalytic converter, trunk, clock reset, roof