NISSAN PRIMERA 1999 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 1821 of 2267

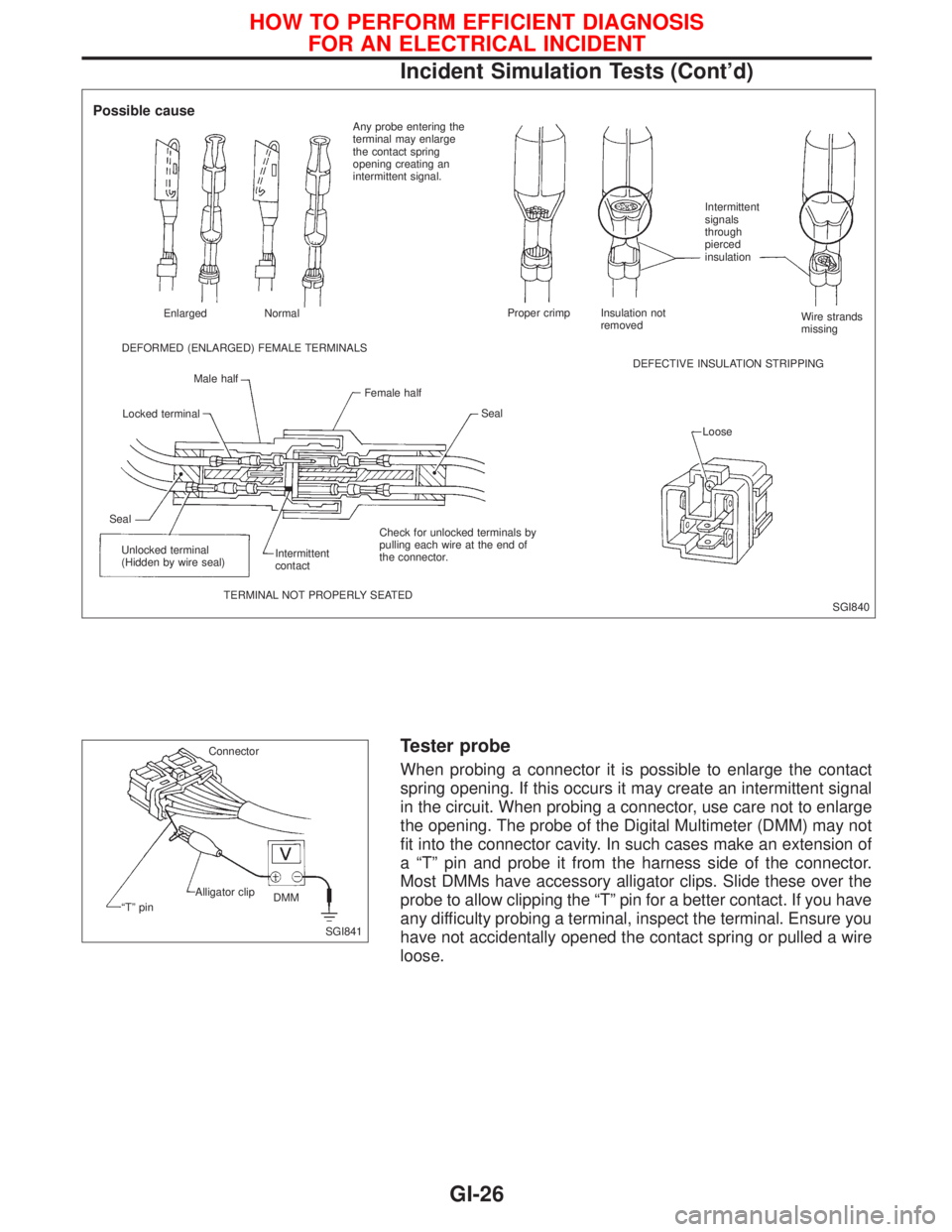

Tester probe

When probing a connector it is possible to enlarge the contact

spring opening. If this occurs it may create an intermittent signal

in the circuit. When probing a connector, use care not to enlarge

the opening. The probe of the Digital Multimeter (DMM) may not

fit into the connector cavity. In such cases make an extension of

a ªTº pin and probe it from the harness side of the connector.

Most DMMs have accessory alligator clips. Slide these over the

probe to allow clipping the ªTº pin for a better contact. If you have

any difficulty probing a terminal, inspect the terminal. Ensure you

have not accidentally opened the contact spring or pulled a wire

loose.

SGI840

Possible causeAny probe entering the

terminal may enlarge

the contact spring

opening creating an

intermittent signal.

Enlarged

NormalProper crimp

Insulation not

removedIntermittent

signals

through

pierced

insulation

Wire strands

missing

DEFORMED (ENLARGED) FEMALE TERMINALS

DEFECTIVE INSULATION STRIPPING

Male half

Female half

Seal

Seal

Unlocked terminal

(Hidden by wire seal)Intermittent

contactCheck for unlocked terminals by

pulling each wire at the end of

the connector.

TERMINAL NOT PROPERLY SEATED Locked terminal

Loose

SGI841 Connector

ªTº pinAlligator clip

DMM

HOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT

Incident Simulation Tests (Cont'd)

GI-26

Page 1822 of 2267

Engine compartment

There are several reasons a vehicle or engine vibration could

cause an electrical complaint. Some of the things to check for

are:

lConnectors not fully seated.

lWiring harness not long enough and is being stressed due

to engine vibrations or rocking.

lWires laying across brackets or moving components.

lLoose, dirty or corroded ground wires.

lWires routed too close to hot components.

To inspect components under the hood, start by verifying the

integrity of ground connections. (Refer to GROUND INSPEC-

TION described later.) First check that the system is properly

grounded. Then check for loose connection bygently shaking

the wiring or components as previously explained. Using the

wiring diagrams inspect the wiring for continuity.

Behind the instrument panel

An improperly routed or improperly clamped harness can

become pinched during accessory installation. Vehicle vibration

can aggravate a harness which is routed along a bracket or near

a screw.

Under seating areas

An unclamped or loose harness can cause wiring to be pinched

by seat components (such as slide guides) during vehicle vibra-

tion. If the wiring runs under seating areas, inspect wire routing

for possible damage or pinching.

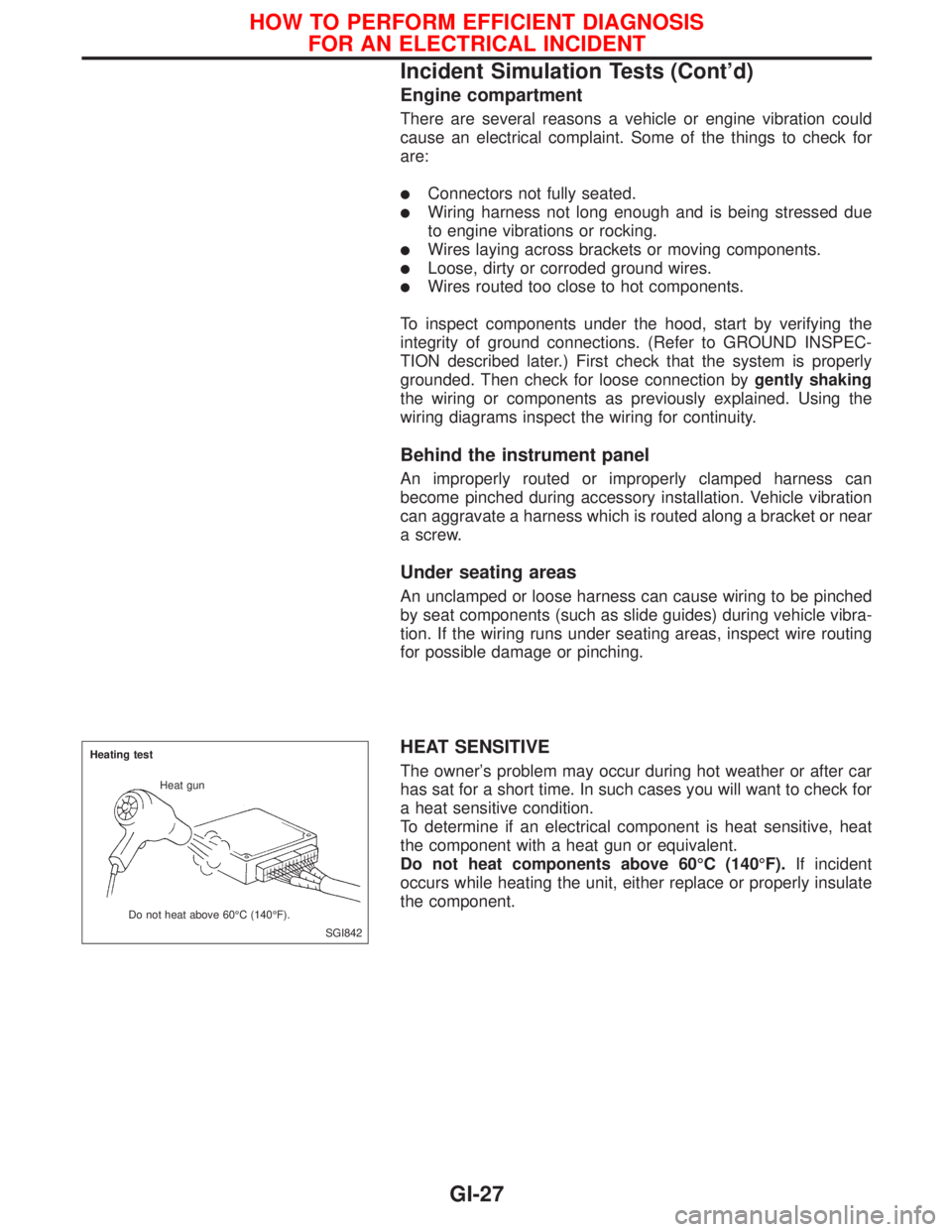

HEAT SENSITIVE

The owner's problem may occur during hot weather or after car

has sat for a short time. In such cases you will want to check for

a heat sensitive condition.

To determine if an electrical component is heat sensitive, heat

the component with a heat gun or equivalent.

Do not heat components above 60ÉC (140ÉF).If incident

occurs while heating the unit, either replace or properly insulate

the component.

SGI842 Heating test

Heat gun

Do not heat above 60ÉC (140ÉF).

HOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT

Incident Simulation Tests (Cont'd)

GI-27

Page 1823 of 2267

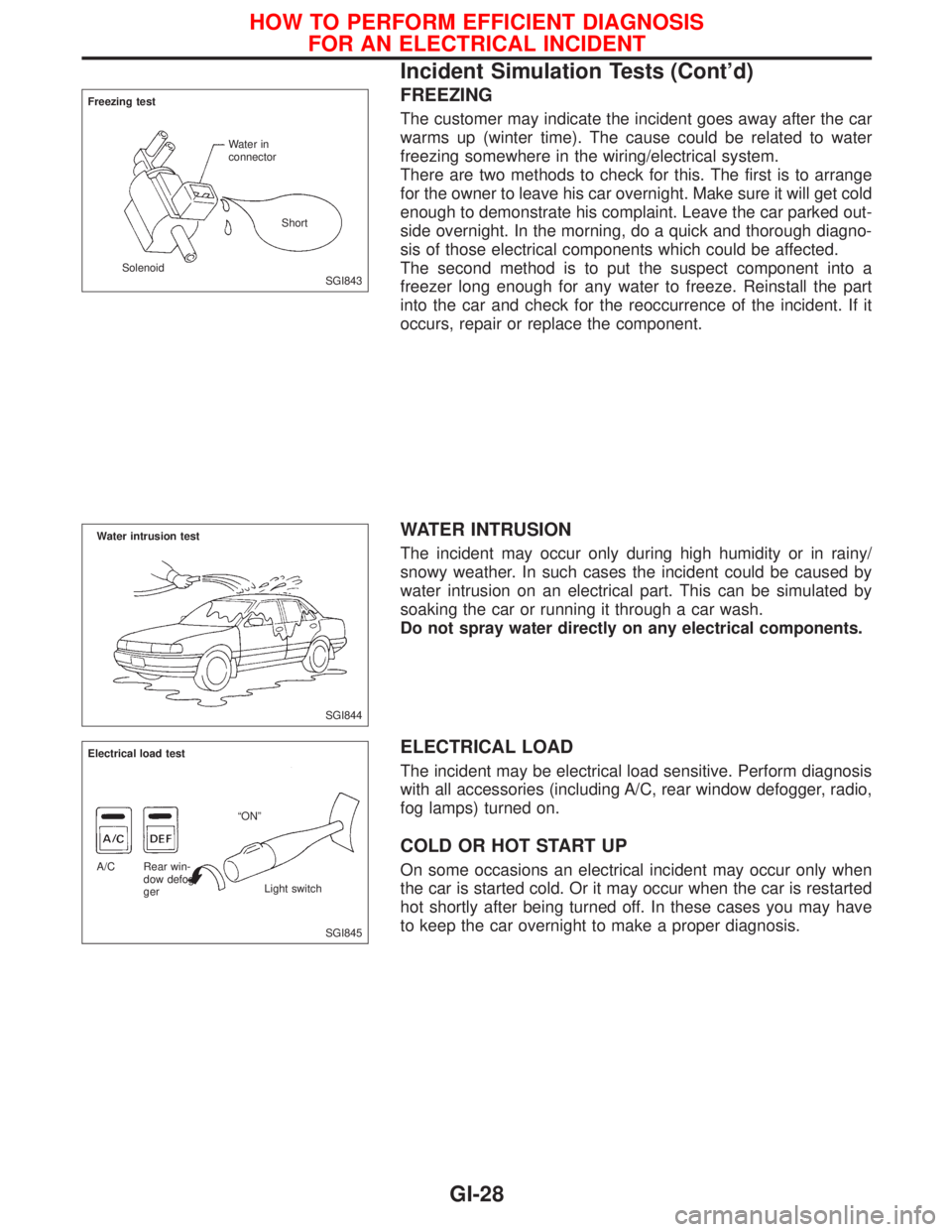

FREEZING

The customer may indicate the incident goes away after the car

warms up (winter time). The cause could be related to water

freezing somewhere in the wiring/electrical system.

There are two methods to check for this. The first is to arrange

for the owner to leave his car overnight. Make sure it will get cold

enough to demonstrate his complaint. Leave the car parked out-

side overnight. In the morning, do a quick and thorough diagno-

sis of those electrical components which could be affected.

The second method is to put the suspect component into a

freezer long enough for any water to freeze. Reinstall the part

into the car and check for the reoccurrence of the incident. If it

occurs, repair or replace the component.

WATER INTRUSION

The incident may occur only during high humidity or in rainy/

snowy weather. In such cases the incident could be caused by

water intrusion on an electrical part. This can be simulated by

soaking the car or running it through a car wash.

Do not spray water directly on any electrical components.

ELECTRICAL LOAD

The incident may be electrical load sensitive. Perform diagnosis

with all accessories (including A/C, rear window defogger, radio,

fog lamps) turned on.

COLD OR HOT START UP

On some occasions an electrical incident may occur only when

the car is started cold. Or it may occur when the car is restarted

hot shortly after being turned off. In these cases you may have

to keep the car overnight to make a proper diagnosis.

SGI843 Freezing test

Water in

connector

SolenoidShort

SGI844

Water intrusion test

SGI845 Electrical load test

ªONº

Rear win-

dow defog-

gerLight switch A/C

HOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT

Incident Simulation Tests (Cont'd)

GI-28

Page 1824 of 2267

Circuit Inspection

INTRODUCTION

In general, testing electrical circuits is an easy task if it is approached in a logical and organized method.

Before beginning it is important to have all available information on the system to be tested. Also, get a

thorough understanding of system operation. Then you will be able to use the appropriate equipment and

follow the correct test procedure.

You may have to simulate vehicle vibrations while testing electrical components.Gently shakethe wiring

harness or electrical component to do this.

OPEN A circuit is open when there is no continuity through a section of the circuit.

SHORT There are two types of shorts.

lSHORT CIRCUITWhen a circuit contacts another circuit and causes the

normal resistance to change.

lSHORT TO GROUNDWhen a circuit contacts a ground source and grounds the

circuit.

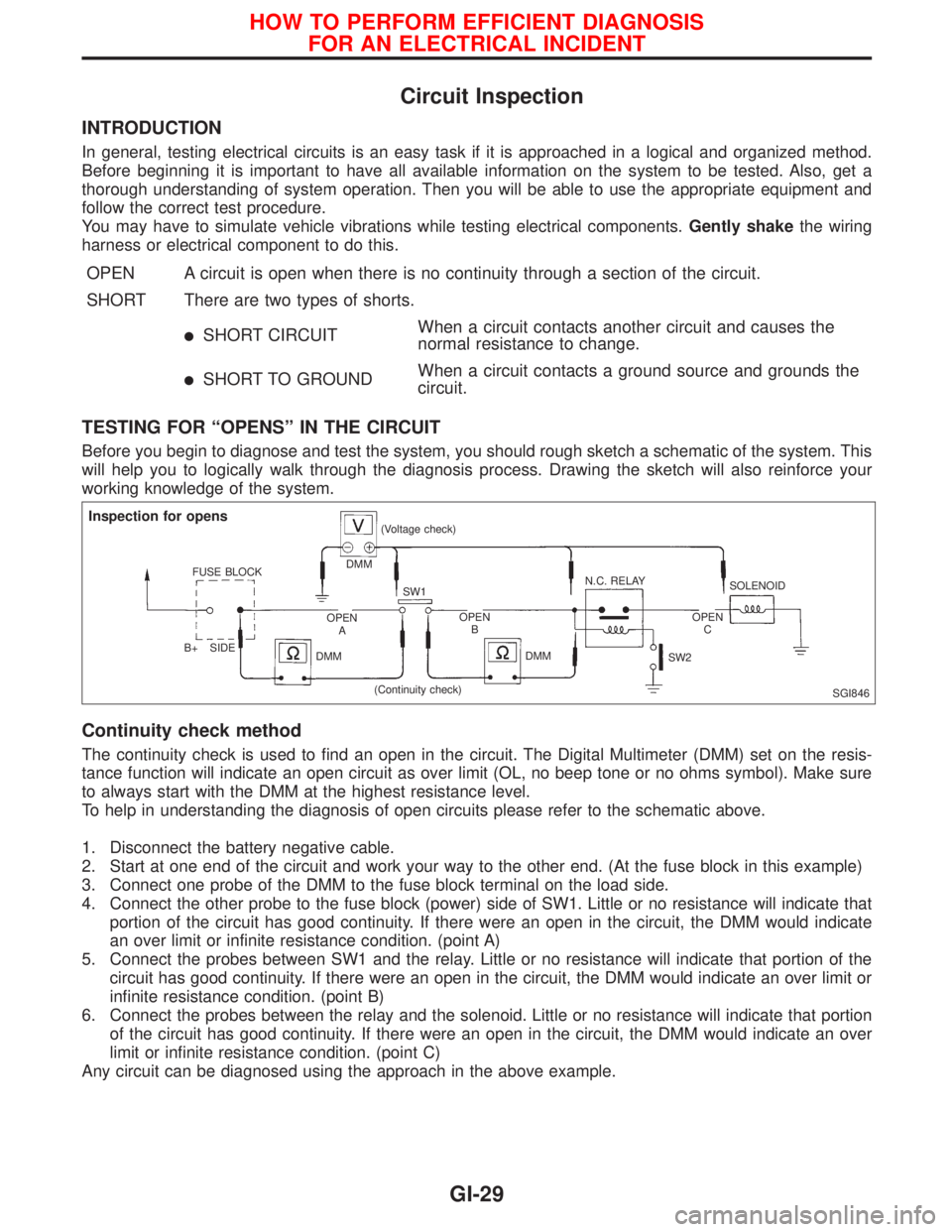

TESTING FOR ªOPENSº IN THE CIRCUIT

Before you begin to diagnose and test the system, you should rough sketch a schematic of the system. This

will help you to logically walk through the diagnosis process. Drawing the sketch will also reinforce your

working knowledge of the system.

Continuity check method

The continuity check is used to find an open in the circuit. The Digital Multimeter (DMM) set on the resis-

tance function will indicate an open circuit as over limit (OL, no beep tone or no ohms symbol). Make sure

to always start with the DMM at the highest resistance level.

To help in understanding the diagnosis of open circuits please refer to the schematic above.

1. Disconnect the battery negative cable.

2. Start at one end of the circuit and work your way to the other end. (At the fuse block in this example)

3. Connect one probe of the DMM to the fuse block terminal on the load side.

4. Connect the other probe to the fuse block (power) side of SW1. Little or no resistance will indicate that

portion of the circuit has good continuity. If there were an open in the circuit, the DMM would indicate

an over limit or infinite resistance condition. (point A)

5. Connect the probes between SW1 and the relay. Little or no resistance will indicate that portion of the

circuit has good continuity. If there were an open in the circuit, the DMM would indicate an over limit or

infinite resistance condition. (point B)

6. Connect the probes between the relay and the solenoid. Little or no resistance will indicate that portion

of the circuit has good continuity. If there were an open in the circuit, the DMM would indicate an over

limit or infinite resistance condition. (point C)

Any circuit can be diagnosed using the approach in the above example.

SGI846

Inspection for opens

FUSE BLOCK

B+ SIDEDMM(Voltage check)

SW1N.C. RELAY

SOLENOID

OPEN

AOPEN

BOPEN

C

DMMDMM

SW2

(Continuity check)

HOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT

GI-29

Page 1825 of 2267

Voltage check method

To help in understanding the diagnosis of open circuits please refer to the previous schematic.

In any powered circuit, an open can be found by methodically checking the system for the presence of volt-

age. This is done by switching the DMM to the voltage function.

1. Connect one probe of the DMM to a known good ground.

2. Begin probing at one end of the circuit and work your way to the other end.

3. With SW1 open, probe at SW1 to check for voltage.

voltage; open is further down the circuit than SW1.

no voltage; open is between fuse block and SW1 (point A).

4. Close SW1 and probe at relay.

voltage; open is further down the circuit than the relay.

no voltage; open is between SW1 and relay (point B).

5. Close the relay and probe at the solenoid.

voltage; open is further down the circuit than the solenoid.

no voltage; open is between relay and solenoid (point C).

Any powered circuit can be diagnosed using the approach in the above example.

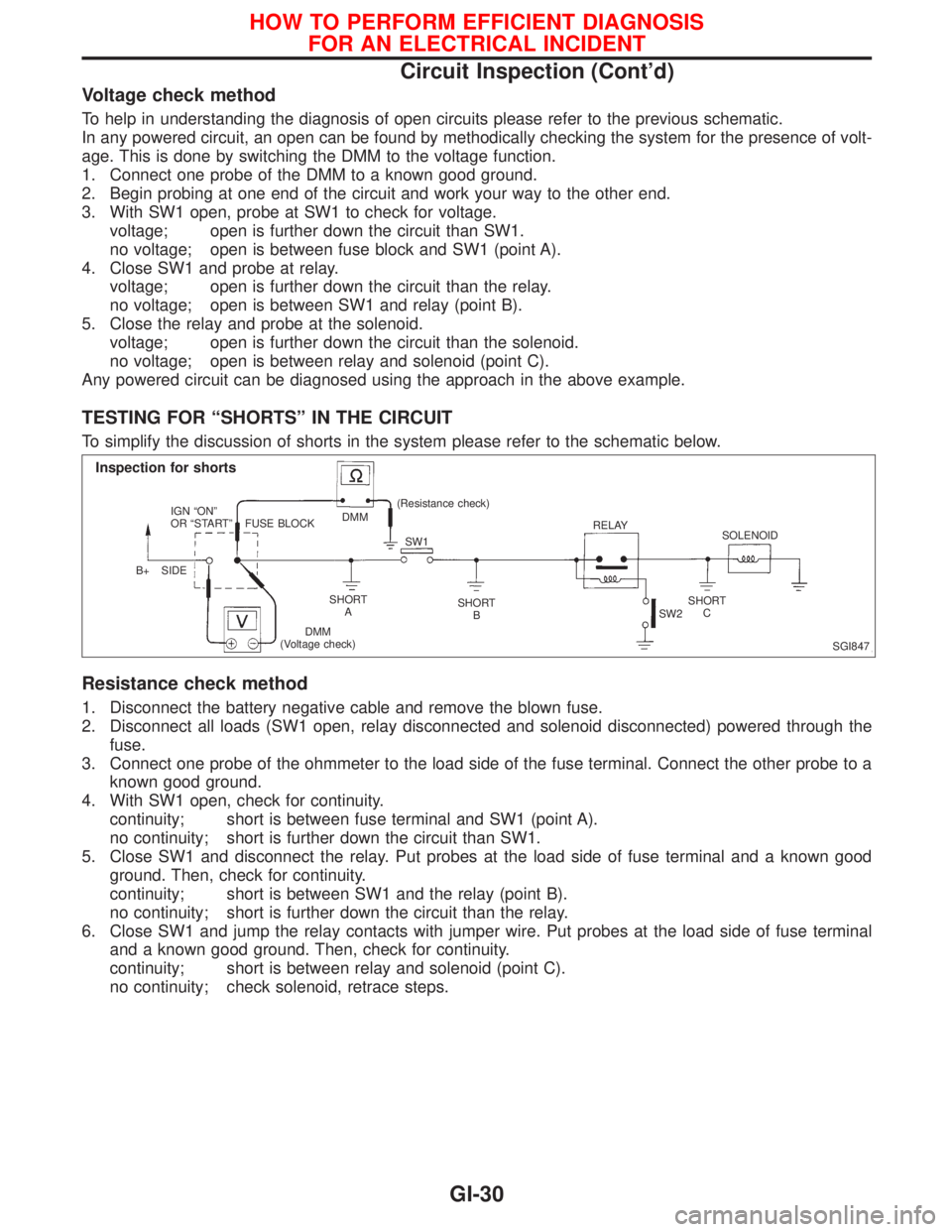

TESTING FOR ªSHORTSº IN THE CIRCUIT

To simplify the discussion of shorts in the system please refer to the schematic below.

Resistance check method

1. Disconnect the battery negative cable and remove the blown fuse.

2. Disconnect all loads (SW1 open, relay disconnected and solenoid disconnected) powered through the

fuse.

3. Connect one probe of the ohmmeter to the load side of the fuse terminal. Connect the other probe to a

known good ground.

4. With SW1 open, check for continuity.

continuity; short is between fuse terminal and SW1 (point A).

no continuity; short is further down the circuit than SW1.

5. Close SW1 and disconnect the relay. Put probes at the load side of fuse terminal and a known good

ground. Then, check for continuity.

continuity; short is between SW1 and the relay (point B).

no continuity; short is further down the circuit than the relay.

6. Close SW1 and jump the relay contacts with jumper wire. Put probes at the load side of fuse terminal

and a known good ground. Then, check for continuity.

continuity; short is between relay and solenoid (point C).

no continuity; check solenoid, retrace steps.

SGI847

Inspection for shorts

IGN ªONº

OR ªSTARTº

B+ SIDEFUSE BLOCKDMM(Resistance check)

SW1RELAY

SOLENOID

SHORT

ASHORT

BSHORT

C

DMM

(Voltage check)SW2

HOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT

Circuit Inspection (Cont'd)

GI-30

Page 1826 of 2267

Voltage check method

1. Remove the blown fuse and disconnect all loads (i.e. SW1 open, relay disconnected and solenoid dis-

connected) powered through the fuse.

2. Turn the ignition key to the ON or START position. Verify battery voltage at the B

+side of the fuse ter-

minal (one lead on the B

+terminal side of the fuse block and one lead on a known good ground).

3. With SW1 open and the DMM leads across both fuse terminals, check for voltage.

voltage; short is between fuse block and SW1 (point A).

no voltage; short is further down the circuit than SW1.

4. With SW1 closed, relay and solenoid disconnected and the DMM leads across both fuse terminals, check

for voltage.

voltage; short is between SW1 and the relay (point B).

no voltage; short is further down the circuit than the relay.

5. With SW1 closed, relay contacts jumped with fused jumper wire check for voltage.

voltage; short is down the circuit of the relay or between the relay and the disconnected solenoid

(point C).

no voltage; retrace steps and check power to fuse block.

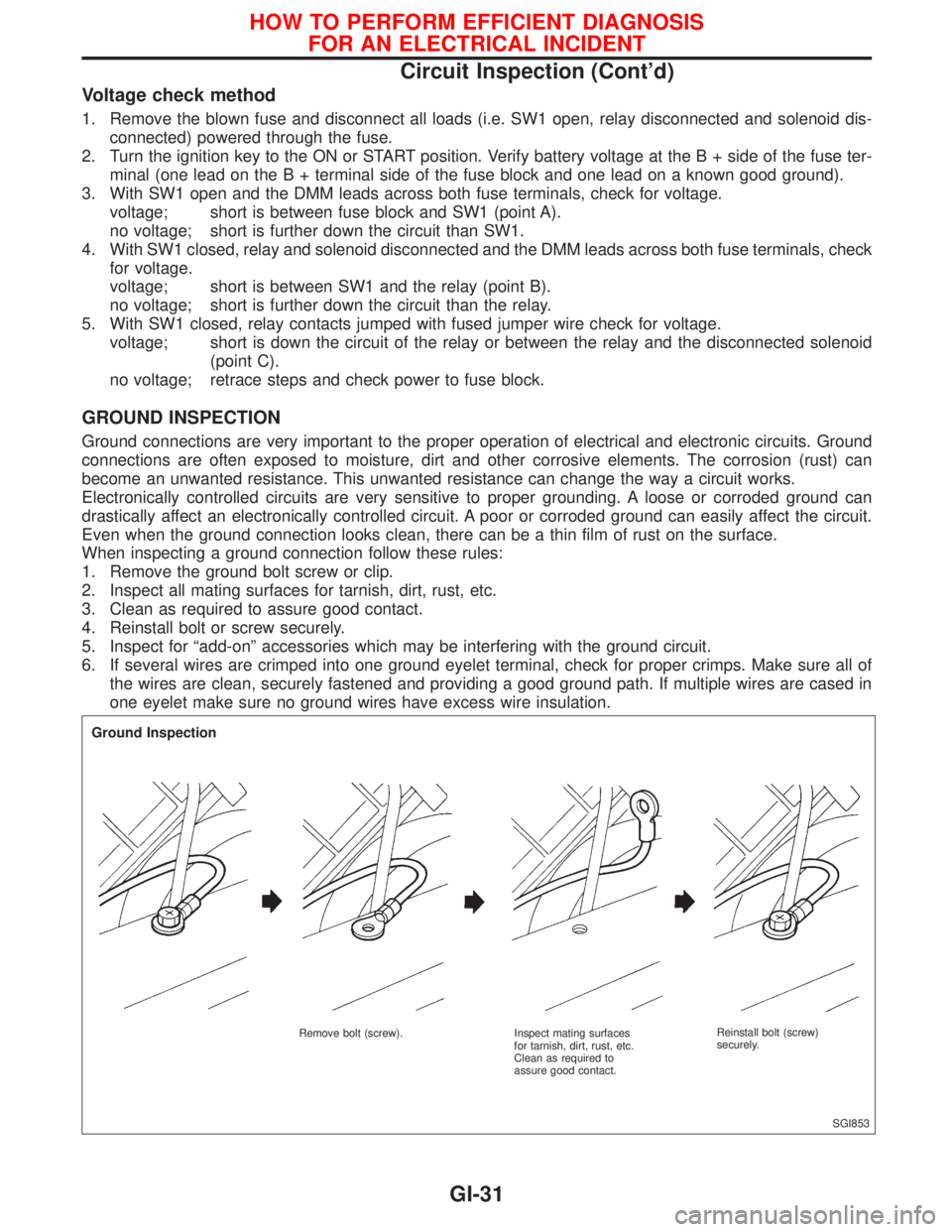

GROUND INSPECTION

Ground connections are very important to the proper operation of electrical and electronic circuits. Ground

connections are often exposed to moisture, dirt and other corrosive elements. The corrosion (rust) can

become an unwanted resistance. This unwanted resistance can change the way a circuit works.

Electronically controlled circuits are very sensitive to proper grounding. A loose or corroded ground can

drastically affect an electronically controlled circuit. A poor or corroded ground can easily affect the circuit.

Even when the ground connection looks clean, there can be a thin film of rust on the surface.

When inspecting a ground connection follow these rules:

1. Remove the ground bolt screw or clip.

2. Inspect all mating surfaces for tarnish, dirt, rust, etc.

3. Clean as required to assure good contact.

4. Reinstall bolt or screw securely.

5. Inspect for ªadd-onº accessories which may be interfering with the ground circuit.

6. If several wires are crimped into one ground eyelet terminal, check for proper crimps. Make sure all of

the wires are clean, securely fastened and providing a good ground path. If multiple wires are cased in

one eyelet make sure no ground wires have excess wire insulation.

SGI853

Ground Inspection

Remove bolt (screw). Inspect mating surfaces

for tarnish, dirt, rust, etc.

Clean as required to

assure good contact.Reinstall bolt (screw)

securely.

HOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT

Circuit Inspection (Cont'd)

GI-31

Page 1827 of 2267

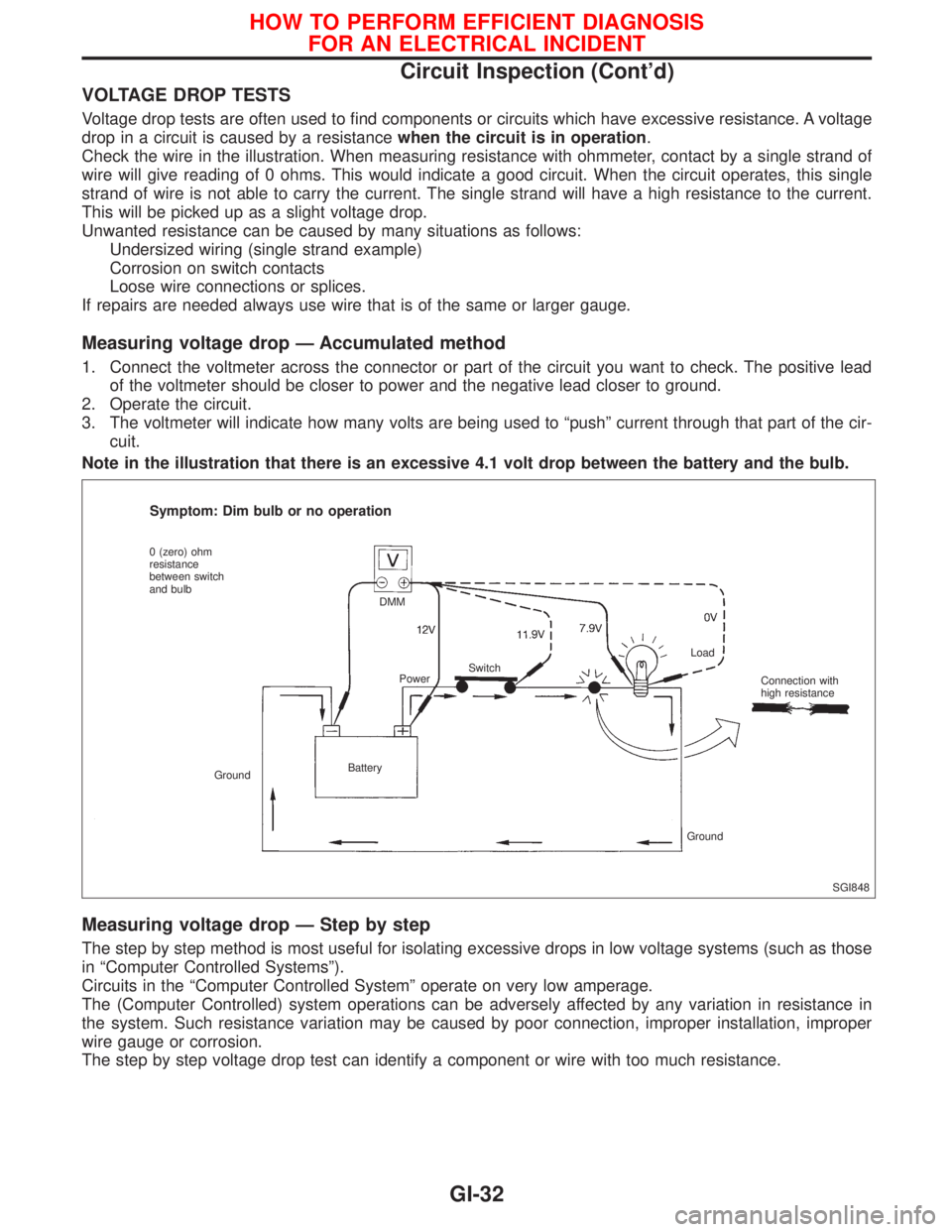

VOLTAGE DROP TESTS

Voltage drop tests are often used to find components or circuits which have excessive resistance. A voltage

drop in a circuit is caused by a resistancewhen the circuit is in operation.

Check the wire in the illustration. When measuring resistance with ohmmeter, contact by a single strand of

wire will give reading of 0 ohms. This would indicate a good circuit. When the circuit operates, this single

strand of wire is not able to carry the current. The single strand will have a high resistance to the current.

This will be picked up as a slight voltage drop.

Unwanted resistance can be caused by many situations as follows:

Undersized wiring (single strand example)

Corrosion on switch contacts

Loose wire connections or splices.

If repairs are needed always use wire that is of the same or larger gauge.

Measuring voltage drop Ð Accumulated method

1. Connect the voltmeter across the connector or part of the circuit you want to check. The positive lead

of the voltmeter should be closer to power and the negative lead closer to ground.

2. Operate the circuit.

3. The voltmeter will indicate how many volts are being used to ªpushº current through that part of the cir-

cuit.

Note in the illustration that there is an excessive 4.1 volt drop between the battery and the bulb.

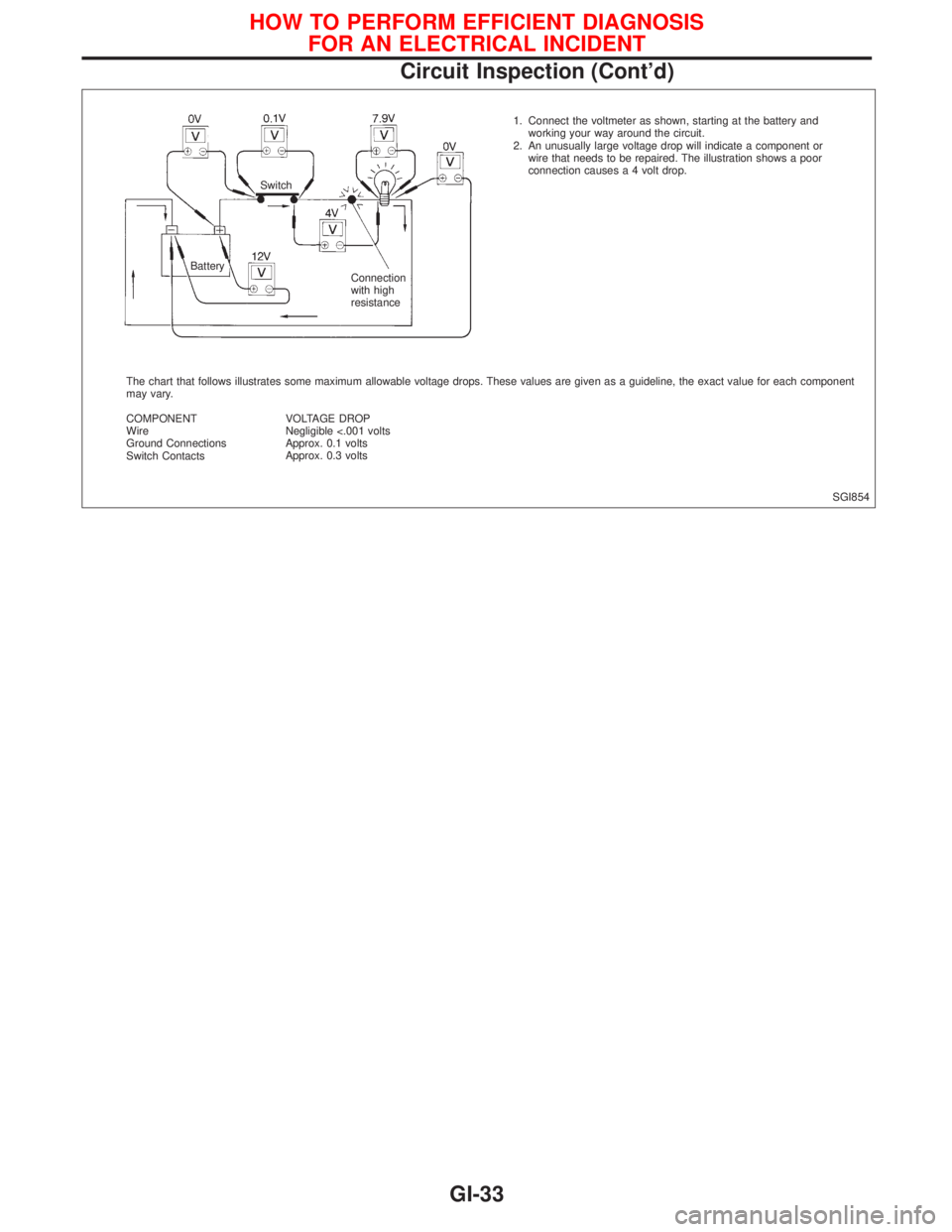

Measuring voltage drop Ð Step by step

The step by step method is most useful for isolating excessive drops in low voltage systems (such as those

in ªComputer Controlled Systemsº).

Circuits in the ªComputer Controlled Systemº operate on very low amperage.

The (Computer Controlled) system operations can be adversely affected by any variation in resistance in

the system. Such resistance variation may be caused by poor connection, improper installation, improper

wire gauge or corrosion.

The step by step voltage drop test can identify a component or wire with too much resistance.

SGI848

Symptom: Dim bulb or no operation

0 (zero) ohm

resistance

between switch

and bulb

GroundBatteryDMM

PowerSwitchLoad

Connection with

high resistance

Ground

HOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT

Circuit Inspection (Cont'd)

GI-32

Page 1828 of 2267

SGI854 1. Connect the voltmeter as shown, starting at the battery and

working your way around the circuit.

2. An unusually large voltage drop will indicate a component or

wire that needs to be repaired. The illustration shows a poor

connection causes a 4 volt drop.

The chart that follows illustrates some maximum allowable voltage drops. These values are given as a guideline, the exact value for each component

may vary.

COMPONENT

Wire

Ground Connections

Switch ContactsVOLTAGE DROP

Negligible <.001 volts

Approx. 0.1 volts

Approx. 0.3 volts BatterySwitch

Connection

with high

resistance

HOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT

Circuit Inspection (Cont'd)

GI-33

Page 1829 of 2267

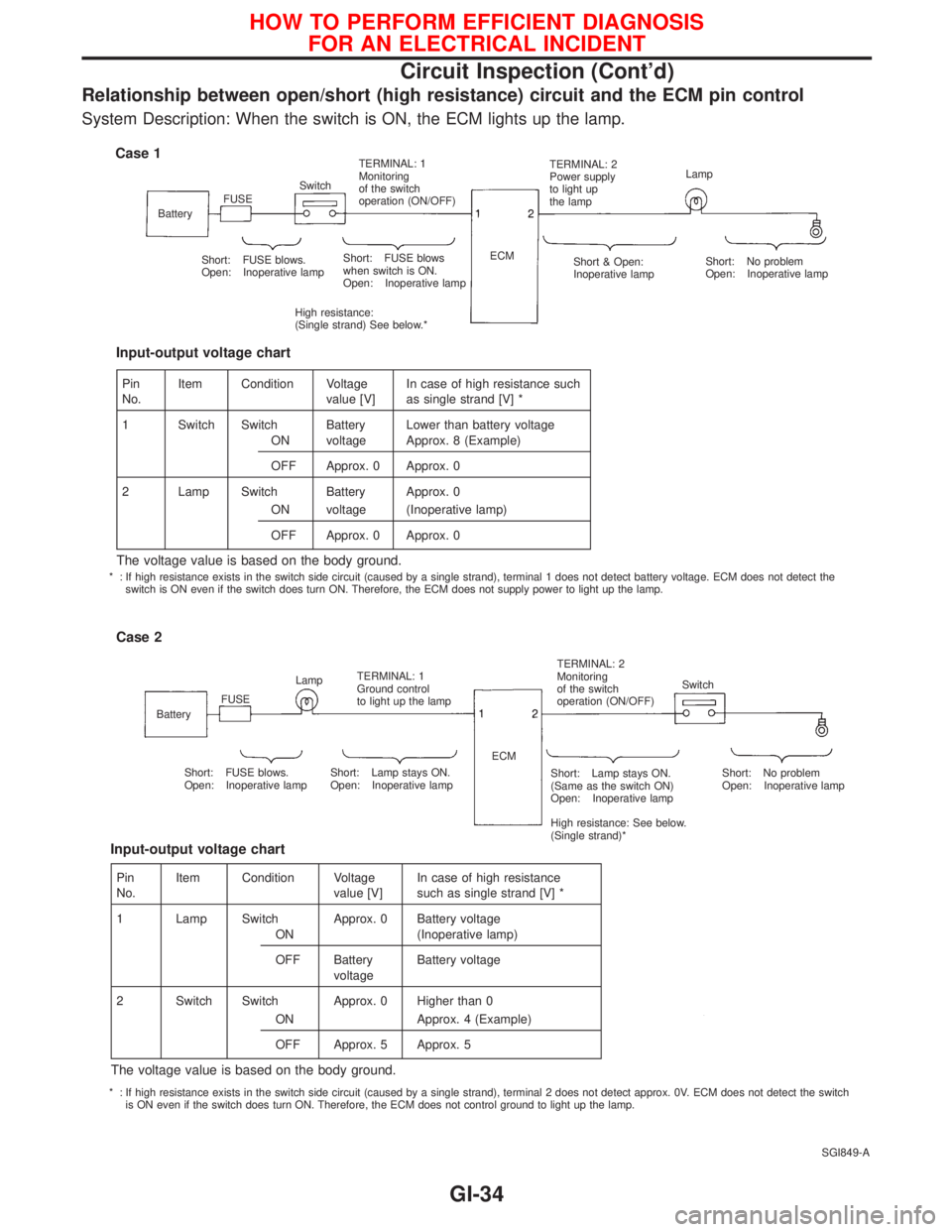

Relationship between open/short (high resistance) circuit and the ECM pin control

System Description: When the switch is ON, the ECM lights up the lamp.

SGI849-A

Case 1

BatteryFUSESwitchTERMINAL: 1

Monitoring

of the switch

operation (ON/OFF)TERMINAL: 2

Power supply

to light up

the lampLamp

Short: FUSE blows.

Open: Inoperative lampShort: FUSE blows

when switch is ON.

Open: Inoperative lamp

High resistance:

(Single strand) See below.*ECM

Short & Open:

Inoperative lampShort: No problem

Open: Inoperative lamp

Case 2

BatteryFUSELampTERMINAL: 1

Ground control

to light up the lampTERMINAL: 2

Monitoring

of the switch

operation (ON/OFF)Switch

Short: FUSE blows.

Open: Inoperative lampShort: Lamp stays ON.

Open: Inoperative lampShort: Lamp stays ON.

(Same as the switch ON)

Open: Inoperative lamp

High resistance: See below.

(Single strand)*Short: No problem

Open: Inoperative lamp ECM

Pin

No.Item Condition Voltage

value [V]In case of high resistance such

as single strand [V] *

1 Switch Switch Battery Lower than battery voltage

ON voltage Approx. 8 (Example)

OFF Approx. 0 Approx. 0

2 Lamp Switch Battery Approx. 0

ON voltage (Inoperative lamp)

OFF Approx. 0 Approx. 0

The voltage value is based on the body ground.

Input-output voltage chart

Pin

No.Item Condition Voltage

value [V]In case of high resistance

such as single strand [V] *

1 Lamp Switch Approx. 0 Battery voltage

ON (Inoperative lamp)

OFF Battery

voltageBattery voltage

2 Switch Switch Approx. 0 Higher than 0

ON Approx. 4 (Example)

OFF Approx. 5 Approx. 5

The voltage value is based on the body ground.

Input-output voltage chart

* : If high resistance exists in the switch side circuit (caused by a single strand), terminal 1 does not detect battery voltage. ECM does not detect the

switch is ON even if the switch does turn ON. Therefore, the ECM does not supply power to light up the lamp.

* : If high resistance exists in the switch side circuit (caused by a single strand), terminal 2 does not detect approx. 0V. ECM does not detect the switch

is ON even if the switch does turn ON. Therefore, the ECM does not control ground to light up the lamp.

HOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT

Circuit Inspection (Cont'd)

GI-34

Page 1830 of 2267

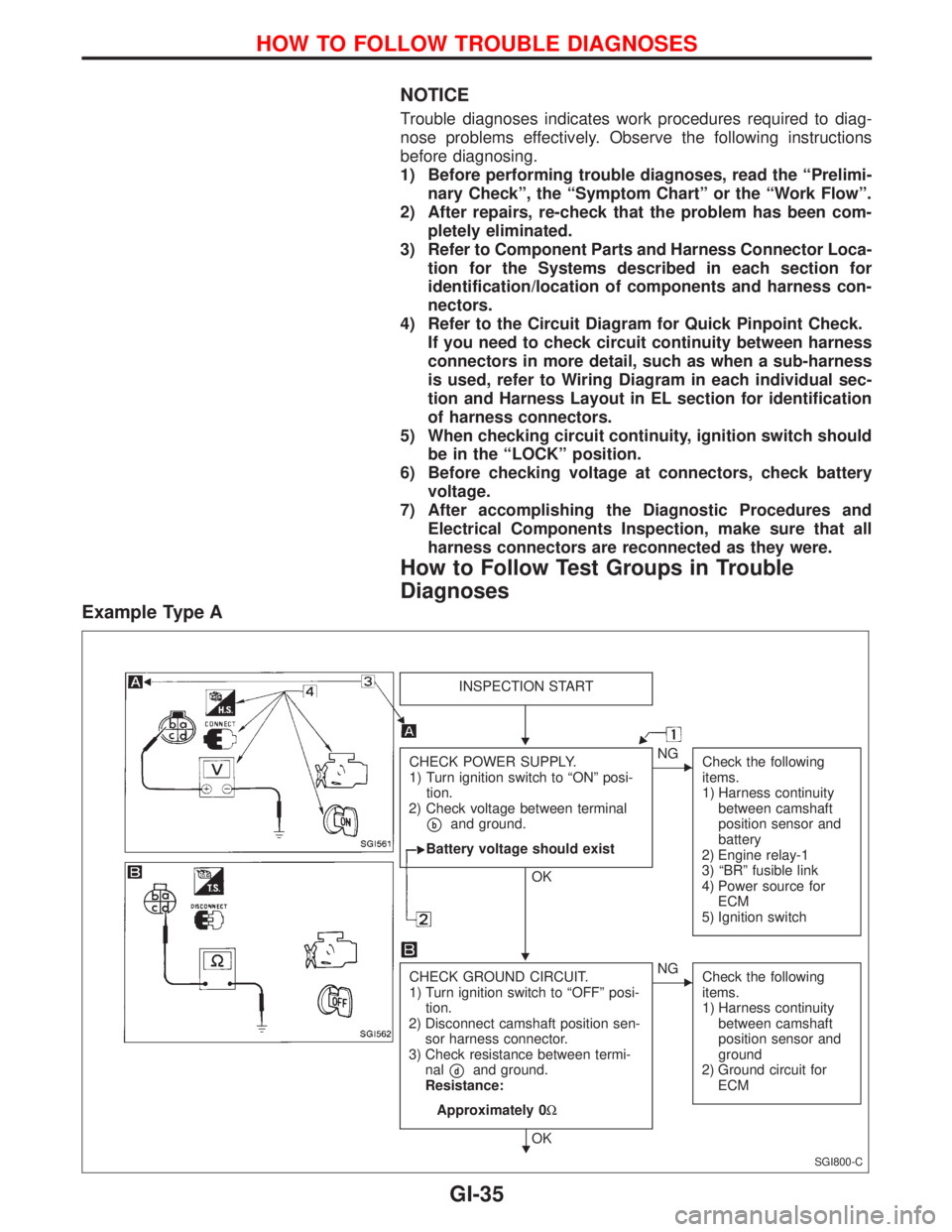

NOTICE

Trouble diagnoses indicates work procedures required to diag-

nose problems effectively. Observe the following instructions

before diagnosing.

1) Before performing trouble diagnoses, read the ªPrelimi-

nary Checkº, the ªSymptom Chartº or the ªWork Flowº.

2) After repairs, re-check that the problem has been com-

pletely eliminated.

3) Refer to Component Parts and Harness Connector Loca-

tion for the Systems described in each section for

identification/location of components and harness con-

nectors.

4) Refer to the Circuit Diagram for Quick Pinpoint Check.

If you need to check circuit continuity between harness

connectors in more detail, such as when a sub-harness

is used, refer to Wiring Diagram in each individual sec-

tion and Harness Layout in EL section for identification

of harness connectors.

5) When checking circuit continuity, ignition switch should

be in the ªLOCKº position.

6) Before checking voltage at connectors, check battery

voltage.

7) After accomplishing the Diagnostic Procedures and

Electrical Components Inspection, make sure that all

harness connectors are reconnected as they were.

How to Follow Test Groups in Trouble

Diagnoses

Example Type A

SGI800-C

INSPECTION START

CHECK POWER SUPPLY.

1) Turn ignition switch to ªONº posi-

tion.

2) Check voltage between terminal

pband ground.

Battery voltage should exist

OK

ENG

Check the following

items.

1) Harness continuity

between camshaft

position sensor and

battery

2) Engine relay-1

3) ªBRº fusible link

4) Power source for

ECM

5) Ignition switch

CHECK GROUND CIRCUIT.

1) Turn ignition switch to ªOFFº posi-

tion.

2) Disconnect camshaft position sen-

sor harness connector.

3) Check resistance between termi-

nal

pdand ground.

Resistance:

Approximately 0W

OK

ENG

Check the following

items.

1) Harness continuity

between camshaft

position sensor and

ground

2) Ground circuit for

ECM

H

H

H

HOW TO FOLLOW TROUBLE DIAGNOSES

GI-35