NISSAN PRIMERA 1999 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 1831 of 2267

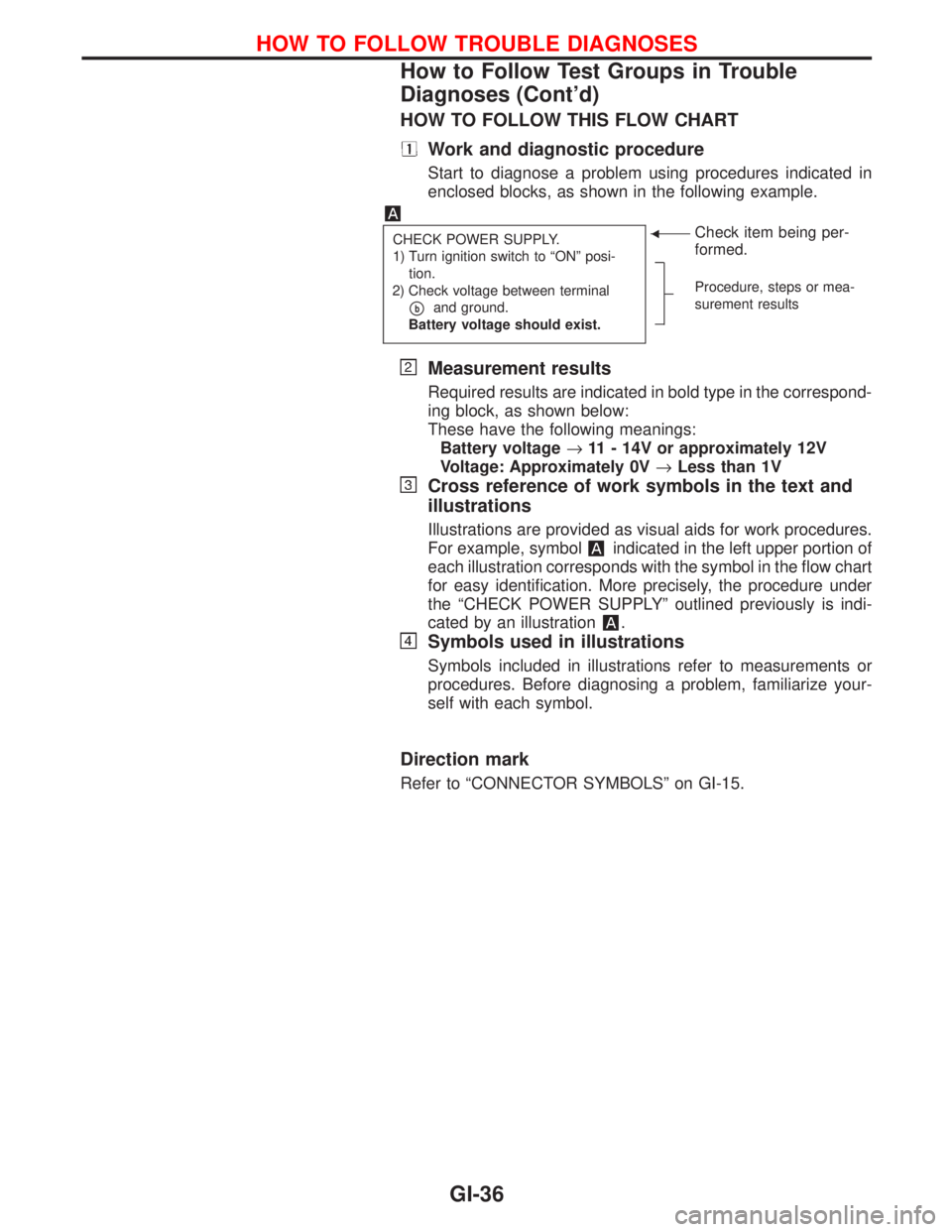

HOW TO FOLLOW THIS FLOW CHART

Work and diagnostic procedure

Start to diagnose a problem using procedures indicated in

enclosed blocks, as shown in the following example.

CHECK POWER SUPPLY.

1) Turn ignition switch to ªONº posi-

tion.

2) Check voltage between terminal

pband ground.

Battery voltage should exist.

FCheck item being per-

formed.

Procedure, steps or mea-

surement results

Measurement results

Required results are indicated in bold type in the correspond-

ing block, as shown below:

These have the following meanings:

Battery voltage®11 - 14V or approximately 12V

Voltage: Approximately 0V®Less than 1V

Cross reference of work symbols in the text and

illustrations

Illustrations are provided as visual aids for work procedures.

For example, symbol

indicated in the left upper portion of

each illustration corresponds with the symbol in the flow chart

for easy identification. More precisely, the procedure under

the ªCHECK POWER SUPPLYº outlined previously is indi-

cated by an illustration

.

Symbols used in illustrations

Symbols included in illustrations refer to measurements or

procedures. Before diagnosing a problem, familiarize your-

self with each symbol.

Direction mark

Refer to ªCONNECTOR SYMBOLSº on GI-15.

HOW TO FOLLOW TROUBLE DIAGNOSES

How to Follow Test Groups in Trouble

Diagnoses (Cont'd)

GI-36

Page 1832 of 2267

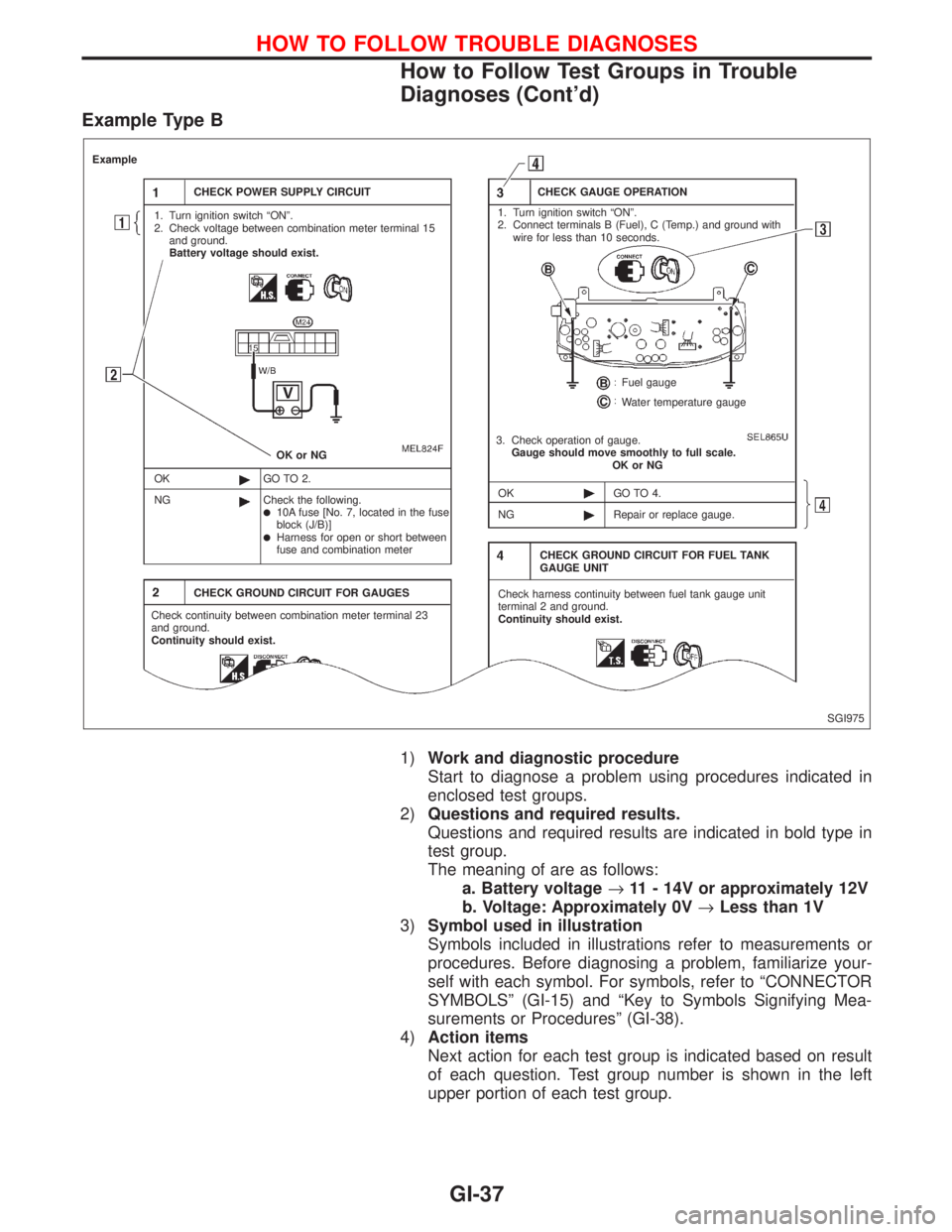

Example Type B

1)Work and diagnostic procedure

Start to diagnose a problem using procedures indicated in

enclosed test groups.

2)Questions and required results.

Questions and required results are indicated in bold type in

test group.

The meaning of are as follows:

a. Battery voltage®11 - 14V or approximately 12V

b. Voltage: Approximately 0V®Less than 1V

3)Symbol used in illustration

Symbols included in illustrations refer to measurements or

procedures. Before diagnosing a problem, familiarize your-

self with each symbol. For symbols, refer to ªCONNECTOR

SYMBOLSº (GI-15) and ªKey to Symbols Signifying Mea-

surements or Proceduresº (GI-38).

4)Action items

Next action for each test group is indicated based on result

of each question. Test group number is shown in the left

upper portion of each test group.

SGI975

Example

CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch ªONº.

2. Check voltage between combination meter terminal 15

and ground.

Battery voltage should exist.

OK or NG

OK

NGGO TO 2.

Check the following.

l10A fuse [No. 7, located in the fuse

block (J/B)]

lHarness for open or short between

fuse and combination meter

CHECK GROUND CIRCUIT FOR GAUGES

Check continuity between combination meter terminal 23

and ground.

Continuity should exist.CHECK GAUGE OPERATION

1. Turn ignition switch ªONº.

2. Connect terminals B (Fuel), C (Temp.) and ground with

wire for less than 10 seconds.

Fuel gauge

Water temperature gauge

3. Check operation of gauge.

Gauge should move smoothly to full scale.

OK or NG

OK

NGGO TO 4.

Repair or replace gauge.

CHECK GROUND CIRCUIT FOR FUEL TANK

GAUGE UNIT

Check harness continuity between fuel tank gauge unit

terminal 2 and ground.

Continuity should exist.

HOW TO FOLLOW TROUBLE DIAGNOSES

How to Follow Test Groups in Trouble

Diagnoses (Cont'd)

GI-37

Page 1833 of 2267

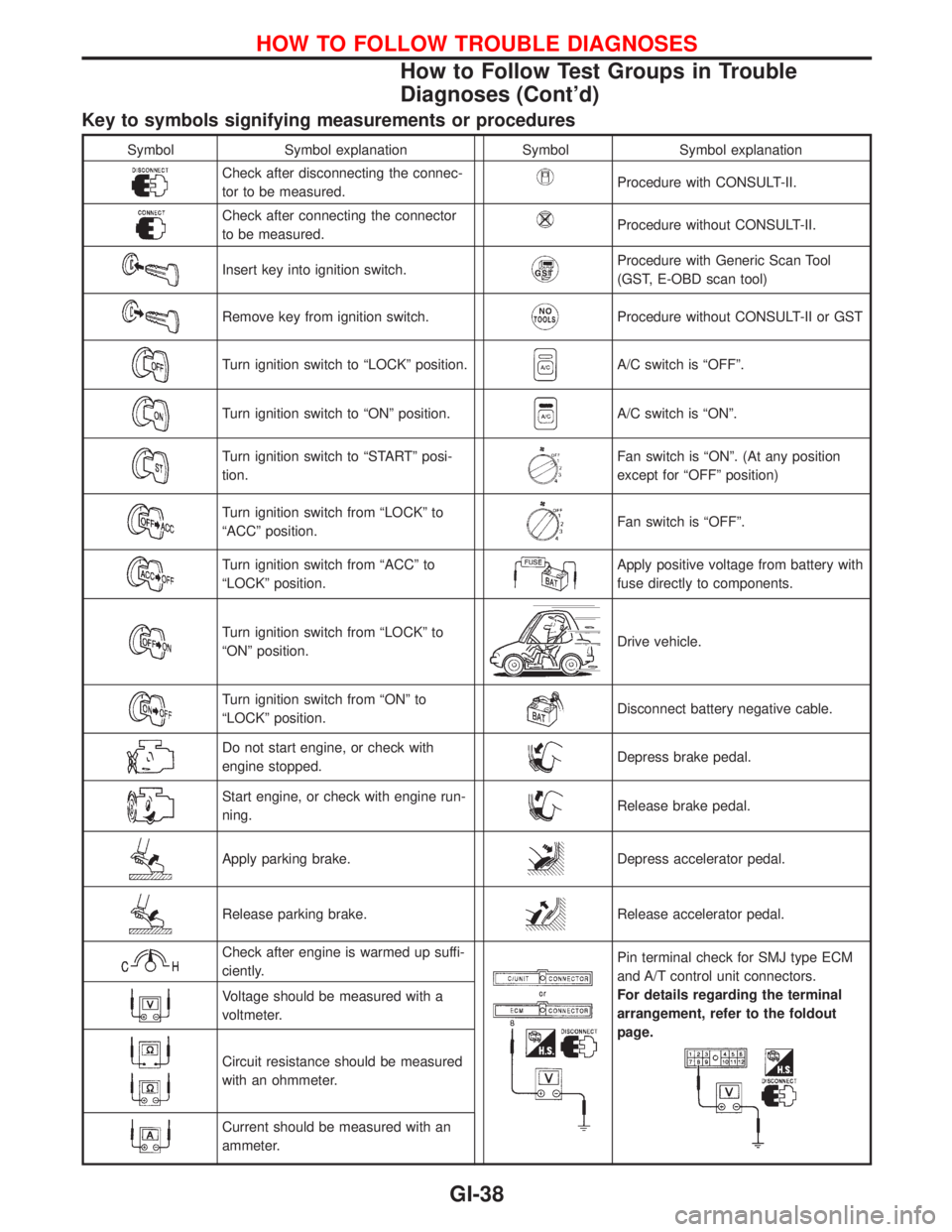

Key to symbols signifying measurements or procedures

Symbol Symbol explanation Symbol Symbol explanation

Check after disconnecting the connec-

tor to be measured.Procedure with CONSULT-II.

Check after connecting the connector

to be measured.Procedure without CONSULT-II.

Insert key into ignition switch.Procedure with Generic Scan Tool

(GST, E-OBD scan tool)

Remove key from ignition switch.Procedure without CONSULT-II or GST

Turn ignition switch to ªLOCKº position.A/C switch is ªOFFº.

Turn ignition switch to ªONº position.A/C switch is ªONº.

Turn ignition switch to ªSTARTº posi-

tion.Fan switch is ªONº. (At any position

except for ªOFFº position)

Turn ignition switch from ªLOCKº to

ªACCº position.Fan switch is ªOFFº.

Turn ignition switch from ªACCº to

ªLOCKº position.Apply positive voltage from battery with

fuse directly to components.

Turn ignition switch from ªLOCKº to

ªONº position.Drive vehicle.

Turn ignition switch from ªONº to

ªLOCKº position.Disconnect battery negative cable.

Do not start engine, or check with

engine stopped.Depress brake pedal.

Start engine, or check with engine run-

ning.Release brake pedal.

Apply parking brake.Depress accelerator pedal.

Release parking brake.Release accelerator pedal.

Check after engine is warmed up suffi-

ciently.Pin terminal check for SMJ type ECM

and A/T control unit connectors.

For details regarding the terminal

arrangement, refer to the foldout

page.

Voltage should be measured with a

voltmeter.

Circuit resistance should be measured

with an ohmmeter.

Current should be measured with an

ammeter.

HOW TO FOLLOW TROUBLE DIAGNOSES

How to Follow Test Groups in Trouble

Diagnoses (Cont'd)

GI-38

Page 1834 of 2267

Function and System Application

Diagnostic

test modeFunction ENGINE H×CVT ABSAIR

BAGNATS

Work supportThis mode enables a technician to adjust some devices faster

and more accurate by following the indications on CONSULT-II.´ÐÐÐÐ

Self-diagnostic

resultsSelf-diagnostic results can be read and erased quickly.´xx´´

Trouble diagnostic

recordCurrent self-diagnostic results and all trouble diagnostic records

previously stored can be read.ÐÐÐxÐ

ECU discriminated

No.Classification number of a replacement ECU can be read to pre-

vent an incorrect ECU from being installed.ÐÐдÐ

Data monitor Input/Output data in the ECM can be read.´xxÐÐ

DTC work supportThis mode enables a technician to set operating conditions to

confirm self-diagnosis status/results.x x ÐÐÐ

Active testDiagnostic Test Mode in which CONSULT-II drives some actua-

tors apart from the ECMs and also shifts some parameters in a

specified range.´ÐxÐÐ

ECM part number ECM part number can be read.´xxÐÐ

Control unit initialisa-

tionAll registered ignition key IDs in NATS components can be initia-

lised and new IDs can be registered.ÐÐÐÐ x

DTC & SRT confirma-

tionThe results of SRT (System Readiness Test) and the self-diag-

nosis status/results can be confirmed.x ÐÐÐÐ

´: Applicable

*1: NATS: Nissan Anti-Theft System

Nickel Metal Hydride Battery Replacement

CONSULT-II contains a nickel metal hydride battery. When replacing the battery obey the following:

WARNING:

Replace the nickel metal hydride battery with genuine CONSULT-II battery only. Use of another bat-

tery may present a risk of fire or explosion. The battery may present a fire or chemical burn hazard

if mistreated. Do not recharge, disassemble of dispose of in fire.

Keep the battery out of reach of children and discard used battery conforming to the local regula-

tions.

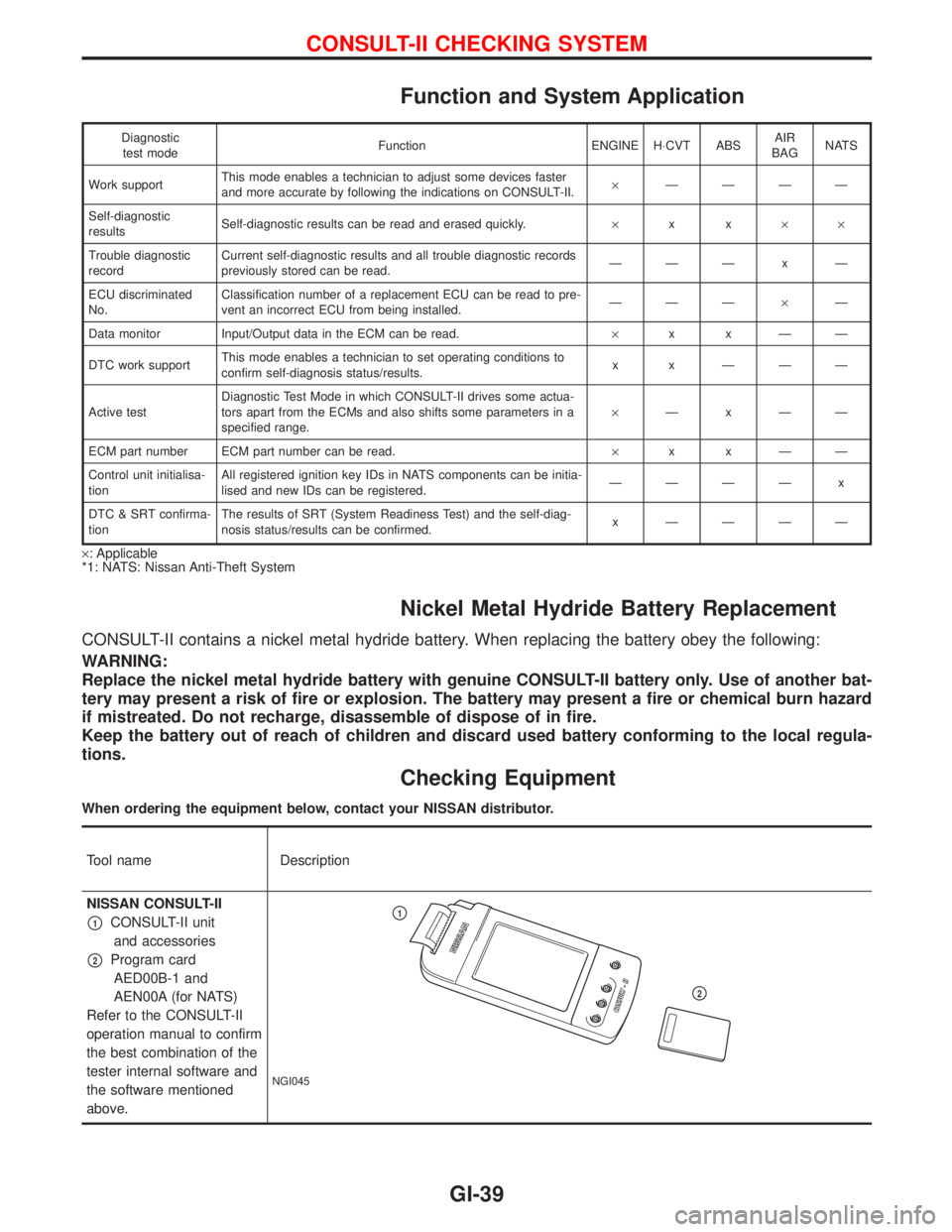

Checking Equipment

When ordering the equipment below, contact your NISSAN distributor.

Tool name Description

NISSAN CONSULT-II

p1CONSULT-II unit

and accessories

p2Program card

AED00B-1 and

AEN00A (for NATS)

Refer to the CONSULT-II

operation manual to confirm

the best combination of the

tester internal software and

the software mentioned

above.

NGI045

p1

p2

CONSULT-II CHECKING SYSTEM

GI-39

Page 1835 of 2267

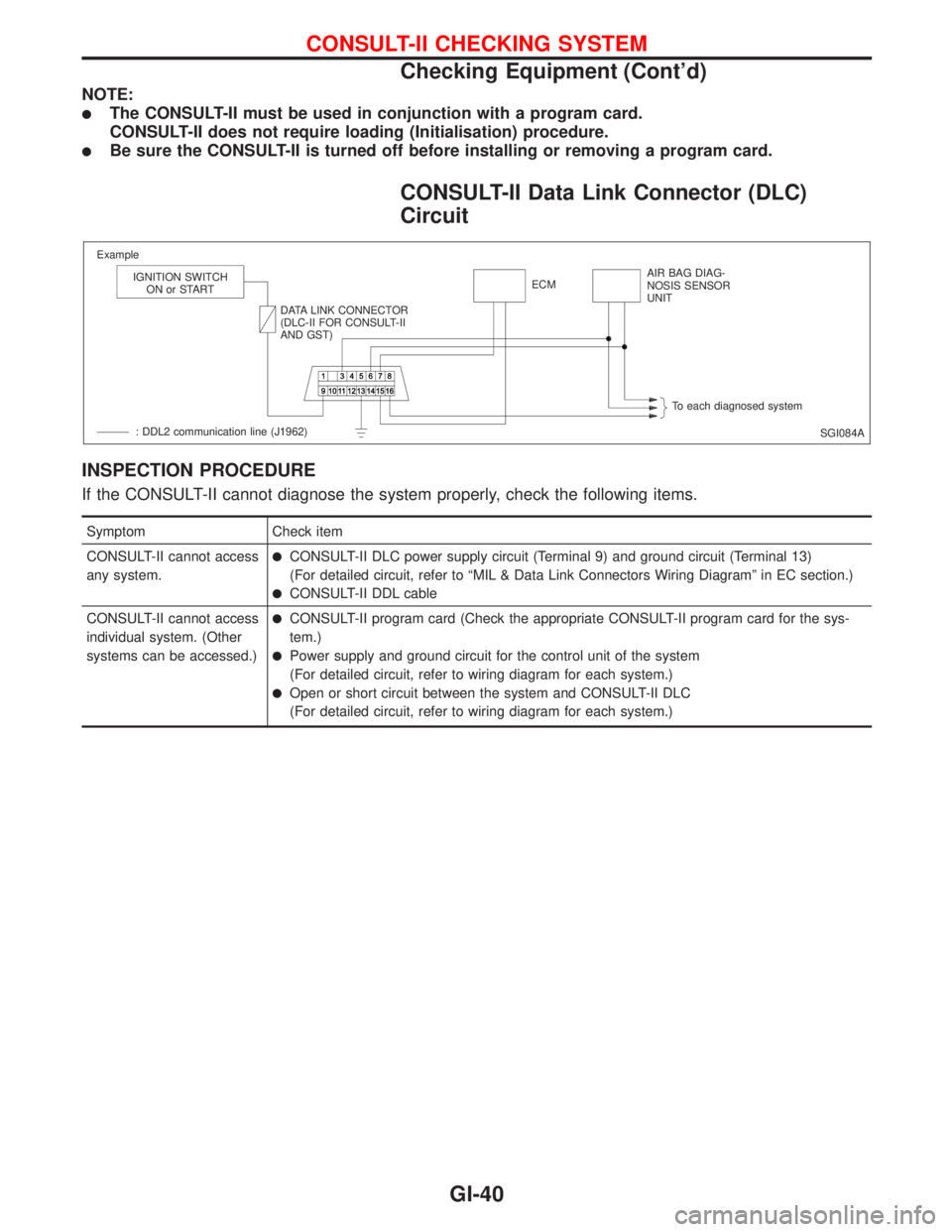

NOTE:

lThe CONSULT-II must be used in conjunction with a program card.

CONSULT-II does not require loading (Initialisation) procedure.

lBe sure the CONSULT-II is turned off before installing or removing a program card.

CONSULT-II Data Link Connector (DLC)

Circuit

INSPECTION PROCEDURE

If the CONSULT-II cannot diagnose the system properly, check the following items.

Symptom Check item

CONSULT-II cannot access

any system.

lCONSULT-II DLC power supply circuit (Terminal 9) and ground circuit (Terminal 13)

(For detailed circuit, refer to ªMIL & Data Link Connectors Wiring Diagramº in EC section.)

lCONSULT-II DDL cable

CONSULT-II cannot access

individual system. (Other

systems can be accessed.)

lCONSULT-II program card (Check the appropriate CONSULT-II program card for the sys-

tem.)

lPower supply and ground circuit for the control unit of the system

(For detailed circuit, refer to wiring diagram for each system.)

lOpen or short circuit between the system and CONSULT-II DLC

(For detailed circuit, refer to wiring diagram for each system.)

SGI084A Example

IGNITION SWITCH

ON or START

DATA LINK CONNECTOR

(DLC-II FOR CONSULT-II

AND GST)ECMAIR BAG DIAG-

NOSIS SENSOR

UNIT

To each diagnosed system

: DDL2 communication line (J1962)

CONSULT-II CHECKING SYSTEM

Checking Equipment (Cont'd)

GI-40

Page 1836 of 2267

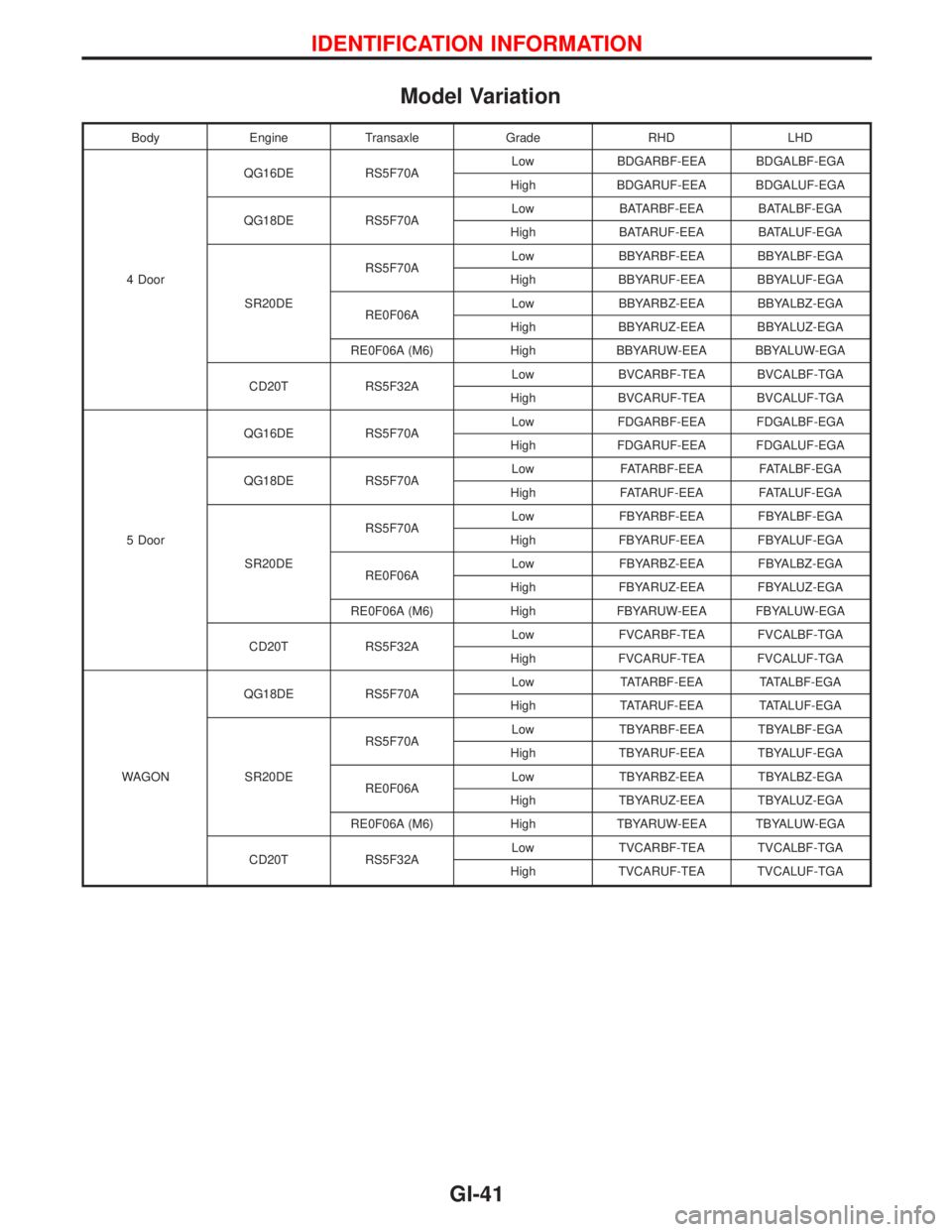

Model Variation

Body Engine Transaxle Grade RHD LHD

4 DoorQG16DE RS5F70ALow BDGARBF-EEA BDGALBF-EGA

High BDGARUF-EEA BDGALUF-EGA

QG18DE RS5F70ALow BATARBF-EEA BATALBF-EGA

High BATARUF-EEA BATALUF-EGA

SR20DERS5F70ALow BBYARBF-EEA BBYALBF-EGA

High BBYARUF-EEA BBYALUF-EGA

RE0F06ALow BBYARBZ-EEA BBYALBZ-EGA

High BBYARUZ-EEA BBYALUZ-EGA

RE0F06A (M6) High BBYARUW-EEA BBYALUW-EGA

CD20T RS5F32ALow BVCARBF-TEA BVCALBF-TGA

High BVCARUF-TEA BVCALUF-TGA

5 DoorQG16DE RS5F70ALow FDGARBF-EEA FDGALBF-EGA

High FDGARUF-EEA FDGALUF-EGA

QG18DE RS5F70ALow FATARBF-EEA FATALBF-EGA

High FATARUF-EEA FATALUF-EGA

SR20DERS5F70ALow FBYARBF-EEA FBYALBF-EGA

High FBYARUF-EEA FBYALUF-EGA

RE0F06ALow FBYARBZ-EEA FBYALBZ-EGA

High FBYARUZ-EEA FBYALUZ-EGA

RE0F06A (M6) High FBYARUW-EEA FBYALUW-EGA

CD20T RS5F32ALow FVCARBF-TEA FVCALBF-TGA

High FVCARUF-TEA FVCALUF-TGA

WAGONQG18DE RS5F70ALow TATARBF-EEATATALBF-EGA

HighTATARUF-EEATATALUF-EGA

SR20DERS5F70ALow TBYARBF-EEA TBYALBF-EGA

High TBYARUF-EEA TBYALUF-EGA

RE0F06ALow TBYARBZ-EEA TBYALBZ-EGA

High TBYARUZ-EEA TBYALUZ-EGA

RE0F06A (M6) High TBYARUW-EEA TBYALUW-EGA

CD20T RS5F32ALow TVCARBF-TEA TVCALBF-TGA

High TVCARUF-TEA TVCALUF-TGA

IDENTIFICATION INFORMATION

GI-41

Page 1837 of 2267

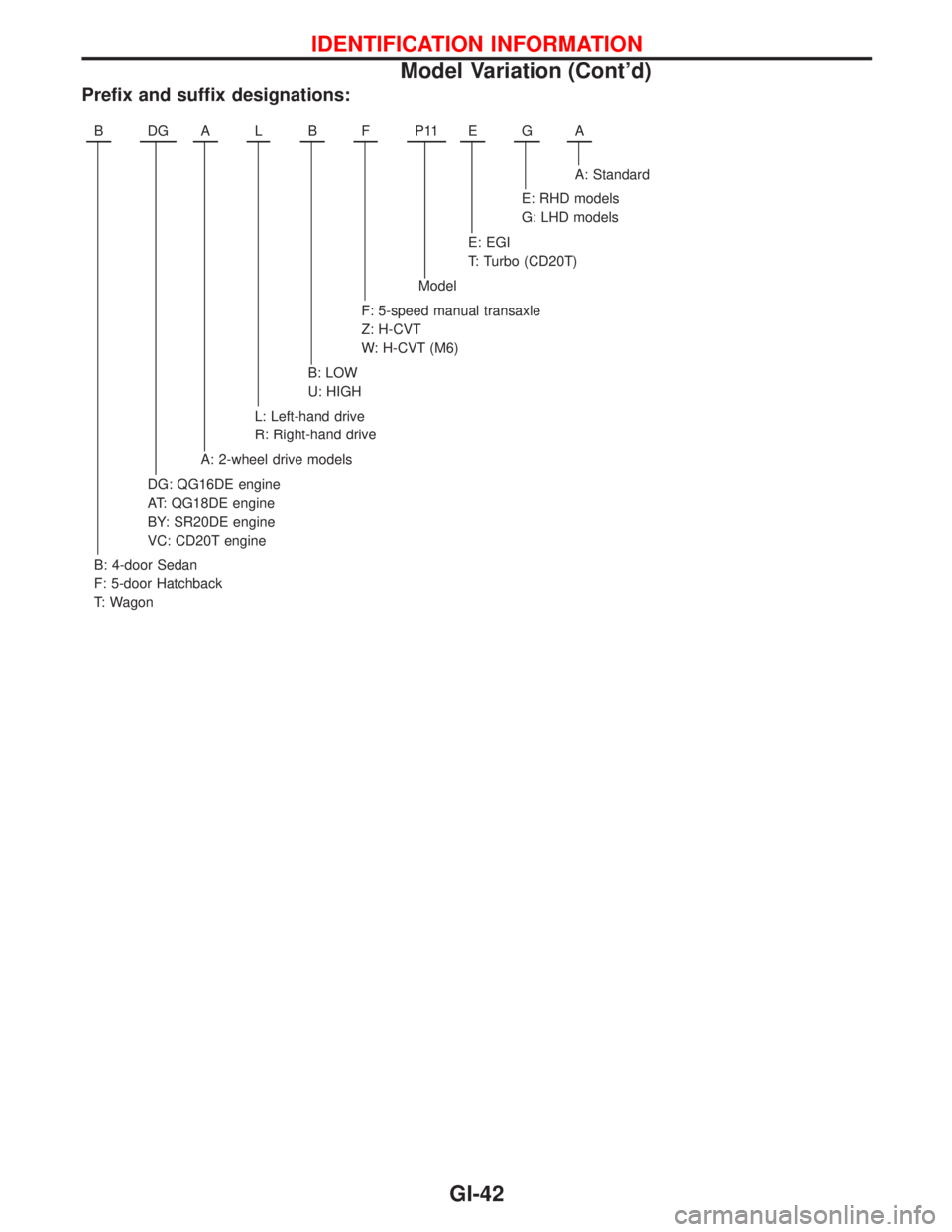

Prefix and suffix designations:

BDGALBFP11EGA

A: Standard

E: RHD models

G: LHD models

E: EGI

T: Turbo (CD20T)

Model

F: 5-speed manual transaxle

Z: H-CVT

W: H-CVT (M6)

B: LOW

U: HIGH

L: Left-hand drive

R: Right-hand drive

A: 2-wheel drive models

DG: QG16DE engine

AT: QG18DE engine

BY: SR20DE engine

VC: CD20T engine

B: 4-door Sedan

F: 5-door Hatchback

T: Wagon

IDENTIFICATION INFORMATION

Model Variation (Cont'd)

GI-42

Page 1838 of 2267

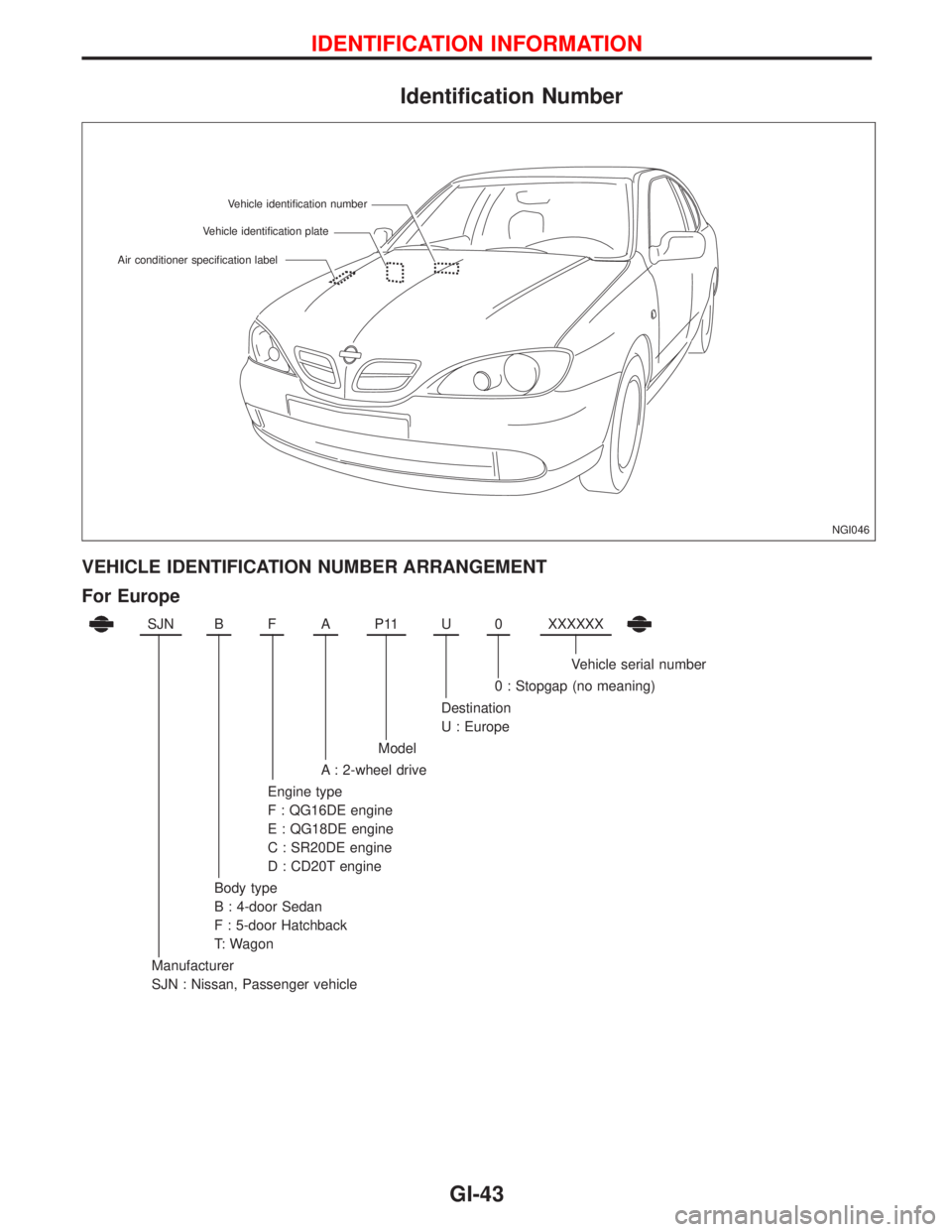

Identification Number

VEHICLE IDENTIFICATION NUMBER ARRANGEMENT

For Europe

SJNBFAP11U0XXXXXX

Vehicle serial number

0 : Stopgap (no meaning)

Destination

U : Europe

Model

A : 2-wheel drive

Engine type

F : QG16DE engine

E : QG18DE engine

C : SR20DE engine

D : CD20T engine

Body type

B : 4-door Sedan

F : 5-door Hatchback

T: Wagon

Manufacturer

SJN : Nissan, Passenger vehicle

NGI046 Vehicle identification plateVehicle identification number

Air conditioner specification label

IDENTIFICATION INFORMATION

GI-43

Page 1839 of 2267

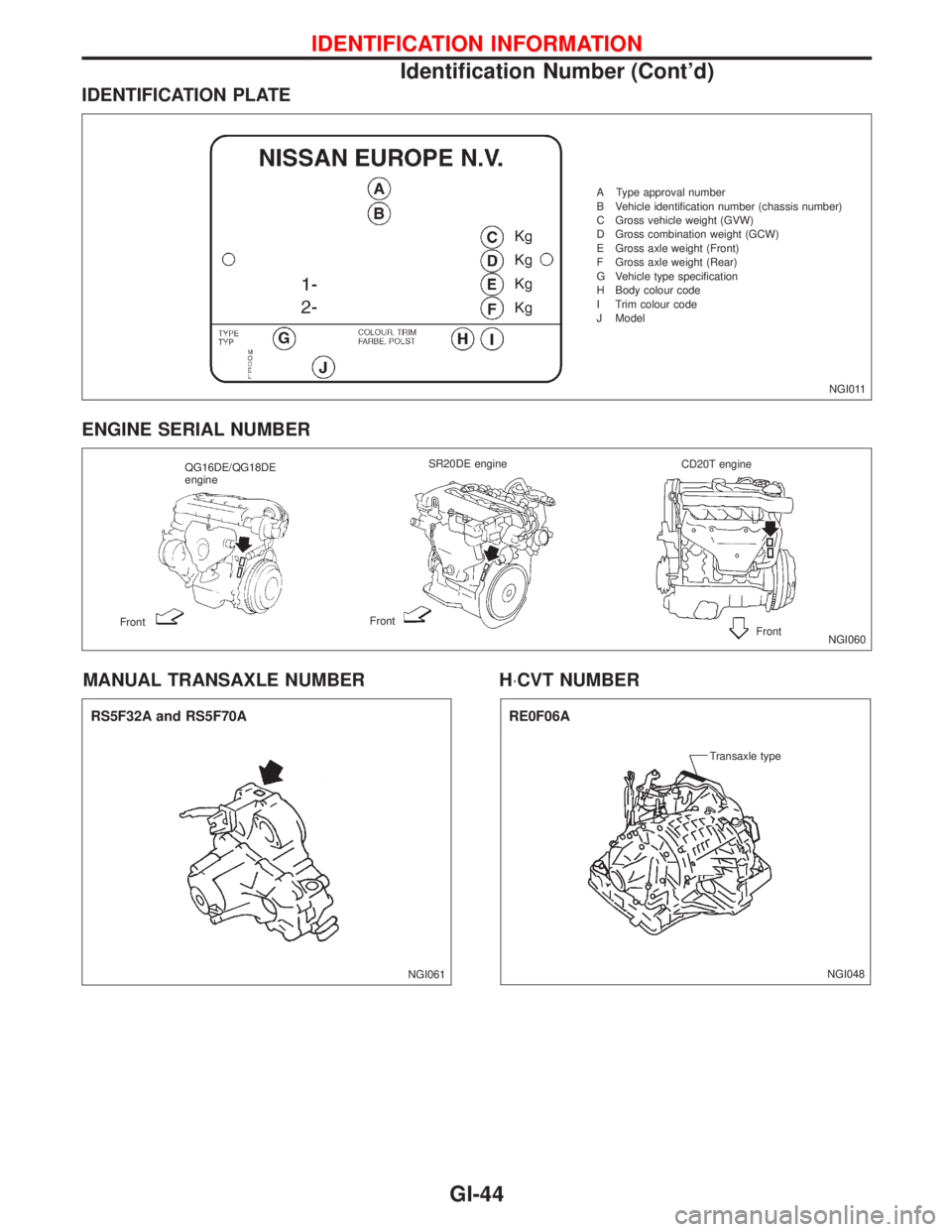

IDENTIFICATION PLATE

ENGINE SERIAL NUMBER

MANUAL TRANSAXLE NUMBER H×CVT NUMBER

NGI011 A Type approval number

B Vehicle identification number (chassis number)

C Gross vehicle weight (GVW)

D Gross combination weight (GCW)

E Gross axle weight (Front)

F Gross axle weight (Rear)

G Vehicle type specification

H Body colour code

I Trim colour code

J Model

NGI060 QG16DE/QG18DE

engineSR20DE engine

CD20T engine

FrontFront

Front

NGI061

RS5F32A and RS5F70A

NGI048 Transaxle type

RE0F06A

IDENTIFICATION INFORMATION

Identification Number (Cont'd)

GI-44

Page 1840 of 2267

Dimensions

Unit: mm (in)

H/B & Sedan Wagon

Overall length 4522 (178.03) 4566 (179.76)

Overall width 1715 (67.52) *1 1715 (67.52) *1

Overall height 1410 (55.51) *2 1410 (55.51) *2

Front tread 1470 (57.87) 1470 (57.87)

Rear tread 1450 (57.09) 1450 (57.09)

Wheelbase 2600 (102.36) 2600 (102.36)

*1: Without mirrors.

*2: Without roof mounted antenna.

Wheels and Tires

Road

wheelSteel 15 x 6J

ÐÐÐ

Offset

mm (in)45 (1.77)

Aluminum

Ð15x6J 15x6J 16x7J

Offset

mm (in)45 (1.77) 45 (1.77) 45 (1.77)

Tire

sizeConven-

tional185/65HR15 195/60VR15 195/60R15 205/50R16

SpareConven-

tionalConven-

tionalConven-

tional185/65

HR15

IDENTIFICATION INFORMATION

GI-45