check engine NISSAN PRIMERA 1999 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 880 of 2267

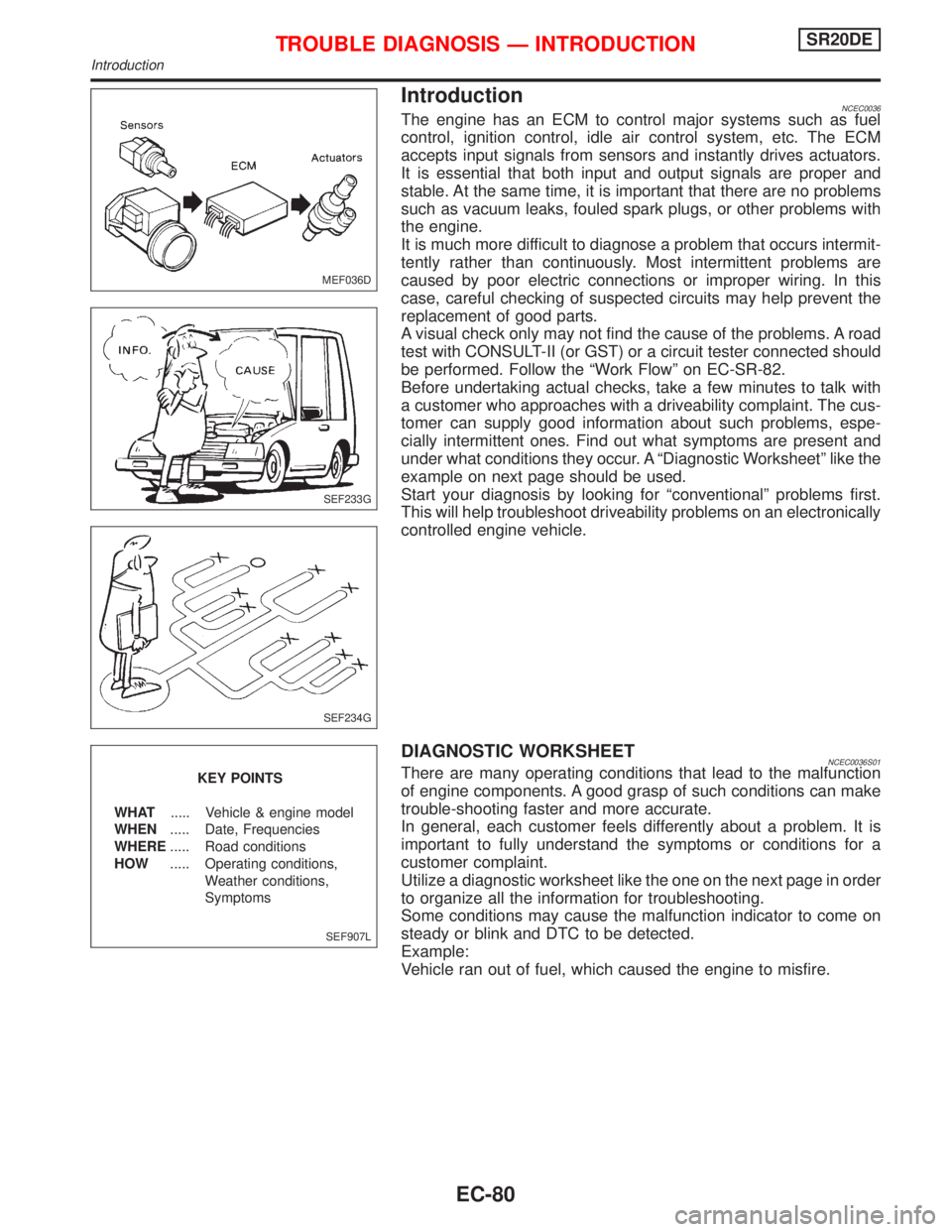

IntroductionNCEC0036The engine has an ECM to control major systems such as fuel

control, ignition control, idle air control system, etc. The ECM

accepts input signals from sensors and instantly drives actuators.

It is essential that both input and output signals are proper and

stable. At the same time, it is important that there are no problems

such as vacuum leaks, fouled spark plugs, or other problems with

the engine.

It is much more difficult to diagnose a problem that occurs intermit-

tently rather than continuously. Most intermittent problems are

caused by poor electric connections or improper wiring. In this

case, careful checking of suspected circuits may help prevent the

replacement of good parts.

A visual check only may not find the cause of the problems. A road

test with CONSULT-II (or GST) or a circuit tester connected should

be performed. Follow the ªWork Flowº on EC-SR-82.

Before undertaking actual checks, take a few minutes to talk with

a customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such problems, espe-

cially intermittent ones. Find out what symptoms are present and

under what conditions they occur. A ªDiagnostic Worksheetº like the

example on next page should be used.

Start your diagnosis by looking for ªconventionalº problems first.

This will help troubleshoot driveability problems on an electronically

controlled engine vehicle.

DIAGNOSTIC WORKSHEETNCEC0036S01There are many operating conditions that lead to the malfunction

of engine components. A good grasp of such conditions can make

trouble-shooting faster and more accurate.

In general, each customer feels differently about a problem. It is

important to fully understand the symptoms or conditions for a

customer complaint.

Utilize a diagnostic worksheet like the one on the next page in order

to organize all the information for troubleshooting.

Some conditions may cause the malfunction indicator to come on

steady or blink and DTC to be detected.

Example:

Vehicle ran out of fuel, which caused the engine to misfire.

MEF036D

SEF233G

SEF234G

SEF907L

KEY POINTS

WHAT..... Vehicle & engine model

WHEN..... Date, Frequencies

WHERE..... Road conditions

HOW..... Operating conditions,

Weather conditions,

Symptoms

TROUBLE DIAGNOSIS Ð INTRODUCTIONSR20DE

Introduction

EC-80

Page 883 of 2267

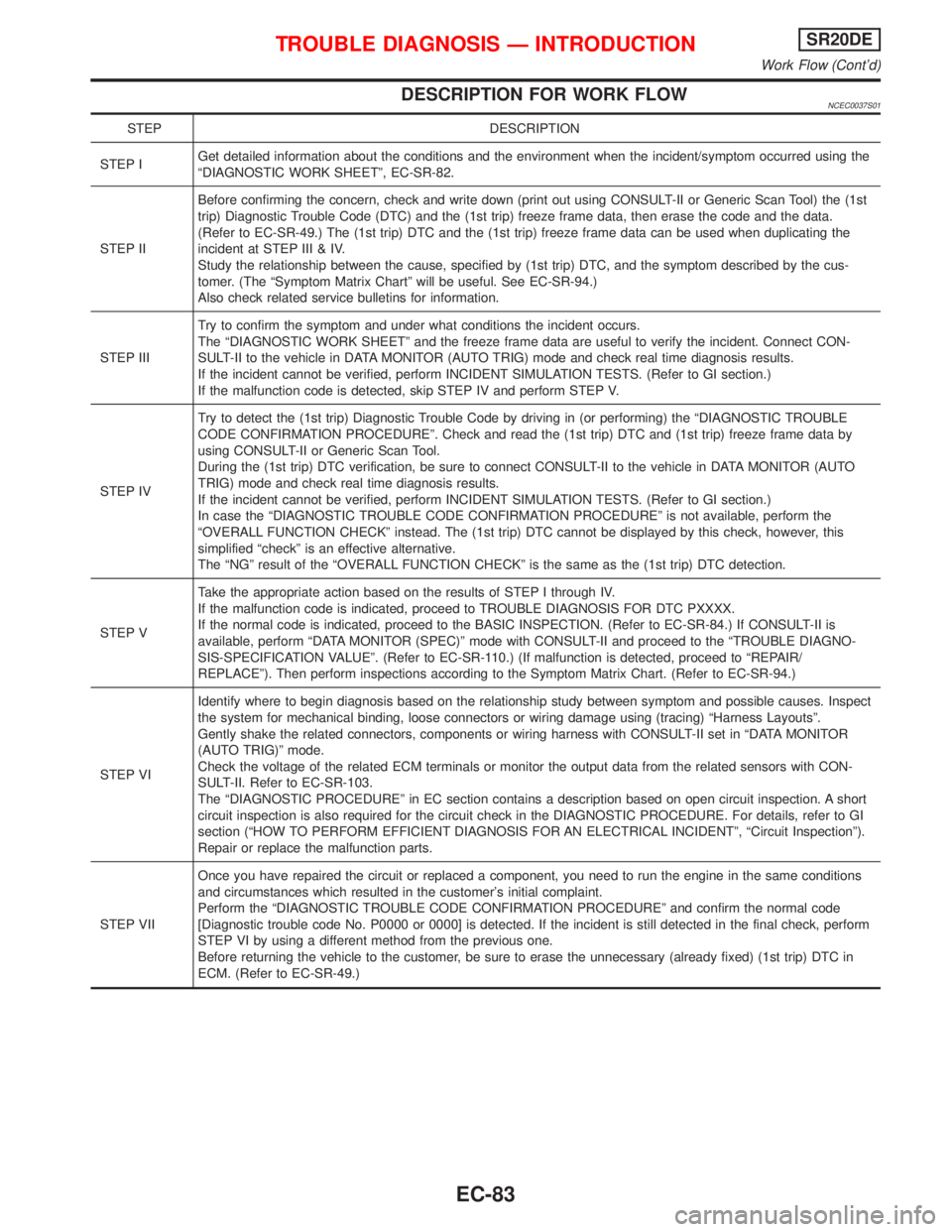

DESCRIPTION FOR WORK FLOWNCEC0037S01

STEP DESCRIPTION

STEP IGet detailed information about the conditions and the environment when the incident/symptom occurred using the

ªDIAGNOSTIC WORK SHEETº, EC-SR-82.

STEP IIBefore confirming the concern, check and write down (print out using CONSULT-II or Generic Scan Tool) the (1st

trip) Diagnostic Trouble Code (DTC) and the (1st trip) freeze frame data, then erase the code and the data.

(Refer to EC-SR-49.) The (1st trip) DTC and the (1st trip) freeze frame data can be used when duplicating the

incident at STEP III & IV.

Study the relationship between the cause, specified by (1st trip) DTC, and the symptom described by the cus-

tomer. (The ªSymptom Matrix Chartº will be useful. See EC-SR-94.)

Also check related service bulletins for information.

STEP IIITry to confirm the symptom and under what conditions the incident occurs.

The ªDIAGNOSTIC WORK SHEETº and the freeze frame data are useful to verify the incident. Connect CON-

SULT-II to the vehicle in DATA MONITOR (AUTO TRIG) mode and check real time diagnosis results.

If the incident cannot be verified, perform INCIDENT SIMULATION TESTS. (Refer to GI section.)

If the malfunction code is detected, skip STEP IV and perform STEP V.

STEP IVTry to detect the (1st trip) Diagnostic Trouble Code by driving in (or performing) the ªDIAGNOSTIC TROUBLE

CODE CONFIRMATION PROCEDUREº. Check and read the (1st trip) DTC and (1st trip) freeze frame data by

using CONSULT-II or Generic Scan Tool.

During the (1st trip) DTC verification, be sure to connect CONSULT-II to the vehicle in DATA MONITOR (AUTO

TRIG) mode and check real time diagnosis results.

If the incident cannot be verified, perform INCIDENT SIMULATION TESTS. (Refer to GI section.)

In case the ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCEDUREº is not available, perform the

ªOVERALL FUNCTION CHECKº instead. The (1st trip) DTC cannot be displayed by this check, however, this

simplified ªcheckº is an effective alternative.

The ªNGº result of the ªOVERALL FUNCTION CHECKº is the same as the (1st trip) DTC detection.

STEP VTake the appropriate action based on the results of STEP I through IV.

If the malfunction code is indicated, proceed to TROUBLE DIAGNOSIS FOR DTC PXXXX.

If the normal code is indicated, proceed to the BASIC INSPECTION. (Refer to EC-SR-84.) If CONSULT-II is

available, perform ªDATA MONITOR (SPEC)º mode with CONSULT-II and proceed to the ªTROUBLE DIAGNO-

SIS-SPECIFICATION VALUEº. (Refer to EC-SR-110.) (If malfunction is detected, proceed to ªREPAIR/

REPLACEº). Then perform inspections according to the Symptom Matrix Chart. (Refer to EC-SR-94.)

STEP VIIdentify where to begin diagnosis based on the relationship study between symptom and possible causes. Inspect

the system for mechanical binding, loose connectors or wiring damage using (tracing) ªHarness Layoutsº.

Gently shake the related connectors, components or wiring harness with CONSULT-II set in ªDATA MONITOR

(AUTO TRIG)º mode.

Check the voltage of the related ECM terminals or monitor the output data from the related sensors with CON-

SULT-II. Refer to EC-SR-103.

The ªDIAGNOSTIC PROCEDUREº in EC section contains a description based on open circuit inspection. A short

circuit inspection is also required for the circuit check in the DIAGNOSTIC PROCEDURE. For details, refer to GI

section (ªHOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENTº, ªCircuit Inspectionº).

Repair or replace the malfunction parts.

STEP VIIOnce you have repaired the circuit or replaced a component, you need to run the engine in the same conditions

and circumstances which resulted in the customer's initial complaint.

Perform the ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCEDUREº and confirm the normal code

[Diagnostic trouble code No. P0000 or 0000] is detected. If the incident is still detected in the final check, perform

STEP VI by using a different method from the previous one.

Before returning the vehicle to the customer, be sure to erase the unnecessary (already fixed) (1st trip) DTC in

ECM. (Refer to EC-SR-49.)

TROUBLE DIAGNOSIS Ð INTRODUCTIONSR20DE

Work Flow (Cont'd)

EC-83

Page 884 of 2267

Basic InspectionNCEC0038Precaution:

Perform Basic Inspection without electrical or mechanical loads applied;

IHeadlamp switch is OFF,

IOn vehicles equipped with daytime running light systems, set lighting switch to the 1st position to light only

small lamps.

IAir conditioner switch is OFF,

IRear window defogger switch is OFF,

ISteering wheel is in the straight-ahead position, etc.

1 INSPECTION START

1. Check service records for any recent repairs that may indicate a related problem, or the current need for scheduled maintenance.

2. Open engine hood and check the following:

IHarness connectors for improper connections

IVacuum hoses for splits, kinks, or improper connections

IWiring for improper connections, pinches, or cuts

IAir cleaner clogging

IHoses and ducts for leaks

SEF983U

©GO TO 2.

2 CHECK THROTTLE DRUM OPERATION

Confirm that throttle drum is in contact with stopper.

OK or NG

OK (With CONSULT-II)©GO TO 5.

OK (Without CONSULT-II)©GO TO 8.

NG©GO TO 3.

3 CHECK ACCELERATOR WIRE INSTALLATION

Check accelerator wire for slack.

OK or NG

OK©GO TO 4.

NG©Adjust accelerator wire. Refer to FE-section, ªAdjusting Accelerator Wireº.

4 CHECK THROTTLE VALVE OPERATION

1. Remove intake air ducts.

2. Check throttle valve operation when moving throttle drum by hand.

OK or NG

OK©Retighten the throttle drum fixing nuts.

NG©Clean the throttle body and throttle valve.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONSR20DE

Basic Inspection

EC-84

Page 885 of 2267

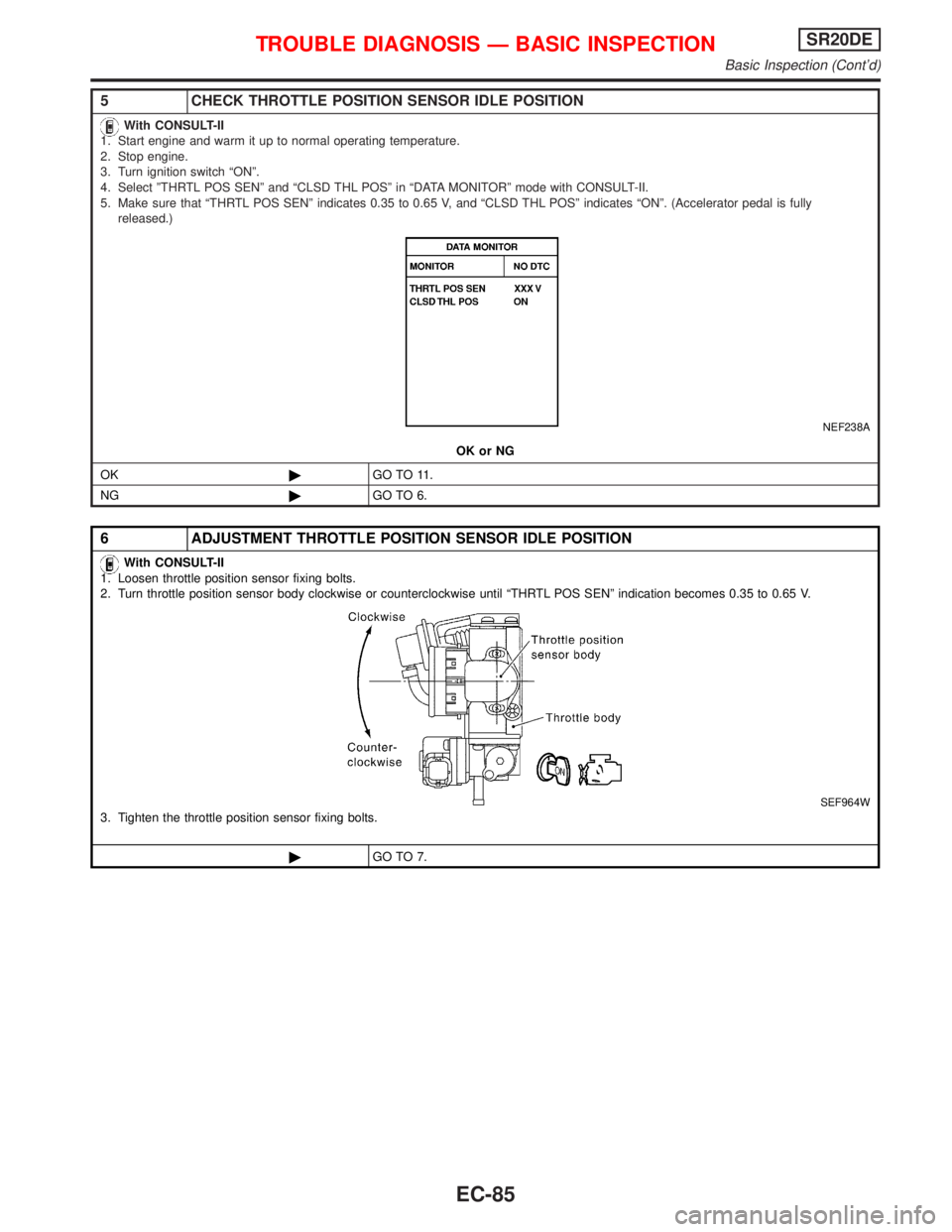

5 CHECK THROTTLE POSITION SENSOR IDLE POSITION

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Stop engine.

3. Turn ignition switch ªONº.

4. Select ºTHRTL POS SENº and ªCLSD THL POSº in ªDATA MONITORº mode with CONSULT-II.

5. Make sure that ªTHRTL POS SENº indicates 0.35 to 0.65 V, and ªCLSD THL POSº indicates ªONº. (Accelerator pedal is fully

released.)

NEF238A

OK or NG

OK©GO TO 11.

NG©GO TO 6.

6 ADJUSTMENT THROTTLE POSITION SENSOR IDLE POSITION

With CONSULT-II

1. Loosen throttle position sensor fixing bolts.

2. Turn throttle position sensor body clockwise or counterclockwise until ªTHRTL POS SENº indication becomes 0.35 to 0.65 V.

SEF964W3. Tighten the throttle position sensor fixing bolts.

©GO TO 7.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONSR20DE

Basic Inspection (Cont'd)

EC-85

Page 886 of 2267

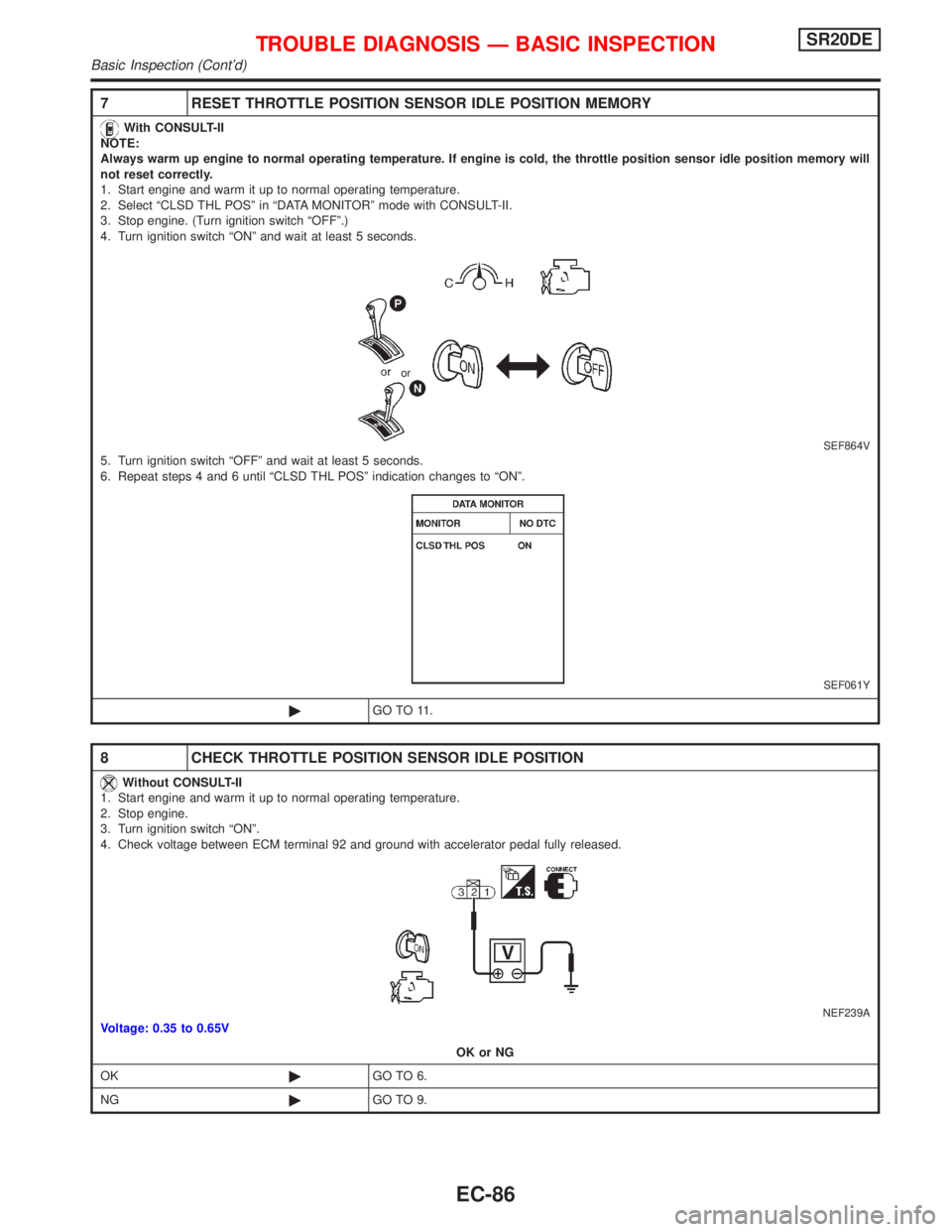

7 RESET THROTTLE POSITION SENSOR IDLE POSITION MEMORY

With CONSULT-II

NOTE:

Always warm up engine to normal operating temperature. If engine is cold, the throttle position sensor idle position memory will

not reset correctly.

1. Start engine and warm it up to normal operating temperature.

2. Select ªCLSD THL POSº in ªDATA MONITORº mode with CONSULT-II.

3. Stop engine. (Turn ignition switch ªOFFº.)

4. Turn ignition switch ªONº and wait at least 5 seconds.

SEF864V5. Turn ignition switch ªOFFº and wait at least 5 seconds.

6. Repeat steps 4 and 6 until ªCLSD THL POSº indication changes to ªONº.

SEF061Y

©GO TO 11.

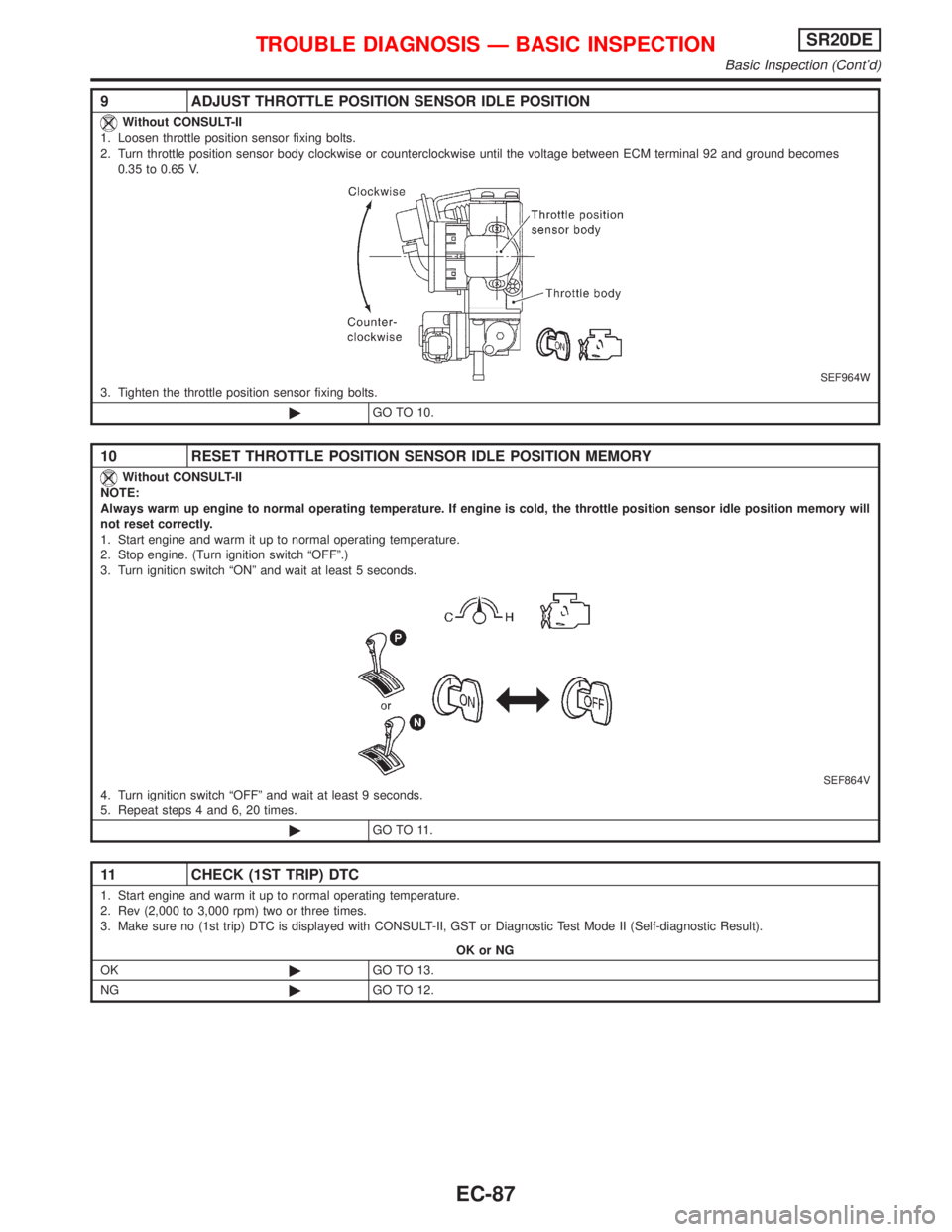

8 CHECK THROTTLE POSITION SENSOR IDLE POSITION

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Stop engine.

3. Turn ignition switch ªONº.

4. Check voltage between ECM terminal 92 and ground with accelerator pedal fully released.

NEF239AVoltage: 0.35 to 0.65V

OK or NG

OK©GO TO 6.

NG©GO TO 9.

or

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONSR20DE

Basic Inspection (Cont'd)

EC-86

Page 887 of 2267

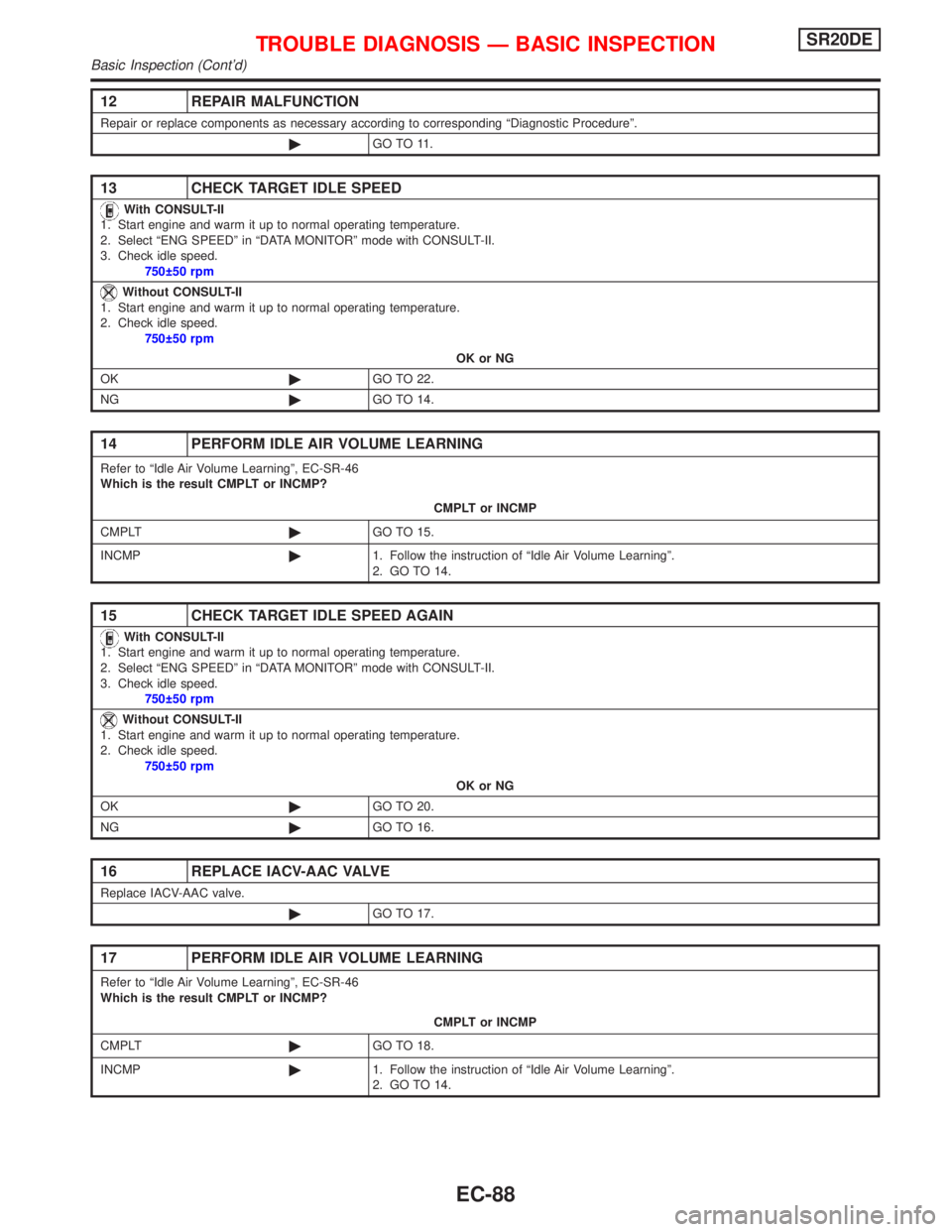

9 ADJUST THROTTLE POSITION SENSOR IDLE POSITION

Without CONSULT-II

1. Loosen throttle position sensor fixing bolts.

2. Turn throttle position sensor body clockwise or counterclockwise until the voltage between ECM terminal 92 and ground becomes

0.35 to 0.65 V.

SEF964W3. Tighten the throttle position sensor fixing bolts.

©GO TO 10.

10 RESET THROTTLE POSITION SENSOR IDLE POSITION MEMORY

Without CONSULT-II

NOTE:

Always warm up engine to normal operating temperature. If engine is cold, the throttle position sensor idle position memory will

not reset correctly.

1. Start engine and warm it up to normal operating temperature.

2. Stop engine. (Turn ignition switch ªOFFº.)

3. Turn ignition switch ªONº and wait at least 5 seconds.

SEF864V4. Turn ignition switch ªOFFº and wait at least 9 seconds.

5. Repeat steps 4 and 6, 20 times.

©GO TO 11.

11 CHECK (1ST TRIP) DTC

1. Start engine and warm it up to normal operating temperature.

2. Rev (2,000 to 3,000 rpm) two or three times.

3. Make sure no (1st trip) DTC is displayed with CONSULT-II, GST or Diagnostic Test Mode II (Self-diagnostic Result).

OK or NG

OK©GO TO 13.

NG©GO TO 12.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONSR20DE

Basic Inspection (Cont'd)

EC-87

Page 888 of 2267

12 REPAIR MALFUNCTION

Repair or replace components as necessary according to corresponding ªDiagnostic Procedureº.

©GO TO 11.

13 CHECK TARGET IDLE SPEED

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Select ªENG SPEEDº in ªDATA MONITORº mode with CONSULT-II.

3. Check idle speed.

750 50 rpm

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed.

750 50 rpm

OK or NG

OK©GO TO 22.

NG©GO TO 14.

14 PERFORM IDLE AIR VOLUME LEARNING

Refer to ªIdle Air Volume Learningº, EC-SR-46

Which is the result CMPLT or INCMP?

CMPLT or INCMP

CMPLT©GO TO 15.

INCMP©1. Follow the instruction of ªIdle Air Volume Learningº.

2. GO TO 14.

15 CHECK TARGET IDLE SPEED AGAIN

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Select ªENG SPEEDº in ªDATA MONITORº mode with CONSULT-II.

3. Check idle speed.

750 50 rpm

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed.

750 50 rpm

OK or NG

OK©GO TO 20.

NG©GO TO 16.

16 REPLACE IACV-AAC VALVE

Replace IACV-AAC valve.

©GO TO 17.

17 PERFORM IDLE AIR VOLUME LEARNING

Refer to ªIdle Air Volume Learningº, EC-SR-46

Which is the result CMPLT or INCMP?

CMPLT or INCMP

CMPLT©GO TO 18.

INCMP©1. Follow the instruction of ªIdle Air Volume Learningº.

2. GO TO 14.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONSR20DE

Basic Inspection (Cont'd)

EC-88

Page 889 of 2267

18 CHECK TARGET IDLE SPEED AGAIN

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Select ªENG SPEEDº in ªDATA MONITORº mode with CONSULT-II.

3. Check idle speed.

750 50 rpm

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed.

750 50 rpm

OK or NG

OK©GO TO 20.

NG©GO TO 19.

19 CHECK ECM FUNCTION

1. Substitute another known-good ECM to check ECM function. (ECM may be the cause of a problem, but this is rarely the case.)

2. Perform initialization of NATS system and registration of NATS ignition key IDs. Refer to ªNATS (Nissan Anti-Theft System)º, EC-SR-

58.

©GO TO 14.

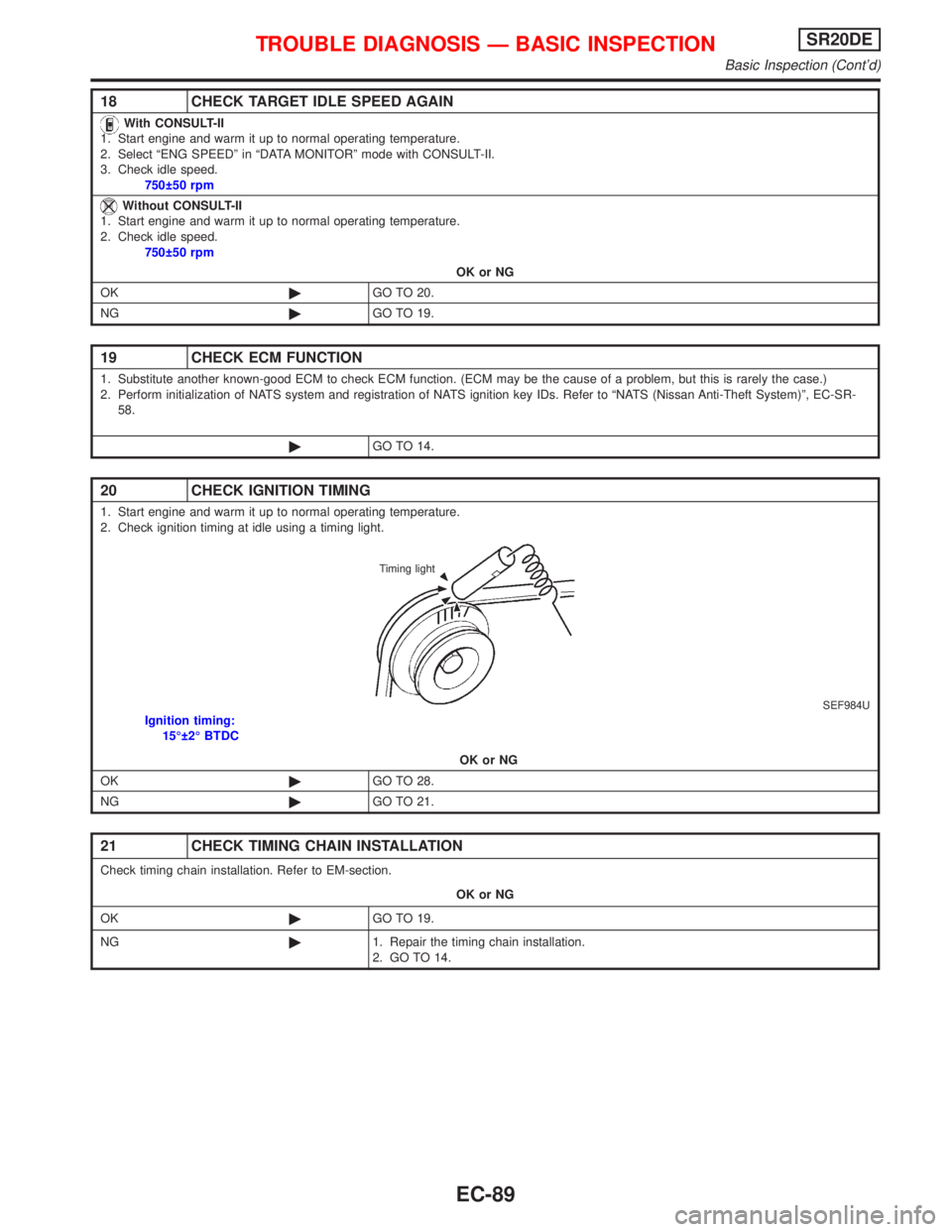

20 CHECK IGNITION TIMING

1. Start engine and warm it up to normal operating temperature.

2. Check ignition timing at idle using a timing light.

SEF984UIgnition timing:

15É 2É BTDC

OK or NG

OK©GO TO 28.

NG©GO TO 21.

21 CHECK TIMING CHAIN INSTALLATION

Check timing chain installation. Refer to EM-section.

OK or NG

OK©GO TO 19.

NG©1. Repair the timing chain installation.

2. GO TO 14.

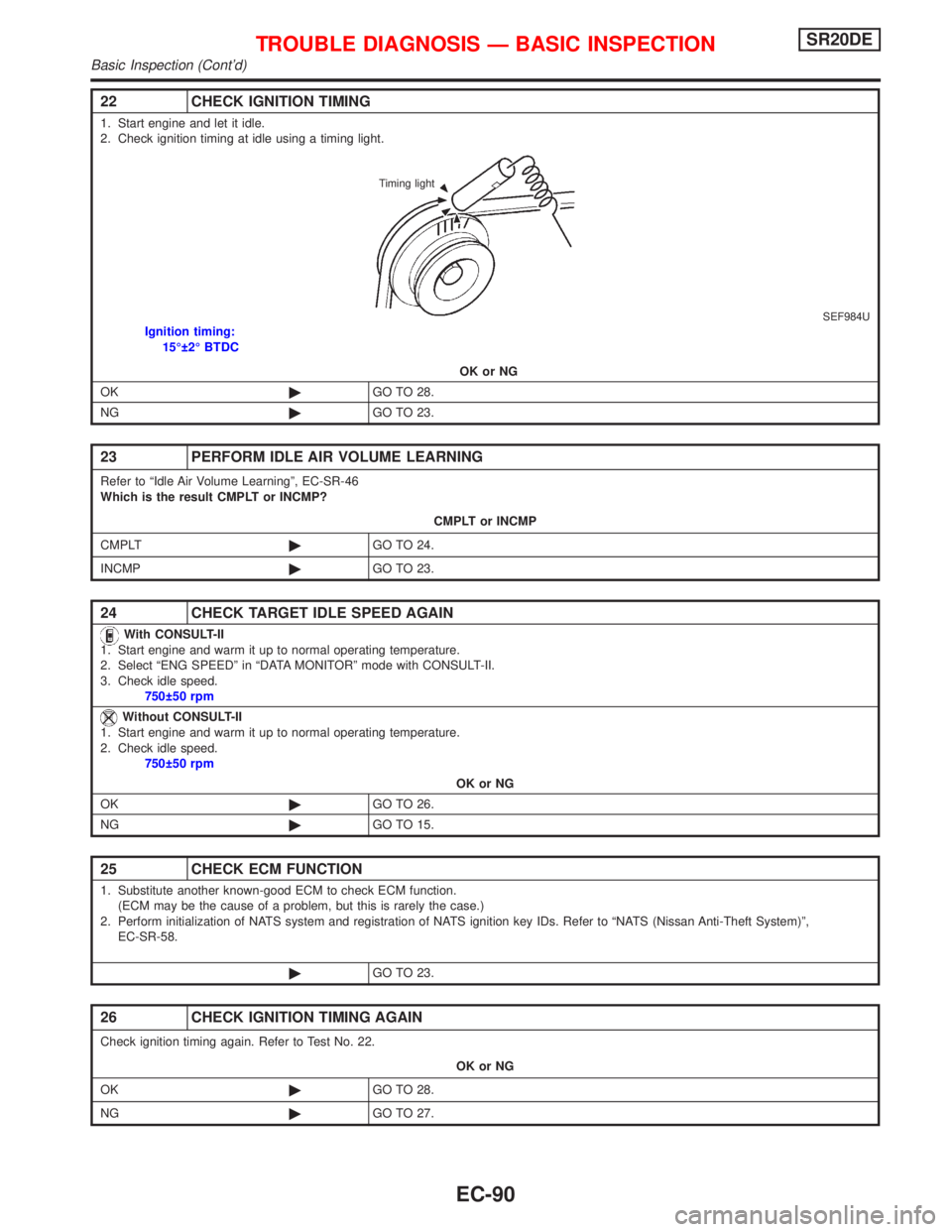

Timing light

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONSR20DE

Basic Inspection (Cont'd)

EC-89

Page 890 of 2267

22 CHECK IGNITION TIMING

1. Start engine and let it idle.

2. Check ignition timing at idle using a timing light.

SEF984UIgnition timing:

15É 2É BTDC

OK or NG

OK©GO TO 28.

NG©GO TO 23.

23 PERFORM IDLE AIR VOLUME LEARNING

Refer to ªIdle Air Volume Learningº, EC-SR-46

Which is the result CMPLT or INCMP?

CMPLT or INCMP

CMPLT©GO TO 24.

INCMP©GO TO 23.

24 CHECK TARGET IDLE SPEED AGAIN

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Select ªENG SPEEDº in ªDATA MONITORº mode with CONSULT-II.

3. Check idle speed.

750 50 rpm

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed.

750 50 rpm

OK or NG

OK©GO TO 26.

NG©GO TO 15.

25 CHECK ECM FUNCTION

1. Substitute another known-good ECM to check ECM function.

(ECM may be the cause of a problem, but this is rarely the case.)

2. Perform initialization of NATS system and registration of NATS ignition key IDs. Refer to ªNATS (Nissan Anti-Theft System)º,

EC-SR-58.

©GO TO 23.

26 CHECK IGNITION TIMING AGAIN

Check ignition timing again. Refer to Test No. 22.

OK or NG

OK©GO TO 28.

NG©GO TO 27.

Timing light

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONSR20DE

Basic Inspection (Cont'd)

EC-90

Page 898 of 2267

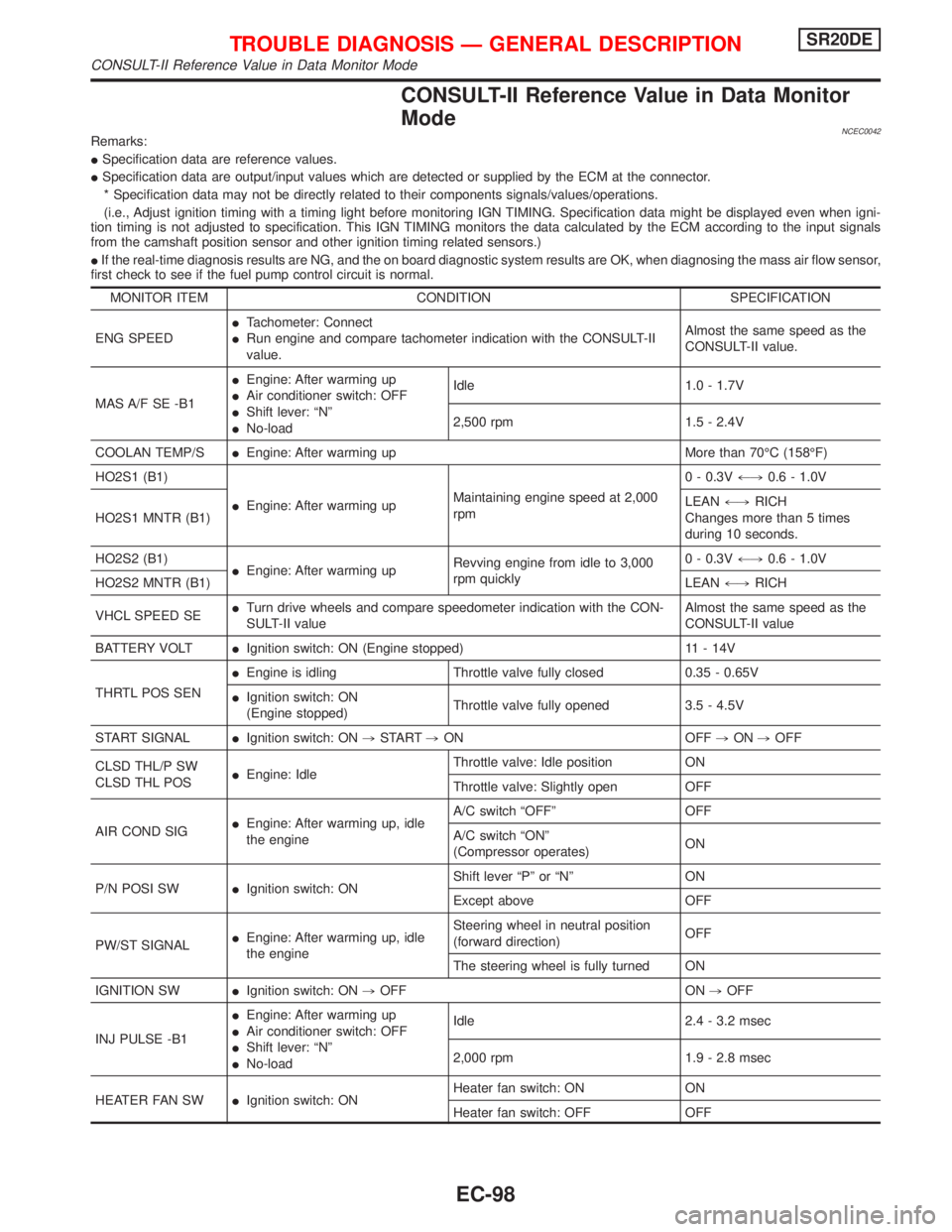

CONSULT-II Reference Value in Data Monitor

Mode

NCEC0042Remarks:

ISpecification data are reference values.

ISpecification data are output/input values which are detected or supplied by the ECM at the connector.

* Specification data may not be directly related to their components signals/values/operations.

(i.e., Adjust ignition timing with a timing light before monitoring IGN TIMING. Specification data might be displayed even when igni-

tion timing is not adjusted to specification. This IGN TIMING monitors the data calculated by the ECM according to the input signals

from the camshaft position sensor and other ignition timing related sensors.)

IIf the real-time diagnosis results are NG, and the on board diagnostic system results are OK, when diagnosing the mass air flow sensor,

first check to see if the fuel pump control circuit is normal.

MONITOR ITEM CONDITION SPECIFICATION

ENG SPEEDITachometer: Connect

IRun engine and compare tachometer indication with the CONSULT-II

value.Almost the same speed as the

CONSULT-II value.

MAS A/F SE -B1IEngine: After warming up

IAir conditioner switch: OFF

IShift lever: ªNº

INo-loadIdle 1.0 - 1.7V

2,500 rpm 1.5 - 2.4V

COOLAN TEMP/SIEngine: After warming up More than 70ÉC (158ÉF)

HO2S1 (B1)

IEngine: After warming upMaintaining engine speed at 2,000

rpm0 - 0.3V+,0.6 - 1.0V

HO2S1 MNTR (B1)LEAN+,RICH

Changes more than 5 times

during 10 seconds.

HO2S2 (B1)

IEngine: After warming upRevving engine from idle to 3,000

rpm quickly0 - 0.3V+,0.6 - 1.0V

HO2S2 MNTR (B1)LEAN+,RICH

VHCL SPEED SEITurn drive wheels and compare speedometer indication with the CON-

SULT-II valueAlmost the same speed as the

CONSULT-II value

BATTERY VOLTIIgnition switch: ON (Engine stopped) 11 - 14V

THRTL POS SENIEngine is idling Throttle valve fully closed 0.35 - 0.65V

IIgnition switch: ON

(Engine stopped)Throttle valve fully opened 3.5 - 4.5V

START SIGNALIIgnition switch: ON,START,ON OFF,ON,OFF

CLSD THL/P SW

CLSD THL POSIEngine: IdleThrottle valve: Idle position ON

Throttle valve: Slightly open OFF

AIR COND SIGIEngine: After warming up, idle

the engineA/C switch ªOFFº OFF

A/C switch ªONº

(Compressor operates)ON

P/N POSI SWIIgnition switch: ONShift lever ªPº or ªNº ON

Except above OFF

PW/ST SIGNALIEngine: After warming up, idle

the engineSteering wheel in neutral position

(forward direction)OFF

The steering wheel is fully turned ON

IGNITION SWIIgnition switch: ON,OFF ON,OFF

INJ PULSE -B1IEngine: After warming up

IAir conditioner switch: OFF

IShift lever: ªNº

INo-loadIdle 2.4 - 3.2 msec

2,000 rpm 1.9 - 2.8 msec

HEATER FAN SWIIgnition switch: ONHeater fan switch: ON ON

Heater fan switch: OFF OFF

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONSR20DE

CONSULT-II Reference Value in Data Monitor Mode

EC-98