check engine NISSAN PRIMERA 1999 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 936 of 2267

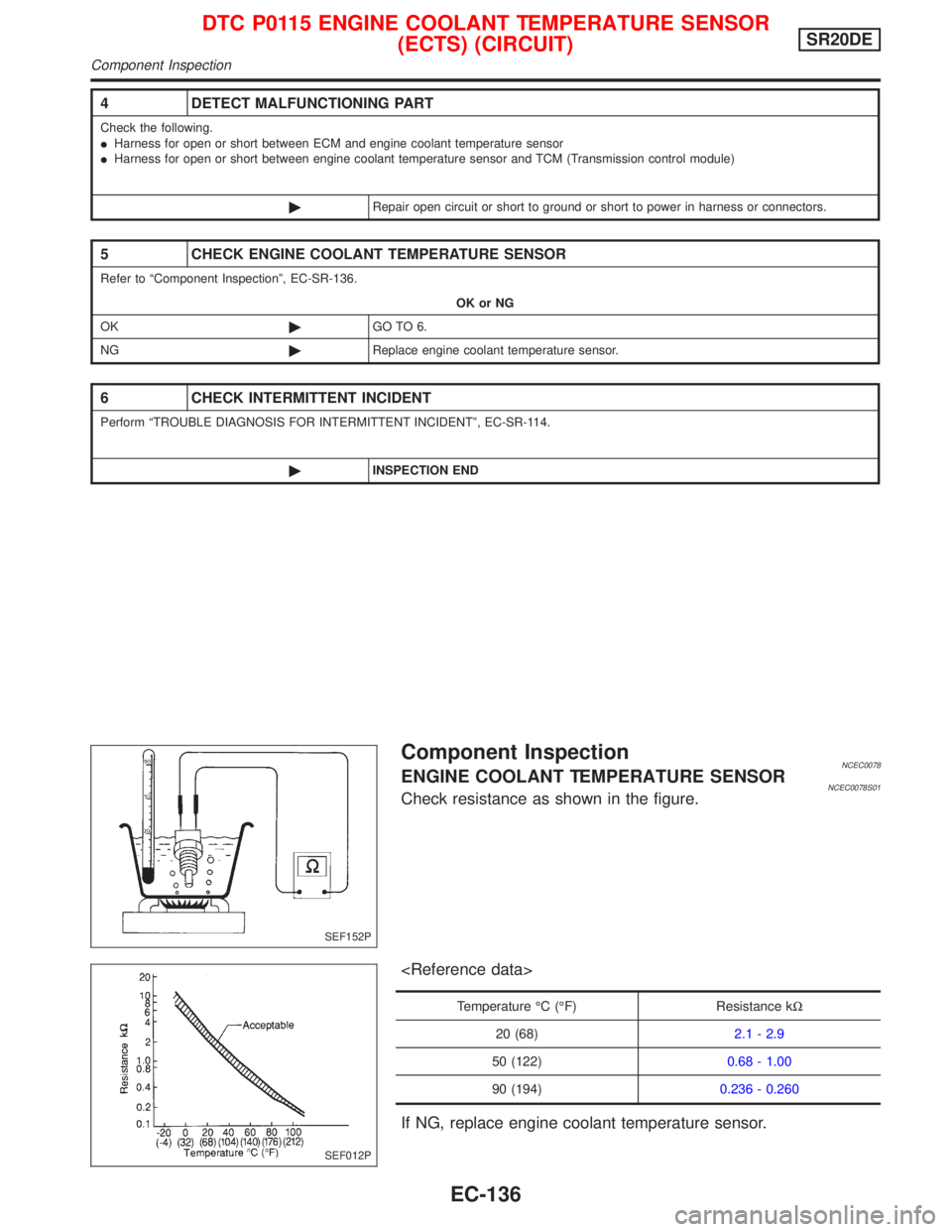

Component InspectionNCEC0078ENGINE COOLANT TEMPERATURE SENSORNCEC0078S01Check resistance as shown in the figure.

Temperature ÉC (ÉF) Resistance kW

20 (68)2.1 - 2.9

50 (122)0.68 - 1.00

90 (194)0.236 - 0.260

If NG, replace engine coolant temperature sensor.

4 DETECT MALFUNCTIONING PART

Check the following.

IHarness for open or short between ECM and engine coolant temperature sensor

IHarness for open or short between engine coolant temperature sensor and TCM (Transmission control module)

©Repair open circuit or short to ground or short to power in harness or connectors.

5 CHECK ENGINE COOLANT TEMPERATURE SENSOR

Refer to ªComponent Inspectionº, EC-SR-136.

OK or NG

OK©GO TO 6.

NG©Replace engine coolant temperature sensor.

6 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-SR-114.

©INSPECTION END

SEF152P

SEF012P

DTC P0115 ENGINE COOLANT TEMPERATURE SENSOR

(ECTS) (CIRCUIT)SR20DE

Component Inspection

EC-136

Page 938 of 2267

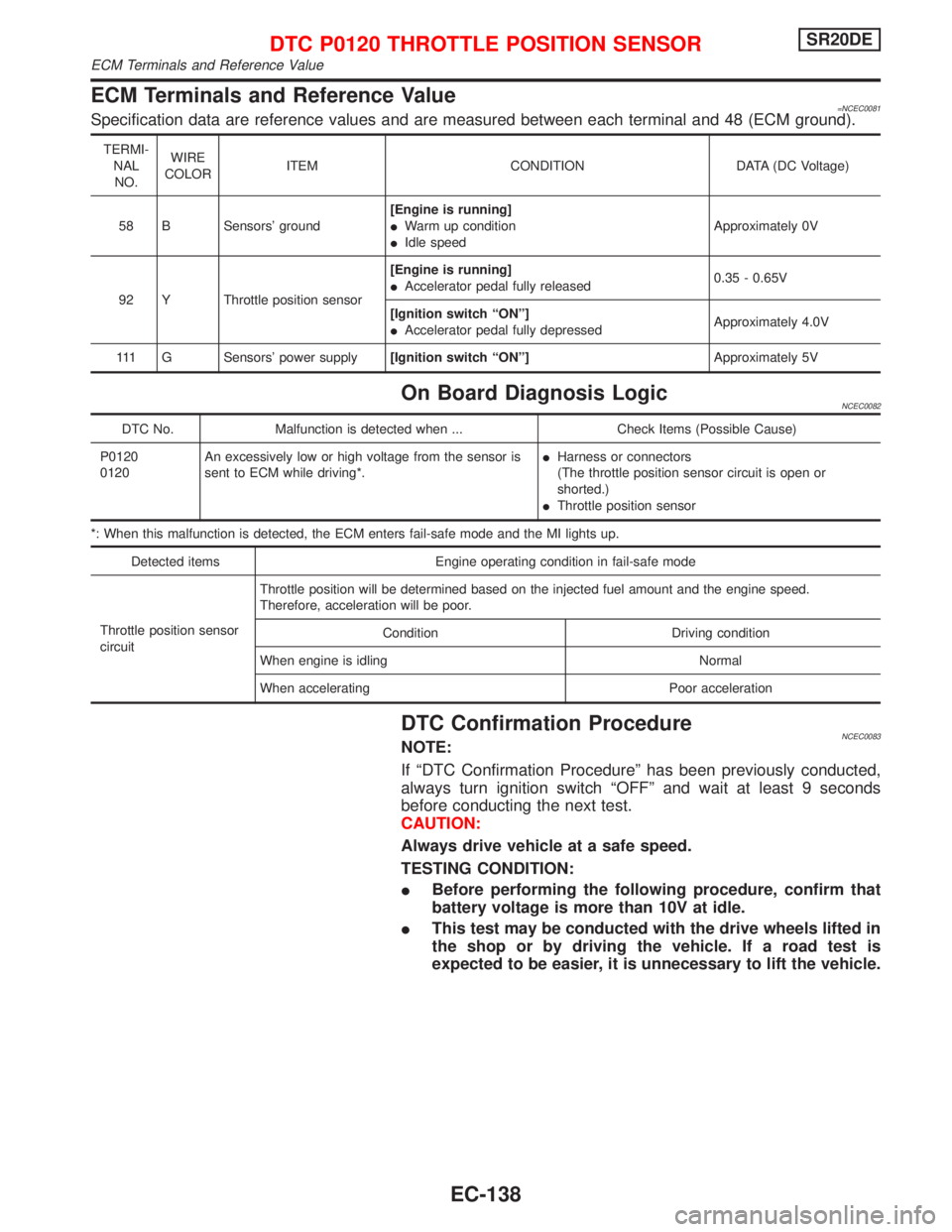

ECM Terminals and Reference Value=NCEC0081Specification data are reference values and are measured between each terminal and 48 (ECM ground).

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

58 B Sensors' ground[Engine is running]

IWarm up condition

IIdle speedApproximately 0V

92 Y Throttle position sensor[Engine is running]

IAccelerator pedal fully released0.35 - 0.65V

[Ignition switch ªONº]

IAccelerator pedal fully depressedApproximately 4.0V

111 G Sensors' power supply[Ignition switch ªONº]Approximately 5V

On Board Diagnosis LogicNCEC0082

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0120

0120An excessively low or high voltage from the sensor is

sent to ECM while driving*.IHarness or connectors

(The throttle position sensor circuit is open or

shorted.)

IThrottle position sensor

*: When this malfunction is detected, the ECM enters fail-safe mode and the MI lights up.

Detected items Engine operating condition in fail-safe mode

Throttle position sensor

circuitThrottle position will be determined based on the injected fuel amount and the engine speed.

Therefore, acceleration will be poor.

Condition Driving condition

When engine is idling Normal

When accelerating Poor acceleration

DTC Confirmation ProcedureNCEC0083NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

CAUTION:

Always drive vehicle at a safe speed.

TESTING CONDITION:

IBefore performing the following procedure, confirm that

battery voltage is more than 10V at idle.

IThis test may be conducted with the drive wheels lifted in

the shop or by driving the vehicle. If a road test is

expected to be easier, it is unnecessary to lift the vehicle.

DTC P0120 THROTTLE POSITION SENSORSR20DE

ECM Terminals and Reference Value

EC-138

Page 941 of 2267

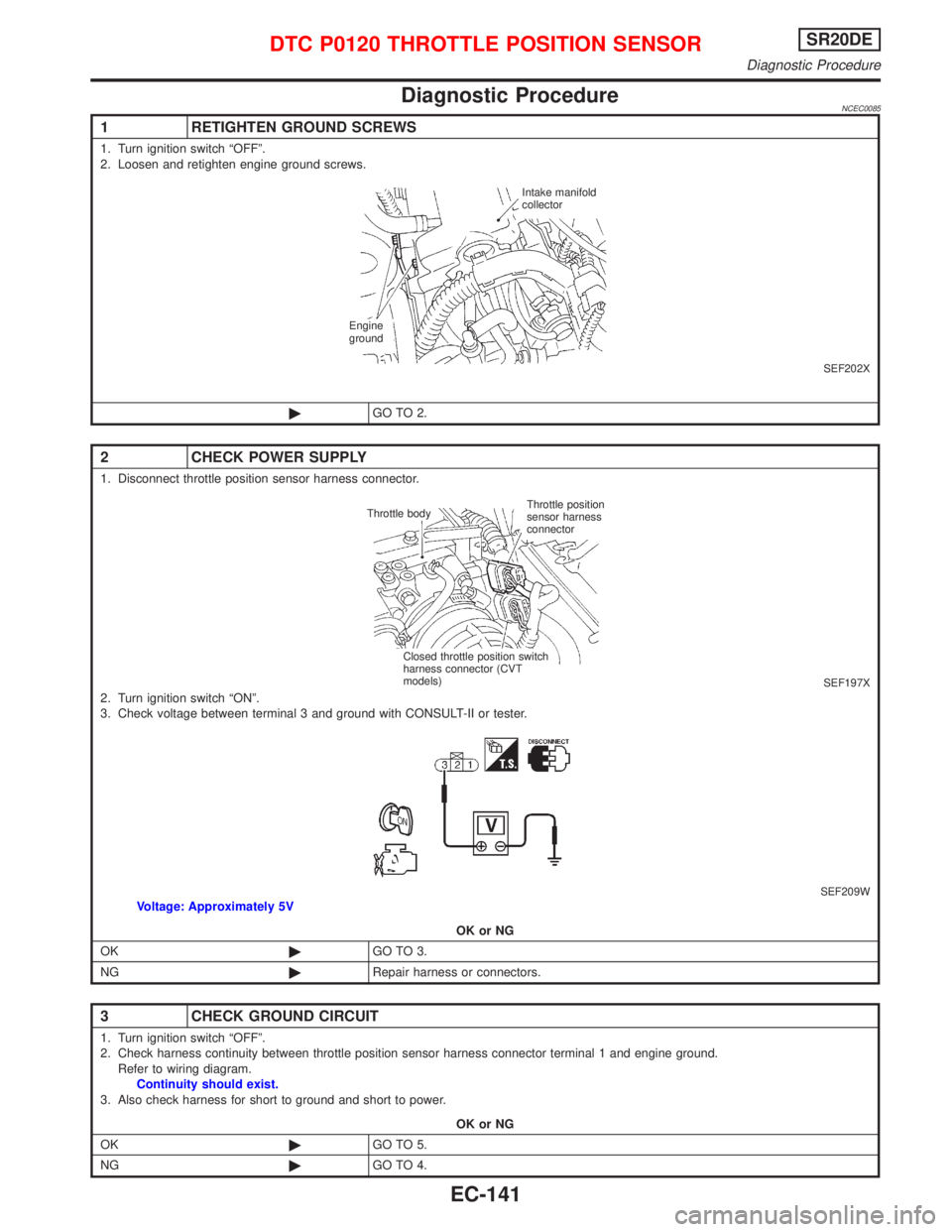

Diagnostic ProcedureNCEC0085

1 RETIGHTEN GROUND SCREWS

1. Turn ignition switch ªOFFº.

2. Loosen and retighten engine ground screws.

SEF202X

©GO TO 2.

2 CHECK POWER SUPPLY

1. Disconnect throttle position sensor harness connector.

SEF197X2. Turn ignition switch ªONº.

3. Check voltage between terminal 3 and ground with CONSULT-II or tester.

SEF209WVoltage: Approximately 5V

OK or NG

OK©GO TO 3.

NG©Repair harness or connectors.

3 CHECK GROUND CIRCUIT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between throttle position sensor harness connector terminal 1 and engine ground.

Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©GO TO 4.

Intake manifold

collector

Engine

ground

Throttle position

sensor harness

connector Throttle body

Closed throttle position switch

harness connector (CVT

models)

DTC P0120 THROTTLE POSITION SENSORSR20DE

Diagnostic Procedure

EC-141

Page 942 of 2267

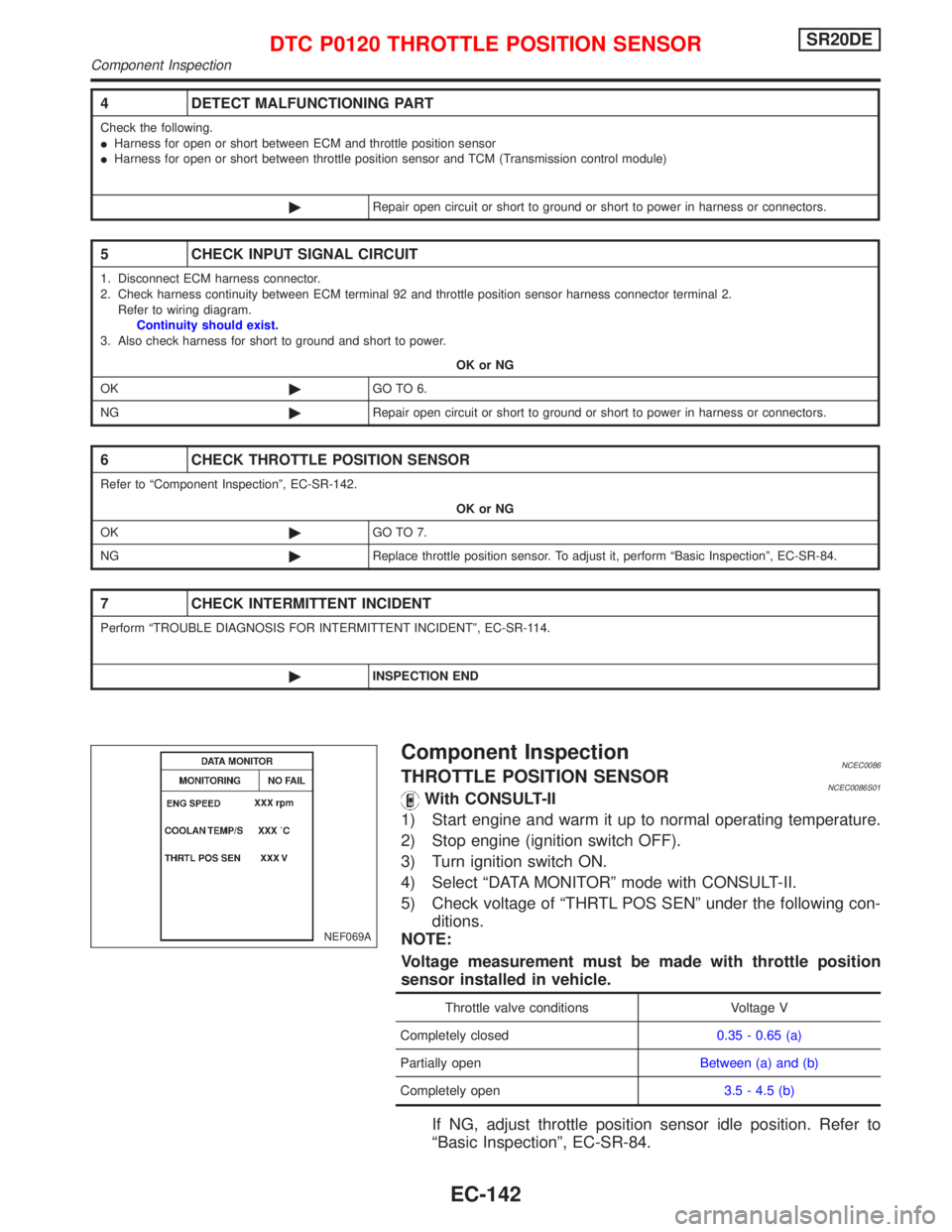

Component InspectionNCEC0086THROTTLE POSITION SENSORNCEC0086S01With CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Stop engine (ignition switch OFF).

3) Turn ignition switch ON.

4) Select ªDATA MONITORº mode with CONSULT-II.

5) Check voltage of ªTHRTL POS SENº under the following con-

ditions.

NOTE:

Voltage measurement must be made with throttle position

sensor installed in vehicle.

Throttle valve conditions Voltage V

Completely closed0.35 - 0.65 (a)

Partially openBetween (a) and (b)

Completely open3.5 - 4.5 (b)

If NG, adjust throttle position sensor idle position. Refer to

ªBasic Inspectionº, EC-SR-84.

4 DETECT MALFUNCTIONING PART

Check the following.

IHarness for open or short between ECM and throttle position sensor

IHarness for open or short between throttle position sensor and TCM (Transmission control module)

©Repair open circuit or short to ground or short to power in harness or connectors.

5 CHECK INPUT SIGNAL CIRCUIT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 92 and throttle position sensor harness connector terminal 2.

Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 6.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

6 CHECK THROTTLE POSITION SENSOR

Refer to ªComponent Inspectionº, EC-SR-142.

OK or NG

OK©GO TO 7.

NG©Replace throttle position sensor. To adjust it, perform ªBasic Inspectionº, EC-SR-84.

7 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-SR-114.

©INSPECTION END

NEF069A

DTC P0120 THROTTLE POSITION SENSORSR20DE

Component Inspection

EC-142

Page 943 of 2267

6) If it is impossible to adjust throttle position sensor idle position

in ªBasic Inspectionº, replace throttle position sensor.

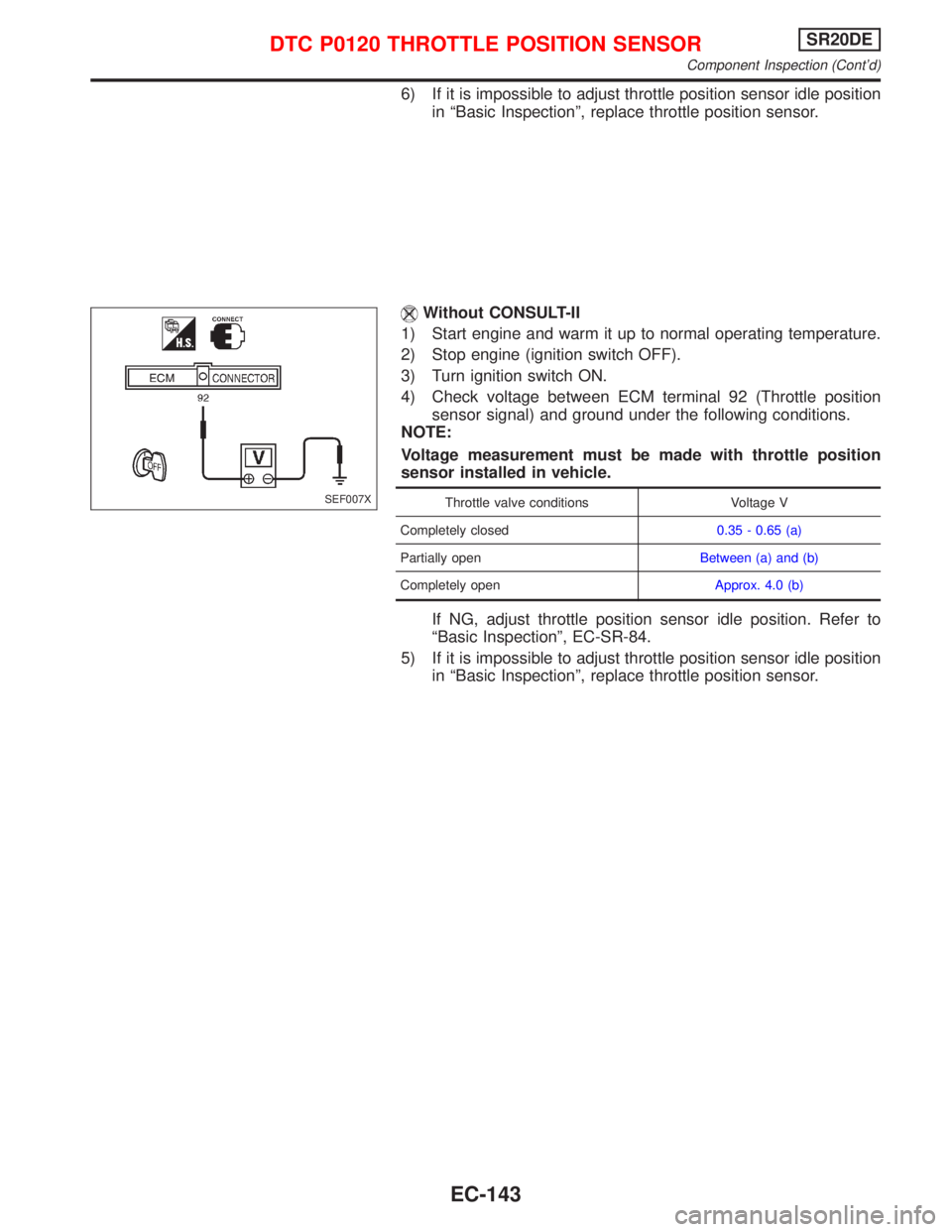

Without CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Stop engine (ignition switch OFF).

3) Turn ignition switch ON.

4) Check voltage between ECM terminal 92 (Throttle position

sensor signal) and ground under the following conditions.

NOTE:

Voltage measurement must be made with throttle position

sensor installed in vehicle.

Throttle valve conditions Voltage V

Completely closed0.35 - 0.65 (a)

Partially openBetween (a) and (b)

Completely openApprox. 4.0 (b)

If NG, adjust throttle position sensor idle position. Refer to

ªBasic Inspectionº, EC-SR-84.

5) If it is impossible to adjust throttle position sensor idle position

in ªBasic Inspectionº, replace throttle position sensor.

SEF007X

DTC P0120 THROTTLE POSITION SENSORSR20DE

Component Inspection (Cont'd)

EC-143

Page 945 of 2267

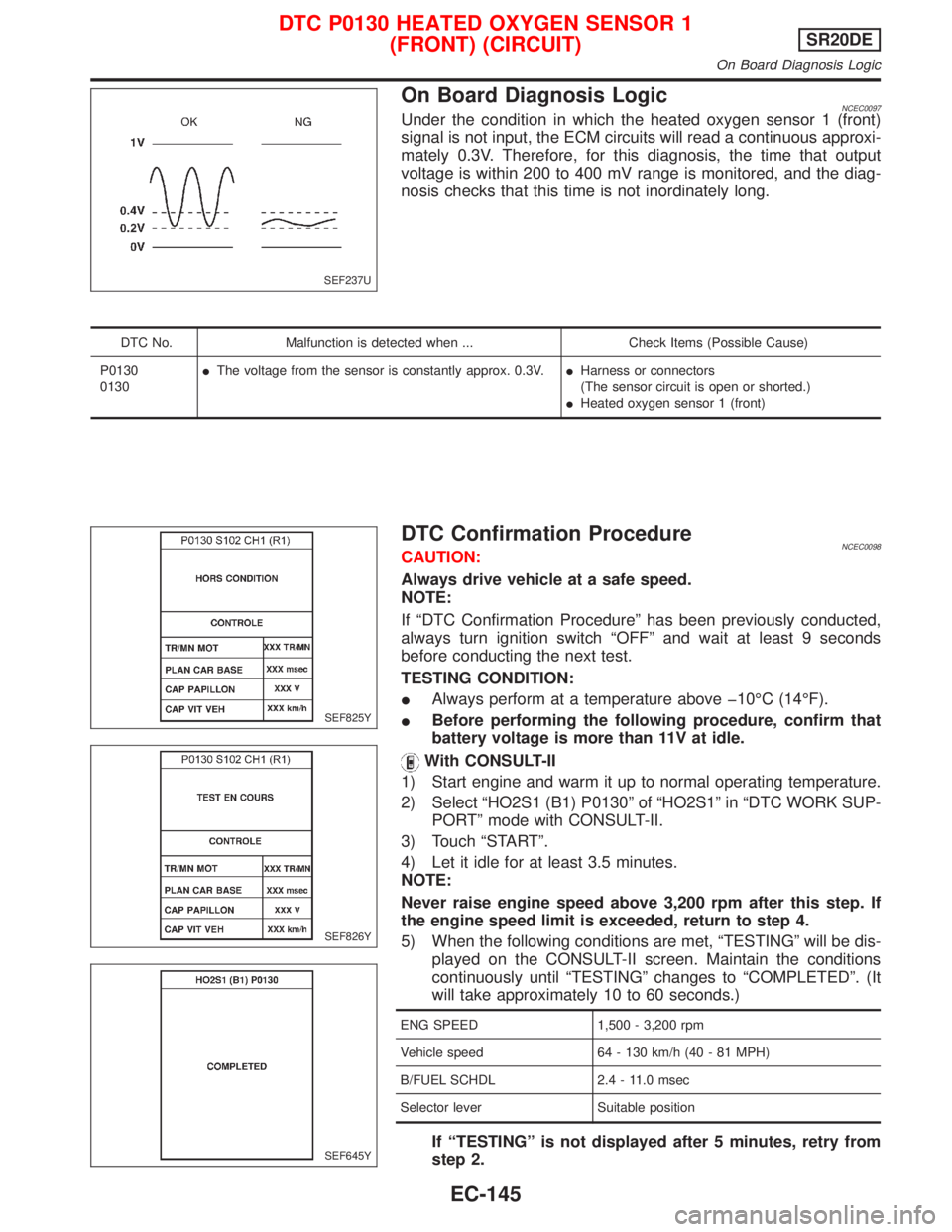

On Board Diagnosis LogicNCEC0097Under the condition in which the heated oxygen sensor 1 (front)

signal is not input, the ECM circuits will read a continuous approxi-

mately 0.3V. Therefore, for this diagnosis, the time that output

voltage is within 200 to 400 mV range is monitored, and the diag-

nosis checks that this time is not inordinately long.

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0130

0130IThe voltage from the sensor is constantly approx. 0.3V.IHarness or connectors

(The sensor circuit is open or shorted.)

IHeated oxygen sensor 1 (front)

DTC Confirmation ProcedureNCEC0098CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

TESTING CONDITION:

IAlways perform at a temperature above þ10ÉC (14ÉF).

IBefore performing the following procedure, confirm that

battery voltage is more than 11V at idle.

With CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Select ªHO2S1 (B1) P0130º of ªHO2S1º in ªDTC WORK SUP-

PORTº mode with CONSULT-II.

3) Touch ªSTARTº.

4) Let it idle for at least 3.5 minutes.

NOTE:

Never raise engine speed above 3,200 rpm after this step. If

the engine speed limit is exceeded, return to step 4.

5) When the following conditions are met, ªTESTINGº will be dis-

played on the CONSULT-II screen. Maintain the conditions

continuously until ªTESTINGº changes to ªCOMPLETEDº. (It

will take approximately 10 to 60 seconds.)

ENG SPEED 1,500 - 3,200 rpm

Vehicle speed 64 - 130 km/h (40 - 81 MPH)

B/FUEL SCHDL 2.4 - 11.0 msec

Selector lever Suitable position

If ªTESTINGº is not displayed after 5 minutes, retry from

step 2.

SEF237U

SEF825Y

SEF826Y

SEF645Y

DTC P0130 HEATED OXYGEN SENSOR 1

(FRONT) (CIRCUIT)SR20DE

On Board Diagnosis Logic

EC-145

Page 946 of 2267

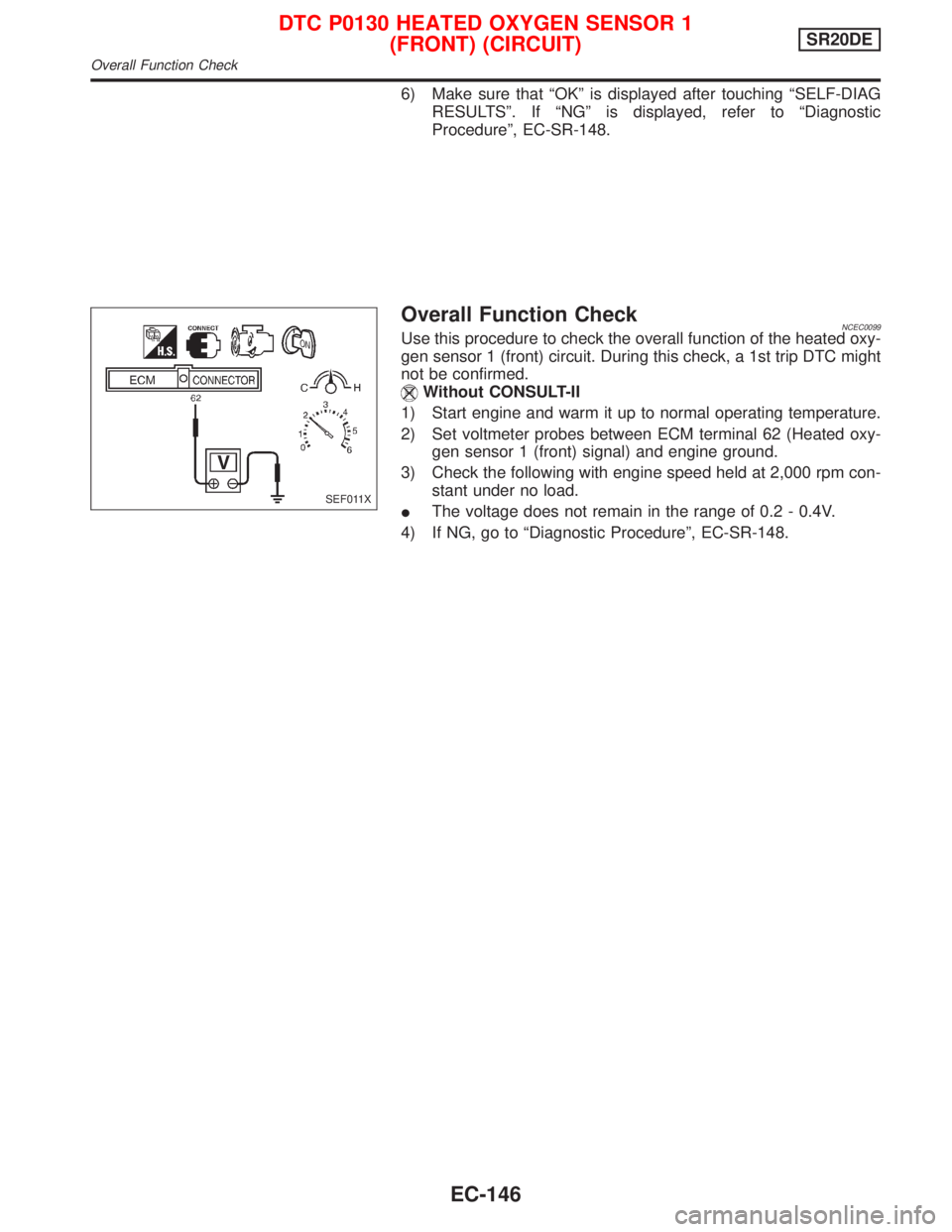

6) Make sure that ªOKº is displayed after touching ªSELF-DIAG

RESULTSº. If ªNGº is displayed, refer to ªDiagnostic

Procedureº, EC-SR-148.

Overall Function CheckNCEC0099Use this procedure to check the overall function of the heated oxy-

gen sensor 1 (front) circuit. During this check, a 1st trip DTC might

not be confirmed.

Without CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Set voltmeter probes between ECM terminal 62 (Heated oxy-

gen sensor 1 (front) signal) and engine ground.

3) Check the following with engine speed held at 2,000 rpm con-

stant under no load.

IThe voltage does not remain in the range of 0.2 - 0.4V.

4) If NG, go to ªDiagnostic Procedureº, EC-SR-148.

SEF011X

DTC P0130 HEATED OXYGEN SENSOR 1

(FRONT) (CIRCUIT)SR20DE

Overall Function Check

EC-146

Page 948 of 2267

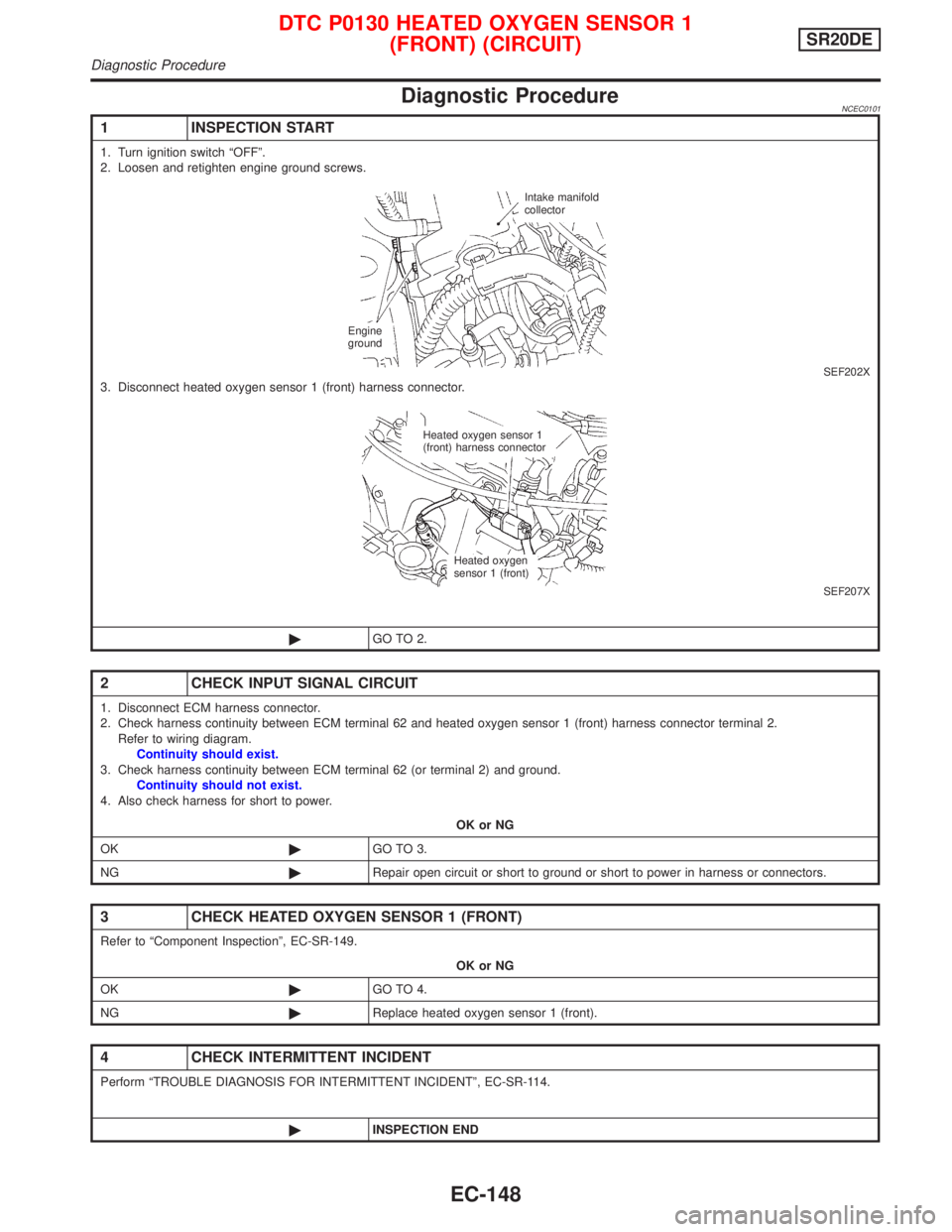

Diagnostic ProcedureNCEC0101

1 INSPECTION START

1. Turn ignition switch ªOFFº.

2. Loosen and retighten engine ground screws.

SEF202X3. Disconnect heated oxygen sensor 1 (front) harness connector.

SEF207X

©GO TO 2.

2 CHECK INPUT SIGNAL CIRCUIT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 62 and heated oxygen sensor 1 (front) harness connector terminal 2.

Refer to wiring diagram.

Continuity should exist.

3. Check harness continuity between ECM terminal 62 (or terminal 2) and ground.

Continuity should not exist.

4. Also check harness for short to power.

OK or NG

OK©GO TO 3.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

3 CHECK HEATED OXYGEN SENSOR 1 (FRONT)

Refer to ªComponent Inspectionº, EC-SR-149.

OK or NG

OK©GO TO 4.

NG©Replace heated oxygen sensor 1 (front).

4 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-SR-114.

©INSPECTION END

Intake manifold

collector

Engine

ground

Heated oxygen sensor 1

(front) harness connector

Heated oxygen

sensor 1 (front)

DTC P0130 HEATED OXYGEN SENSOR 1

(FRONT) (CIRCUIT)SR20DE

Diagnostic Procedure

EC-148

Page 949 of 2267

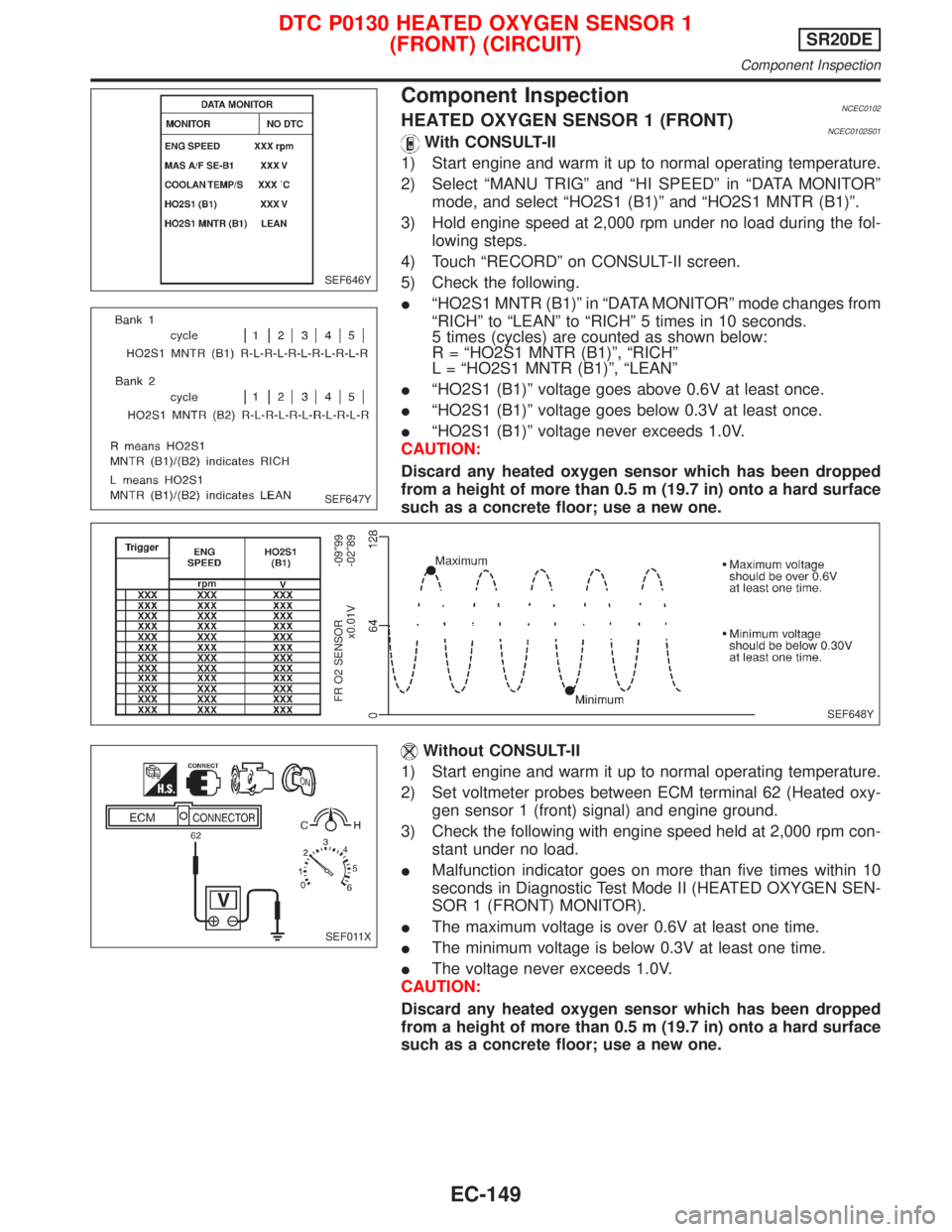

Component InspectionNCEC0102HEATED OXYGEN SENSOR 1 (FRONT)NCEC0102S01With CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Select ªMANU TRIGº and ªHI SPEEDº in ªDATA MONITORº

mode, and select ªHO2S1 (B1)º and ªHO2S1 MNTR (B1)º.

3) Hold engine speed at 2,000 rpm under no load during the fol-

lowing steps.

4) Touch ªRECORDº on CONSULT-II screen.

5) Check the following.

IªHO2S1 MNTR (B1)º in ªDATA MONITORº mode changes from

ªRICHº to ªLEANº to ªRICHº 5 times in 10 seconds.

5 times (cycles) are counted as shown below:

R = ªHO2S1 MNTR (B1)º, ªRICHº

L = ªHO2S1 MNTR (B1)º, ªLEANº

IªHO2S1 (B1)º voltage goes above 0.6V at least once.

IªHO2S1 (B1)º voltage goes below 0.3V at least once.

IªHO2S1 (B1)º voltage never exceeds 1.0V.

CAUTION:

Discard any heated oxygen sensor which has been dropped

from a height of more than 0.5 m (19.7 in) onto a hard surface

such as a concrete floor; use a new one.

Without CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Set voltmeter probes between ECM terminal 62 (Heated oxy-

gen sensor 1 (front) signal) and engine ground.

3) Check the following with engine speed held at 2,000 rpm con-

stant under no load.

IMalfunction indicator goes on more than five times within 10

seconds in Diagnostic Test Mode II (HEATED OXYGEN SEN-

SOR 1 (FRONT) MONITOR).

IThe maximum voltage is over 0.6V at least one time.

IThe minimum voltage is below 0.3V at least one time.

IThe voltage never exceeds 1.0V.

CAUTION:

Discard any heated oxygen sensor which has been dropped

from a height of more than 0.5 m (19.7 in) onto a hard surface

such as a concrete floor; use a new one.

SEF646Y

SEF647Y

SEF648Y

FR O2 SENSOR

x0.01V-09²99

-02²89

SEF011X

DTC P0130 HEATED OXYGEN SENSOR 1

(FRONT) (CIRCUIT)SR20DE

Component Inspection

EC-149

Page 951 of 2267

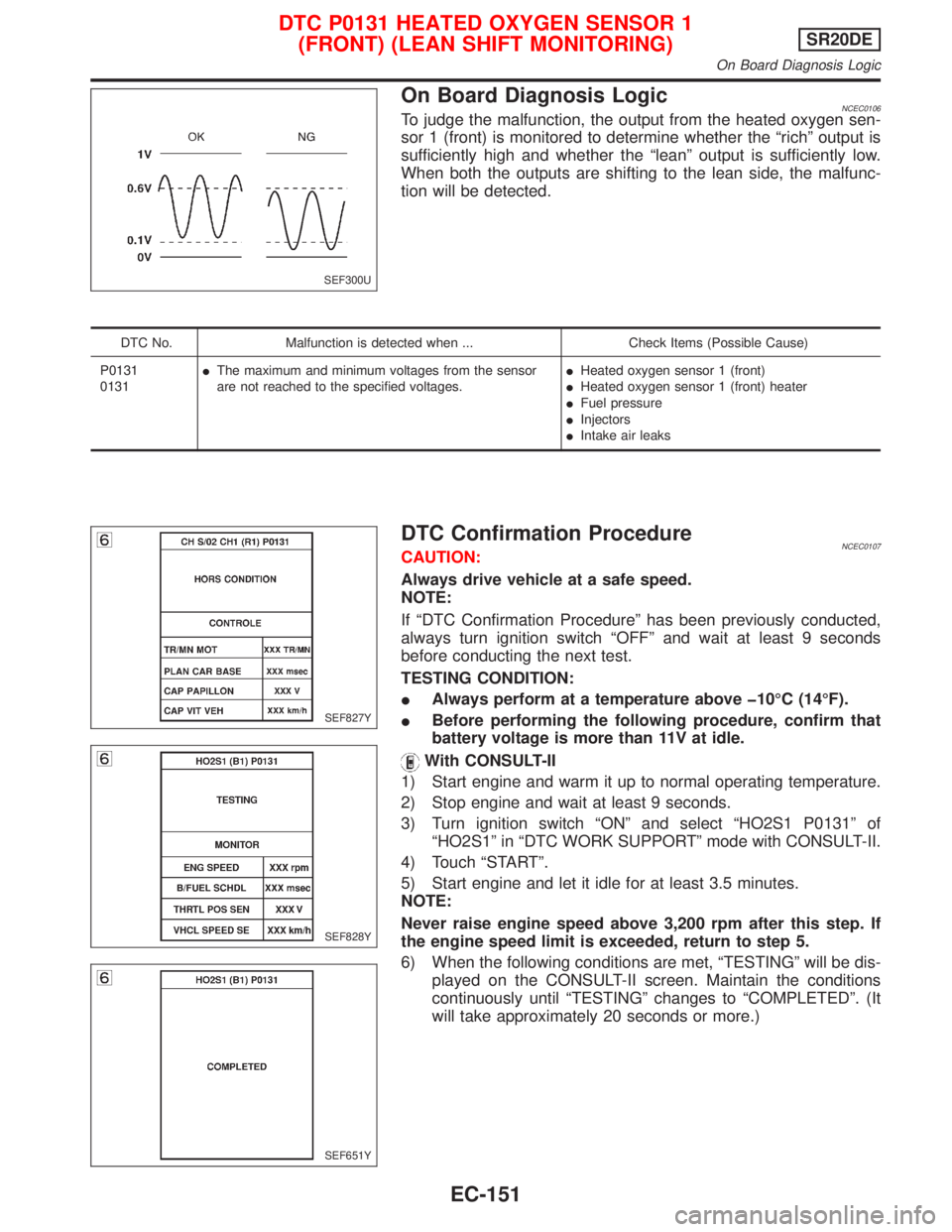

On Board Diagnosis LogicNCEC0106To judge the malfunction, the output from the heated oxygen sen-

sor 1 (front) is monitored to determine whether the ªrichº output is

sufficiently high and whether the ªleanº output is sufficiently low.

When both the outputs are shifting to the lean side, the malfunc-

tion will be detected.

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0131

0131IThe maximum and minimum voltages from the sensor

are not reached to the specified voltages.IHeated oxygen sensor 1 (front)

IHeated oxygen sensor 1 (front) heater

IFuel pressure

IInjectors

IIntake air leaks

DTC Confirmation ProcedureNCEC0107CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

TESTING CONDITION:

IAlways perform at a temperature above þ10ÉC (14ÉF).

IBefore performing the following procedure, confirm that

battery voltage is more than 11V at idle.

With CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Stop engine and wait at least 9 seconds.

3) Turn ignition switch ªONº and select ªHO2S1 P0131º of

ªHO2S1º in ªDTC WORK SUPPORTº mode with CONSULT-II.

4) Touch ªSTARTº.

5) Start engine and let it idle for at least 3.5 minutes.

NOTE:

Never raise engine speed above 3,200 rpm after this step. If

the engine speed limit is exceeded, return to step 5.

6) When the following conditions are met, ªTESTINGº will be dis-

played on the CONSULT-II screen. Maintain the conditions

continuously until ªTESTINGº changes to ªCOMPLETEDº. (It

will take approximately 20 seconds or more.)

SEF300U

SEF827Y

SEF828Y

SEF651Y

DTC P0131 HEATED OXYGEN SENSOR 1

(FRONT) (LEAN SHIFT MONITORING)SR20DE

On Board Diagnosis Logic

EC-151