check engine NISSAN PRIMERA 1999 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 750 of 2267

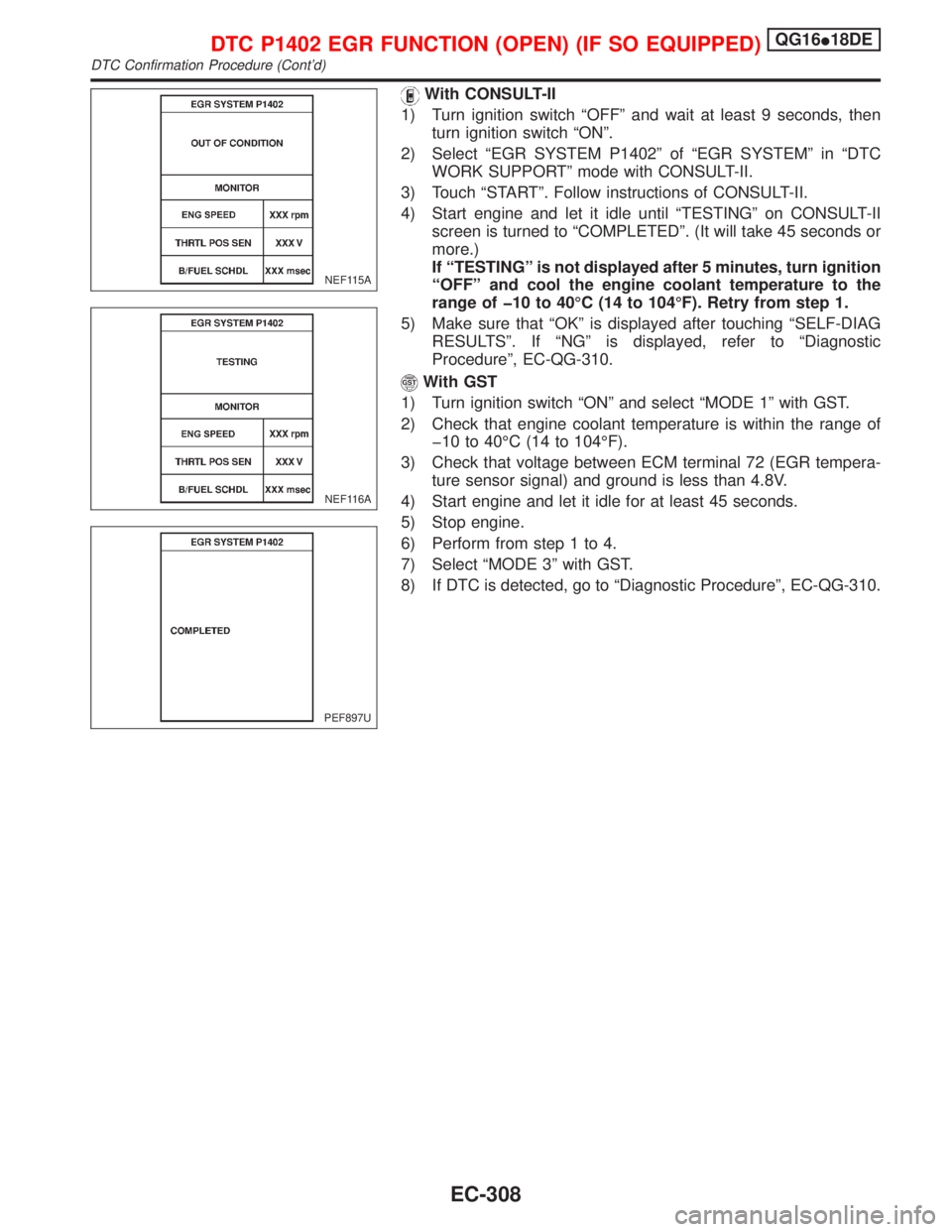

With CONSULT-II

1) Turn ignition switch ªOFFº and wait at least 9 seconds, then

turn ignition switch ªONº.

2) Select ªEGR SYSTEM P1402º of ªEGR SYSTEMº in ªDTC

WORK SUPPORTº mode with CONSULT-II.

3) Touch ªSTARTº. Follow instructions of CONSULT-II.

4) Start engine and let it idle until ªTESTINGº on CONSULT-II

screen is turned to ªCOMPLETEDº. (It will take 45 seconds or

more.)

If ªTESTINGº is not displayed after 5 minutes, turn ignition

ªOFFº and cool the engine coolant temperature to the

range of þ10 to 40ÉC (14 to 104ÉF). Retry from step 1.

5) Make sure that ªOKº is displayed after touching ªSELF-DIAG

RESULTSº. If ªNGº is displayed, refer to ªDiagnostic

Procedureº, EC-QG-310.

With GST

1) Turn ignition switch ªONº and select ªMODE 1º with GST.

2) Check that engine coolant temperature is within the range of

þ10 to 40ÉC (14 to 104ÉF).

3) Check that voltage between ECM terminal 72 (EGR tempera-

ture sensor signal) and ground is less than 4.8V.

4) Start engine and let it idle for at least 45 seconds.

5) Stop engine.

6) Perform from step 1 to 4.

7) Select ªMODE 3º with GST.

8) If DTC is detected, go to ªDiagnostic Procedureº, EC-QG-310.

NEF115A

NEF116A

PEF897U

DTC P1402 EGR FUNCTION (OPEN) (IF SO EQUIPPED)QG16I18DE

DTC Confirmation Procedure (Cont'd)

EC-308

Page 752 of 2267

Diagnostic ProcedureNCEC0353

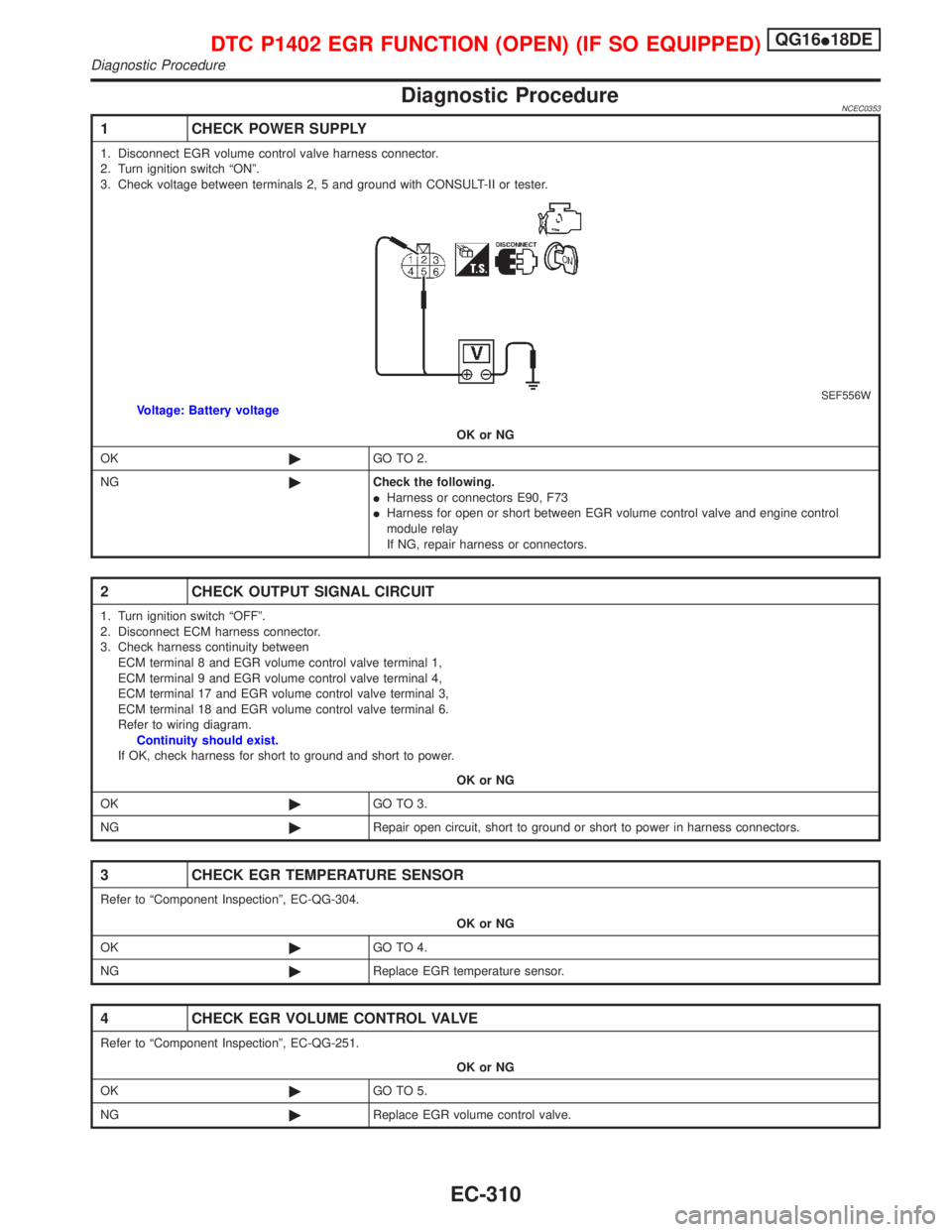

1 CHECK POWER SUPPLY

1. Disconnect EGR volume control valve harness connector.

2. Turn ignition switch ªONº.

3. Check voltage between terminals 2, 5 and ground with CONSULT-II or tester.

SEF556WVoltage: Battery voltage

OK or NG

OK©GO TO 2.

NG©Check the following.

IHarness or connectors E90, F73

IHarness for open or short between EGR volume control valve and engine control

module relay

If NG, repair harness or connectors.

2 CHECK OUTPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between

ECM terminal 8 and EGR volume control valve terminal 1,

ECM terminal 9 and EGR volume control valve terminal 4,

ECM terminal 17 and EGR volume control valve terminal 3,

ECM terminal 18 and EGR volume control valve terminal 6.

Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short to ground and short to power.

OK or NG

OK©GO TO 3.

NG©Repair open circuit, short to ground or short to power in harness connectors.

3 CHECK EGR TEMPERATURE SENSOR

Refer to ªComponent Inspectionº, EC-QG-304.

OK or NG

OK©GO TO 4.

NG©Replace EGR temperature sensor.

4 CHECK EGR VOLUME CONTROL VALVE

Refer to ªComponent Inspectionº, EC-QG-251.

OK or NG

OK©GO TO 5.

NG©Replace EGR volume control valve.

DTC P1402 EGR FUNCTION (OPEN) (IF SO EQUIPPED)QG16I18DE

Diagnostic Procedure

EC-310

Page 755 of 2267

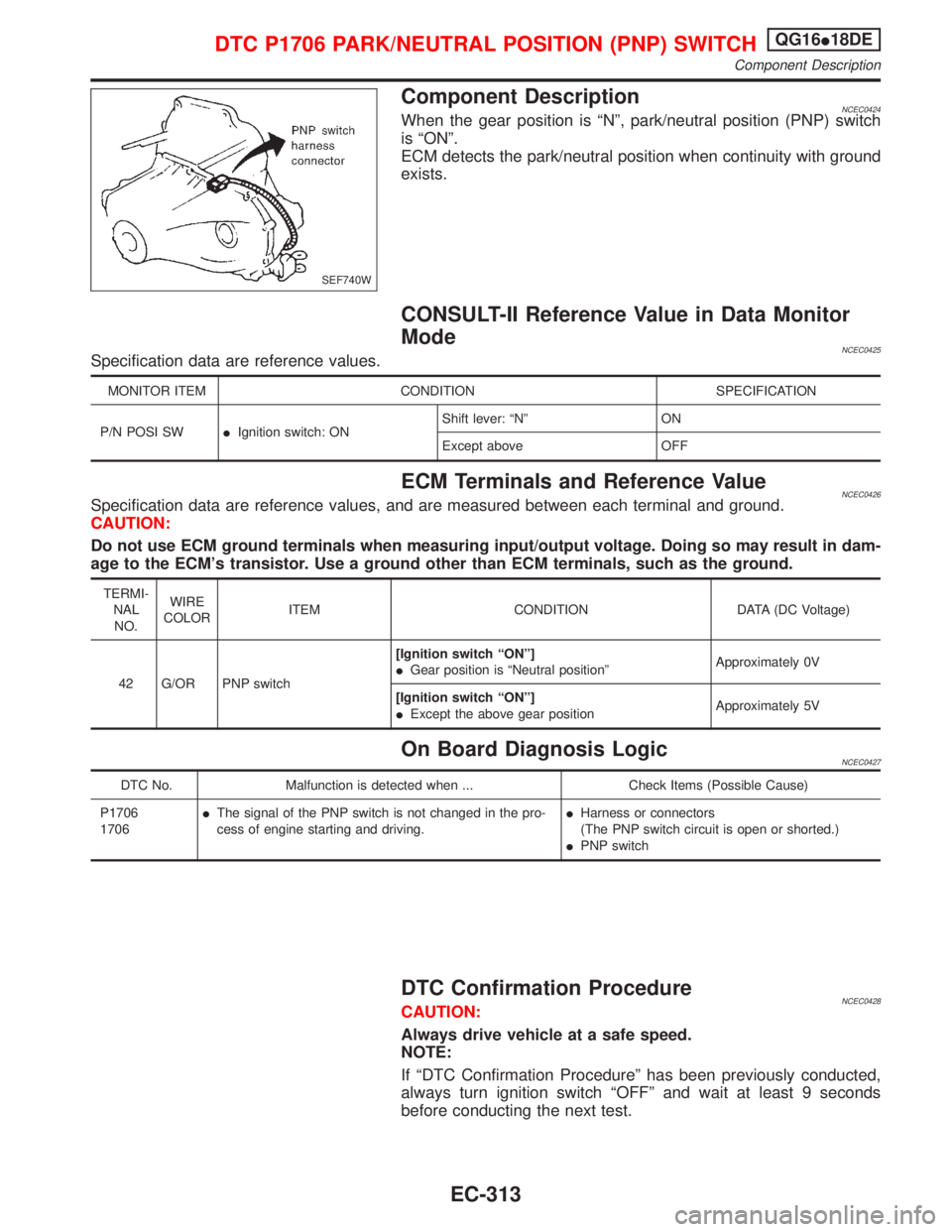

Component DescriptionNCEC0424When the gear position is ªNº, park/neutral position (PNP) switch

is ªONº.

ECM detects the park/neutral position when continuity with ground

exists.

CONSULT-II Reference Value in Data Monitor

Mode

NCEC0425Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

P/N POSI SWIIgnition switch: ONShift lever: ªNº ON

Except above OFF

ECM Terminals and Reference ValueNCEC0426Specification data are reference values, and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

42 G/OR PNP switch[Ignition switch ªONº]

IGear position is ªNeutral positionºApproximately 0V

[Ignition switch ªONº]

IExcept the above gear positionApproximately 5V

On Board Diagnosis LogicNCEC0427

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P1706

1706IThe signal of the PNP switch is not changed in the pro-

cess of engine starting and driving.IHarness or connectors

(The PNP switch circuit is open or shorted.)

IPNP switch

DTC Confirmation ProcedureNCEC0428CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

SEF740W

DTC P1706 PARK/NEUTRAL POSITION (PNP) SWITCHQG16I18DE

Component Description

EC-313

Page 756 of 2267

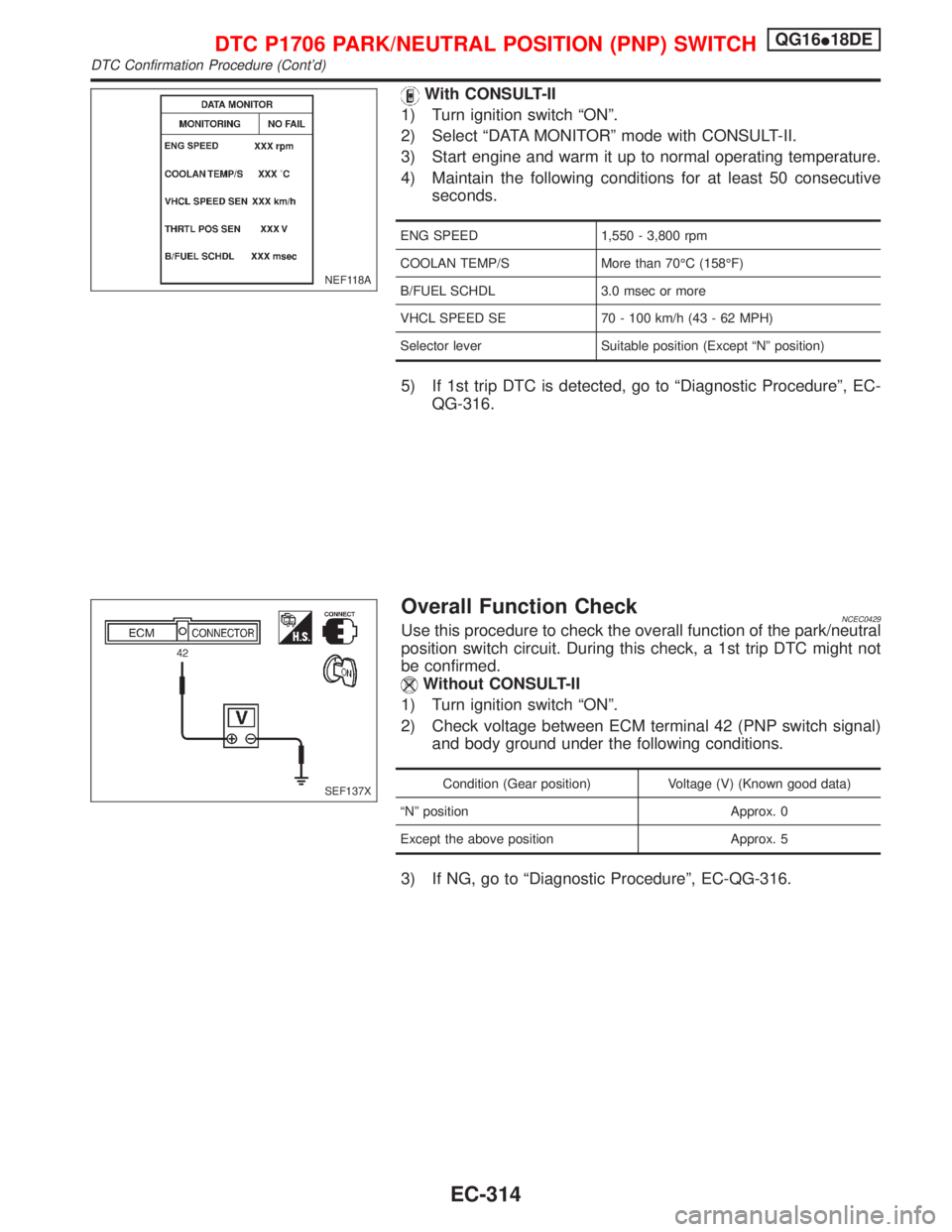

With CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and warm it up to normal operating temperature.

4) Maintain the following conditions for at least 50 consecutive

seconds.

ENG SPEED 1,550 - 3,800 rpm

COOLAN TEMP/S More than 70ÉC (158ÉF)

B/FUEL SCHDL 3.0 msec or more

VHCL SPEED SE 70 - 100 km/h (43 - 62 MPH)

Selector lever Suitable position (Except ªNº position)

5) If 1st trip DTC is detected, go to ªDiagnostic Procedureº, EC-

QG-316.

Overall Function CheckNCEC0429Use this procedure to check the overall function of the park/neutral

position switch circuit. During this check, a 1st trip DTC might not

be confirmed.

Without CONSULT-II

1) Turn ignition switch ªONº.

2) Check voltage between ECM terminal 42 (PNP switch signal)

and body ground under the following conditions.

Condition (Gear position) Voltage (V) (Known good data)

ªNº position Approx. 0

Except the above position Approx. 5

3) If NG, go to ªDiagnostic Procedureº, EC-QG-316.

NEF118A

SEF137X

DTC P1706 PARK/NEUTRAL POSITION (PNP) SWITCHQG16I18DE

DTC Confirmation Procedure (Cont'd)

EC-314

Page 762 of 2267

Diagnostic ProcedureNCEC0438

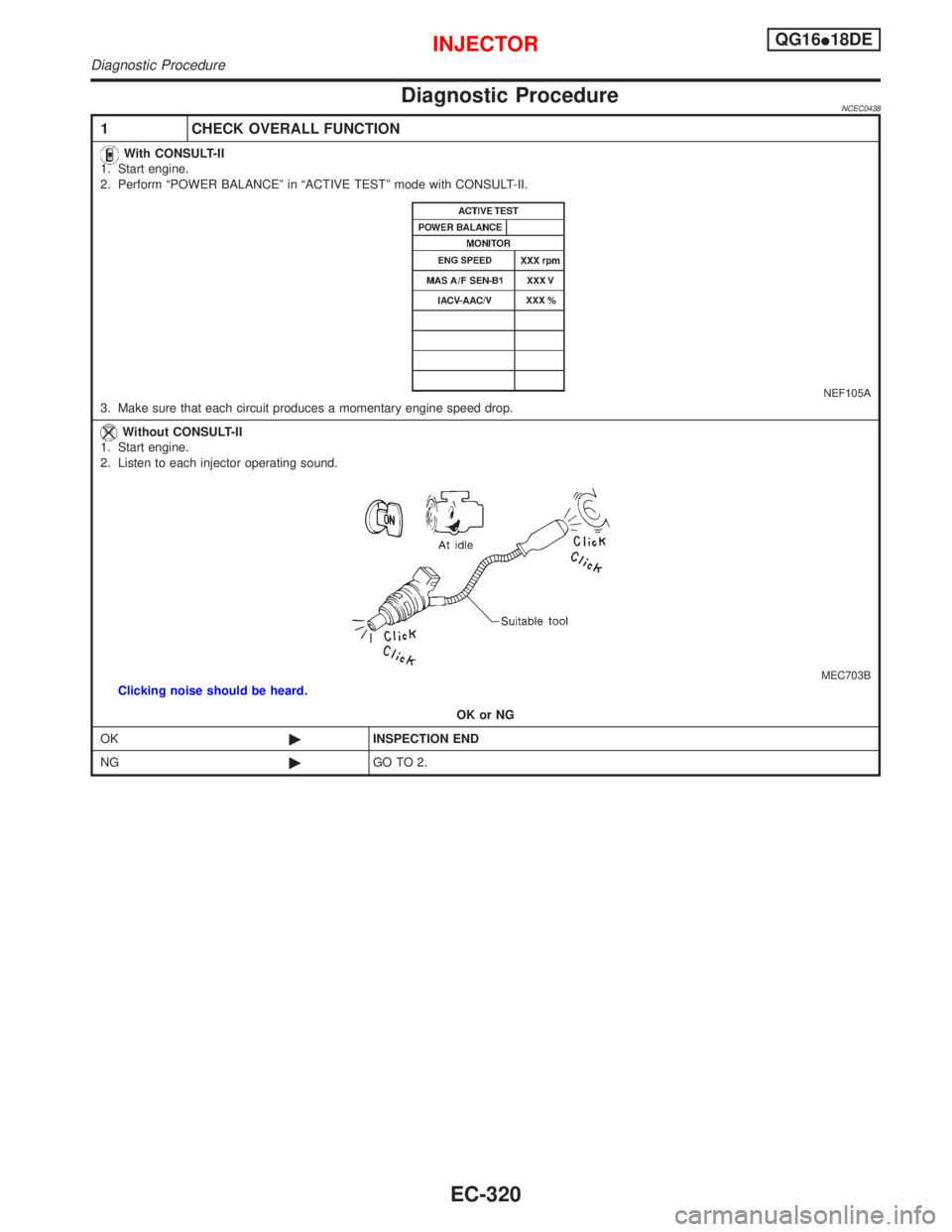

1 CHECK OVERALL FUNCTION

With CONSULT-II

1. Start engine.

2. Perform ªPOWER BALANCEº in ªACTIVE TESTº mode with CONSULT-II.

NEF105A3. Make sure that each circuit produces a momentary engine speed drop.

Without CONSULT-II

1. Start engine.

2. Listen to each injector operating sound.

MEC703BClicking noise should be heard.

OK or NG

OK©INSPECTION END

NG©GO TO 2.

INJECTORQG16I18DE

Diagnostic Procedure

EC-320

Page 763 of 2267

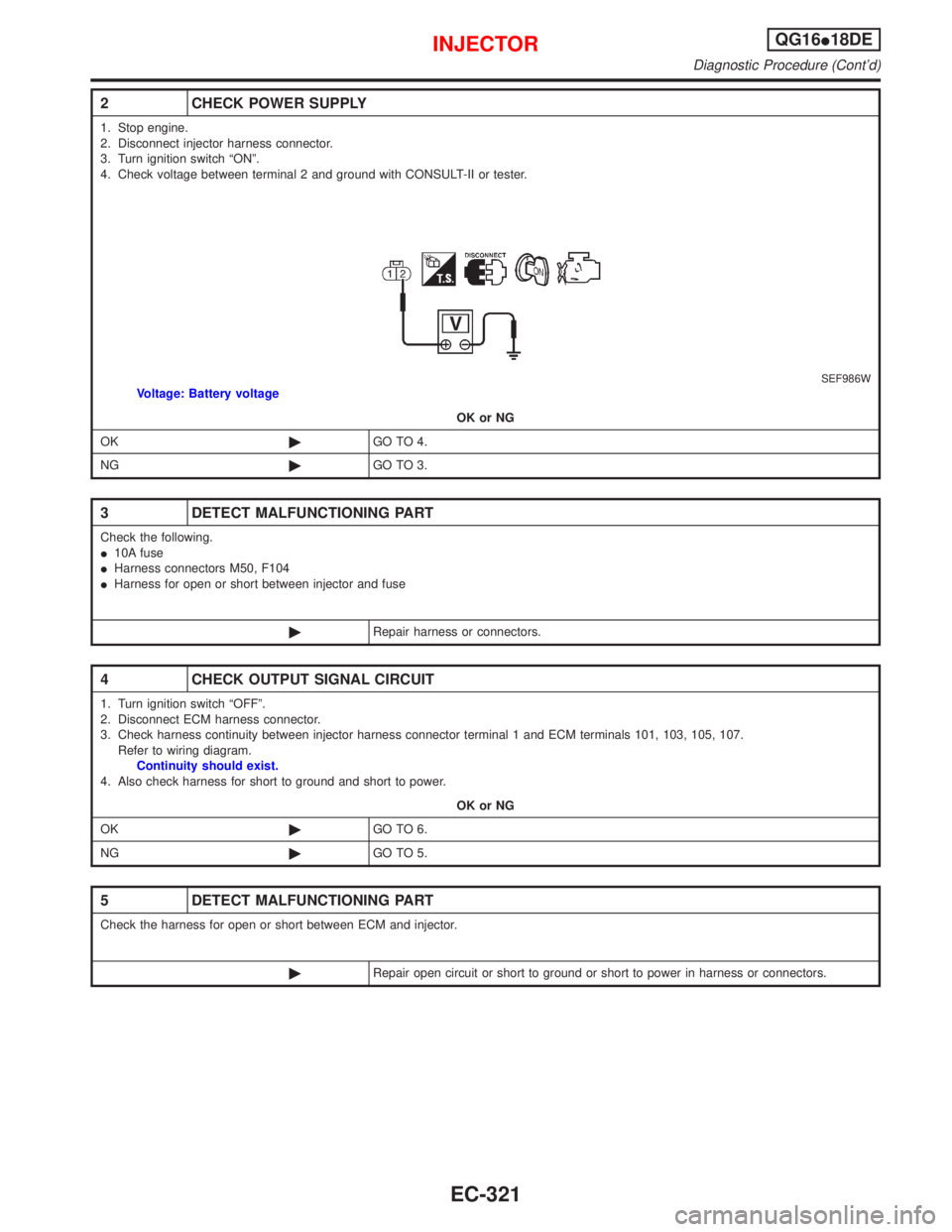

2 CHECK POWER SUPPLY

1. Stop engine.

2. Disconnect injector harness connector.

3. Turn ignition switch ªONº.

4. Check voltage between terminal 2 and ground with CONSULT-II or tester.

SEF986WVoltage: Battery voltage

OK or NG

OK©GO TO 4.

NG©GO TO 3.

3 DETECT MALFUNCTIONING PART

Check the following.

I10A fuse

IHarness connectors M50, F104

IHarness for open or short between injector and fuse

©Repair harness or connectors.

4 CHECK OUTPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between injector harness connector terminal 1 and ECM terminals 101, 103, 105, 107.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the harness for open or short between ECM and injector.

©Repair open circuit or short to ground or short to power in harness or connectors.

INJECTORQG16I18DE

Diagnostic Procedure (Cont'd)

EC-321

Page 768 of 2267

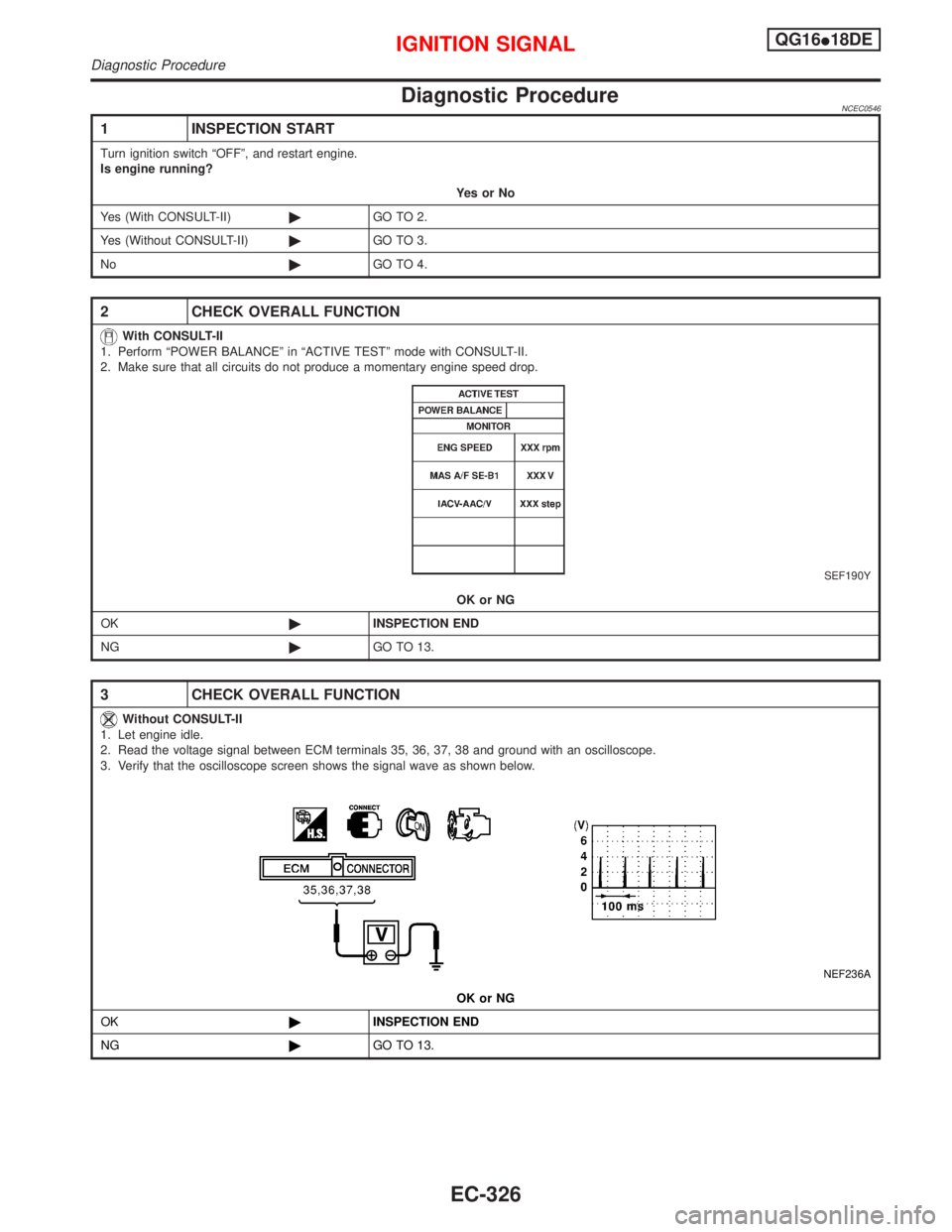

Diagnostic ProcedureNCEC0546

1 INSPECTION START

Turn ignition switch ªOFFº, and restart engine.

Is engine running?

YesorNo

Yes (With CONSULT-II)©GO TO 2.

Yes (Without CONSULT-II)©GO TO 3.

No©GO TO 4.

2 CHECK OVERALL FUNCTION

With CONSULT-II

1. Perform ªPOWER BALANCEº in ªACTIVE TESTº mode with CONSULT-II.

2. Make sure that all circuits do not produce a momentary engine speed drop.

SEF190Y

OK or NG

OK©INSPECTION END

NG©GO TO 13.

3 CHECK OVERALL FUNCTION

Without CONSULT-II

1. Let engine idle.

2. Read the voltage signal between ECM terminals 35, 36, 37, 38 and ground with an oscilloscope.

3. Verify that the oscilloscope screen shows the signal wave as shown below.

NEF236A

OK or NG

OK©INSPECTION END

NG©GO TO 13.

IGNITION SIGNALQG16I18DE

Diagnostic Procedure

EC-326

Page 771 of 2267

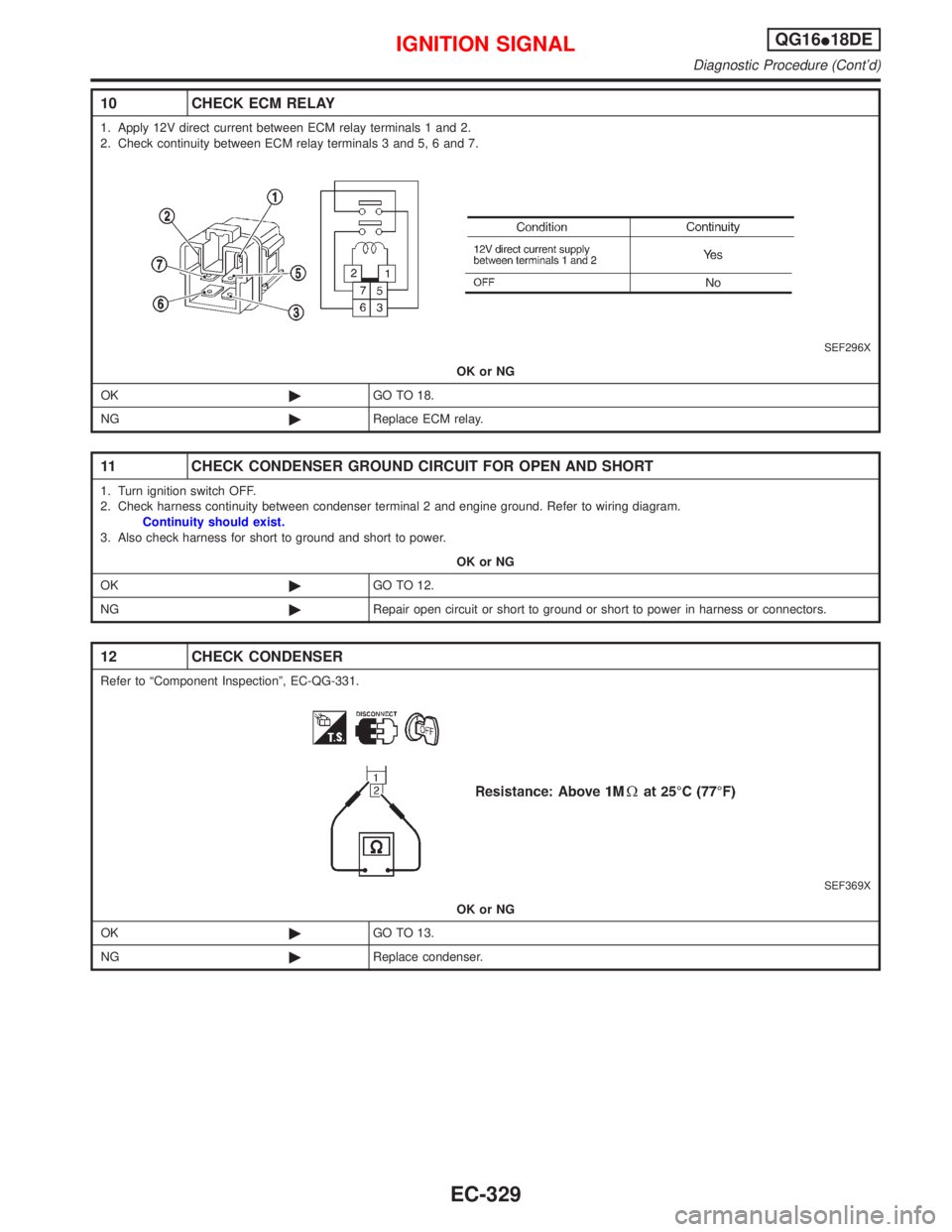

10 CHECK ECM RELAY

1. Apply 12V direct current between ECM relay terminals 1 and 2.

2. Check continuity between ECM relay terminals 3 and 5, 6 and 7.

SEF296X

OK or NG

OK©GO TO 18.

NG©Replace ECM relay.

11 CHECK CONDENSER GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Check harness continuity between condenser terminal 2 and engine ground. Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 12.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

12 CHECK CONDENSER

Refer to ªComponent Inspectionº, EC-QG-331.

SEF369X

OK or NG

OK©GO TO 13.

NG©Replace condenser.

IGNITION SIGNALQG16I18DE

Diagnostic Procedure (Cont'd)

EC-329

Page 772 of 2267

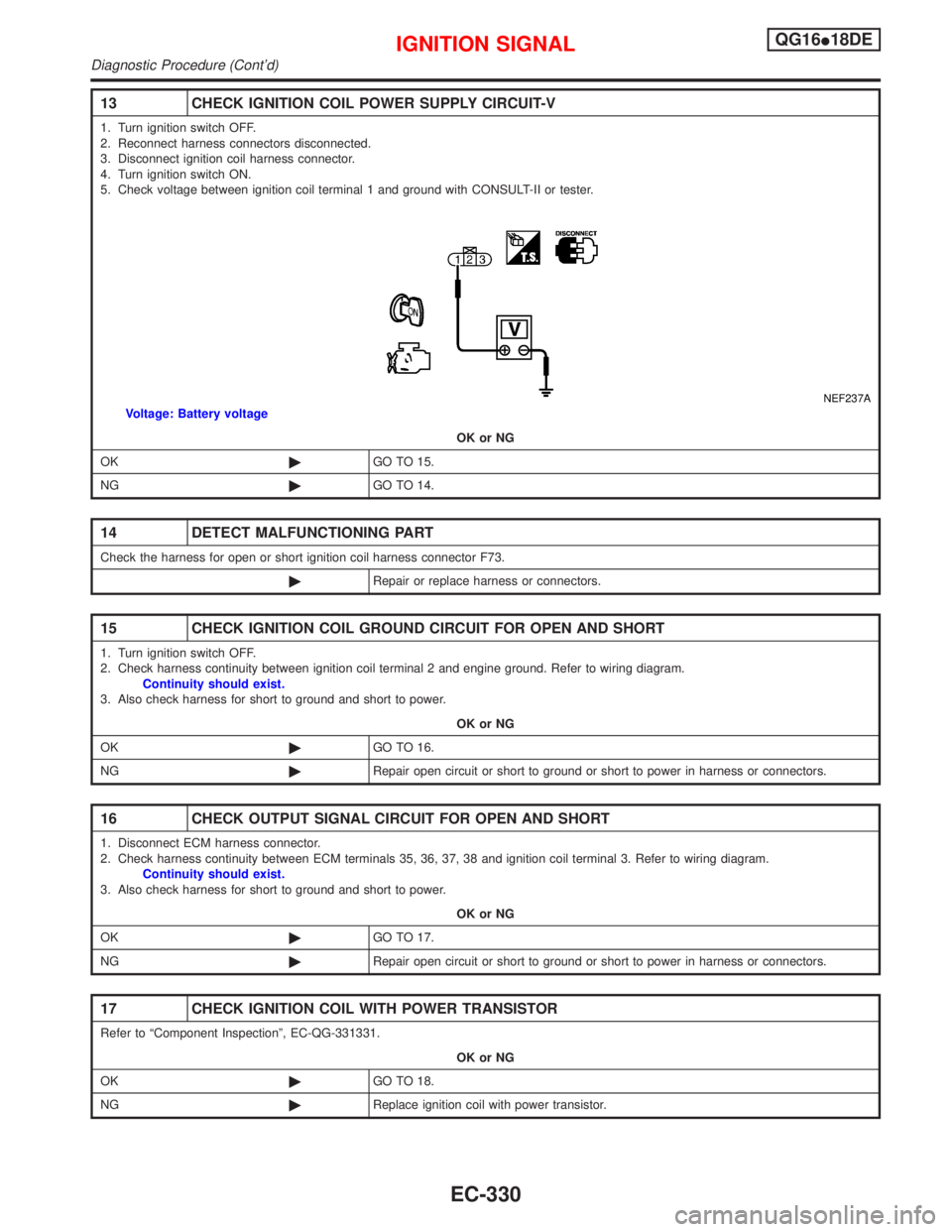

13 CHECK IGNITION COIL POWER SUPPLY CIRCUIT-V

1. Turn ignition switch OFF.

2. Reconnect harness connectors disconnected.

3. Disconnect ignition coil harness connector.

4. Turn ignition switch ON.

5. Check voltage between ignition coil terminal 1 and ground with CONSULT-II or tester.

NEF237AVoltage: Battery voltage

OK or NG

OK©GO TO 15.

NG©GO TO 14.

14 DETECT MALFUNCTIONING PART

Check the harness for open or short ignition coil harness connector F73.

©Repair or replace harness or connectors.

15 CHECK IGNITION COIL GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Check harness continuity between ignition coil terminal 2 and engine ground. Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 16.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

16 CHECK OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminals 35, 36, 37, 38 and ignition coil terminal 3. Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 17.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

17 CHECK IGNITION COIL WITH POWER TRANSISTOR

Refer to ªComponent Inspectionº, EC-QG-331331.

OK or NG

OK©GO TO 18.

NG©Replace ignition coil with power transistor.

IGNITION SIGNALQG16I18DE

Diagnostic Procedure (Cont'd)

EC-330

Page 786 of 2267

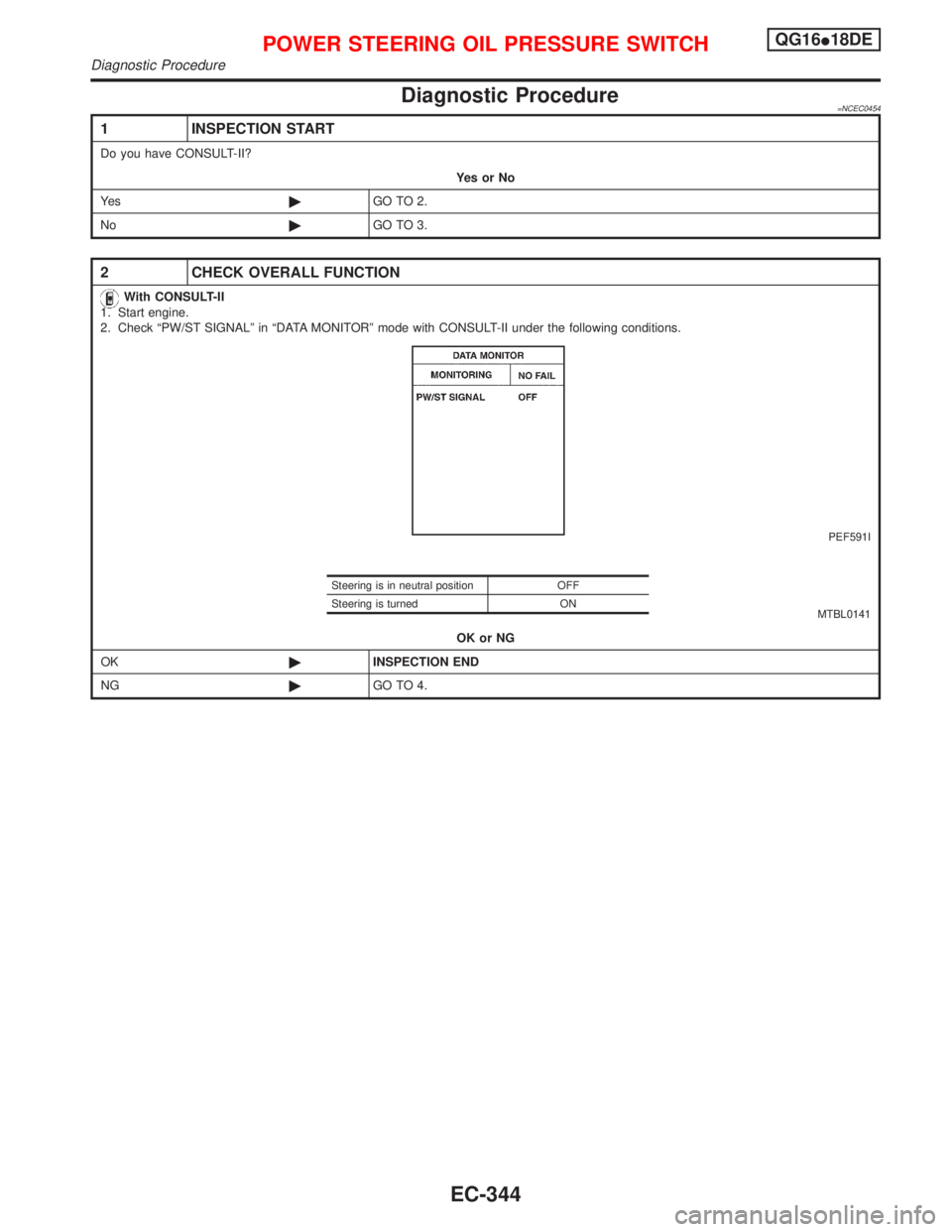

Diagnostic Procedure=NCEC0454

1 INSPECTION START

Do you have CONSULT-II?

YesorNo

Ye s©GO TO 2.

No©GO TO 3.

2 CHECK OVERALL FUNCTION

With CONSULT-II

1. Start engine.

2. Check ªPW/ST SIGNALº in ªDATA MONITORº mode with CONSULT-II under the following conditions.

PEF591I

MTBL0141

OK or NG

OK©INSPECTION END

NG©GO TO 4.

Steering is in neutral position OFF

Steering is turned ON

POWER STEERING OIL PRESSURE SWITCHQG16I18DE

Diagnostic Procedure

EC-344