check engine NISSAN PRIMERA 1999 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 906 of 2267

![NISSAN PRIMERA 1999 Electronic Repair Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

36*1 G Ignition check[Engine is running]

IWarm-up condition

IIdle speedApproximately 13V

SEF998V

[Engine is running]

IEngine speed is 2,000 rpm NISSAN PRIMERA 1999 Electronic Repair Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

36*1 G Ignition check[Engine is running]

IWarm-up condition

IIdle speedApproximately 13V

SEF998V

[Engine is running]

IEngine speed is 2,000 rpm](/img/5/57377/w960_57377-905.png)

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

36*1 G Ignition check[Engine is running]

IWarm-up condition

IIdle speedApproximately 13V

SEF998V

[Engine is running]

IEngine speed is 2,000 rpmApproximately 12V

SEF999V

40 YThrottle position switch

(Closed position)[Engine is running]

IAccelerator pedal releasedBATTERY VOLTAGE

(11 - 14V)

[Ignition switch ªONº]

IAccelerator pedal depressedApproximately 0V

41 B/Y Start signal[Ignition switch ªONº]Approximately 0V

[Ignition switch ªSTARTº]9 - 12V

42 G/OR PNP switch[Ignition switch ªONº]

IGear position is ªNeutral positionº (M/T mod-

els)

IGear position is ªPº or ªNº (CVT models)Approximately 0V

[Ignition switch ªONº]

IExcept the above gear positionBATTERY VOLTAGE

(11 - 14V)

43 B/R Ignition switch[Ignition switch ªOFFº]0V

[Ignition switch ªONº]BATTERY VOLTAGE

(11 - 14V)

44 Ð Air conditioner switch[Engine is running]

IBoth air conditioner switch and blower switch

are ªONº (Compressor operates)Approximately 0V

[Engine is running]

IAir conditioner switch is ªOFFºApproximately 5V

46 PU/WPower steering oil pres-

sure switch[Engine is running]

ISteering wheel is fully turnedApproximately 0V

[Engine is running]

ISteering wheel is not turnedApproximately 5V

48 B ECM ground[Engine is running]

IIdle speedEngine ground

(Probe this terminal with (þ)

tester probe when measuring)

50 R Electric load signal[Engine is running]

IHeadlamp switch or rear window defogger

switch is ªONºBATTERY VOLTAGE

(11 - 14V)

*1: If so equipped

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONSR20DE

ECM Terminals and Reference Value (Cont'd)

EC-106

Page 909 of 2267

![NISSAN PRIMERA 1999 Electronic Repair Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

86 OR/WVehicle speed sensor or

ABS actuator and elec-

tric unit (control unit)[Engine is running]

ILift up the vehicle

IIn 2nd gear position

IV NISSAN PRIMERA 1999 Electronic Repair Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

86 OR/WVehicle speed sensor or

ABS actuator and elec-

tric unit (control unit)[Engine is running]

ILift up the vehicle

IIn 2nd gear position

IV](/img/5/57377/w960_57377-908.png)

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

86 OR/WVehicle speed sensor or

ABS actuator and elec-

tric unit (control unit)[Engine is running]

ILift up the vehicle

IIn 2nd gear position

IVehicle speed is 40 km/h (25 MPH)Approximately 2.5V

SEF976W

91 PU/Y CVT check signal[Engine is running]

IIdle speed0 - Approximately 5V

93*1 G/R Data link connector[Engine is running]

lIdle speed (CONSULT-II or GST is discon-

nected)Approximately 0V

101

103

105

107R/B

Y/B

G/B

L/BInjector No. 1

Injector No. 2

Injector No. 3

Injector No. 4[Engine is running]

IWarm-up condition

IIdle speedBATTERY VOLTAGE

(11 - 14V)

SEF011W

[Engine is running]

IWarm-up condition

IEngine speed is 2,000 rpmBATTERY VOLTAGE

(11 - 14V)

SEF012W

106

108B/Y ECM ground[Engine is running]

IIdle speed0V

11 0

11 2R

RPower supply for ECM[Ignition switch ªONº]BATTERY VOLTAGE

(11 - 14V)

111 G Sensors' power supply[Ignition switch ªONº]Approximately 5V

114*1 G/W Adjust switch[Engine is running]

IIdle speed0V

115 BR/W Data link connector[Engine is running]

IIdle speed (CONSULT-II or GST is discon-

nected)0 - 10V

11 6Refer to

EL

sectionImmobilizer[Engine is running]

IIdle speedBATTERY VOLTAGE

(11 - 14V)

*1: If so equipped

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONSR20DE

ECM Terminals and Reference Value (Cont'd)

EC-109

Page 916 of 2267

ECM TERMINALS AND REFERENCE VALUENCEC0048Specification data are reference values and are measured between each terminal and 48 (ECM ground).

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

31 W/G ECM relay (Self shut-off)[Engine is running]

[Ignition switch ªOFFº]

IFor 9 seconds after turning ignition switch ªOFFº0-1V

[Ignition switch ªOFFº]

I9 seconds passed after turning ignition switch

ªOFFºBATTERY VOLTAGE

(11 - 14V)

43 B/R Ignition switch[Ignition switch ªOFFº]0V

[Ignition switch ªONº]BATTERY VOLTAGE

(11 - 14V)

48 B ECM ground[Engine is running]

IIdle speedEngine ground

(Probe this terminal with

(þ) tester probe when

measuring)

57 B ECM ground[Engine is running]

IIdle speedEngine ground

67 W/LPower supply for ECM

(Back-up)[Ignition switch ªOFFº]BATTERY VOLTAGE

(11 - 14V)

106

108B/Y

B/YECM ground[Engine is running]

IIdle speedEngine ground

11 0

11 2R

RPower supply for ECM[Ignition switch ªONº]BATTERY VOLTAGE

(11 - 14V)

DIAGNOSTIC PROCEDURENCEC0049

1 INSPECTION START

Start engine.

Is engine running?

YesorNo

Ye s©GO TO 4.

No©GO TO 2.

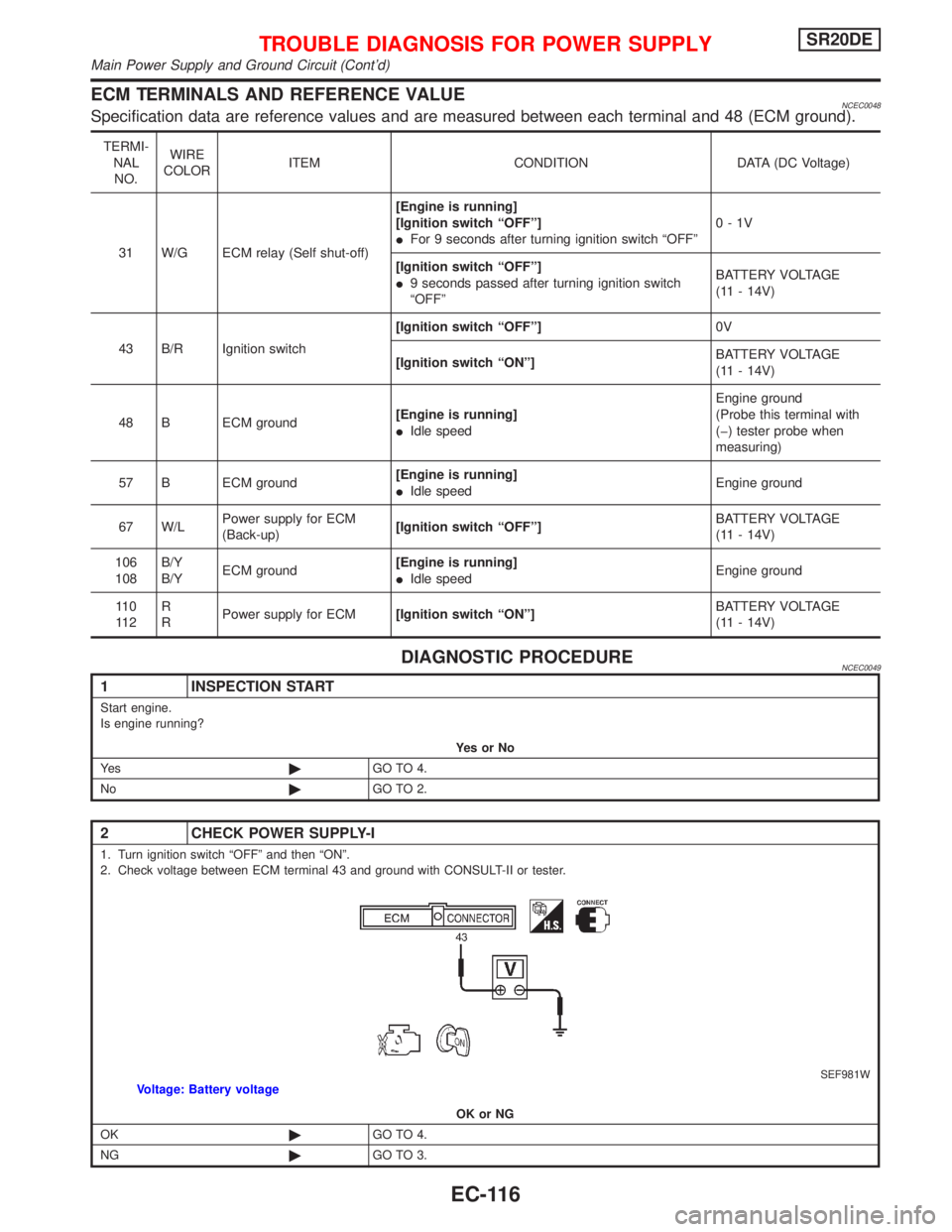

2 CHECK POWER SUPPLY-I

1. Turn ignition switch ªOFFº and then ªONº.

2. Check voltage between ECM terminal 43 and ground with CONSULT-II or tester.

SEF981WVoltage: Battery voltage

OK or NG

OK©GO TO 4.

NG©GO TO 3.

TROUBLE DIAGNOSIS FOR POWER SUPPLYSR20DE

Main Power Supply and Ground Circuit (Cont'd)

EC-116

Page 917 of 2267

3 DETECT MALFUNCTIONING PART

Check the following.

IFuse 10A, 40A

IHarness connectors M50, F104 (CVT: M81, F115)

IHarness for open or short between ECM and fuse block

IHarness for open or short between fuse block and ignition switch. Refer to wiring diagram.

©Repair harness or connectors.

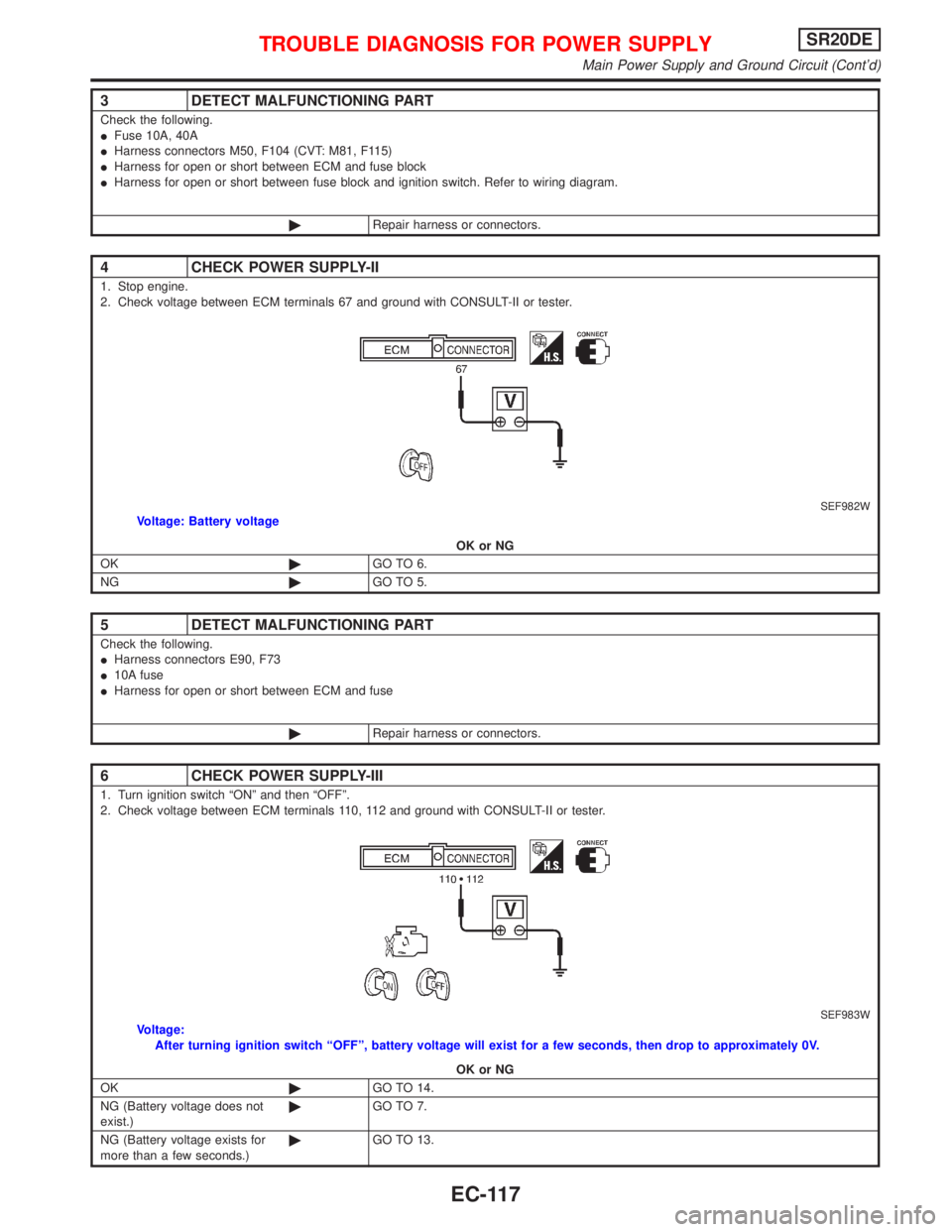

4 CHECK POWER SUPPLY-II

1. Stop engine.

2. Check voltage between ECM terminals 67 and ground with CONSULT-II or tester.

SEF982WVoltage: Battery voltage

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E90, F73

I10A fuse

IHarness for open or short between ECM and fuse

©Repair harness or connectors.

6 CHECK POWER SUPPLY-III

1. Turn ignition switch ªONº and then ªOFFº.

2. Check voltage between ECM terminals 110, 112 and ground with CONSULT-II or tester.

SEF983WVoltage:

After turning ignition switch ªOFFº, battery voltage will exist for a few seconds, then drop to approximately 0V.

OK or NG

OK©GO TO 14.

NG (Battery voltage does not

exist.)©GO TO 7.

NG (Battery voltage exists for

more than a few seconds.)©GO TO 13.

TROUBLE DIAGNOSIS FOR POWER SUPPLYSR20DE

Main Power Supply and Ground Circuit (Cont'd)

EC-117

Page 919 of 2267

11 CHECK OUTPUT SIGNAL CIRCUIT

1. Check harness continuity between ECM terminal 31 and relay terminal 2.

Refer to wiring diagram.

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 13.

NG©GO TO 12.

12 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E42, F4

IHarness for open or short between ECM relay and ECM

©Repair open circuit or short to ground or short to power in harness or connectors.

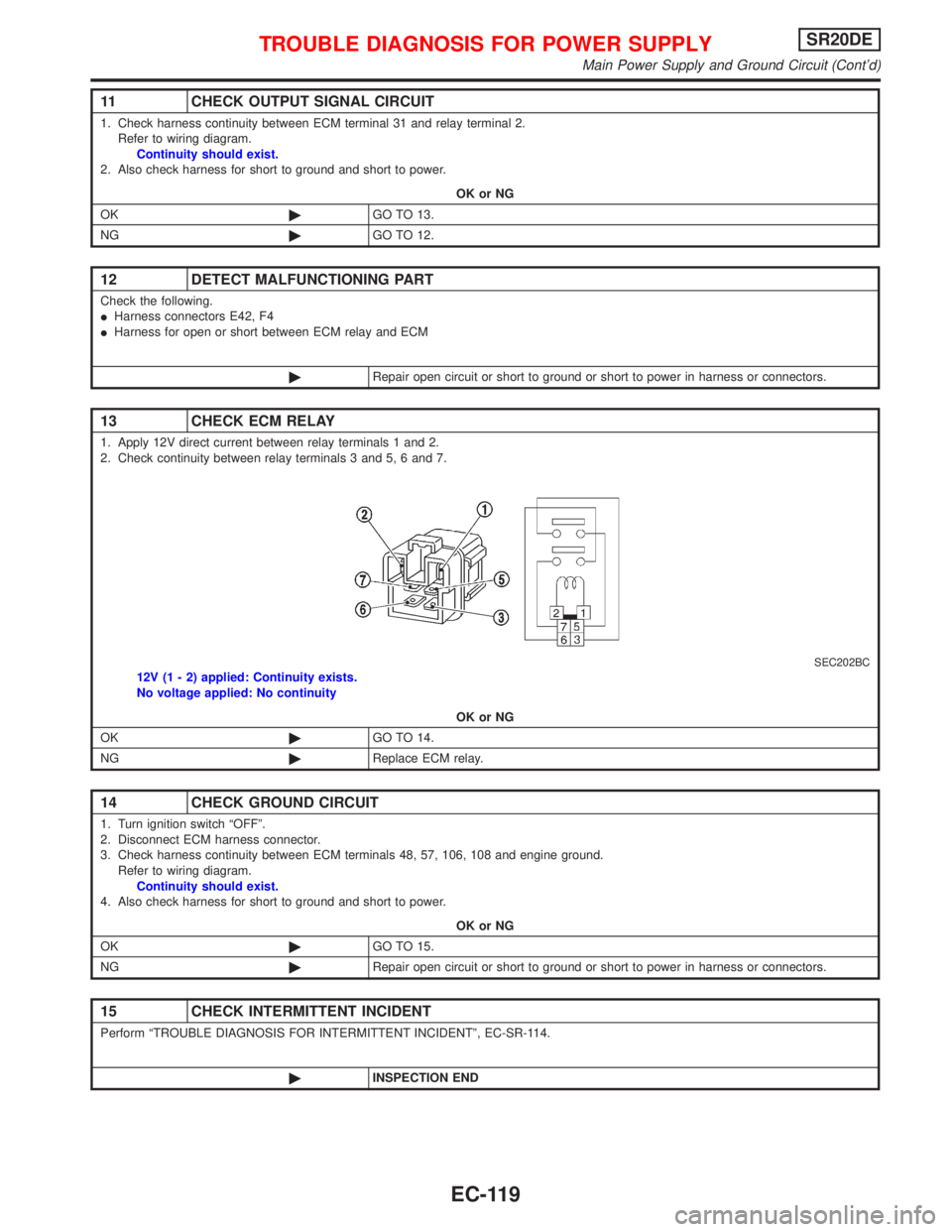

13 CHECK ECM RELAY

1. Apply 12V direct current between relay terminals 1 and 2.

2. Check continuity between relay terminals 3 and 5, 6 and 7.

SEC202BC12V (1 - 2) applied: Continuity exists.

No voltage applied: No continuity

OK or NG

OK©GO TO 14.

NG©Replace ECM relay.

14 CHECK GROUND CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminals 48, 57, 106, 108 and engine ground.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 15.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

15 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-SR-114.

©INSPECTION END

TROUBLE DIAGNOSIS FOR POWER SUPPLYSR20DE

Main Power Supply and Ground Circuit (Cont'd)

EC-119

Page 920 of 2267

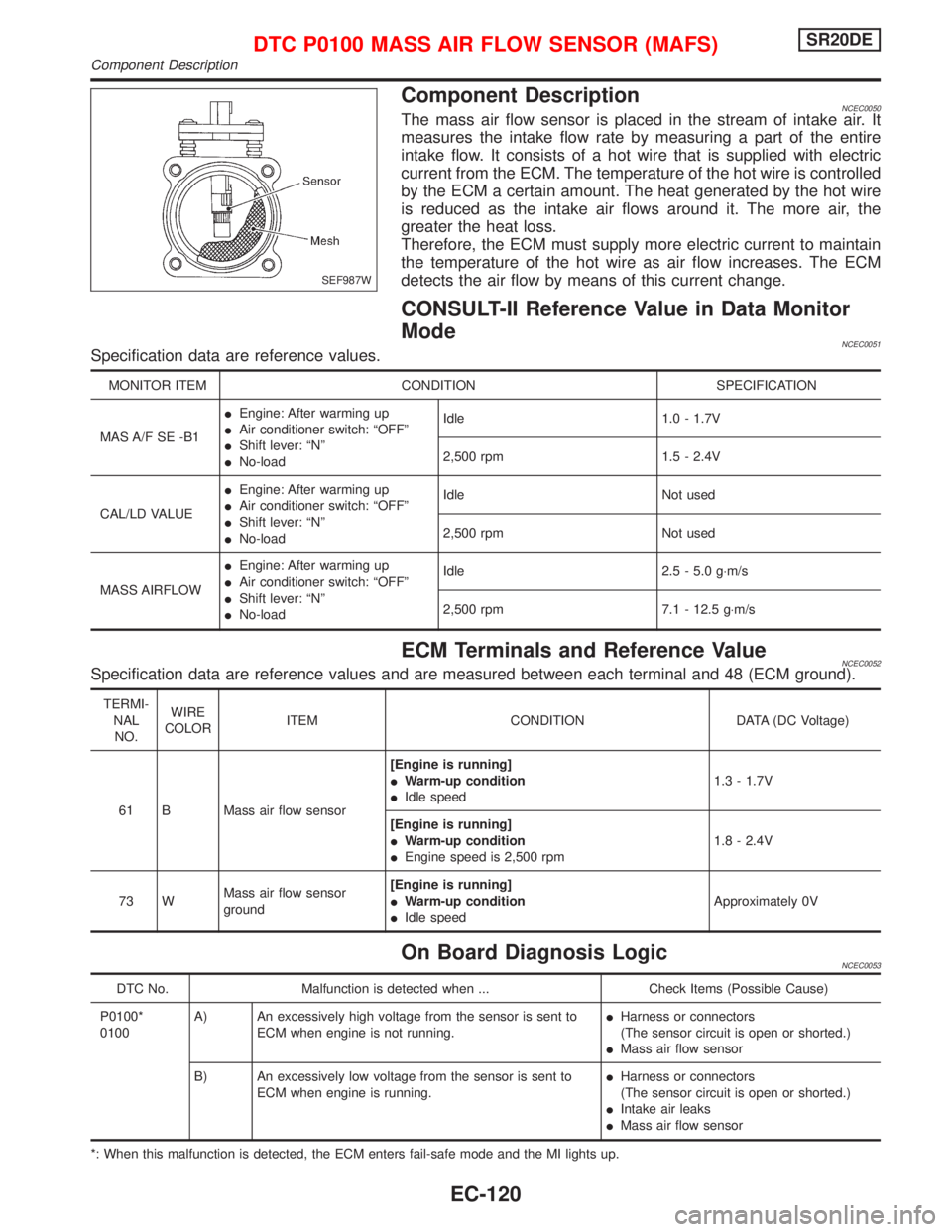

Component DescriptionNCEC0050The mass air flow sensor is placed in the stream of intake air. It

measures the intake flow rate by measuring a part of the entire

intake flow. It consists of a hot wire that is supplied with electric

current from the ECM. The temperature of the hot wire is controlled

by the ECM a certain amount. The heat generated by the hot wire

is reduced as the intake air flows around it. The more air, the

greater the heat loss.

Therefore, the ECM must supply more electric current to maintain

the temperature of the hot wire as air flow increases. The ECM

detects the air flow by means of this current change.

CONSULT-II Reference Value in Data Monitor

Mode

NCEC0051Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

MAS A/F SE -B1IEngine: After warming up

IAir conditioner switch: ªOFFº

IShift lever: ªNº

INo-loadIdle 1.0 - 1.7V

2,500 rpm 1.5 - 2.4V

CAL/LD VALUEIEngine: After warming up

IAir conditioner switch: ªOFFº

IShift lever: ªNº

INo-loadIdle Not used

2,500 rpm Not used

MASS AIRFLOWIEngine: After warming up

IAir conditioner switch: ªOFFº

IShift lever: ªNº

INo-loadIdle 2.5 - 5.0 g×m/s

2,500 rpm 7.1 - 12.5 g×m/s

ECM Terminals and Reference ValueNCEC0052Specification data are reference values and are measured between each terminal and 48 (ECM ground).

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

61 B Mass air flow sensor[Engine is running]

IWarm-up condition

IIdle speed1.3 - 1.7V

[Engine is running]

IWarm-up condition

IEngine speed is 2,500 rpm1.8 - 2.4V

73 WMass air flow sensor

ground[Engine is running]

IWarm-up condition

IIdle speedApproximately 0V

On Board Diagnosis LogicNCEC0053

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0100*

0100A) An excessively high voltage from the sensor is sent to

ECM when engine is not running.IHarness or connectors

(The sensor circuit is open or shorted.)

IMass air flow sensor

B) An excessively low voltage from the sensor is sent to

ECM when engine is running.IHarness or connectors

(The sensor circuit is open or shorted.)

IIntake air leaks

IMass air flow sensor

*: When this malfunction is detected, the ECM enters fail-safe mode and the MI lights up.

SEF987W

DTC P0100 MASS AIR FLOW SENSOR (MAFS)SR20DE

Component Description

EC-120

Page 923 of 2267

Diagnostic ProcedureNCEC0057

1 INSPECTION START

Which malfunction (A or B) is duplicated?

Malfunction A or B

A©GO TO 3.

B©GO TO 2.

2 CHECK INTAKE SYSTEM

Check the following for connection.

IAir cut

IVacuum hoses

IIntake air passage between air duct to collector

OK or NG

OK©GO TO 3.

NG©Reconnect the parts.

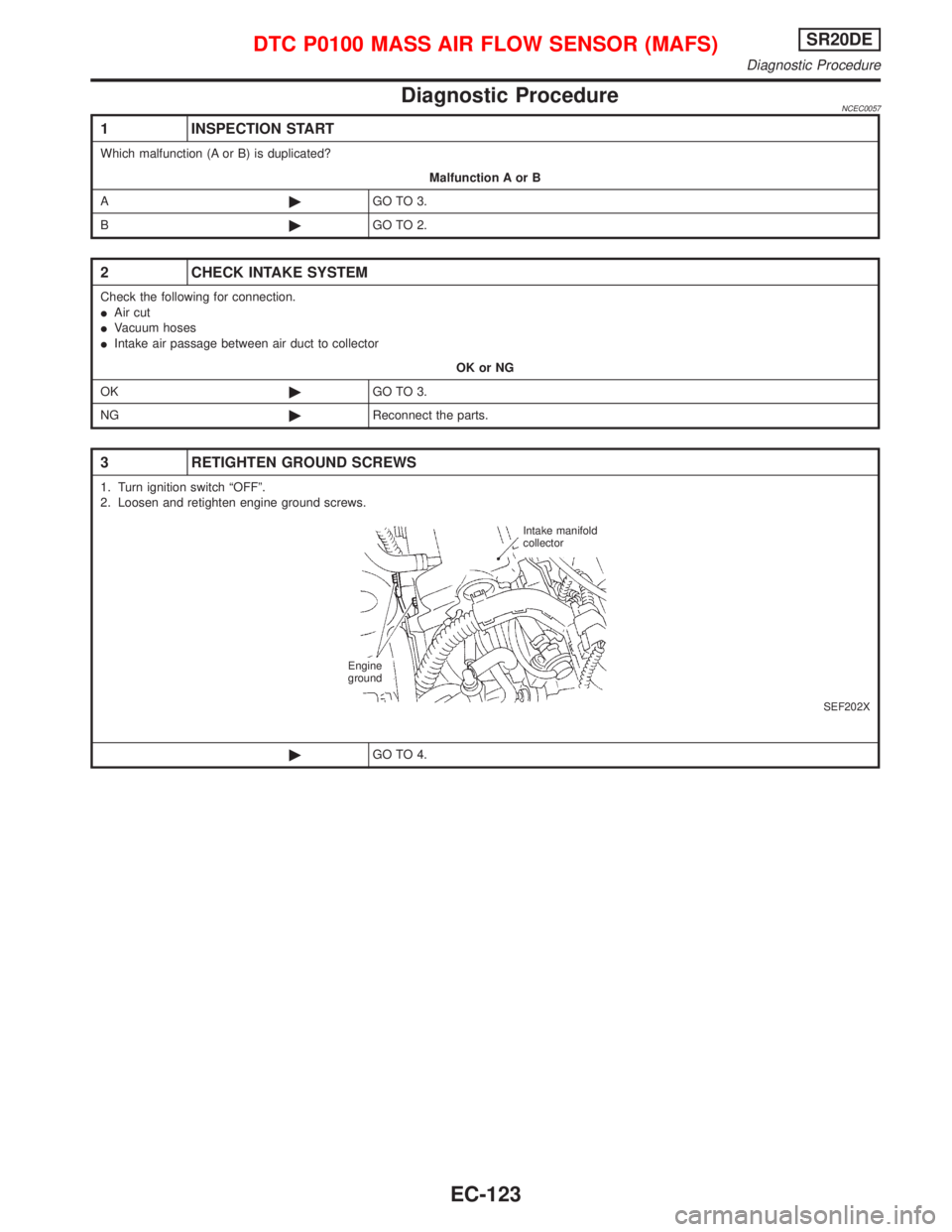

3 RETIGHTEN GROUND SCREWS

1. Turn ignition switch ªOFFº.

2. Loosen and retighten engine ground screws.

SEF202X

©GO TO 4.

Intake manifold

collector

Engine

ground

DTC P0100 MASS AIR FLOW SENSOR (MAFS)SR20DE

Diagnostic Procedure

EC-123

Page 926 of 2267

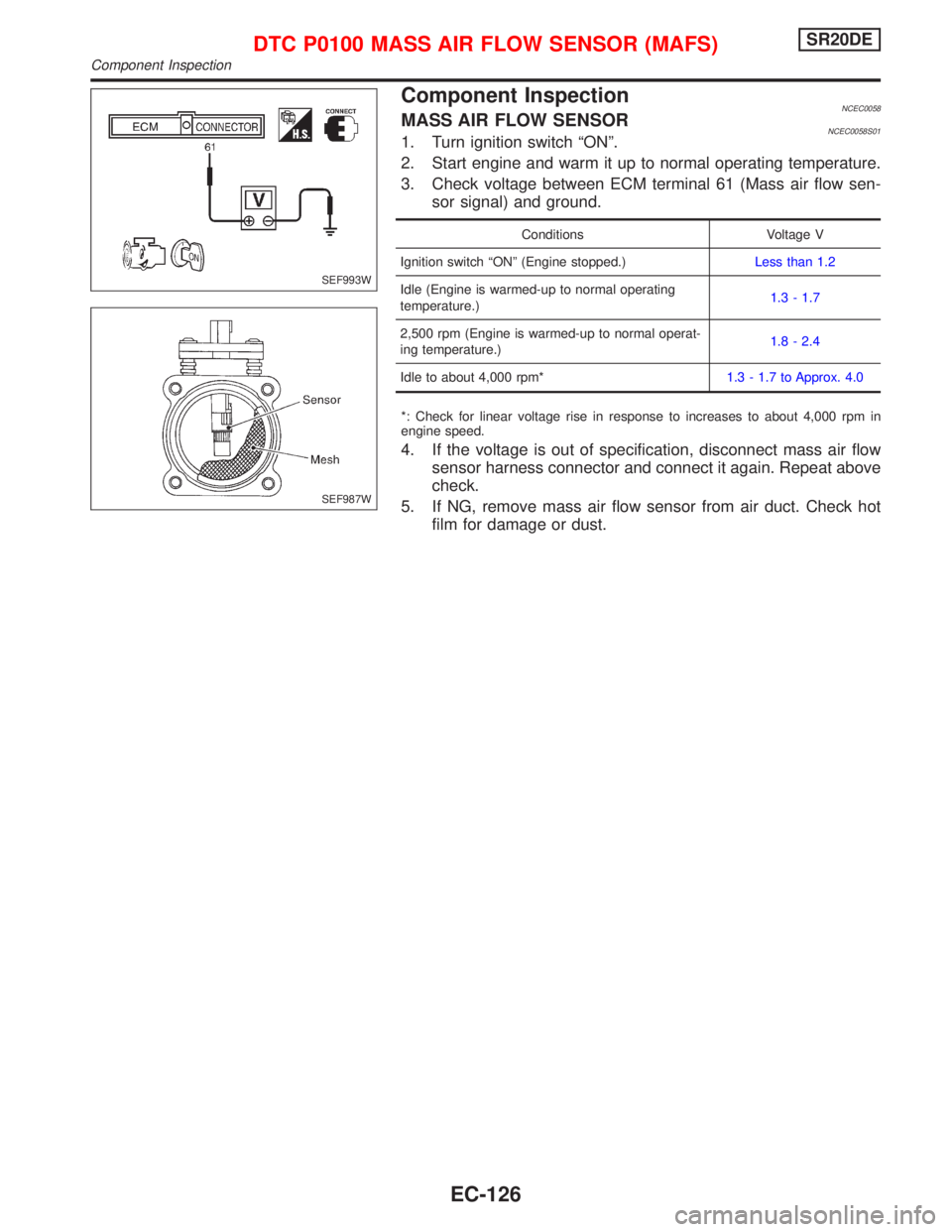

Component InspectionNCEC0058MASS AIR FLOW SENSORNCEC0058S011. Turn ignition switch ªONº.

2. Start engine and warm it up to normal operating temperature.

3. Check voltage between ECM terminal 61 (Mass air flow sen-

sor signal) and ground.

Conditions Voltage V

Ignition switch ªONº (Engine stopped.)Less than 1.2

Idle (Engine is warmed-up to normal operating

temperature.)1.3 - 1.7

2,500 rpm (Engine is warmed-up to normal operat-

ing temperature.)1.8 - 2.4

Idle to about 4,000 rpm*1.3 - 1.7 to Approx. 4.0

*: Check for linear voltage rise in response to increases to about 4,000 rpm in

engine speed.

4. If the voltage is out of specification, disconnect mass air flow

sensor harness connector and connect it again. Repeat above

check.

5. If NG, remove mass air flow sensor from air duct. Check hot

film for damage or dust.

SEF993W

SEF987W

DTC P0100 MASS AIR FLOW SENSOR (MAFS)SR20DE

Component Inspection

EC-126

Page 932 of 2267

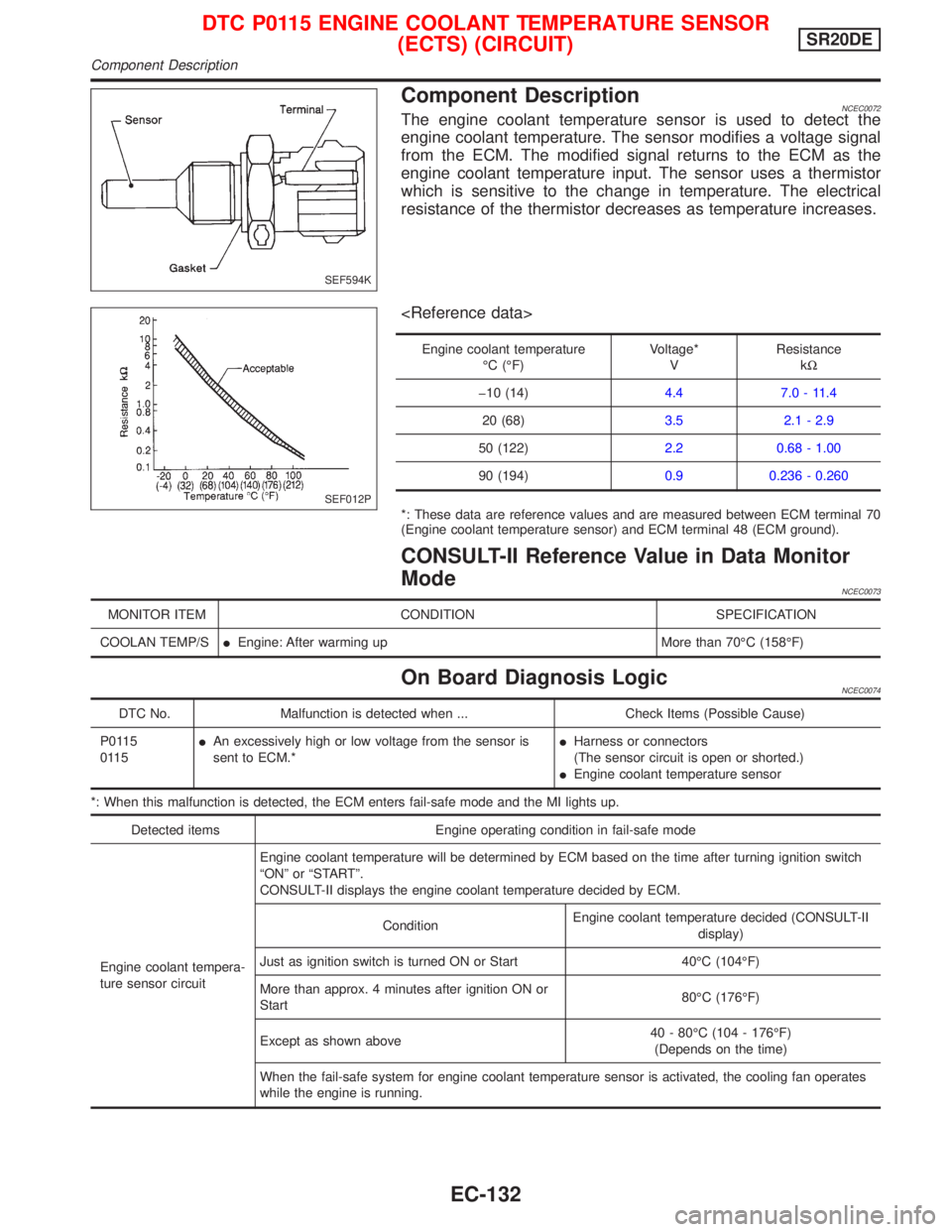

Component DescriptionNCEC0072The engine coolant temperature sensor is used to detect the

engine coolant temperature. The sensor modifies a voltage signal

from the ECM. The modified signal returns to the ECM as the

engine coolant temperature input. The sensor uses a thermistor

which is sensitive to the change in temperature. The electrical

resistance of the thermistor decreases as temperature increases.

Engine coolant temperature

ÉC (ÉF)Voltage*

VResistance

kW

þ10 (14)4.4 7.0 - 11.4

20 (68)3.5 2.1 - 2.9

50 (122)2.2 0.68 - 1.00

90 (194)0.9 0.236 - 0.260

*: These data are reference values and are measured between ECM terminal 70

(Engine coolant temperature sensor) and ECM terminal 48 (ECM ground).

CONSULT-II Reference Value in Data Monitor

Mode

NCEC0073

MONITOR ITEM CONDITION SPECIFICATION

COOLAN TEMP/SIEngine: After warming up More than 70ÉC (158ÉF)

On Board Diagnosis LogicNCEC0074

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0115

0115IAn excessively high or low voltage from the sensor is

sent to ECM.*IHarness or connectors

(The sensor circuit is open or shorted.)

IEngine coolant temperature sensor

*: When this malfunction is detected, the ECM enters fail-safe mode and the MI lights up.

Detected items Engine operating condition in fail-safe mode

Engine coolant tempera-

ture sensor circuitEngine coolant temperature will be determined by ECM based on the time after turning ignition switch

ªONº or ªSTARTº.

CONSULT-II displays the engine coolant temperature decided by ECM.

ConditionEngine coolant temperature decided (CONSULT-II

display)

Just as ignition switch is turned ON or Start 40ÉC (104ÉF)

More than approx. 4 minutes after ignition ON or

Start80ÉC (176ÉF)

Except as shown above40 - 80ÉC (104 - 176ÉF)

(Depends on the time)

When the fail-safe system for engine coolant temperature sensor is activated, the cooling fan operates

while the engine is running.

SEF594K

SEF012P

DTC P0115 ENGINE COOLANT TEMPERATURE SENSOR

(ECTS) (CIRCUIT)SR20DE

Component Description

EC-132

Page 935 of 2267

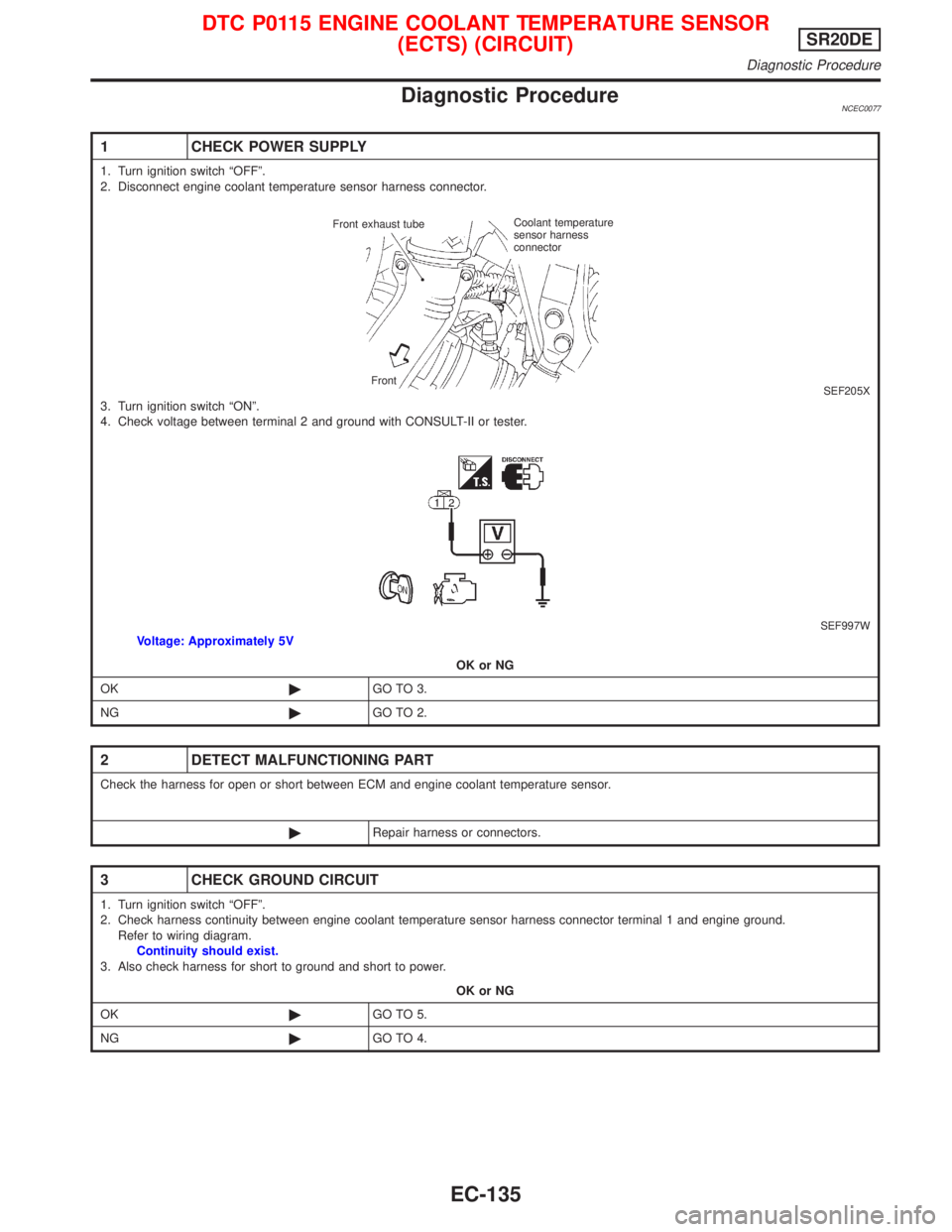

Diagnostic ProcedureNCEC0077

1 CHECK POWER SUPPLY

1. Turn ignition switch ªOFFº.

2. Disconnect engine coolant temperature sensor harness connector.

SEF205X3. Turn ignition switch ªONº.

4. Check voltage between terminal 2 and ground with CONSULT-II or tester.

SEF997WVoltage: Approximately 5V

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 DETECT MALFUNCTIONING PART

Check the harness for open or short between ECM and engine coolant temperature sensor.

©Repair harness or connectors.

3 CHECK GROUND CIRCUIT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between engine coolant temperature sensor harness connector terminal 1 and engine ground.

Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©GO TO 4.

Front exhaust tube

FrontCoolant temperature

sensor harness

connector

DTC P0115 ENGINE COOLANT TEMPERATURE SENSOR

(ECTS) (CIRCUIT)SR20DE

Diagnostic Procedure

EC-135