check engine NISSAN PRIMERA 1999 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 844 of 2267

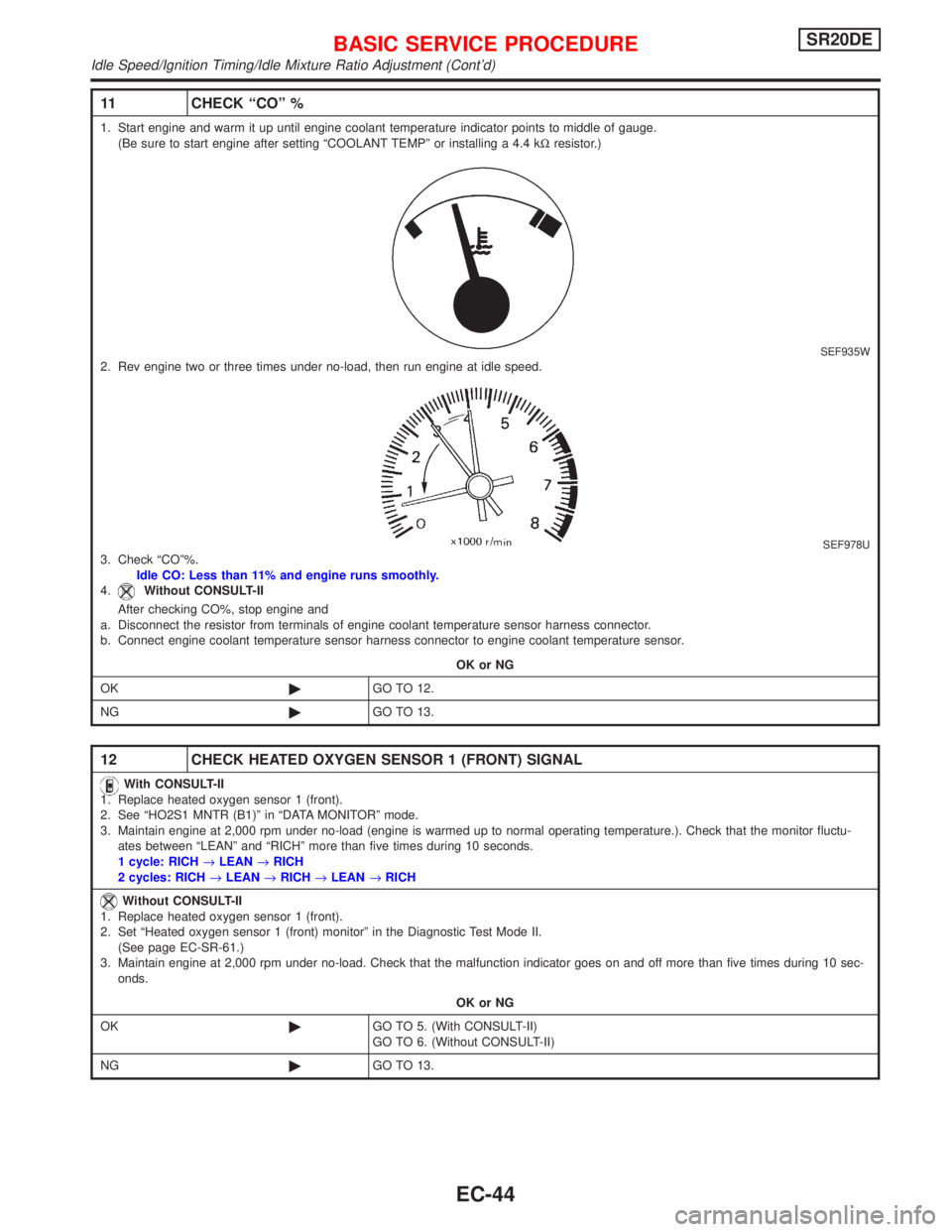

11 CHECK ªCOº %

1. Start engine and warm it up until engine coolant temperature indicator points to middle of gauge.

(Be sure to start engine after setting ªCOOLANT TEMPº or installing a 4.4 kWresistor.)

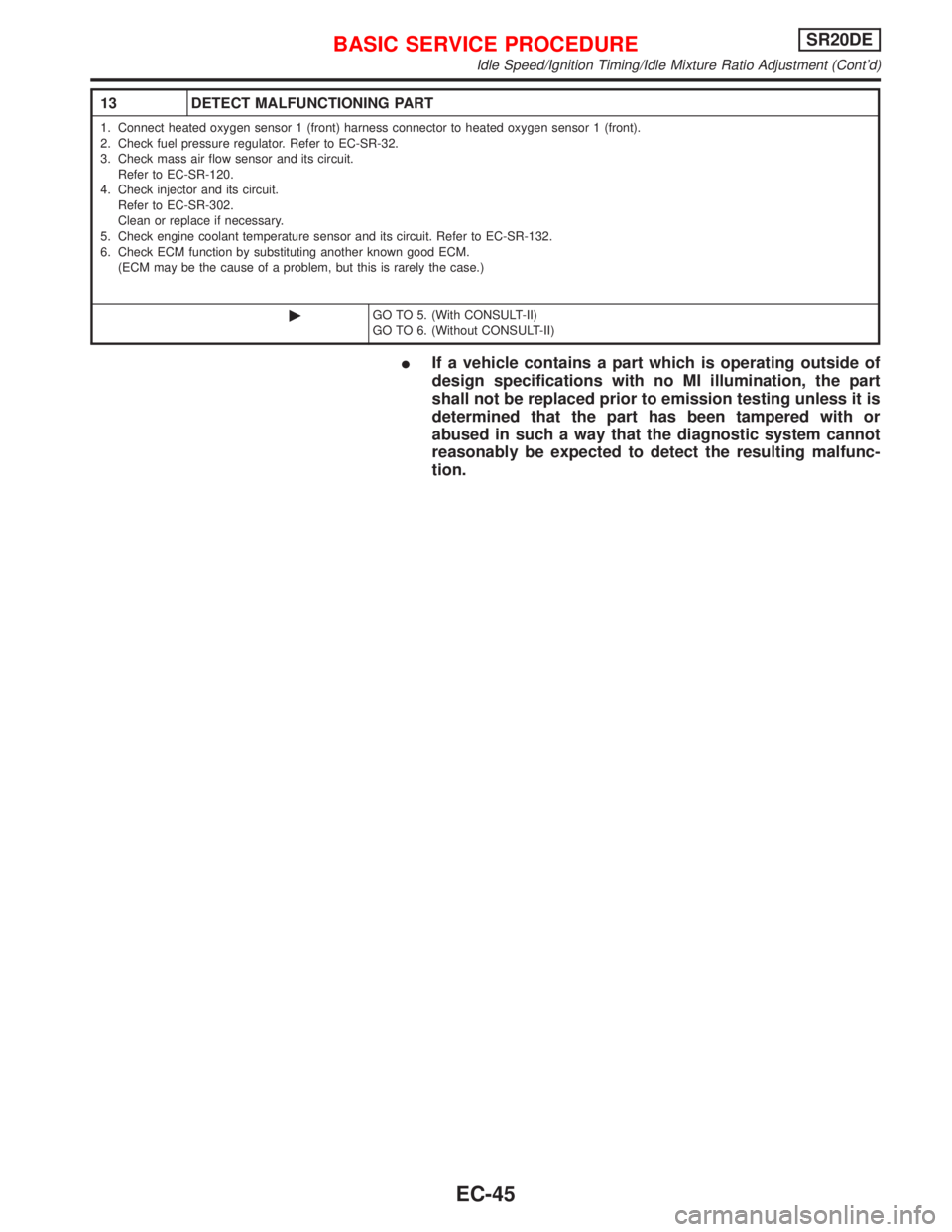

SEF935W2. Rev engine two or three times under no-load, then run engine at idle speed.

SEF978U3. Check ªCOº%.

Idle CO: Less than 11% and engine runs smoothly.

4.

Without CONSULT-II

After checking CO%, stop engine and

a. Disconnect the resistor from terminals of engine coolant temperature sensor harness connector.

b. Connect engine coolant temperature sensor harness connector to engine coolant temperature sensor.

OK or NG

OK©GO TO 12.

NG©GO TO 13.

12 CHECK HEATED OXYGEN SENSOR 1 (FRONT) SIGNAL

With CONSULT-II

1. Replace heated oxygen sensor 1 (front).

2. See ªHO2S1 MNTR (B1)º in ªDATA MONITORº mode.

3. Maintain engine at 2,000 rpm under no-load (engine is warmed up to normal operating temperature.). Check that the monitor fluctu-

ates between ªLEANº and ªRICHº more than five times during 10 seconds.

1 cycle: RICH®LEAN®RICH

2 cycles: RICH®LEAN®RICH®LEAN®RICH

Without CONSULT-II

1. Replace heated oxygen sensor 1 (front).

2. Set ªHeated oxygen sensor 1 (front) monitorº in the Diagnostic Test Mode II.

(See page EC-SR-61.)

3. Maintain engine at 2,000 rpm under no-load. Check that the malfunction indicator goes on and off more than five times during 10 sec-

onds.

OK or NG

OK©GO TO 5. (With CONSULT-II)

GO TO 6. (Without CONSULT-II)

NG©GO TO 13.

BASIC SERVICE PROCEDURESR20DE

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment (Cont'd)

EC-44

Page 845 of 2267

13 DETECT MALFUNCTIONING PART

1. Connect heated oxygen sensor 1 (front) harness connector to heated oxygen sensor 1 (front).

2. Check fuel pressure regulator. Refer to EC-SR-32.

3. Check mass air flow sensor and its circuit.

Refer to EC-SR-120.

4. Check injector and its circuit.

Refer to EC-SR-302.

Clean or replace if necessary.

5. Check engine coolant temperature sensor and its circuit. Refer to EC-SR-132.

6. Check ECM function by substituting another known good ECM.

(ECM may be the cause of a problem, but this is rarely the case.)

©GO TO 5. (With CONSULT-II)

GO TO 6. (Without CONSULT-II)

IIf a vehicle contains a part which is operating outside of

design specifications with no MI illumination, the part

shall not be replaced prior to emission testing unless it is

determined that the part has been tampered with or

abused in such a way that the diagnostic system cannot

reasonably be expected to detect the resulting malfunc-

tion.

BASIC SERVICE PROCEDURESR20DE

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment (Cont'd)

EC-45

Page 846 of 2267

Idle Air Volume LearningNCEC0541DESCRIPTIONNCEC0541S01ªIdle Air Volume Learningº is an operation to learn the idle air vol-

ume that keeps each engine within the specific range. It must be

performed under any of the following conditions:

IEach time IACV-AAC valve, throttle body or ECM is replaced.

IIdle speed or ignition timing is out of specification.

PRE-CONDITIONINGNCEC0541S04Before performing ªIdle Air Volume Learningº, make sure that all of

the following conditions are satisfied.

Learning will be cancelled if any of the following conditions are

missed for even a moment.

IBattery voltage: More than 12.9V (At idle)

IEngine coolant temperature: 70 - 94ÉC (158 - 201ÉF)

IPNP switch: ON

IElectric load switch: OFF

(Air conditioner, headlamp, rear window defogger)

On vehicles equipped with daytime running light systems, set

lighting switch to the 1st position to light only small lamps.

ICooling fan motor: Not operating

ISteering wheel: Neutral (Straight-ahead position)

IVehicle speed: Stopped

ITransmission : Warmed up

For CVT models with CONSULT-II, drive vehicle until ªFLUID

TEMP SEº in ªDATA MONITORº mode of ªCVTº system indi-

cates less than 0.9V.

For CVT models without CONSULT-II and M/T models, drive

vehicle for 10 minutes.

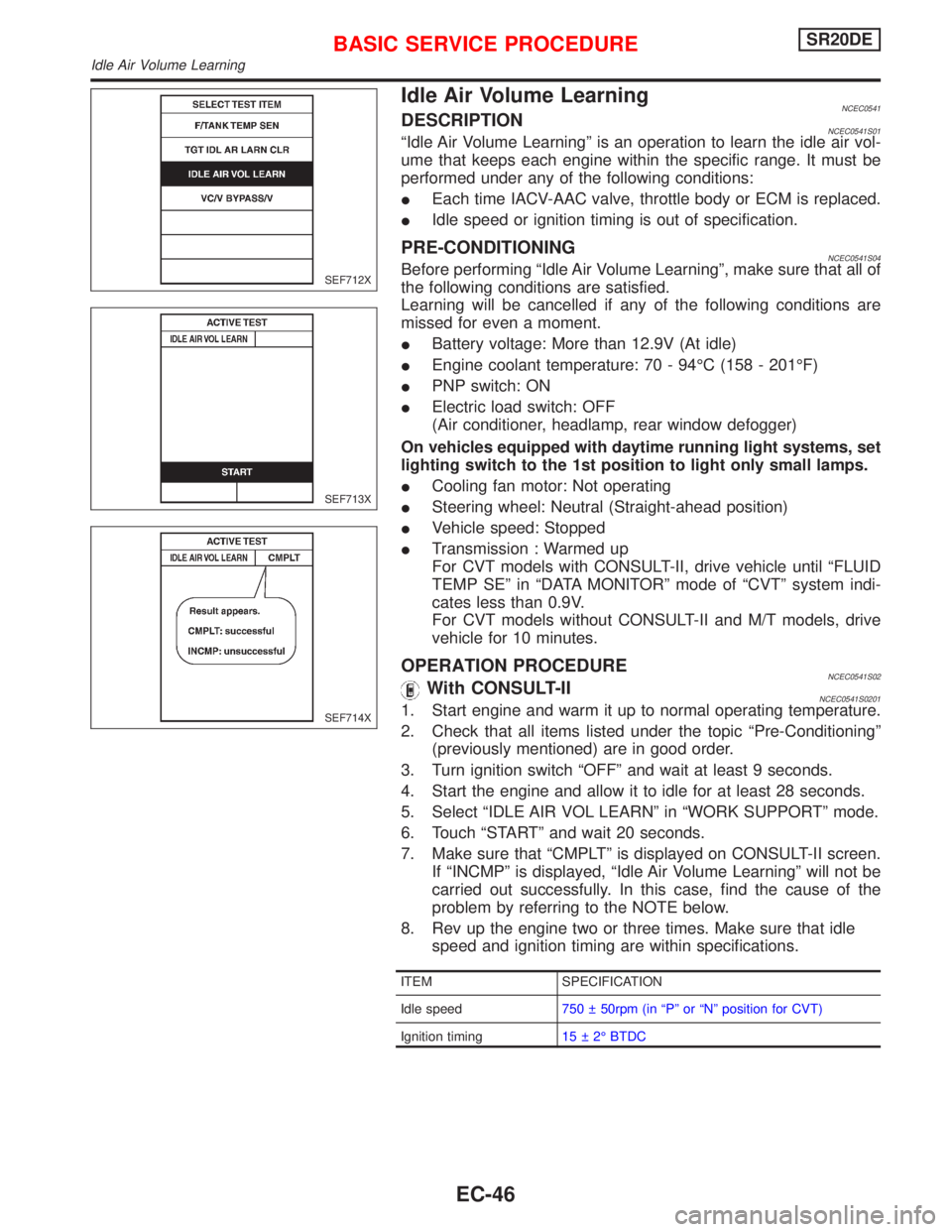

OPERATION PROCEDURENCEC0541S02With CONSULT-IINCEC0541S02011. Start engine and warm it up to normal operating temperature.

2. Check that all items listed under the topic ªPre-Conditioningº

(previously mentioned) are in good order.

3. Turn ignition switch ªOFFº and wait at least 9 seconds.

4. Start the engine and allow it to idle for at least 28 seconds.

5. Select ªIDLE AIR VOL LEARNº in ªWORK SUPPORTº mode.

6. Touch ªSTARTº and wait 20 seconds.

7. Make sure that ªCMPLTº is displayed on CONSULT-II screen.

If ªINCMPº is displayed, ªIdle Air Volume Learningº will not be

carried out successfully. In this case, find the cause of the

problem by referring to the NOTE below.

8. Rev up the engine two or three times. Make sure that idle

speed and ignition timing are within specifications.

ITEM SPECIFICATION

Idle speed750 50rpm (in ªPº or ªNº position for CVT)

Ignition timing15 2É BTDC

SEF712X

SEF713X

SEF714X

BASIC SERVICE PROCEDURESR20DE

Idle Air Volume Learning

EC-46

Page 847 of 2267

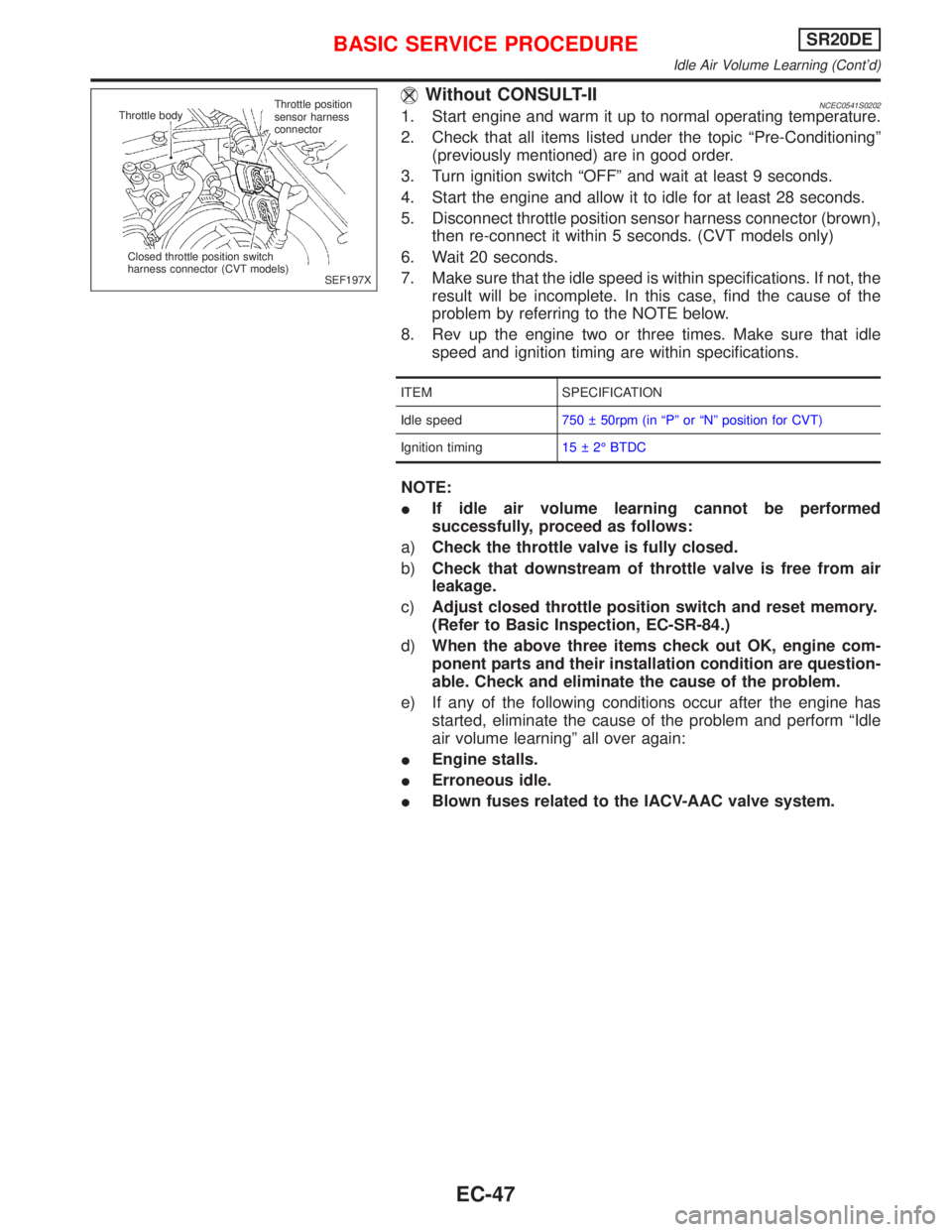

Without CONSULT-IINCEC0541S02021. Start engine and warm it up to normal operating temperature.

2. Check that all items listed under the topic ªPre-Conditioningº

(previously mentioned) are in good order.

3. Turn ignition switch ªOFFº and wait at least 9 seconds.

4. Start the engine and allow it to idle for at least 28 seconds.

5. Disconnect throttle position sensor harness connector (brown),

then re-connect it within 5 seconds. (CVT models only)

6. Wait 20 seconds.

7. Make sure that the idle speed is within specifications. If not, the

result will be incomplete. In this case, find the cause of the

problem by referring to the NOTE below.

8. Rev up the engine two or three times. Make sure that idle

speed and ignition timing are within specifications.

ITEM SPECIFICATION

Idle speed750 50rpm (in ªPº or ªNº position for CVT)

Ignition timing15 2É BTDC

NOTE:

IIf idle air volume learning cannot be performed

successfully, proceed as follows:

a)Check the throttle valve is fully closed.

b)Check that downstream of throttle valve is free from air

leakage.

c)Adjust closed throttle position switch and reset memory.

(Refer to Basic Inspection, EC-SR-84.)

d)When the above three items check out OK, engine com-

ponent parts and their installation condition are question-

able. Check and eliminate the cause of the problem.

e) If any of the following conditions occur after the engine has

started, eliminate the cause of the problem and perform ªIdle

air volume learningº all over again:

IEngine stalls.

IErroneous idle.

IBlown fuses related to the IACV-AAC valve system.

SEF197X

Throttle bodyThrottle position

sensor harness

connector

Closed throttle position switch

harness connector (CVT models)

BASIC SERVICE PROCEDURESR20DE

Idle Air Volume Learning (Cont'd)

EC-47

Page 848 of 2267

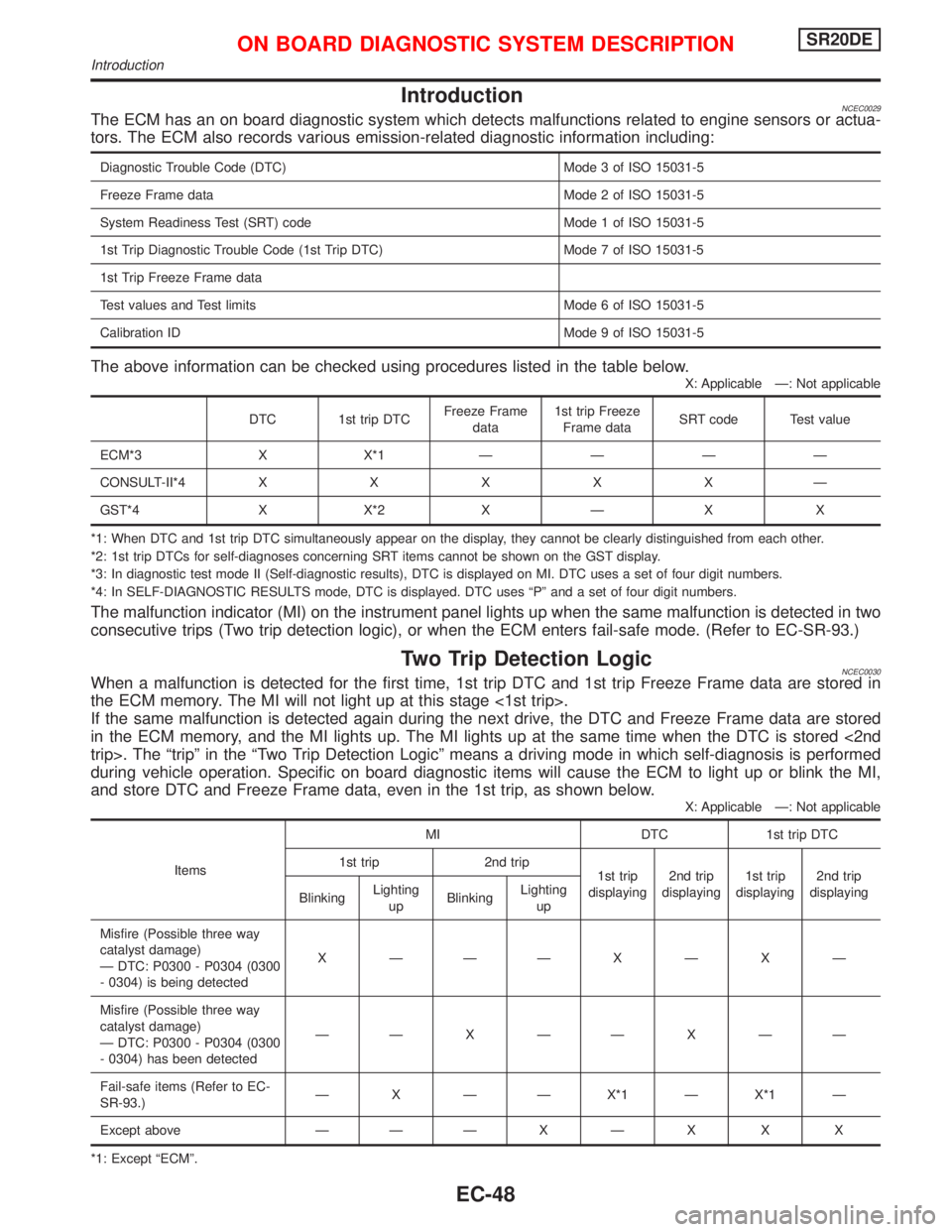

IntroductionNCEC0029The ECM has an on board diagnostic system which detects malfunctions related to engine sensors or actua-

tors. The ECM also records various emission-related diagnostic information including:

Diagnostic Trouble Code (DTC) Mode 3 of ISO 15031-5

Freeze Frame data Mode 2 of ISO 15031-5

System Readiness Test (SRT) code Mode 1 of ISO 15031-5

1st Trip Diagnostic Trouble Code (1st Trip DTC) Mode 7 of ISO 15031-5

1st Trip Freeze Frame data

Test values and Test limits Mode 6 of ISO 15031-5

Calibration ID Mode 9 of ISO 15031-5

The above information can be checked using procedures listed in the table below.

X: Applicable Ð: Not applicable

DTC 1st trip DTCFreeze Frame

data1st trip Freeze

Frame dataSRT code Test value

ECM*3 X X*1ÐÐÐÐ

CONSULT-II*4XXXXXÐ

GST*4 X X*2 X Ð X X

*1: When DTC and 1st trip DTC simultaneously appear on the display, they cannot be clearly distinguished from each other.

*2: 1st trip DTCs for self-diagnoses concerning SRT items cannot be shown on the GST display.

*3: In diagnostic test mode II (Self-diagnostic results), DTC is displayed on MI. DTC uses a set of four digit numbers.

*4: In SELF-DIAGNOSTIC RESULTS mode, DTC is displayed. DTC uses ªPº and a set of four digit numbers.

The malfunction indicator (MI) on the instrument panel lights up when the same malfunction is detected in two

consecutive trips (Two trip detection logic), or when the ECM enters fail-safe mode. (Refer to EC-SR-93.)

Two Trip Detection LogicNCEC0030When a malfunction is detected for the first time, 1st trip DTC and 1st trip Freeze Frame data are stored in

the ECM memory. The MI will not light up at this stage <1st trip>.

If the same malfunction is detected again during the next drive, the DTC and Freeze Frame data are stored

in the ECM memory, and the MI lights up. The MI lights up at the same time when the DTC is stored <2nd

trip>. The ªtripº in the ªTwo Trip Detection Logicº means a driving mode in which self-diagnosis is performed

during vehicle operation. Specific on board diagnostic items will cause the ECM to light up or blink the MI,

and store DTC and Freeze Frame data, even in the 1st trip, as shown below.

X: Applicable Ð: Not applicable

ItemsMI DTC 1st trip DTC

1st trip 2nd trip

1st trip

displaying2nd trip

displaying1st trip

displaying2nd trip

displaying

BlinkingLighting

upBlinkingLighting

up

Misfire (Possible three way

catalyst damage)

Ð DTC: P0300 - P0304 (0300

- 0304) is being detectedXÐÐÐXÐXÐ

Misfire (Possible three way

catalyst damage)

Ð DTC: P0300 - P0304 (0300

- 0304) has been detectedÐÐXÐÐXÐÐ

Fail-safe items (Refer to EC-

SR-93.)Ð X Ð Ð X*1 Ð X*1 Ð

Except above Ð ÐÐXÐX X X

*1: Except ªECMº.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONSR20DE

Introduction

EC-48

Page 853 of 2267

IThe time required for each diagnosis varies with road surface conditions, weather, altitude, individual driv-

ing habits, etc.

Zone A refers to the range where the time required, for the diagnosis under normal conditions*, is the

shortest. Zone B refers to the range where the diagnosis can still be performed if the diagnosis is not

completed within zone A.

*: Normal conditions refer to the following:

þ Sea level

þ Flat road

þ Ambient air temperature: 20 - 30ÉC (68 - 86ÉF)

þ Diagnosis is performed as quickly as possible under normal conditions.

Under different conditions [For example: ambient air temperature other than 20 - 30ÉC (68 - 86ÉF)], diagnosis may

also be performed.

Pattern 1:

IThe engine is started at the engine coolant temperature of þ10 to 35ÉC (14 to 95ÉF) (where the volt-

age between the ECM terminals 70 and 58 is 3.0 - 4.3V).

IThe engine must be operated at idle speed until the engine coolant temperature is greater than 70ÉC

(158ÉF) (where the voltage between the ECM terminals 70 and 58 is lower than 1.4V).

Pattern 2:

IWhen steady-state driving is performed again even after it is interrupted, each diagnosis can be conducted.

In this case, the time required for diagnosis may be extended.

*1: Depress the accelerator pedal until vehicle speed is 90 km/h (56 MPH), then release the accelerator pedal

and keep it released for more than 10 seconds. Depress the accelerator pedal until vehicle speed is 90 km/h

(56 MPH) again.

*2: Checking the vehicle speed with CONSULT-II or GST is advised.

Suggested transmission gear position for CVT models

Set the selector lever in the ªDº position with ªSPORTS MODE SWº ªOFFº or without ªMANUAL MODEº.

Suggested upshift speeds for M/T models

Shown below are suggested vehicle speeds for shifting into a higher gear. These suggestions relate to fuel

economy and vehicle performance. Actual upshift speeds will vary according to road conditions, the weather

and individual driving habits.

Gear changeACCEL shift point

km/h (MPH)

1st to 2nd 15 (9)

2nd to 3rd 35 (22)

3rd to 4th 50 (31)

4th to 5th 70 (43)

TEST VALUE AND TEST LIMIT (GST ONLY Ð NOT APPLICABLE TO CONSULT-II)NCEC0031S04The following is the information specified in Mode 6 of ISO 15031-5.

The test value is a parameter used to determine whether a system/circuit diagnostic test is ªOKº or ªNGº while

being monitored by the ECM during self-diagnosis. The test limit is a reference value which is specified as the

maximum or minimum value and is compared with the test value being monitored.

Items for which these data (test value and test limit) are displayed are the same as SRT code items (6 test

items).

These data (test value and test limit) are specified by Test ID (TID) and Component ID (CID) and can be dis-

played on the GST screen.

X: Applicable Ð: Not applicable

SRT item Self-diagnostic test itemTest value (GST display)

Test limit Application

TID CID

CATALYST Three way catalyst function01H 01H Max. X

02H 81H Min. X

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONSR20DE

Emission-related Diagnostic Information (Cont'd)

EC-53

Page 859 of 2267

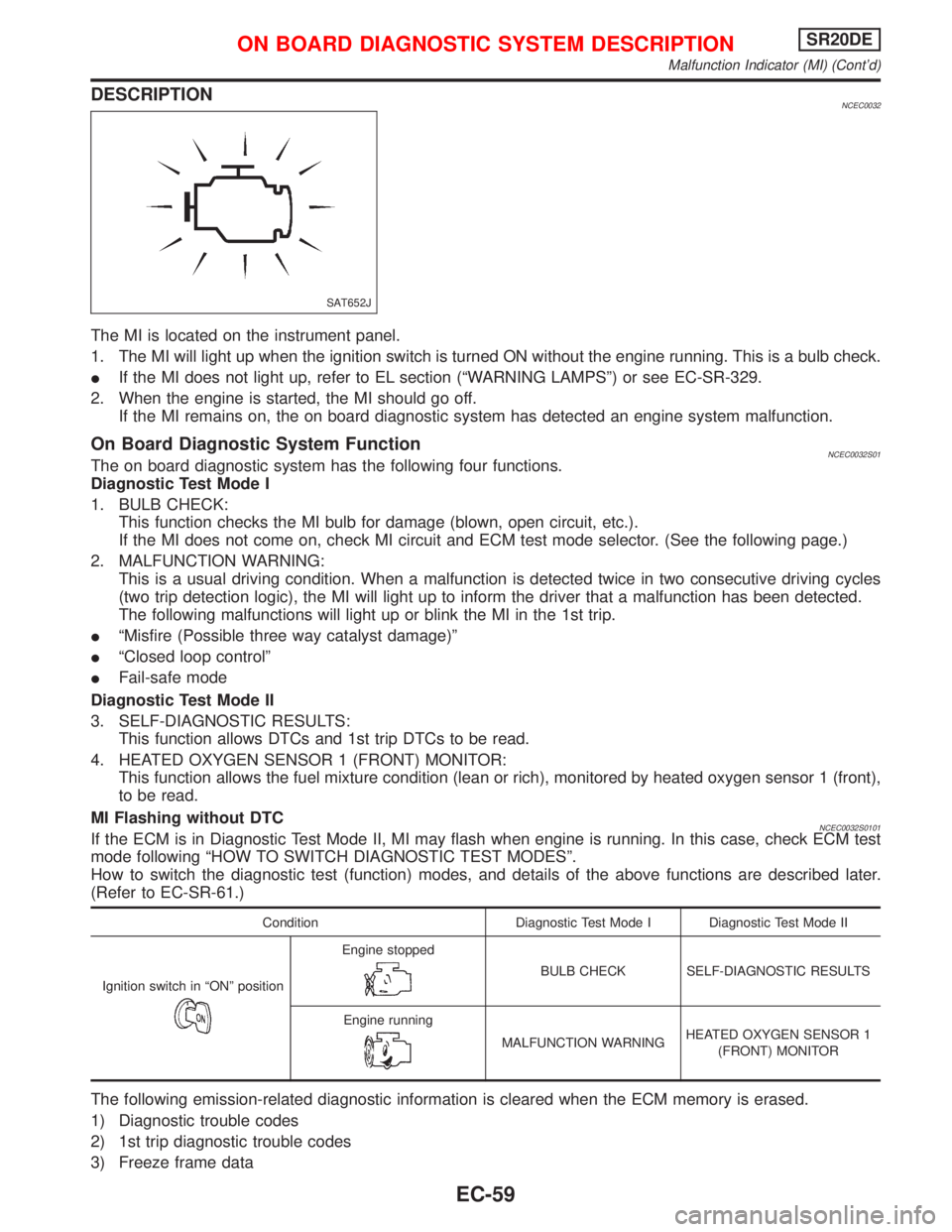

DESCRIPTIONNCEC0032

The MI is located on the instrument panel.

1. The MI will light up when the ignition switch is turned ON without the engine running. This is a bulb check.

IIf the MI does not light up, refer to EL section (ªWARNING LAMPSº) or see EC-SR-329.

2. When the engine is started, the MI should go off.

If the MI remains on, the on board diagnostic system has detected an engine system malfunction.

On Board Diagnostic System FunctionNCEC0032S01The on board diagnostic system has the following four functions.

Diagnostic Test Mode I

1. BULB CHECK:

This function checks the MI bulb for damage (blown, open circuit, etc.).

If the MI does not come on, check MI circuit and ECM test mode selector. (See the following page.)

2. MALFUNCTION WARNING:

This is a usual driving condition. When a malfunction is detected twice in two consecutive driving cycles

(two trip detection logic), the MI will light up to inform the driver that a malfunction has been detected.

The following malfunctions will light up or blink the MI in the 1st trip.

IªMisfire (Possible three way catalyst damage)º

IªClosed loop controlº

IFail-safe mode

Diagnostic Test Mode II

3. SELF-DIAGNOSTIC RESULTS:

This function allows DTCs and 1st trip DTCs to be read.

4. HEATED OXYGEN SENSOR 1 (FRONT) MONITOR:

This function allows the fuel mixture condition (lean or rich), monitored by heated oxygen sensor 1 (front),

to be read.

MI Flashing without DTC

NCEC0032S0101If the ECM is in Diagnostic Test Mode II, MI may flash when engine is running. In this case, check ECM test

mode following ªHOW TO SWITCH DIAGNOSTIC TEST MODESº.

How to switch the diagnostic test (function) modes, and details of the above functions are described later.

(Refer to EC-SR-61.)

Condition Diagnostic Test Mode I Diagnostic Test Mode II

Ignition switch in ªONº position

Engine stopped

BULB CHECK SELF-DIAGNOSTIC RESULTS

Engine running

MALFUNCTION WARNINGHEATED OXYGEN SENSOR 1

(FRONT) MONITOR

The following emission-related diagnostic information is cleared when the ECM memory is erased.

1) Diagnostic trouble codes

2) 1st trip diagnostic trouble codes

3) Freeze frame data

SAT652J

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONSR20DE

Malfunction Indicator (MI) (Cont'd)

EC-59

Page 861 of 2267

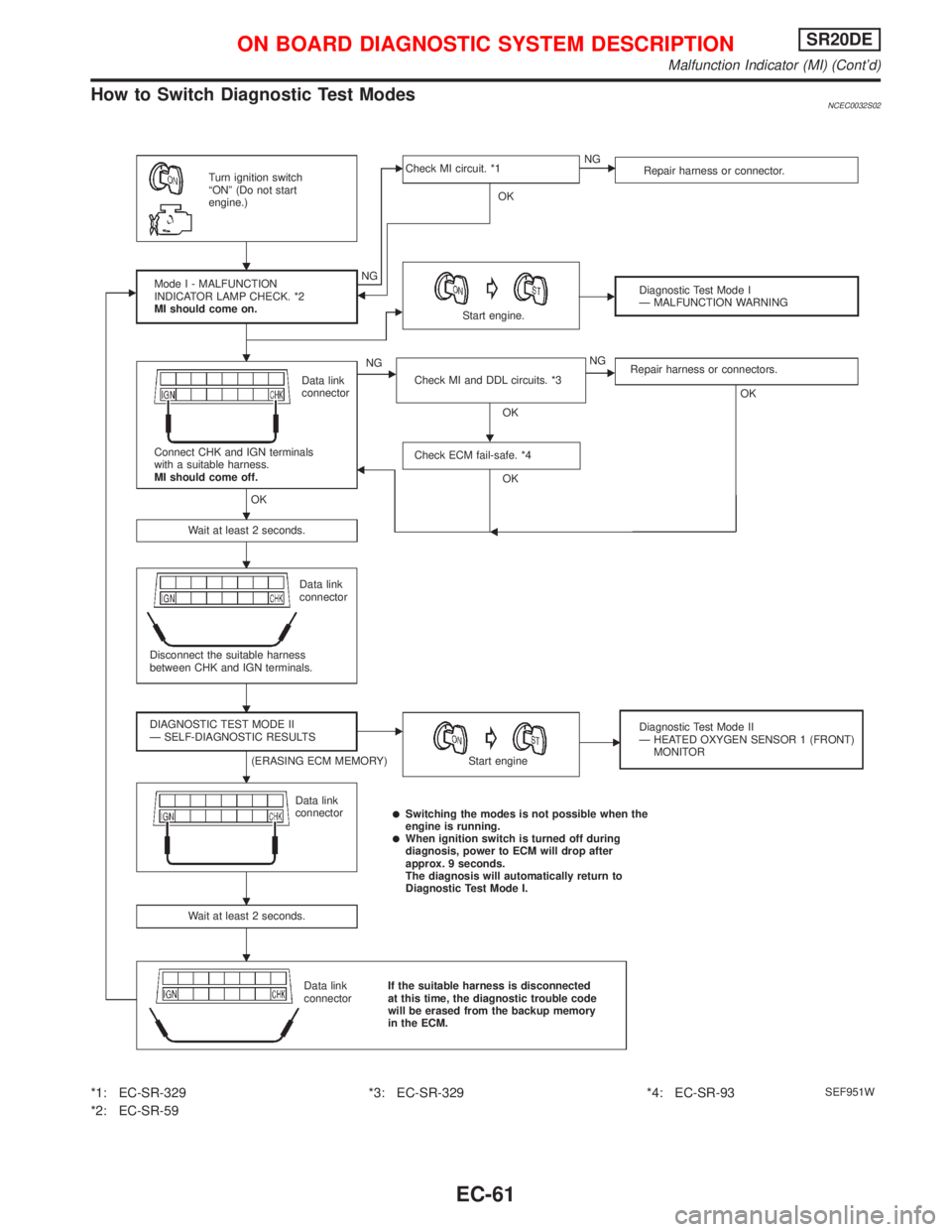

How to Switch Diagnostic Test ModesNCEC0032S02

*1: EC-SR-329

*2: EC-SR-59*3: EC-SR-329 *4: EC-SR-93SEF951W Turn ignition switch

ªONº (Do not start

engine.)

Mode I - MALFUNCTION

INDICATOR LAMP CHECK. *2

MI should come on.Check MI circuit. *1

Repair harness or connector.

Start engine.Diagnostic Test Mode I

Ð MALFUNCTION WARNING

Data link

connector

Connect CHK and IGN terminals

with a suitable harness.

MI should come off.Check MI and DDL circuits. *3

Check ECM fail-safe. *4Repair harness or connectors.

Wait at least 2 seconds.

Data link

connector

Disconnect the suitable harness

between CHK and IGN terminals.

DIAGNOSTIC TEST MODE II

Ð SELF-DIAGNOSTIC RESULTS

(ERASING ECM MEMORY) Start engineDiagnostic Test Mode II

Ð HEATED OXYGEN SENSOR 1 (FRONT)

MONITOR

Data link

connector

Wait at least 2 seconds.

lSwitching the modes is not possible when the

engine is running.

lWhen ignition switch is turned off during

diagnosis, power to ECM will drop after

approx. 9 seconds.

The diagnosis will automatically return to

Diagnostic Test Mode I.

Data link

connectorIf the suitable harness is disconnected

at this time, the diagnostic trouble code

will be erased from the backup memory

in the ECM. NG

NGNG

OK

NG

OK

OK

OK

OK

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONSR20DE

Malfunction Indicator (MI) (Cont'd)

EC-61

Page 863 of 2267

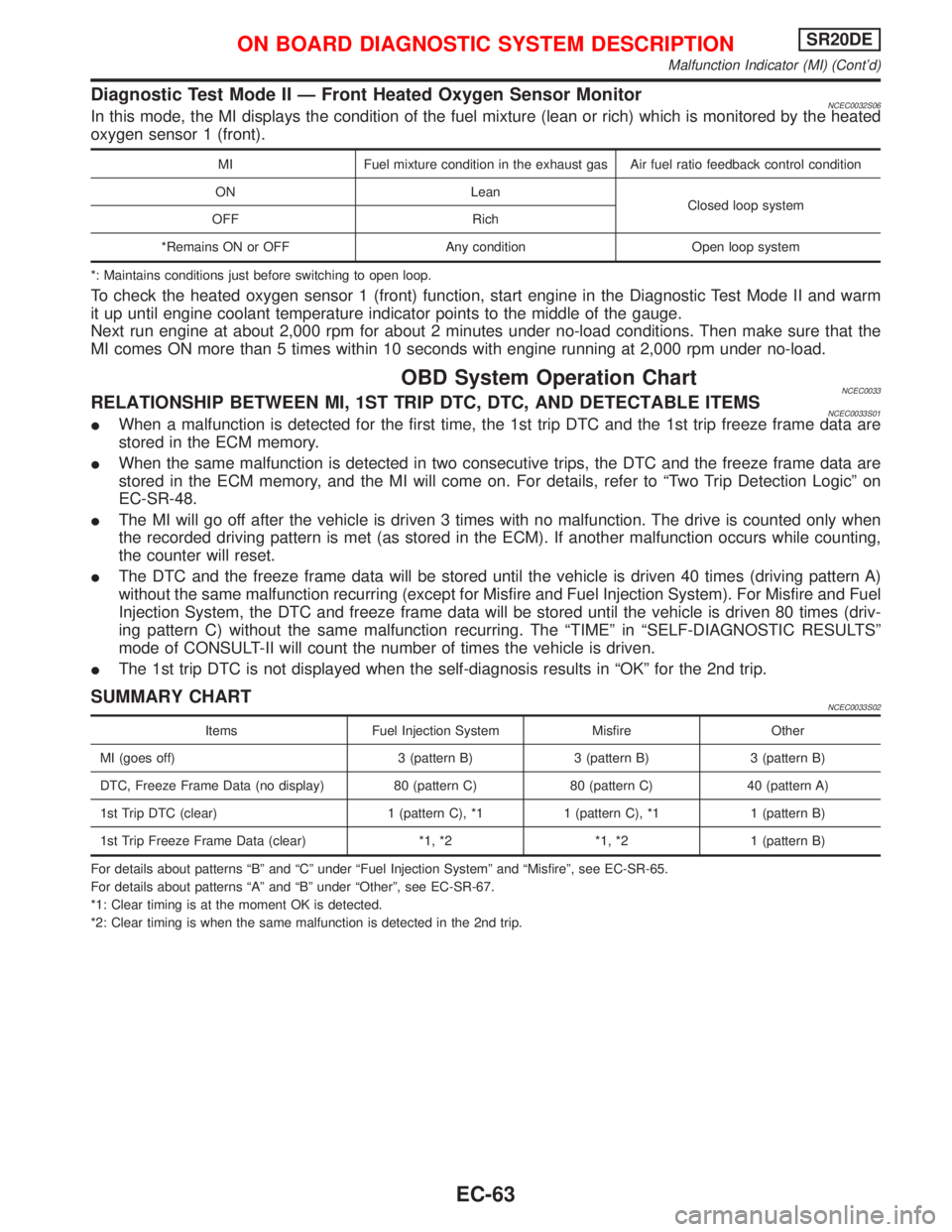

Diagnostic Test Mode II Ð Front Heated Oxygen Sensor MonitorNCEC0032S06In this mode, the MI displays the condition of the fuel mixture (lean or rich) which is monitored by the heated

oxygen sensor 1 (front).

MI Fuel mixture condition in the exhaust gas Air fuel ratio feedback control condition

ON Lean

Closed loop system

OFF Rich

*Remains ON or OFF Any condition Open loop system

*: Maintains conditions just before switching to open loop.

To check the heated oxygen sensor 1 (front) function, start engine in the Diagnostic Test Mode II and warm

it up until engine coolant temperature indicator points to the middle of the gauge.

Next run engine at about 2,000 rpm for about 2 minutes under no-load conditions. Then make sure that the

MI comes ON more than 5 times within 10 seconds with engine running at 2,000 rpm under no-load.

OBD System Operation ChartNCEC0033RELATIONSHIP BETWEEN MI, 1ST TRIP DTC, DTC, AND DETECTABLE ITEMSNCEC0033S01IWhen a malfunction is detected for the first time, the 1st trip DTC and the 1st trip freeze frame data are

stored in the ECM memory.

IWhen the same malfunction is detected in two consecutive trips, the DTC and the freeze frame data are

stored in the ECM memory, and the MI will come on. For details, refer to ªTwo Trip Detection Logicº on

EC-SR-48.

IThe MI will go off after the vehicle is driven 3 times with no malfunction. The drive is counted only when

the recorded driving pattern is met (as stored in the ECM). If another malfunction occurs while counting,

the counter will reset.

IThe DTC and the freeze frame data will be stored until the vehicle is driven 40 times (driving pattern A)

without the same malfunction recurring (except for Misfire and Fuel Injection System). For Misfire and Fuel

Injection System, the DTC and freeze frame data will be stored until the vehicle is driven 80 times (driv-

ing pattern C) without the same malfunction recurring. The ªTIMEº in ªSELF-DIAGNOSTIC RESULTSº

mode of CONSULT-II will count the number of times the vehicle is driven.

IThe 1st trip DTC is not displayed when the self-diagnosis results in ªOKº for the 2nd trip.

SUMMARY CHARTNCEC0033S02

Items Fuel Injection System Misfire Other

MI (goes off) 3 (pattern B) 3 (pattern B) 3 (pattern B)

DTC, Freeze Frame Data (no display) 80 (pattern C) 80 (pattern C) 40 (pattern A)

1st Trip DTC (clear) 1 (pattern C), *1 1 (pattern C), *1 1 (pattern B)

1st Trip Freeze Frame Data (clear) *1, *2 *1, *2 1 (pattern B)

For details about patterns ªBº and ªCº under ªFuel Injection Systemº and ªMisfireº, see EC-SR-65.

For details about patterns ªAº and ªBº under ªOtherº, see EC-SR-67.

*1: Clear timing is at the moment OK is detected.

*2: Clear timing is when the same malfunction is detected in the 2nd trip.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONSR20DE

Malfunction Indicator (MI) (Cont'd)

EC-63

Page 875 of 2267

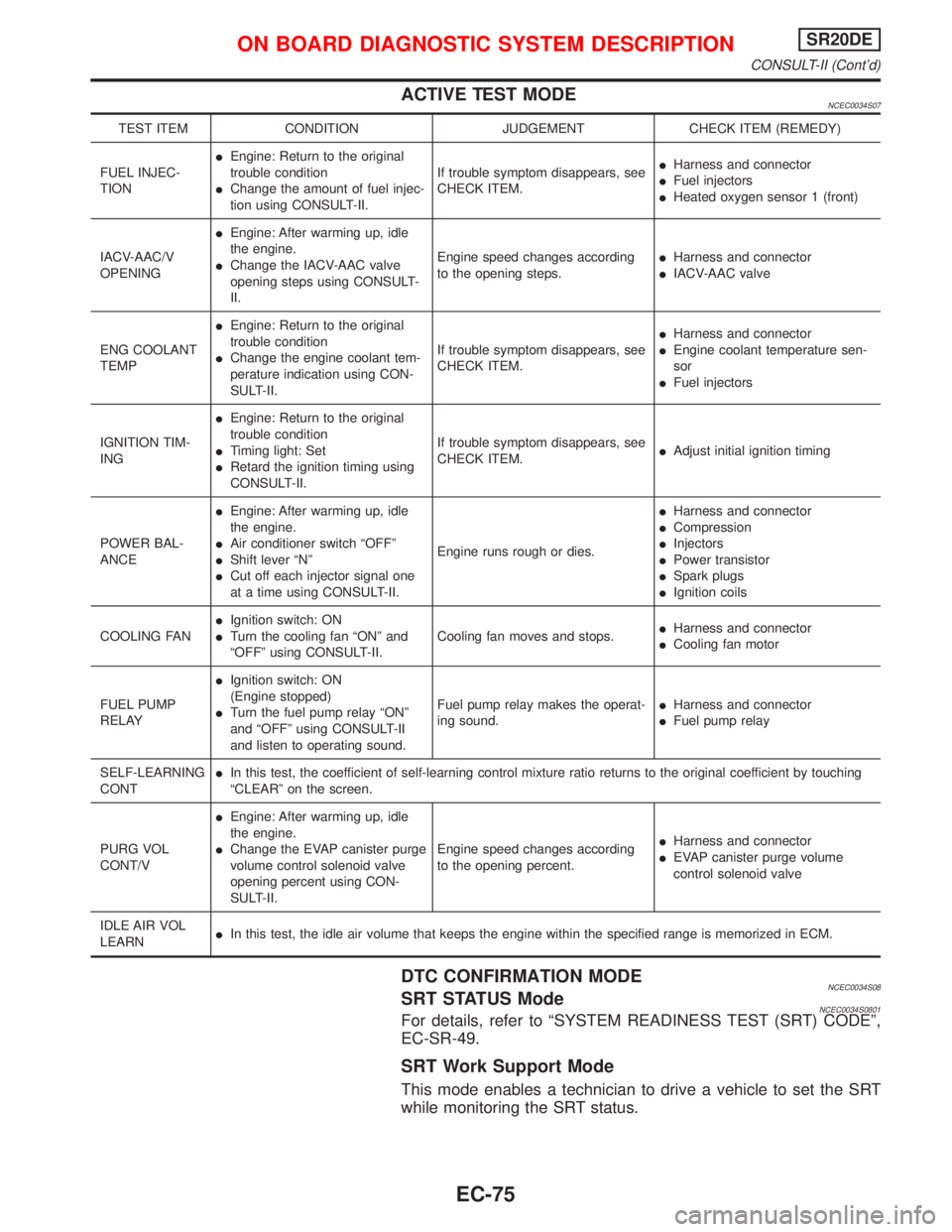

ACTIVE TEST MODENCEC0034S07

TEST ITEM CONDITION JUDGEMENT CHECK ITEM (REMEDY)

FUEL INJEC-

TIONIEngine: Return to the original

trouble condition

IChange the amount of fuel injec-

tion using CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.IHarness and connector

IFuel injectors

IHeated oxygen sensor 1 (front)

IACV-AAC/V

OPENINGIEngine: After warming up, idle

the engine.

IChange the IACV-AAC valve

opening steps using CONSULT-

II.Engine speed changes according

to the opening steps.IHarness and connector

IIACV-AAC valve

ENG COOLANT

TEMPIEngine: Return to the original

trouble condition

IChange the engine coolant tem-

perature indication using CON-

SULT-II.If trouble symptom disappears, see

CHECK ITEM.IHarness and connector

IEngine coolant temperature sen-

sor

IFuel injectors

IGNITION TIM-

INGIEngine: Return to the original

trouble condition

ITiming light: Set

IRetard the ignition timing using

CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.IAdjust initial ignition timing

POWER BAL-

ANCEIEngine: After warming up, idle

the engine.

IAir conditioner switch ªOFFº

IShift lever ªNº

ICut off each injector signal one

at a time using CONSULT-II.Engine runs rough or dies.IHarness and connector

ICompression

IInjectors

IPower transistor

ISpark plugs

IIgnition coils

COOLING FANIIgnition switch: ON

ITurn the cooling fan ªONº and

ªOFFº using CONSULT-II.Cooling fan moves and stops.IHarness and connector

ICooling fan motor

FUEL PUMP

RELAYIIgnition switch: ON

(Engine stopped)

ITurn the fuel pump relay ªONº

and ªOFFº using CONSULT-II

and listen to operating sound.Fuel pump relay makes the operat-

ing sound.IHarness and connector

IFuel pump relay

SELF-LEARNING

CONTIIn this test, the coefficient of self-learning control mixture ratio returns to the original coefficient by touching

ªCLEARº on the screen.

PURG VOL

CONT/VIEngine: After warming up, idle

the engine.

IChange the EVAP canister purge

volume control solenoid valve

opening percent using CON-

SULT-II.Engine speed changes according

to the opening percent.IHarness and connector

IEVAP canister purge volume

control solenoid valve

IDLE AIR VOL

LEARNIIn this test, the idle air volume that keeps the engine within the specified range is memorized in ECM.

DTC CONFIRMATION MODENCEC0034S08SRT STATUS ModeNCEC0034S0801For details, refer to ªSYSTEM READINESS TEST (SRT) CODEº,

EC-SR-49.

SRT Work Support Mode

This mode enables a technician to drive a vehicle to set the SRT

while monitoring the SRT status.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONSR20DE

CONSULT-II (Cont'd)

EC-75