check engine NISSAN PRIMERA 1999 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 787 of 2267

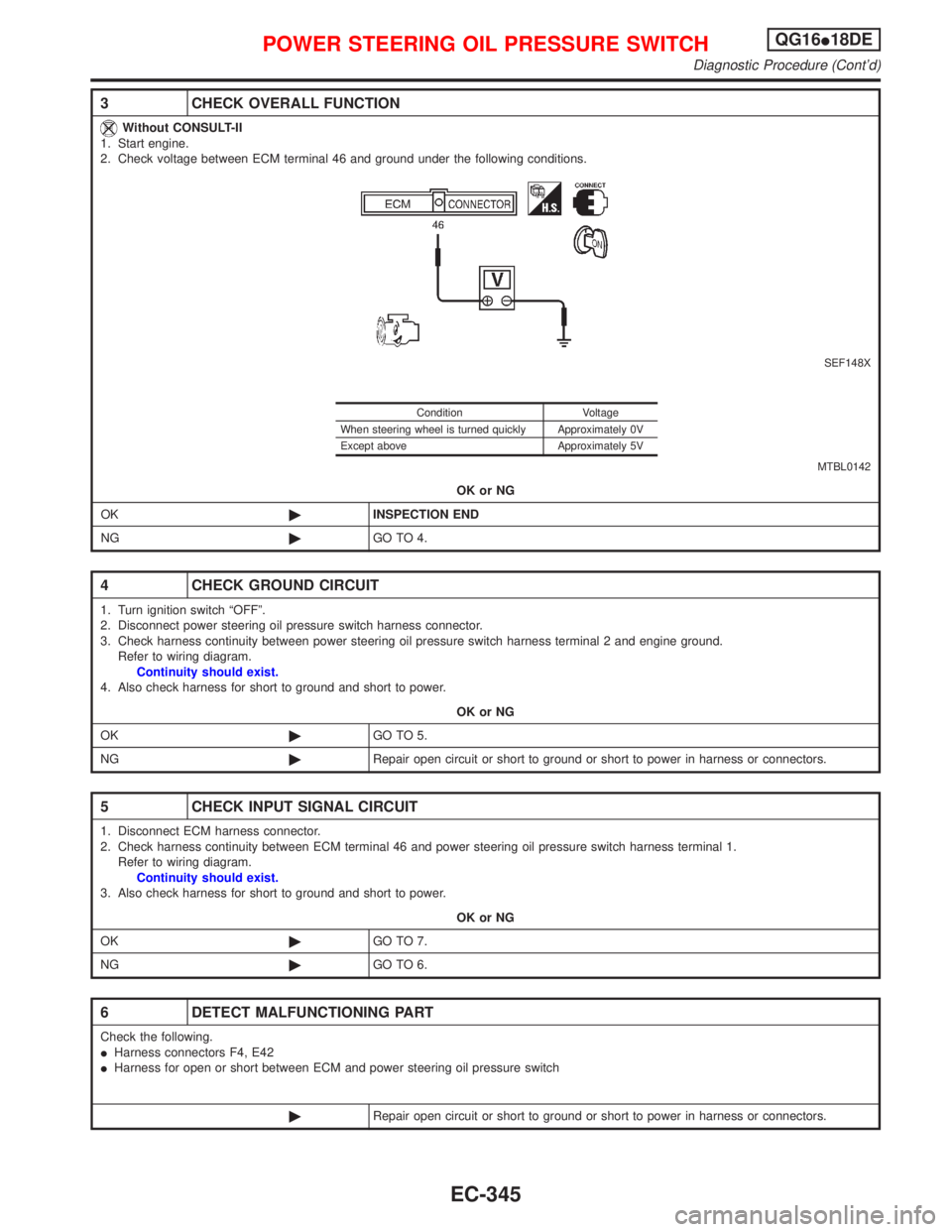

3 CHECK OVERALL FUNCTION

Without CONSULT-II

1. Start engine.

2. Check voltage between ECM terminal 46 and ground under the following conditions.

SEF148X

MTBL0142

OK or NG

OK©INSPECTION END

NG©GO TO 4.

4 CHECK GROUND CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect power steering oil pressure switch harness connector.

3. Check harness continuity between power steering oil pressure switch harness terminal 2 and engine ground.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

5 CHECK INPUT SIGNAL CIRCUIT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 46 and power steering oil pressure switch harness terminal 1.

Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 7.

NG©GO TO 6.

6 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors F4, E42

IHarness for open or short between ECM and power steering oil pressure switch

©Repair open circuit or short to ground or short to power in harness or connectors.

Condition Voltage

When steering wheel is turned quickly Approximately 0V

Except above Approximately 5V

POWER STEERING OIL PRESSURE SWITCHQG16I18DE

Diagnostic Procedure (Cont'd)

EC-345

Page 788 of 2267

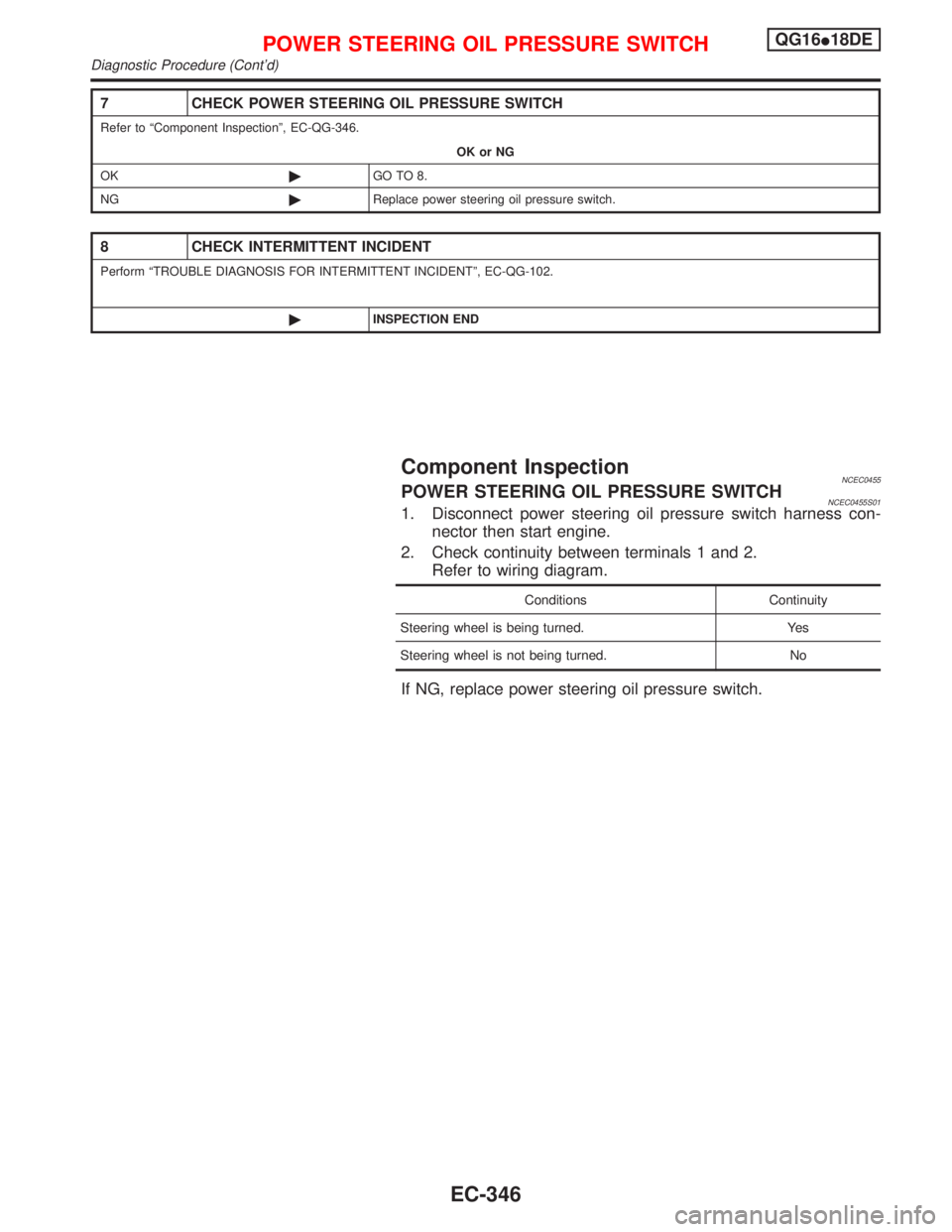

7 CHECK POWER STEERING OIL PRESSURE SWITCH

Refer to ªComponent Inspectionº, EC-QG-346.

OK or NG

OK©GO TO 8.

NG©Replace power steering oil pressure switch.

8 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-QG-102.

©INSPECTION END

Component InspectionNCEC0455POWER STEERING OIL PRESSURE SWITCHNCEC0455S011. Disconnect power steering oil pressure switch harness con-

nector then start engine.

2. Check continuity between terminals 1 and 2.

Refer to wiring diagram.

Conditions Continuity

Steering wheel is being turned. Yes

Steering wheel is not being turned. No

If NG, replace power steering oil pressure switch.

POWER STEERING OIL PRESSURE SWITCHQG16I18DE

Diagnostic Procedure (Cont'd)

EC-346

Page 791 of 2267

Diagnostic ProcedureNLEC0590

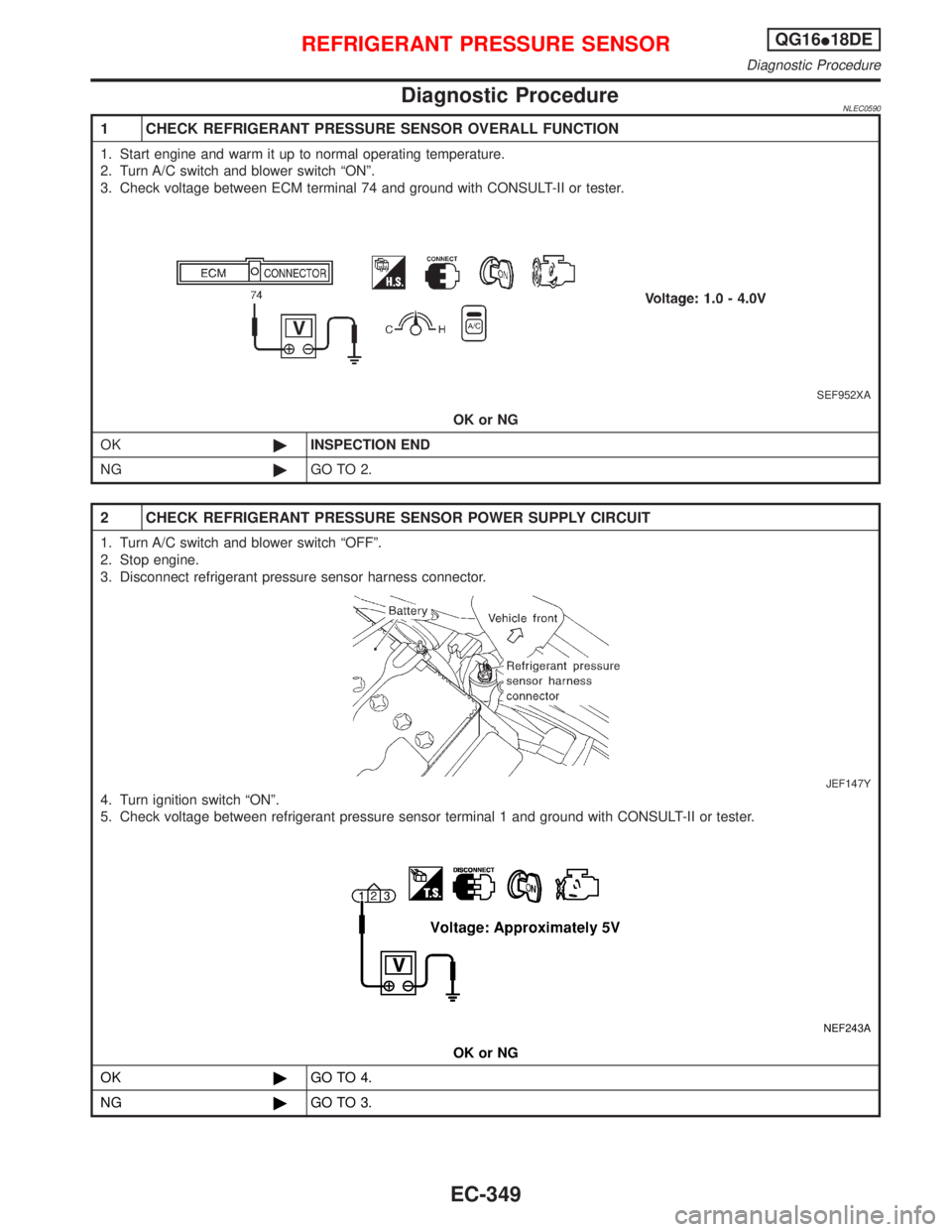

1 CHECK REFRIGERANT PRESSURE SENSOR OVERALL FUNCTION

1. Start engine and warm it up to normal operating temperature.

2. Turn A/C switch and blower switch ªONº.

3. Check voltage between ECM terminal 74 and ground with CONSULT-II or tester.

SEF952XA

OK or NG

OK©INSPECTION END

NG©GO TO 2.

2 CHECK REFRIGERANT PRESSURE SENSOR POWER SUPPLY CIRCUIT

1. Turn A/C switch and blower switch ªOFFº.

2. Stop engine.

3. Disconnect refrigerant pressure sensor harness connector.

JEF147Y

4. Turn ignition switch ªONº.

5. Check voltage between refrigerant pressure sensor terminal 1 and ground with CONSULT-II or tester.

NEF243A

OK or NG

OK©GO TO 4.

NG©GO TO 3.

REFRIGERANT PRESSURE SENSORQG16I18DE

Diagnostic Procedure

EC-349

Page 792 of 2267

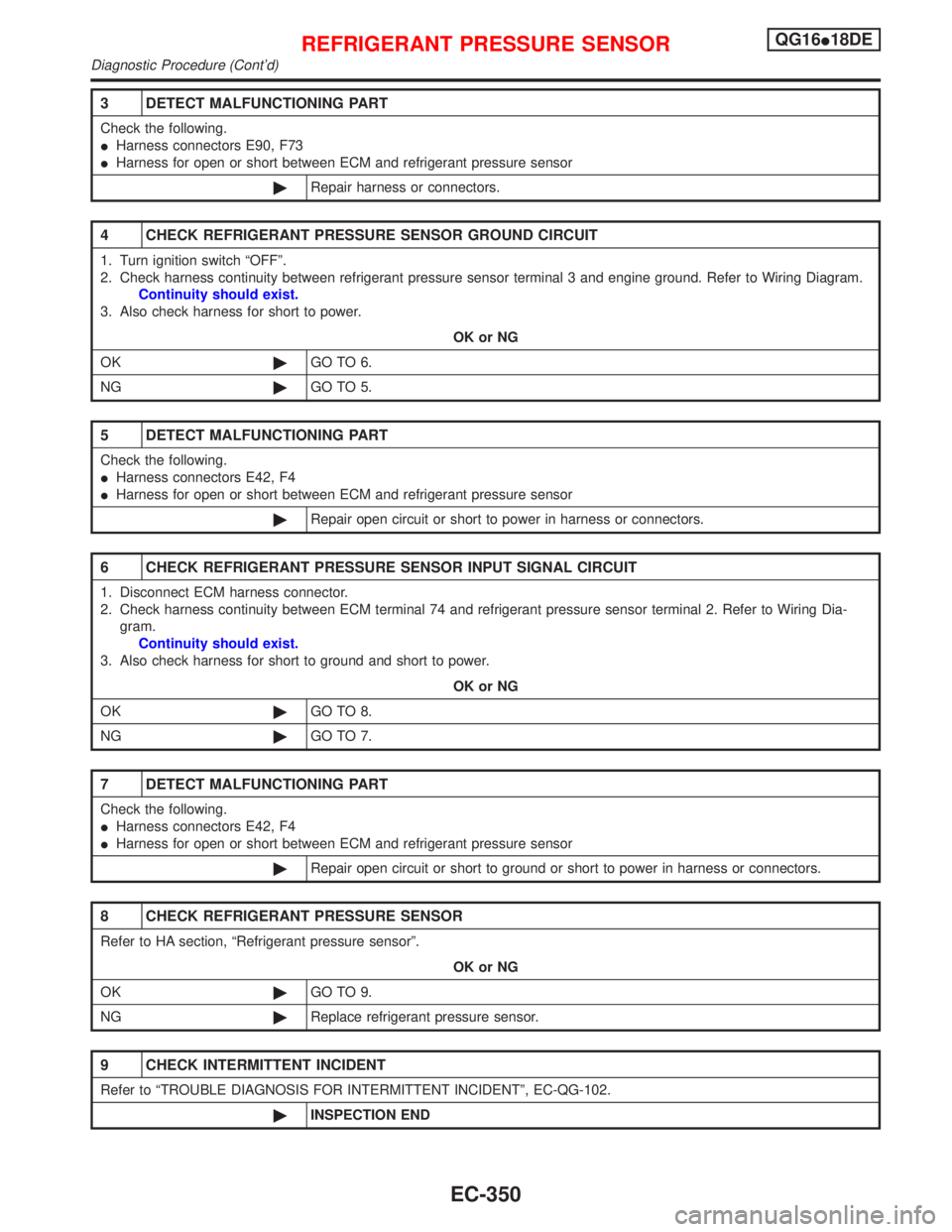

3 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E90, F73

IHarness for open or short between ECM and refrigerant pressure sensor

©Repair harness or connectors.

4 CHECK REFRIGERANT PRESSURE SENSOR GROUND CIRCUIT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between refrigerant pressure sensor terminal 3 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to power.

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E42, F4

IHarness for open or short between ECM and refrigerant pressure sensor

©Repair open circuit or short to power in harness or connectors.

6 CHECK REFRIGERANT PRESSURE SENSOR INPUT SIGNAL CIRCUIT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 74 and refrigerant pressure sensor terminal 2. Refer to Wiring Dia-

gram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 8.

NG©GO TO 7.

7 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E42, F4

IHarness for open or short between ECM and refrigerant pressure sensor

©Repair open circuit or short to ground or short to power in harness or connectors.

8 CHECK REFRIGERANT PRESSURE SENSOR

Refer to HA section, ªRefrigerant pressure sensorº.

OK or NG

OK©GO TO 9.

NG©Replace refrigerant pressure sensor.

9 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-QG-102.

©INSPECTION END

REFRIGERANT PRESSURE SENSORQG16I18DE

Diagnostic Procedure (Cont'd)

EC-350

Page 801 of 2267

ENGINE CONTROL SYSTEM

SECTION

EC

CONTENTS

SR20DE

TROUBLE DIAGNOSIS - INDEX....................................6

Alphabetical & P No. Index for DTC ...........................6

PRECAUTIONS.............................................................10

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER².............10

Precautions for On Board Diagnostic (OBD)

System of Engine and CVT .......................................10

Engine Fuel & Emission Control System .................. 11

Precautions ................................................................12

Wiring Diagrams and Trouble Diagnosis ...................13

PREPARATION.............................................................14

Special Service Tools ................................................14

Commercial Service Tool ...........................................14

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM.........................................................................15

Engine Control Component Parts Location ...............15

Circuit Diagram ..........................................................19

System Diagram ........................................................20

Vacuum Hose Drawing ..............................................21

System Chart .............................................................22

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTION...............................................23

Multiport Fuel Injection (MFI) System .......................23

Distributor Ignition (DI) System .................................25

Air Conditioning Cut Control ......................................26

Fuel Cut Control (at no load & high engine

speed) ........................................................................27

Evaporative Emission System ...................................27

Positive Crankcase Ventilation ..................................30

BASIC SERVICE PROCEDURE...................................31

Fuel Pressure Release ..............................................31

Fuel Pressure Check .................................................31

Fuel Pressure Regulator Check ................................32

Injector .......................................................................32

Idle Speed/Ignition Timing/Idle Mixture Ratio

Adjustment .................................................................34Idle Air Volume Learning ...........................................46

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION...............................................................48

Introduction ................................................................48

Two Trip Detection Logic ...........................................48

Emission-related Diagnostic Information ...................49

Malfunction Indicator (MI) ..........................................58

OBD System Operation Chart ...................................63

CONSULT-II ...............................................................68

Generic Scan Tool (GST) ..........................................78

TROUBLE DIAGNOSIS - INTRODUCTION..................80

Introduction ................................................................80

Work Flow ..................................................................82

TROUBLE DIAGNOSIS - BASIC INSPECTION...........84

Basic Inspection.........................................................84

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION...............................................................92

DTC Inspection Priority Chart....................................92

Fail-safe Chart ...........................................................93

Symptom Matrix Chart ...............................................94

CONSULT-II Reference Value in Data Monitor

Mode ..........................................................................98

Major Sensor Reference Graph in Data Monitor

Mode ........................................................................100

ECM Terminals and Reference Value .....................103

TROUBLE DIAGNOSIS - SPECIFICATION VALUE.. 110

Description ............................................................... 110

Testing Condition ..................................................... 110

Inspection Procedure ............................................... 110

Diagnostic Procedure .............................................. 111

TROUBLE DIAGNOSIS FOR INTERMITTENT

INCIDENT..................................................................... 114

Description ............................................................... 114

Diagnostic Procedure .............................................. 114

TROUBLE DIAGNOSIS FOR POWER SUPPLY........ 115

Main Power Supply and Ground Circuit .................. 115

EC

Page 802 of 2267

DTC P0100 MASS AIR FLOW SENSOR (MAFS)......120

Component Description ...........................................120

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................120

ECM Terminals and Reference Value .....................120

On Board Diagnosis Logic.......................................120

DTC Confirmation Procedure ..................................121

Wiring Diagram ........................................................122

Diagnostic Procedure ..............................................123

Component Inspection .............................................126

DTC P0110 INTAKE AIR TEMPERATURE

SENSOR......................................................................127

Component Description ...........................................127

On Board Diagnosis Logic.......................................127

DTC Confirmation Procedure ..................................127

Wiring Diagram ........................................................128

Diagnostic Procedure ..............................................129

Component Inspection .............................................131

DTC P0115 ENGINE COOLANT TEMPERATURE

SENSOR (ECTS) (CIRCUIT).......................................132

Component Description ...........................................132

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................132

On Board Diagnosis Logic.......................................132

DTC Confirmation Procedure ..................................133

Wiring Diagram ........................................................134

Diagnostic Procedure ..............................................135

Component Inspection .............................................136

DTC P0120 THROTTLE POSITION SENSOR...........137

Component Description ...........................................137

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................137

ECM Terminals and Reference Value .....................138

On Board Diagnosis Logic.......................................138

DTC Confirmation Procedure ..................................138

Wiring Diagram ........................................................140

Diagnostic Procedure ..............................................141

Component Inspection .............................................142

DTC P0130 HEATED OXYGEN SENSOR 1

(FRONT) (CIRCUIT).....................................................144

Component Description ...........................................144

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................144

ECM Terminals and Reference Value .....................144

On Board Diagnosis Logic.......................................145

DTC Confirmation Procedure ..................................145

Overall Function Check ...........................................146

Wiring Diagram ........................................................147

Diagnostic Procedure ..............................................148

Component Inspection .............................................149DTC P0131 HEATED OXYGEN SENSOR 1

(FRONT) (LEAN SHIFT MONITORING).....................150

Component Description ...........................................150

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................150

ECM Terminals and Reference Value .....................150

On Board Diagnosis Logic.......................................151

DTC Confirmation Procedure ..................................151

Overall Function Check ...........................................152

Diagnostic Procedure ..............................................153

Component Inspection .............................................154

DTC P0132 HEATED OXYGEN SENSOR 1

(FRONT) (RICH SHIFT MONITORING)......................156

Component Description ...........................................156

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................156

ECM Terminals and Reference Value .....................156

On Board Diagnosis Logic.......................................157

DTC Confirmation Procedure ..................................157

Overall Function Check ...........................................158

Diagnostic Procedure ..............................................159

Component Inspection .............................................160

DTC P0133 HEATED OXYGEN SENSOR 1

(FRONT) (RESPONSE MONITORING).......................162

Component Description ...........................................162

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................162

ECM Terminals and Reference Value .....................162

On Board Diagnosis Logic.......................................163

DTC Confirmation Procedure ..................................163

Overall Function Check ...........................................164

Wiring Diagram ........................................................165

Diagnostic Procedure ..............................................166

Component Inspection .............................................169

DTC P0134 HEATED OXYGEN SENSOR 1

(FRONT) (HIGH VOLTAGE)........................................170

Component Description ...........................................170

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................170

ECM Terminals and Reference Value .....................170

On Board Diagnosis Logic.......................................171

DTC Confirmation Procedure ..................................171

Wiring Diagram ........................................................172

Diagnostic Procedure ..............................................173

Component Inspection .............................................174

DTC P0135 HEATED OXYGEN SENSOR 1

(FRONT) HEATER.......................................................175

Description ...............................................................175

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................175

ECM Terminals and Reference Value .....................175

On Board Diagnosis Logic.......................................175

CONTENTS(Cont'd)

EC-2

Page 828 of 2267

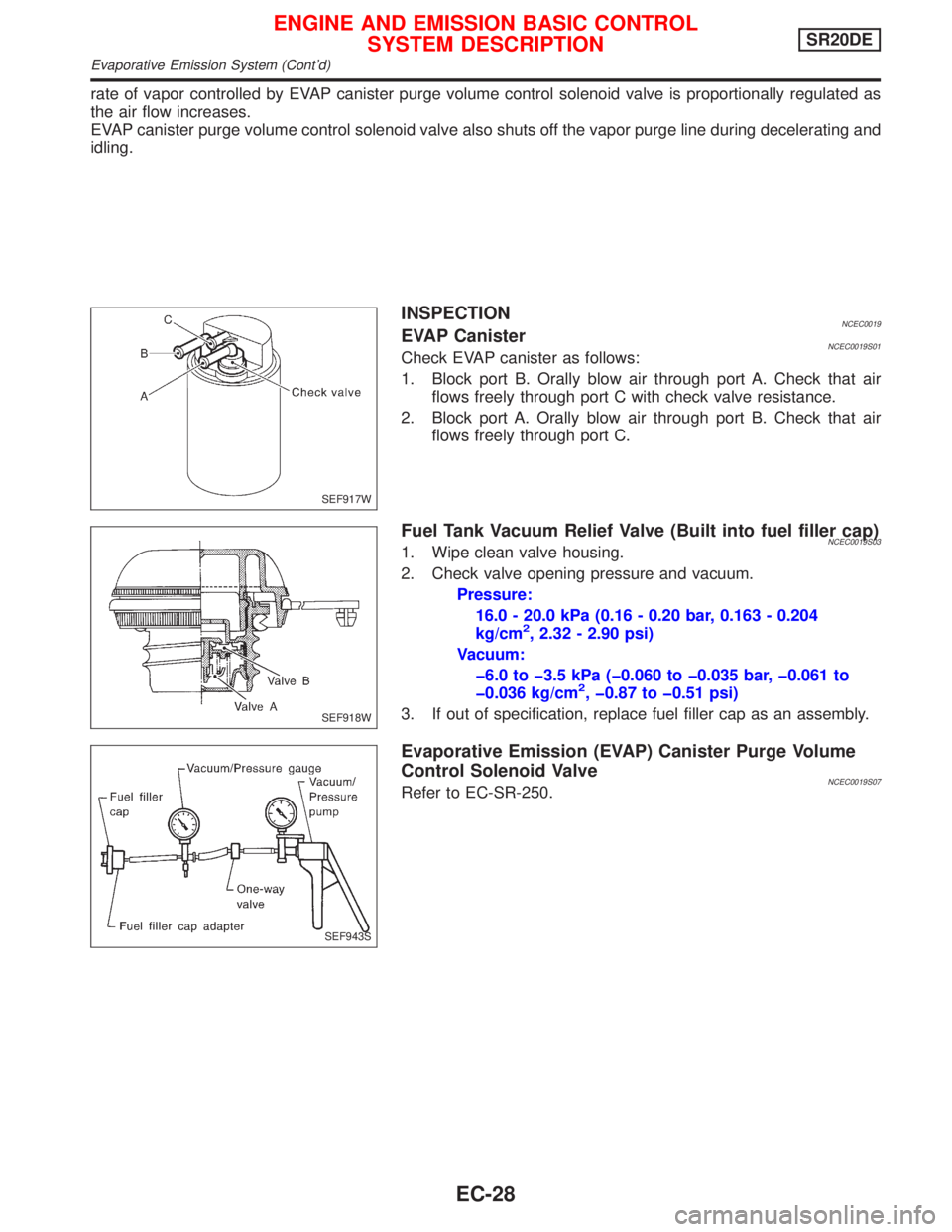

rate of vapor controlled by EVAP canister purge volume control solenoid valve is proportionally regulated as

the air flow increases.

EVAP canister purge volume control solenoid valve also shuts off the vapor purge line during decelerating and

idling.

INSPECTIONNCEC0019EVAP CanisterNCEC0019S01Check EVAP canister as follows:

1. Block port B. Orally blow air through port A. Check that air

flows freely through port C with check valve resistance.

2. Block port A. Orally blow air through port B. Check that air

flows freely through port C.

Fuel Tank Vacuum Relief Valve (Built into fuel filler cap)NCEC0019S031. Wipe clean valve housing.

2. Check valve opening pressure and vacuum.

Pressure:

16.0 - 20.0 kPa (0.16 - 0.20 bar, 0.163 - 0.204

kg/cm

2, 2.32 - 2.90 psi)

Vacuum:

þ6.0 to þ3.5 kPa (þ0.060 to þ0.035 bar, þ0.061 to

þ0.036 kg/cm

2, þ0.87 to þ0.51 psi)

3. If out of specification, replace fuel filler cap as an assembly.

Evaporative Emission (EVAP) Canister Purge Volume

Control Solenoid Valve

NCEC0019S07Refer to EC-SR-250.

SEF917W

SEF918W

SEF943S

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTIONSR20DE

Evaporative Emission System (Cont'd)

EC-28

Page 830 of 2267

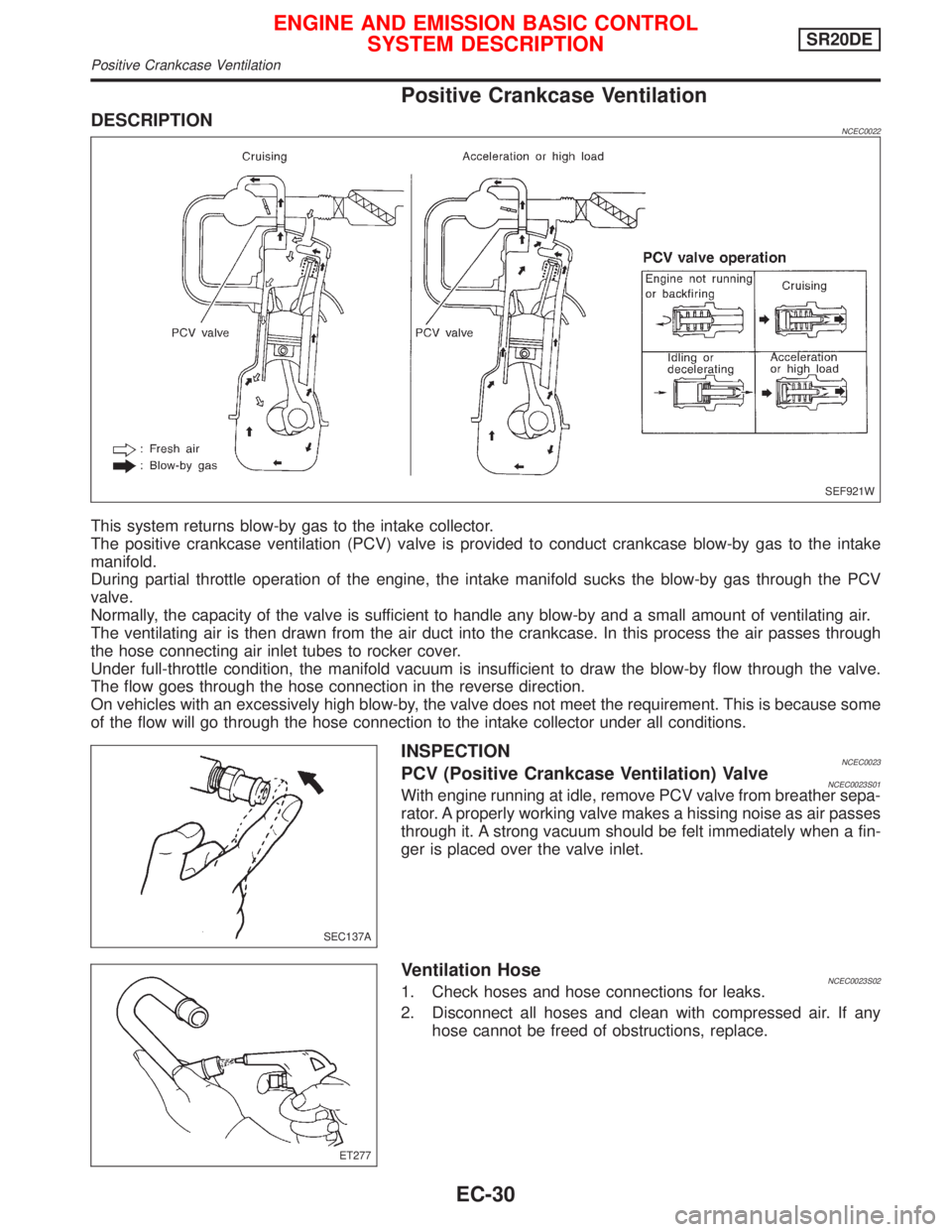

Positive Crankcase Ventilation

DESCRIPTIONNCEC0022

This system returns blow-by gas to the intake collector.

The positive crankcase ventilation (PCV) valve is provided to conduct crankcase blow-by gas to the intake

manifold.

During partial throttle operation of the engine, the intake manifold sucks the blow-by gas through the PCV

valve.

Normally, the capacity of the valve is sufficient to handle any blow-by and a small amount of ventilating air.

The ventilating air is then drawn from the air duct into the crankcase. In this process the air passes through

the hose connecting air inlet tubes to rocker cover.

Under full-throttle condition, the manifold vacuum is insufficient to draw the blow-by flow through the valve.

The flow goes through the hose connection in the reverse direction.

On vehicles with an excessively high blow-by, the valve does not meet the requirement. This is because some

of the flow will go through the hose connection to the intake collector under all conditions.

INSPECTIONNCEC0023PCV (Positive Crankcase Ventilation) ValveNCEC0023S01With engine running at idle, remove PCV valve from breather sepa-

rator. A properly working valve makes a hissing noise as air passes

through it. A strong vacuum should be felt immediately when a fin-

ger is placed over the valve inlet.

Ventilation HoseNCEC0023S021. Check hoses and hose connections for leaks.

2. Disconnect all hoses and clean with compressed air. If any

hose cannot be freed of obstructions, replace.

SEF921W

SEC137A

ET277

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTIONSR20DE

Positive Crankcase Ventilation

EC-30

Page 831 of 2267

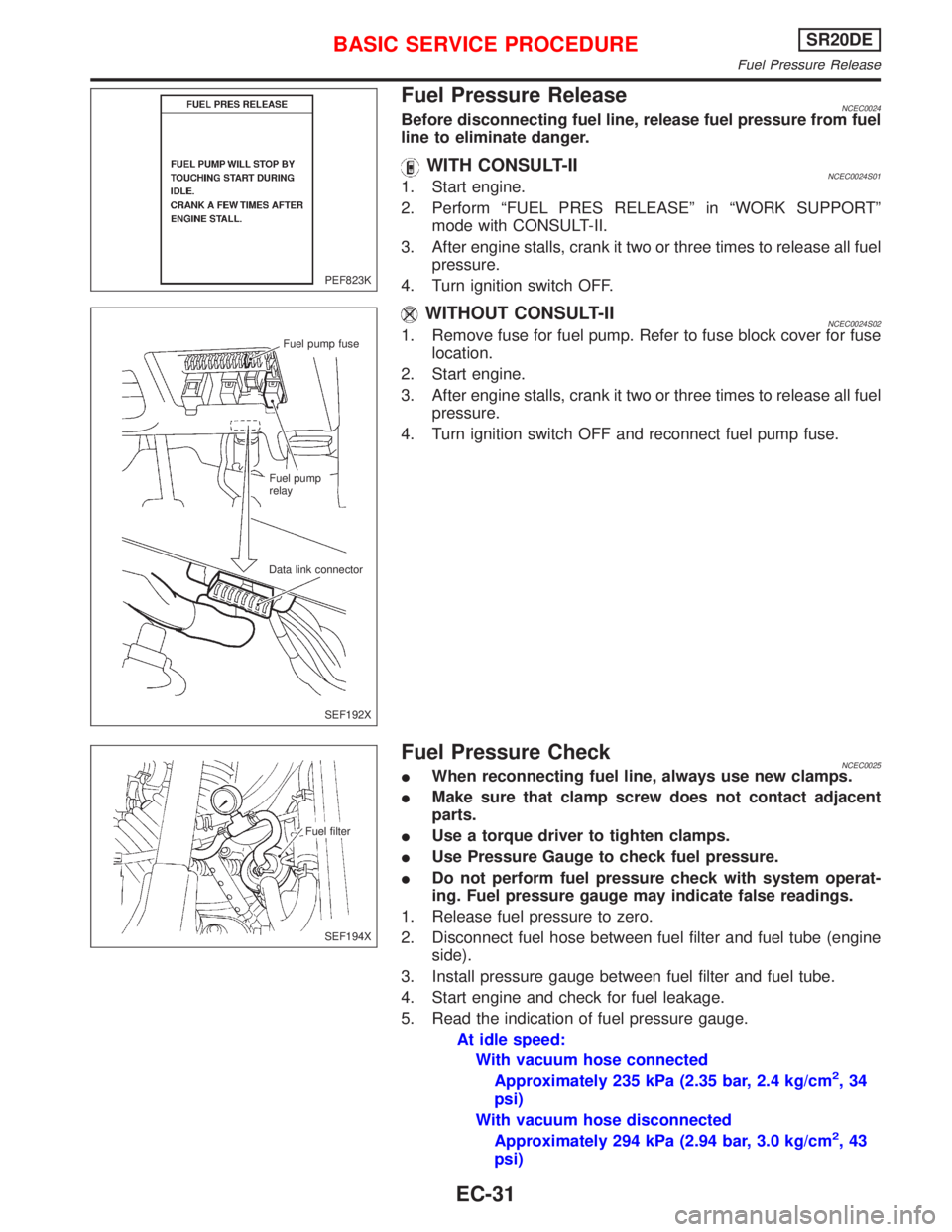

Fuel Pressure ReleaseNCEC0024Before disconnecting fuel line, release fuel pressure from fuel

line to eliminate danger.

WITH CONSULT-IINCEC0024S011. Start engine.

2. Perform ªFUEL PRES RELEASEº in ªWORK SUPPORTº

mode with CONSULT-II.

3. After engine stalls, crank it two or three times to release all fuel

pressure.

4. Turn ignition switch OFF.

WITHOUT CONSULT-IINCEC0024S021. Remove fuse for fuel pump. Refer to fuse block cover for fuse

location.

2. Start engine.

3. After engine stalls, crank it two or three times to release all fuel

pressure.

4. Turn ignition switch OFF and reconnect fuel pump fuse.

Fuel Pressure CheckNCEC0025IWhen reconnecting fuel line, always use new clamps.

IMake sure that clamp screw does not contact adjacent

parts.

IUse a torque driver to tighten clamps.

IUse Pressure Gauge to check fuel pressure.

IDo not perform fuel pressure check with system operat-

ing. Fuel pressure gauge may indicate false readings.

1. Release fuel pressure to zero.

2. Disconnect fuel hose between fuel filter and fuel tube (engine

side).

3. Install pressure gauge between fuel filter and fuel tube.

4. Start engine and check for fuel leakage.

5. Read the indication of fuel pressure gauge.

At idle speed:

With vacuum hose connected

Approximately 235 kPa (2.35 bar, 2.4 kg/cm

2,34

psi)

With vacuum hose disconnected

Approximately 294 kPa (2.94 bar, 3.0 kg/cm

2,43

psi)

PEF823K

Fuel pump fuse

Fuel pump

relay

Data link connector

SEF192X

Fuel filter

SEF194X

BASIC SERVICE PROCEDURESR20DE

Fuel Pressure Release

EC-31

Page 832 of 2267

If results are unsatisfactory, perform Fuel Pressure Regulator

Check, EC-SR-32.

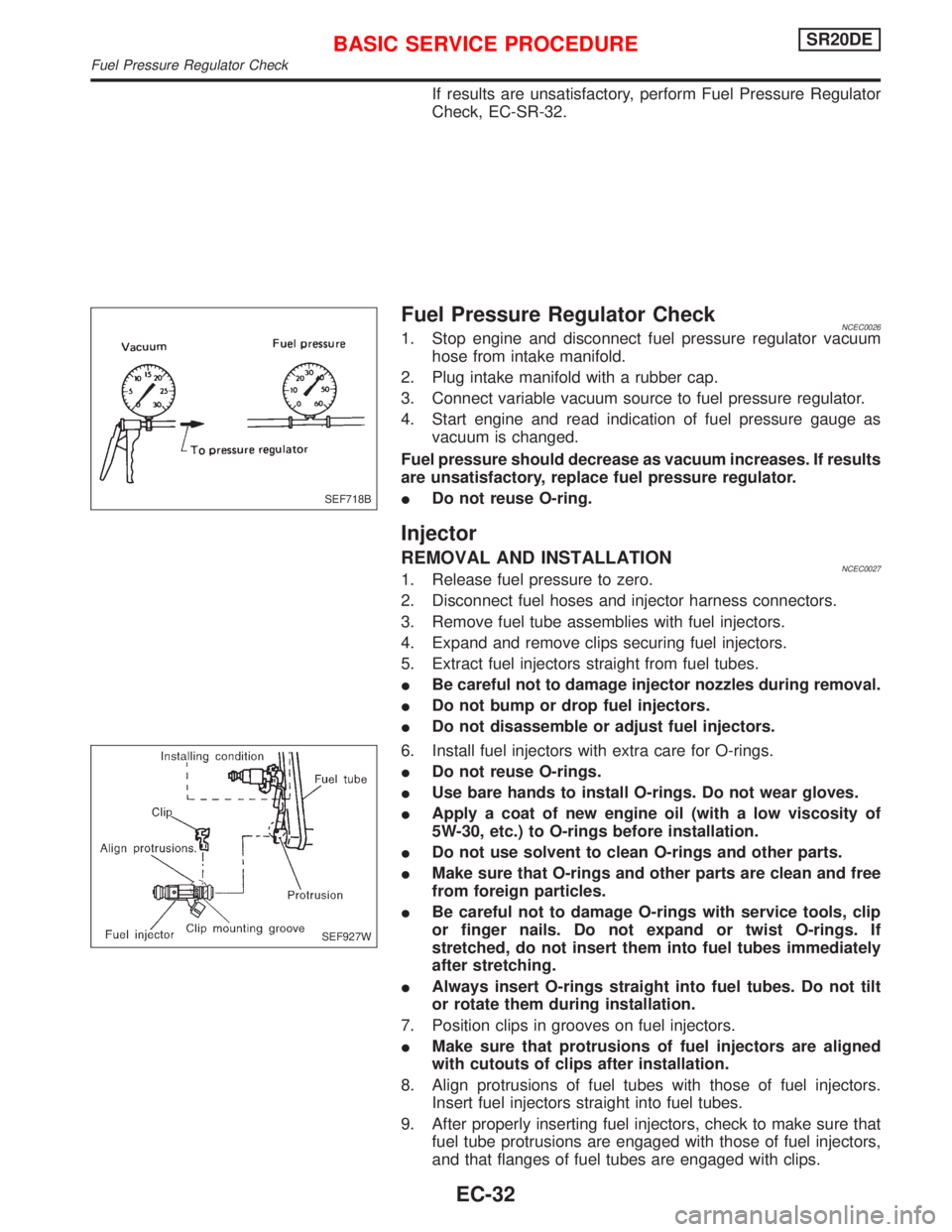

Fuel Pressure Regulator CheckNCEC00261. Stop engine and disconnect fuel pressure regulator vacuum

hose from intake manifold.

2. Plug intake manifold with a rubber cap.

3. Connect variable vacuum source to fuel pressure regulator.

4. Start engine and read indication of fuel pressure gauge as

vacuum is changed.

Fuel pressure should decrease as vacuum increases. If results

are unsatisfactory, replace fuel pressure regulator.

IDo not reuse O-ring.

Injector

REMOVAL AND INSTALLATIONNCEC00271. Release fuel pressure to zero.

2. Disconnect fuel hoses and injector harness connectors.

3. Remove fuel tube assemblies with fuel injectors.

4. Expand and remove clips securing fuel injectors.

5. Extract fuel injectors straight from fuel tubes.

IBe careful not to damage injector nozzles during removal.

IDo not bump or drop fuel injectors.

IDo not disassemble or adjust fuel injectors.

6. Install fuel injectors with extra care for O-rings.

IDo not reuse O-rings.

IUse bare hands to install O-rings. Do not wear gloves.

IApply a coat of new engine oil (with a low viscosity of

5W-30, etc.) to O-rings before installation.

IDo not use solvent to clean O-rings and other parts.

IMake sure that O-rings and other parts are clean and free

from foreign particles.

IBe careful not to damage O-rings with service tools, clip

or finger nails. Do not expand or twist O-rings. If

stretched, do not insert them into fuel tubes immediately

after stretching.

IAlways insert O-rings straight into fuel tubes. Do not tilt

or rotate them during installation.

7. Position clips in grooves on fuel injectors.

IMake sure that protrusions of fuel injectors are aligned

with cutouts of clips after installation.

8. Align protrusions of fuel tubes with those of fuel injectors.

Insert fuel injectors straight into fuel tubes.

9. After properly inserting fuel injectors, check to make sure that

fuel tube protrusions are engaged with those of fuel injectors,

and that flanges of fuel tubes are engaged with clips.

SEF718B

SEF927W

BASIC SERVICE PROCEDURESR20DE

Fuel Pressure Regulator Check

EC-32