NISSAN PRIMERA 1999 Electronic Repair Manual

PRIMERA 1999

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57377/w960_57377-0.png

NISSAN PRIMERA 1999 Electronic Repair Manual

Trending: display, jack points, gas mileage, trunk release, junction box, phone, CD player

Page 761 of 2267

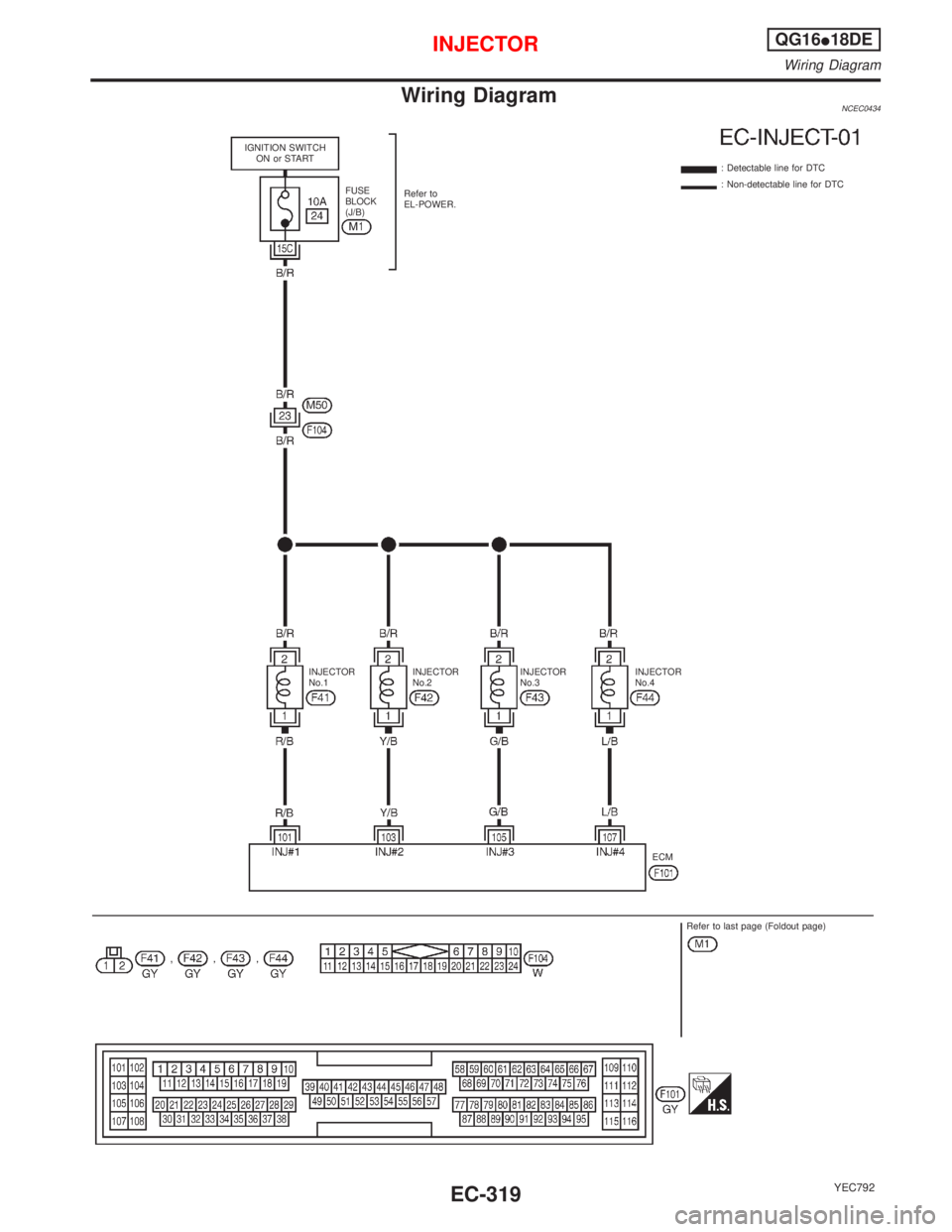

Wiring DiagramNCEC0434

YEC792

IGNITION SWITCH

ON or START

Refer to

EL-POWER.: Detectable line for DTC

: Non-detectable line for DTC

FUSE

BLOCK

(J/B)

ECM

Refer to last page (Foldout page) INJECTOR

No.1INJECTOR

No.2INJECTOR

No.3INJECTOR

No.4

INJECTORQG16I18DE

Wiring Diagram

EC-319

Page 762 of 2267

Diagnostic ProcedureNCEC0438

1 CHECK OVERALL FUNCTION

With CONSULT-II

1. Start engine.

2. Perform ªPOWER BALANCEº in ªACTIVE TESTº mode with CONSULT-II.

NEF105A3. Make sure that each circuit produces a momentary engine speed drop.

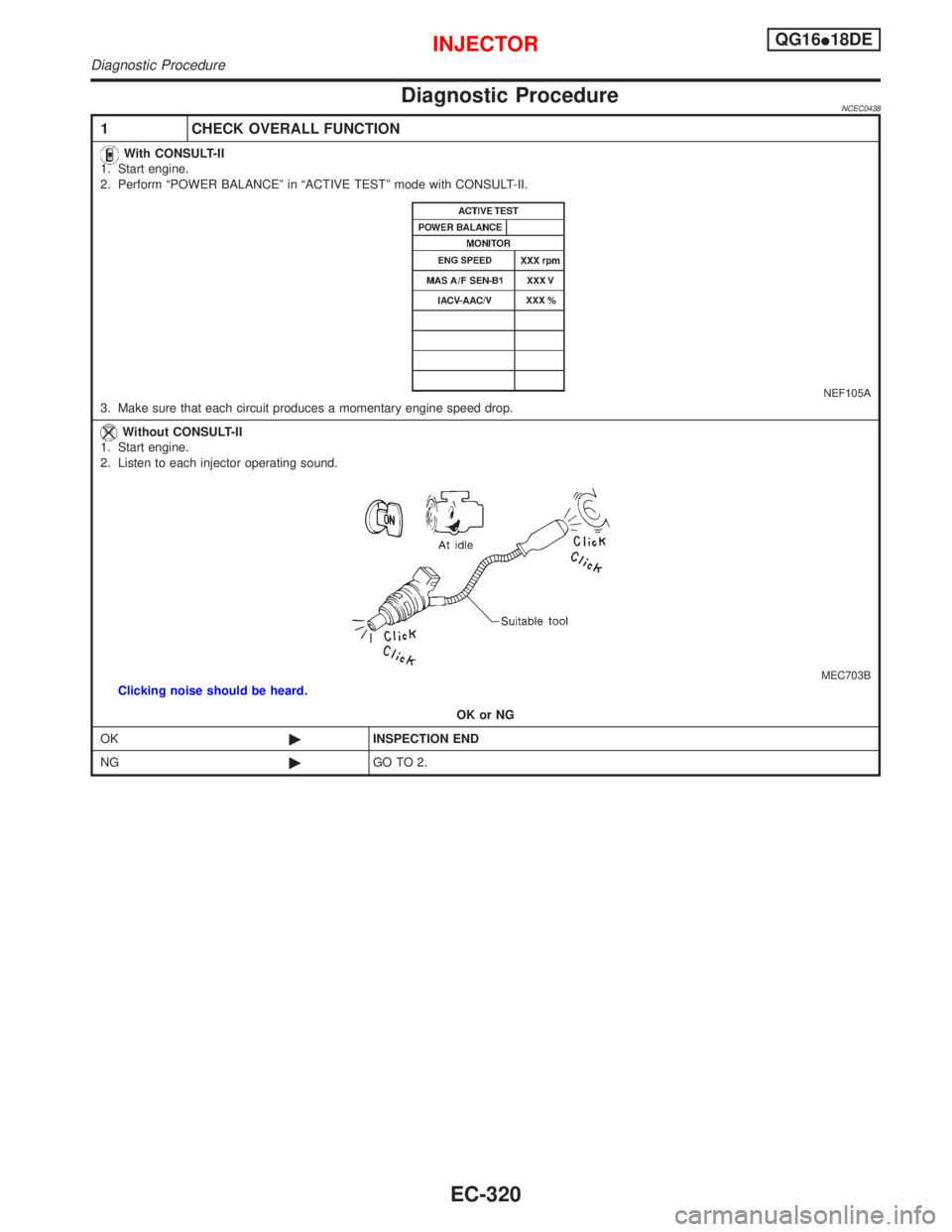

Without CONSULT-II

1. Start engine.

2. Listen to each injector operating sound.

MEC703BClicking noise should be heard.

OK or NG

OK©INSPECTION END

NG©GO TO 2.

INJECTORQG16I18DE

Diagnostic Procedure

EC-320

Page 763 of 2267

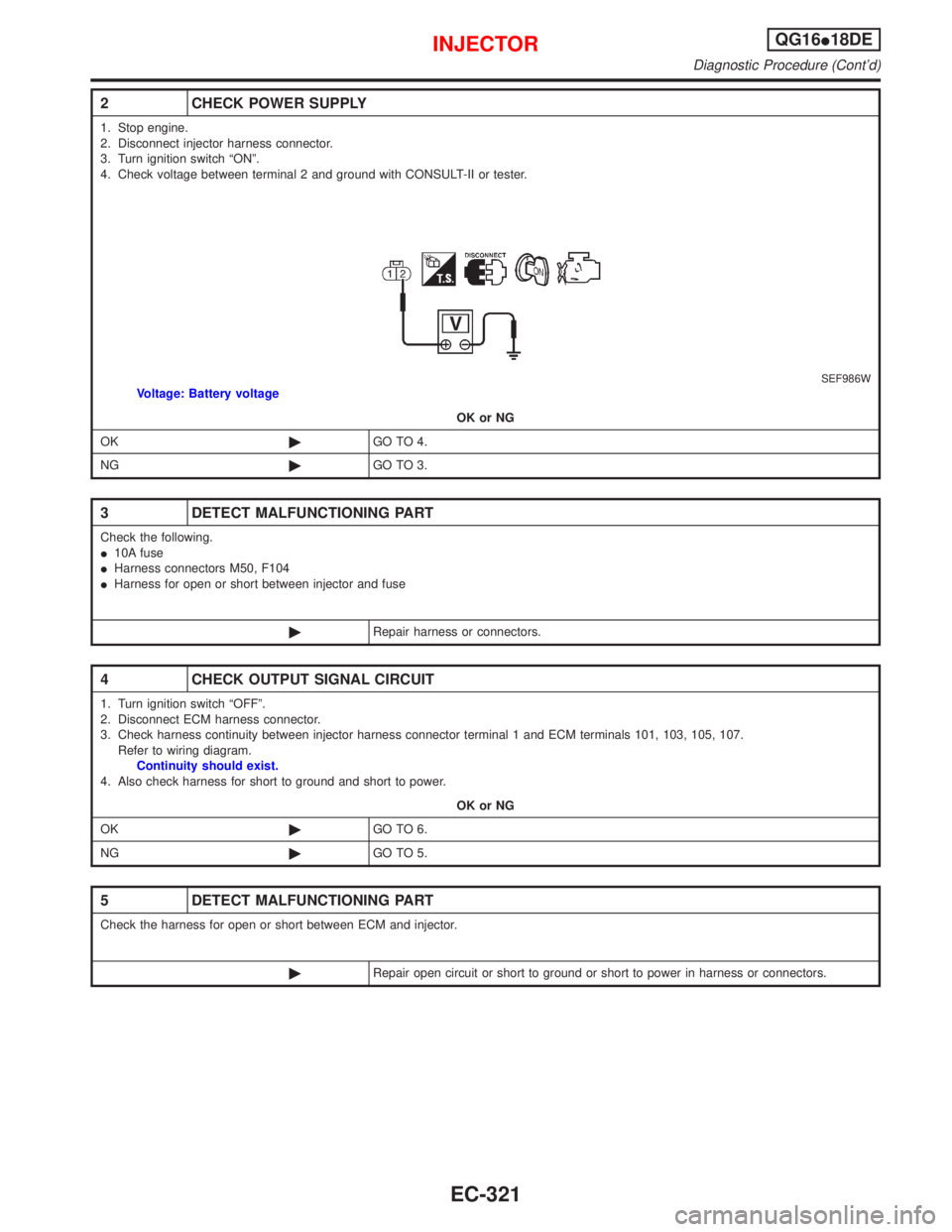

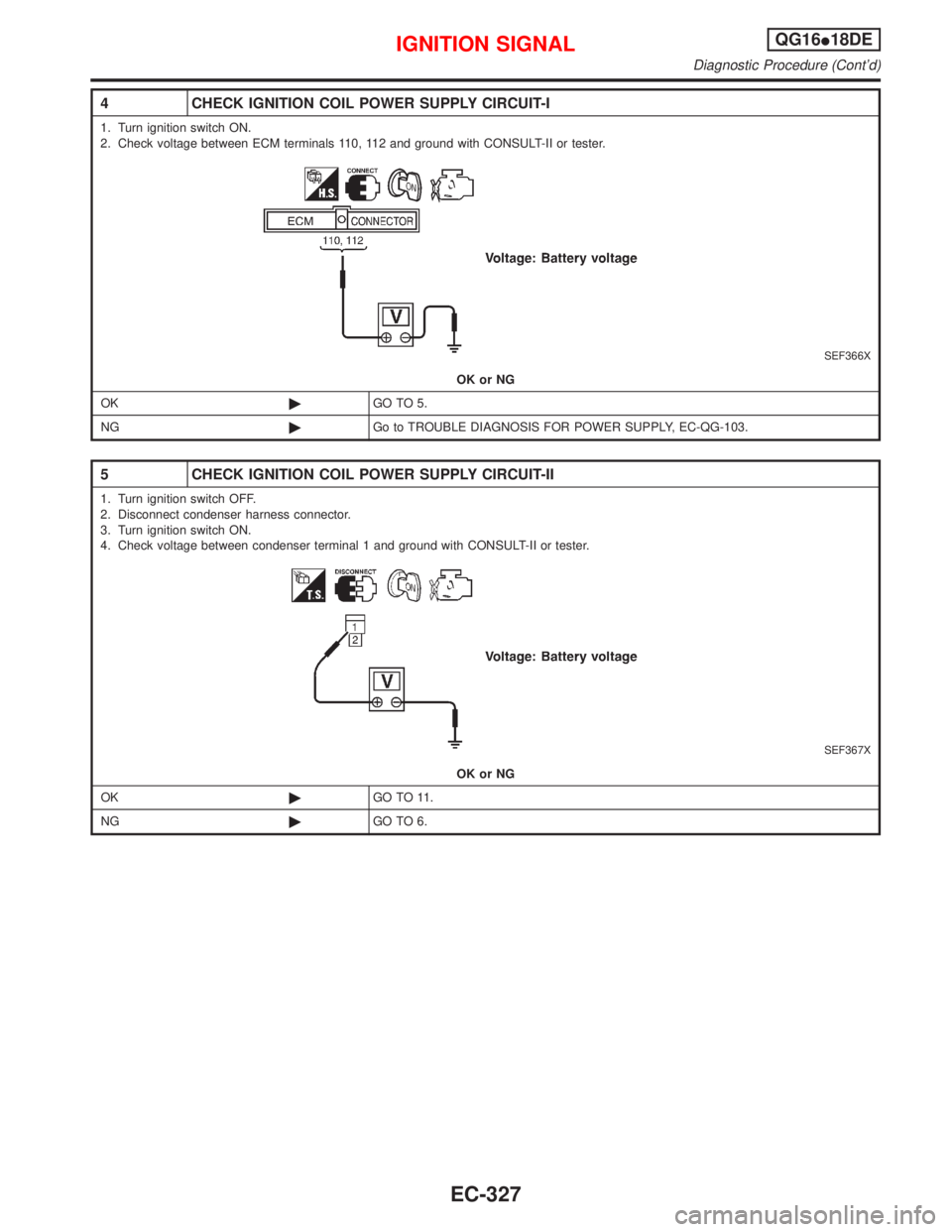

2 CHECK POWER SUPPLY

1. Stop engine.

2. Disconnect injector harness connector.

3. Turn ignition switch ªONº.

4. Check voltage between terminal 2 and ground with CONSULT-II or tester.

SEF986WVoltage: Battery voltage

OK or NG

OK©GO TO 4.

NG©GO TO 3.

3 DETECT MALFUNCTIONING PART

Check the following.

I10A fuse

IHarness connectors M50, F104

IHarness for open or short between injector and fuse

©Repair harness or connectors.

4 CHECK OUTPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between injector harness connector terminal 1 and ECM terminals 101, 103, 105, 107.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the harness for open or short between ECM and injector.

©Repair open circuit or short to ground or short to power in harness or connectors.

INJECTORQG16I18DE

Diagnostic Procedure (Cont'd)

EC-321

Page 764 of 2267

6 CHECK INJECTOR

Refer to ªComponent Inspectionº, EC-QG-322.

OK or NG

OK©GO TO 7.

NG©Replace injector.

7 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-QG-102.

©INSPECTION END

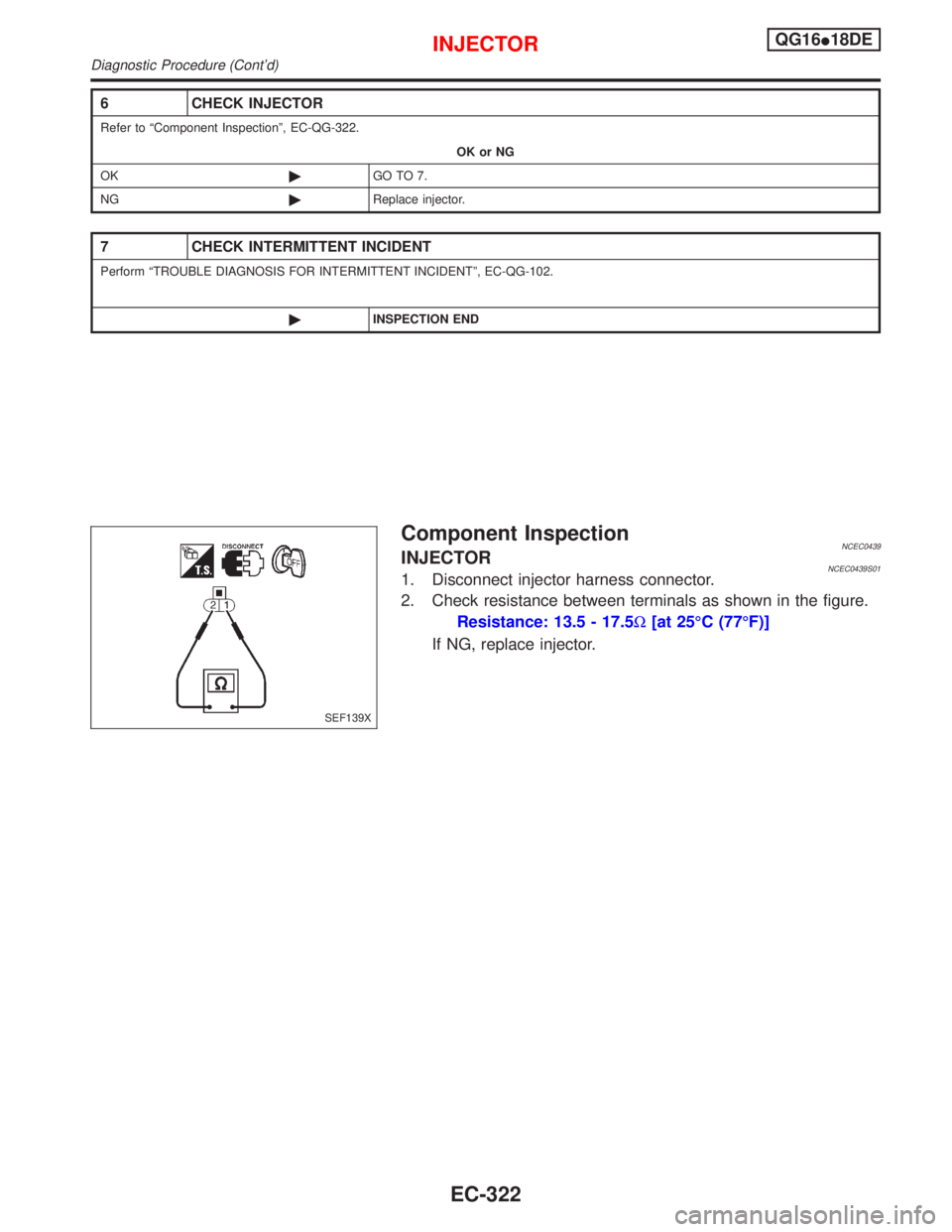

Component InspectionNCEC0439INJECTORNCEC0439S011. Disconnect injector harness connector.

2. Check resistance between terminals as shown in the figure.

Resistance: 13.5 - 17.5W[at 25ÉC (77ÉF)]

If NG, replace injector.

SEF139X

INJECTORQG16I18DE

Diagnostic Procedure (Cont'd)

EC-322

Page 765 of 2267

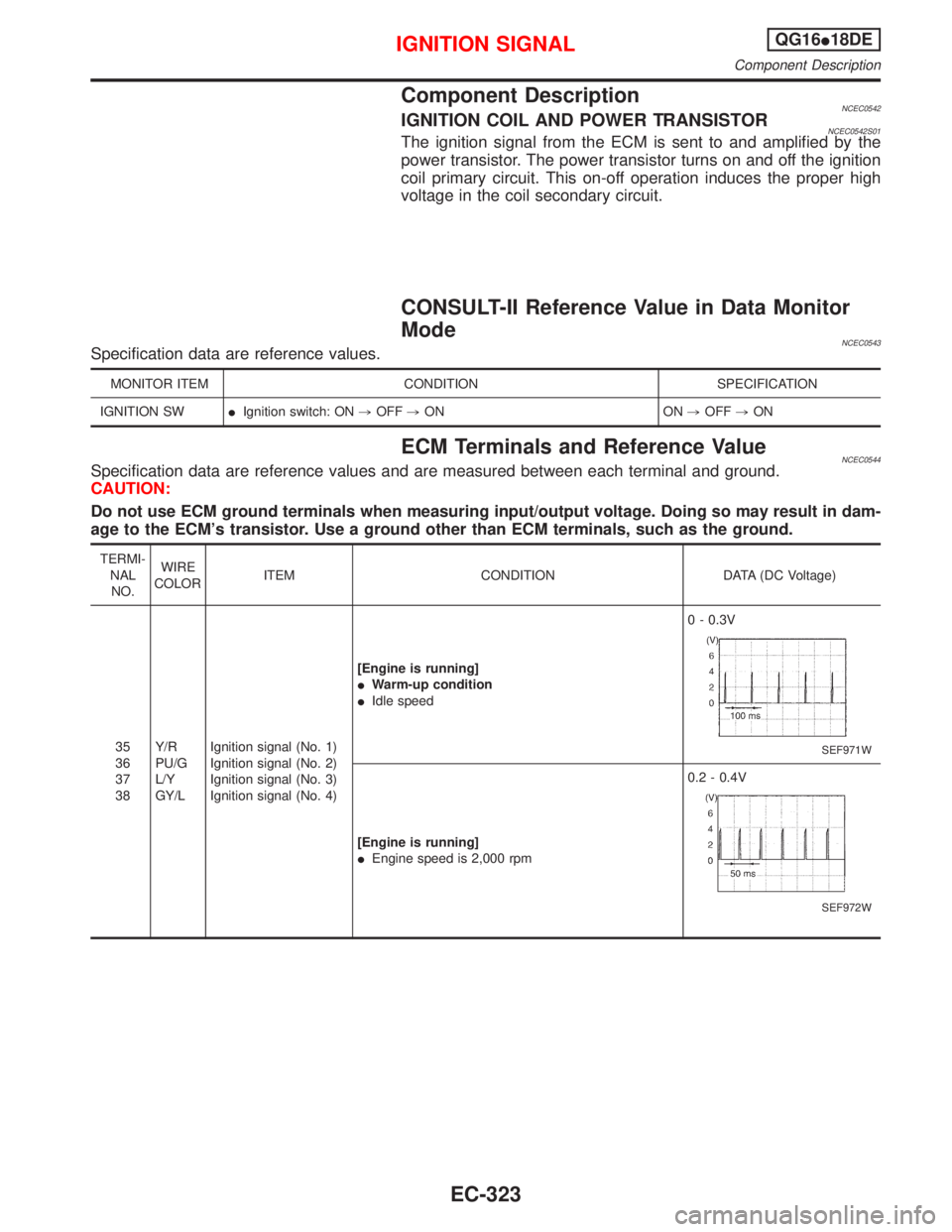

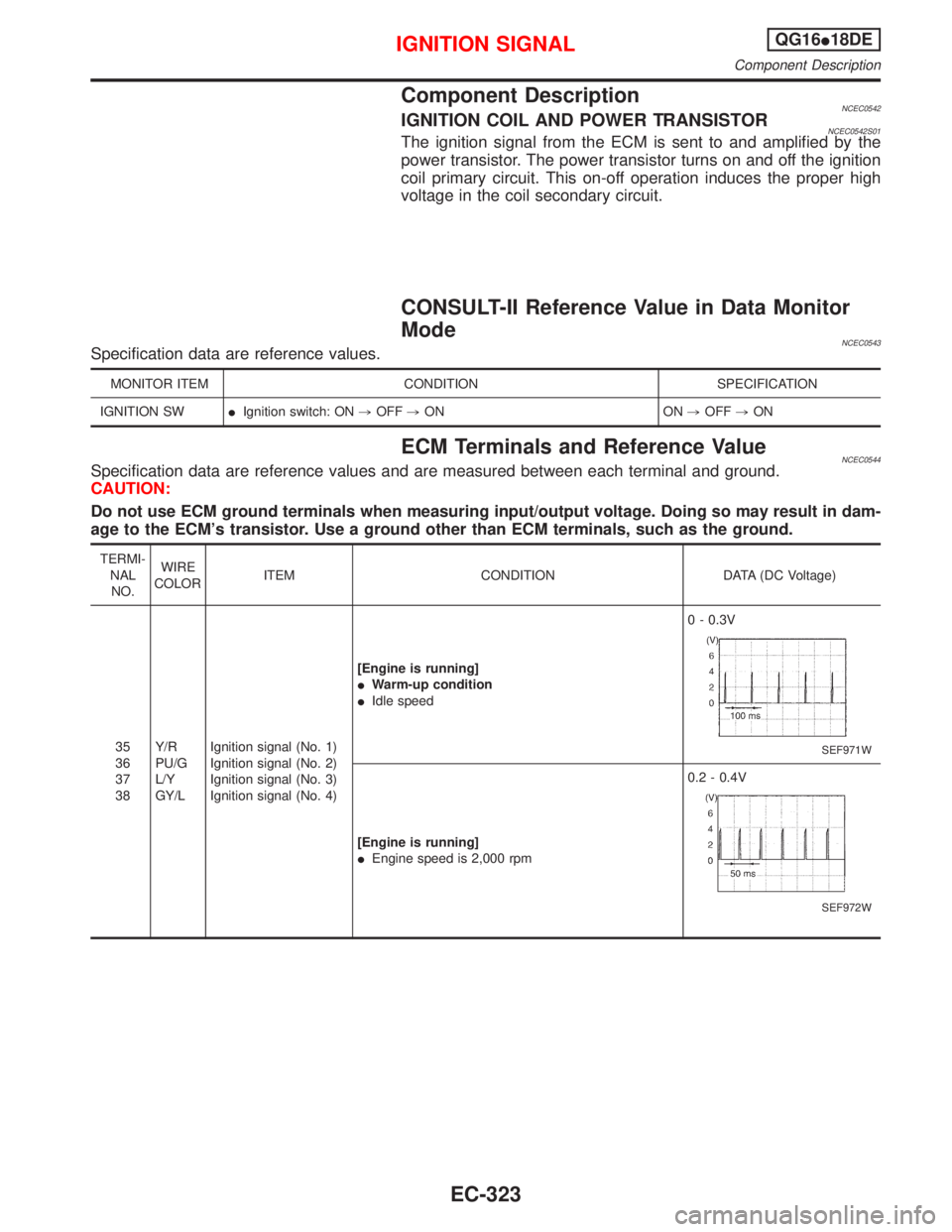

Component DescriptionNCEC0542IGNITION COIL AND POWER TRANSISTORNCEC0542S01The ignition signal from the ECM is sent to and amplified by the

power transistor. The power transistor turns on and off the ignition

coil primary circuit. This on-off operation induces the proper high

voltage in the coil secondary circuit.

CONSULT-II Reference Value in Data Monitor

Mode

NCEC0543Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

IGNITION SWIIgnition switch: ON,OFF,ON ON,OFF,ON

ECM Terminals and Reference ValueNCEC0544Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

35

36

37

38Y/R

PU/G

L/Y

GY/LIgnition signal (No. 1)

Ignition signal (No. 2)

Ignition signal (No. 3)

Ignition signal (No. 4)[Engine is running]

IWarm-up condition

IIdle speed0 - 0.3V

SEF971W

[Engine is running]

IEngine speed is 2,000 rpm0.2 - 0.4V

SEF972W

IGNITION SIGNALQG16I18DE

Component Description

EC-323

Page 766 of 2267

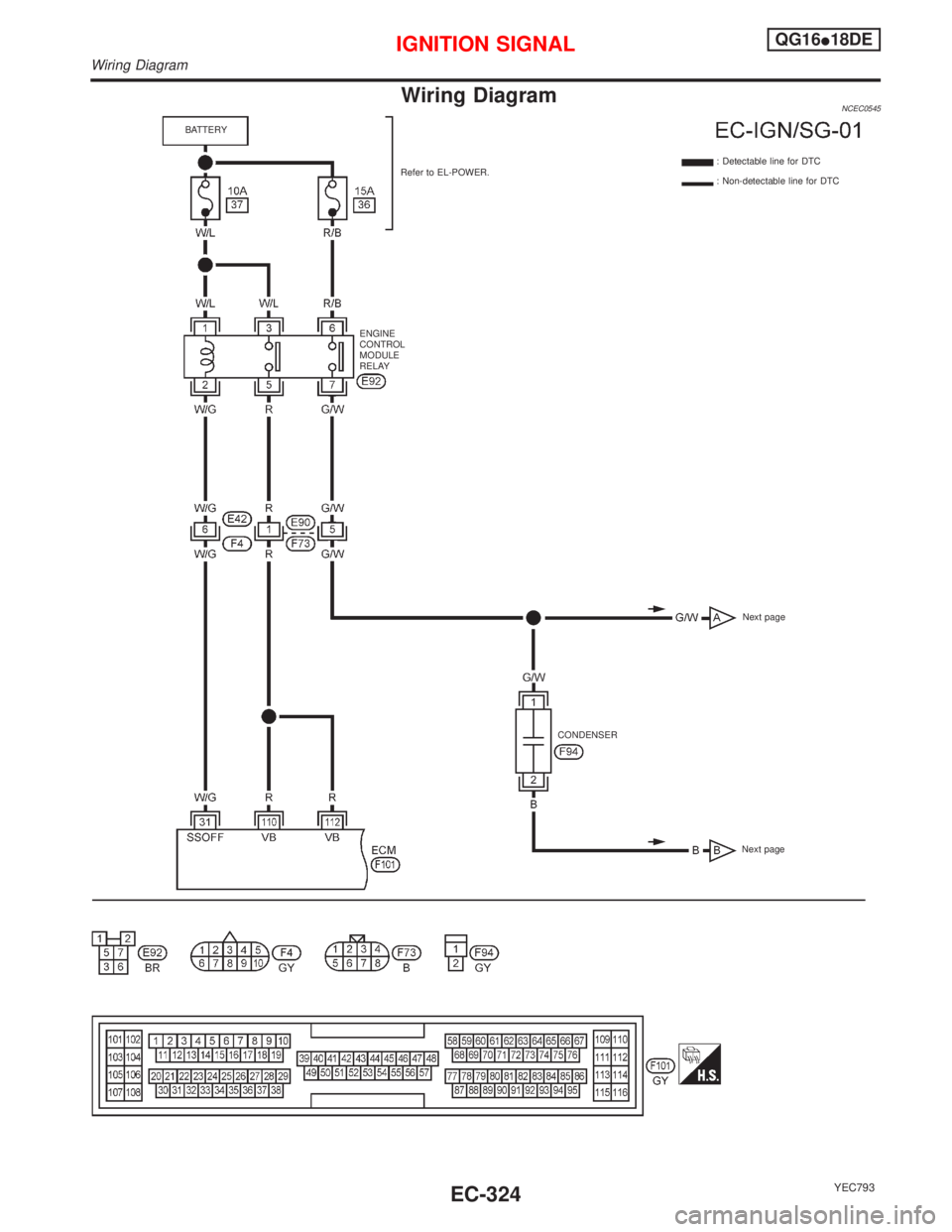

Wiring DiagramNCEC0545

YEC793

ENGINE

CONTROL

MODULE

RELAY

CONDENSER Refer to EL-POWER. BATTERY

: Detectable line for DTC

: Non-detectable line for DTC

Next pageNext page

IGNITION SIGNALQG16I18DE

Wiring Diagram

EC-324

Page 767 of 2267

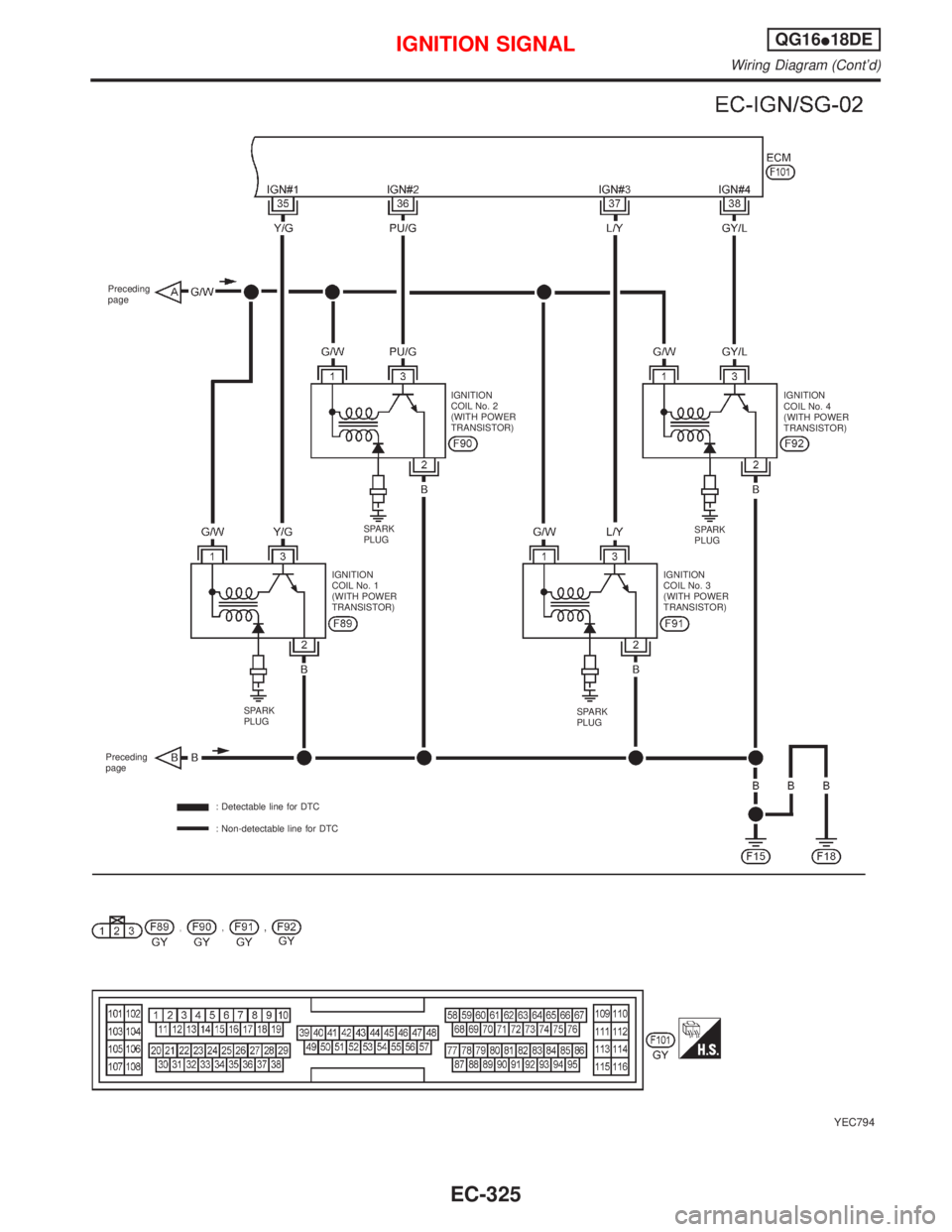

YEC794

Preceding

page

IGNITION

COIL No. 4

(WITH POWER

TRANSISTOR) IGNITION

COIL No. 2

(WITH POWER

TRANSISTOR)

SPARK

PLUG

IGNITION

COIL No. 1

(WITH POWER

TRANSISTOR)IGNITION

COIL No. 3

(WITH POWER

TRANSISTOR)SPARK

PLUG

SPARK

PLUGSPARK

PLUG

Preceding

page

: Detectable line for DTC

: Non-detectable line for DTC

IGNITION SIGNALQG16I18DE

Wiring Diagram (Cont'd)

EC-325

Page 768 of 2267

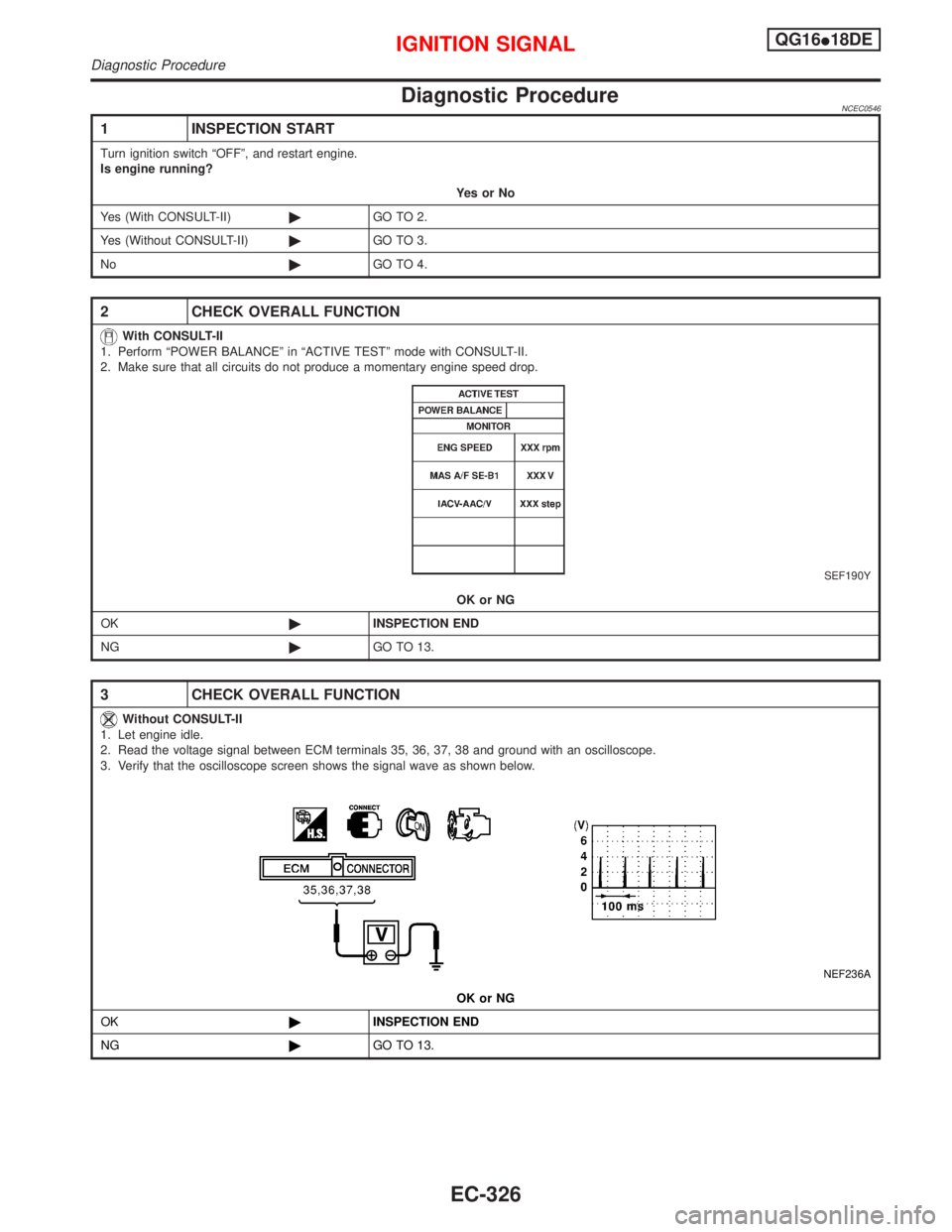

Diagnostic ProcedureNCEC0546

1 INSPECTION START

Turn ignition switch ªOFFº, and restart engine.

Is engine running?

YesorNo

Yes (With CONSULT-II)©GO TO 2.

Yes (Without CONSULT-II)©GO TO 3.

No©GO TO 4.

2 CHECK OVERALL FUNCTION

With CONSULT-II

1. Perform ªPOWER BALANCEº in ªACTIVE TESTº mode with CONSULT-II.

2. Make sure that all circuits do not produce a momentary engine speed drop.

SEF190Y

OK or NG

OK©INSPECTION END

NG©GO TO 13.

3 CHECK OVERALL FUNCTION

Without CONSULT-II

1. Let engine idle.

2. Read the voltage signal between ECM terminals 35, 36, 37, 38 and ground with an oscilloscope.

3. Verify that the oscilloscope screen shows the signal wave as shown below.

NEF236A

OK or NG

OK©INSPECTION END

NG©GO TO 13.

IGNITION SIGNALQG16I18DE

Diagnostic Procedure

EC-326

Page 769 of 2267

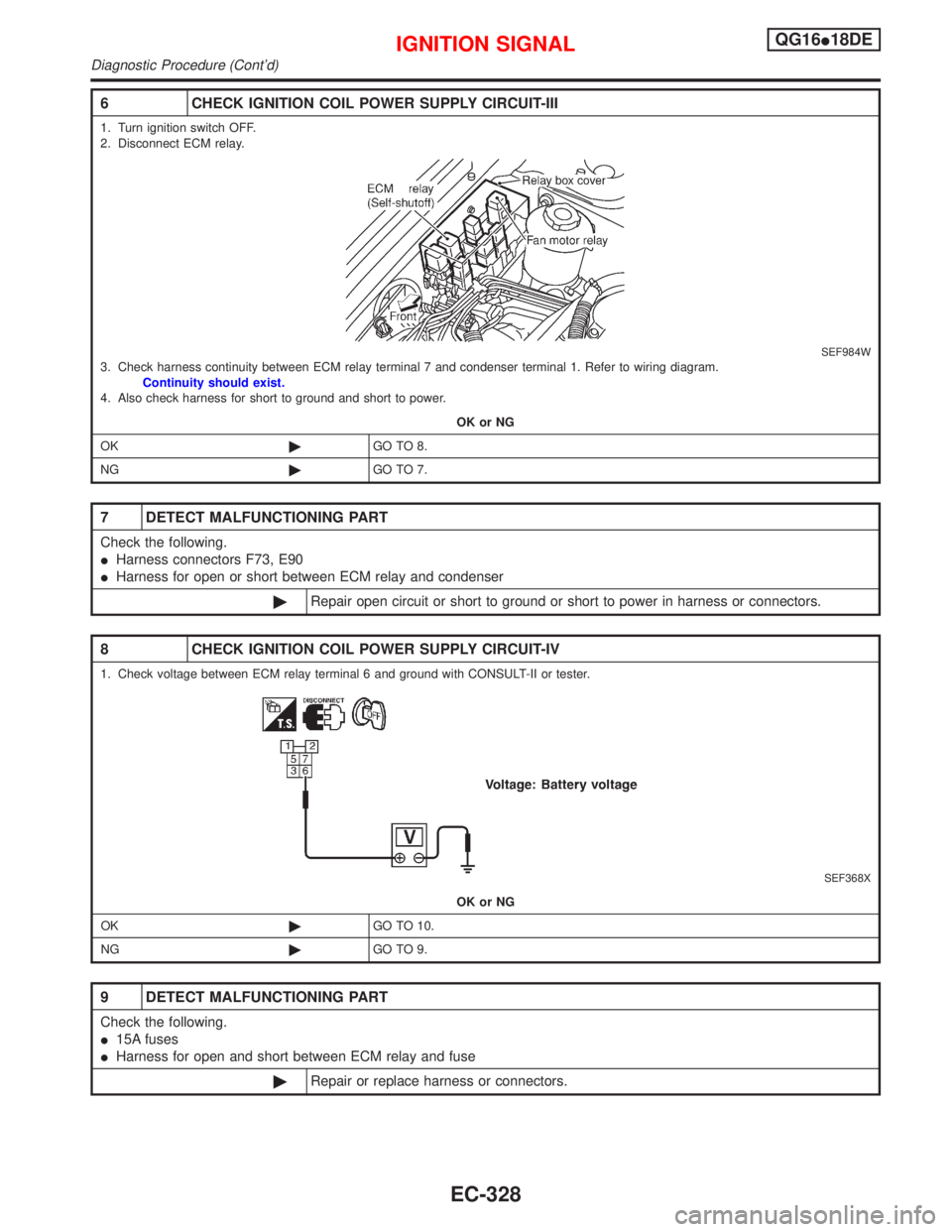

4 CHECK IGNITION COIL POWER SUPPLY CIRCUIT-I

1. Turn ignition switch ON.

2. Check voltage between ECM terminals 110, 112 and ground with CONSULT-II or tester.

SEF366X

OK or NG

OK©GO TO 5.

NG©Go to TROUBLE DIAGNOSIS FOR POWER SUPPLY, EC-QG-103.

5 CHECK IGNITION COIL POWER SUPPLY CIRCUIT-II

1. Turn ignition switch OFF.

2. Disconnect condenser harness connector.

3. Turn ignition switch ON.

4. Check voltage between condenser terminal 1 and ground with CONSULT-II or tester.

SEF367X

OK or NG

OK©GO TO 11.

NG©GO TO 6.

IGNITION SIGNALQG16I18DE

Diagnostic Procedure (Cont'd)

EC-327

Page 770 of 2267

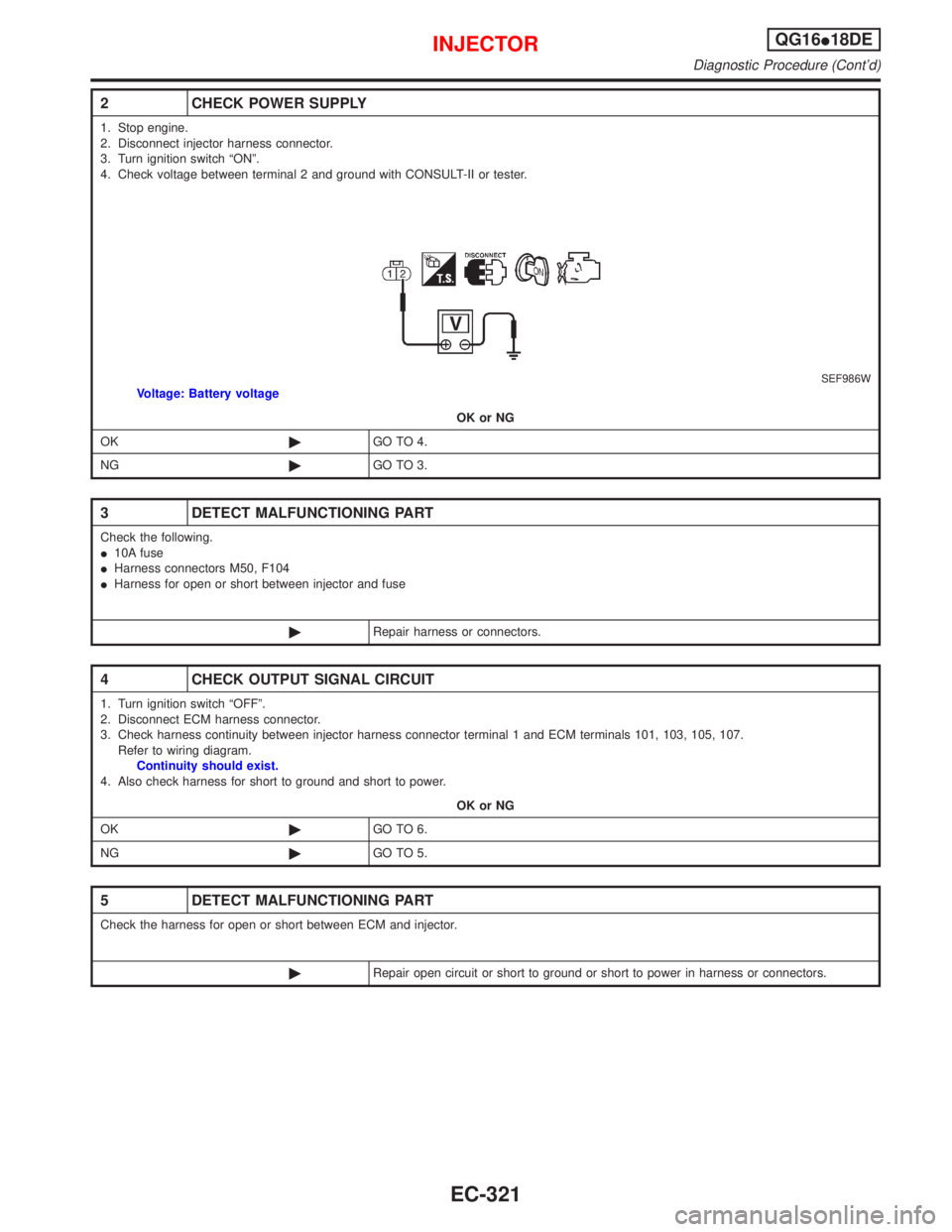

6 CHECK IGNITION COIL POWER SUPPLY CIRCUIT-III

1. Turn ignition switch OFF.

2. Disconnect ECM relay.

SEF984W3. Check harness continuity between ECM relay terminal 7 and condenser terminal 1. Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 8.

NG©GO TO 7.

7 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors F73, E90

IHarness for open or short between ECM relay and condenser

©Repair open circuit or short to ground or short to power in harness or connectors.

8 CHECK IGNITION COIL POWER SUPPLY CIRCUIT-IV

1. Check voltage between ECM relay terminal 6 and ground with CONSULT-II or tester.

SEF368X

OK or NG

OK©GO TO 10.

NG©GO TO 9.

9 DETECT MALFUNCTIONING PART

Check the following.

I15A fuses

IHarness for open and short between ECM relay and fuse

©Repair or replace harness or connectors.

IGNITION SIGNALQG16I18DE

Diagnostic Procedure (Cont'd)

EC-328

Trending: ad blue, spare box, wheel size, trunk, OBD port, distributor, p0325