NISSAN PRIMERA 1999 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 781 of 2267

Diagnostic ProcedureNCEC0448

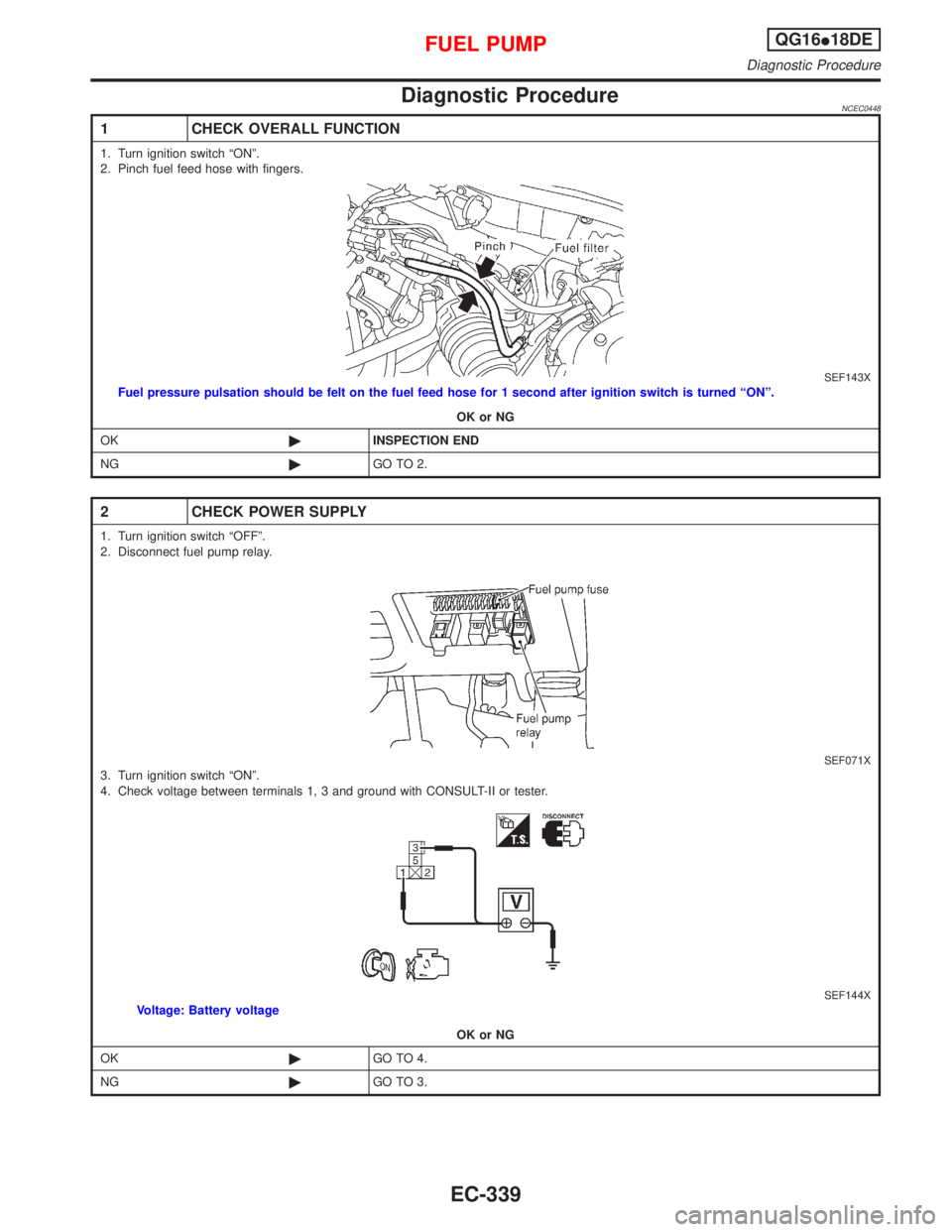

1 CHECK OVERALL FUNCTION

1. Turn ignition switch ªONº.

2. Pinch fuel feed hose with fingers.

SEF143XFuel pressure pulsation should be felt on the fuel feed hose for 1 second after ignition switch is turned ªONº.

OK or NG

OK©INSPECTION END

NG©GO TO 2.

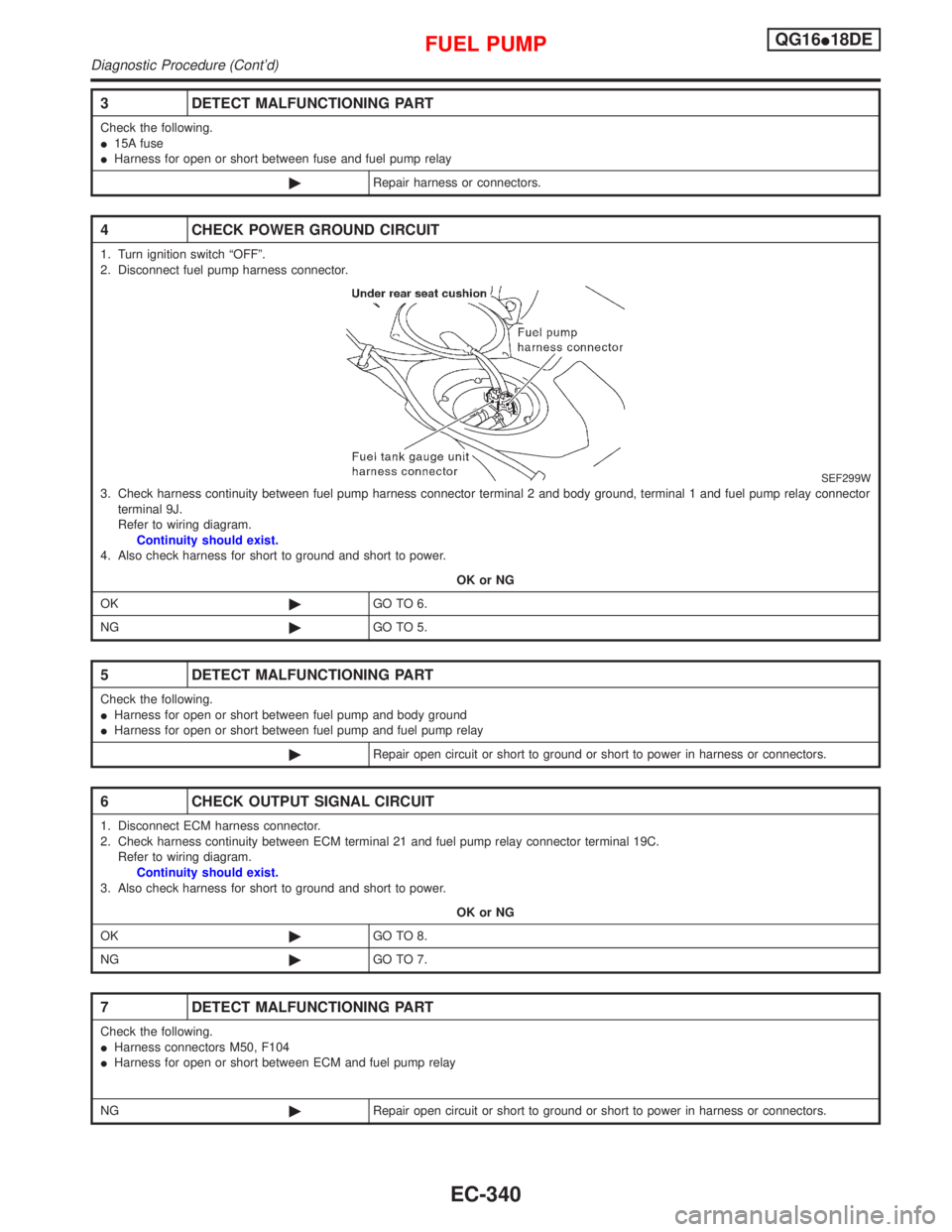

2 CHECK POWER SUPPLY

1. Turn ignition switch ªOFFº.

2. Disconnect fuel pump relay.

SEF071X3. Turn ignition switch ªONº.

4. Check voltage between terminals 1, 3 and ground with CONSULT-II or tester.

SEF144XVoltage: Battery voltage

OK or NG

OK©GO TO 4.

NG©GO TO 3.

FUEL PUMPQG16I18DE

Diagnostic Procedure

EC-339

Page 782 of 2267

3 DETECT MALFUNCTIONING PART

Check the following.

I15A fuse

IHarness for open or short between fuse and fuel pump relay

©Repair harness or connectors.

4 CHECK POWER GROUND CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect fuel pump harness connector.

SEF299W3. Check harness continuity between fuel pump harness connector terminal 2 and body ground, terminal 1 and fuel pump relay connector

terminal 9J.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

IHarness for open or short between fuel pump and body ground

IHarness for open or short between fuel pump and fuel pump relay

©Repair open circuit or short to ground or short to power in harness or connectors.

6 CHECK OUTPUT SIGNAL CIRCUIT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 21 and fuel pump relay connector terminal 19C.

Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 8.

NG©GO TO 7.

7 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M50, F104

IHarness for open or short between ECM and fuel pump relay

NG©Repair open circuit or short to ground or short to power in harness or connectors.

FUEL PUMPQG16I18DE

Diagnostic Procedure (Cont'd)

EC-340

Page 783 of 2267

8 CHECK FUEL PUMP RELAY

Refer to ªComponent Inspectionº, EC-QG-341.

OK or NG

OK©GO TO 9.

NG©Replace fuel pump relay.

9 CHECK FUEL PUMP

Refer to ªComponent Inspectionº, EC-QG-341.

OK or NG

OK©GO TO 10.

NG©Replace fuel pump.

10 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-QG-102.

©INSPECTION END

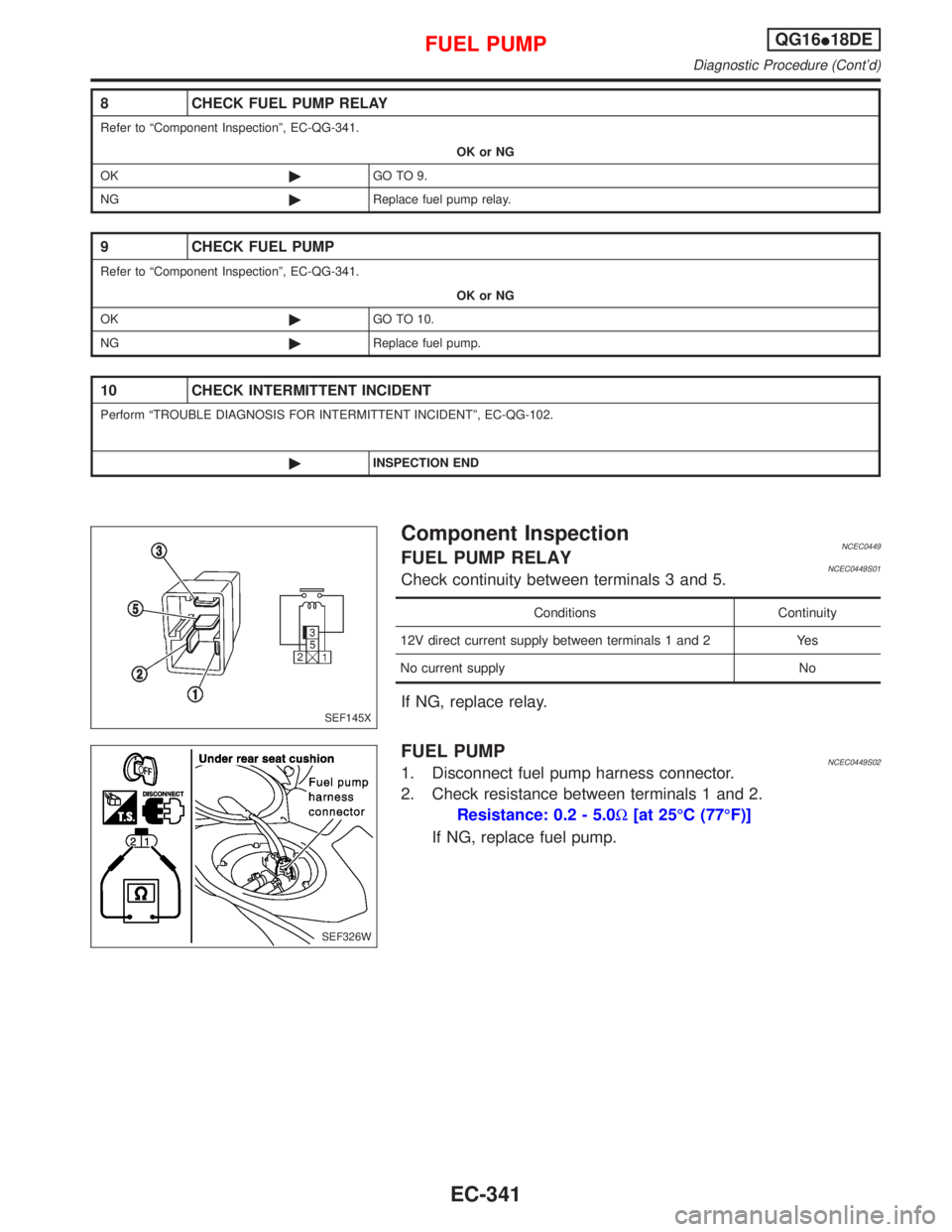

Component InspectionNCEC0449FUEL PUMP RELAYNCEC0449S01Check continuity between terminals 3 and 5.

Conditions Continuity

12V direct current supply between terminals 1 and 2 Yes

No current supply No

If NG, replace relay.

FUEL PUMPNCEC0449S021. Disconnect fuel pump harness connector.

2. Check resistance between terminals 1 and 2.

Resistance: 0.2 - 5.0W[at 25ÉC (77ÉF)]

If NG, replace fuel pump.

SEF145X

SEF326W

FUEL PUMPQG16I18DE

Diagnostic Procedure (Cont'd)

EC-341

Page 784 of 2267

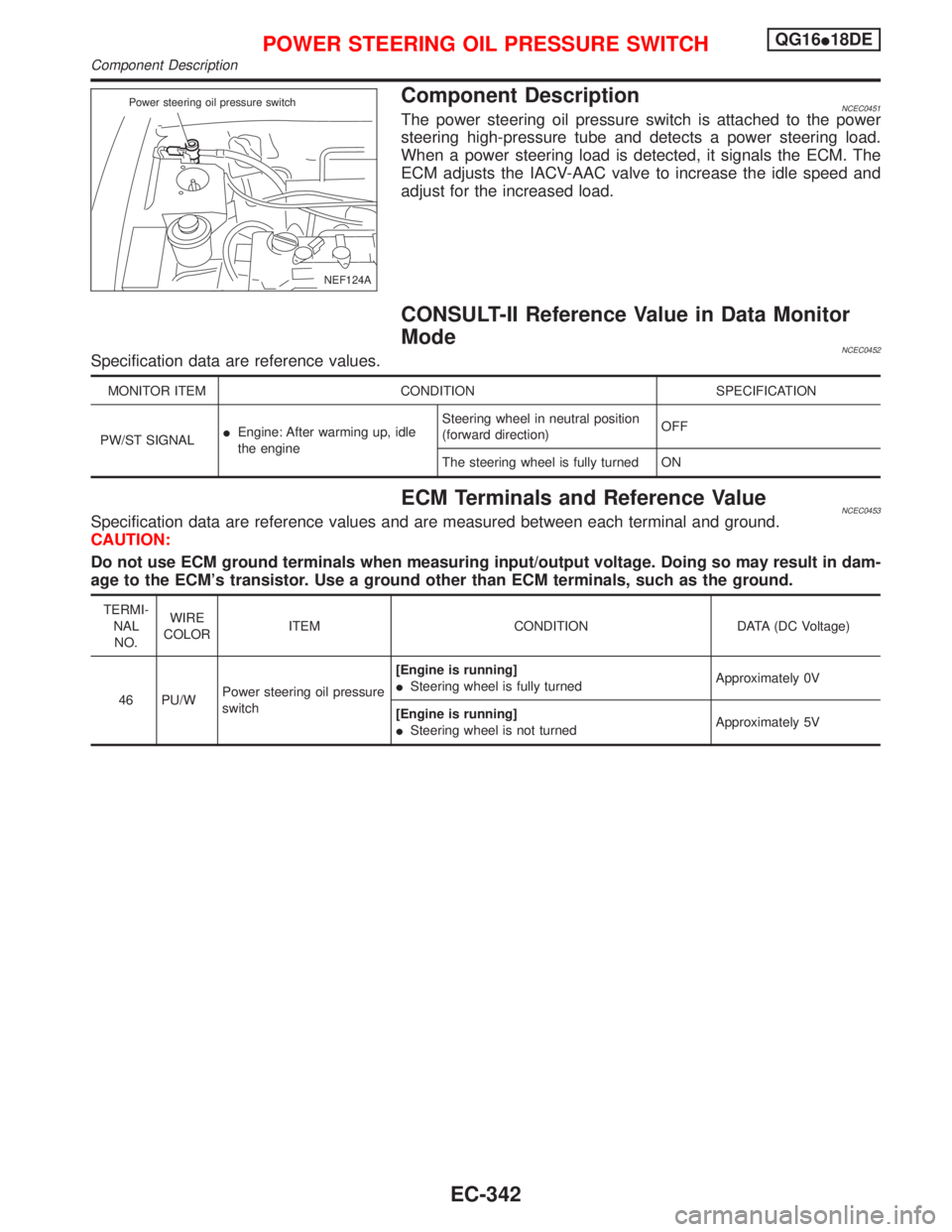

Component DescriptionNCEC0451The power steering oil pressure switch is attached to the power

steering high-pressure tube and detects a power steering load.

When a power steering load is detected, it signals the ECM. The

ECM adjusts the IACV-AAC valve to increase the idle speed and

adjust for the increased load.

CONSULT-II Reference Value in Data Monitor

Mode

NCEC0452Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

PW/ST SIGNALIEngine: After warming up, idle

the engineSteering wheel in neutral position

(forward direction)OFF

The steering wheel is fully turned ON

ECM Terminals and Reference ValueNCEC0453Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

46 PU/WPower steering oil pressure

switch[Engine is running]

ISteering wheel is fully turnedApproximately 0V

[Engine is running]

ISteering wheel is not turnedApproximately 5V

NEF124A Power steering oil pressure switch

POWER STEERING OIL PRESSURE SWITCHQG16I18DE

Component Description

EC-342

Page 785 of 2267

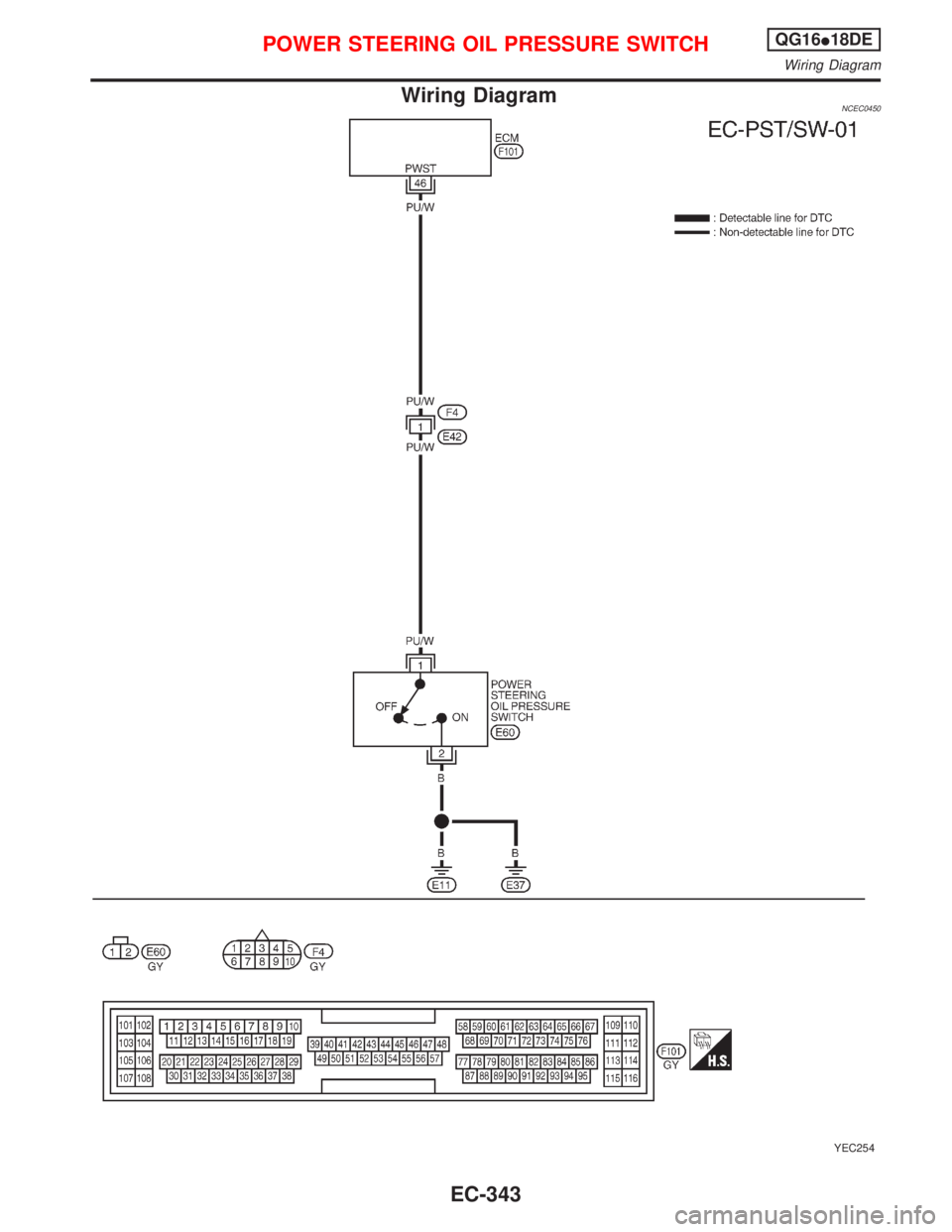

Wiring DiagramNCEC0450

YEC254

POWER STEERING OIL PRESSURE SWITCHQG16I18DE

Wiring Diagram

EC-343

Page 786 of 2267

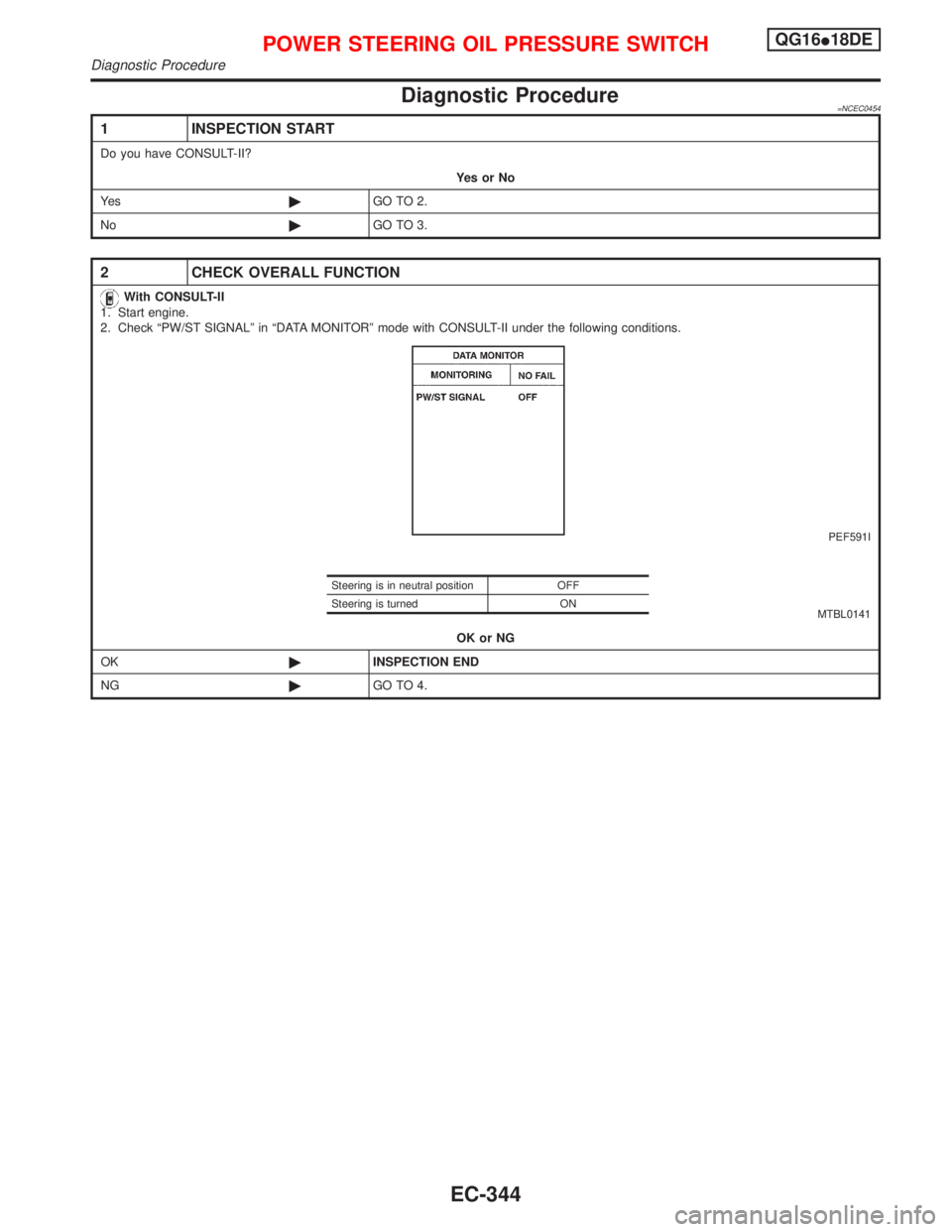

Diagnostic Procedure=NCEC0454

1 INSPECTION START

Do you have CONSULT-II?

YesorNo

Ye s©GO TO 2.

No©GO TO 3.

2 CHECK OVERALL FUNCTION

With CONSULT-II

1. Start engine.

2. Check ªPW/ST SIGNALº in ªDATA MONITORº mode with CONSULT-II under the following conditions.

PEF591I

MTBL0141

OK or NG

OK©INSPECTION END

NG©GO TO 4.

Steering is in neutral position OFF

Steering is turned ON

POWER STEERING OIL PRESSURE SWITCHQG16I18DE

Diagnostic Procedure

EC-344

Page 787 of 2267

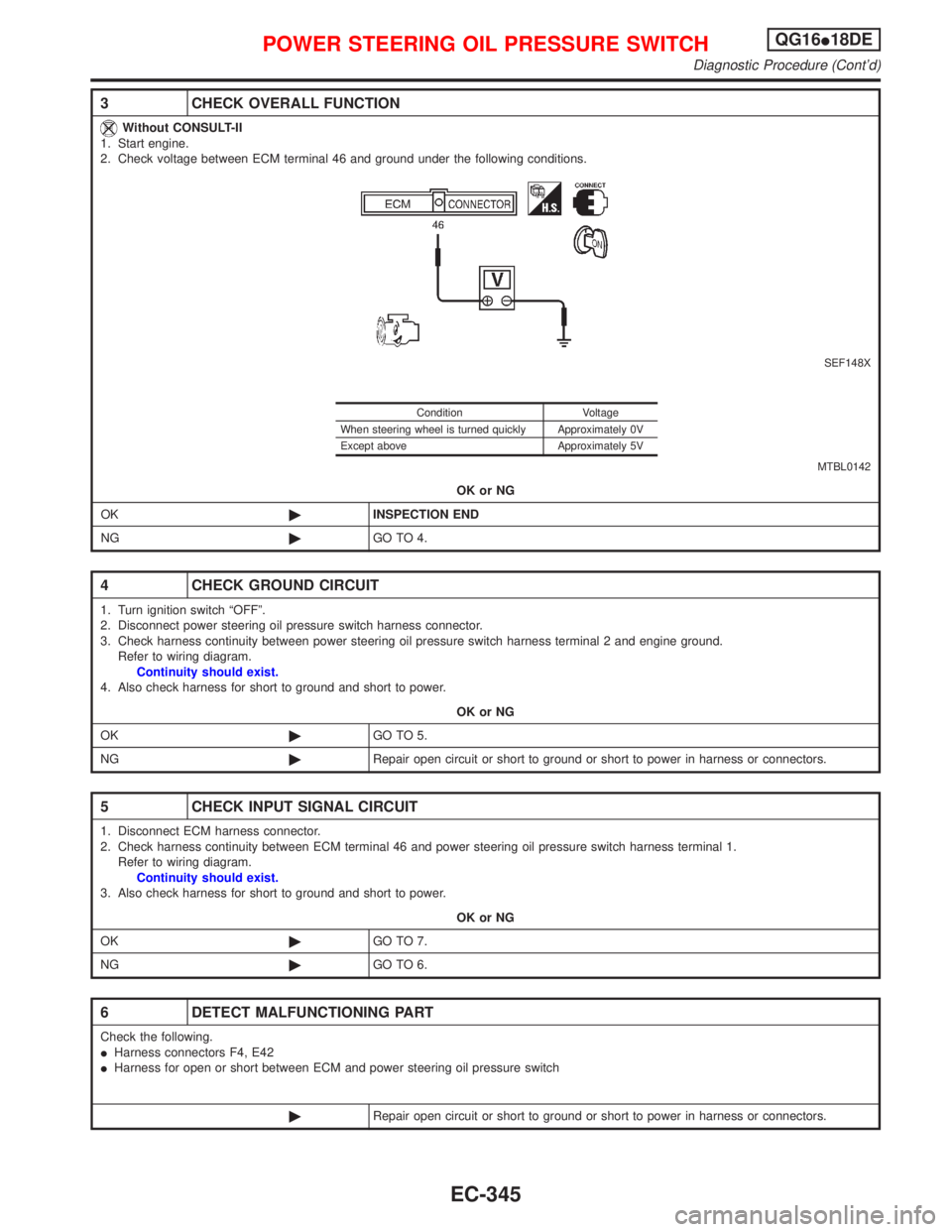

3 CHECK OVERALL FUNCTION

Without CONSULT-II

1. Start engine.

2. Check voltage between ECM terminal 46 and ground under the following conditions.

SEF148X

MTBL0142

OK or NG

OK©INSPECTION END

NG©GO TO 4.

4 CHECK GROUND CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect power steering oil pressure switch harness connector.

3. Check harness continuity between power steering oil pressure switch harness terminal 2 and engine ground.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

5 CHECK INPUT SIGNAL CIRCUIT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 46 and power steering oil pressure switch harness terminal 1.

Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 7.

NG©GO TO 6.

6 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors F4, E42

IHarness for open or short between ECM and power steering oil pressure switch

©Repair open circuit or short to ground or short to power in harness or connectors.

Condition Voltage

When steering wheel is turned quickly Approximately 0V

Except above Approximately 5V

POWER STEERING OIL PRESSURE SWITCHQG16I18DE

Diagnostic Procedure (Cont'd)

EC-345

Page 788 of 2267

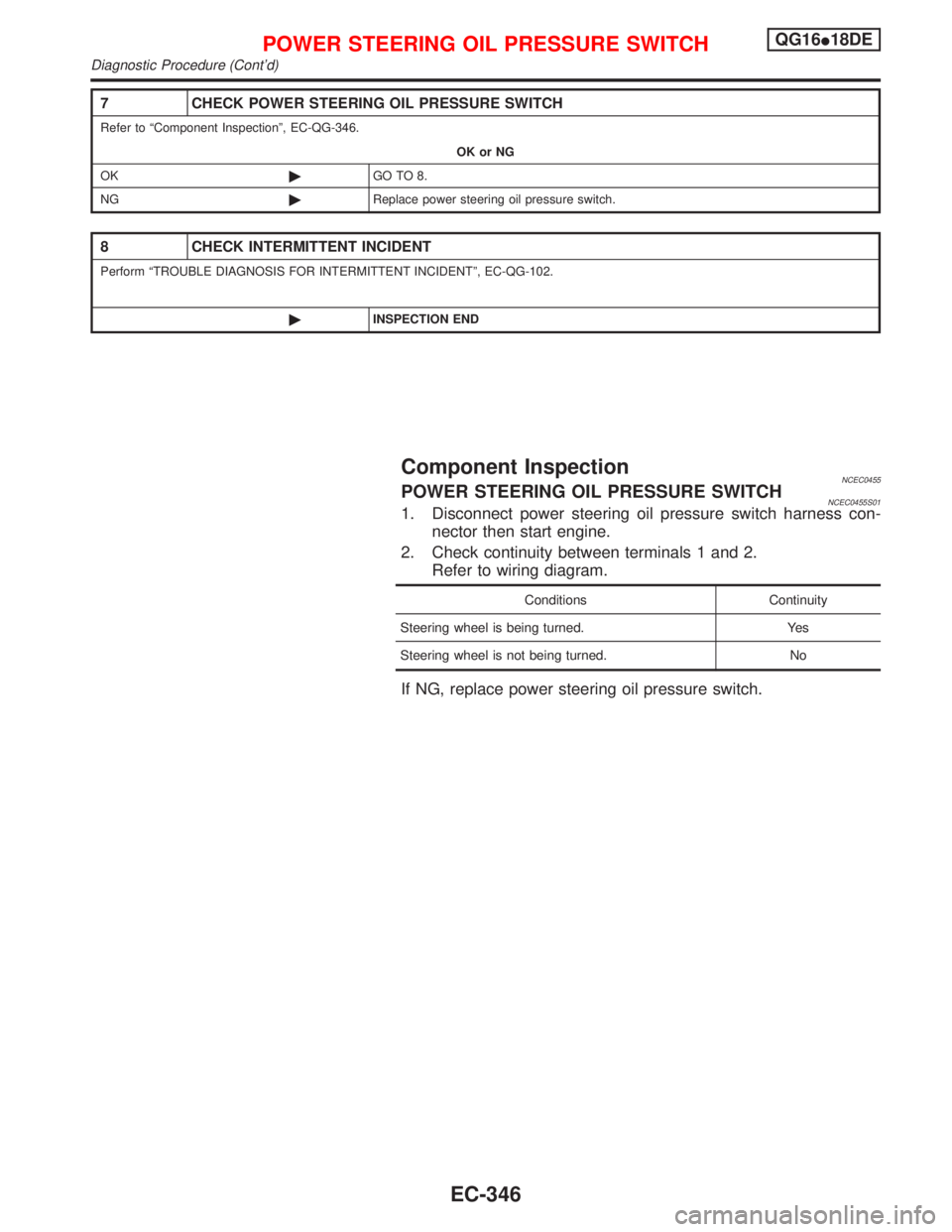

7 CHECK POWER STEERING OIL PRESSURE SWITCH

Refer to ªComponent Inspectionº, EC-QG-346.

OK or NG

OK©GO TO 8.

NG©Replace power steering oil pressure switch.

8 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-QG-102.

©INSPECTION END

Component InspectionNCEC0455POWER STEERING OIL PRESSURE SWITCHNCEC0455S011. Disconnect power steering oil pressure switch harness con-

nector then start engine.

2. Check continuity between terminals 1 and 2.

Refer to wiring diagram.

Conditions Continuity

Steering wheel is being turned. Yes

Steering wheel is not being turned. No

If NG, replace power steering oil pressure switch.

POWER STEERING OIL PRESSURE SWITCHQG16I18DE

Diagnostic Procedure (Cont'd)

EC-346

Page 789 of 2267

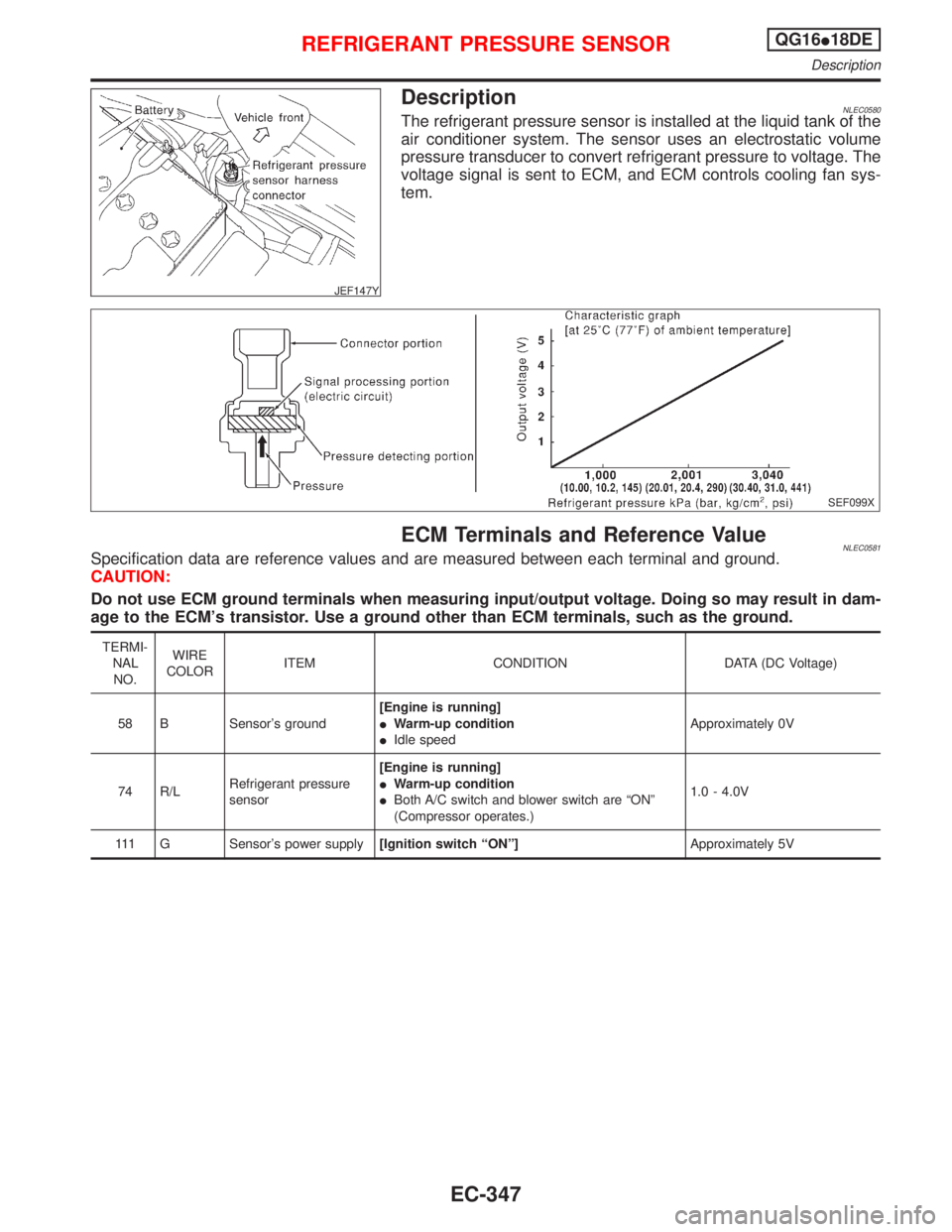

JEF147Y

DescriptionNLEC0580The refrigerant pressure sensor is installed at the liquid tank of the

air conditioner system. The sensor uses an electrostatic volume

pressure transducer to convert refrigerant pressure to voltage. The

voltage signal is sent to ECM, and ECM controls cooling fan sys-

tem.

SEF099X

ECM Terminals and Reference ValueNLEC0581Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

58 B Sensor's ground[Engine is running]

IWarm-up condition

IIdle speedApproximately 0V

74 R/LRefrigerant pressure

sensor[Engine is running]

IWarm-up condition

IBoth A/C switch and blower switch are ªONº

(Compressor operates.)1.0 - 4.0V

111 G Sensor's power supply[Ignition switch ªONº]Approximately 5V

REFRIGERANT PRESSURE SENSORQG16I18DE

Description

EC-347

Page 790 of 2267

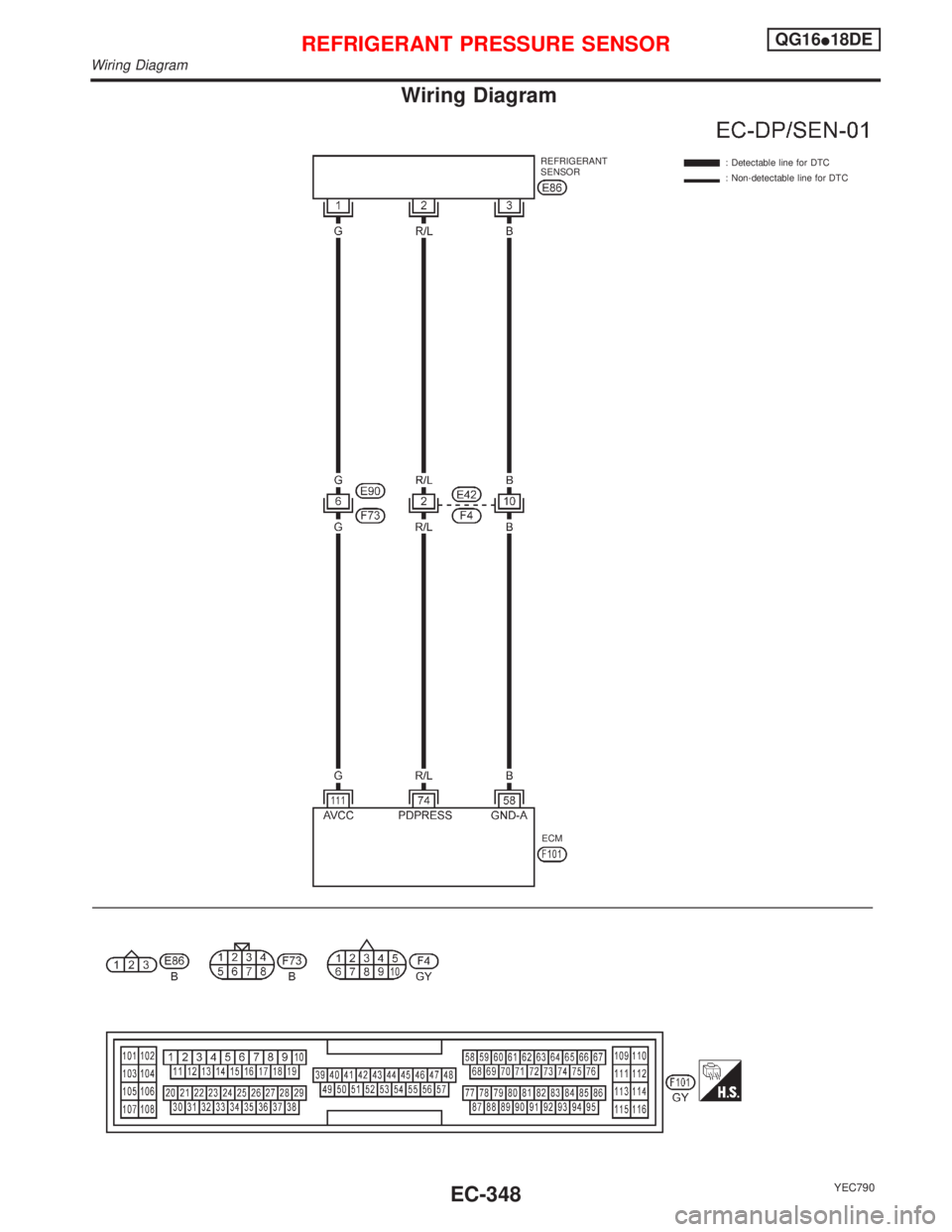

Wiring Diagram

YEC790

: Detectable line for DTC

: Non-detectable line for DTC REFRIGERANT

SENSOR

ECM

REFRIGERANT PRESSURE SENSORQG16I18DE

Wiring Diagram

EC-348