NISSAN PRIMERA 1999 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 741 of 2267

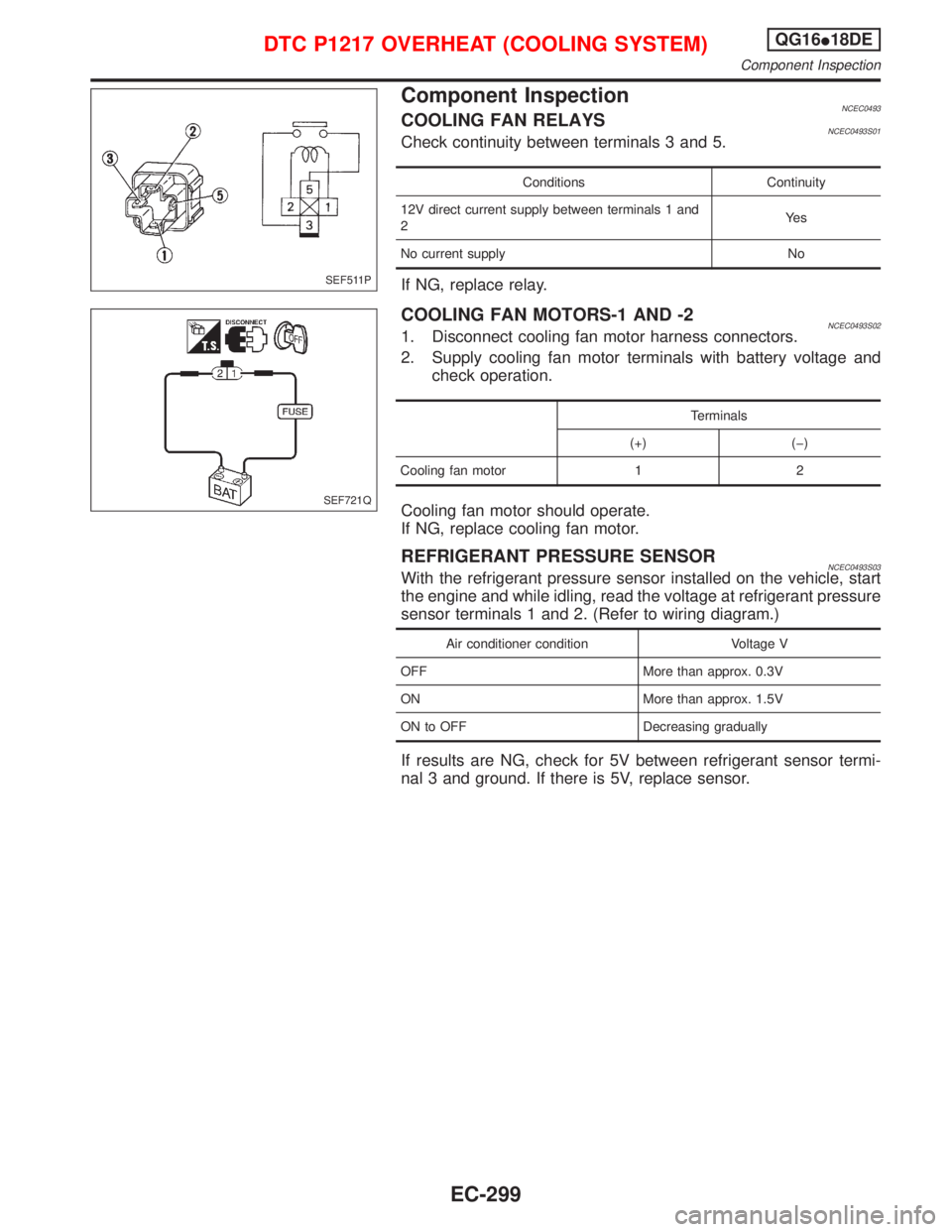

Component InspectionNCEC0493COOLING FAN RELAYSNCEC0493S01Check continuity between terminals 3 and 5.

Conditions Continuity

12V direct current supply between terminals 1 and

2Ye s

No current supply No

If NG, replace relay.

COOLING FAN MOTORS-1 AND -2NCEC0493S021. Disconnect cooling fan motor harness connectors.

2. Supply cooling fan motor terminals with battery voltage and

check operation.

Terminals

(+) (þ)

Cooling fan motor 1 2

Cooling fan motor should operate.

If NG, replace cooling fan motor.

REFRIGERANT PRESSURE SENSORNCEC0493S03With the refrigerant pressure sensor installed on the vehicle, start

the engine and while idling, read the voltage at refrigerant pressure

sensor terminals 1 and 2. (Refer to wiring diagram.)

Air conditioner condition Voltage V

OFF More than approx. 0.3V

ON More than approx. 1.5V

ON to OFF Decreasing gradually

If results are NG, check for 5V between refrigerant sensor termi-

nal 3 and ground. If there is 5V, replace sensor.

SEF511P

SEF721Q

DTC P1217 OVERHEAT (COOLING SYSTEM)QG16I18DE

Component Inspection

EC-299

Page 742 of 2267

Component DescriptionNCEC0342The EGR temperature sensor detects temperature changes in the

EGR passageway. When the EGR volume control valve opens, hot

exhaust gases flow, and the temperature in the passageway

changes. The EGR temperature sensor is a thermistor that modi-

fies a voltage signal sent from the ECM. This modified signal then

returns to the ECM as an input signal. As the temperature

increases, EGR temperature sensor resistance decreases. This

sensor is not used to control the engine system.

It is used only for the on board diagnosis.

EGR temperature

ÉC (ÉF)Voltage*

VResistance

MW

0 (32) 4.56 0.62 - 1.05

50 (122) 2.25 0.065 - 0.094

100 (212) 0.59 0.011 - 0.015

*: These data are reference values and are measured between ECM terminal 72

(EGR temperature sensor) and ground.

When EGR system is operating.

Voltage: 0 - 1.5V

CAUTION:

Do not use ECM ground terminals when measuring input/

output voltage. Doing so may result in damage to the ECM's

transistor. Use a ground other than ECM terminals, such as

the ground.

On Board Diagnosis LogicNCEC0343

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P1401

1401A) An excessively low voltage from the EGR tempera-

ture sensor is sent to ECM even when engine cool-

ant temperature is low.IHarness or connectors

(The EGR temperature sensor circuit is shorted.)

IEGR temperature sensor

IMalfunction of EGR function

B) An excessively high voltage from the EGR tempera-

ture sensor is sent to ECM even when engine cool-

ant temperature is high.IHarness or connectors

(The EGR temperature sensor circuit is open.)

IEGR temperature sensor

IMalfunction of EGR function

DTC Confirmation ProcedureNCEC0344Perform ªPROCEDURE FOR MALFUNCTION Aº first. If 1st trip

DTC cannot be confirmed, perform ªPROCEDURE FOR MAL-

FUNCTION Bº.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

SEF599K

SEF068X

DTC P1401 EGR TEMPERATURE SENSOR

(IF SO EQUIPPED)QG16I18DE

Component Description

EC-300

Page 743 of 2267

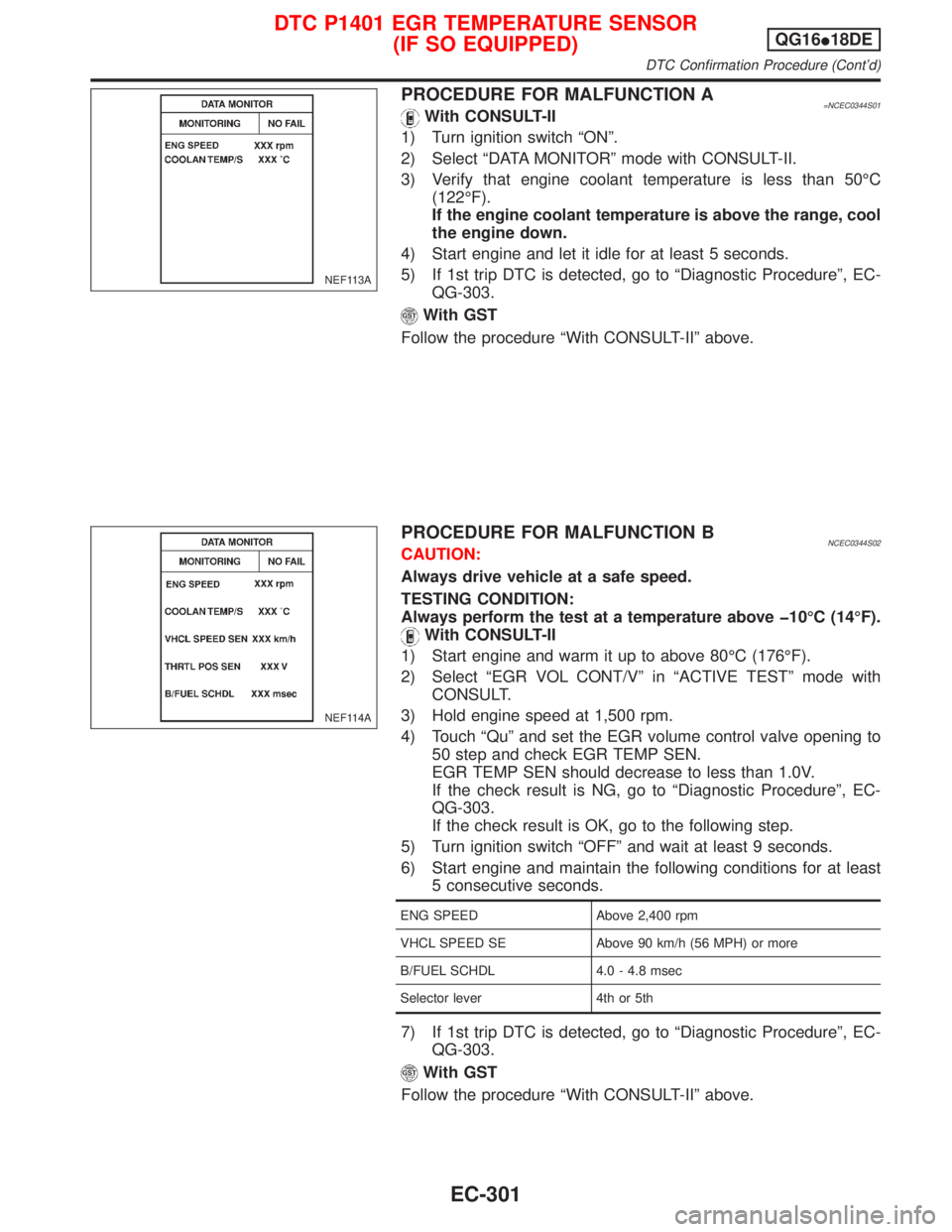

PROCEDURE FOR MALFUNCTION A=NCEC0344S01With CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Verify that engine coolant temperature is less than 50ÉC

(122ÉF).

If the engine coolant temperature is above the range, cool

the engine down.

4) Start engine and let it idle for at least 5 seconds.

5) If 1st trip DTC is detected, go to ªDiagnostic Procedureº, EC-

QG-303.

With GST

Follow the procedure ªWith CONSULT-IIº above.

PROCEDURE FOR MALFUNCTION BNCEC0344S02CAUTION:

Always drive vehicle at a safe speed.

TESTING CONDITION:

Always perform the test at a temperature above þ10ÉC (14ÉF).

With CONSULT-II

1) Start engine and warm it up to above 80ÉC (176ÉF).

2) Select ªEGR VOL CONT/Vº in ªACTIVE TESTº mode with

CONSULT.

3) Hold engine speed at 1,500 rpm.

4) Touch ªQuº and set the EGR volume control valve opening to

50 step and check EGR TEMP SEN.

EGR TEMP SEN should decrease to less than 1.0V.

If the check result is NG, go to ªDiagnostic Procedureº, EC-

QG-303.

If the check result is OK, go to the following step.

5) Turn ignition switch ªOFFº and wait at least 9 seconds.

6) Start engine and maintain the following conditions for at least

5 consecutive seconds.

ENG SPEED Above 2,400 rpm

VHCL SPEED SE Above 90 km/h (56 MPH) or more

B/FUEL SCHDL 4.0 - 4.8 msec

Selector lever 4th or 5th

7) If 1st trip DTC is detected, go to ªDiagnostic Procedureº, EC-

QG-303.

With GST

Follow the procedure ªWith CONSULT-IIº above.

NEF113A

NEF114A

DTC P1401 EGR TEMPERATURE SENSOR

(IF SO EQUIPPED)QG16I18DE

DTC Confirmation Procedure (Cont'd)

EC-301

Page 744 of 2267

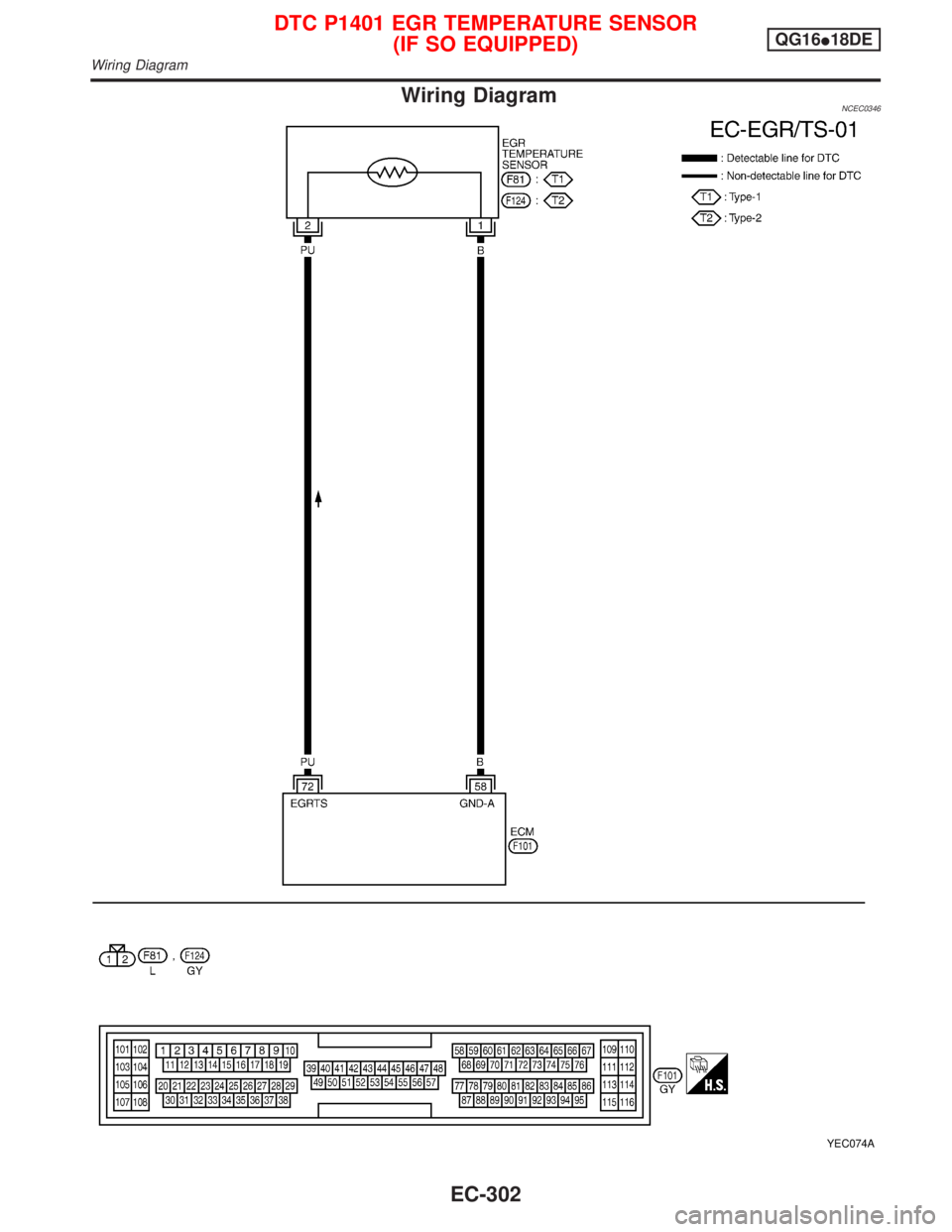

Wiring DiagramNCEC0346

YEC074A

DTC P1401 EGR TEMPERATURE SENSOR

(IF SO EQUIPPED)QG16I18DE

Wiring Diagram

EC-302

Page 745 of 2267

Diagnostic ProcedureNCEC0347

1 CHECK POWER SUPPLY

1. Turn ignition switch ªOFFº.

2. Disconnect EGR temperature sensor harness connector.

SEF127X3. Turn ignition switch ªONº.

4. Check voltage between terminal 2 and ground with CONSULT-II or tester.

SEF128XVoltage: Approximately 5V

OK or NG

OK©GO TO 2.

NG©Repair harness or connectors.

2 CHECK GROUND CIRCUIT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between EGR temperature sensor harness terminal 1 and engine ground. Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 4.

NG©GO TO 3.

3 DETECT MALFUNCTIONING PART

Check the harness for open or short between EGR temperature sensor and ECM.

©Repair open circuit or short to ground or short to power in harness or connector.

4 CHECK EGR TEMPERATURE SENSOR

Refer to ªComponent Inspectionº, EC-QG-304.

OK or NG

OK©GO TO 5.

NG©Replace EGR temperature sensor.

DTC P1401 EGR TEMPERATURE SENSOR

(IF SO EQUIPPED)QG16I18DE

Diagnostic Procedure

EC-303

Page 746 of 2267

5 CHECK EGR VOLUME CONTROL VALVE

Refer to ªComponent Inspectionº, EC-QG-251.

OK or NG

OK©GO TO 6.

NG©Replace EGR volume control valve.

6 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-QG-102.

©INSPECTION END

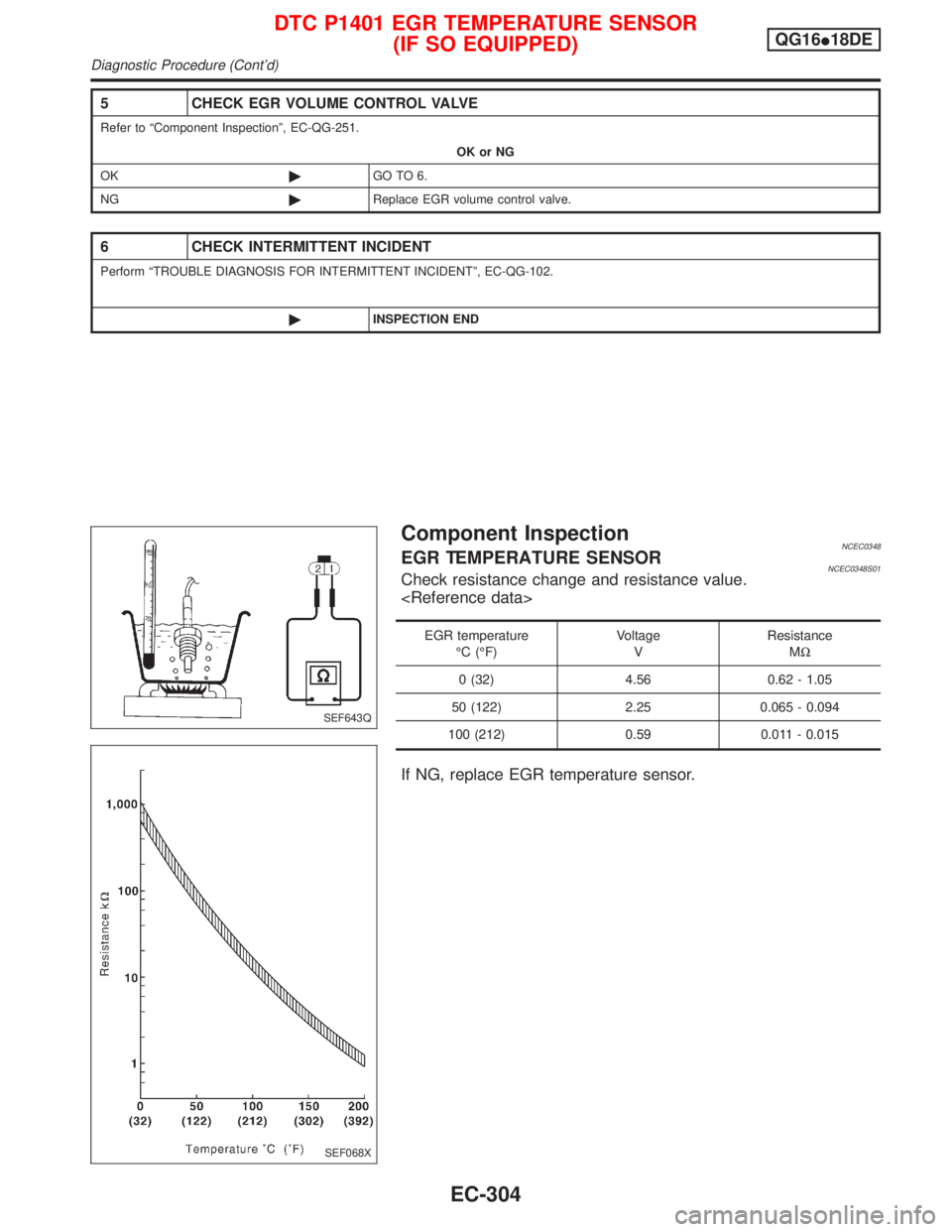

Component InspectionNCEC0348EGR TEMPERATURE SENSORNCEC0348S01Check resistance change and resistance value.

EGR temperature

ÉC (ÉF)Voltage

VResistance

MW

0 (32) 4.56 0.62 - 1.05

50 (122) 2.25 0.065 - 0.094

100 (212) 0.59 0.011 - 0.015

If NG, replace EGR temperature sensor.

SEF643Q

SEF068X

DTC P1401 EGR TEMPERATURE SENSOR

(IF SO EQUIPPED)QG16I18DE

Diagnostic Procedure (Cont'd)

EC-304

Page 747 of 2267

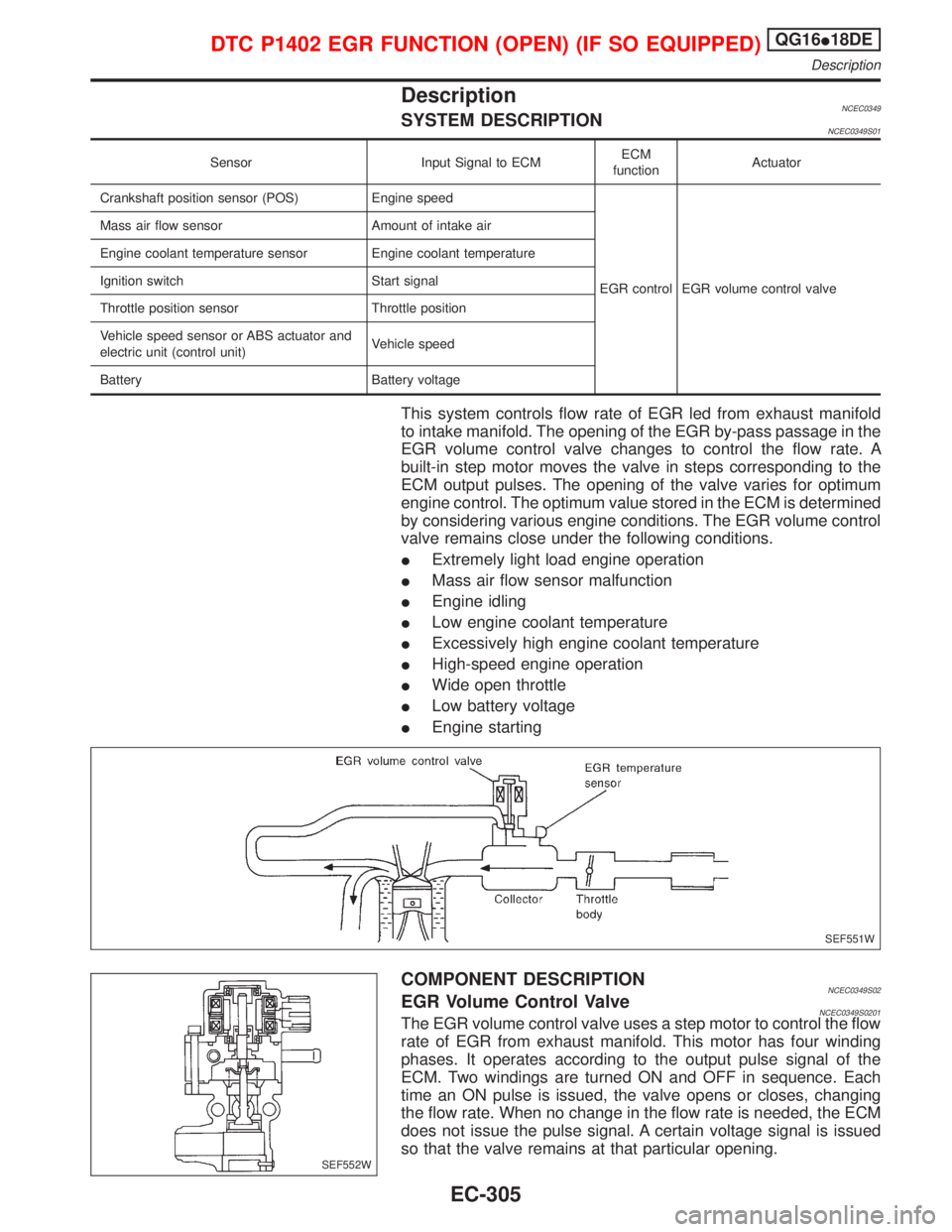

DescriptionNCEC0349SYSTEM DESCRIPTIONNCEC0349S01

Sensor Input Signal to ECMECM

functionActuator

Crankshaft position sensor (POS) Engine speed

EGR control EGR volume control valve Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Ignition switch Start signal

Throttle position sensor Throttle position

Vehicle speed sensor or ABS actuator and

electric unit (control unit)Vehicle speed

Battery Battery voltage

This system controls flow rate of EGR led from exhaust manifold

to intake manifold. The opening of the EGR by-pass passage in the

EGR volume control valve changes to control the flow rate. A

built-in step motor moves the valve in steps corresponding to the

ECM output pulses. The opening of the valve varies for optimum

engine control. The optimum value stored in the ECM is determined

by considering various engine conditions. The EGR volume control

valve remains close under the following conditions.

IExtremely light load engine operation

IMass air flow sensor malfunction

IEngine idling

ILow engine coolant temperature

IExcessively high engine coolant temperature

IHigh-speed engine operation

IWide open throttle

ILow battery voltage

IEngine starting

COMPONENT DESCRIPTIONNCEC0349S02EGR Volume Control ValveNCEC0349S0201The EGR volume control valve uses a step motor to control the flow

rate of EGR from exhaust manifold. This motor has four winding

phases. It operates according to the output pulse signal of the

ECM. Two windings are turned ON and OFF in sequence. Each

time an ON pulse is issued, the valve opens or closes, changing

the flow rate. When no change in the flow rate is needed, the ECM

does not issue the pulse signal. A certain voltage signal is issued

so that the valve remains at that particular opening.

SEF551W

SEF552W

DTC P1402 EGR FUNCTION (OPEN) (IF SO EQUIPPED)QG16I18DE

Description

EC-305

Page 748 of 2267

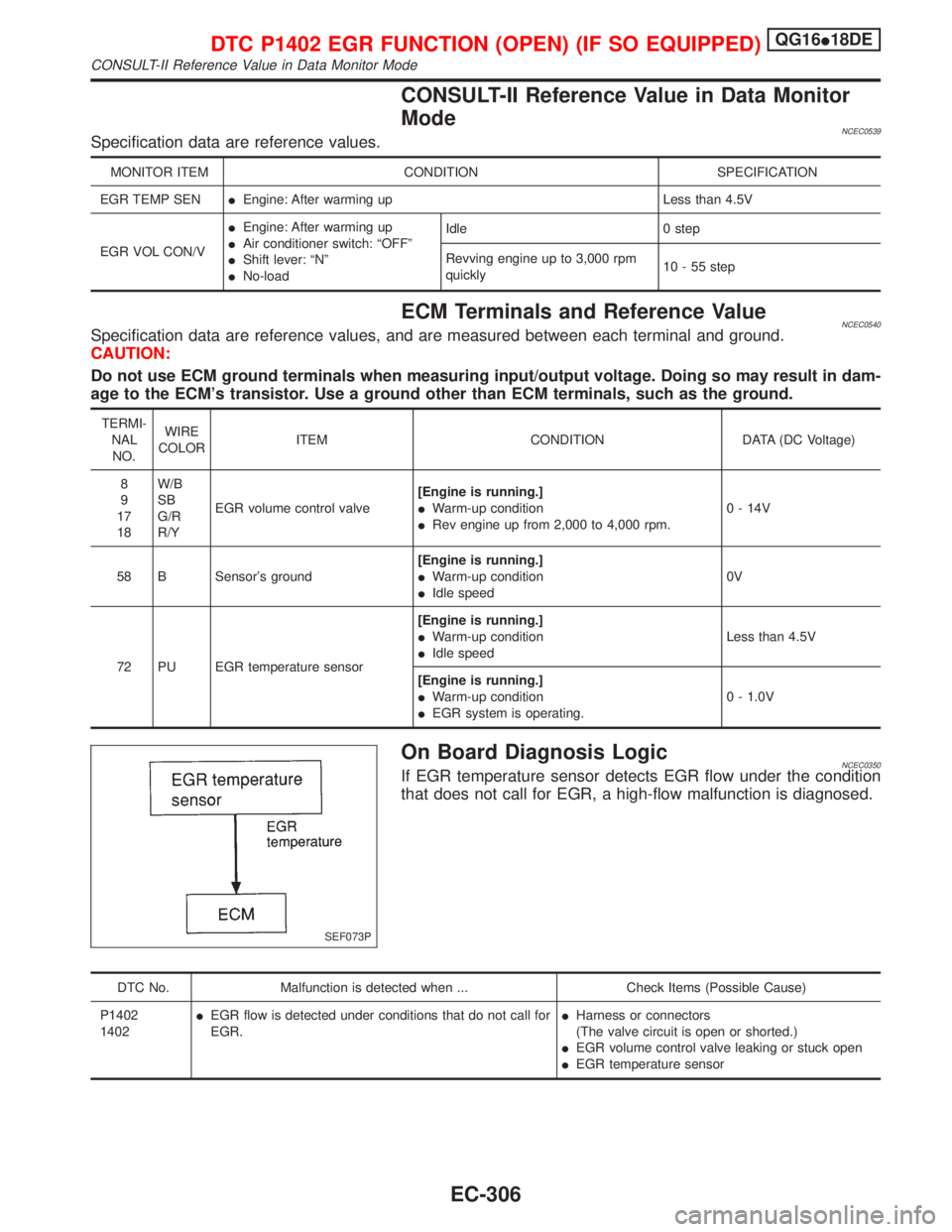

CONSULT-II Reference Value in Data Monitor

Mode

NCEC0539Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

EGR TEMP SENIEngine: After warming up Less than 4.5V

EGR VOL CON/VIEngine: After warming up

IAir conditioner switch: ªOFFº

IShift lever: ªNº

INo-loadIdle 0 step

Revving engine up to 3,000 rpm

quickly10 - 55 step

ECM Terminals and Reference ValueNCEC0540Specification data are reference values, and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

8

9

17

18W/B

SB

G/R

R/YEGR volume control valve[Engine is running.]

IWarm-up condition

IRev engine up from 2,000 to 4,000 rpm.0 - 14V

58 B Sensor's ground[Engine is running.]

IWarm-up condition

IIdle speed0V

72 PU EGR temperature sensor[Engine is running.]

IWarm-up condition

IIdle speedLess than 4.5V

[Engine is running.]

IWarm-up condition

IEGR system is operating.0 - 1.0V

On Board Diagnosis LogicNCEC0350If EGR temperature sensor detects EGR flow under the condition

that does not call for EGR, a high-flow malfunction is diagnosed.

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P1402

1402IEGR flow is detected under conditions that do not call for

EGR.IHarness or connectors

(The valve circuit is open or shorted.)

IEGR volume control valve leaking or stuck open

IEGR temperature sensor

SEF073P

DTC P1402 EGR FUNCTION (OPEN) (IF SO EQUIPPED)QG16I18DE

CONSULT-II Reference Value in Data Monitor Mode

EC-306

Page 749 of 2267

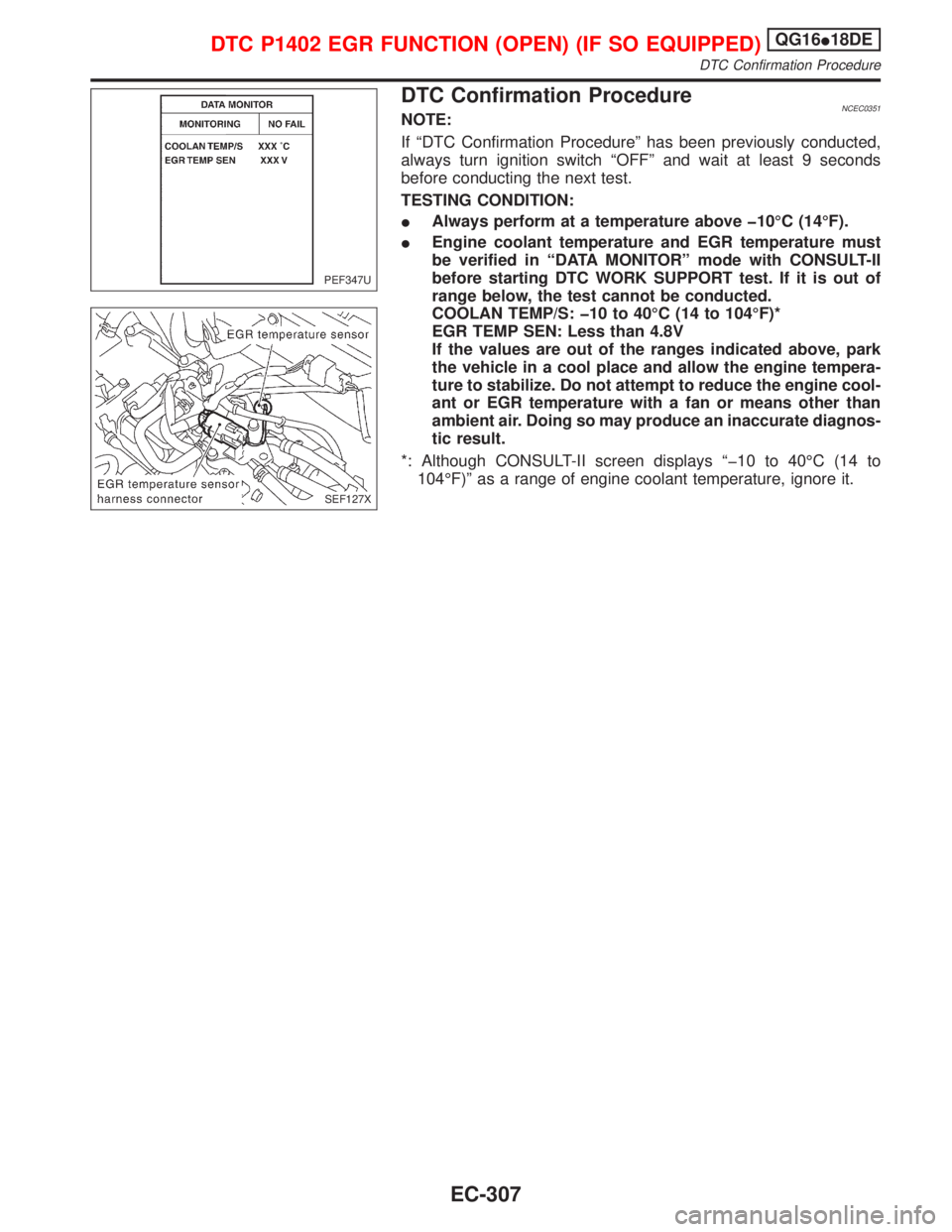

DTC Confirmation ProcedureNCEC0351NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

TESTING CONDITION:

IAlways perform at a temperature above þ10ÉC (14ÉF).

IEngine coolant temperature and EGR temperature must

be verified in ªDATA MONITORº mode with CONSULT-II

before starting DTC WORK SUPPORT test. If it is out of

range below, the test cannot be conducted.

COOLAN TEMP/S: þ10 to 40ÉC (14 to 104ÉF)*

EGR TEMP SEN: Less than 4.8V

If the values are out of the ranges indicated above, park

the vehicle in a cool place and allow the engine tempera-

ture to stabilize. Do not attempt to reduce the engine cool-

ant or EGR temperature with a fan or means other than

ambient air. Doing so may produce an inaccurate diagnos-

tic result.

*: Although CONSULT-II screen displays ªþ10 to 40ÉC (14 to

104ÉF)º as a range of engine coolant temperature, ignore it.

PEF347U

SEF127X

DTC P1402 EGR FUNCTION (OPEN) (IF SO EQUIPPED)QG16I18DE

DTC Confirmation Procedure

EC-307

Page 750 of 2267

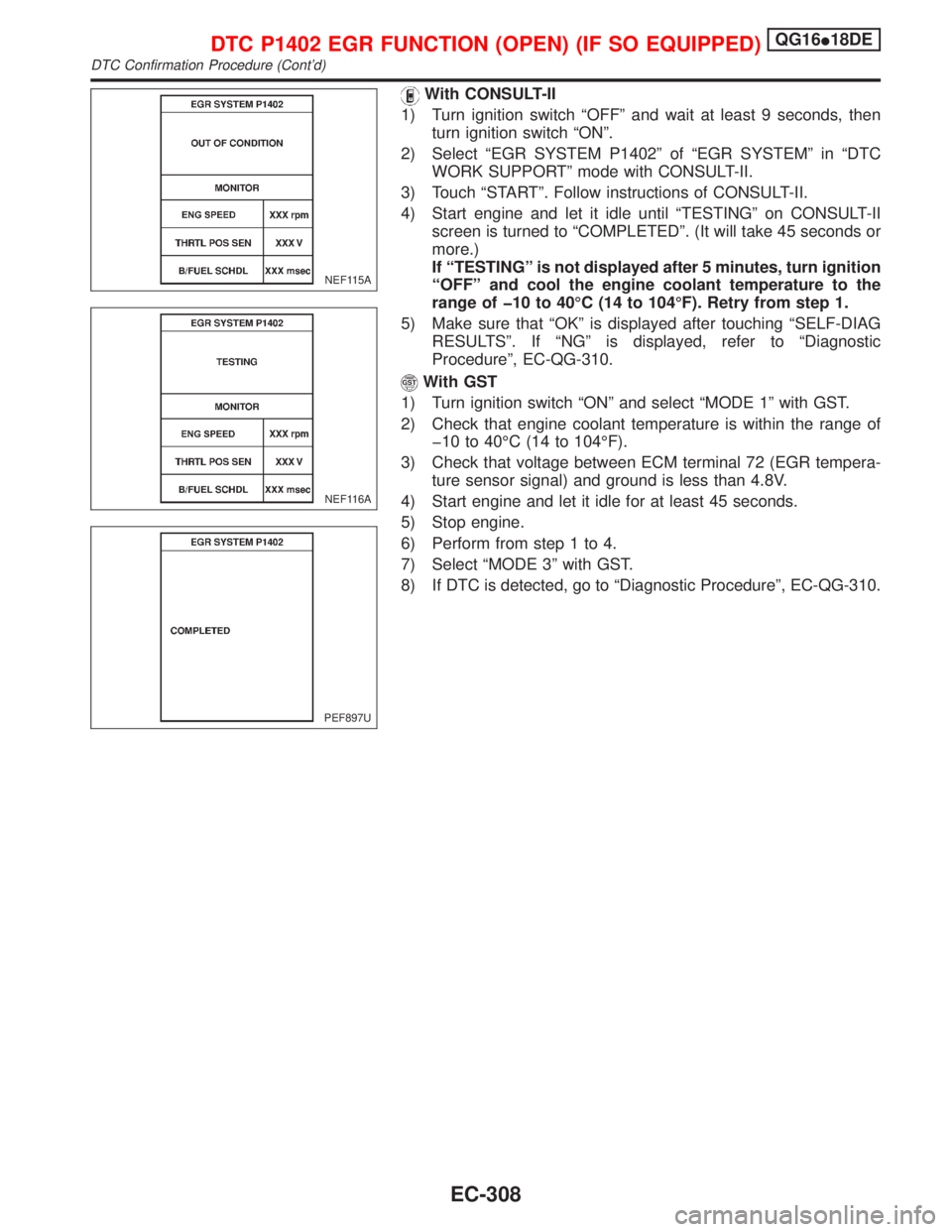

With CONSULT-II

1) Turn ignition switch ªOFFº and wait at least 9 seconds, then

turn ignition switch ªONº.

2) Select ªEGR SYSTEM P1402º of ªEGR SYSTEMº in ªDTC

WORK SUPPORTº mode with CONSULT-II.

3) Touch ªSTARTº. Follow instructions of CONSULT-II.

4) Start engine and let it idle until ªTESTINGº on CONSULT-II

screen is turned to ªCOMPLETEDº. (It will take 45 seconds or

more.)

If ªTESTINGº is not displayed after 5 minutes, turn ignition

ªOFFº and cool the engine coolant temperature to the

range of þ10 to 40ÉC (14 to 104ÉF). Retry from step 1.

5) Make sure that ªOKº is displayed after touching ªSELF-DIAG

RESULTSº. If ªNGº is displayed, refer to ªDiagnostic

Procedureº, EC-QG-310.

With GST

1) Turn ignition switch ªONº and select ªMODE 1º with GST.

2) Check that engine coolant temperature is within the range of

þ10 to 40ÉC (14 to 104ÉF).

3) Check that voltage between ECM terminal 72 (EGR tempera-

ture sensor signal) and ground is less than 4.8V.

4) Start engine and let it idle for at least 45 seconds.

5) Stop engine.

6) Perform from step 1 to 4.

7) Select ªMODE 3º with GST.

8) If DTC is detected, go to ªDiagnostic Procedureº, EC-QG-310.

NEF115A

NEF116A

PEF897U

DTC P1402 EGR FUNCTION (OPEN) (IF SO EQUIPPED)QG16I18DE

DTC Confirmation Procedure (Cont'd)

EC-308