NISSAN PRIMERA 1999 Electronic Repair Manual

PRIMERA 1999

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57377/w960_57377-0.png

NISSAN PRIMERA 1999 Electronic Repair Manual

Trending: oil dipstick, charging, check transmission fluid, dead battery, warning, jump start, remove seats

Page 771 of 2267

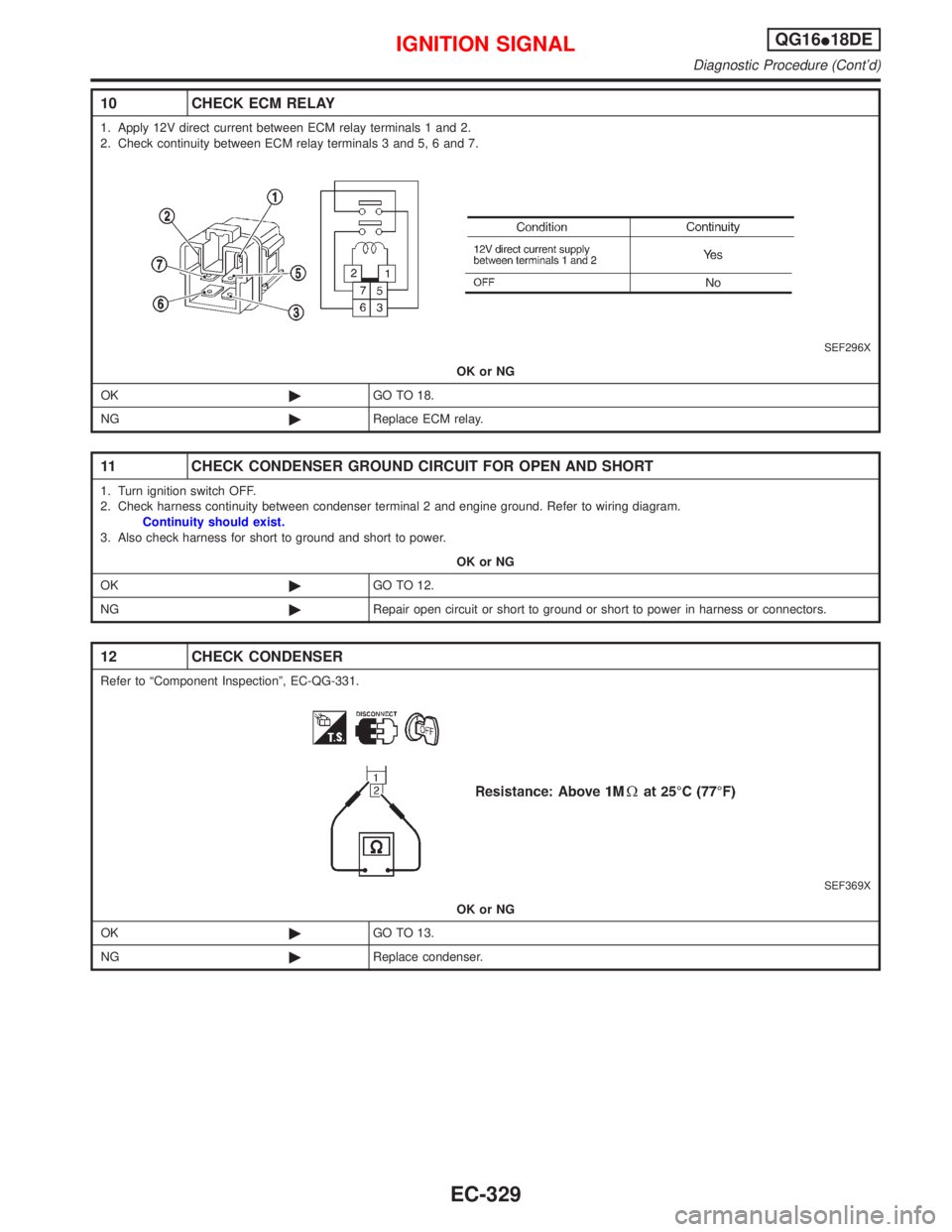

10 CHECK ECM RELAY

1. Apply 12V direct current between ECM relay terminals 1 and 2.

2. Check continuity between ECM relay terminals 3 and 5, 6 and 7.

SEF296X

OK or NG

OK©GO TO 18.

NG©Replace ECM relay.

11 CHECK CONDENSER GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Check harness continuity between condenser terminal 2 and engine ground. Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 12.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

12 CHECK CONDENSER

Refer to ªComponent Inspectionº, EC-QG-331.

SEF369X

OK or NG

OK©GO TO 13.

NG©Replace condenser.

IGNITION SIGNALQG16I18DE

Diagnostic Procedure (Cont'd)

EC-329

Page 772 of 2267

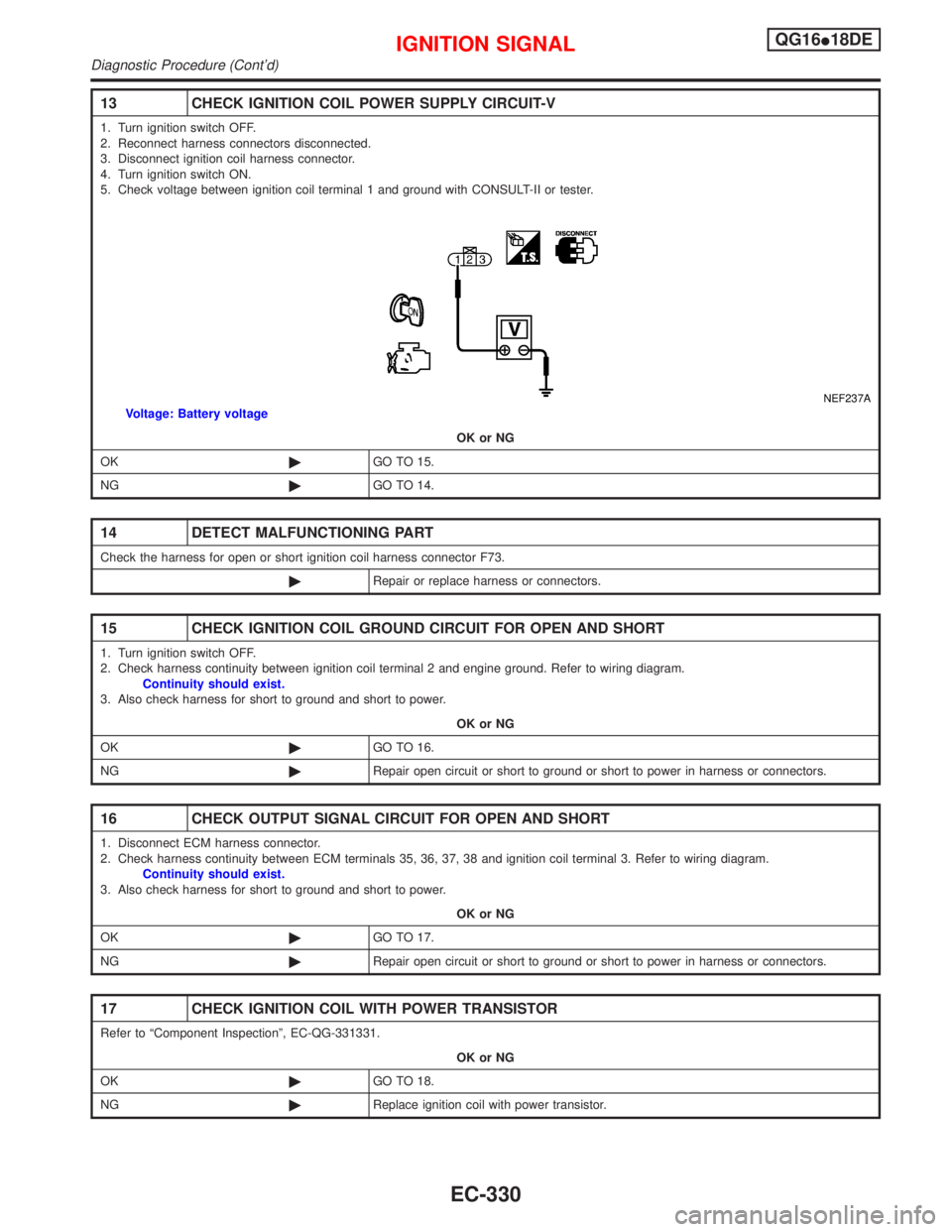

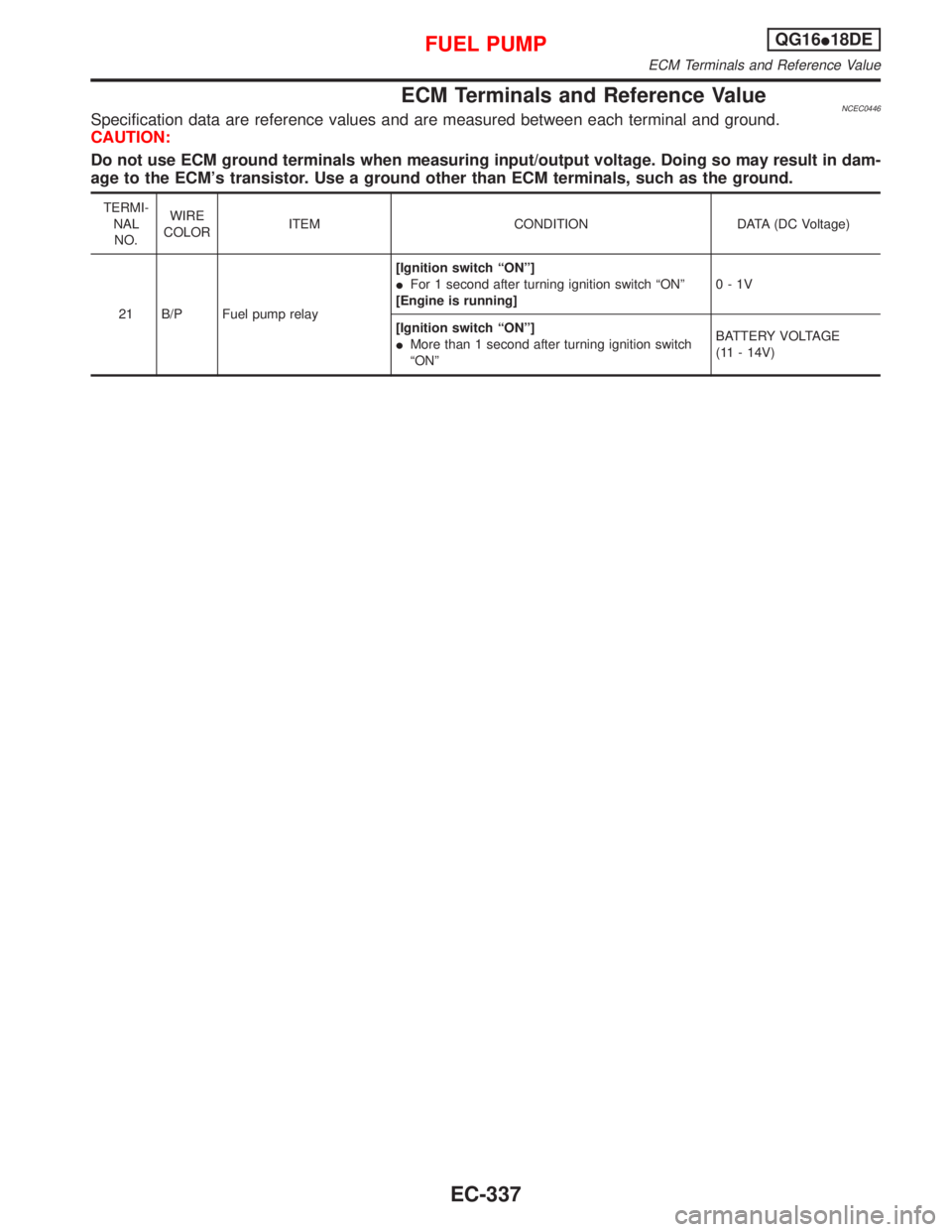

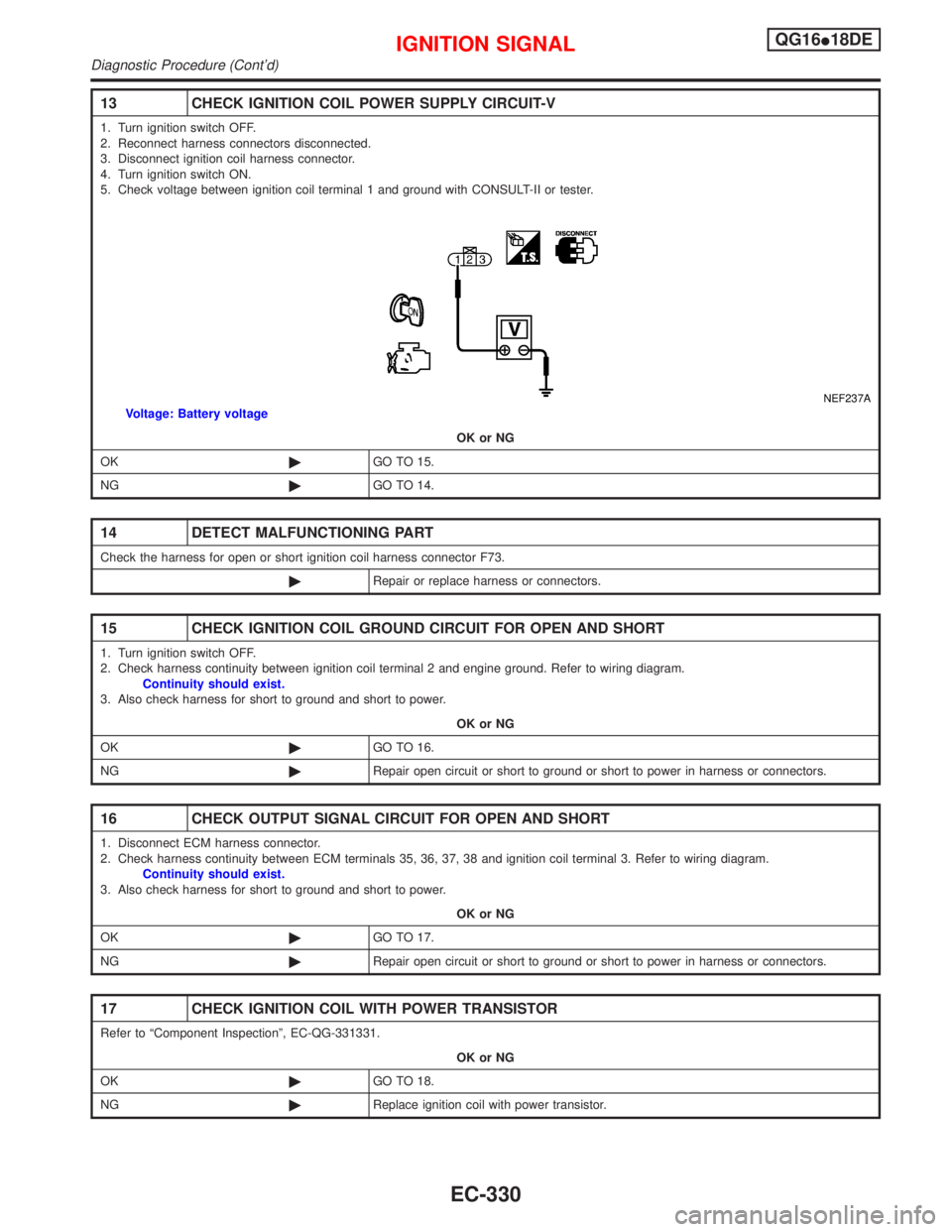

13 CHECK IGNITION COIL POWER SUPPLY CIRCUIT-V

1. Turn ignition switch OFF.

2. Reconnect harness connectors disconnected.

3. Disconnect ignition coil harness connector.

4. Turn ignition switch ON.

5. Check voltage between ignition coil terminal 1 and ground with CONSULT-II or tester.

NEF237AVoltage: Battery voltage

OK or NG

OK©GO TO 15.

NG©GO TO 14.

14 DETECT MALFUNCTIONING PART

Check the harness for open or short ignition coil harness connector F73.

©Repair or replace harness or connectors.

15 CHECK IGNITION COIL GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Check harness continuity between ignition coil terminal 2 and engine ground. Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 16.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

16 CHECK OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminals 35, 36, 37, 38 and ignition coil terminal 3. Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 17.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

17 CHECK IGNITION COIL WITH POWER TRANSISTOR

Refer to ªComponent Inspectionº, EC-QG-331331.

OK or NG

OK©GO TO 18.

NG©Replace ignition coil with power transistor.

IGNITION SIGNALQG16I18DE

Diagnostic Procedure (Cont'd)

EC-330

Page 773 of 2267

18 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-QG-102.

©INSPECTION END

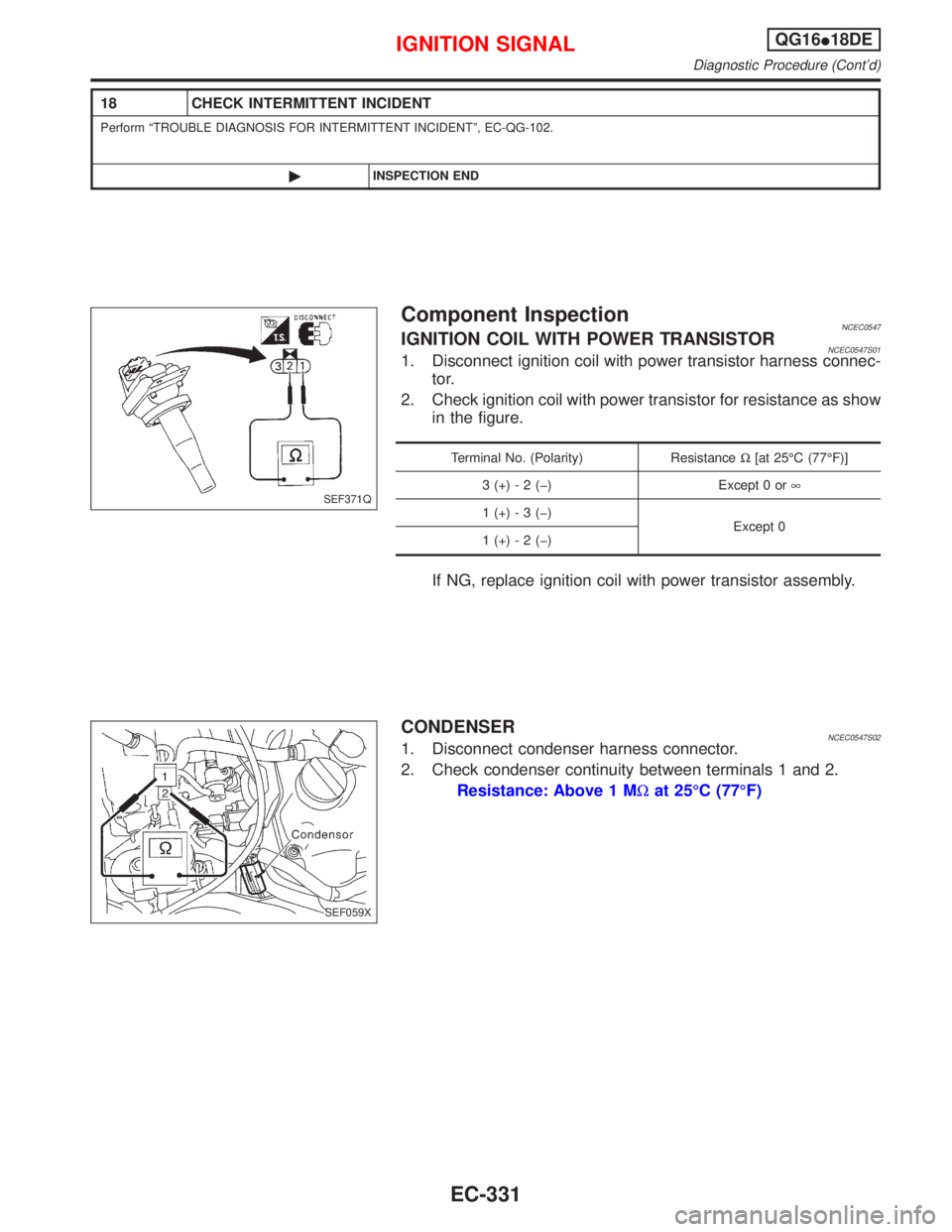

Component InspectionNCEC0547IGNITION COIL WITH POWER TRANSISTORNCEC0547S011. Disconnect ignition coil with power transistor harness connec-

tor.

2. Check ignition coil with power transistor for resistance as show

in the figure.

Terminal No. (Polarity) ResistanceW[at 25ÉC (77ÉF)]

3 (+) - 2 (þ) Except 0 or¥

1 (+) - 3 (þ)

Except 0

1 (+) - 2 (þ)

If NG, replace ignition coil with power transistor assembly.

CONDENSERNCEC0547S021. Disconnect condenser harness connector.

2. Check condenser continuity between terminals 1 and 2.

Resistance: Above 1 MWat 25ÉC (77ÉF)

SEF371Q

SEF059X

IGNITION SIGNALQG16I18DE

Diagnostic Procedure (Cont'd)

EC-331

Page 774 of 2267

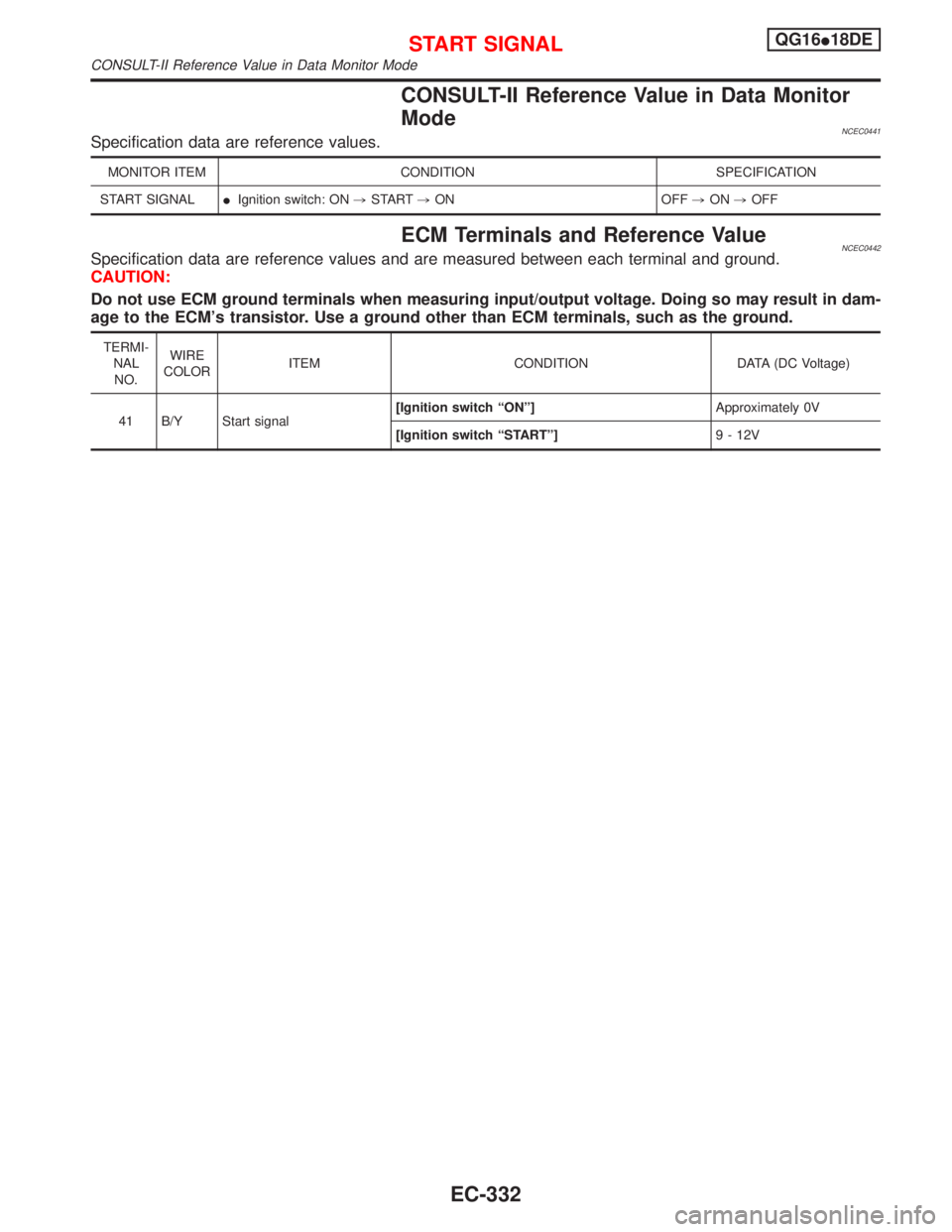

CONSULT-II Reference Value in Data Monitor

Mode

NCEC0441Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

START SIGNALIIgnition switch: ON,START,ON OFF,ON,OFF

ECM Terminals and Reference ValueNCEC0442Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

41 B/Y Start signal[Ignition switch ªONº]Approximately 0V

[Ignition switch ªSTARTº]9 - 12V

START SIGNALQG16I18DE

CONSULT-II Reference Value in Data Monitor Mode

EC-332

Page 775 of 2267

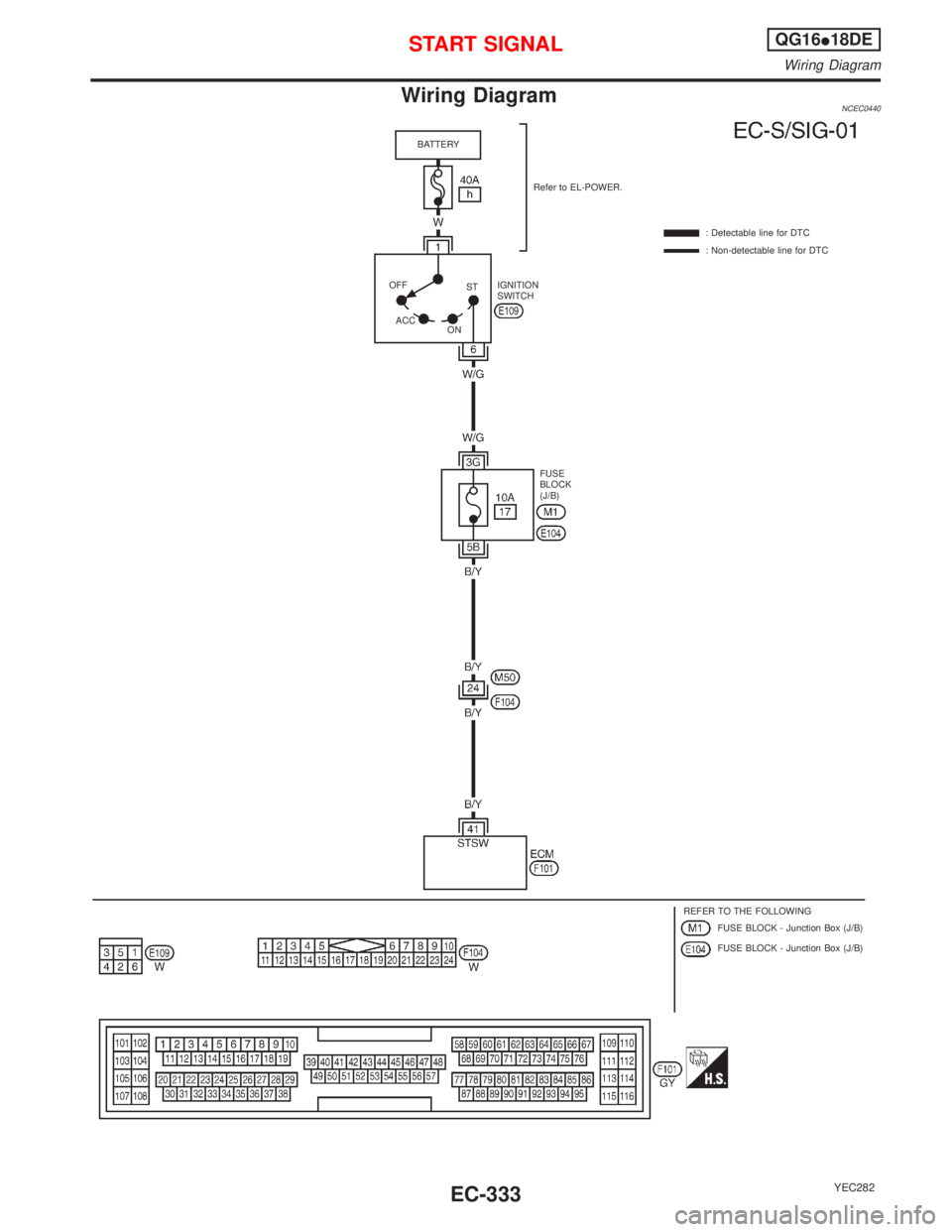

Wiring DiagramNCEC0440

YEC282

BATTERY

Refer to EL-POWER.

: Detectable line for DTC

: Non-detectable line for DTC

FUSE

BLOCK

(J/B) IGNITION

SWITCH

REFER TO THE FOLLOWING

FUSE BLOCK - Junction Box (J/B)

FUSE BLOCK - Junction Box (J/B) OFF

ACC

ONST

START SIGNALQG16I18DE

Wiring Diagram

EC-333

Page 776 of 2267

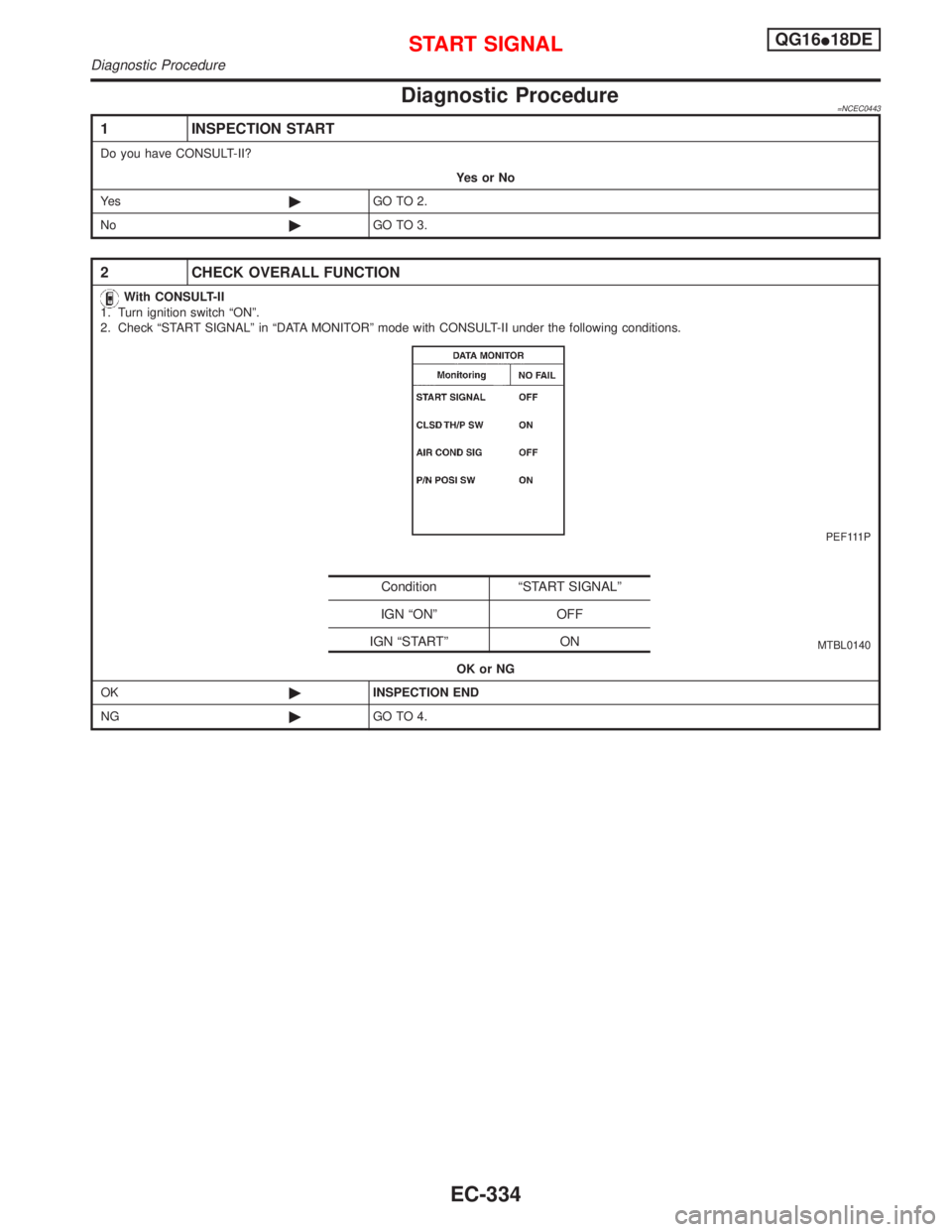

Diagnostic Procedure=NCEC0443

1 INSPECTION START

Do you have CONSULT-II?

YesorNo

Ye s©GO TO 2.

No©GO TO 3.

2 CHECK OVERALL FUNCTION

With CONSULT-II

1. Turn ignition switch ªONº.

2. Check ªSTART SIGNALº in ªDATA MONITORº mode with CONSULT-II under the following conditions.

PEF111P

MTBL0140

OK or NG

OK©INSPECTION END

NG©GO TO 4.

Condition ªSTART SIGNALº

IGN ªONº OFF

IGN ªSTARTº ON

START SIGNALQG16I18DE

Diagnostic Procedure

EC-334

Page 777 of 2267

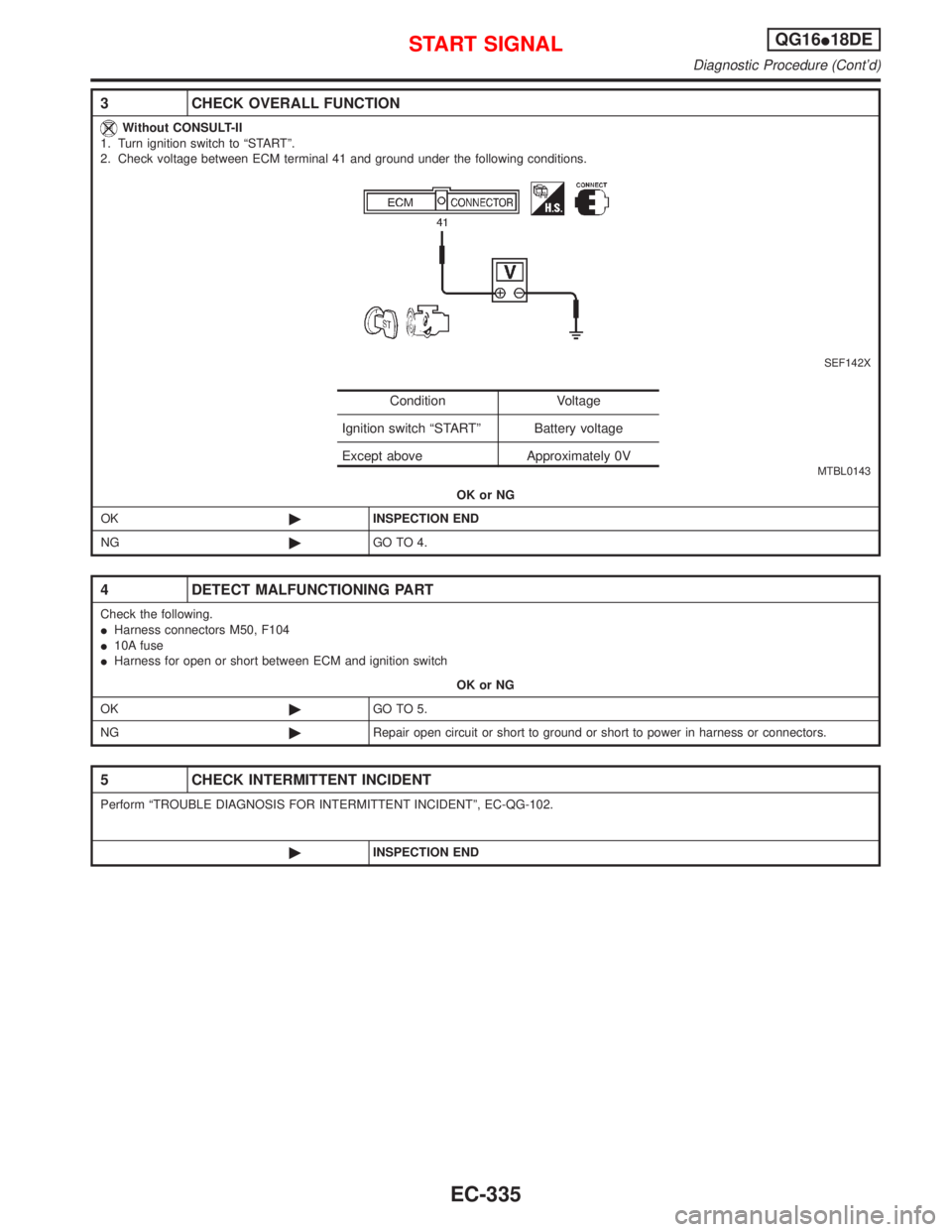

3 CHECK OVERALL FUNCTION

Without CONSULT-II

1. Turn ignition switch to ªSTARTº.

2. Check voltage between ECM terminal 41 and ground under the following conditions.

SEF142X

MTBL0143

OK or NG

OK©INSPECTION END

NG©GO TO 4.

4 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M50, F104

I10A fuse

IHarness for open or short between ECM and ignition switch

OK or NG

OK©GO TO 5.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

5 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-QG-102.

©INSPECTION END

Condition Voltage

Ignition switch ªSTARTº Battery voltage

Except above Approximately 0V

START SIGNALQG16I18DE

Diagnostic Procedure (Cont'd)

EC-335

Page 778 of 2267

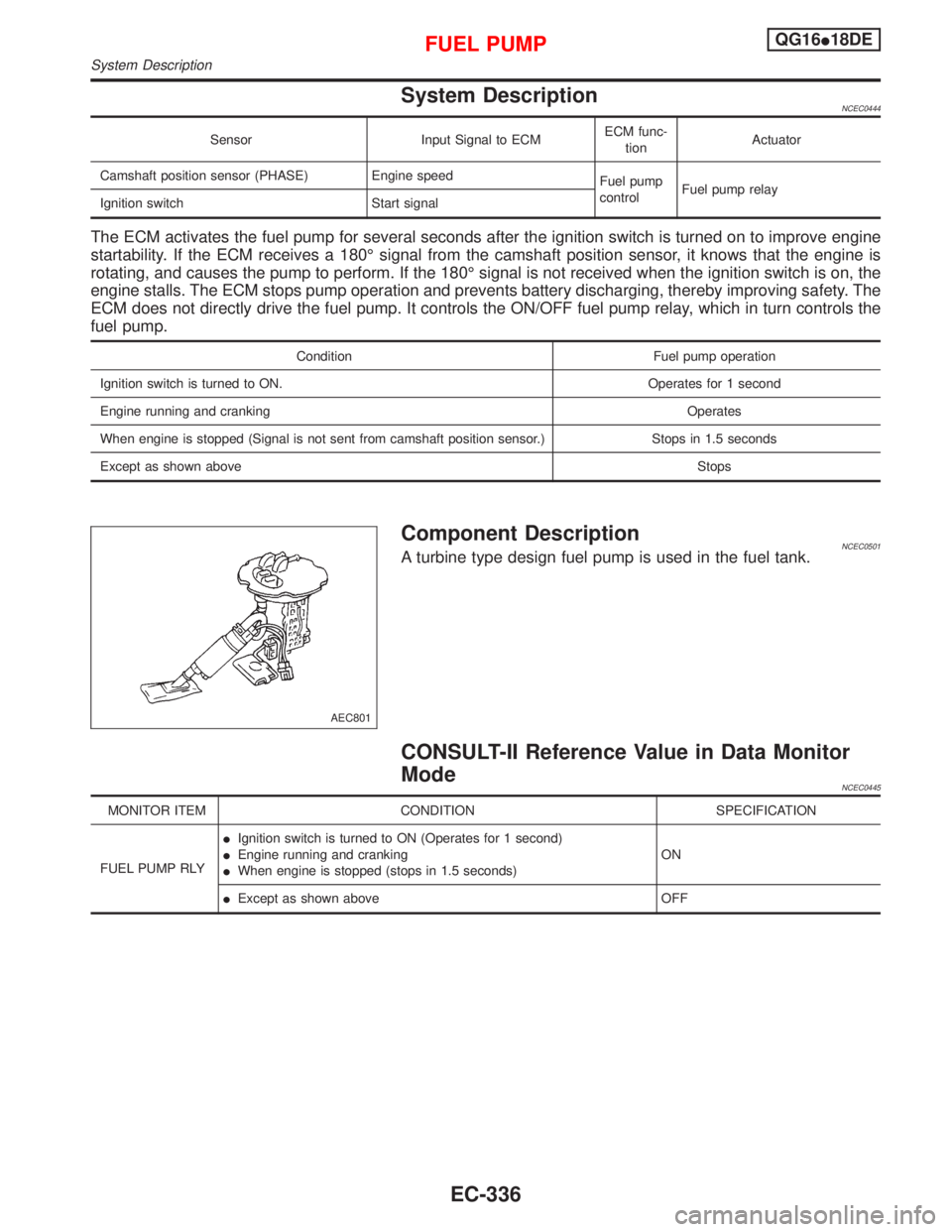

System DescriptionNCEC0444

Sensor Input Signal to ECMECM func-

tionActuator

Camshaft position sensor (PHASE) Engine speed

Fuel pump

controlFuel pump relay

Ignition switch Start signal

The ECM activates the fuel pump for several seconds after the ignition switch is turned on to improve engine

startability. If the ECM receives a 180É signal from the camshaft position sensor, it knows that the engine is

rotating, and causes the pump to perform. If the 180É signal is not received when the ignition switch is on, the

engine stalls. The ECM stops pump operation and prevents battery discharging, thereby improving safety. The

ECM does not directly drive the fuel pump. It controls the ON/OFF fuel pump relay, which in turn controls the

fuel pump.

Condition Fuel pump operation

Ignition switch is turned to ON. Operates for 1 second

Engine running and cranking Operates

When engine is stopped (Signal is not sent from camshaft position sensor.) Stops in 1.5 seconds

Except as shown aboveStops

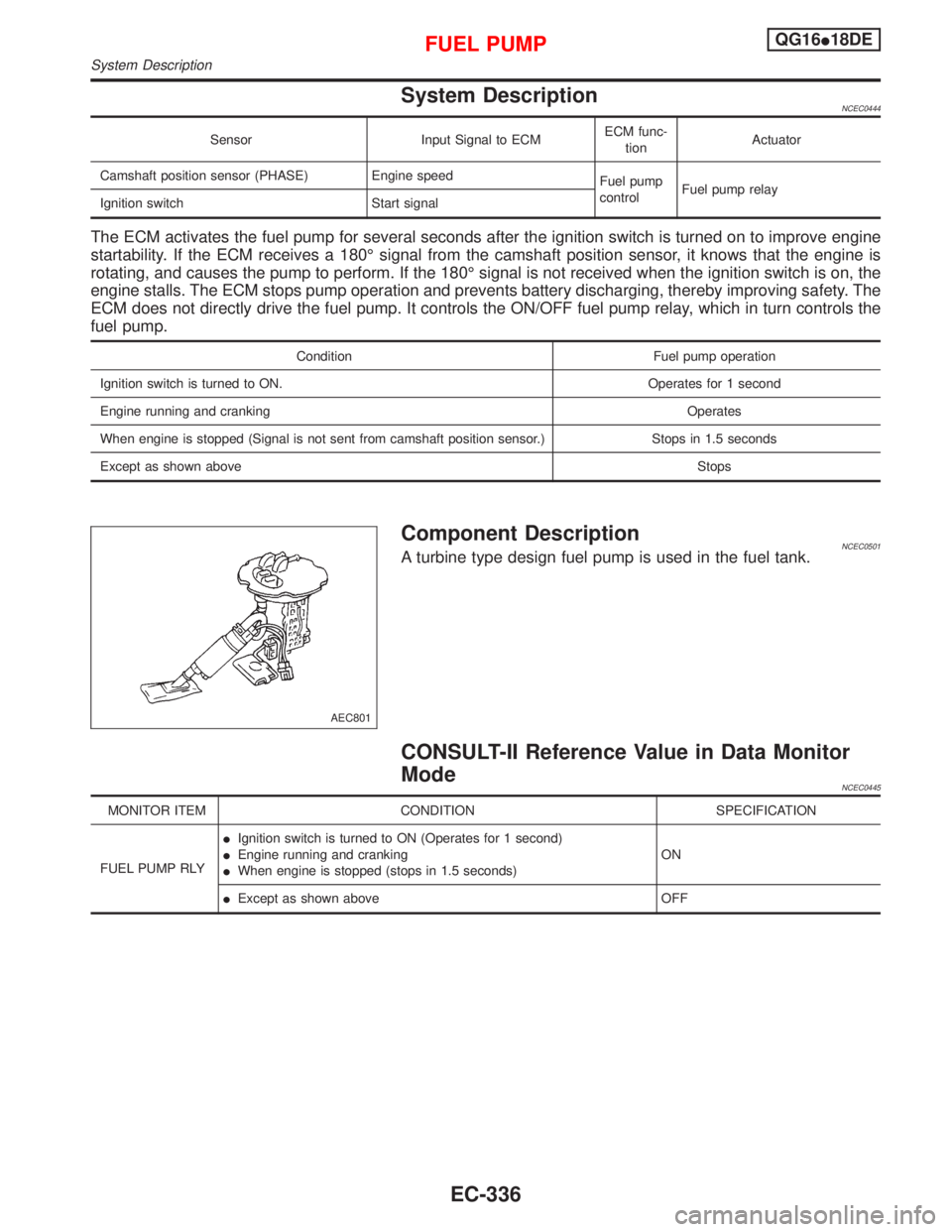

Component DescriptionNCEC0501A turbine type design fuel pump is used in the fuel tank.

CONSULT-II Reference Value in Data Monitor

Mode

NCEC0445

MONITOR ITEM CONDITION SPECIFICATION

FUEL PUMP RLYIIgnition switch is turned to ON (Operates for 1 second)

IEngine running and cranking

IWhen engine is stopped (stops in 1.5 seconds)ON

IExcept as shown above OFF

AEC801

FUEL PUMPQG16I18DE

System Description

EC-336

Page 779 of 2267

ECM Terminals and Reference ValueNCEC0446Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

21 B/P Fuel pump relay[Ignition switch ªONº]

IFor 1 second after turning ignition switch ªONº

[Engine is running]0-1V

[Ignition switch ªONº]

IMore than 1 second after turning ignition switch

ªONºBATTERY VOLTAGE

(11 - 14V)

FUEL PUMPQG16I18DE

ECM Terminals and Reference Value

EC-337

Page 780 of 2267

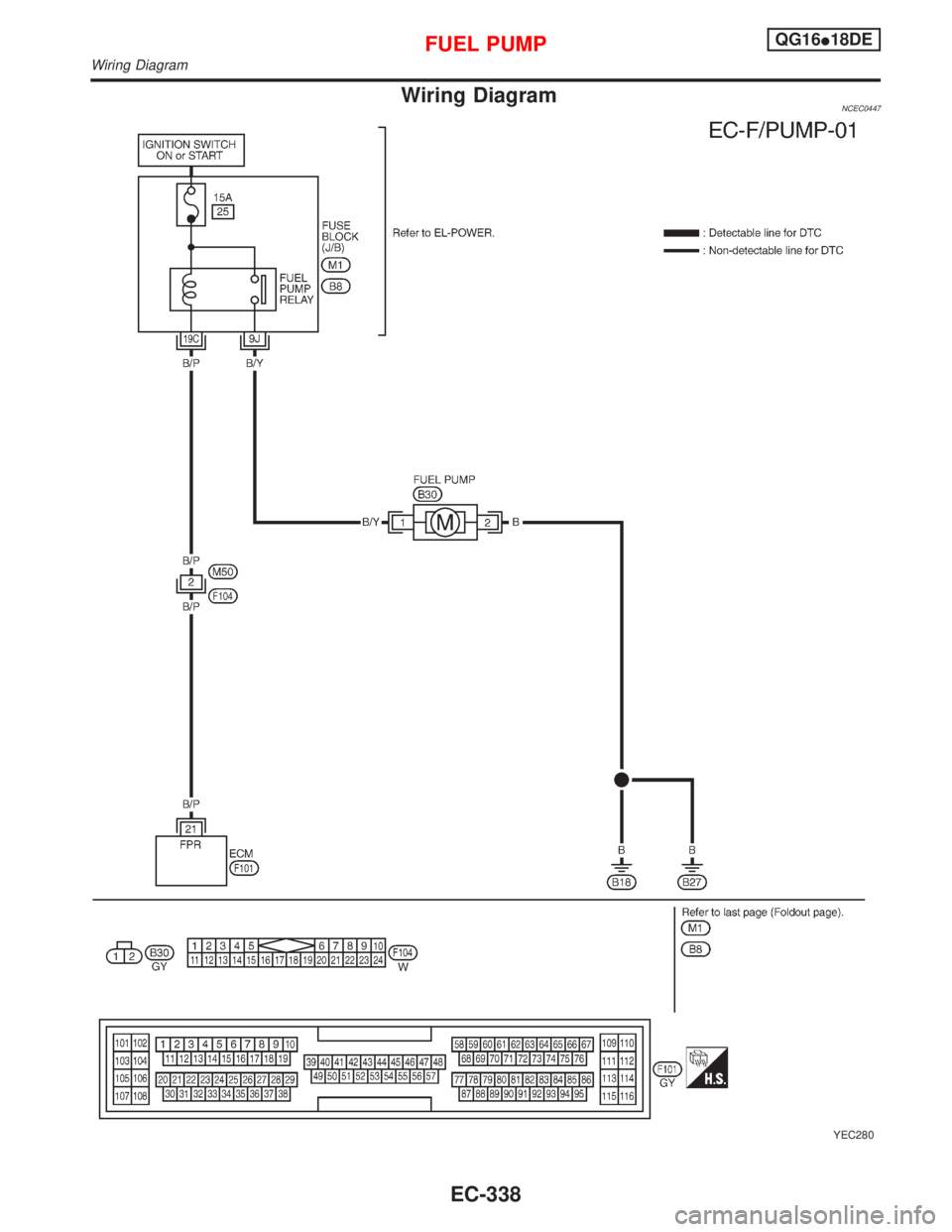

Wiring DiagramNCEC0447

YEC280

FUEL PUMPQG16I18DE

Wiring Diagram

EC-338

Trending: suspension, brakes, length, language, tires, steering wheel adjustment, warning