NISSAN PULSAR 1987 Owner's Guide

Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 31 of 238

Engine Tune-up

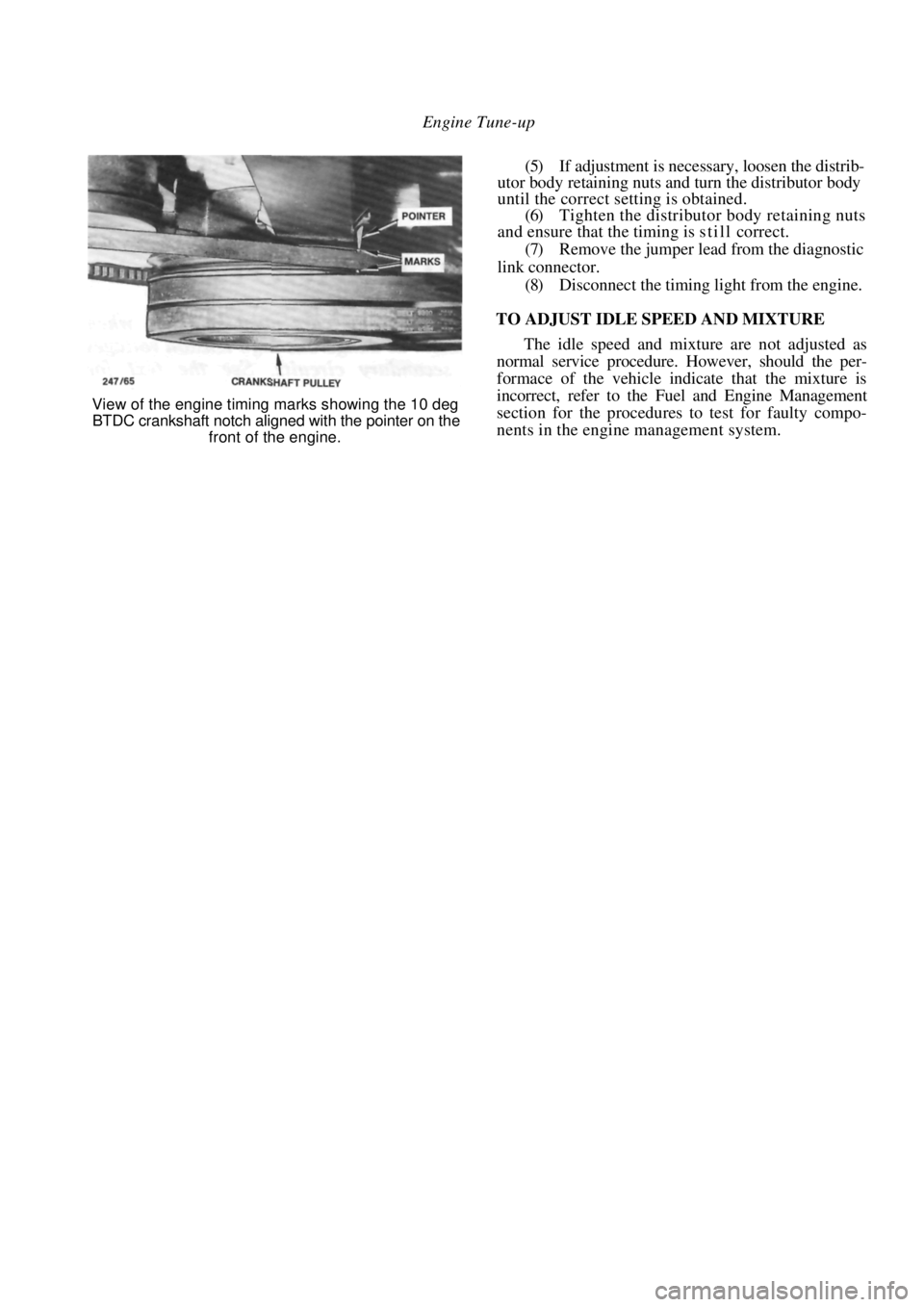

View of the engine timing marks showing the 10 deg

BTDC crankshaft notch aligned with the pointer on the

front of the engine.

(5) If adjustment is necessary, loosen the distrib-

utor body retaining nuts and turn the distributor body

until the correct setting is obtained.

(6) Tighten the distributor body retaining nuts

and ensure that the timing is still correct.

(7) Remove the jumper lead from the diagnostic

link connector.

(8) Disconnect the timing light from the engine.

TO ADJUST IDLE SPEED AND MIXTURE

The idle speed and mixt ure are not adjusted as

normal service procedure. However, should the per-

formace of the vehicle indicate that the mixture is

incorrect, refer to the Fuel and Engine Management

section for the procedures to test for faulty compo-

nents in the engine management system.

Page 32 of 238

32

ROADSIDE TROUBLE SHOOTING

CAUTION: To prevent severe electrical shock extreme care must be taken w\

hen

working on or near the electronic ignition system as dangerous high tension voltages

are produced in both the primary and secondary circuits. See the text fo\

r

precautionary notes.

This section deals with the common causes of

engine failure to start, as inevitably there will come a

time when every driver will experience this problem

and will therefore need to call upon his own resources

to rectify the trouble. Roadside breakdowns other

than engine failure can be identified by reference to

the Trouble Shooting section on the particular com-

ponent affected.

1. TROUBLE SHOOTING

Trouble shooting is only a process of elimination

and provided the procedure is carried out correctly

and systematically an accur ate diagnosis of the trouble

can be made in the minimum amount of time.

For an internal combustion engine to run there

are three basic requirements, these are ignition, fuel

and compression. There are other factors of course

but as a rule an engine's failure to start can be

attributed to a fault in one of these three systems.

Reports from field engineers of motoring organi-

sations prove that the bigg est percentage of engine

breakdowns are in the order of ignition or electrical

failure first, followed by fuel, with mechanical or

compression failure the least common.

Should the engine fail to start, first check that

there is adequate fuel in the tank and if so. carry out

the following checking procedures in the order de-

scribed.

TO JUMP START A VEHICLE

NOTE: Jump starting a vehicle can be

dangerous if the procedure described below

is not performed correctly. If any doubt

exists, it is recommended that the services of

a competent mechanic be obtained.

The vehicles covered by this manual are

equipped with complex electronic circuitry

which can be damaged by voltage surges.

These voltage surges can be generated when

jump starting, or being jump started by

another vehicle. If av ailable use jumper

leads equipped with a surge protection de-

vice and follow the lead manufacturers in-

structions carefully, particularly regarding

the connection and disconnection of the

leads.

(1) Ensure that the booster battery is 12 volts

and the negative terminal is earthed.

(2) Ensure that the vehicles are not touching and

that the ignition and all accessories on both vehicles

are switched Off. (3) Ensure that the transmissions on both vehi-

cles are in Park or Neutral and the handbrakes are

firmly applied. (4) Remove the vent caps from the battery and

check the electrolyte level. Replenish with distilled

water as necessary.

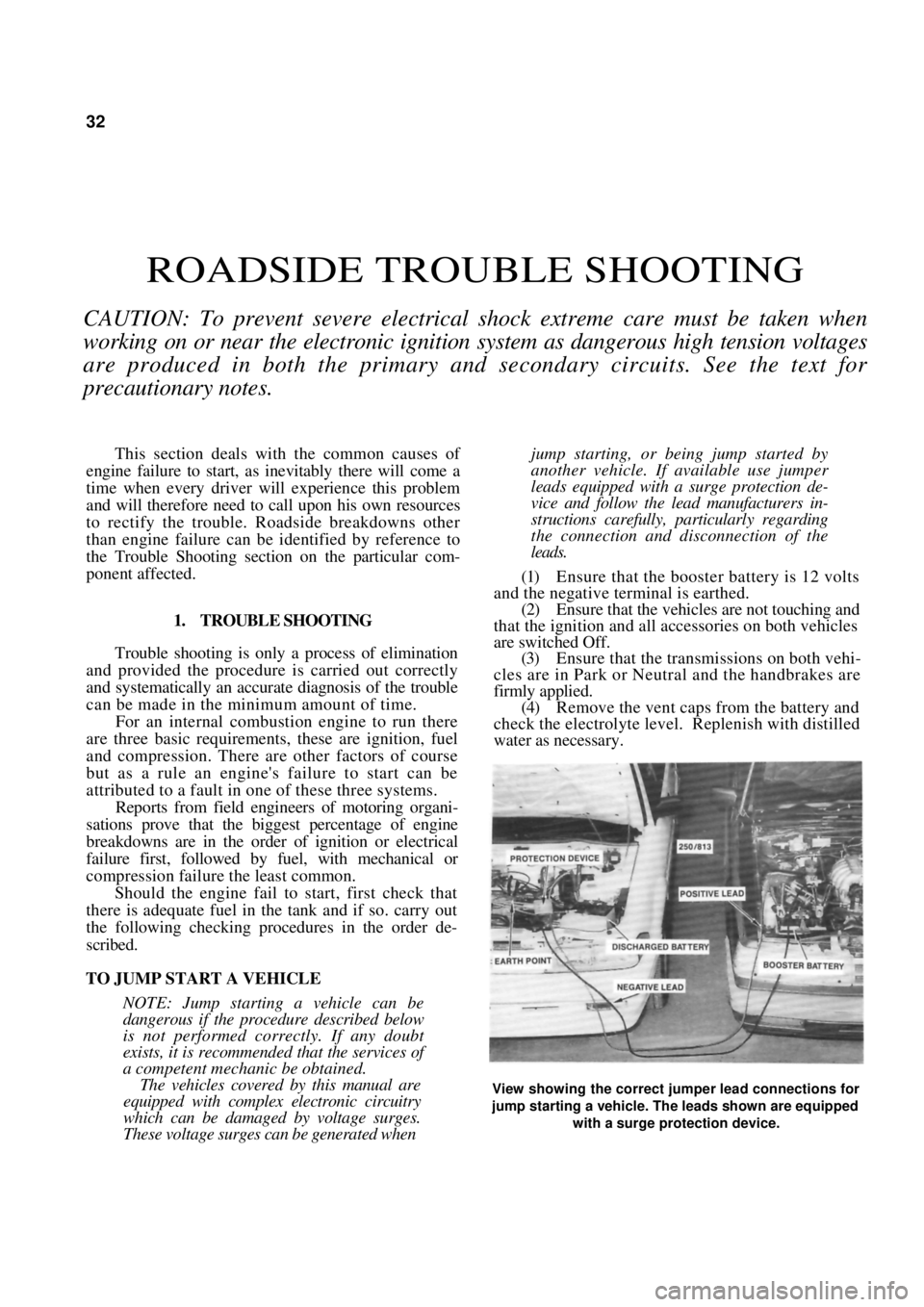

View showing the correct jumper lead connections for

jump starting a vehicle. The leads shown are equipped

with a surge protection device.

Page 33 of 238

Roadside Trouble Shooting

(5) Place the vent caps loosely over the cell

apertures.

(6) Connect one end of the red jumper lead to

the positive ( + ) battery terminal of the booster

battery and the other end of the red lead to the

positive (+) battery terminal of the discharged bat-

tery.

NOTE: The battery emits hydrogen gas

which is explosive. Do not expose the battery

to naked /lames or sparks.

Do not lean over the battery when con-

necting the jumper leads.

Do not allow the ends of the jumper leads

to touch one another or any part of the

engine.

(7) Connect one end of the black juniper lead to

the negative (-) battery terminal of the booster

battery and the other end of the black lead to a good

earthing point on the engine of the vehicle with the

discharged battery.

NOTE: Do not connect the jumper lead

directly to the negative (-) battery terminal

of the discharged battery.

(8) Start the engine on the vehicle with the

booster battery and run the engine at a moderate

speed. (9) Start the engine on the vehicle with the

discharged battery.

(10) If possible, leave the engines of both vehi-

cles running for 10 minutes.

(11) Disconnect the jumper leads in the reverse

order of the sequence in which they were connected.

2. TO CHECK IGNITION AND ELECTRICAL SYSTEM

(1) Switch on the ignition and check for warning

lamp illumination on the dashboard. (2) Operate the starter and check that the starter

rotates the engine at a steady speed.

(3) Switch on the headlamps and check for good

light intensity. Should the lamps not illum inate or the starter

motor not turn the engine, carry out the following

steps:

(a) Remove the battery terminals and clean both

terminals and posts. Connect the terminals and where

applicable tighten firmly but not excessively.

(b) Check that the earth lead from the battery to

the engine or body frame is not broken and that the

connections are clean and secure. . (c) Check that the lead from the battery to the

starter motor or starter solenoid is intact and has a

clean and secure connection.

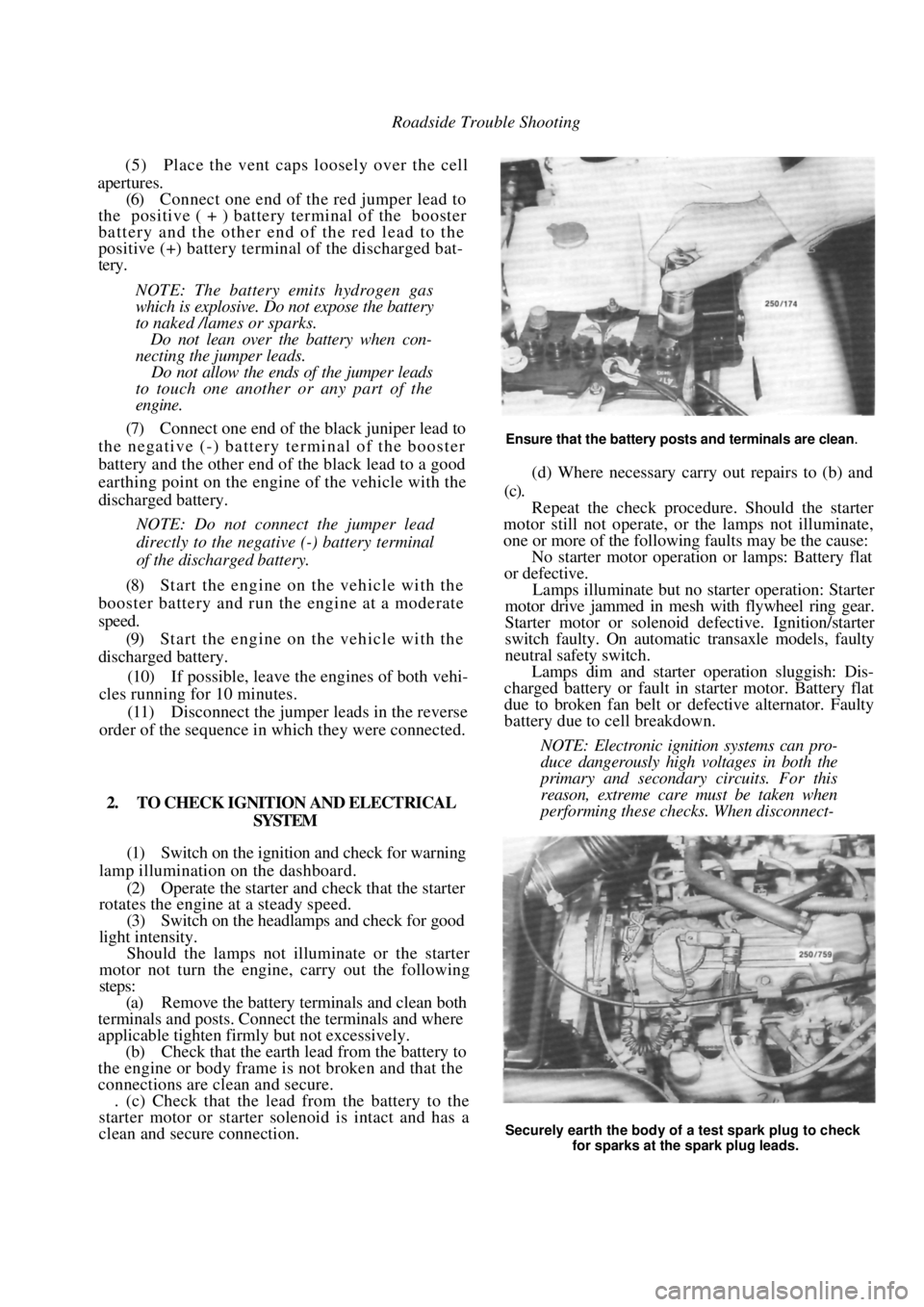

Ensure that the battery posts and terminals are clean.

(d) Where necessary carry out repairs to (b) and

(c).

Repeat the check procedur e. Should the starter

motor still not operate, or the lamps not illuminate,

one or more of the following faults may be the cause:

No starter motor operation or lamps: Battery flat

or defective.

Lamps illuminate but no starter operation: Starter

motor drive jammed in mesh with flywheel ring gear.

Starter motor or solenoid defective. Ignition/starter

switch faulty. On automatic transaxle models, faulty

neutral safety switch.

Lamps dim and starter operation sluggish: Dis-

charged battery or fault in starter motor. Battery flat

due to broken fan belt or de fective alternator. Faulty

battery due to cell breakdown.

NOTE: Electronic ignition systems can pro-

duce dangerously high voltages in both the

primary and secondary circuits. For this

reason, extreme care must be taken when

performing these checks. When disconnect-

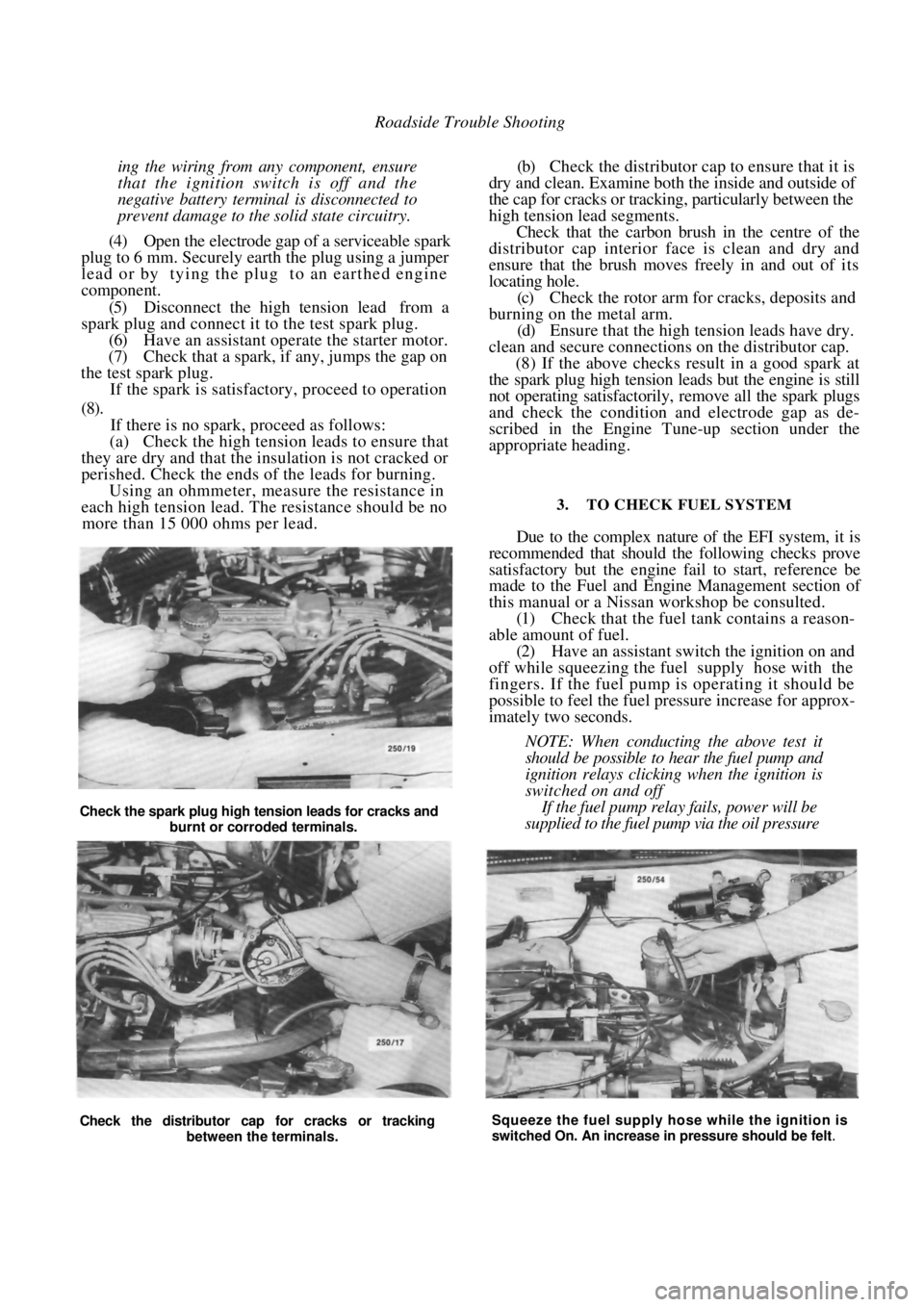

Securely earth the body of a test spark plug to check

for sparks at the spark plug leads.

Page 34 of 238

Roadside Trouble Shooting

ing the wiring from any component, ensure

that the ignition switch is off and the

negative battery terminal is disconnected to

prevent damage to the solid state circuitry.

(4) Open the electrode gap of a serviceable spark

plug to 6 mm. Securely earth the plug using a jumper

lead or by tying the plug to an earthed engine

component.

(5) Disconnect the high tension lead from a

spark plug and connect it to the test spark plug.

(6) Have an assistant operate the starter motor.

(7) Check that a spark, if any, jumps the gap on

the test spark plug. If the spark is satisfactory, proceed to operation

(8).

If there is no spark, proceed as follows:

(a) Check the high tension leads to ensure that

they are dry and that the insulation is not cracked or

perished. Check the ends of the leads for burning. Using an ohmmeter, measure the resistance in

each high tension lead. The resistance should be no

more than 15 000 ohms per lead.

(b) Check the distributor cap to ensure that it is

dry and clean. Examine both the inside and outside of

the cap for cracks or tracki ng, particularly between the

high tension lead segments.

Check that the carbon brush in the centre of the

distributor cap interior fa ce is clean and dry and

ensure that the brush moves freely in and out of its

locating hole.

(c) Check the rotor arm for cracks, deposits and

burning on the metal arm. (d) Ensure that the high tension leads have dry.

clean and secure connections on the distributor cap. (8) If the above checks r esult in a good spark at

the spark plug high tension leads but the engine is still

not operating satisfac torily, remove all the spark plugs

and check the condition and electrode gap as de-

scribed in the Engine Tune-up section under the

appropriate heading.

3. TO CHECK FUEL SYSTEM

Due to the complex nature of the EFI system, it is

recommended that should the following checks prove

satisfactory but the engine fail to start, reference be

made to the Fuel and Engine Management section of

this manual or a Nissan workshop be consulted.

(1) Check that the fuel tank contains a reason-

able amount of fuel. (2) Have an assistant switch the ignition on and

off while squeezing the fuel supply hose with the

fingers. If the fuel pump is operating it should be

possible to feel the fuel pr essure increase for approx-

imately two seconds.

NOTE: When conducting the above test it

should be possible to hear the fuel pump and

ignition relays clicking when the ignition is

switched on and off

If the fuel pump relay fails, power will be

supplied to the fuel pump via the oil pressure

Check the distributor cap for cracks or tracking between the terminals. Squeeze the fuel supply hose while the ignition is

switched On. An increase in pressure should be felt.

Check the spark plug high tension leads for cracks and

burnt or corroded terminals.

Page 35 of 238

Roadside Trouble Shooting 35

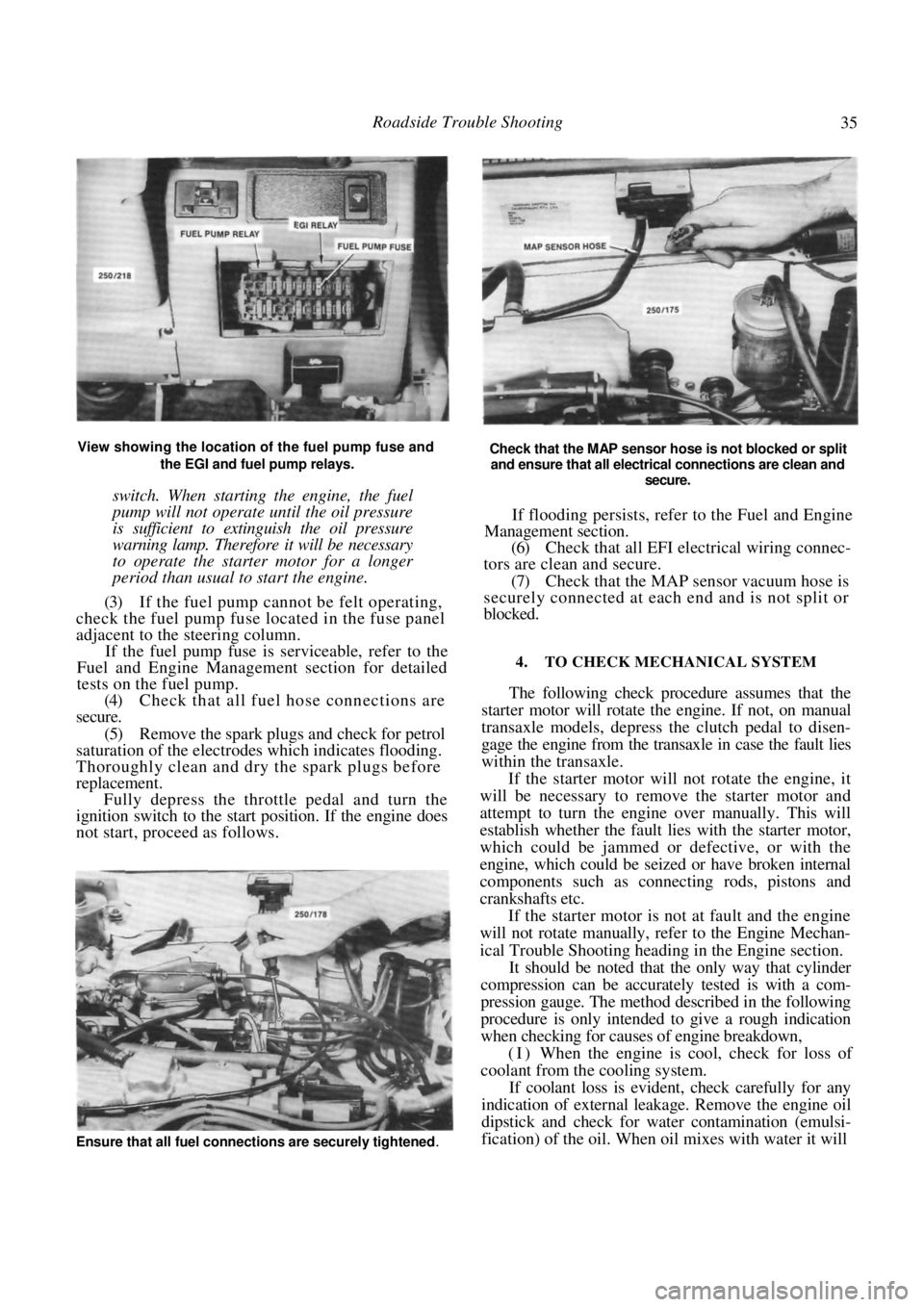

View showing the location of the fuel pump fuse and the EGI and fuel pump relays.

switch. When starting the engine, the fuel

pump will not operate until the oil pressure

is sufficient to extinguish the oil pressure

warning lamp. Therefore it will be necessary

to operate the starter motor for a longer

period than usual to start the engine.

(3) If the fuel pump cannot be felt operating,

check the fuel pump fuse located in the fuse panel

adjacent to the steering column.

If the fuel pump fuse is serviceable, refer to the

Fuel and Engine Management section for detailed

tests on the fuel pump.

(4) Check that all fuel hose connections are

secure.

(5) Remove the spark plugs and check for petrol

saturation of the electrodes which indicates flooding.

Thoroughly clean and dry the spark plugs before

replacement. Fully depress the throttle pedal and turn the

ignition switch to the start position. If the engine does

not start, proceed as follows.

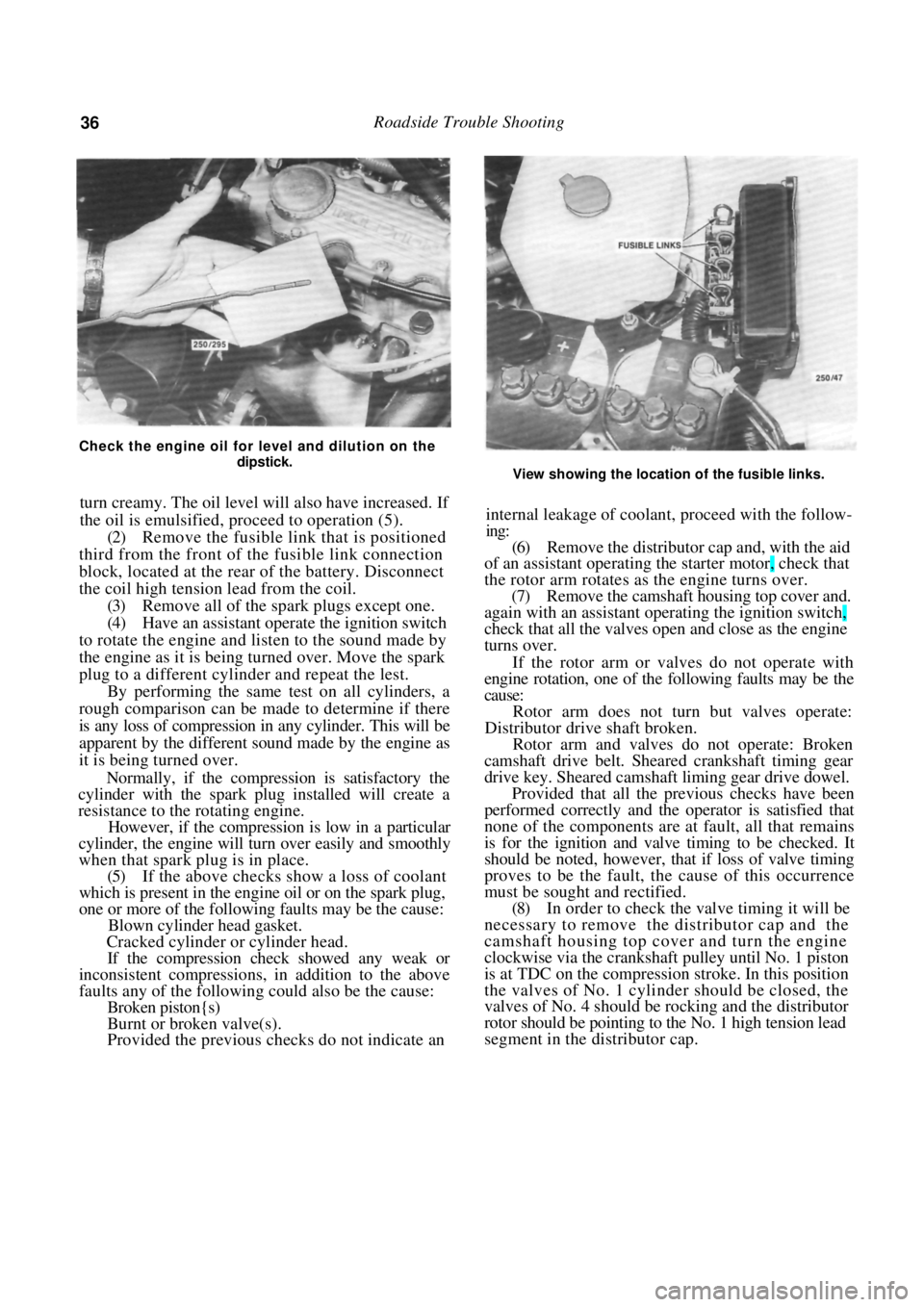

Check that the MAP sensor hose is not blocked or split

and ensure that all electrical connections are clean and

secure.

If flooding persists, refer to the Fuel and Engine

Management section.

(6) Check that all EFI electrical wiring connec-

tors are clean and secure.

(7) Check that the MAP sensor vacuum hose is

securely connected at each end and is not split or

blocked.

4. TO CHECK MECHANICAL SYSTEM

The following check procedure assumes that the

starter motor will rotate the engine. If not, on manual

transaxle models, depress the clutch pedal to disen-

gage the engine from the tr ansaxle in case the fault lies

within the transaxle.

If the starter motor will not rotate the engine, it

will be necessary to remove the starter motor and

attempt to turn the engine over manually. This will

establish whether the fault lies with the starter motor,

which could be jammed or defective, or with the

engine, which could be seized or have broken internal

components such as connecting rods, pistons and

crankshafts etc.

If the starter motor is not at fault and the engine

will not rotate manually, refer to the Engine Mechan-

ical Trouble Shooting heading in the Engine section.

It should be noted that the only way that cylinder

compression can be accurately tested is with a com-

pression gauge. The method described in the following

procedure is only intended to give a rough indication

when checking for causes of engine breakdown,

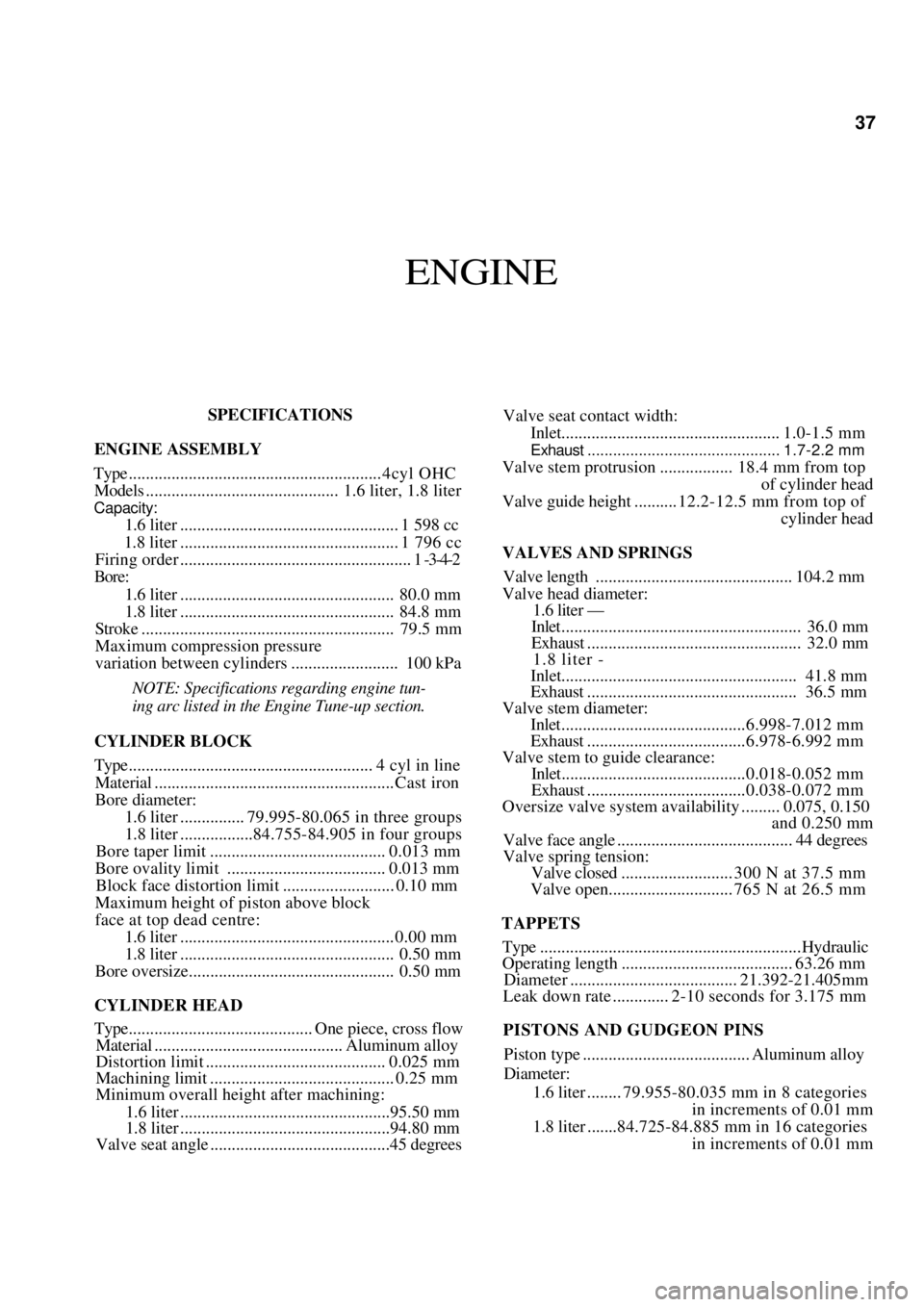

(I) When the engine is cool, check for loss of

coolant from the cooling system.

If coolant loss is evident, check carefully for any

indication of external leakage. Remove the engine oil

dipstick and check for wate r contamination (emulsi-

fication) of the oil. When oil mixes with water it will

Ensure that all fuel connections are securely tightened.

Page 36 of 238

36 Roadside Trouble Shooting

Check the engine oil for level and dilution on the dipstick.

turn creamy. The oil level will also have increased. If

the oil is emulsified, proceed to operation (5).

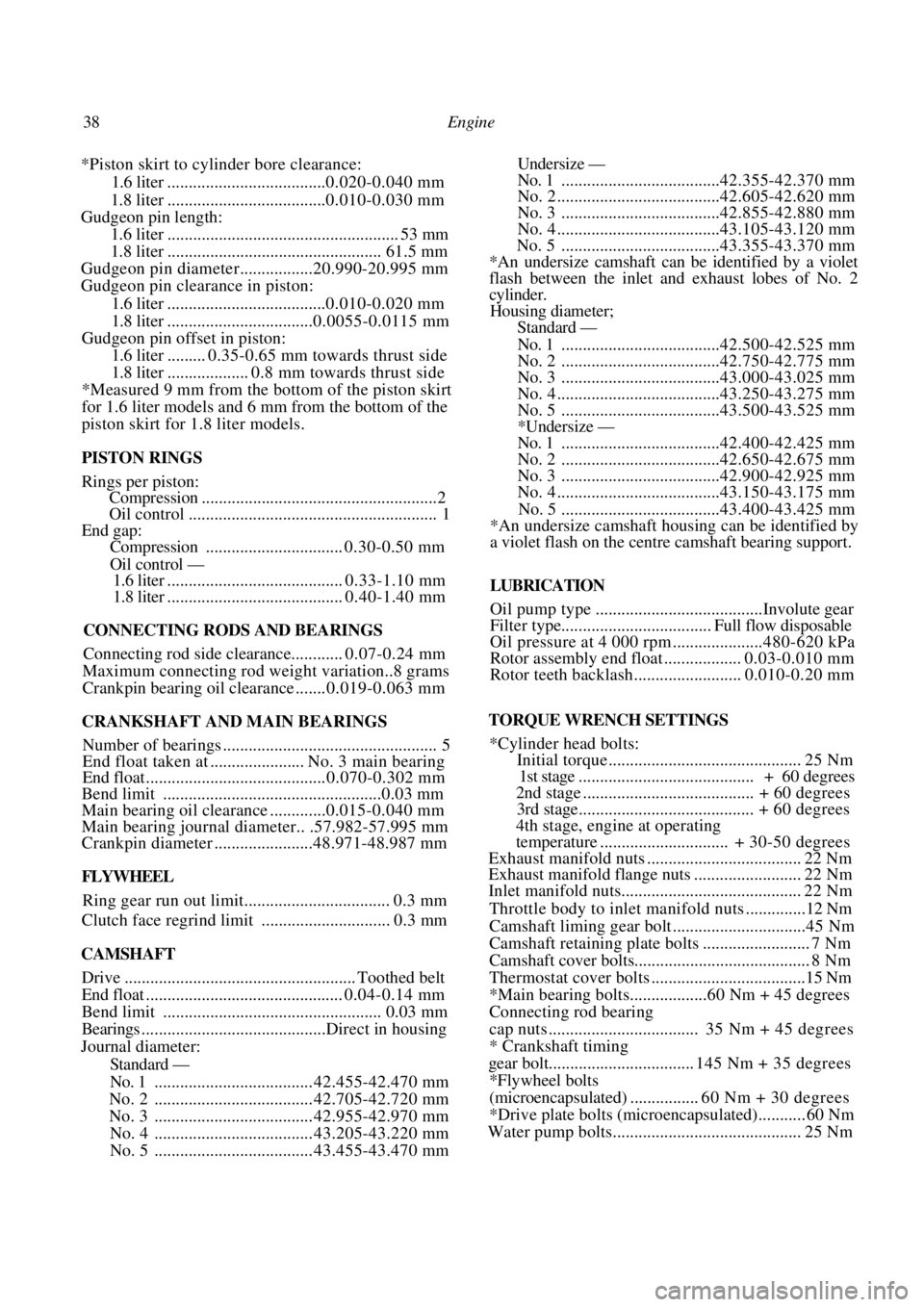

(2) Remove the fusible link that is positioned

third from the front of th e fusible link connection

block, located at the rear of the battery. Disconnect

the coil high tension lead from the coil. (3) Remove all of the spark plugs except one.

(4) Have an assistant operate the ignition switch

to rotate the engine and listen to the sound made by

the engine as it is being turned over. Move the spark

plug to a different cylinder and repeat the lest. By performing the same test on all cylinders, a

rough comparison can be made to determine if there

is any loss of compression in any cylinder. This will be

apparent by the different sound made by the engine as

it is being turned over.

Normally, if the compression is satisfactory the

cylinder with the spark plug installed will create a

resistance to the rotating engine.

However, if the compression is low in a particular

cylinder, the engine will tu rn over easily and smoothly

when that spark plug is in place.

(5) If the above checks show a loss of coolant

which is present in the engine oil or on the spark plug,

one or more of the following faults may be the cause:

Blown cylinder head gasket.

Cracked cylinder or cylinder head.

If the compression check showed any weak or

inconsistent compressions, in addition to the above

faults any of the following could also be the cause:

Broken piston{s)

Burnt or broken valve(s).

Provided the previous checks do not indicate an

View showing the location of the fusible links.

internal leakage of coolant, proceed with the follow-

ing:

(6) Remove the distributor cap and, with the aid

of an assistant operating th e starter motor, check that

the rotor arm rotates as the engine turns over. (7) Remove the camshaft hous ing top cover and.

again with an assistant operating the ignition switch,

check that all the valves open and close as the engine

turns over.

If the rotor arm or valves do not operate with

engine rotation, one of the following faults may be the

cause:

Rotor arm does not turn but valves operate:

Distributor drive shaft broken.

Rotor arm and valves do not operate: Broken

camshaft drive belt. Sheare d crankshaft timing gear

drive key. Sheared camshaft liming gear drive dowel.

Provided that all the previous checks have been

performed correctly and the operator is satisfied that

none of the components are at fault, all that remains

is for the ignition and valve timing to be checked. It

should be noted, however, that if loss of valve timing

proves to be the fault, th e cause of this occurrence

must be sought and rectified.

(8) In order to check the valve timing it will be

necessary to remove the distributor cap and the

camshaft housing top cover and turn the engine

clockwise via the crankshaft pulley until No. 1 piston

is at TDC on the compression stroke. In this position

the valves of No. 1 cylinder should be closed, the

valves of No. 4 should be rocking and the distributor

rotor should be pointing to the No. 1 high tension lead

segment in the distributor cap.

Page 37 of 238

37

ENGINE

SPECIFICATIONS

ENGINE ASSEMBLY

Type........................................................... 4cyl OHC

Models ............................................. 1.6 liter, 1.8 liter

Capacity:

1.6 liter ................................................... 1 598 cc

1.8 liter ................................................... 1 796 cc

Firing order ...................................................... 1 -3-4-2

Bore:

1.6 liter.................................................. 80.0 mm

1.8 liter.................................................. 84.8 mm

Stroke ........................................................... 79.5 mm

Maximum compression pressure

variation between cylinders ......................... 100 kPa

NOTE: Specifications re garding engine tun-

ing arc listed in the Engine Tune-up section.

CYLINDER BLOCK

Type......................................................... 4 cyl in line

Material ........................................................ Cast iron

Bore diameter:

1.6 liter ............... 79. 995-80.065 in three groups

1.8 liter .................84. 755-84.905 in four groups

Bore taper limit ......................................... 0. 013 mm

Bore ovality limit ..................................... 0.013 mm

Block face distortion limit .......................... 0.10 mm

Maximum height of piston above block

face at top dead centre:

1.6 liter.................................................. 0.00 mm

1.8 liter.................................................. 0.50 mm

Bore oversize................................................ 0.50 mm

CYLINDER HEAD

Type........................................... One piece, cross flow

Material ............................................ Aluminum alloy

Distortion limit .......................................... 0.025 mm

Machining li mit ........................................... 0.25 mm

Minimum overall height after machining:

1.6 liter .................................................95.50 mm

1.8 liter .................................................94.80 mm

Valve seat angle ..........................................45 degrees

Valve seat contact width:

Inlet................................................... 1.0-1.5 mm

Exhaust ............................................. 1.7-2.2 mm

Valve stem protrusion ................. 18.4 mm from top

of cylinder head

Valve guide height .......... 12.2-12.5 mm from top of

cylinder head

VALVES AND SPRINGS

Valve length .............................................. 104. 2 mm

Valve head diameter:

1.6 liter —

Inlet........................................................ 36.0 mm

Exhaust .................................................. 32.0 mm

1.8 liter -

Inlet....................................................... 41.8 mm

Exhaust ................................................. 36.5 mm

Valve stem diameter:

Inlet...........................................6. 998-7.012 mm

Exhaust .....................................6.978-6.992 mm

Valve stem to guide clearance:

Inlet...........................................0.018-0.052 mm

Exhaust .....................................0.038-0.072 mm

Oversize valve system availability......... 0.075, 0.150

and 0.250 mm

Valve face angle ......................................... 44 degrees

Valve spring tension:

Valve closed .......................... 300 N at 37.5 mm

Valve open............................. 765 N at 26.5 mm

TAPPETS

Type .............................................................Hydraulic

Operating length ........................................ 63.26 mm

Diameter ....................................... 21.392-21.405mm

Leak down rate ............. 2-10 sec onds for 3.175 mm

PISTONS AND GUDGEON PINS

Piston type ....................................... Aluminum alloy

Diameter:

1.6 liter ........ 79. 955-80.035 mm in 8 categories

in increments of 0.01 mm

1.8 liter .......84.725-84.885 mm in 16 categories

in increments of 0.01 mm

Page 38 of 238

38 Engine

*Piston skirt to cylinder bore clearance:

1.6 liter .....................................0. 020-0.040 mm

1.8 liter .....................................0. 010-0.030 mm

Gudgeon pin length:

1.6 liter ...................................................... 53 mm

1.8 liter .................................................. 61.5 mm

Gudgeon pin diameter.................20.990-20.995 mm

Gudgeon pin clearance in piston:

1.6 liter .....................................0. 010-0.020 mm

1.8 liter ..................................0. 0055-0.0115 mm

Gudgeon pin offset in piston:

1.6 liter......... 0.35-0.65 mm towards thrust side

1.8 liter................... 0.8 mm towards thrust side

*Measured 9 mm from the bottom of the piston skirt

for 1.6 liter models and 6 mm from the bottom of the

piston skirt for 1.8 liter models.

PISTON RINGS

Rings per piston:

Compression .......................................................2

Oil contro l .......................................................... 1

End gap:

Compression ................................ 0.30-0.50 mm

Oil control —

1.6 liter ......................................... 0.33-1.10 mm

1.8 liter ......................................... 0.40-1.40 mm

CONNECTING RODS AND BEARINGS

Connecting rod side clearance............ 0.07-0.24 mm

Maximum connecting rod weight variation..8 grams

Crankpin bearing oil clearance ....... 0. 019-0.063 mm

CRANKSHAFT AND MAIN BEARINGS

Number of bearings .................................................. 5

End float taken at ...................... No. 3 main bearing

End float .......................................... 0.070-0.302 mm

Bend limit ...................................................0.03 mm

Main bearing oil clearance .............0. 015-0.040 mm

Main bearing journal diameter.. .57.982-57.995 mm

Crankpin diameter .......................48.971-48.987 mm

FLYWHEEL

Ring gear run out limit.................................. 0.3 mm

Clutch face regrind limit .............................. 0.3 mm

CAMSHAFT

Drive ...................................................... Toothed belt

End float .............................................. 0.04-0.14 mm

Bend limit ................................................... 0.03 mm

Bearings ...........................................Direct in housing

Journal diameter:

Standard —

No. 1 ..................................... 42. 455-42.470 mm

No. 2 ..................................... 42. 705-42.720 mm

No. 3 ..................................... 42.955-42.970 mm

No. 4 ..................................... 43.205-43.220 mm

No. 5 ..................................... 43.455-43.470 mm

Undersize —

No. 1 .....................................42.355-42.370 mm

No. 2 ......................................42.605-42.620 mm

No. 3 .....................................42.855-42.880 mm

No. 4 ......................................43.105-43.120 mm

No. 5 .....................................43. 355-43.370 mm

*An undersize camshaft can be identified by a violet

flash between the inlet and exhaust lobes of No. 2

cylinder.

Housing diameter;

Standard —

No. 1 .....................................42. 500-42.525 mm

No. 2 .....................................42.750-42.775 mm

No. 3 .....................................43.000-43.025 mm

No. 4 ......................................43.250-43.275 mm

No. 5 .....................................43.500-43.525 mm

*Undersize —

No. 1 .....................................42.400-42.425 mm

No. 2 .....................................42.650-42.675 mm

No. 3 .....................................42.900-42.925 mm

No. 4 ......................................43.150-43.175 mm

No. 5 .....................................43.400-43.425 mm

*An undersize camshaft housing can be identified by

a violet flash on the centre camshaft bearing support.

LUBRICATION

Oil pump type .......................................Involute gear

Filter type................................... Full flow disposable

Oil pressure at 4 000 rpm .....................480-620 kPa

Rotor assembly end float .................. 0.03-0. 010 mm

Rotor teeth backlash ......................... 0.010-0.20 mm

TORQUE WRENCH SETTINGS

*Cylinder head bolts:

Initial torque ............................................. 25 Nm

1st stage ......................................... + 60 degrees

2nd stage ........................................ + 60 degrees

3rd stage......................................... + 60 degrees

4th stage, engine at operating

temperature .............................. + 30-50 degrees

Exhaust manifold nuts .................................... 22 Nm

Exhaust manifold flange nuts ......................... 22 Nm

Inlet manifold nuts.......................................... 22 Nm

Throttle body to inlet manifold nuts ..............12 Nm

Camshaft liming gear bolt ...............................45 Nm

Camshaft retainin g plate bolts ......................... 7 Nm

Camshaft cover bolts......................................... 8 Nm

Thermostat cover bolts ....................................15 Nm

*Main bearing bolts..................60 Nm + 45 degrees

Connecting rod bearing

cap nuts ................................... 35 Nm + 45 degrees

* Crankshaft timing

gear bolt.................................. 145 Nm + 35 degrees

*Flywheel bolts

(microencapsulated) ................ 60 Nm + 30 degrees

*Drive plate bolts (microencapsulated)........... 60 Nm

Water pump bolts............................................ 25 Nm

Page 39 of 238

Engine 39

Oil pump cover plate screws............................ 6 Nm

Oil pump mounting bolts.................................. 6 Nm

Oil pump pickup bolts

(coat with Loctite 242)..................................... 8 Nm

Sump bolts (coat with Loctite 242) .................. 5 Nm

Sump drain plug .............................................. 35 Nm

*Use new bolts

Head bolts maximum torque 135 Nm

1. ENGINE MECHANICAL TROUBLE

SHOOTING

ENGINE MISSES AT IDLING SPEED

NOTE: For other causes of engine misfire,

refer to the Fuel and Engine Management

section.

(1) Blown head gasket: Check the cylinder com-

pressions and renew the he ad gasket as necessary.

(2) Burnt valves or seats in the cylinder head:

Check the cylinder compressions and overhaul the

cylinder head as necessary. (3) Broken or worn piston rings: Check the

cylinder compressions and renew the piston rings as

necessary.

(4) Weak or broken valve springs: Remove the

camshaft housing top cover and check the condition

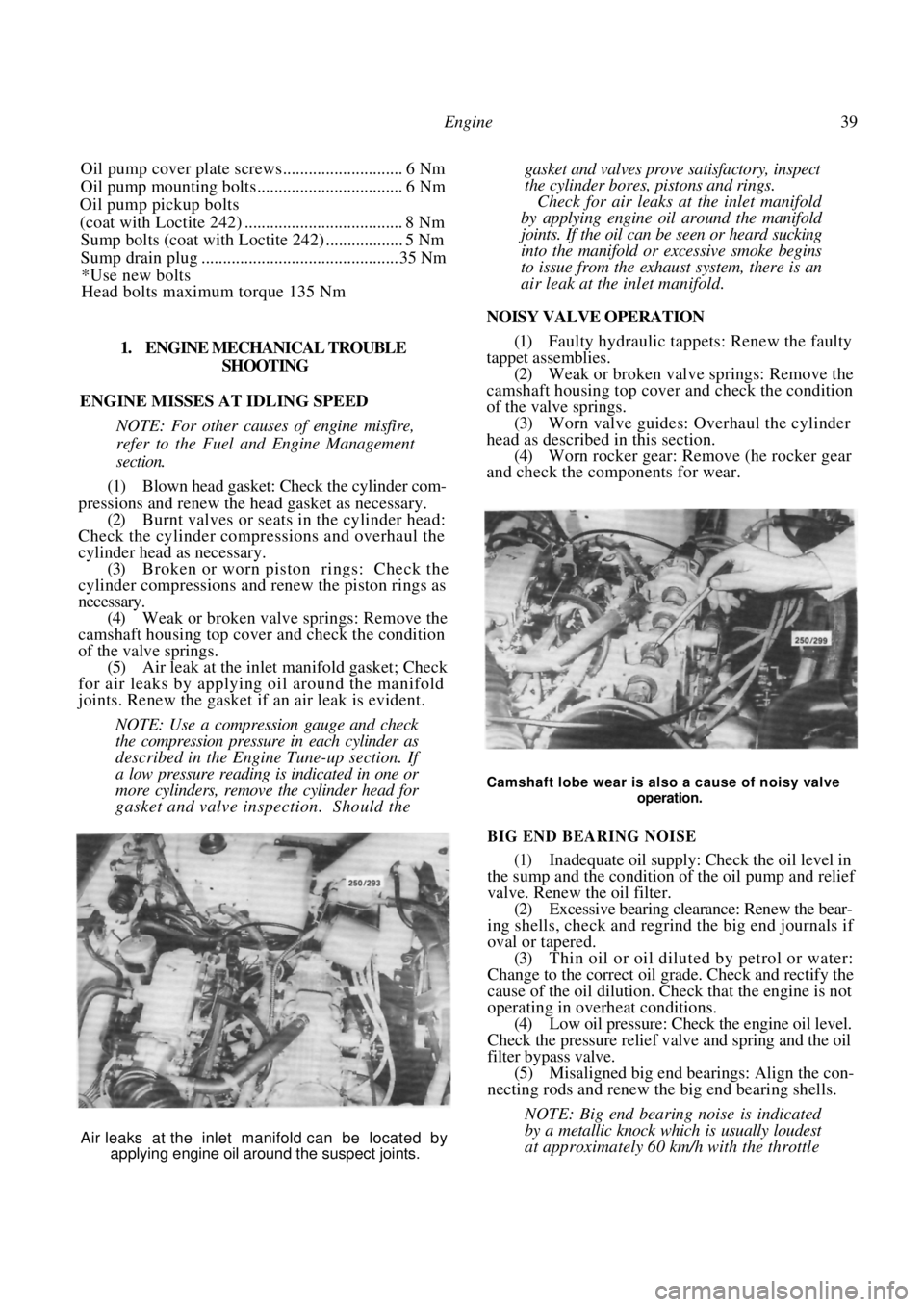

of the valve springs. (5) Air leak at the inlet manifold gasket; Check

for air leaks by applying oil around the manifold

joints. Renew the gasket if an air leak is evident.

NOTE: Use a compre ssion gauge and check

the compression pressure in each cylinder as

described in the Engine Tune-up section. If

a low pressure reading is indicated in one or

more cylinders, remove the cylinder head for

gasket and valve inspection. Should the

gasket and valves prove satisfactory, inspect

the cylinder bores, pistons and rings.

Check for air leaks at the inlet manifold

by applying engine oil around the manifold

joints. If the oil can be seen or heard sucking

into the manifold or excessive smoke begins

to issue from the exhaust system, there is an

air leak at the inlet manifold.

NOISY VALVE OPERATION

(1) Faulty hydraulic tappets: Renew the faulty

tappet assemblies. (2) Weak or broken valve springs: Remove the

camshaft housing top cover and check the condition

of the valve springs. (3) Worn valve guides: Overhaul the cylinder

head as described in this section. (4) Worn rocker gear: Remove (he rocker gear

and check the components for wear.

Camshaft lobe wear is also a cause of noisy valve

operation.

BIG END BEARING NOISE

(1) Inadequate oil supply: Check the oil level in

the sump and the condition of the oil pump and relief

valve. Renew the oil filter.

(2) Excessive bearing clearance: Renew the bear-

ing shells, check and regrind the big end journals if

oval or tapered. (3) Thin oil or oil diluted by petrol or water:

Change to the correct oil grade. Check and rectify the

cause of the oil dilution. Ch eck that the engine is not

operating in overheat conditions.

(4) Low oil pressure: Check the engine oil level.

Check the pressure relief valve and spring and the oil

filter bypass valve. (5) Misaligned big end bearings: Align the con-

necting rods and renew the big end bearing shells.

NOTE: Big end bearing noise is indicated

by a metallic knock wh ich is usually loudest

at approximately 60 km/h with the throttle

Air leaks at the inlet manifold can be located by

applying engine oil around the suspect joints.

Page 40 of 238

40 Engine

Check the engine oil for level and dilution on the dipstick.

dosed. Before dismantling the engine to

inspect the big ends check the engine oil for

correct level and dilution on the dipstick.

Also, remove the oil pressure sender unit

and connect an oil pressure gauge into the

oil gallery to check the oil pressure readings.

MAIN BEARING NOISE (APPARENT)

(1) Loose flywheel: Tighten the flywheel securing

bolls to the specified torque. (2) Low oil pressure: Check the bearing to

journal clearance. Check the condition of the oil

pump and pressure relief valve. Recondition the oil

pump as necessary. (3) Excessive crankshaft end float: Renew the

main bearings. (4) Crankshaft journals out of round and exces-

sive bearing to journal clear ance: Regrind the journals

and renew the bearings (undersize).

(5) Insufficient oil supply: Replenish the oil in

the sump to the correct level.

NOTE: Main bearing noise is indicated by a

heavy but dull knock when the engine is

under load. A loose flywheel is indicated by

a thud or dull click when the ignition is

turned off. It is us ually accompanied by

vibration.

Crankshaft end float noise is indicated by

a sharp rap at idle speed. The crankshaft

can be readily checked for excessive end

float by levering the crankshaft backwards

and forwards.

If the oil pressure is not satisfactory,

remove the main bearing caps and assess

the bearing clearance using the Plastigage

method as described in this section. Ovality

and wear on the main bearing journals can

only be checked with a micrometer after the

crankshaft has been removed.

EXCESSIVE OIL CONSUMPTION

(1) Oil leaks: Check and renew the engine gas-

kets or seals as necessary.

(2) Damaged or worn valve stem oil seals:

Dismantle the cylinder head and renew the damaged

or worn oil seals. (3) Excessive valve stem to valve guide clear-

ance: Ream the valve guides and renew the valves as

necessary. (4) Worn or broken piston rings: Renew the

piston rings on all pistons. (5) Rings too tight or stuck in the grooves:

Renew the rings and clean the ring grooves.

(6) Excessive wear in the cylinders, pistons and

rings: Recondition the cylinders and renew the pistons

and rings. (7) Compression rings incorrectly installed. Oil

rings clogged or broken: Renew the piston rings.

NOTE: Before checking the engine for oil

leaks the engine should be completely de-

greased and cleaned. Run the engine at

operating temperature for a period and

visually check for oil leakage. By placing

white paper on the floor directly beneath the

engine any excessive leak can be readily

pinpointed.

Damaged or worn valve stem oil seals

which allow oil to be drawn down past the

valve stems into the combustion chambers

can be diagnosed by allowing the engine to

idle for a few minutes and then opening the

throttle. If oil is being drawn past the valve

stems a heavy discharge of blue smoke will

be seen at the tailpipe.

Piston, ring and cylinder bore troubles are

normally accompanied by a loss of compres-

sion. Cylinder compression can only be

accurately assessed by using a compression

gauge.

Run the engine over white paper to check for oil leaks.