NISSAN TEANA 2008 Service Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 1141 of 5121

CO-18

< ON-VEHICLE REPAIR >

WATER PUMP

WATER PUMP

Exploded ViewINFOID:0000000003793179

Removal and InstallationINFOID:0000000003793180

CAUTION:

When removing water pump assembly, be careful not to get engine coolant on drive belt.

Water pump cannot be disassembled and should be replaced as a unit.

After installing water pump, connect hose and clamp securely, then check for leakage using the radi-

ator cap tester (commercial service tool) and the radiator cap tester adapter (commercial service

tool).

REMOVAL

1. Remove the following parts.

Air duct (inlet): Refer to EM-26, "

Exploded View".

Engine cover: Refer to EM-24, "

Exploded View".

Engine under cover

Front road wheel and tire

Splash guard (RH): Refer to EXT-22, "

FENDER PROTECTOR : Exploded View".

2. Drain engine coolant from radiator. Refer to CO-8, "

Draining".

CAUTION:

Perform this step when the engine is cold.

Never spill engine coolant on drive belt.

3. Remove drive belt. Refer to EM-12, "

Removal and Installation".

4. Remove idler pulleys. Refer to EM-25, "

Exploded View".

5. Remove reservoir tank of radiator. Refer to CO-13, "

Exploded View".

6. Remove reservoir tank of power steering oil pump with piping connected, and move it to aside. Refer to

ST-34, "

Exploded View".

7. Support oil pan (lower) bottom with transmission jack.

8. Remove engine mounting insulator (RH), engine mounting bracket (RH) and upper torque rod. Refer to

EM-67, "

Exploded View".

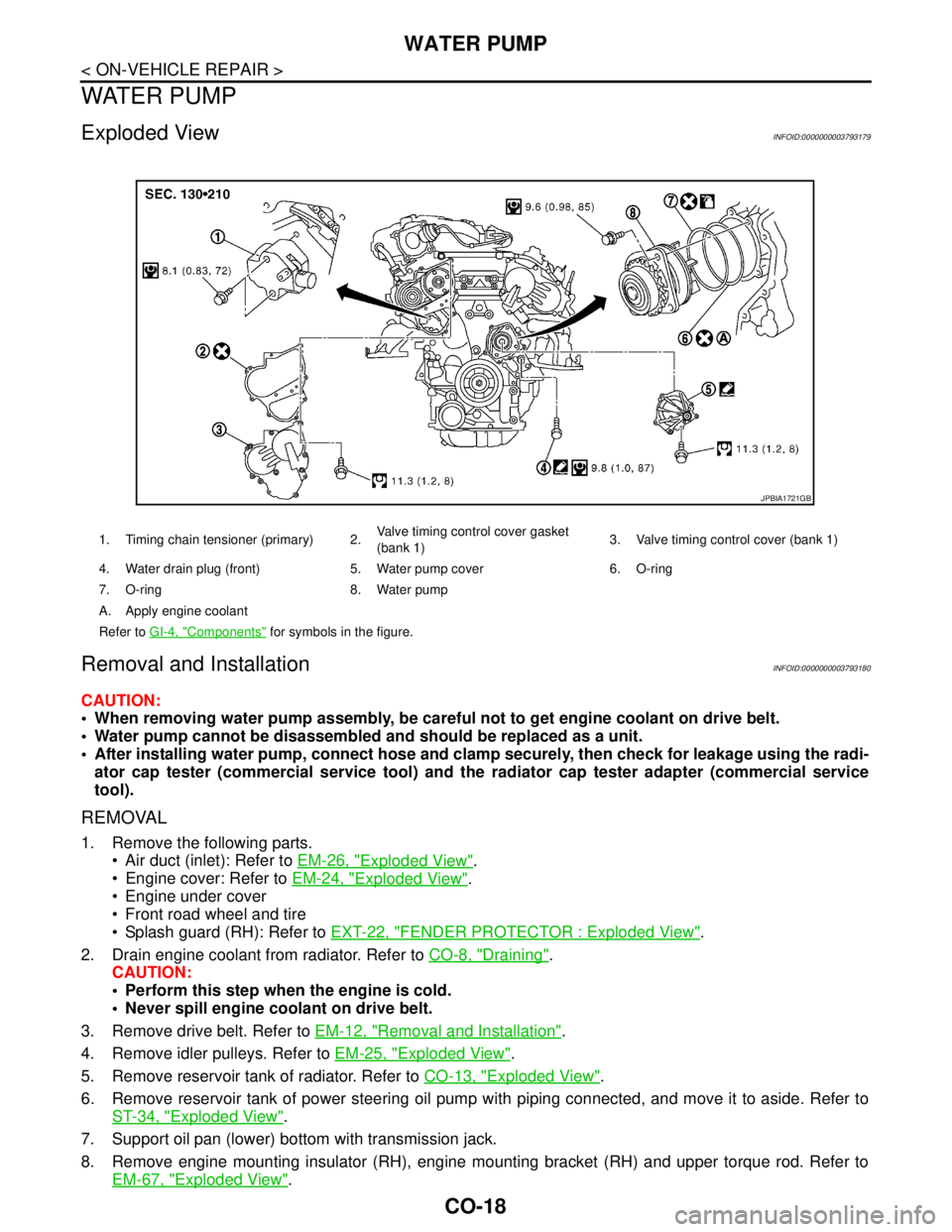

1. Timing chain tensioner (primary) 2.Valve timing control cover gasket

(bank 1)3. Valve timing control cover (bank 1)

4. Water drain plug (front) 5. Water pump cover 6. O-ring

7. O-ring 8. Water pump

A. Apply engine coolant

Refer to GI-4, "

Components" for symbols in the figure.

JPBIA1721GB

Page 1142 of 5121

WATER PUMP

CO-19

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

9. Remove water drain plug (front) on water pump side of cylinder block to drain engine coolant from engine

inside.

10. Remove valve timing control cover (bank 1) and water pump cover from front timing chain case.

Use the seal cutter [SST: KV10111100 (J37228)] to cut liquid gasket for removal.

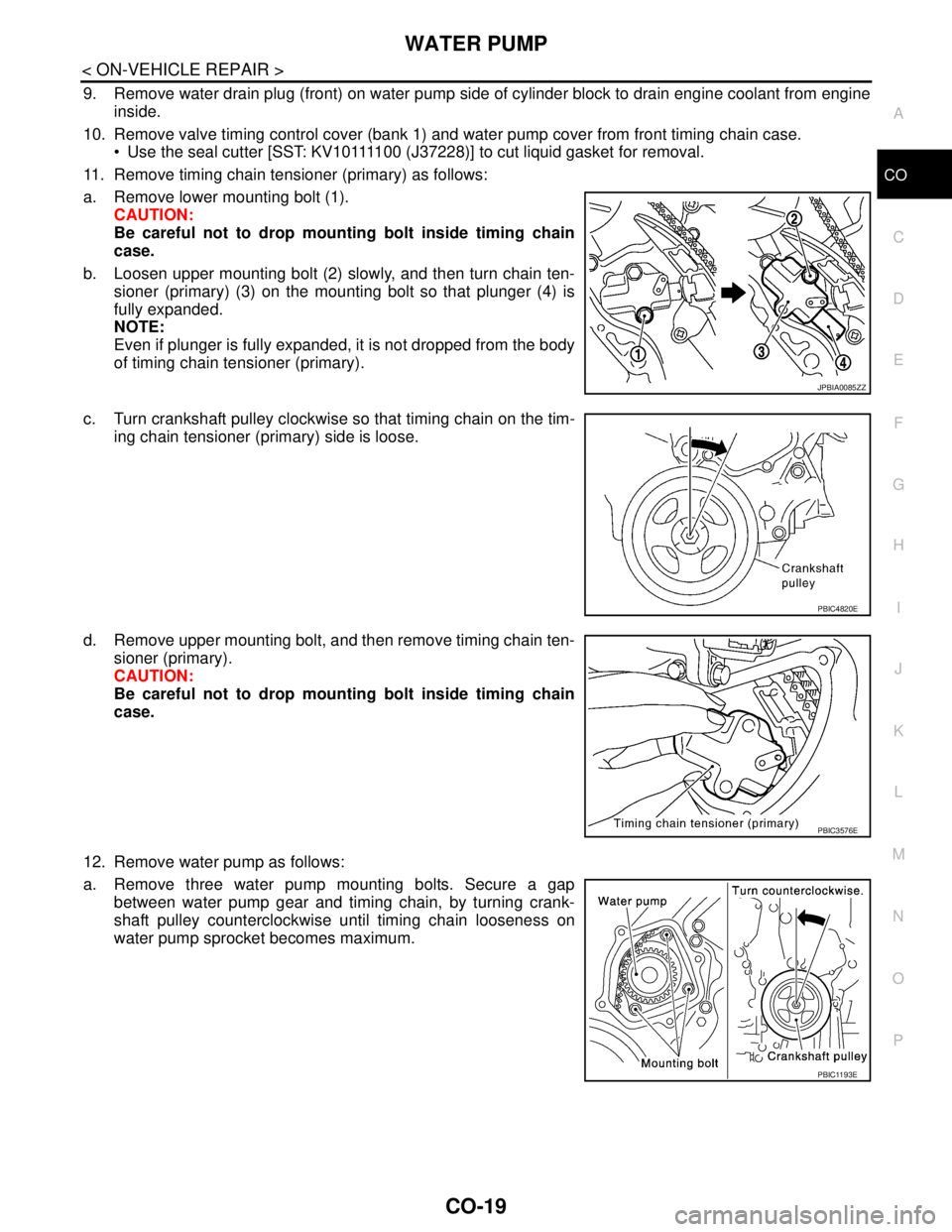

11. Remove timing chain tensioner (primary) as follows:

a. Remove lower mounting bolt (1).

CAUTION:

Be careful not to drop mounting bolt inside timing chain

case.

b. Loosen upper mounting bolt (2) slowly, and then turn chain ten-

sioner (primary) (3) on the mounting bolt so that plunger (4) is

fully expanded.

NOTE:

Even if plunger is fully expanded, it is not dropped from the body

of timing chain tensioner (primary).

c. Turn crankshaft pulley clockwise so that timing chain on the tim-

ing chain tensioner (primary) side is loose.

d. Remove upper mounting bolt, and then remove timing chain ten-

sioner (primary).

CAUTION:

Be careful not to drop mounting bolt inside timing chain

case.

12. Remove water pump as follows:

a. Remove three water pump mounting bolts. Secure a gap

between water pump gear and timing chain, by turning crank-

shaft pulley counterclockwise until timing chain looseness on

water pump sprocket becomes maximum.

JPBIA0085ZZ

PBIC4820E

PBIC3576E

PBIC1193E

Page 1143 of 5121

![NISSAN TEANA 2008 Service Manual CO-20

< ON-VEHICLE REPAIR >

WATER PUMP

b. Screw M8 bolts [pitch: 1.25 mm (0.0492 in) length: approxi-

mately 50 mm (1.97 in)] into water pumps upper and lower

mounting bolt holes until they reach timi NISSAN TEANA 2008 Service Manual CO-20

< ON-VEHICLE REPAIR >

WATER PUMP

b. Screw M8 bolts [pitch: 1.25 mm (0.0492 in) length: approxi-

mately 50 mm (1.97 in)] into water pumps upper and lower

mounting bolt holes until they reach timi](/img/5/57391/w960_57391-1142.png)

CO-20

< ON-VEHICLE REPAIR >

WATER PUMP

b. Screw M8 bolts [pitch: 1.25 mm (0.0492 in) length: approxi-

mately 50 mm (1.97 in)] into water pumps upper and lower

mounting bolt holes until they reach timing chain case. Then,

alternately tighten each bolt for a half turn, and pull out water

pump.

CAUTION:

Pull straight out while preventing vane from contacting

socket in installation area.

Remove water pump without causing sprocket to contact

timing chain.

c. Remove M8 bolts and O-rings from water pump.

CAUTION:

Never disassemble water pump.

INSTALLATION

1. Install new O-rings to water pump.

Apply engine oil and engine coolant to O-rings as shown in the

figure.

Locate O-ring with white paint mark to engine front side.

2. Install water pump.

CAUTION:

Never allow cylinder block to nip O-rings when installing

water pump.

Check that timing chain and water pump sprocket are

engaged.

Insert water pump by tightening mounting bolts alternately and

evenly.

3. Install timing chain tensioner (primary) as follows:

a. Turn crankshaft pulley clockwise so that timing chain on the tim-

ing chain tensioner (primary) side is loose.

JLC357B

PBIC1397E

SLC031B

PBIC4820E

Page 1144 of 5121

WATER PUMP

CO-21

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

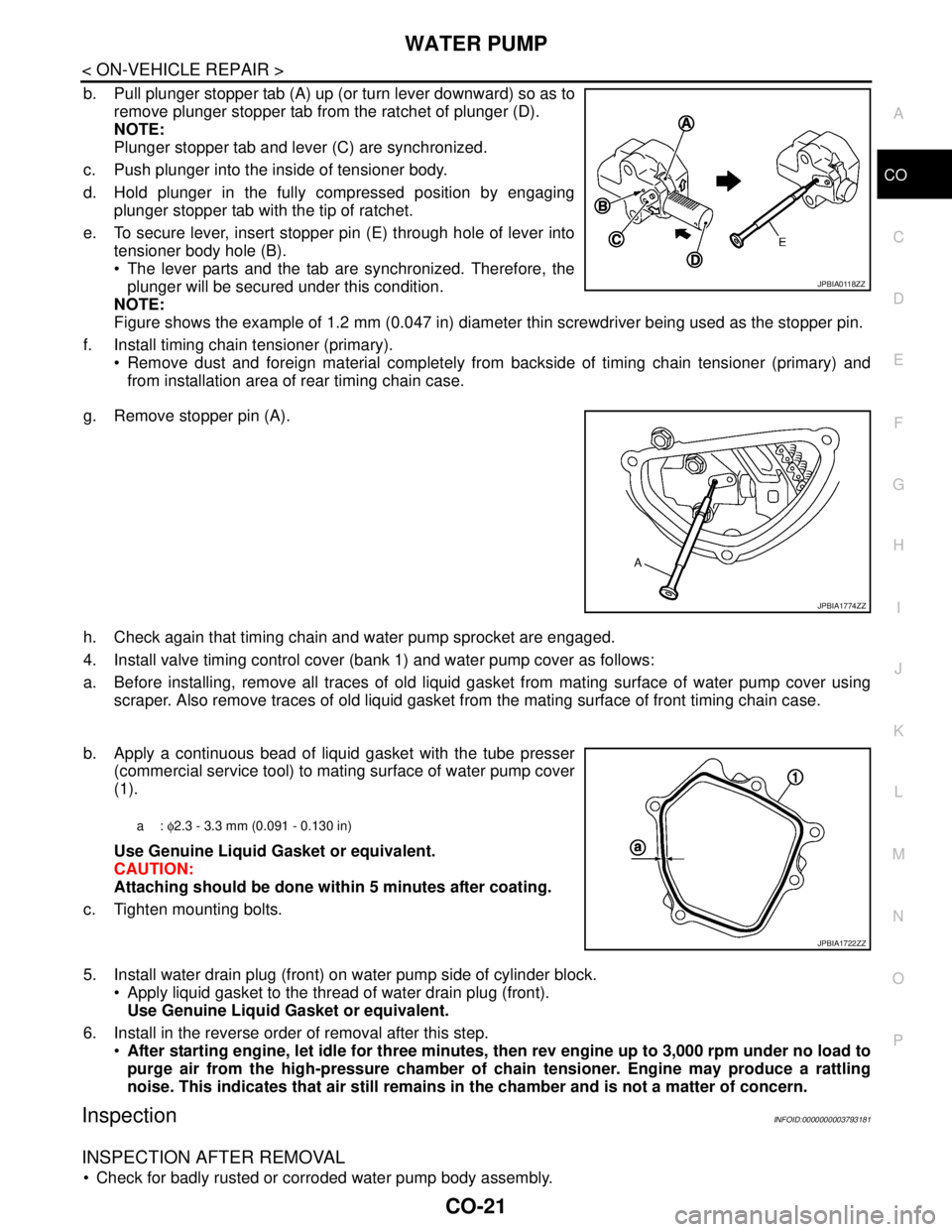

b. Pull plunger stopper tab (A) up (or turn lever downward) so as to

remove plunger stopper tab from the ratchet of plunger (D).

NOTE:

Plunger stopper tab and lever (C) are synchronized.

c. Push plunger into the inside of tensioner body.

d. Hold plunger in the fully compressed position by engaging

plunger stopper tab with the tip of ratchet.

e. To secure lever, insert stopper pin (E) through hole of lever into

tensioner body hole (B).

The lever parts and the tab are synchronized. Therefore, the

plunger will be secured under this condition.

NOTE:

Figure shows the example of 1.2 mm (0.047 in) diameter thin screwdriver being used as the stopper pin.

f. Install timing chain tensioner (primary).

Remove dust and foreign material completely from backside of timing chain tensioner (primary) and

from installation area of rear timing chain case.

g. Remove stopper pin (A).

h. Check again that timing chain and water pump sprocket are engaged.

4. Install valve timing control cover (bank 1) and water pump cover as follows:

a. Before installing, remove all traces of old liquid gasket from mating surface of water pump cover using

scraper. Also remove traces of old liquid gasket from the mating surface of front timing chain case.

b. Apply a continuous bead of liquid gasket with the tube presser

(commercial service tool) to mating surface of water pump cover

(1).

Use Genuine Liquid Gasket or equivalent.

CAUTION:

Attaching should be done within 5 minutes after coating.

c. Tighten mounting bolts.

5. Install water drain plug (front) on water pump side of cylinder block.

Apply liquid gasket to the thread of water drain plug (front).

Use Genuine Liquid Gasket or equivalent.

6. Install in the reverse order of removal after this step.

After starting engine, let idle for three minutes, then rev engine up to 3,000 rpm under no load to

purge air from the high-pressure chamber of chain tensioner. Engine may produce a rattling

noise. This indicates that air still remains in the chamber and is not a matter of concern.

InspectionINFOID:0000000003793181

INSPECTION AFTER REMOVAL

Check for badly rusted or corroded water pump body assembly.

JPBIA0118ZZ

JPBIA1774ZZ

a: φ2.3 - 3.3 mm (0.091 - 0.130 in)

JPBIA1722ZZ

Page 1145 of 5121

CO-22

< ON-VEHICLE REPAIR >

WATER PUMP

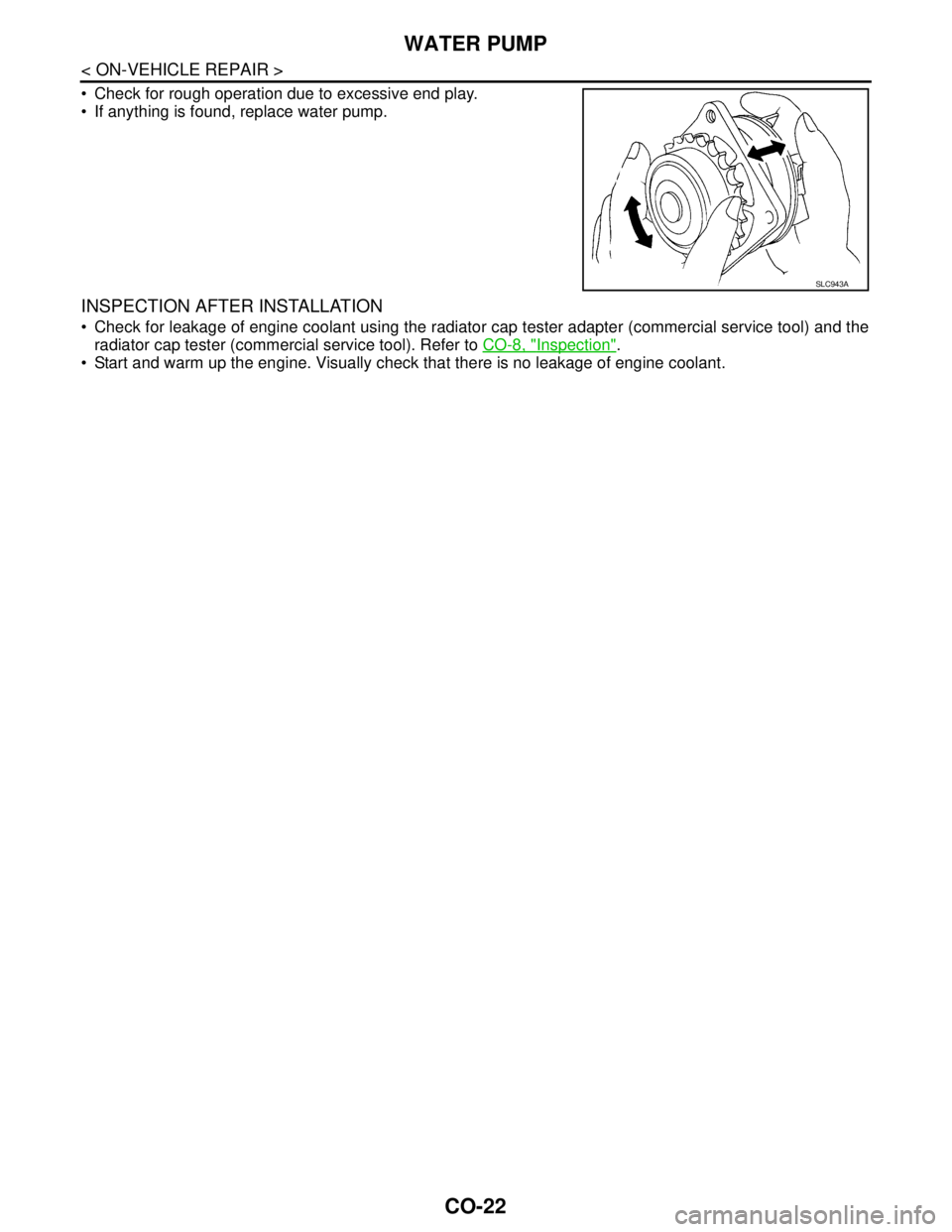

Check for rough operation due to excessive end play.

If anything is found, replace water pump.

INSPECTION AFTER INSTALLATION

Check for leakage of engine coolant using the radiator cap tester adapter (commercial service tool) and the

radiator cap tester (commercial service tool). Refer to CO-8, "

Inspection".

Start and warm up the engine. Visually check that there is no leakage of engine coolant.

SLC943A

Page 1146 of 5121

WATER INLET AND THERMOSTAT ASSEMBLY

CO-23

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

WATER INLET AND THERMOSTAT ASSEMBLY

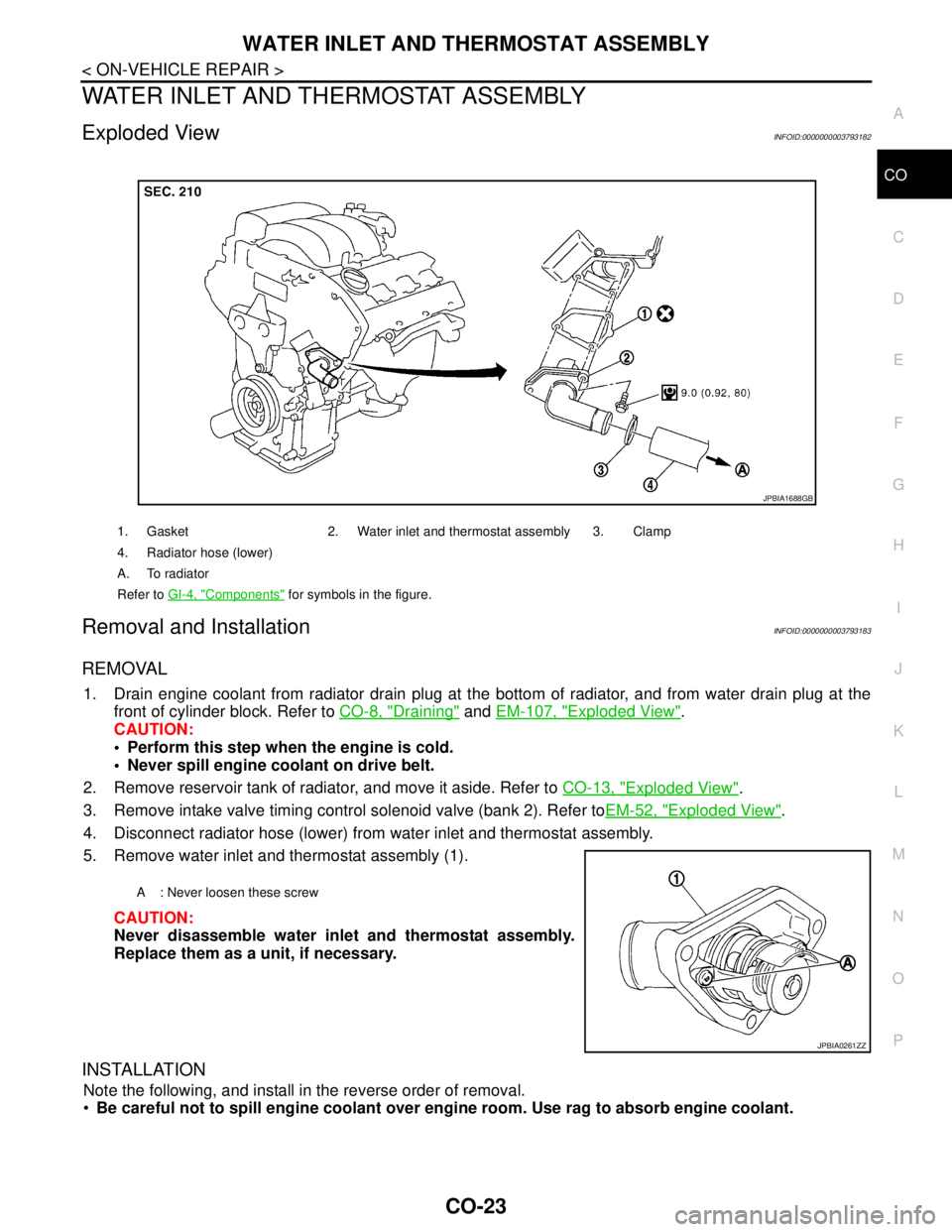

Exploded ViewINFOID:0000000003793182

Removal and InstallationINFOID:0000000003793183

REMOVAL

1. Drain engine coolant from radiator drain plug at the bottom of radiator, and from water drain plug at the

front of cylinder block. Refer to CO-8, "

Draining" and EM-107, "Exploded View".

CAUTION:

Perform this step when the engine is cold.

Never spill engine coolant on drive belt.

2. Remove reservoir tank of radiator, and move it aside. Refer to CO-13, "

Exploded View".

3. Remove intake valve timing control solenoid valve (bank 2). Refer toEM-52, "

Exploded View".

4. Disconnect radiator hose (lower) from water inlet and thermostat assembly.

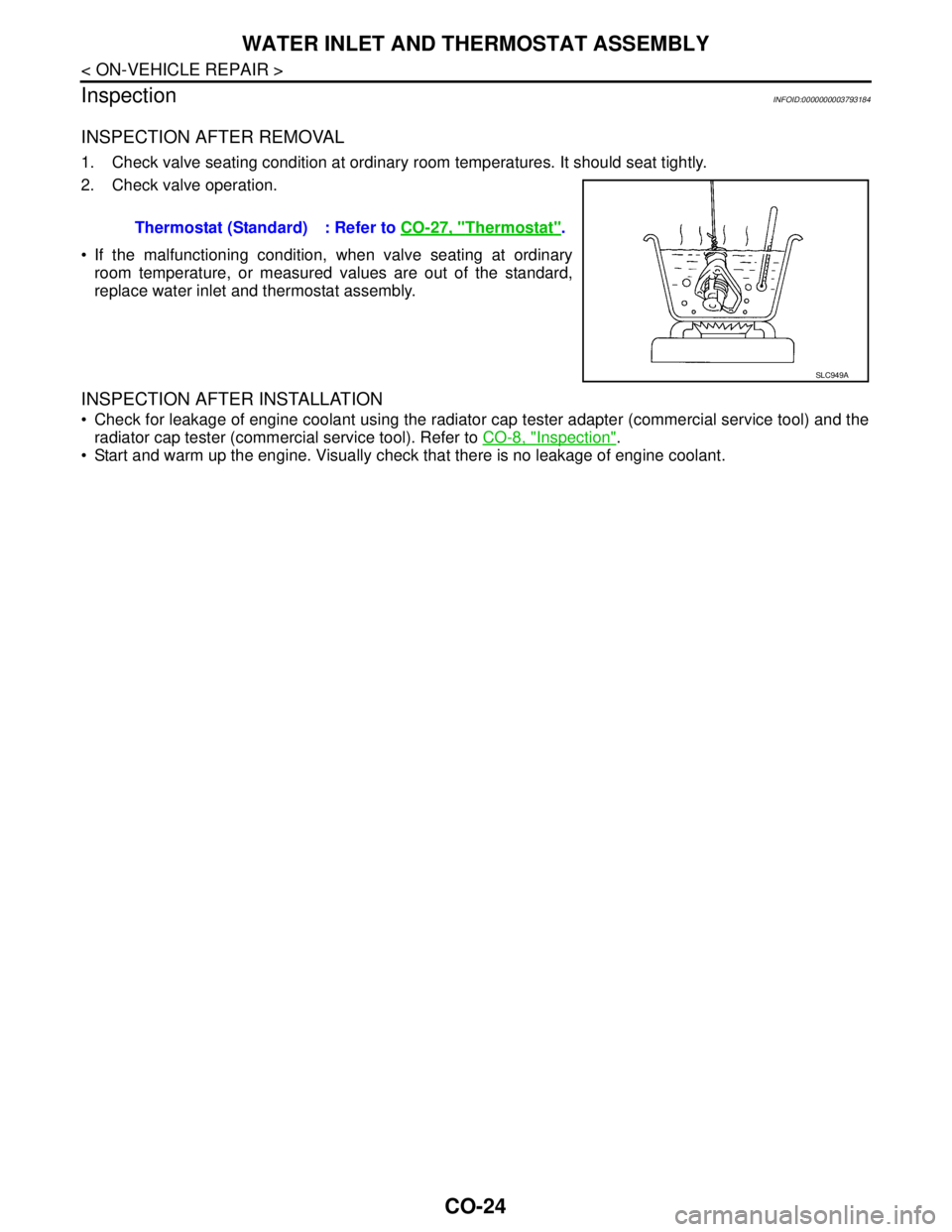

5. Remove water inlet and thermostat assembly (1).

CAUTION:

Never disassemble water inlet and thermostat assembly.

Replace them as a unit, if necessary.

INSTALLATION

Note the following, and install in the reverse order of removal.

Be careful not to spill engine coolant over engine room. Use rag to absorb engine coolant.

1. Gasket 2. Water inlet and thermostat assembly 3. Clamp

4. Radiator hose (lower)

A. To radiator

Refer to GI-4, "

Components" for symbols in the figure.

JPBIA1688GB

A : Never loosen these screw

JPBIA0261ZZ

Page 1147 of 5121

CO-24

< ON-VEHICLE REPAIR >

WATER INLET AND THERMOSTAT ASSEMBLY

Inspection

INFOID:0000000003793184

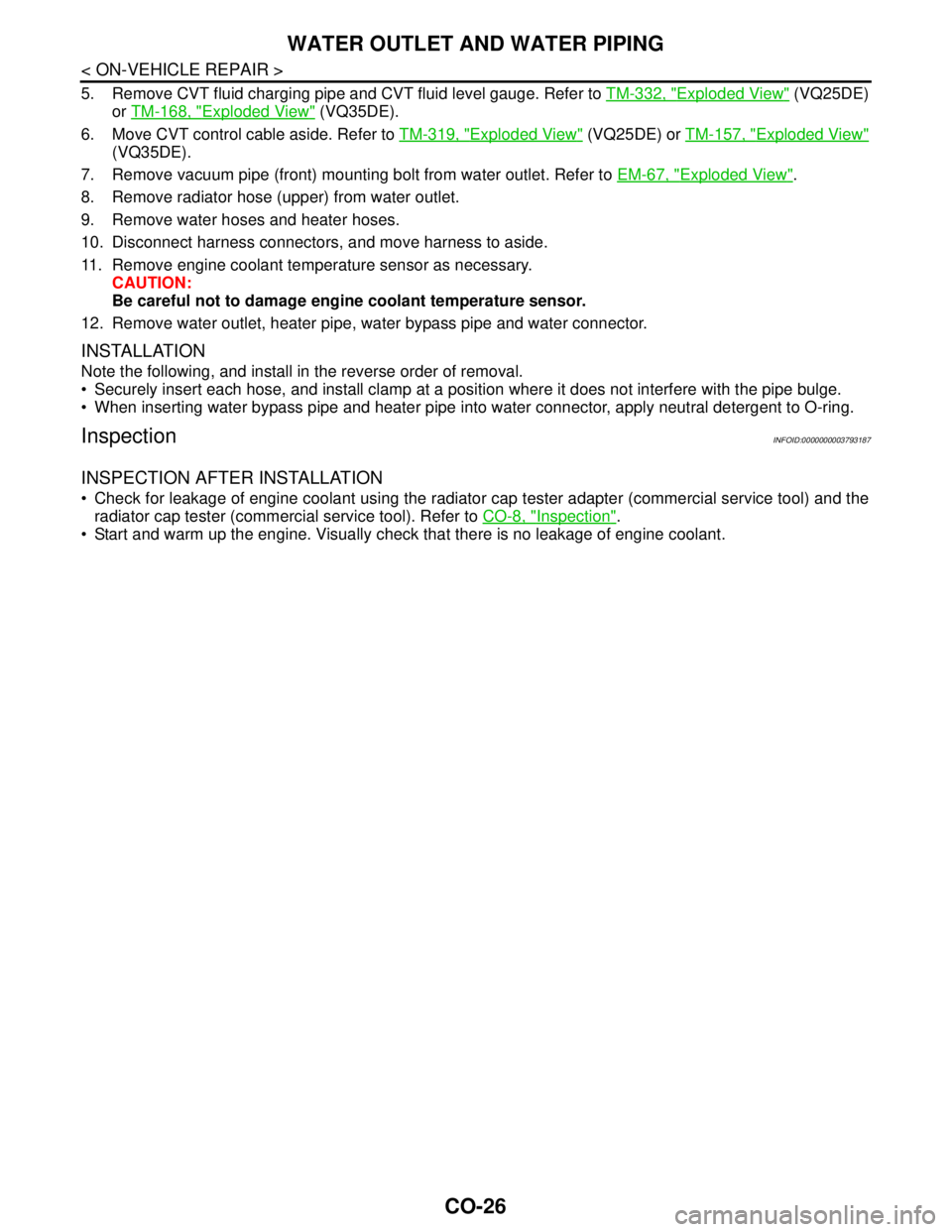

INSPECTION AFTER REMOVAL

1. Check valve seating condition at ordinary room temperatures. It should seat tightly.

2. Check valve operation.

If the malfunctioning condition, when valve seating at ordinary

room temperature, or measured values are out of the standard,

replace water inlet and thermostat assembly.

INSPECTION AFTER INSTALLATION

Check for leakage of engine coolant using the radiator cap tester adapter (commercial service tool) and the

radiator cap tester (commercial service tool). Refer to CO-8, "

Inspection".

Start and warm up the engine. Visually check that there is no leakage of engine coolant. Thermostat (Standard) : Refer to CO-27, "

Thermostat".

SLC949A

Page 1148 of 5121

WATER OUTLET AND WATER PIPING

CO-25

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

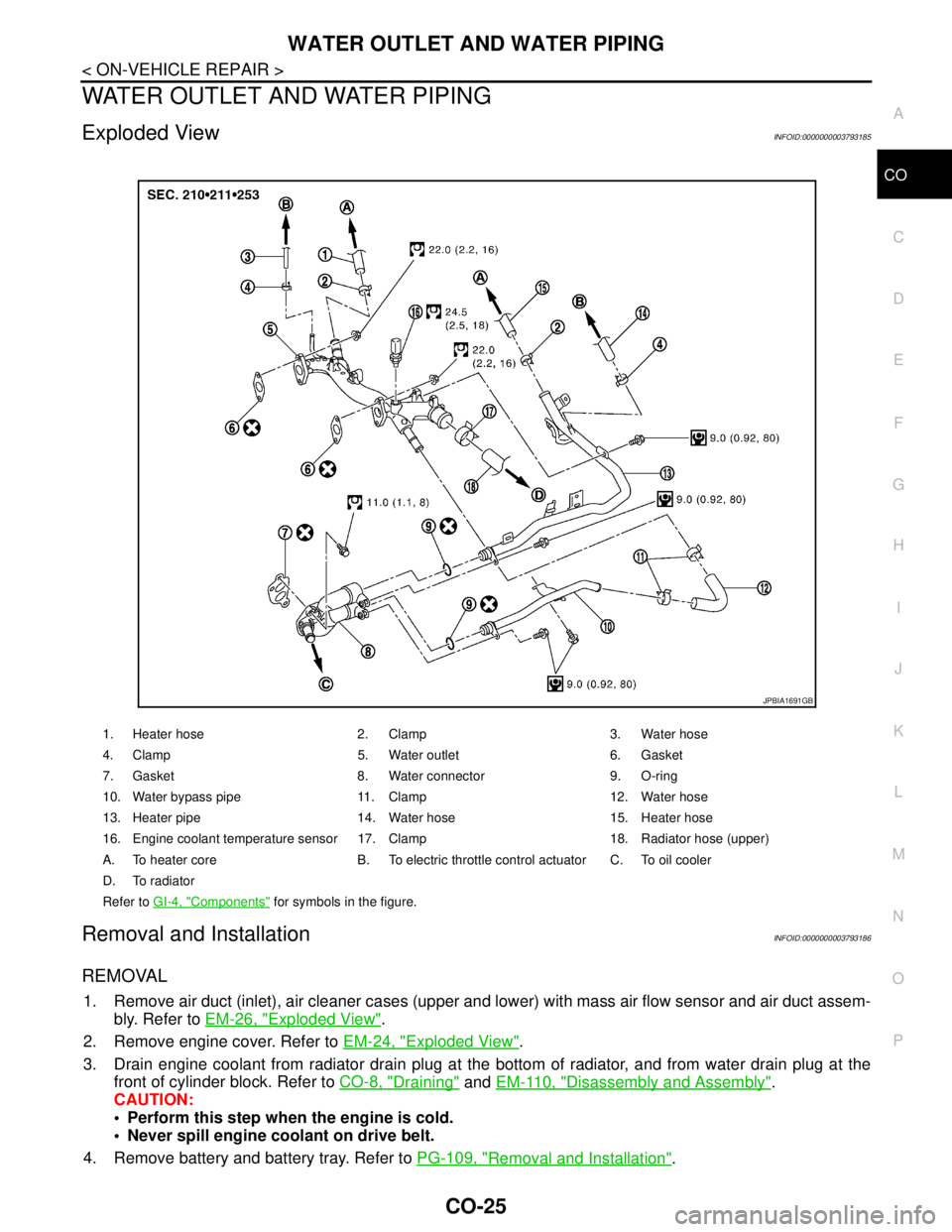

WATER OUTLET AND WATER PIPING

Exploded ViewINFOID:0000000003793185

Removal and InstallationINFOID:0000000003793186

REMOVAL

1. Remove air duct (inlet), air cleaner cases (upper and lower) with mass air flow sensor and air duct assem-

bly. Refer to EM-26, "

Exploded View".

2. Remove engine cover. Refer to EM-24, "

Exploded View".

3. Drain engine coolant from radiator drain plug at the bottom of radiator, and from water drain plug at the

front of cylinder block. Refer to CO-8, "

Draining" and EM-110, "Disassembly and Assembly".

CAUTION:

Perform this step when the engine is cold.

Never spill engine coolant on drive belt.

4. Remove battery and battery tray. Refer to PG-109, "

Removal and Installation".

1. Heater hose 2. Clamp 3. Water hose

4. Clamp 5. Water outlet 6. Gasket

7. Gasket 8. Water connector 9. O-ring

10. Water bypass pipe 11. Clamp 12. Water hose

13. Heater pipe 14. Water hose 15. Heater hose

16. Engine coolant temperature sensor 17. Clamp 18. Radiator hose (upper)

A. To heater core B. To electric throttle control actuator C. To oil cooler

D. To radiator

Refer to GI-4, "

Components" for symbols in the figure.

JPBIA1691GB

Page 1149 of 5121

CO-26

< ON-VEHICLE REPAIR >

WATER OUTLET AND WATER PIPING

5. Remove CVT fluid charging pipe and CVT fluid level gauge. Refer to TM-332, "Exploded View" (VQ25DE)

or TM-168, "

Exploded View" (VQ35DE).

6. Move CVT control cable aside. Refer to TM-319, "

Exploded View" (VQ25DE) or TM-157, "Exploded View"

(VQ35DE).

7. Remove vacuum pipe (front) mounting bolt from water outlet. Refer to EM-67, "

Exploded View".

8. Remove radiator hose (upper) from water outlet.

9. Remove water hoses and heater hoses.

10. Disconnect harness connectors, and move harness to aside.

11. Remove engine coolant temperature sensor as necessary.

CAUTION:

Be careful not to damage engine coolant temperature sensor.

12. Remove water outlet, heater pipe, water bypass pipe and water connector.

INSTALLATION

Note the following, and install in the reverse order of removal.

Securely insert each hose, and install clamp at a position where it does not interfere with the pipe bulge.

When inserting water bypass pipe and heater pipe into water connector, apply neutral detergent to O-ring.

InspectionINFOID:0000000003793187

INSPECTION AFTER INSTALLATION

Check for leakage of engine coolant using the radiator cap tester adapter (commercial service tool) and the

radiator cap tester (commercial service tool). Refer to CO-8, "

Inspection".

Start and warm up the engine. Visually check that there is no leakage of engine coolant.

Page 1150 of 5121

SERVICE DATA AND SPECIFICATIONS (SDS)

CO-27

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

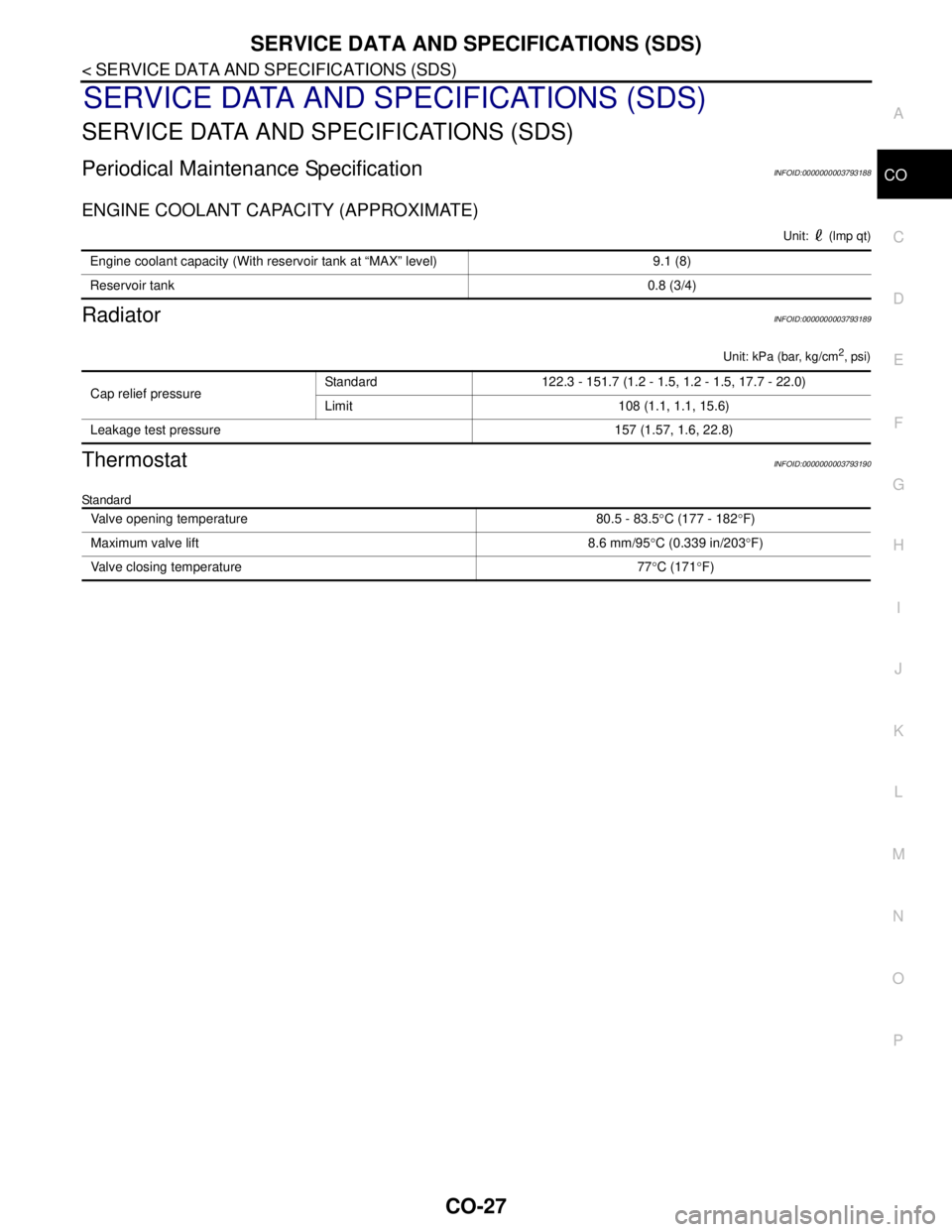

Periodical Maintenance SpecificationINFOID:0000000003793188

ENGINE COOLANT CAPACITY (APPROXIMATE)

Unit: (lmp qt)

RadiatorINFOID:0000000003793189

Unit: kPa (bar, kg/cm2, psi)

ThermostatINFOID:0000000003793190

Standard

Engine coolant capacity (With reservoir tank at “MAX” level) 9.1 (8)

Reservoir tank0.8 (3/4)

Cap relief pressureStandard 122.3 - 151.7 (1.2 - 1.5, 1.2 - 1.5, 17.7 - 22.0)

Limit 108 (1.1, 1.1, 15.6)

Leakage test pressure 157 (1.57, 1.6, 22.8)

Valve opening temperature 80.5 - 83.5°C (177 - 182°F)

Maximum valve lift 8.6 mm/95°C (0.339 in/203°F)

Valve closing temperature 77°C (171°F)