NISSAN TEANA 2008 Service Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 1901 of 5121

EM-26

< ON-VEHICLE REPAIR >

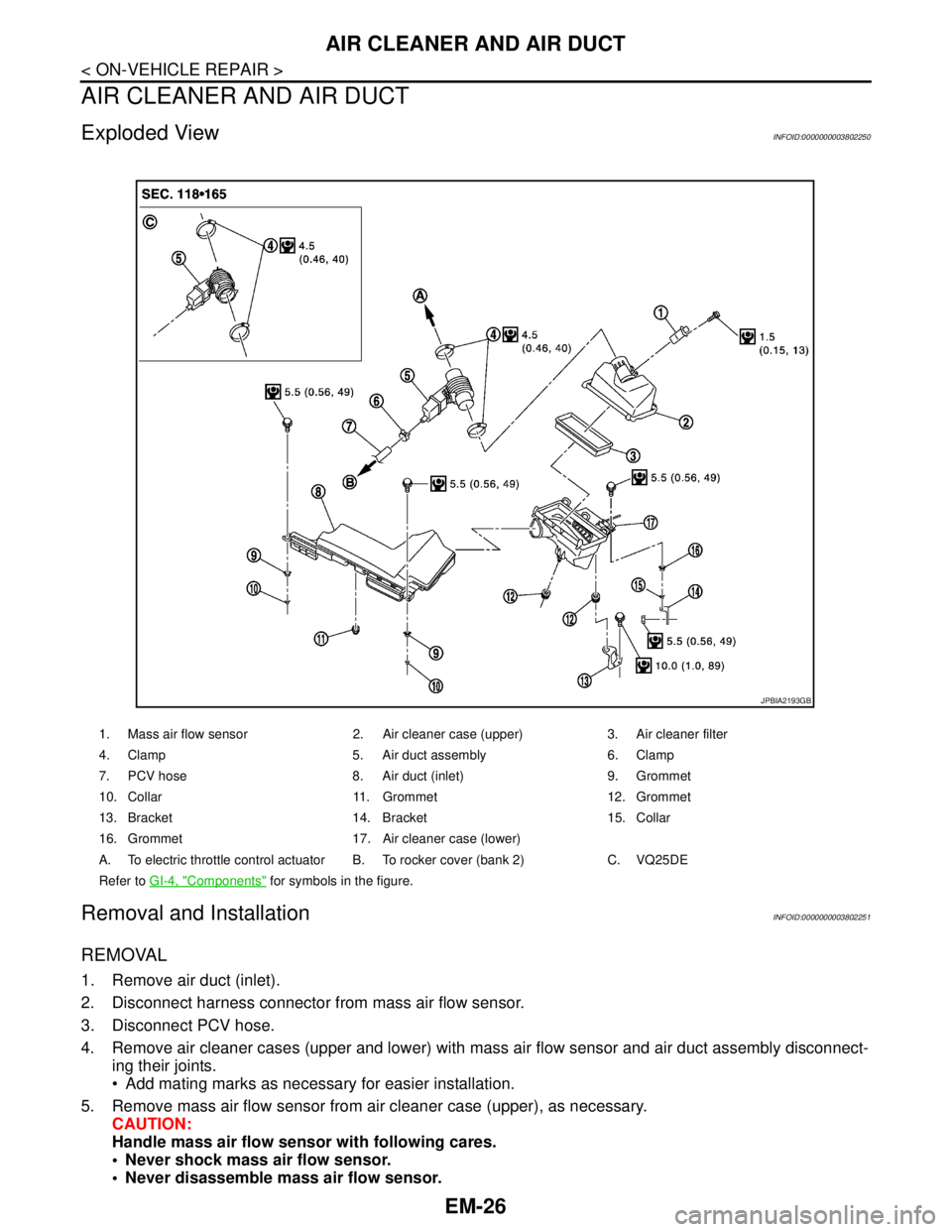

AIR CLEANER AND AIR DUCT

AIR CLEANER AND AIR DUCT

Exploded ViewINFOID:0000000003802250

Removal and InstallationINFOID:0000000003802251

REMOVAL

1. Remove air duct (inlet).

2. Disconnect harness connector from mass air flow sensor.

3. Disconnect PCV hose.

4. Remove air cleaner cases (upper and lower) with mass air flow sensor and air duct assembly disconnect-

ing their joints.

Add mating marks as necessary for easier installation.

5. Remove mass air flow sensor from air cleaner case (upper), as necessary.

CAUTION:

Handle mass air flow sensor with following cares.

Never shock mass air flow sensor.

Never disassemble mass air flow sensor.

1. Mass air flow sensor 2. Air cleaner case (upper) 3. Air cleaner filter

4. Clamp 5. Air duct assembly 6. Clamp

7. PCV hose 8. Air duct (inlet) 9. Grommet

10. Collar 11. Grommet 12. Grommet

13. Bracket 14. Bracket 15. Collar

16. Grommet 17. Air cleaner case (lower)

A. To electric throttle control actuator B. To rocker cover (bank 2) C. VQ25DE

Refer to GI-4, "

Components" for symbols in the figure.

JPBIA2193GB

Page 1902 of 5121

AIR CLEANER AND AIR DUCT

EM-27

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Never touch mass air flow sensor.

INSTALLATION

Note the following, and install in the reverse order of removal.

Align marks. Attach each joint. Screw clamps firmly.

InspectionINFOID:0000000003802252

INSPECTION AFTER REMOVAL

Inspect air duct assembly for crack or tear.

If anything found, replace air duct assembly.

Page 1903 of 5121

EM-28

< ON-VEHICLE REPAIR >

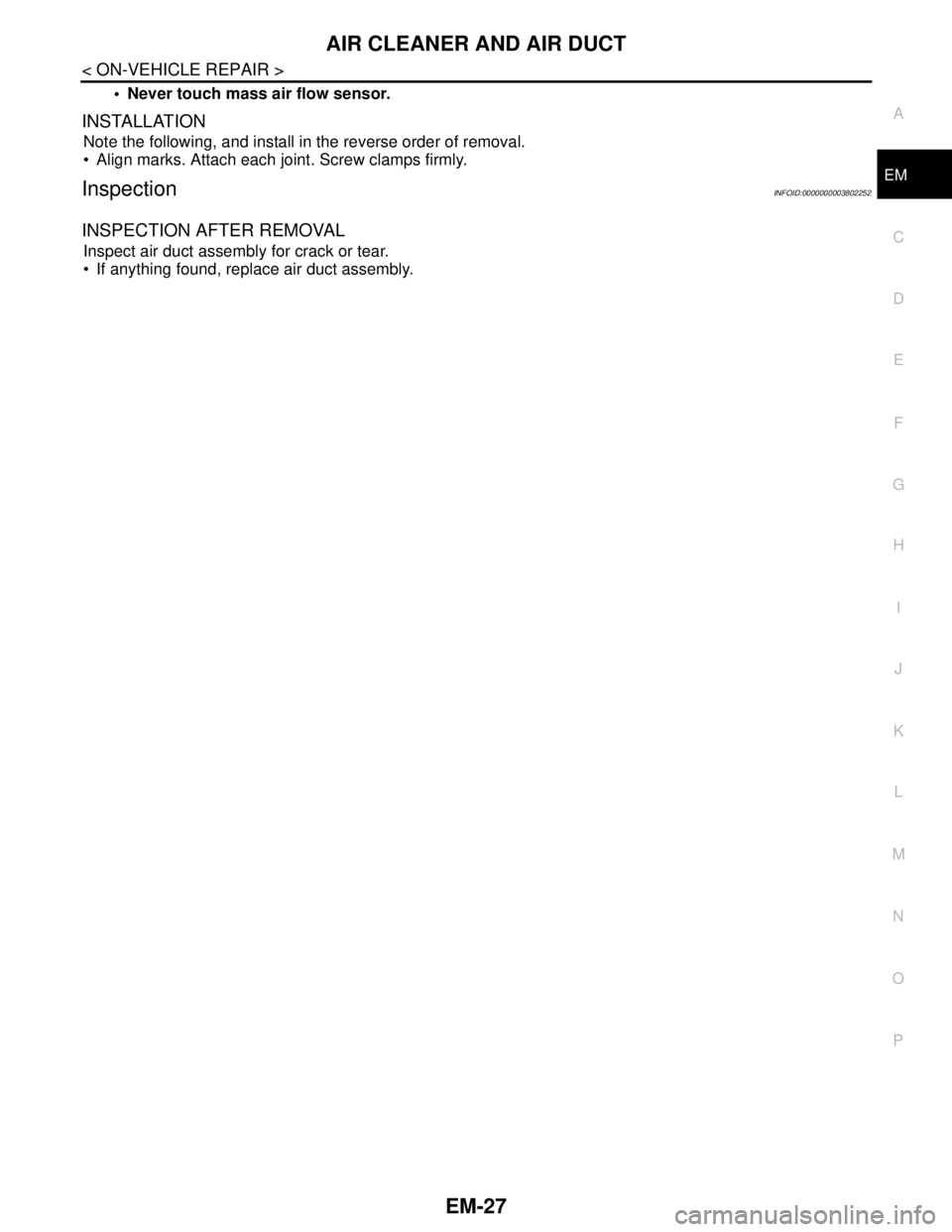

INTAKE MANIFOLD COLLECTOR

INTAKE MANIFOLD COLLECTOR

Exploded ViewINFOID:0000000003802253

VQ25DE

VQ35DE

1. Vacuum hose 2. Clamp 3. Clamp

4. PCV hose 5. Intake manifold collector 6. Gasket

7. Vacuum hose 8. VIAS control solenoid valve 9. Vacuum hose

10. Bracket 11.Electronic controlled engine mount

control solenoid valve12. Vacuum hose

13. Vacuum hose 14. Vacuum gallery 15. Vacuum hose

16.EVAP canister purge control solenoid

valve17. Clamp 18. EVAP hose

19. Service port 20. Bracket 21. EVAP hose

22. EVAP hose 23. EVAP pipe 24. EVAP hose

25. Clamp 26. Water hose 27. Water hose

28. Bracket 29. Electric throttle control actuator 30. Gasket

A. To brake booster B. To rocker cover (bank 1) C. To vacuum tube (rear)

D. To vacuum pipe E. To heater pipe F. To water outlet

: Engine front

Refer to GI-4, "

Components" for symbols in the figure.

JPBIA2194GB

Page 1904 of 5121

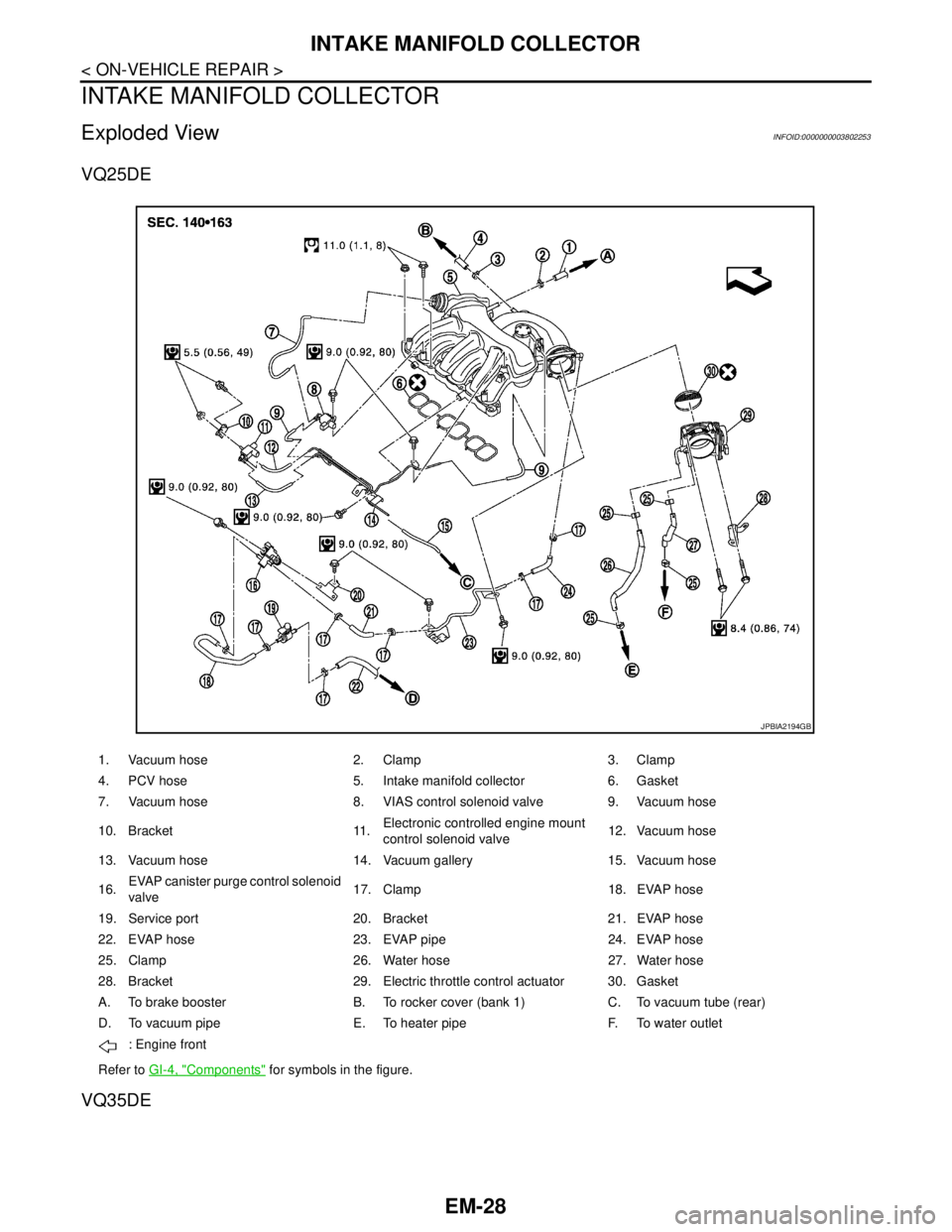

INTAKE MANIFOLD COLLECTOR

EM-29

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Removal and InstallationINFOID:0000000003802254

REMOVAL

WARNING:

To avoid the danger of being scalded, never drain engine coolant when the engine is hot.

1. Remove engine cover. Refer to EM-24, "

Exploded View".

CAUTION:

Be careful not to damage or scratch engine cover.

1. Vacuum hose 2. Clamp 3. Clamp

4. PCV hose 5. Intake manifold collector 6. Gasket

7. Vacuum hose 8. Bracket 9.Electronic controlled engine mount

control solenoid valve

10. Vacuum hose 11. Vacuum hose 12. Vacuum hose

13. Vacuum gallery 14. Vacuum hose 15. Vacuum hose

16. VIAS control solenoid valve 2 17. VIAS control solenoid valve 1 18.EVAP canister purge control solenoid

valve

19. Clamp 20. EVAP hose 21. Service port

22. Bracket 23. EVAP hose 24. EVAP hose

25. EVAP pipe 26. EVAP hose 27. Clamp

28. Water hose 29. Water hose 30. Bracket

31. Electric throttle control actuator 32. Gasket

A. To brake booster B. To rocker cover (bank 1) C. To vacuum tube (rear)

D. To vacuum pipe E. To heater pipe F. To water outlet

: Engine front

Refer to GI-4, "

Components" for symbols in the figure.

JPBIA1713GB

Page 1905 of 5121

EM-30

< ON-VEHICLE REPAIR >

INTAKE MANIFOLD COLLECTOR

2. Remove air cleaner cases (upper and lower) with mass air flow sensor and air duct assembly. Refer to

EM-26, "

Exploded View".

3. Drain engine coolant, or when water hoses are disconnected, attach plug to prevent engine coolant leak-

age. Refer to CO-8, "

Draining".

CAUTION:

Perform this step when the engine is cold.

4. Remove front wiper arm and extension cowl top. Refer to WW-105, "

Exploded View" and EXT-20,

"Exploded View".

5. Disconnect water hoses from electric throttle control actuator.

When engine coolant is not drained from radiator, attach plug to water hoses to prevent engine coolant

leakage.

6. Remove electric throttle control actuator as follows:

a. Disconnect harness connector.

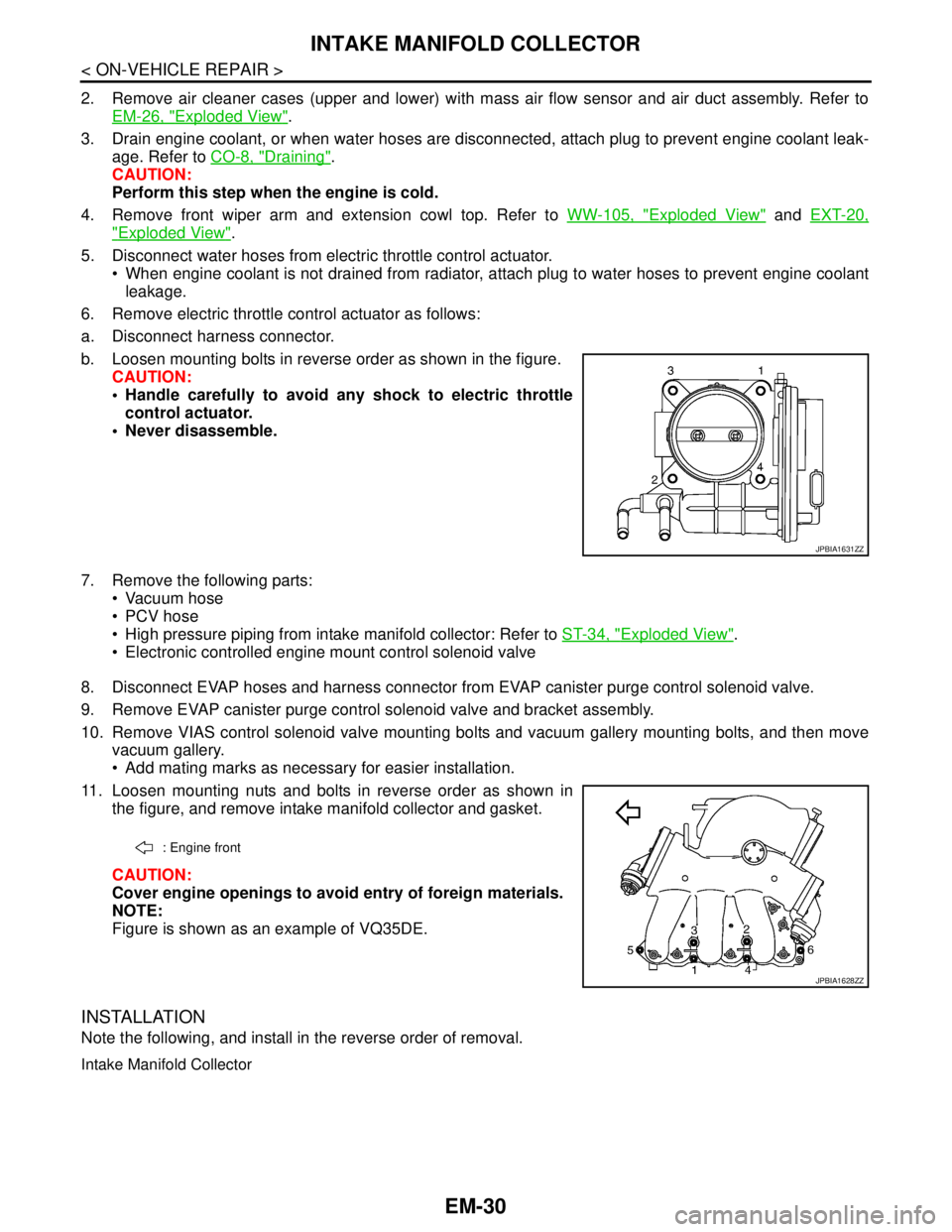

b. Loosen mounting bolts in reverse order as shown in the figure.

CAUTION:

Handle carefully to avoid any shock to electric throttle

control actuator.

Never disassemble.

7. Remove the following parts:

Vacuum hose

PCV hose

High pressure piping from intake manifold collector: Refer to ST-34, "

Exploded View".

Electronic controlled engine mount control solenoid valve

8. Disconnect EVAP hoses and harness connector from EVAP canister purge control solenoid valve.

9. Remove EVAP canister purge control solenoid valve and bracket assembly.

10. Remove VIAS control solenoid valve mounting bolts and vacuum gallery mounting bolts, and then move

vacuum gallery.

Add mating marks as necessary for easier installation.

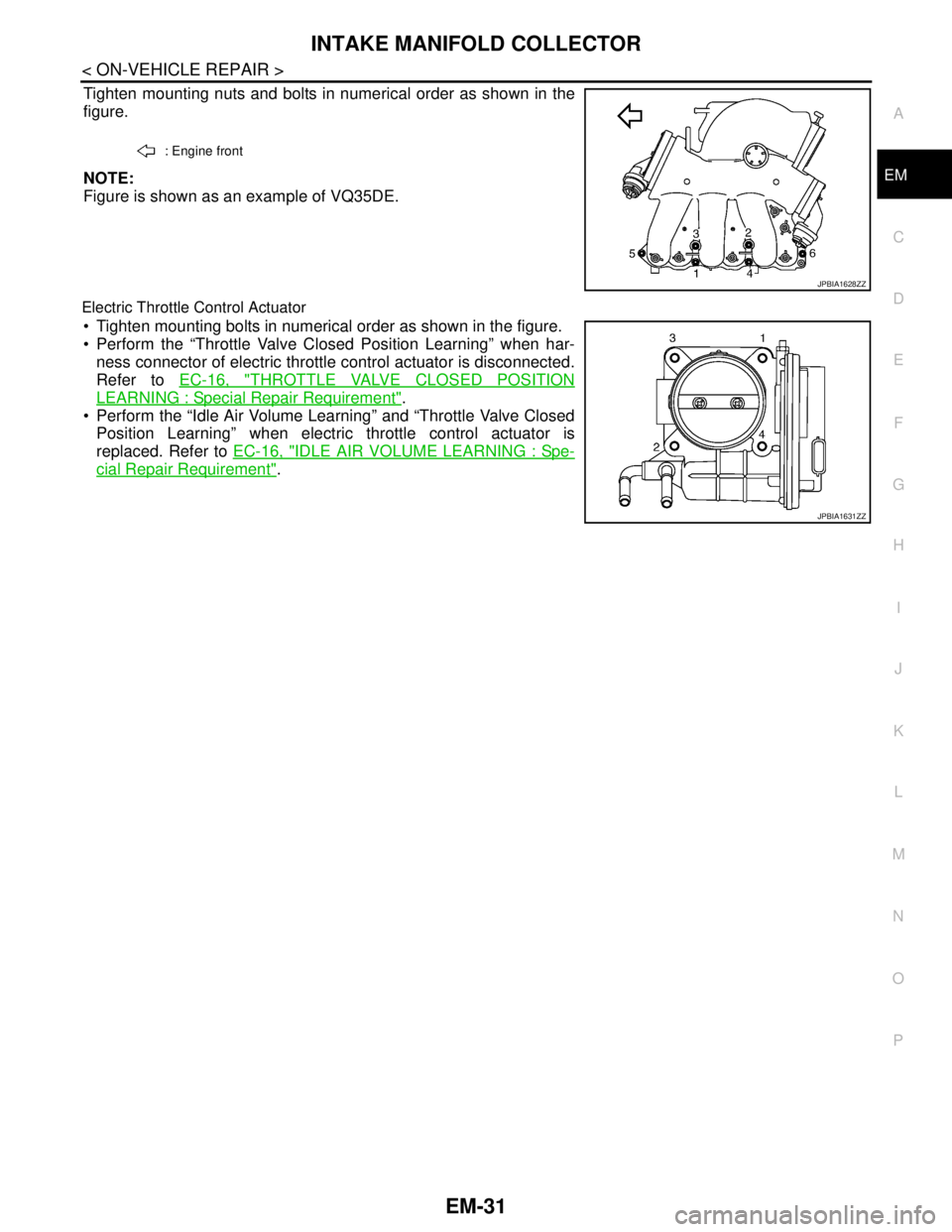

11. Loosen mounting nuts and bolts in reverse order as shown in

the figure, and remove intake manifold collector and gasket.

CAUTION:

Cover engine openings to avoid entry of foreign materials.

NOTE:

Figure is shown as an example of VQ35DE.

INSTALLATION

Note the following, and install in the reverse order of removal.

Intake Manifold Collector

JPBIA1631ZZ

: Engine front

JPBIA1628ZZ

Page 1906 of 5121

INTAKE MANIFOLD COLLECTOR

EM-31

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Tighten mounting nuts and bolts in numerical order as shown in the

figure.

NOTE:

Figure is shown as an example of VQ35DE.

Electric Throttle Control Actuator

Tighten mounting bolts in numerical order as shown in the figure.

Perform the “Throttle Valve Closed Position Learning” when har-

ness connector of electric throttle control actuator is disconnected.

Refer to EC-16, "

THROTTLE VALVE CLOSED POSITION

LEARNING : Special Repair Requirement".

Perform the “Idle Air Volume Learning” and “Throttle Valve Closed

Position Learning” when electric throttle control actuator is

replaced. Refer to EC-16, "

IDLE AIR VOLUME LEARNING : Spe-

cial Repair Requirement".

: Engine front

JPBIA1628ZZ

JPBIA1631ZZ

Page 1907 of 5121

EM-32

< ON-VEHICLE REPAIR >

INTAKE MANIFOLD

INTAKE MANIFOLD

Exploded ViewINFOID:0000000003802255

Removal and InstallationINFOID:0000000003802256

REMOVAL

1. Release fuel pressure. Refer to EC-411, "Inspection".

2. Remove intake manifold collector. Refer to EM-28, "

Exploded View".

3. Remove fuel tube and fuel injector assembly. Refer to EM-44, "

Exploded View".

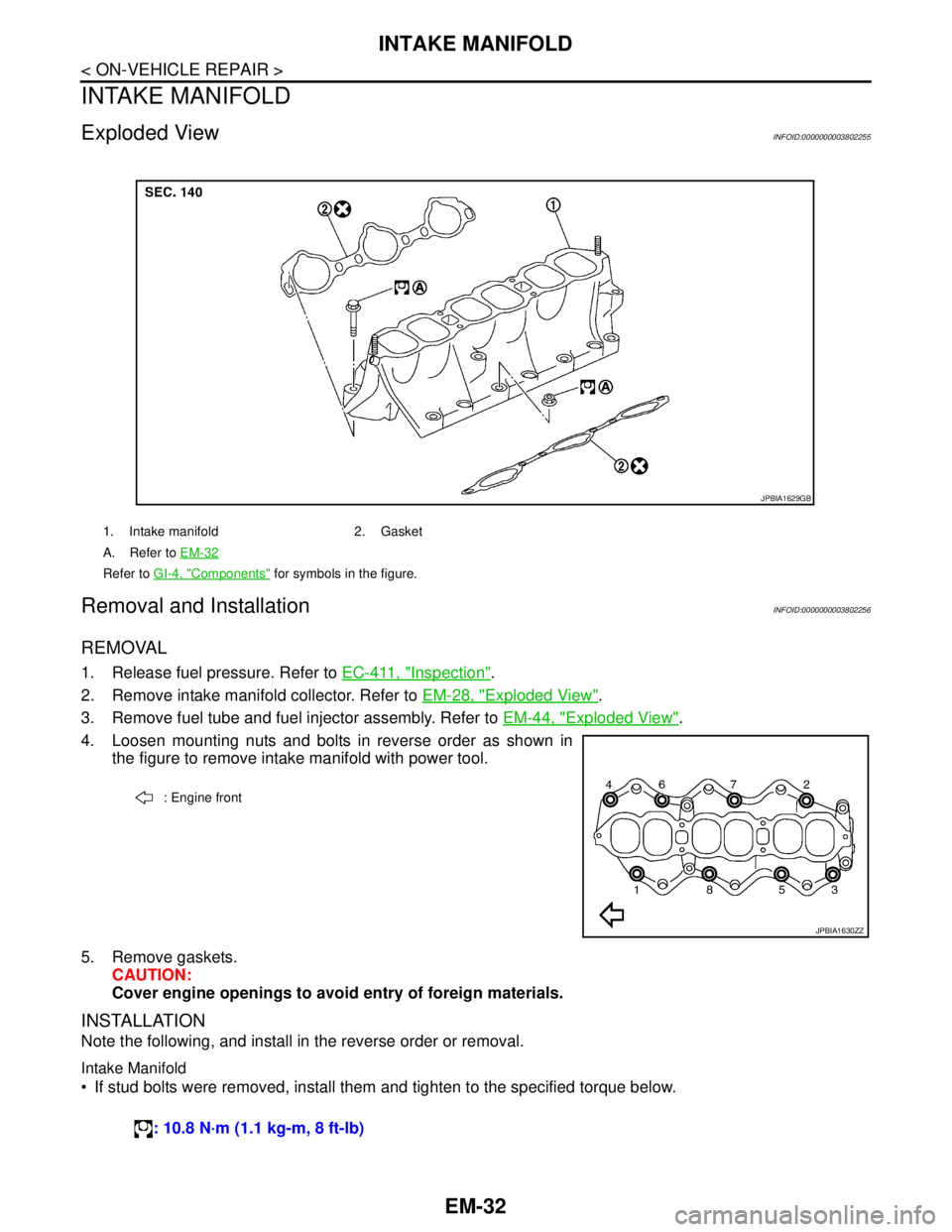

4. Loosen mounting nuts and bolts in reverse order as shown in

the figure to remove intake manifold with power tool.

5. Remove gaskets.

CAUTION:

Cover engine openings to avoid entry of foreign materials.

INSTALLATION

Note the following, and install in the reverse order or removal.

Intake Manifold

If stud bolts were removed, install them and tighten to the specified torque below.

1. Intake manifold 2. Gasket

A. Refer to EM-32

Refer to GI-4, "Components" for symbols in the figure.

JPBIA1629GB

: Engine front

JPBIA1630ZZ

: 10.8 N·m (1.1 kg-m, 8 ft-lb)

Page 1908 of 5121

INTAKE MANIFOLD

EM-33

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Tighten all mounting nuts and bolts to the specified torque in two or

more steps in numerical order shown in the figure.

InspectionINFOID:0000000003802257

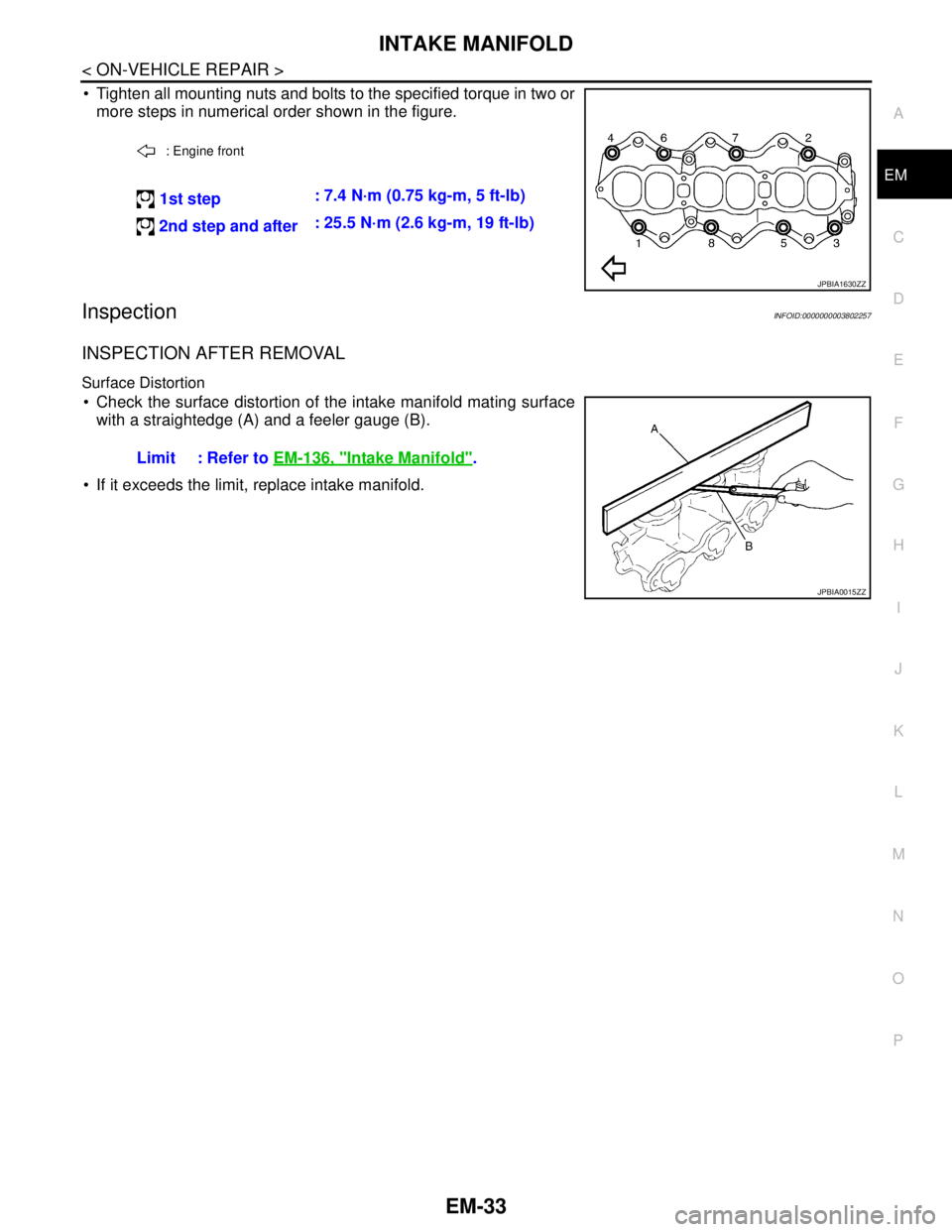

INSPECTION AFTER REMOVAL

Surface Distortion

Check the surface distortion of the intake manifold mating surface

with a straightedge (A) and a feeler gauge (B).

If it exceeds the limit, replace intake manifold.

: Engine front

1st step: 7.4 N·m (0.75 kg-m, 5 ft-lb)

2nd step and after: 25.5 N·m (2.6 kg-m, 19 ft-lb)

JPBIA1630ZZ

Limit : Refer to EM-136, "Intake Manifold".

JPBIA0015ZZ

Page 1909 of 5121

EM-34

< ON-VEHICLE REPAIR >

EXHAUST MANIFOLD AND THREE WAY CATALYST

EXHAUST MANIFOLD AND THREE WAY CATALYST

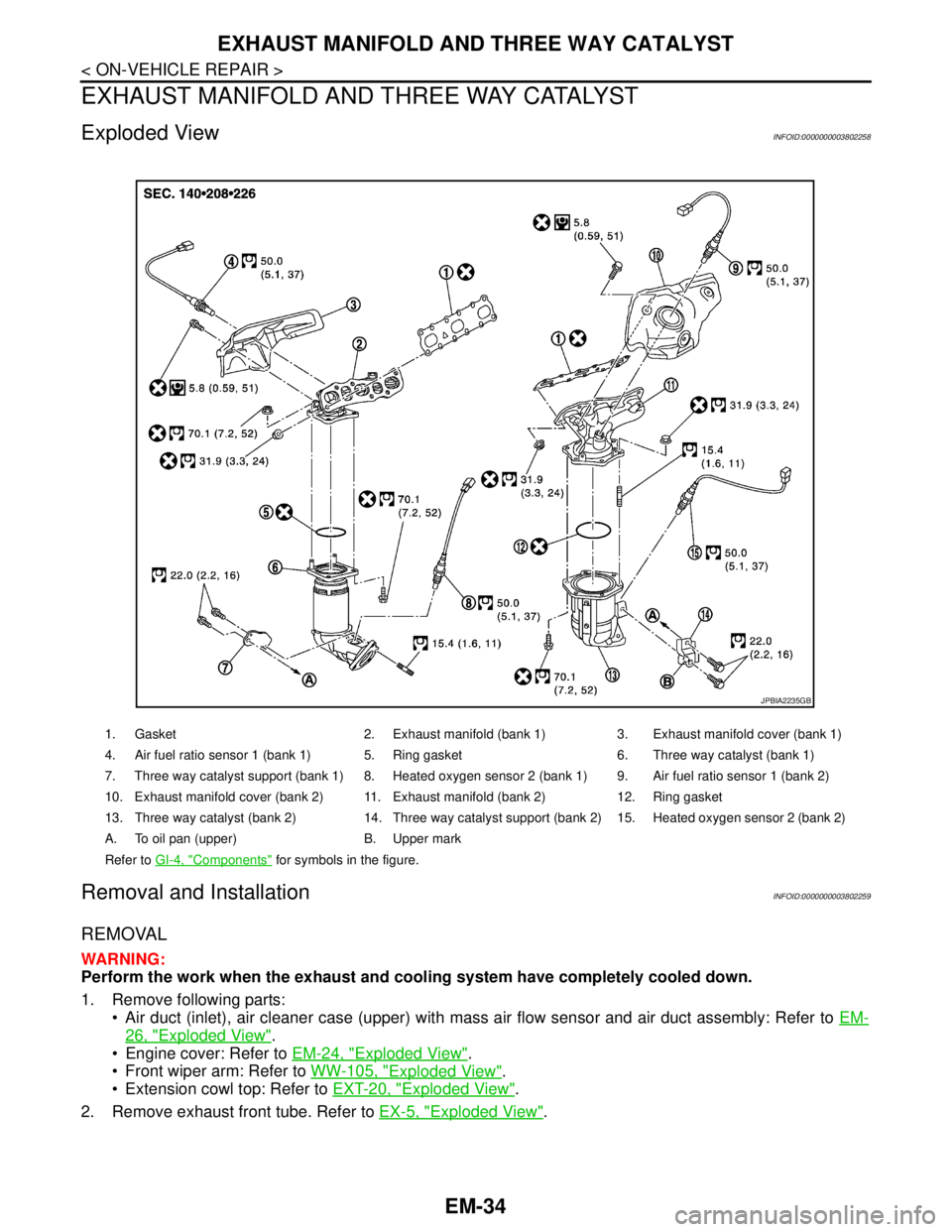

Exploded ViewINFOID:0000000003802258

Removal and InstallationINFOID:0000000003802259

REMOVAL

WARNING:

Perform the work when the exhaust and cooling system have completely cooled down.

1. Remove following parts:

Air duct (inlet), air cleaner case (upper) with mass air flow sensor and air duct assembly: Refer to EM-

26, "Exploded View".

Engine cover: Refer to EM-24, "

Exploded View".

Front wiper arm: Refer to WW-105, "

Exploded View".

Extension cowl top: Refer to EXT-20, "

Exploded View".

2. Remove exhaust front tube. Refer to EX-5, "

Exploded View".

1. Gasket 2. Exhaust manifold (bank 1) 3. Exhaust manifold cover (bank 1)

4. Air fuel ratio sensor 1 (bank 1) 5. Ring gasket 6. Three way catalyst (bank 1)

7. Three way catalyst support (bank 1) 8. Heated oxygen sensor 2 (bank 1) 9. Air fuel ratio sensor 1 (bank 2)

10. Exhaust manifold cover (bank 2) 11. Exhaust manifold (bank 2) 12. Ring gasket

13. Three way catalyst (bank 2) 14. Three way catalyst support (bank 2) 15. Heated oxygen sensor 2 (bank 2)

A. To oil pan (upper) B. Upper mark

Refer to GI-4, "

Components" for symbols in the figure.

JPBIA2235GB

Page 1910 of 5121

EXHAUST MANIFOLD AND THREE WAY CATALYST

EM-35

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

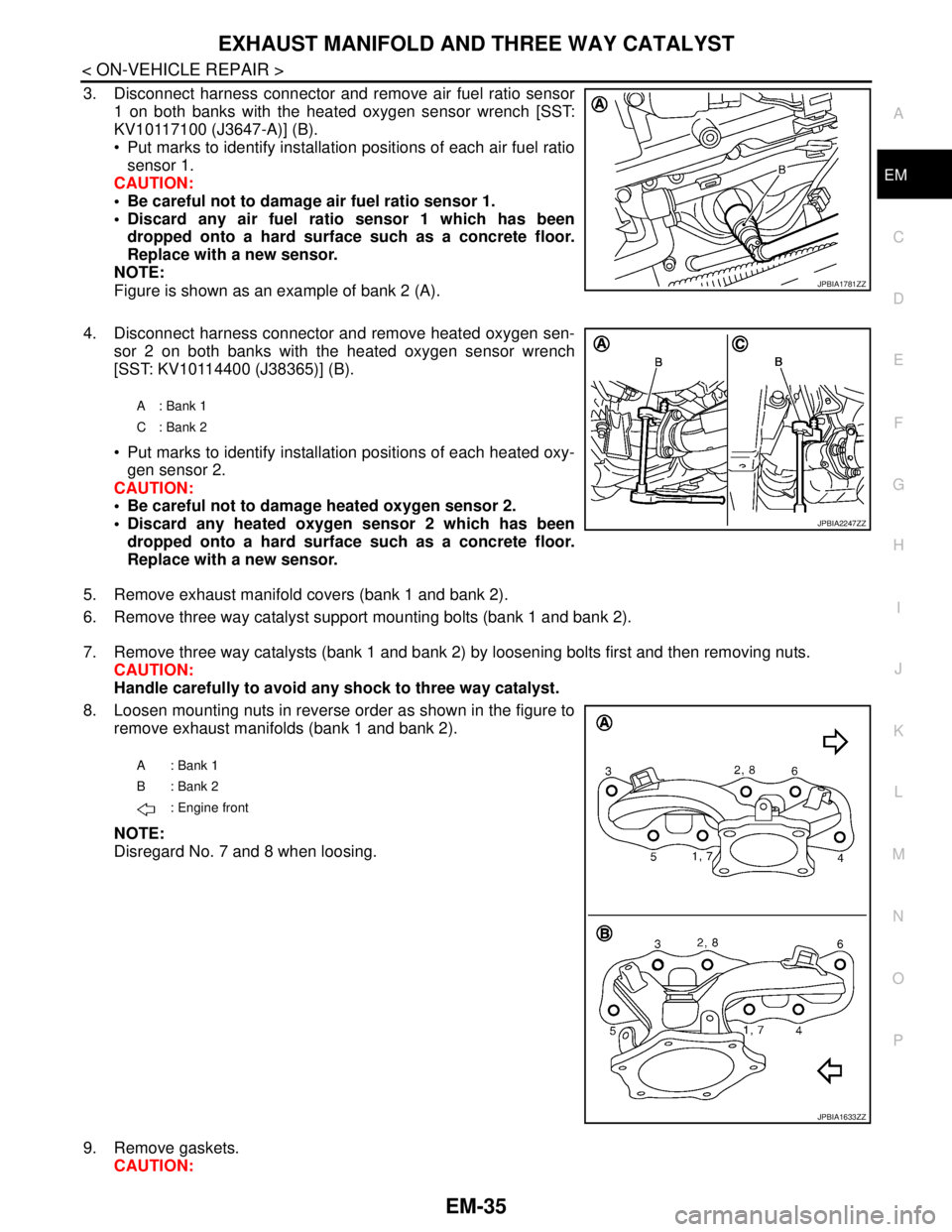

3. Disconnect harness connector and remove air fuel ratio sensor

1 on both banks with the heated oxygen sensor wrench [SST:

KV10117100 (J3647-A)] (B).

Put marks to identify installation positions of each air fuel ratio

sensor 1.

CAUTION:

Be careful not to damage air fuel ratio sensor 1.

Discard any air fuel ratio sensor 1 which has been

dropped onto a hard surface such as a concrete floor.

Replace with a new sensor.

NOTE:

Figure is shown as an example of bank 2 (A).

4. Disconnect harness connector and remove heated oxygen sen-

sor 2 on both banks with the heated oxygen sensor wrench

[SST: KV10114400 (J38365)] (B).

Put marks to identify installation positions of each heated oxy-

gen sensor 2.

CAUTION:

Be careful not to damage heated oxygen sensor 2.

Discard any heated oxygen sensor 2 which has been

dropped onto a hard surface such as a concrete floor.

Replace with a new sensor.

5. Remove exhaust manifold covers (bank 1 and bank 2).

6. Remove three way catalyst support mounting bolts (bank 1 and bank 2).

7. Remove three way catalysts (bank 1 and bank 2) by loosening bolts first and then removing nuts.

CAUTION:

Handle carefully to avoid any shock to three way catalyst.

8. Loosen mounting nuts in reverse order as shown in the figure to

remove exhaust manifolds (bank 1 and bank 2).

NOTE:

Disregard No. 7 and 8 when loosing.

9. Remove gaskets.

CAUTION:

JPBIA1781ZZ

A : Bank 1

C : Bank 2

JPBIA2247ZZ

A: Bank 1

B: Bank 2

: Engine front

JPBIA1633ZZ