NISSAN TEANA 2008 Service Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 1931 of 5121

EM-56

< ON-VEHICLE REPAIR >

TIMING CHAIN

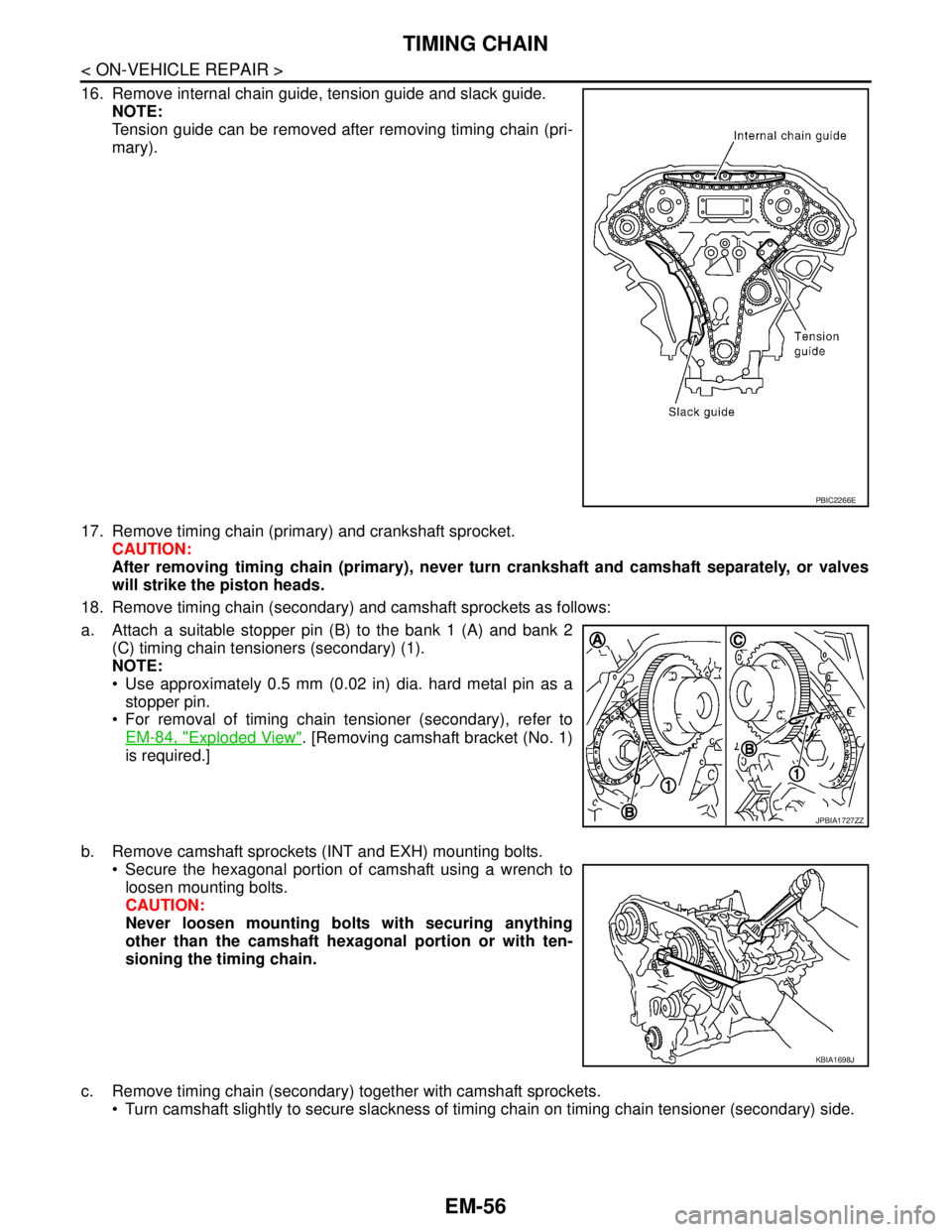

16. Remove internal chain guide, tension guide and slack guide.

NOTE:

Tension guide can be removed after removing timing chain (pri-

mary).

17. Remove timing chain (primary) and crankshaft sprocket.

CAUTION:

After removing timing chain (primary), never turn crankshaft and camshaft separately, or valves

will strike the piston heads.

18. Remove timing chain (secondary) and camshaft sprockets as follows:

a. Attach a suitable stopper pin (B) to the bank 1 (A) and bank 2

(C) timing chain tensioners (secondary) (1).

NOTE:

Use approximately 0.5 mm (0.02 in) dia. hard metal pin as a

stopper pin.

For removal of timing chain tensioner (secondary), refer to

EM-84, "

Exploded View". [Removing camshaft bracket (No. 1)

is required.]

b. Remove camshaft sprockets (INT and EXH) mounting bolts.

Secure the hexagonal portion of camshaft using a wrench to

loosen mounting bolts.

CAUTION:

Never loosen mounting bolts with securing anything

other than the camshaft hexagonal portion or with ten-

sioning the timing chain.

c. Remove timing chain (secondary) together with camshaft sprockets.

Turn camshaft slightly to secure slackness of timing chain on timing chain tensioner (secondary) side.

PBIC2266E

JPBIA1727ZZ

KBIA1698J

Page 1932 of 5121

TIMING CHAIN

EM-57

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Insert 0.5 mm (0.020 in) thick metal or resin plate between tim-

ing chain and timing chain tensioner plunger (guide) (F).

Remove timing chain (secondary) (1) together with camshaft

sprockets with timing chain loose from guide groove.

CAUTION:

Be careful of plunger coming-off when removing timing chain (secondary). This is because

plunger of timing chain tensioner (secondary) moves during operation, leading to coming-off of

fixed stopper pin.

NOTE:

Camshaft sprocket (INT) is two-for-one structure of sprockets for timing chain (primary) and for timing

chain (secondary).

Figure is shown as an example of bank 1.

When handling camshaft sprocket (INT), be careful of the following caution:

CAUTION:

Handle carefully to avoid any shock to camshaft sprocket.

Never disassemble. [Never loosen bolts (A) as shown in

the figure].

19. Remove timing chain tensioners (secondary) from cylinder head as follows, if necessary.

Remove timing chain tensioners (secondary) with a stopper pin attached.

20. Use a scraper to remove all traces of old liquid gasket from front

timing chain case, and opposite mating surfaces.

Remove old liquid gasket from bolt hole (B) and thread.

A: Bank 1

B : Timing chain tensioner (Body)

C: View C

D : Stopper pin

E: Plate

JPBIA1725ZZ

PBIC2980E

SEM737G

A : Remove sticking old liquid gasket

JPBIA0051ZZ

Page 1933 of 5121

EM-58

< ON-VEHICLE REPAIR >

TIMING CHAIN

21. Use a scraper to remove all traces of old liquid gasket from

water pump cover.

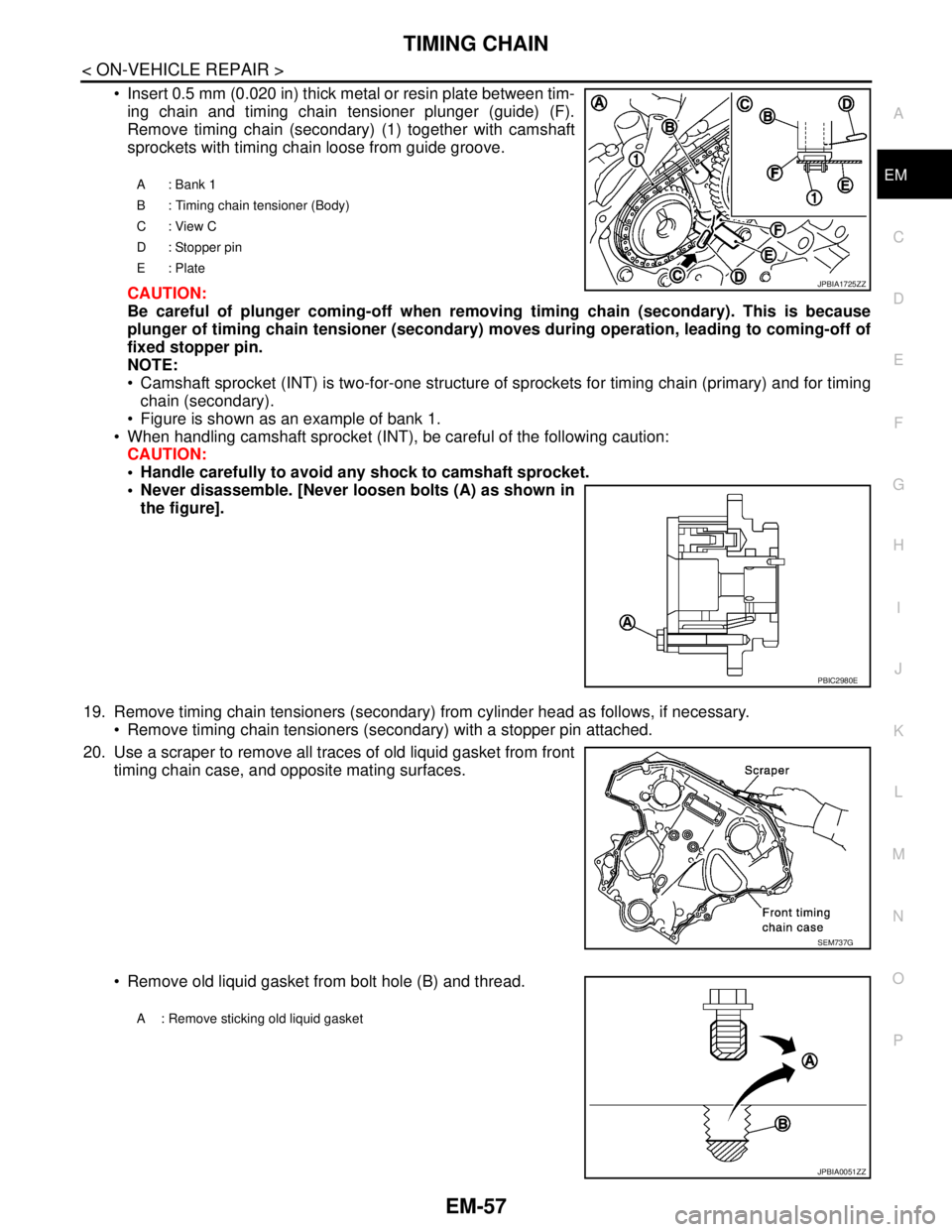

INSTALLATION

NOTE:

The below figure shows the relationship between the mating mark on each timing chain and that on the corre-

sponding sprocket, with the components installed.

1. Install timing chain tensioners (secondary) to cylinder head as follows if removed. Refer to EM-84,

"Exploded View".

Install timing chain tensioners (secondary) with a stopper pin attached and new O-ring.

SEM926E

1. Internal chain guide 2. Camshaft sprocket (INT) 3. Timing chain (secondary)

4. Camshaft sprocket (EXH) 5. Timing chain tensioner (primary) 6. Slack guide

7. Timing chain (primary) 8. Crankshaft sprocket 9. Water pump

10. Tension guide 11. Timing chain tensioner (secondary) 12. Crankshaft key

A. Mating mark B. Mating mark (pink link) C. Mating mark (punched)

D. Mating mark (orange) E. Mating mark (notched)

JPBIA1716GB

Page 1934 of 5121

TIMING CHAIN

EM-59

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

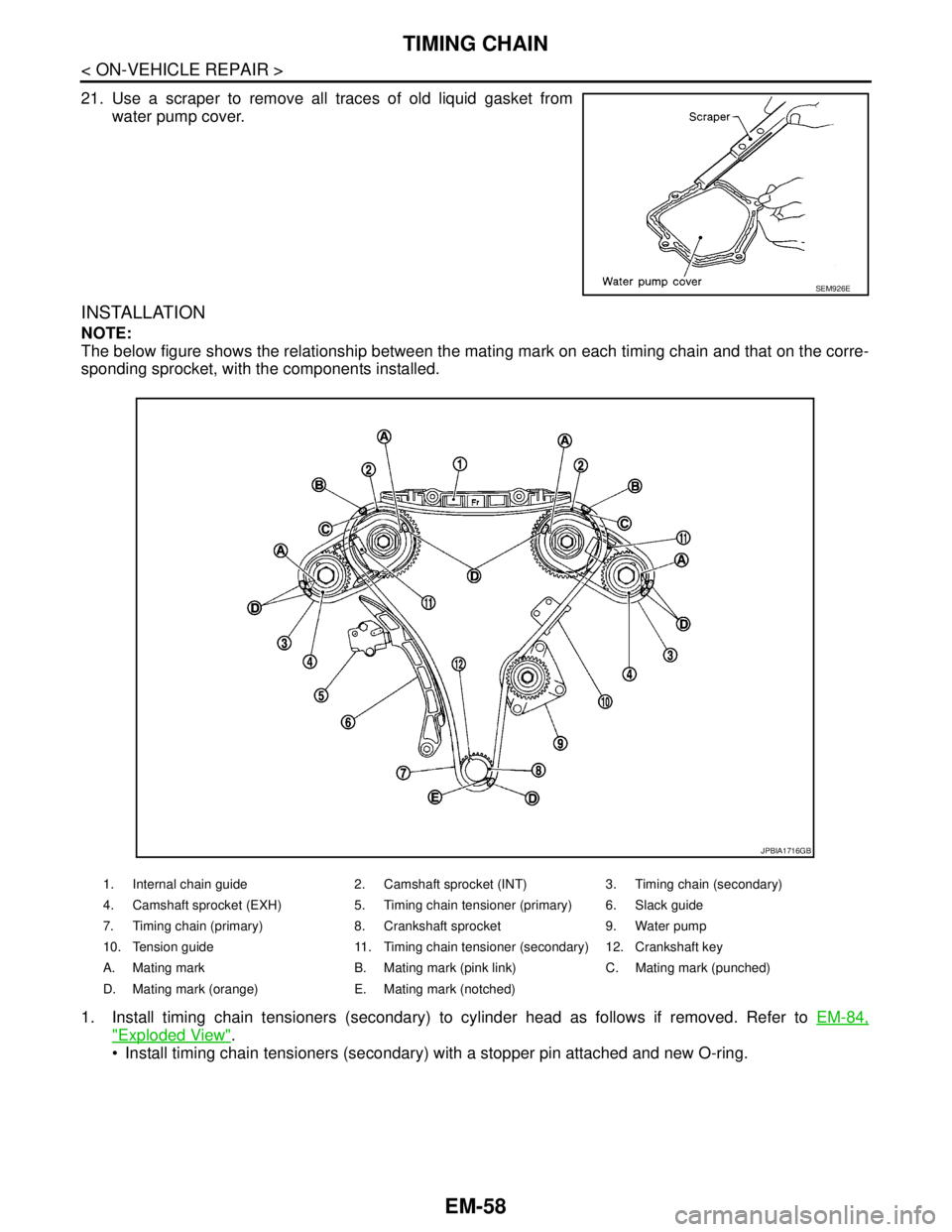

2. Check that dowel pin hole, dowel pin and crankshaft key are

located as shown in the figure. (No. 1 cylinder at compression

TDC)

NOTE:

Though camshaft does not stop at the position as shown in the

figure, for the placement of cam nose, it is generally accepted

camshaft is placed for the same direction of the figure.

CAUTION:

Hole on small dia. side must be used for intake side dowel pin hole. Never misidentify (ignore big

dia. side).

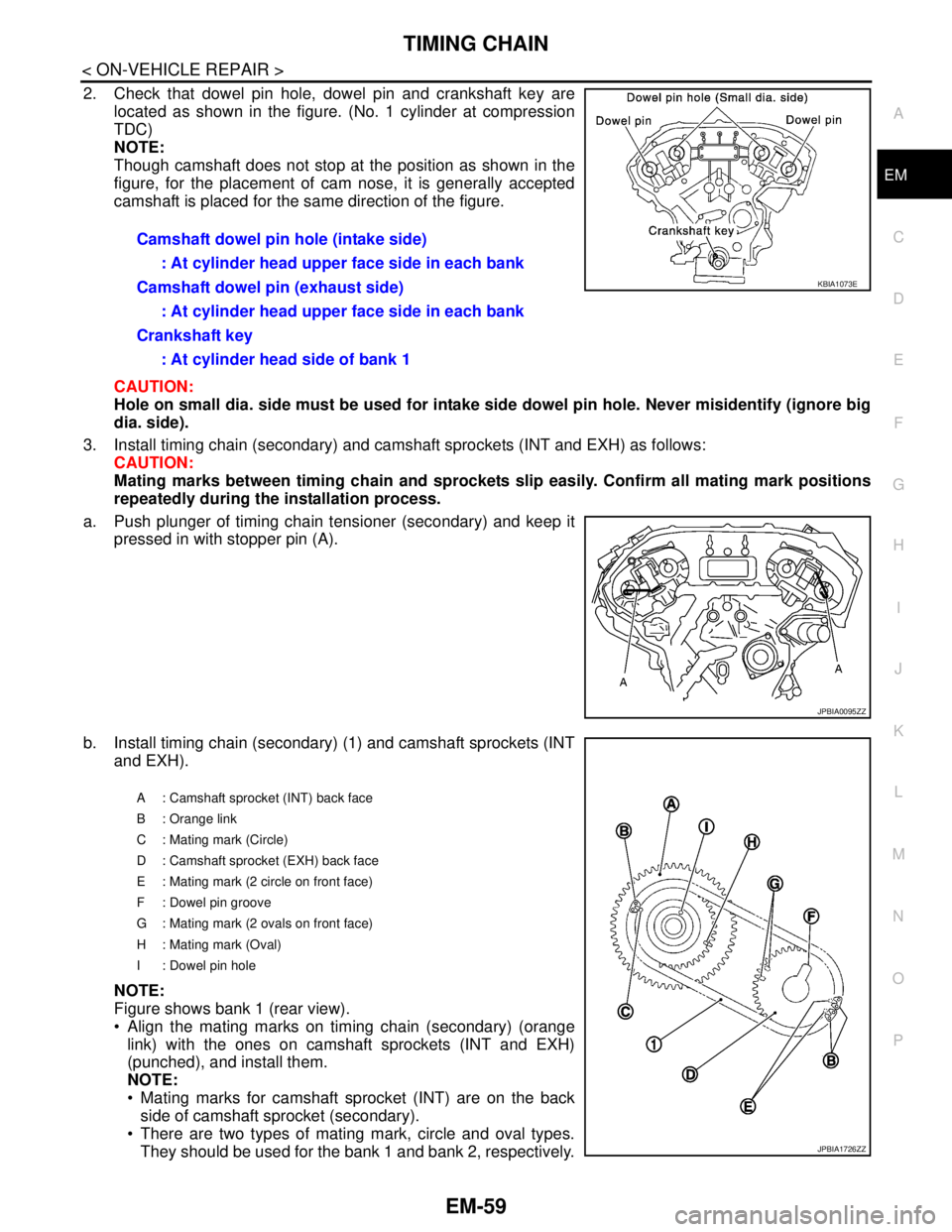

3. Install timing chain (secondary) and camshaft sprockets (INT and EXH) as follows:

CAUTION:

Mating marks between timing chain and sprockets slip easily. Confirm all mating mark positions

repeatedly during the installation process.

a. Push plunger of timing chain tensioner (secondary) and keep it

pressed in with stopper pin (A).

b. Install timing chain (secondary) (1) and camshaft sprockets (INT

and EXH).

NOTE:

Figure shows bank 1 (rear view).

Align the mating marks on timing chain (secondary) (orange

link) with the ones on camshaft sprockets (INT and EXH)

(punched), and install them.

NOTE:

Mating marks for camshaft sprocket (INT) are on the back

side of camshaft sprocket (secondary).

There are two types of mating mark, circle and oval types.

They should be used for the bank 1 and bank 2, respectively. Camshaft dowel pin hole (intake side)

: At cylinder head upper face side in each bank

Camshaft dowel pin (exhaust side)

: At cylinder head upper face side in each bank

Crankshaft key

: At cylinder head side of bank 1

KBIA1073E

JPBIA0095ZZ

A : Camshaft sprocket (INT) back face

B : Orange link

C : Mating mark (Circle)

D : Camshaft sprocket (EXH) back face

E : Mating mark (2 circle on front face)

F : Dowel pin groove

G : Mating mark (2 ovals on front face)

H : Mating mark (Oval)

I : Dowel pin hole

JPBIA1726ZZ

Page 1935 of 5121

EM-60

< ON-VEHICLE REPAIR >

TIMING CHAIN

Align dowel pin and pin hole on camshafts with the groove and dowel pin on sprockets, and install them.

On the intake side, align pin hole on the small diameter side of the camshaft front end with dowel pin on

the back side of camshaft sprocket, and install them.

On the exhaust side, align dowel pin on camshaft front end with pin groove on camshaft sprocket, and

install them.

In case that positions of each mating mark and each dowel pin are not fit on mating parts, make fine

adjustment to the position holding the hexagonal portion on camshaft with wrench or equivalent.

Mounting bolts for camshaft sprockets must be tightened in the next step. Tightening them by hand is

enough to prevent the dislocation of dowel pins.

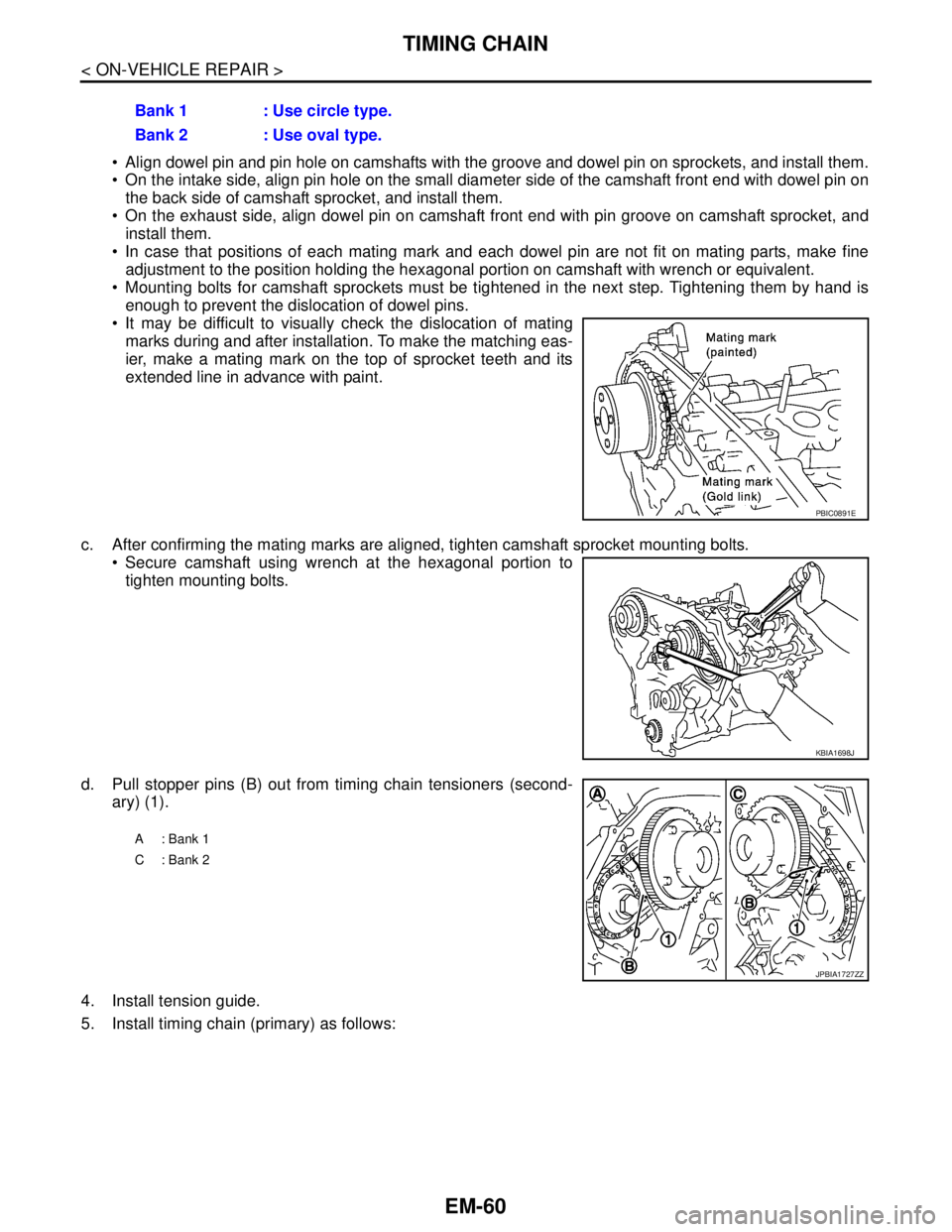

It may be difficult to visually check the dislocation of mating

marks during and after installation. To make the matching eas-

ier, make a mating mark on the top of sprocket teeth and its

extended line in advance with paint.

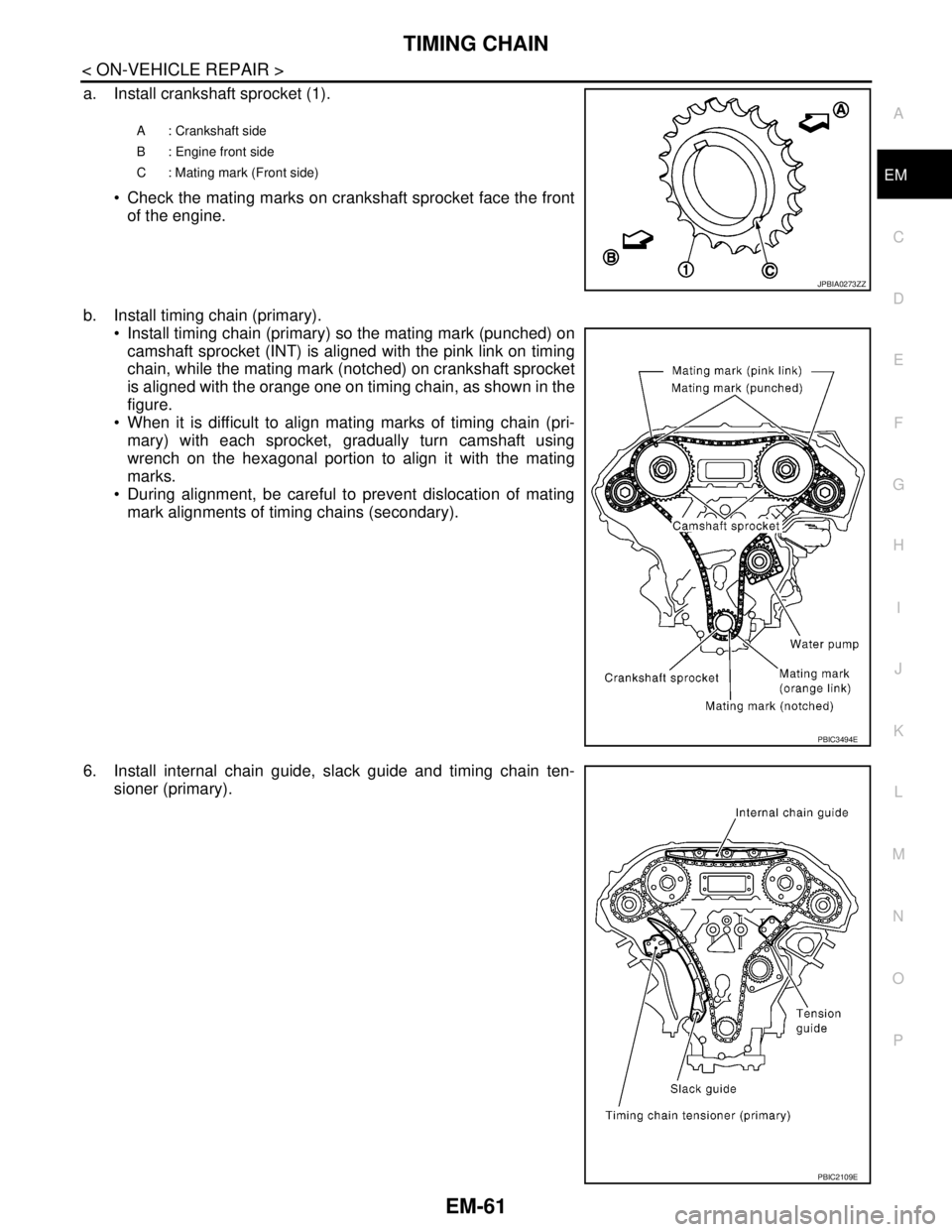

c. After confirming the mating marks are aligned, tighten camshaft sprocket mounting bolts.

Secure camshaft using wrench at the hexagonal portion to

tighten mounting bolts.

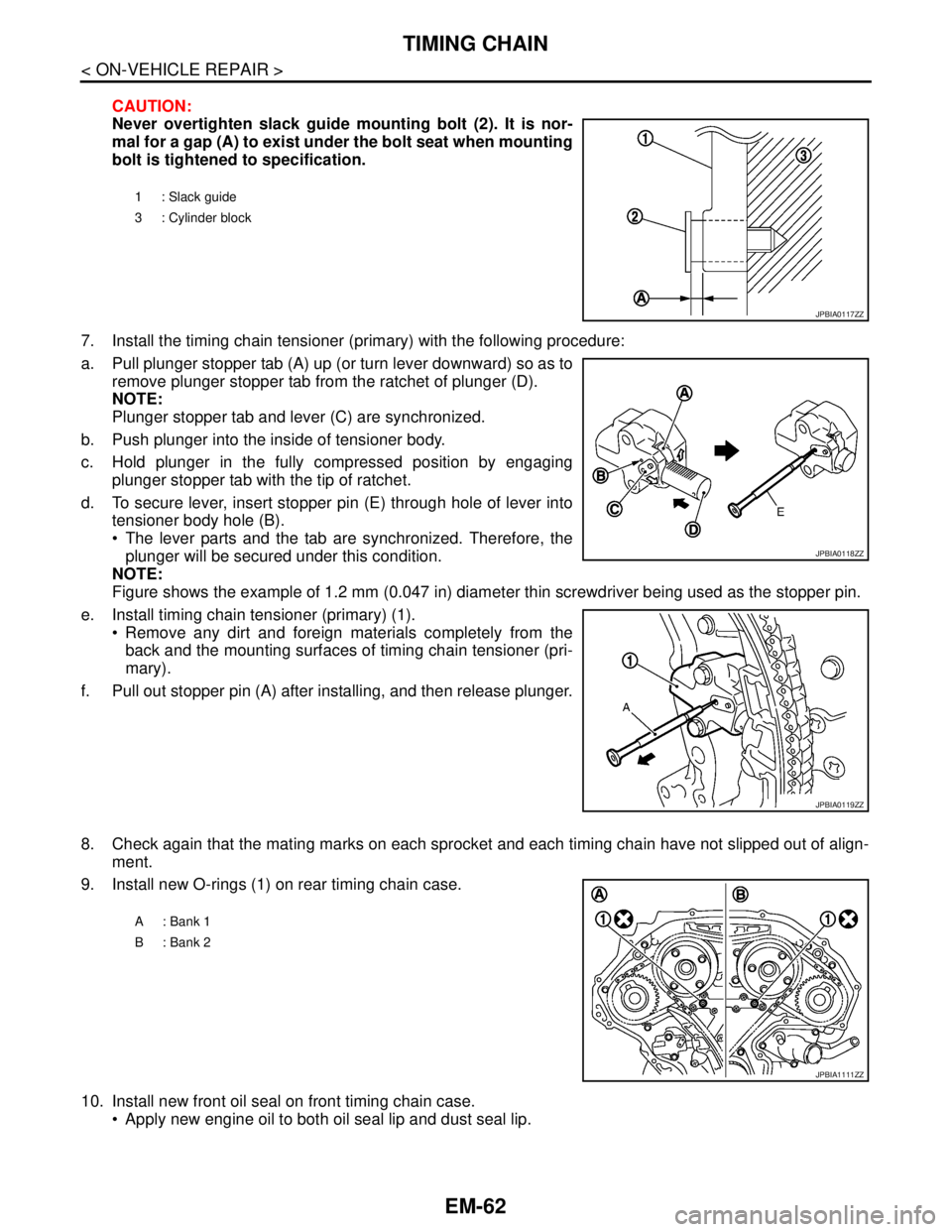

d. Pull stopper pins (B) out from timing chain tensioners (second-

ary) (1).

4. Install tension guide.

5. Install timing chain (primary) as follows:Bank 1 : Use circle type.

Bank 2 : Use oval type.

PBIC0891E

KBIA1698J

A: Bank 1

C: Bank 2

JPBIA1727ZZ

Page 1936 of 5121

TIMING CHAIN

EM-61

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

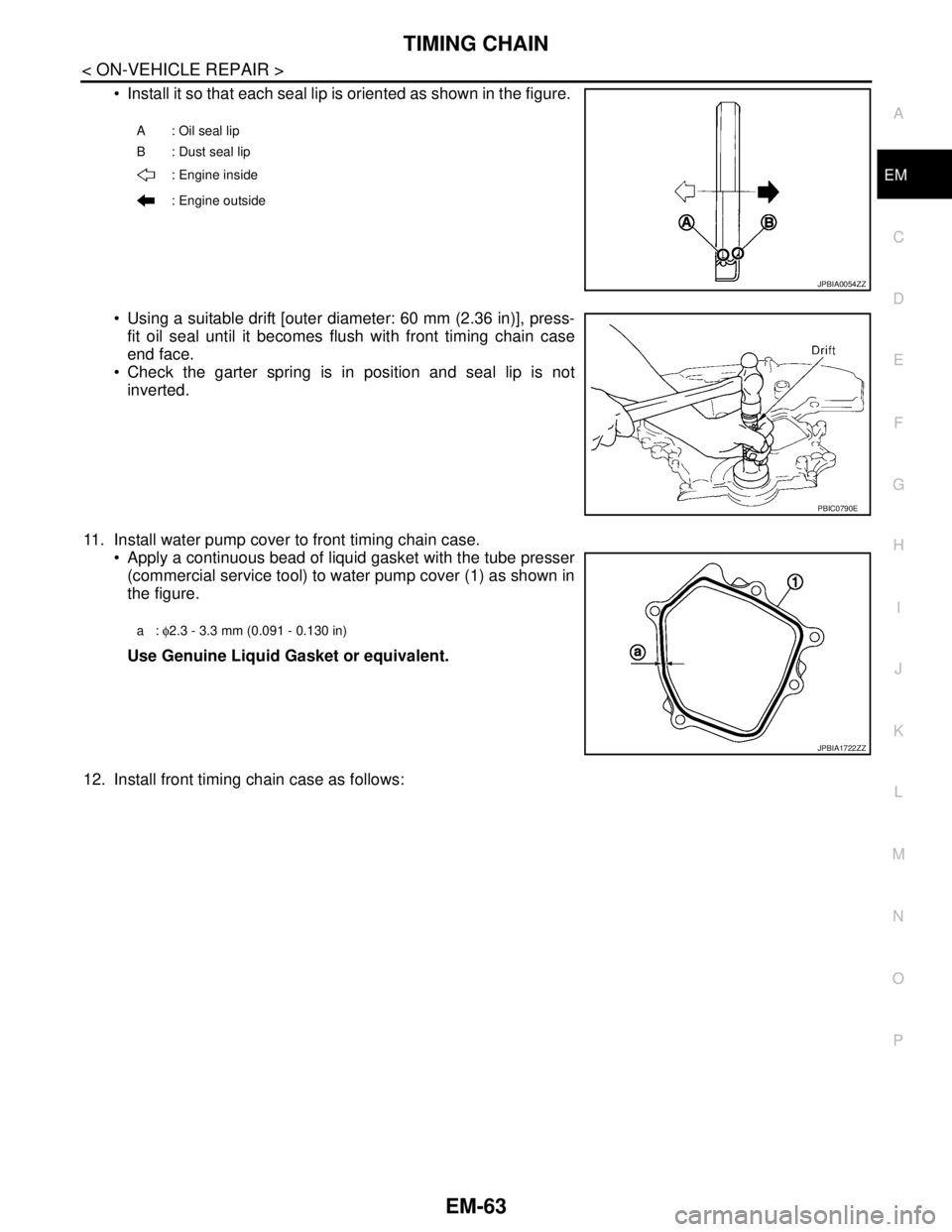

a. Install crankshaft sprocket (1).

Check the mating marks on crankshaft sprocket face the front

of the engine.

b. Install timing chain (primary).

Install timing chain (primary) so the mating mark (punched) on

camshaft sprocket (INT) is aligned with the pink link on timing

chain, while the mating mark (notched) on crankshaft sprocket

is aligned with the orange one on timing chain, as shown in the

figure.

When it is difficult to align mating marks of timing chain (pri-

mary) with each sprocket, gradually turn camshaft using

wrench on the hexagonal portion to align it with the mating

marks.

During alignment, be careful to prevent dislocation of mating

mark alignments of timing chains (secondary).

6. Install internal chain guide, slack guide and timing chain ten-

sioner (primary).

A : Crankshaft side

B : Engine front side

C : Mating mark (Front side)

JPBIA0273ZZ

PBIC3494E

PBIC2109E

Page 1937 of 5121

EM-62

< ON-VEHICLE REPAIR >

TIMING CHAIN

CAUTION:

Never overtighten slack guide mounting bolt (2). It is nor-

mal for a gap (A) to exist under the bolt seat when mounting

bolt is tightened to specification.

7. Install the timing chain tensioner (primary) with the following procedure:

a. Pull plunger stopper tab (A) up (or turn lever downward) so as to

remove plunger stopper tab from the ratchet of plunger (D).

NOTE:

Plunger stopper tab and lever (C) are synchronized.

b. Push plunger into the inside of tensioner body.

c. Hold plunger in the fully compressed position by engaging

plunger stopper tab with the tip of ratchet.

d. To secure lever, insert stopper pin (E) through hole of lever into

tensioner body hole (B).

The lever parts and the tab are synchronized. Therefore, the

plunger will be secured under this condition.

NOTE:

Figure shows the example of 1.2 mm (0.047 in) diameter thin screwdriver being used as the stopper pin.

e. Install timing chain tensioner (primary) (1).

Remove any dirt and foreign materials completely from the

back and the mounting surfaces of timing chain tensioner (pri-

mary).

f. Pull out stopper pin (A) after installing, and then release plunger.

8. Check again that the mating marks on each sprocket and each timing chain have not slipped out of align-

ment.

9. Install new O-rings (1) on rear timing chain case.

10. Install new front oil seal on front timing chain case.

Apply new engine oil to both oil seal lip and dust seal lip.

1 : Slack guide

3 : Cylinder block

JPBIA0117ZZ

JPBIA0118ZZ

JPBIA0119ZZ

A: Bank 1

B: Bank 2

JPBIA1111ZZ

Page 1938 of 5121

TIMING CHAIN

EM-63

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Install it so that each seal lip is oriented as shown in the figure.

Using a suitable drift [outer diameter: 60 mm (2.36 in)], press-

fit oil seal until it becomes flush with front timing chain case

end face.

Check the garter spring is in position and seal lip is not

inverted.

11. Install water pump cover to front timing chain case.

Apply a continuous bead of liquid gasket with the tube presser

(commercial service tool) to water pump cover (1) as shown in

the figure.

Use Genuine Liquid Gasket or equivalent.

12. Install front timing chain case as follows:

A: Oil seal lip

B : Dust seal lip

: Engine inside

: Engine outside

JPBIA0054ZZ

PBIC0790E

a: φ2.3 - 3.3 mm (0.091 - 0.130 in)

JPBIA1722ZZ

Page 1939 of 5121

EM-64

< ON-VEHICLE REPAIR >

TIMING CHAIN

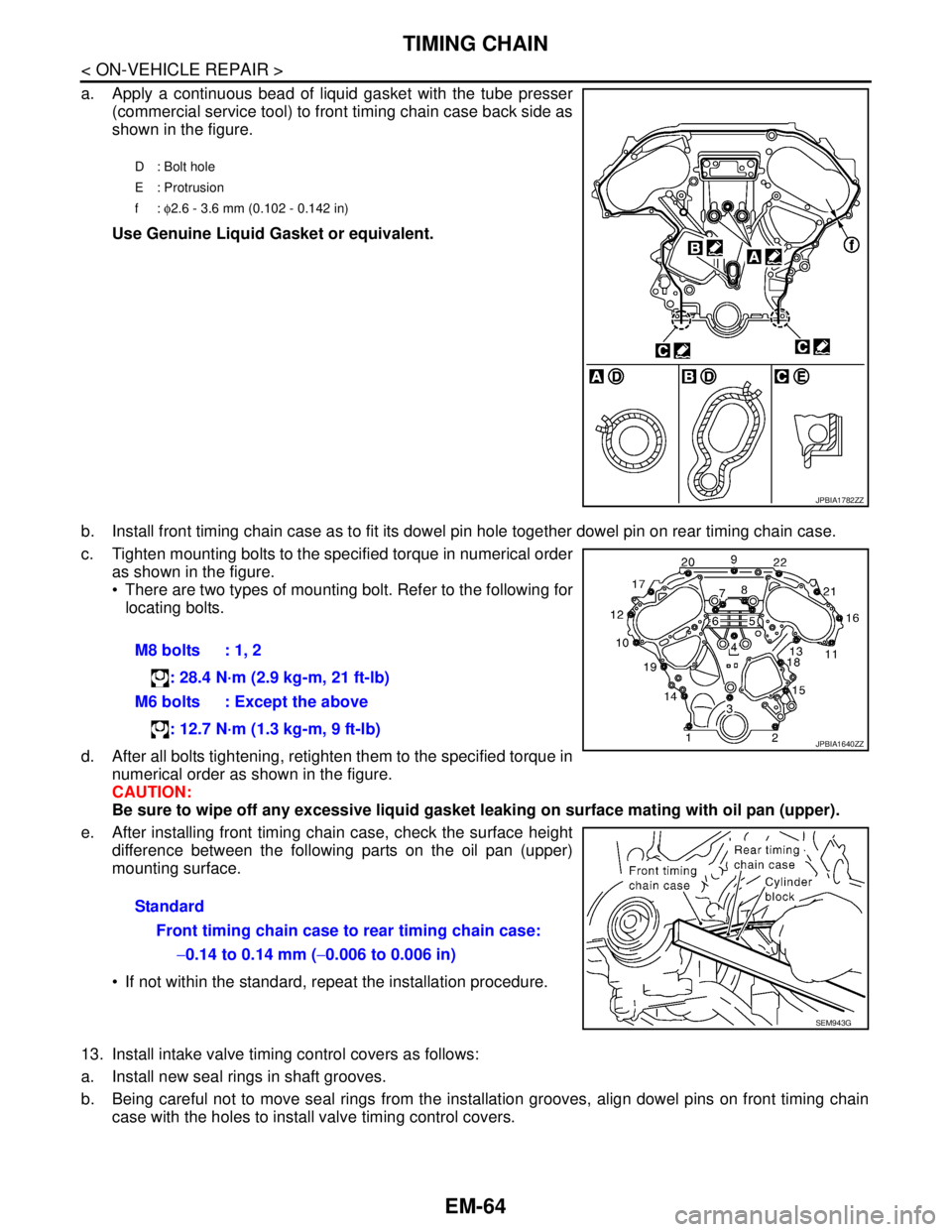

a. Apply a continuous bead of liquid gasket with the tube presser

(commercial service tool) to front timing chain case back side as

shown in the figure.

Use Genuine Liquid Gasket or equivalent.

b. Install front timing chain case as to fit its dowel pin hole together dowel pin on rear timing chain case.

c. Tighten mounting bolts to the specified torque in numerical order

as shown in the figure.

There are two types of mounting bolt. Refer to the following for

locating bolts.

d. After all bolts tightening, retighten them to the specified torque in

numerical order as shown in the figure.

CAUTION:

Be sure to wipe off any excessive liquid gasket leaking on surface mating with oil pan (upper).

e. After installing front timing chain case, check the surface height

difference between the following parts on the oil pan (upper)

mounting surface.

If not within the standard, repeat the installation procedure.

13. Install intake valve timing control covers as follows:

a. Install new seal rings in shaft grooves.

b. Being careful not to move seal rings from the installation grooves, align dowel pins on front timing chain

case with the holes to install valve timing control covers.

D: Bolt hole

E : Protrusion

f: φ2.6 - 3.6 mm (0.102 - 0.142 in)

JPBIA1782ZZ

M8 bolts : 1, 2

: 28.4 N·m (2.9 kg-m, 21 ft-lb)

M6 bolts : Except the above

: 12.7 N·m (1.3 kg-m, 9 ft-lb)

Standard

Front timing chain case to rear timing chain case:

−0.14 to 0.14 mm (−0.006 to 0.006 in)

JPBIA1640ZZ

SEM943G

Page 1940 of 5121

TIMING CHAIN

EM-65

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

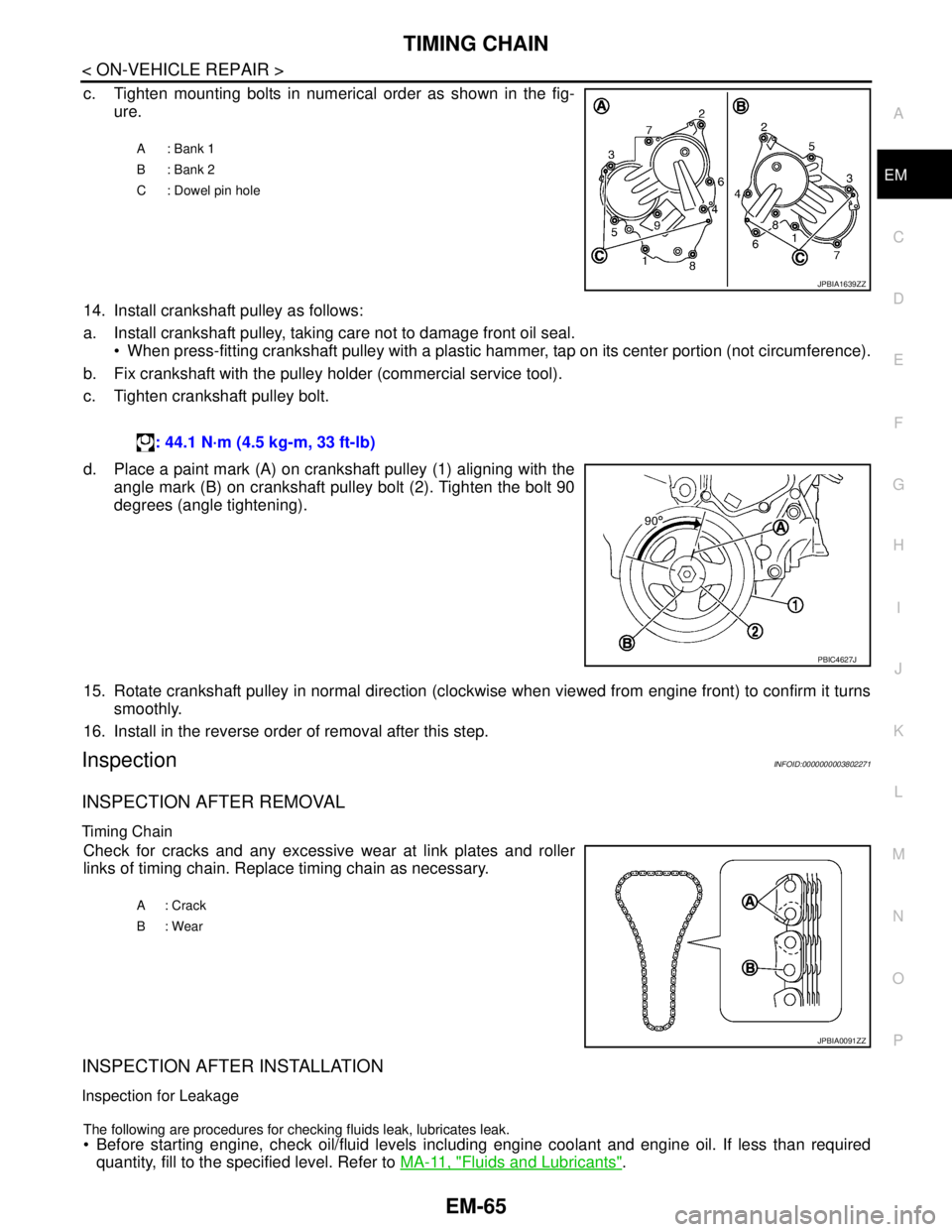

c. Tighten mounting bolts in numerical order as shown in the fig-

ure.

14. Install crankshaft pulley as follows:

a. Install crankshaft pulley, taking care not to damage front oil seal.

When press-fitting crankshaft pulley with a plastic hammer, tap on its center portion (not circumference).

b. Fix crankshaft with the pulley holder (commercial service tool).

c. Tighten crankshaft pulley bolt.

d. Place a paint mark (A) on crankshaft pulley (1) aligning with the

angle mark (B) on crankshaft pulley bolt (2). Tighten the bolt 90

degrees (angle tightening).

15. Rotate crankshaft pulley in normal direction (clockwise when viewed from engine front) to confirm it turns

smoothly.

16. Install in the reverse order of removal after this step.

InspectionINFOID:0000000003802271

INSPECTION AFTER REMOVAL

Timing Chain

Check for cracks and any excessive wear at link plates and roller

links of timing chain. Replace timing chain as necessary.

INSPECTION AFTER INSTALLATION

Inspection for Leakage

The following are procedures for checking fluids leak, lubricates leak.

Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-11, "

Fluids and Lubricants".

A: Bank 1

B: Bank 2

C : Dowel pin hole

JPBIA1639ZZ

: 44.1 N·m (4.5 kg-m, 33 ft-lb)

PBIC4627J

A: Crack

B: Wear

JPBIA0091ZZ