NISSAN TEANA 2008 Service Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 1891 of 5121

EM-16

< ON-VEHICLE MAINTENANCE >

SPARK PLUG

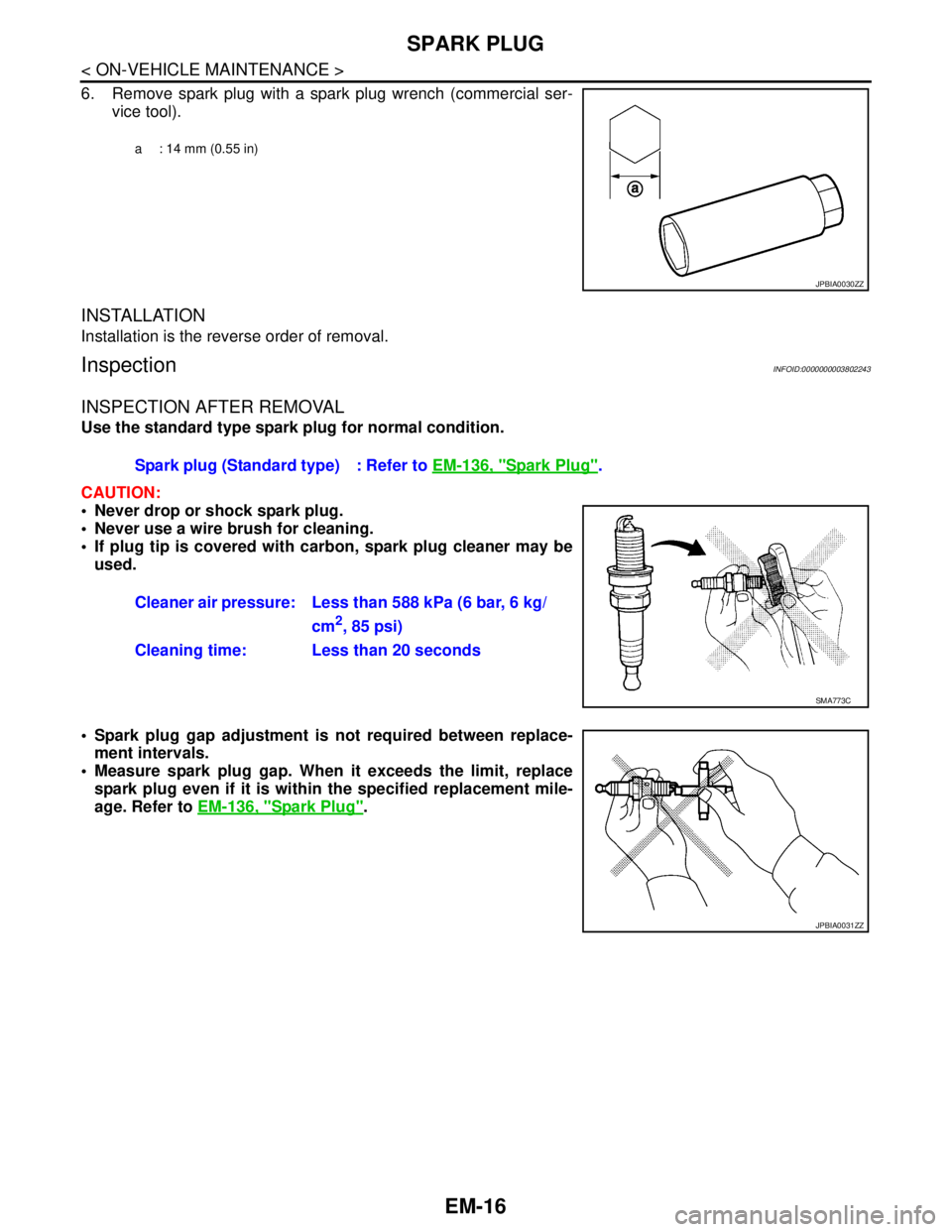

6. Remove spark plug with a spark plug wrench (commercial ser-

vice tool).

INSTALLATION

Installation is the reverse order of removal.

InspectionINFOID:0000000003802243

INSPECTION AFTER REMOVAL

Use the standard type spark plug for normal condition.

CAUTION:

Never drop or shock spark plug.

Never use a wire brush for cleaning.

If plug tip is covered with carbon, spark plug cleaner may be

used.

Spark plug gap adjustment is not required between replace-

ment intervals.

Measure spark plug gap. When it exceeds the limit, replace

spark plug even if it is within the specified replacement mile-

age. Refer to EM-136, "

Spark Plug".

a : 14 mm (0.55 in)

JPBIA0030ZZ

Spark plug (Standard type) : Refer to EM-136, "Spark Plug".

Cleaner air pressure: Less than 588 kPa (6 bar, 6 kg/

cm

2, 85 psi)

Cleaning time: Less than 20 seconds

SMA773C

JPBIA0031ZZ

Page 1892 of 5121

CAMSHAFT VALVE CLEARANCE

EM-17

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

CAMSHAFT VALVE CLEARANCE

Inspection and AdjustmentINFOID:0000000003802244

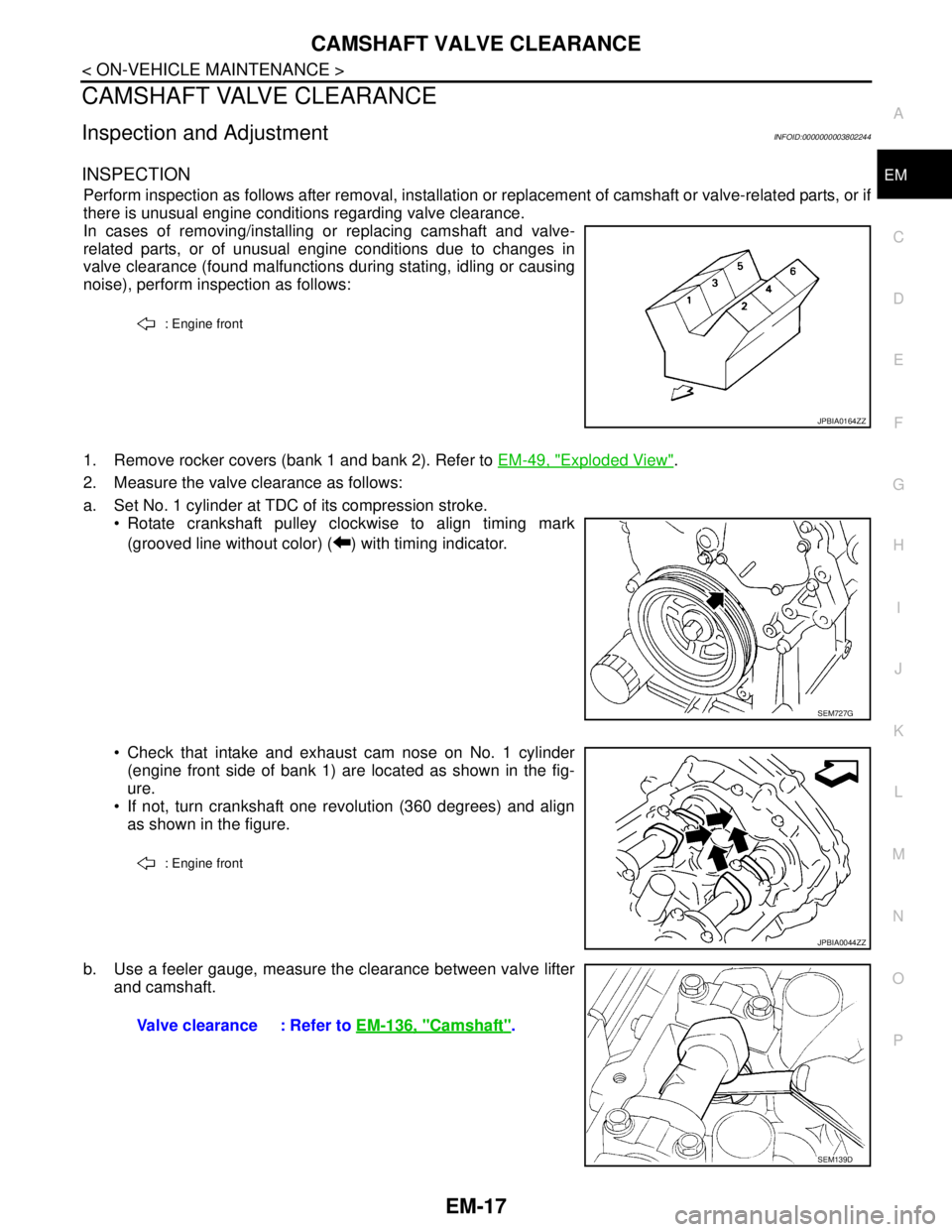

INSPECTION

Perform inspection as follows after removal, installation or replacement of camshaft or valve-related parts, or if

there is unusual engine conditions regarding valve clearance.

In cases of removing/installing or replacing camshaft and valve-

related parts, or of unusual engine conditions due to changes in

valve clearance (found malfunctions during stating, idling or causing

noise), perform inspection as follows:

1. Remove rocker covers (bank 1 and bank 2). Refer to EM-49, "

Exploded View".

2. Measure the valve clearance as follows:

a. Set No. 1 cylinder at TDC of its compression stroke.

Rotate crankshaft pulley clockwise to align timing mark

(grooved line without color) ( ) with timing indicator.

Check that intake and exhaust cam nose on No. 1 cylinder

(engine front side of bank 1) are located as shown in the fig-

ure.

If not, turn crankshaft one revolution (360 degrees) and align

as shown in the figure.

b. Use a feeler gauge, measure the clearance between valve lifter

and camshaft.

: Engine front

JPBIA0164ZZ

SEM727G

: Engine front

JPBIA0044ZZ

Valve clearance : Refer to EM-136, "Camshaft".

SEM139D

Page 1893 of 5121

EM-18

< ON-VEHICLE MAINTENANCE >

CAMSHAFT VALVE CLEARANCE

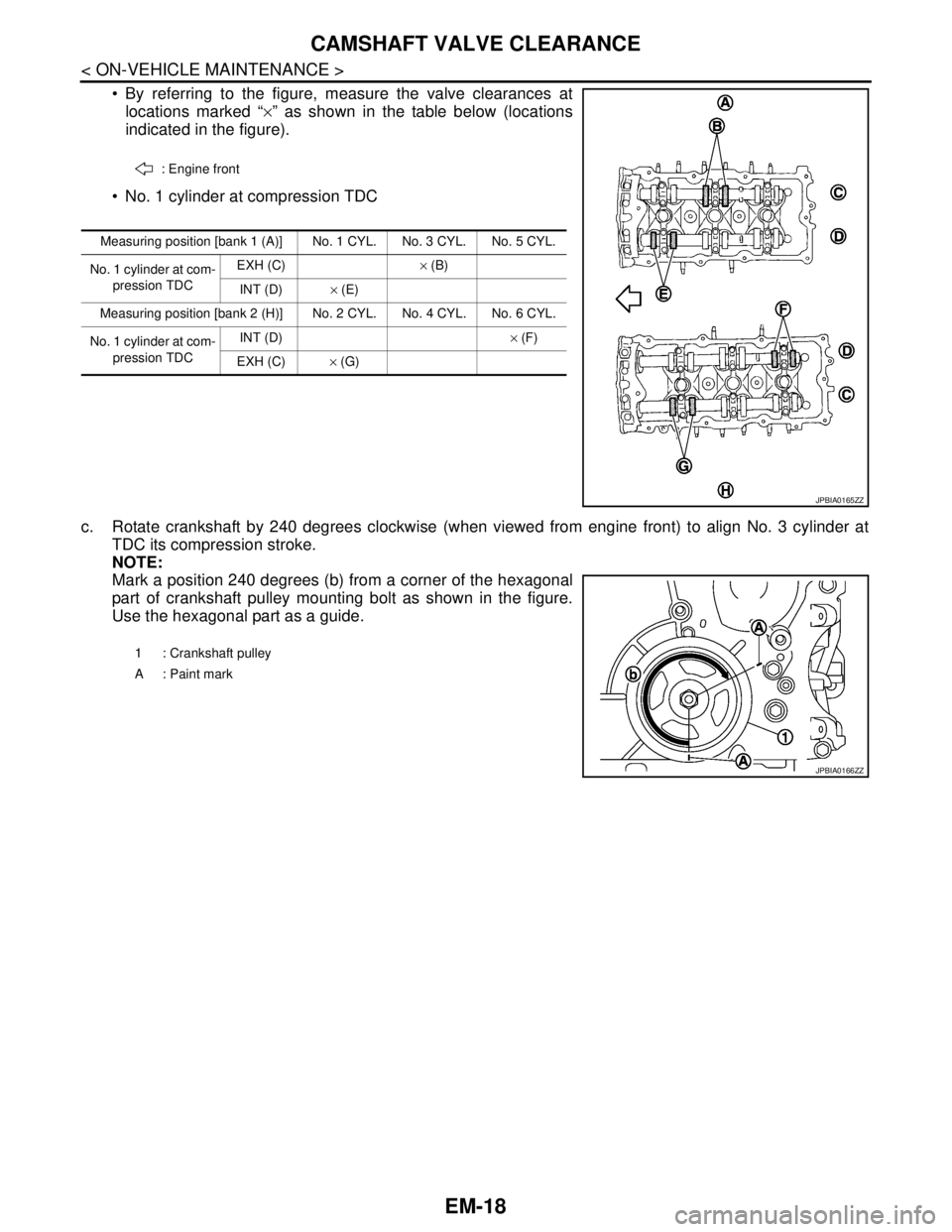

By referring to the figure, measure the valve clearances at

locations marked “×” as shown in the table below (locations

indicated in the figure).

No. 1 cylinder at compression TDC

c. Rotate crankshaft by 240 degrees clockwise (when viewed from engine front) to align No. 3 cylinder at

TDC its compression stroke.

NOTE:

Mark a position 240 degrees (b) from a corner of the hexagonal

part of crankshaft pulley mounting bolt as shown in the figure.

Use the hexagonal part as a guide.

: Engine front

Measuring position [bank 1 (A)] No. 1 CYL. No. 3 CYL. No. 5 CYL.

No. 1 cylinder at com-

pression TDCEXH (C)× (B)

INT (D)× (E)

Measuring position [bank 2 (H)] No. 2 CYL. No. 4 CYL. No. 6 CYL.

No. 1 cylinder at com-

pression TDCINT (D)× (F)

EXH (C)× (G)

JPBIA0165ZZ

1 : Crankshaft pulley

A : Paint mark

JPBIA0166ZZ

Page 1894 of 5121

CAMSHAFT VALVE CLEARANCE

EM-19

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

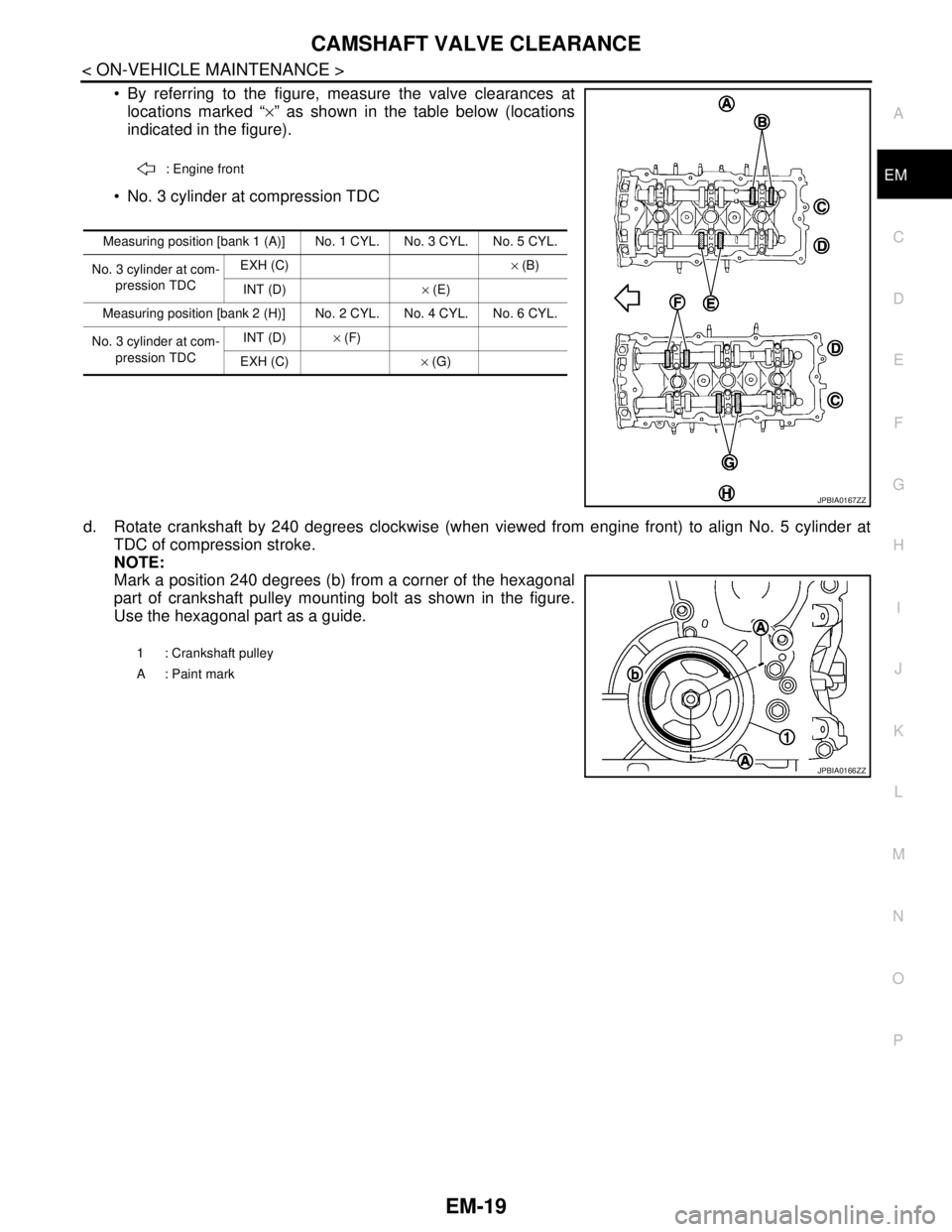

By referring to the figure, measure the valve clearances at

locations marked “×” as shown in the table below (locations

indicated in the figure).

No. 3 cylinder at compression TDC

d. Rotate crankshaft by 240 degrees clockwise (when viewed from engine front) to align No. 5 cylinder at

TDC of compression stroke.

NOTE:

Mark a position 240 degrees (b) from a corner of the hexagonal

part of crankshaft pulley mounting bolt as shown in the figure.

Use the hexagonal part as a guide.

: Engine front

Measuring position [bank 1 (A)] No. 1 CYL. No. 3 CYL. No. 5 CYL.

No. 3 cylinder at com-

pression TDCEXH (C)× (B)

INT (D)× (E)

Measuring position [bank 2 (H)] No. 2 CYL. No. 4 CYL. No. 6 CYL.

No. 3 cylinder at com-

pression TDCINT (D)× (F)

EXH (C)× (G)

JPBIA0167ZZ

1 : Crankshaft pulley

A : Paint mark

JPBIA0166ZZ

Page 1895 of 5121

EM-20

< ON-VEHICLE MAINTENANCE >

CAMSHAFT VALVE CLEARANCE

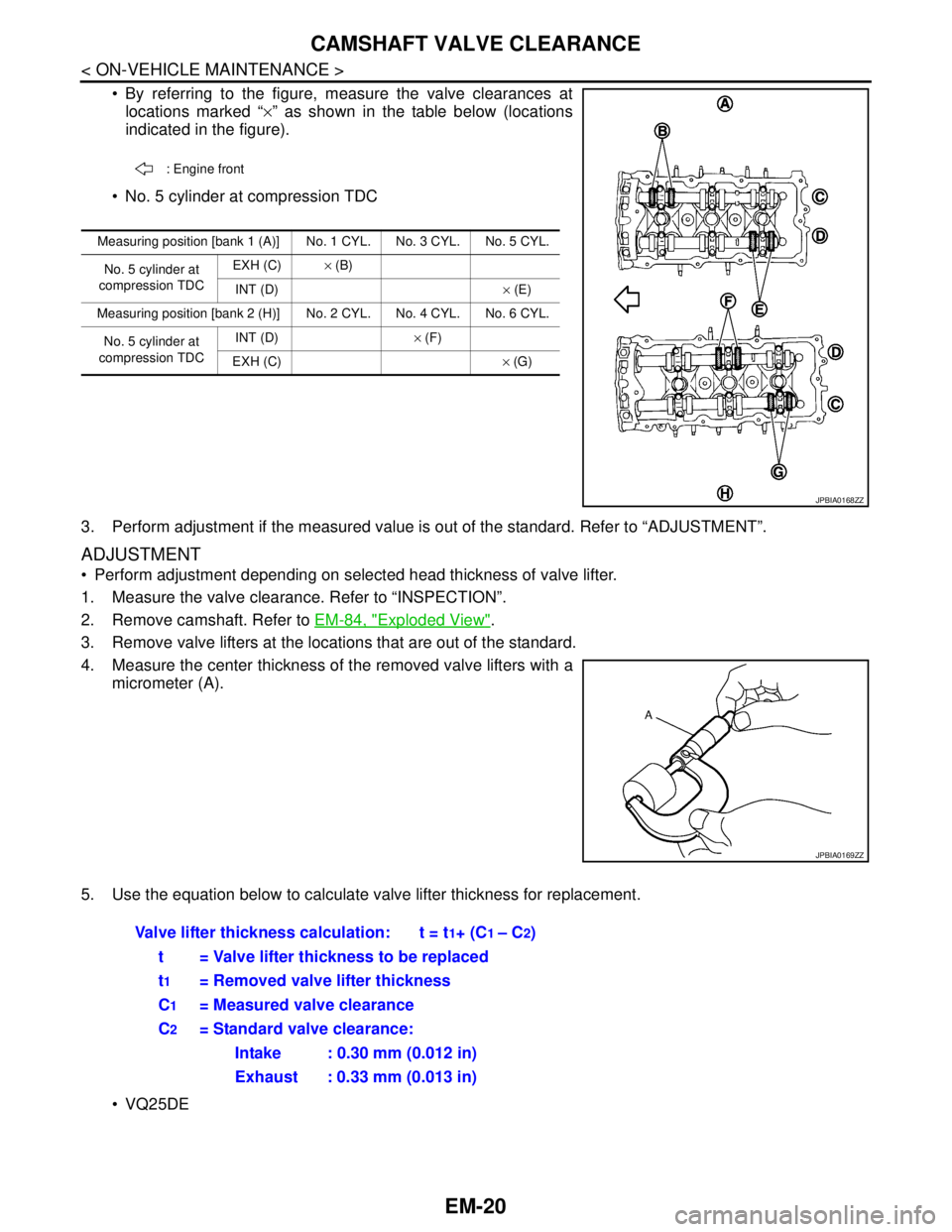

By referring to the figure, measure the valve clearances at

locations marked “×” as shown in the table below (locations

indicated in the figure).

No. 5 cylinder at compression TDC

3. Perform adjustment if the measured value is out of the standard. Refer to “ADJUSTMENT”.

ADJUSTMENT

Perform adjustment depending on selected head thickness of valve lifter.

1. Measure the valve clearance. Refer to “INSPECTION”.

2. Remove camshaft. Refer to EM-84, "

Exploded View".

3. Remove valve lifters at the locations that are out of the standard.

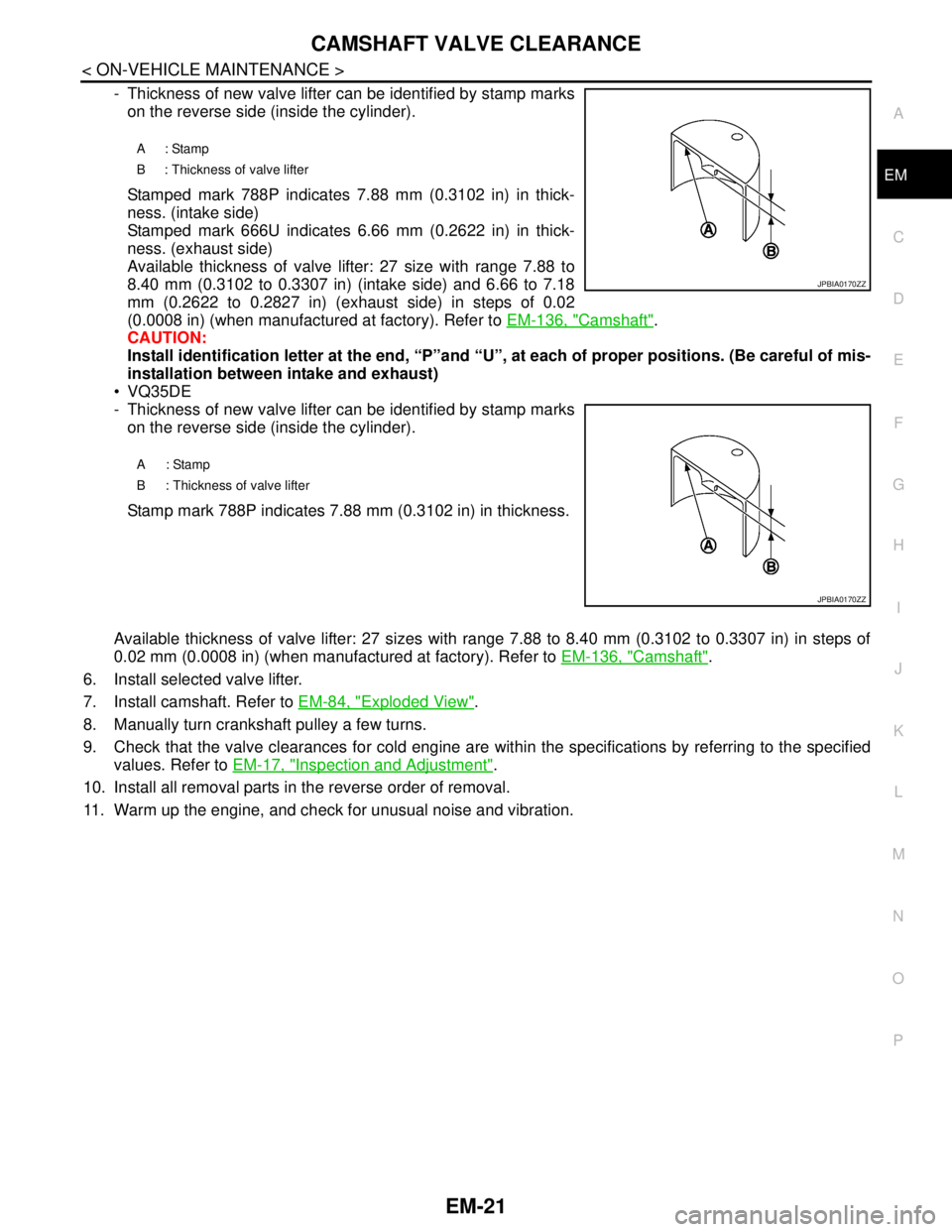

4. Measure the center thickness of the removed valve lifters with a

micrometer (A).

5. Use the equation below to calculate valve lifter thickness for replacement.

VQ25DE

: Engine front

Measuring position [bank 1 (A)] No. 1 CYL. No. 3 CYL. No. 5 CYL.

No. 5 cylinder at

compression TDCEXH (C)× (B)

INT (D)× (E)

Measuring position [bank 2 (H)] No. 2 CYL. No. 4 CYL. No. 6 CYL.

No. 5 cylinder at

compression TDCINT (D)× (F)

EXH (C)× (G)

JPBIA0168ZZ

JPBIA0169ZZ

Valve lifter thickness calculation: t = t1+ (C1 – C2)

t = Valve lifter thickness to be replaced

t

1= Removed valve lifter thickness

C

1= Measured valve clearance

C

2= Standard valve clearance:

Intake : 0.30 mm (0.012 in)

Exhaust : 0.33 mm (0.013 in)

Page 1896 of 5121

CAMSHAFT VALVE CLEARANCE

EM-21

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

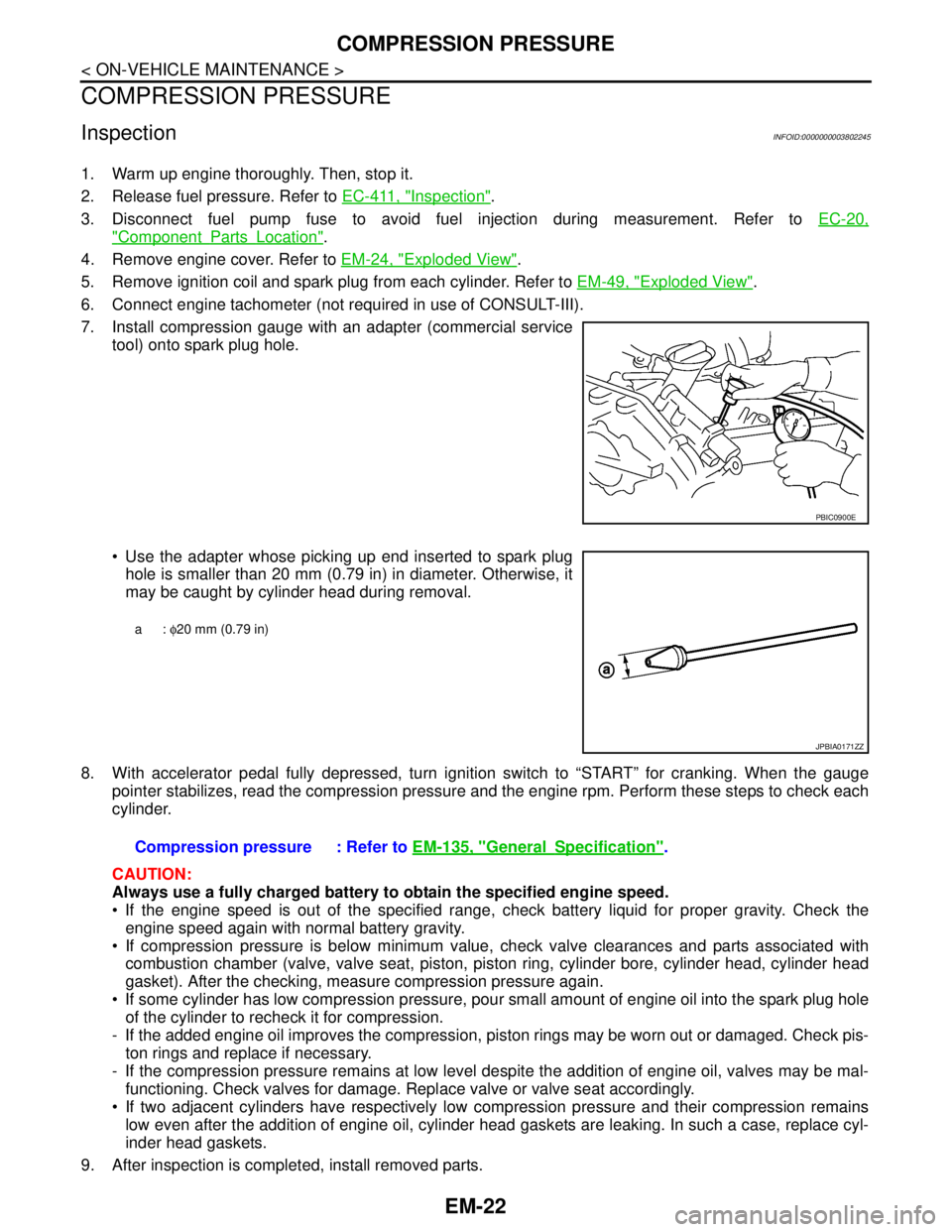

- Thickness of new valve lifter can be identified by stamp marks

on the reverse side (inside the cylinder).

Stamped mark 788P indicates 7.88 mm (0.3102 in) in thick-

ness. (intake side)

Stamped mark 666U indicates 6.66 mm (0.2622 in) in thick-

ness. (exhaust side)

Available thickness of valve lifter: 27 size with range 7.88 to

8.40 mm (0.3102 to 0.3307 in) (intake side) and 6.66 to 7.18

mm (0.2622 to 0.2827 in) (exhaust side) in steps of 0.02

(0.0008 in) (when manufactured at factory). Refer to EM-136, "

Camshaft".

CAUTION:

Install identification letter at the end, “P”and “U”, at each of proper positions. (Be careful of mis-

installation between intake and exhaust)

VQ35DE

- Thickness of new valve lifter can be identified by stamp marks

on the reverse side (inside the cylinder).

Stamp mark 788P indicates 7.88 mm (0.3102 in) in thickness.

Available thickness of valve lifter: 27 sizes with range 7.88 to 8.40 mm (0.3102 to 0.3307 in) in steps of

0.02 mm (0.0008 in) (when manufactured at factory). Refer to EM-136, "

Camshaft".

6. Install selected valve lifter.

7. Install camshaft. Refer to EM-84, "

Exploded View".

8. Manually turn crankshaft pulley a few turns.

9. Check that the valve clearances for cold engine are within the specifications by referring to the specified

values. Refer to EM-17, "

Inspection and Adjustment".

10. Install all removal parts in the reverse order of removal.

11. Warm up the engine, and check for unusual noise and vibration.

A: Stamp

B : Thickness of valve lifter

A: Stamp

B : Thickness of valve lifter

JPBIA0170ZZ

JPBIA0170ZZ

Page 1897 of 5121

EM-22

< ON-VEHICLE MAINTENANCE >

COMPRESSION PRESSURE

COMPRESSION PRESSURE

InspectionINFOID:0000000003802245

1. Warm up engine thoroughly. Then, stop it.

2. Release fuel pressure. Refer to EC-411, "

Inspection".

3. Disconnect fuel pump fuse to avoid fuel injection during measurement. Refer to EC-20,

"ComponentPartsLocation".

4. Remove engine cover. Refer to EM-24, "

Exploded View".

5. Remove ignition coil and spark plug from each cylinder. Refer to EM-49, "

Exploded View".

6. Connect engine tachometer (not required in use of CONSULT-III).

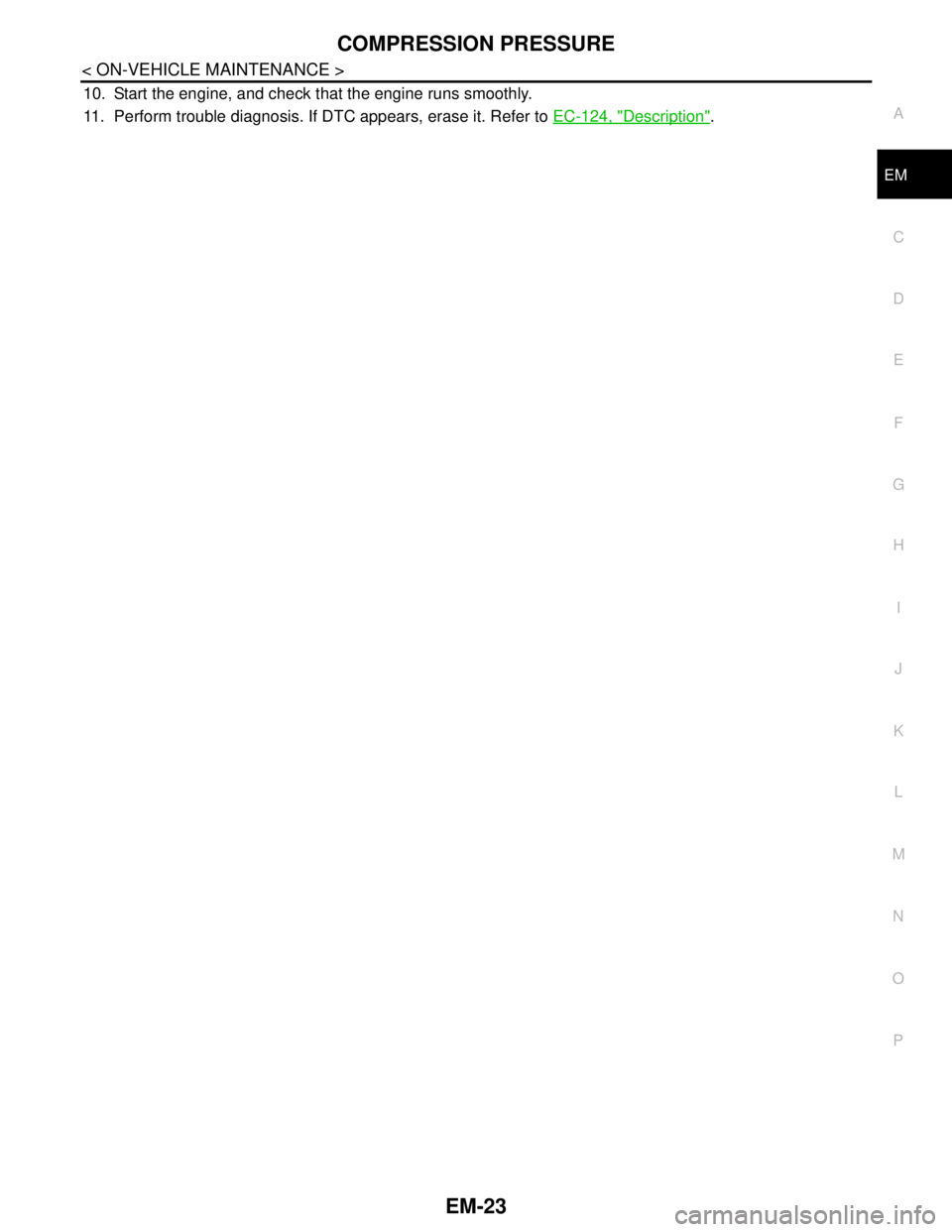

7. Install compression gauge with an adapter (commercial service

tool) onto spark plug hole.

Use the adapter whose picking up end inserted to spark plug

hole is smaller than 20 mm (0.79 in) in diameter. Otherwise, it

may be caught by cylinder head during removal.

8. With accelerator pedal fully depressed, turn ignition switch to “START” for cranking. When the gauge

pointer stabilizes, read the compression pressure and the engine rpm. Perform these steps to check each

cylinder.

CAUTION:

Always use a fully charged battery to obtain the specified engine speed.

If the engine speed is out of the specified range, check battery liquid for proper gravity. Check the

engine speed again with normal battery gravity.

If compression pressure is below minimum value, check valve clearances and parts associated with

combustion chamber (valve, valve seat, piston, piston ring, cylinder bore, cylinder head, cylinder head

gasket). After the checking, measure compression pressure again.

If some cylinder has low compression pressure, pour small amount of engine oil into the spark plug hole

of the cylinder to recheck it for compression.

- If the added engine oil improves the compression, piston rings may be worn out or damaged. Check pis-

ton rings and replace if necessary.

- If the compression pressure remains at low level despite the addition of engine oil, valves may be mal-

functioning. Check valves for damage. Replace valve or valve seat accordingly.

If two adjacent cylinders have respectively low compression pressure and their compression remains

low even after the addition of engine oil, cylinder head gaskets are leaking. In such a case, replace cyl-

inder head gaskets.

9. After inspection is completed, install removed parts.

PBIC0900E

a: φ20 mm (0.79 in)

JPBIA0171ZZ

Compression pressure : Refer to EM-135, "GeneralSpecification".

Page 1898 of 5121

COMPRESSION PRESSURE

EM-23

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

10. Start the engine, and check that the engine runs smoothly.

11. Perform trouble diagnosis. If DTC appears, erase it. Refer to EC-124, "

Description".

Page 1899 of 5121

EM-24

< ON-VEHICLE REPAIR >

ENGINE COVER

ON-VEHICLE REPAIR

ENGINE COVER

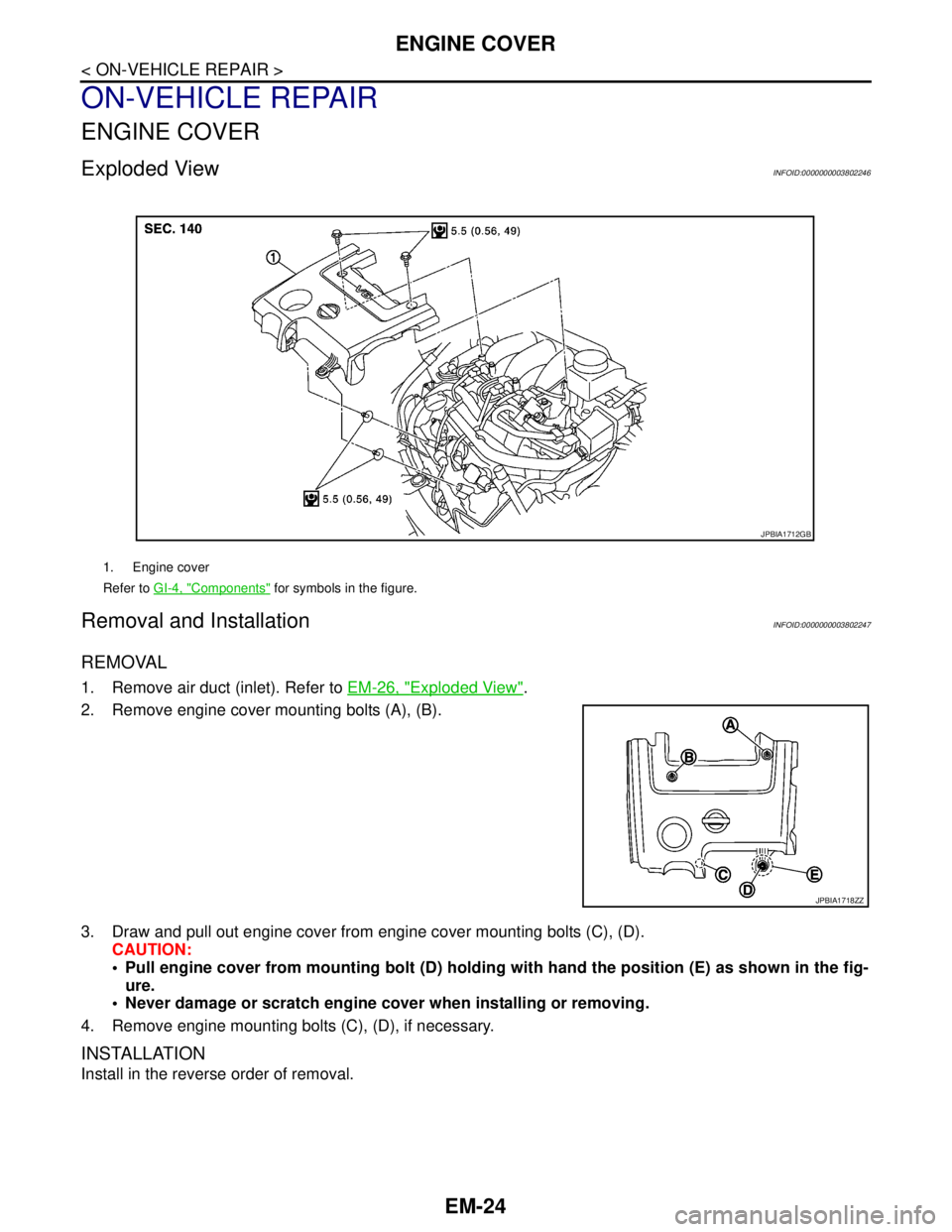

Exploded ViewINFOID:0000000003802246

Removal and InstallationINFOID:0000000003802247

REMOVAL

1. Remove air duct (inlet). Refer to EM-26, "Exploded View".

2. Remove engine cover mounting bolts (A), (B).

3. Draw and pull out engine cover from engine cover mounting bolts (C), (D).

CAUTION:

Pull engine cover from mounting bolt (D) holding with hand the position (E) as shown in the fig-

ure.

Never damage or scratch engine cover when installing or removing.

4. Remove engine mounting bolts (C), (D), if necessary.

INSTALLATION

Install in the reverse order of removal.

1. Engine cover

Refer to GI-4, "

Components" for symbols in the figure.

JPBIA1712GB

JPBIA1718ZZ

Page 1900 of 5121

DRIVE BELT AUTO TENSIONER AND IDLER PULLEY

EM-25

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

DRIVE BELT AUTO TENSIONER AND IDLER PULLEY

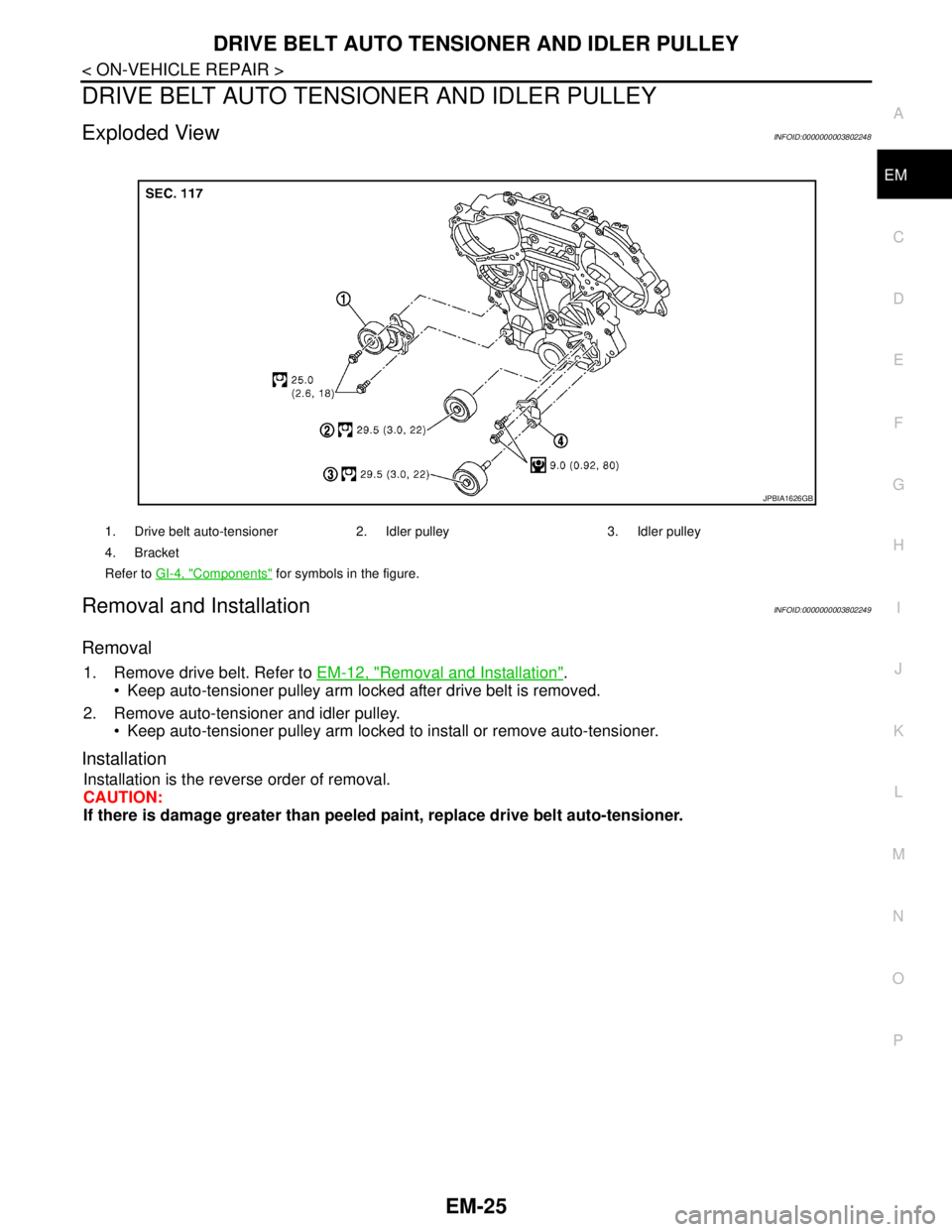

Exploded ViewINFOID:0000000003802248

Removal and InstallationINFOID:0000000003802249

Removal

1. Remove drive belt. Refer to EM-12, "Removal and Installation".

Keep auto-tensioner pulley arm locked after drive belt is removed.

2. Remove auto-tensioner and idler pulley.

Keep auto-tensioner pulley arm locked to install or remove auto-tensioner.

Installation

Installation is the reverse order of removal.

CAUTION:

If there is damage greater than peeled paint, replace drive belt auto-tensioner.

1. Drive belt auto-tensioner 2. Idler pulley 3. Idler pulley

4. Bracket

Refer to GI-4, "

Components" for symbols in the figure.

JPBIA1626GB