NISSAN TEANA 2008 Service Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 1971 of 5121

EM-96

< DISASSEMBLY AND ASSEMBLY >

CYLINDER HEAD

CYLINDER HEAD

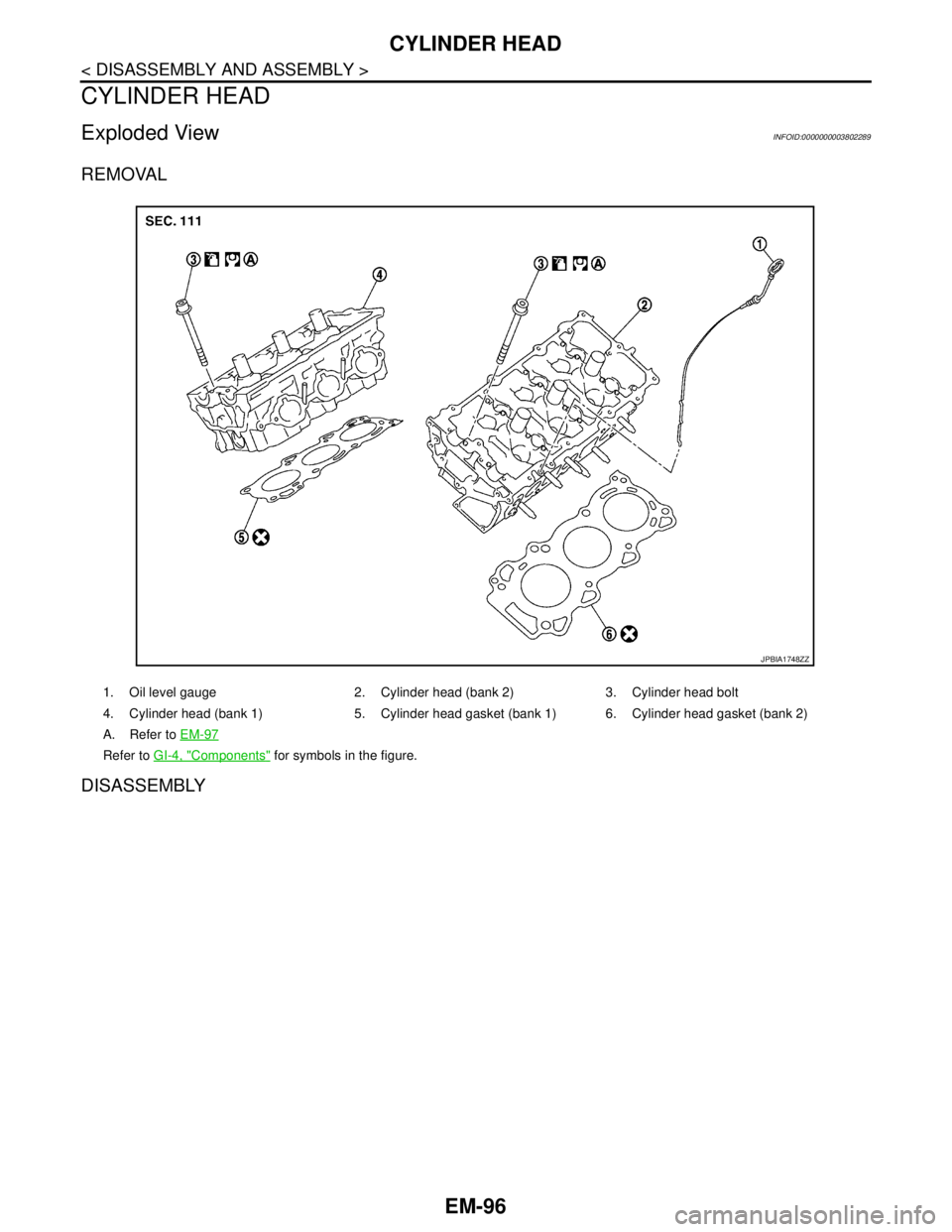

Exploded ViewINFOID:0000000003802289

REMOVAL

DISASSEMBLY

1. Oil level gauge 2. Cylinder head (bank 2) 3. Cylinder head bolt

4. Cylinder head (bank 1) 5. Cylinder head gasket (bank 1) 6. Cylinder head gasket (bank 2)

A. Refer to EM-97

Refer to GI-4, "Components" for symbols in the figure.

JPBIA1748ZZ

Page 1972 of 5121

CYLINDER HEAD

EM-97

< DISASSEMBLY AND ASSEMBLY >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Removal and InstallationINFOID:0000000003802290

REMOVAL

1. Remove the following parts:

Oil level gauge

Intake manifold collector: Refer to EM-28, "

Exploded View".

Rocker cover: Refer to EM-49, "

Exploded View".

Fuel tube and fuel injector assembly: Refer to EM-44, "

Exploded View".

Intake manifold: Refer to EM-32, "

Exploded View".

Exhaust manifold: Refer to EM-34, "

Exploded View".

Water inlet and thermostat assembly: Refer to CO-23, "

Exploded View".

Water outlet, water connector, water bypass pipe and heater pipe: Refer to CO-25, "

Exploded View".

Timing chain and rear timing chain case: Refer to EM-52, "

Exploded View" and EM-79, "Exploded

View".

Camshaft: Refer to EM-84, "

Exploded View".

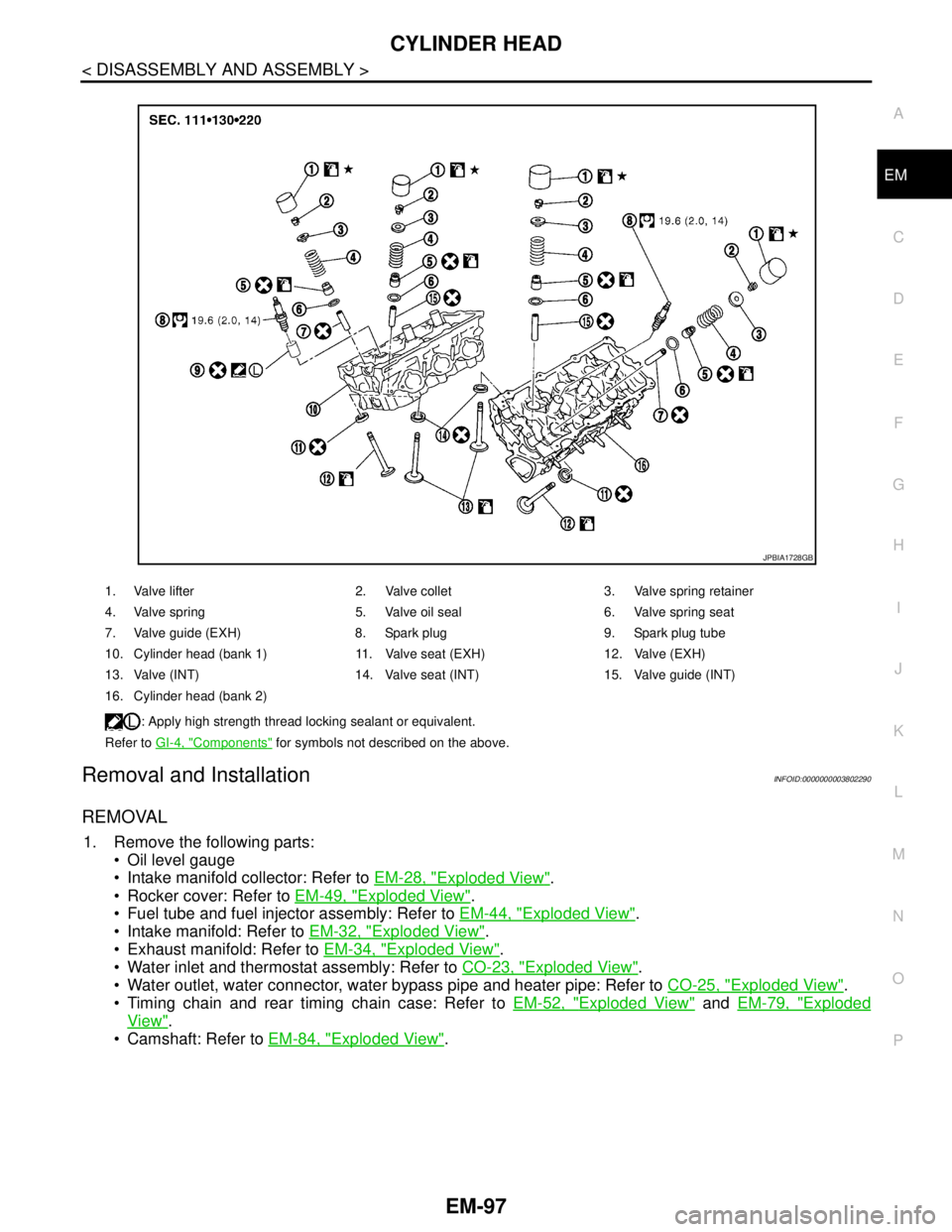

1. Valve lifter 2. Valve collet 3. Valve spring retainer

4. Valve spring 5. Valve oil seal 6. Valve spring seat

7. Valve guide (EXH) 8. Spark plug 9. Spark plug tube

10. Cylinder head (bank 1) 11. Valve seat (EXH) 12. Valve (EXH)

13. Valve (INT) 14. Valve seat (INT) 15. Valve guide (INT)

16. Cylinder head (bank 2)

: Apply high strength thread locking sealant or equivalent.

Refer to GI-4, "

Components" for symbols not described on the above.

JPBIA1728GB

Page 1973 of 5121

EM-98

< DISASSEMBLY AND ASSEMBLY >

CYLINDER HEAD

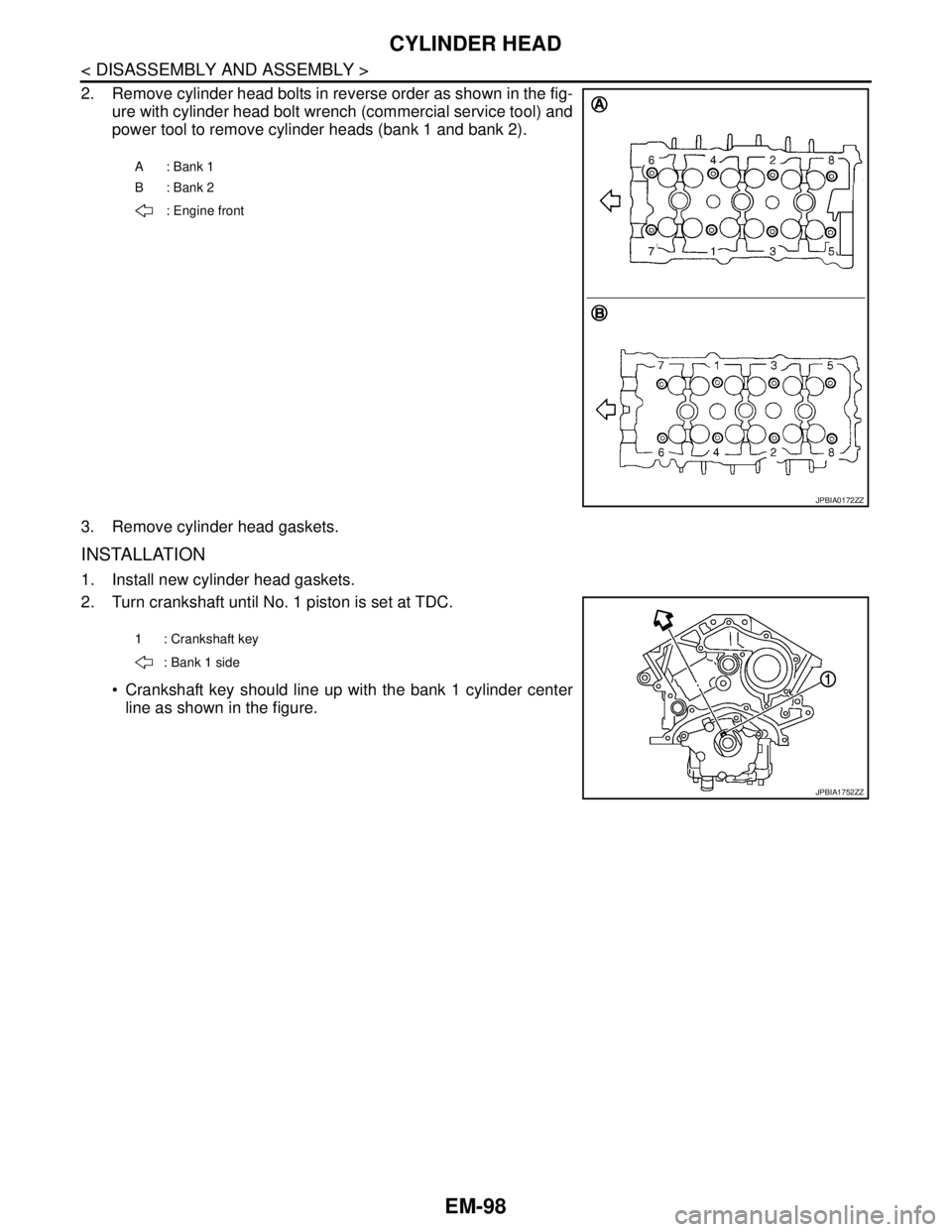

2. Remove cylinder head bolts in reverse order as shown in the fig-

ure with cylinder head bolt wrench (commercial service tool) and

power tool to remove cylinder heads (bank 1 and bank 2).

3. Remove cylinder head gaskets.

INSTALLATION

1. Install new cylinder head gaskets.

2. Turn crankshaft until No. 1 piston is set at TDC.

Crankshaft key should line up with the bank 1 cylinder center

line as shown in the figure.

A: Bank 1

B: Bank 2

: Engine front

JPBIA0172ZZ

1 : Crankshaft key

: Bank 1 side

JPBIA1752ZZ

Page 1974 of 5121

CYLINDER HEAD

EM-99

< DISASSEMBLY AND ASSEMBLY >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

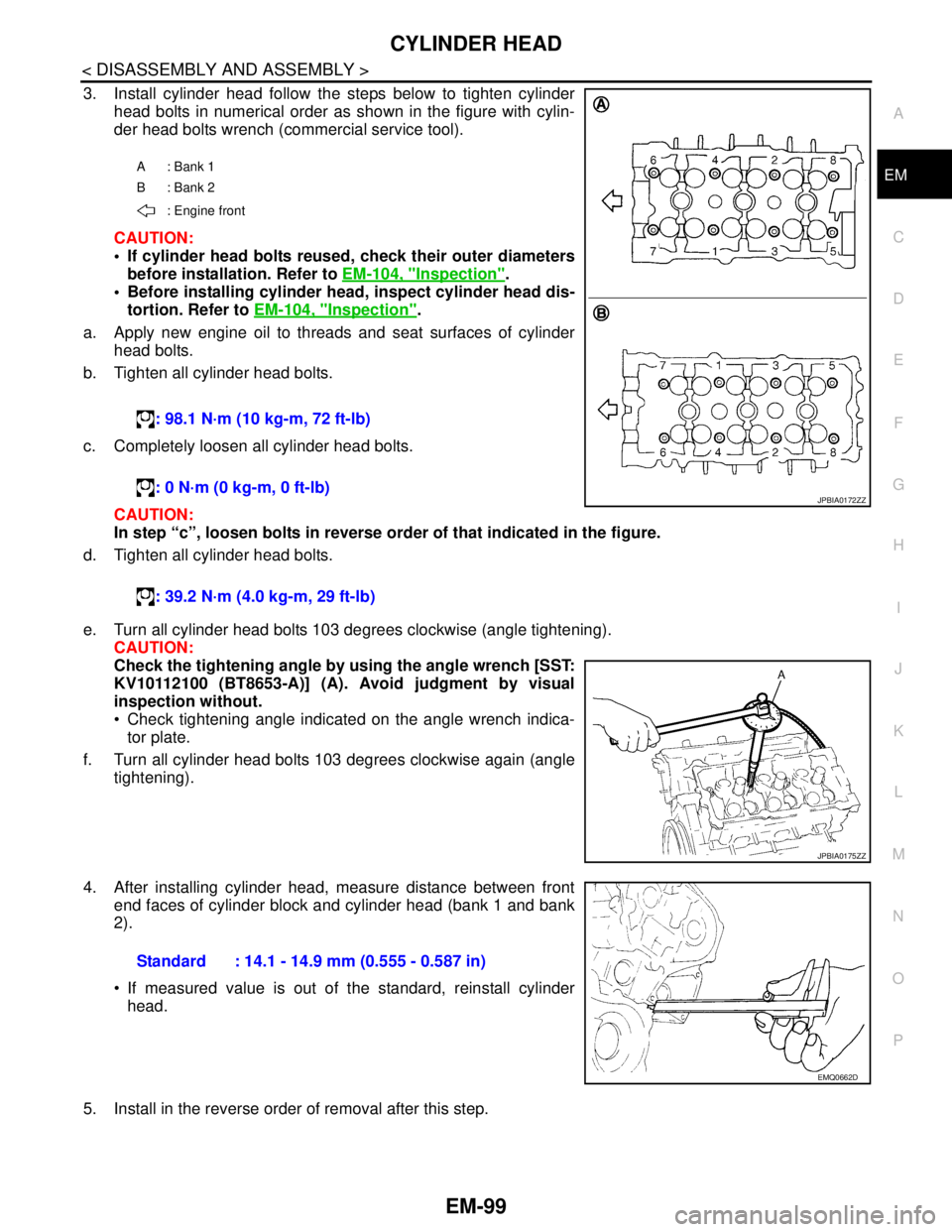

3. Install cylinder head follow the steps below to tighten cylinder

head bolts in numerical order as shown in the figure with cylin-

der head bolts wrench (commercial service tool).

CAUTION:

If cylinder head bolts reused, check their outer diameters

before installation. Refer to EM-104, "

Inspection".

Before installing cylinder head, inspect cylinder head dis-

tortion. Refer to EM-104, "

Inspection".

a. Apply new engine oil to threads and seat surfaces of cylinder

head bolts.

b. Tighten all cylinder head bolts.

c. Completely loosen all cylinder head bolts.

CAUTION:

In step “c”, loosen bolts in reverse order of that indicated in the figure.

d. Tighten all cylinder head bolts.

e. Turn all cylinder head bolts 103 degrees clockwise (angle tightening).

CAUTION:

Check the tightening angle by using the angle wrench [SST:

KV10112100 (BT8653-A)] (A). Avoid judgment by visual

inspection without.

Check tightening angle indicated on the angle wrench indica-

tor plate.

f. Turn all cylinder head bolts 103 degrees clockwise again (angle

tightening).

4. After installing cylinder head, measure distance between front

end faces of cylinder block and cylinder head (bank 1 and bank

2).

If measured value is out of the standard, reinstall cylinder

head.

5. Install in the reverse order of removal after this step.

A: Bank 1

B: Bank 2

: Engine front

: 98.1 N·m (10 kg-m, 72 ft-lb)

: 0 N·m (0 kg-m, 0 ft-lb)

: 39.2 N·m (4.0 kg-m, 29 ft-lb)

JPBIA0172ZZ

JPBIA0175ZZ

Standard : 14.1 - 14.9 mm (0.555 - 0.587 in)

EMQ0662D

Page 1975 of 5121

EM-100

< DISASSEMBLY AND ASSEMBLY >

CYLINDER HEAD

Disassembly and Assembly

INFOID:0000000003802291

DISASSEMBLY

1. Remove spark plug with spark plug wrench (commercial service tool).

2. Remove valve lifter.

Identify installation positions, and store them without mixing them up.

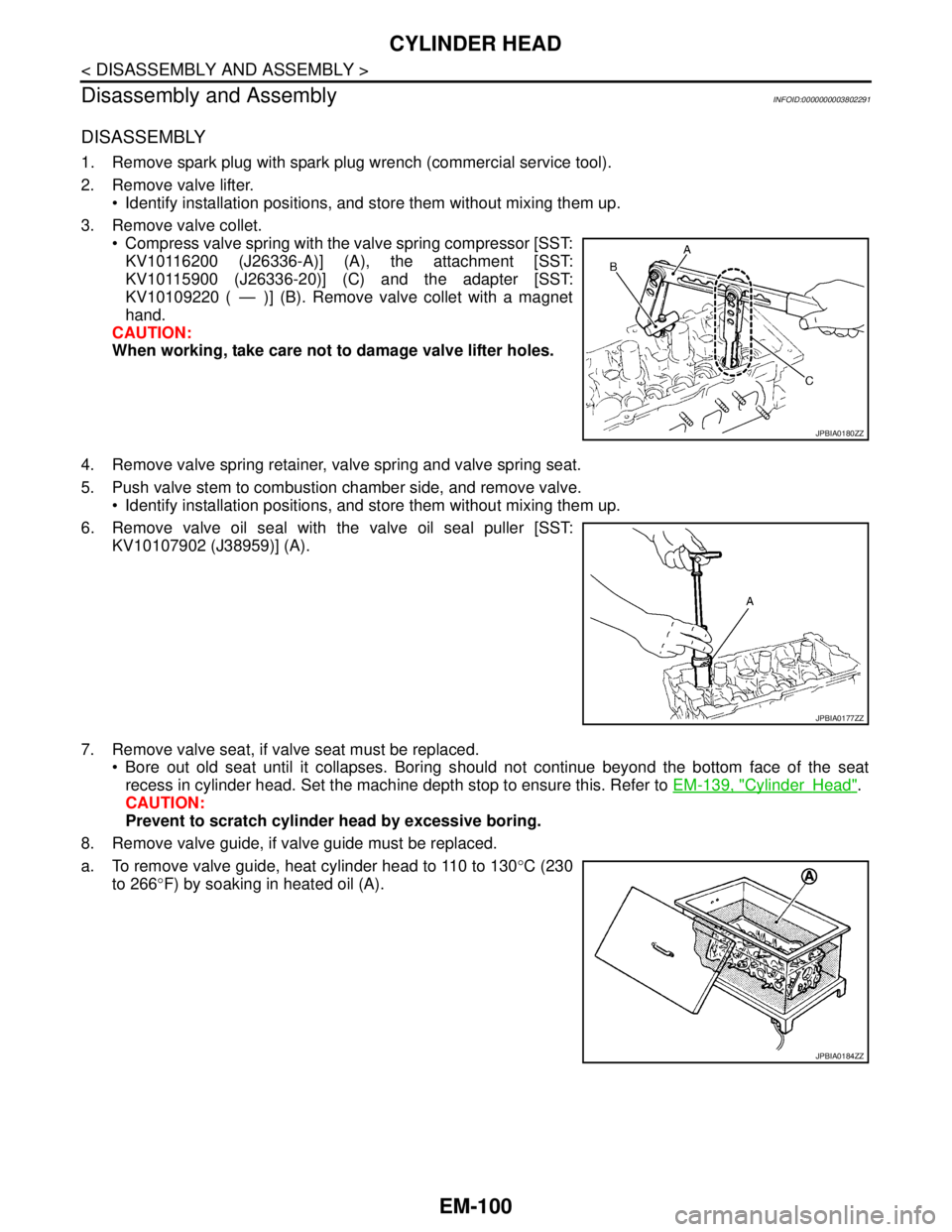

3. Remove valve collet.

Compress valve spring with the valve spring compressor [SST:

KV10116200 (J26336-A)] (A), the attachment [SST:

KV10115900 (J26336-20)] (C) and the adapter [SST:

KV10109220 ( — )] (B). Remove valve collet with a magnet

hand.

CAUTION:

When working, take care not to damage valve lifter holes.

4. Remove valve spring retainer, valve spring and valve spring seat.

5. Push valve stem to combustion chamber side, and remove valve.

Identify installation positions, and store them without mixing them up.

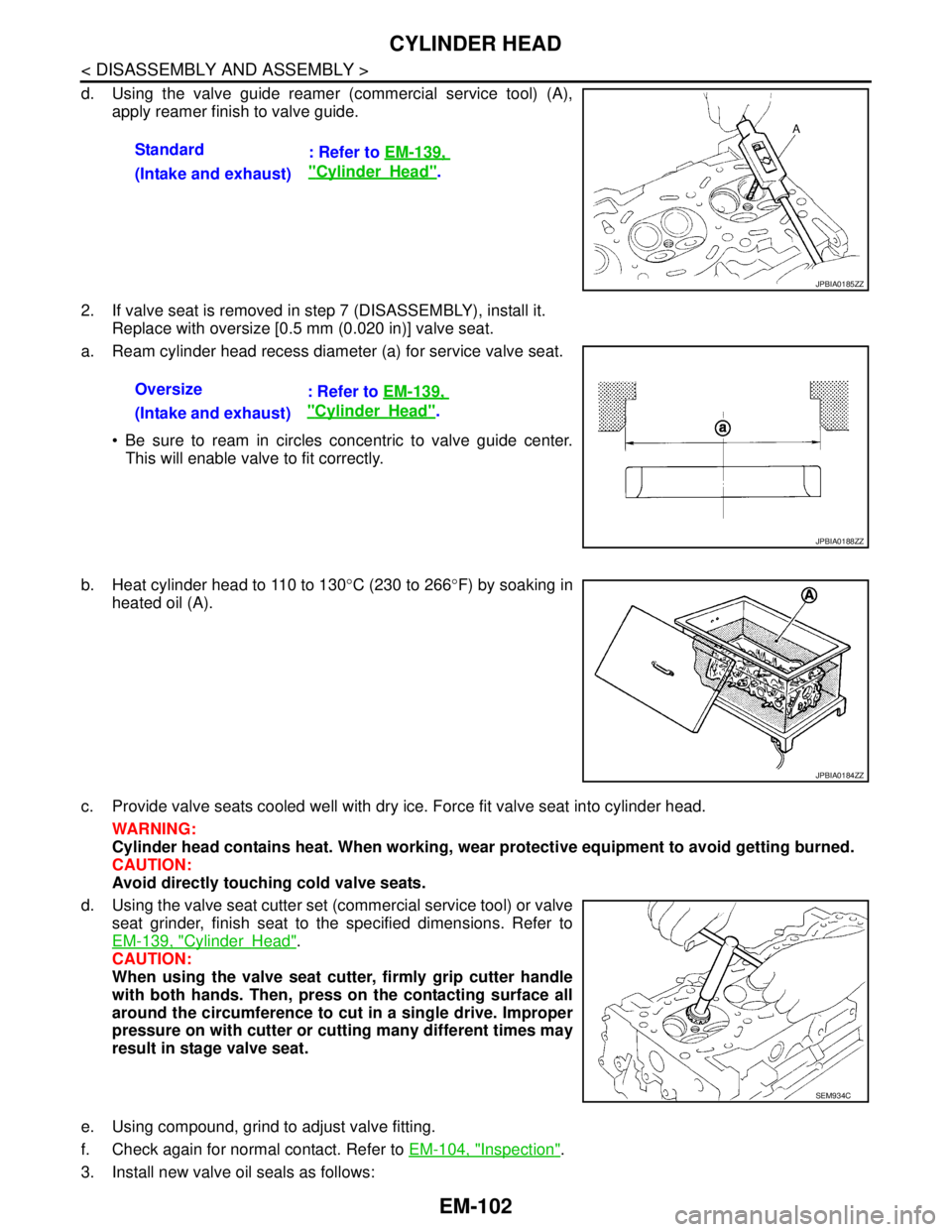

6. Remove valve oil seal with the valve oil seal puller [SST:

KV10107902 (J38959)] (A).

7. Remove valve seat, if valve seat must be replaced.

Bore out old seat until it collapses. Boring should not continue beyond the bottom face of the seat

recess in cylinder head. Set the machine depth stop to ensure this. Refer to EM-139, "

CylinderHead".

CAUTION:

Prevent to scratch cylinder head by excessive boring.

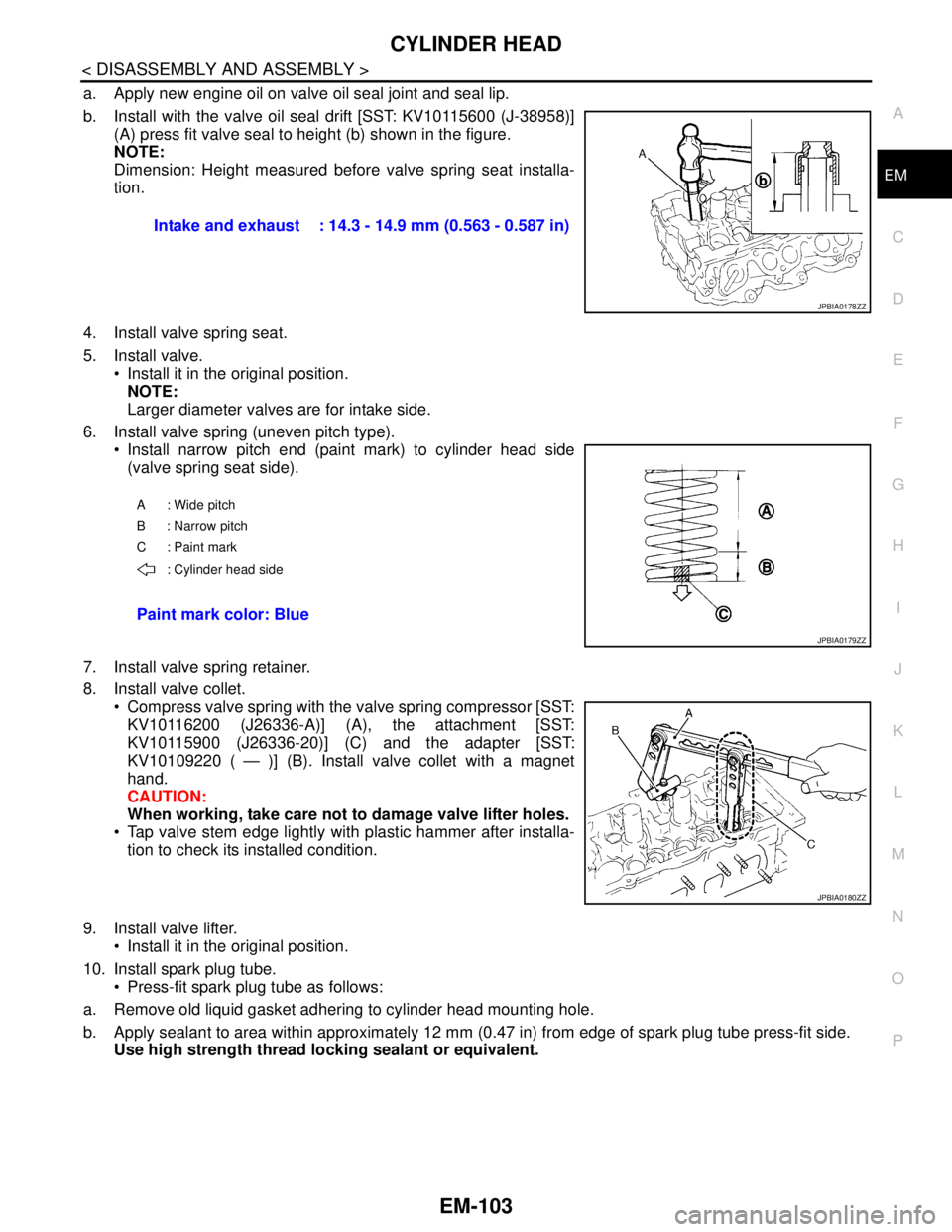

8. Remove valve guide, if valve guide must be replaced.

a. To remove valve guide, heat cylinder head to 110 to 130°C (230

to 266°F) by soaking in heated oil (A).

JPBIA0180ZZ

JPBIA0177ZZ

JPBIA0184ZZ

Page 1976 of 5121

![NISSAN TEANA 2008 Service Manual CYLINDER HEAD

EM-101

< DISASSEMBLY AND ASSEMBLY >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

b. Drive out valve guide with a press [under a 20 kN (2 ton, 2.0 lmp

ton) pressure] or a hammer and the valve guide dr NISSAN TEANA 2008 Service Manual CYLINDER HEAD

EM-101

< DISASSEMBLY AND ASSEMBLY >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

b. Drive out valve guide with a press [under a 20 kN (2 ton, 2.0 lmp

ton) pressure] or a hammer and the valve guide dr](/img/5/57391/w960_57391-1975.png)

CYLINDER HEAD

EM-101

< DISASSEMBLY AND ASSEMBLY >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

b. Drive out valve guide with a press [under a 20 kN (2 ton, 2.0 lmp

ton) pressure] or a hammer and the valve guide drift (commer-

cial service tool).

WARNING:

Cylinder head contains heat. When working, wear protec-

tive equipment to avoid getting burned.

9. Remove spark plug tube, as necessary.

Using a pliers, pull spark plug tube out of cylinder head.

CAUTION:

Take care not to damage cylinder head.

Once removed, spark plug tube will be deformed and cannot be reused. Never remove it unless

absolutely necessary.

ASSEMBLY

1. If valve guide is removed in step 8 (DISASSEMBLY), install it.

Replace with oversized [0.2 mm (0.008 in)] valve guide.

a. Using the valve guide reamer (commercial service tool) (A),

ream cylinder head valve guide hole.

b. Heat cylinder head to 110 to 130°C (230 to 266°F) by soaking in

heated oil (A).

c. Using the valve guide drift (commercial service tool), press valve

guide from camshaft side to the dimensions as in the figure.

WARNING:

Cylinder head contains heat. When working, wear protec-

tive equipment to avoid getting burned.

SEM931C

Valve guide hole diameter (for service parts):

Intake and exhaust

: Refer to EM-139, "

CylinderHead".

JPBIA0185ZZ

JPBIA0184ZZ

Projection (A)

Intake and exhaust

: Refer to EM-139, "

CylinderHead".

JPBIA0186ZZ

Page 1977 of 5121

EM-102

< DISASSEMBLY AND ASSEMBLY >

CYLINDER HEAD

d. Using the valve guide reamer (commercial service tool) (A),

apply reamer finish to valve guide.

2. If valve seat is removed in step 7 (DISASSEMBLY), install it.

Replace with oversize [0.5 mm (0.020 in)] valve seat.

a. Ream cylinder head recess diameter (a) for service valve seat.

Be sure to ream in circles concentric to valve guide center.

This will enable valve to fit correctly.

b. Heat cylinder head to 110 to 130°C (230 to 266°F) by soaking in

heated oil (A).

c. Provide valve seats cooled well with dry ice. Force fit valve seat into cylinder head.

WARNING:

Cylinder head contains heat. When working, wear protective equipment to avoid getting burned.

CAUTION:

Avoid directly touching cold valve seats.

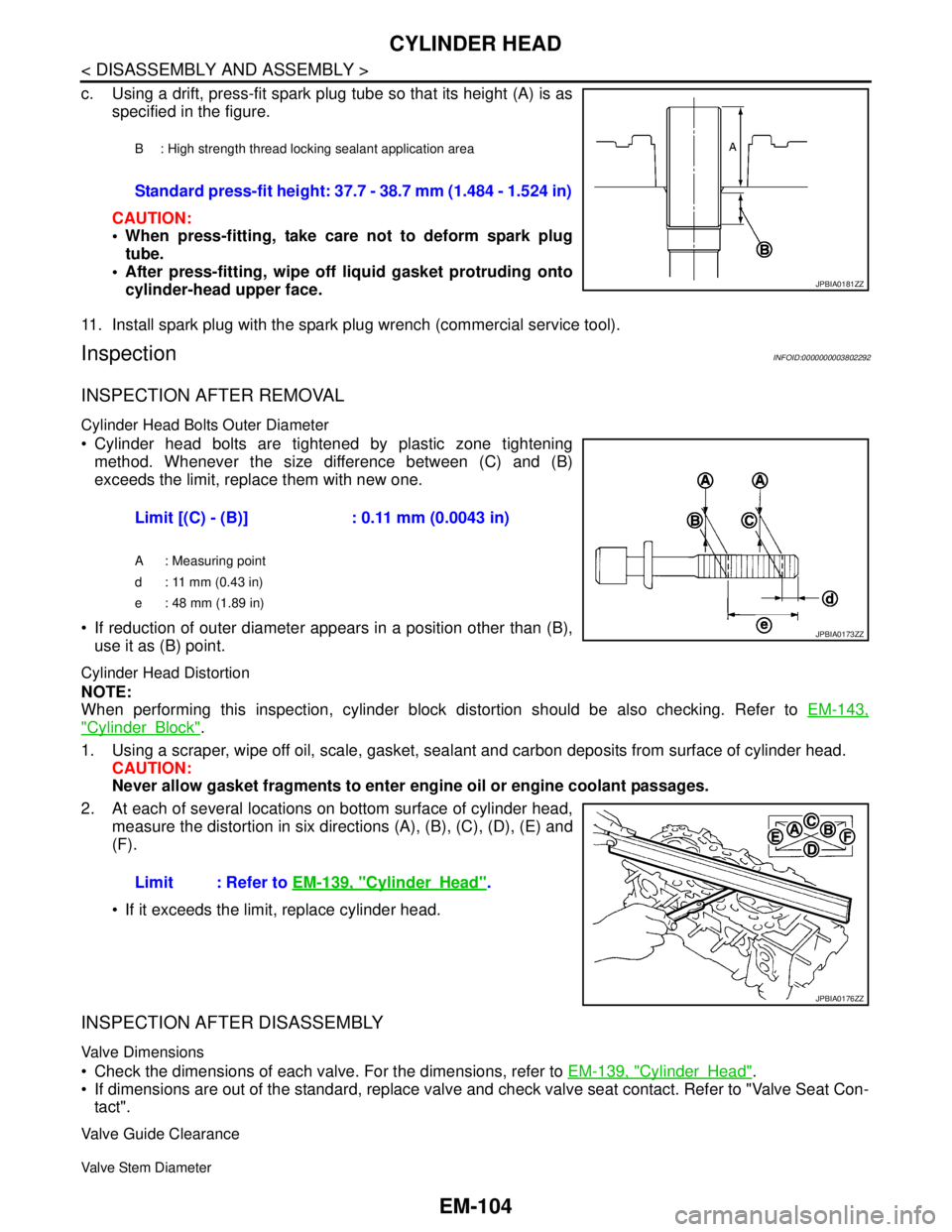

d. Using the valve seat cutter set (commercial service tool) or valve

seat grinder, finish seat to the specified dimensions. Refer to

EM-139, "

CylinderHead".

CAUTION:

When using the valve seat cutter, firmly grip cutter handle

with both hands. Then, press on the contacting surface all

around the circumference to cut in a single drive. Improper

pressure on with cutter or cutting many different times may

result in stage valve seat.

e. Using compound, grind to adjust valve fitting.

f. Check again for normal contact. Refer to EM-104, "

Inspection".

3. Install new valve oil seals as follows:Standard

: Refer to EM-139,

"CylinderHead".

(Intake and exhaust)

JPBIA0185ZZ

Oversize

: Refer to EM-139,

"CylinderHead".

(Intake and exhaust)

JPBIA0188ZZ

JPBIA0184ZZ

SEM934C

Page 1978 of 5121

CYLINDER HEAD

EM-103

< DISASSEMBLY AND ASSEMBLY >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

a. Apply new engine oil on valve oil seal joint and seal lip.

b. Install with the valve oil seal drift [SST: KV10115600 (J-38958)]

(A) press fit valve seal to height (b) shown in the figure.

NOTE:

Dimension: Height measured before valve spring seat installa-

tion.

4. Install valve spring seat.

5. Install valve.

Install it in the original position.

NOTE:

Larger diameter valves are for intake side.

6. Install valve spring (uneven pitch type).

Install narrow pitch end (paint mark) to cylinder head side

(valve spring seat side).

7. Install valve spring retainer.

8. Install valve collet.

Compress valve spring with the valve spring compressor [SST:

KV10116200 (J26336-A)] (A), the attachment [SST:

KV10115900 (J26336-20)] (C) and the adapter [SST:

KV10109220 ( — )] (B). Install valve collet with a magnet

hand.

CAUTION:

When working, take care not to damage valve lifter holes.

Tap valve stem edge lightly with plastic hammer after installa-

tion to check its installed condition.

9. Install valve lifter.

Install it in the original position.

10. Install spark plug tube.

Press-fit spark plug tube as follows:

a. Remove old liquid gasket adhering to cylinder head mounting hole.

b. Apply sealant to area within approximately 12 mm (0.47 in) from edge of spark plug tube press-fit side.

Use high strength thread locking sealant or equivalent. Intake and exhaust : 14.3 - 14.9 mm (0.563 - 0.587 in)

JPBIA0178ZZ

A : Wide pitch

B : Narrow pitch

C : Paint mark

: Cylinder head side

Paint mark color: Blue

JPBIA0179ZZ

JPBIA0180ZZ

Page 1979 of 5121

EM-104

< DISASSEMBLY AND ASSEMBLY >

CYLINDER HEAD

c. Using a drift, press-fit spark plug tube so that its height (A) is as

specified in the figure.

CAUTION:

When press-fitting, take care not to deform spark plug

tube.

After press-fitting, wipe off liquid gasket protruding onto

cylinder-head upper face.

11. Install spark plug with the spark plug wrench (commercial service tool).

InspectionINFOID:0000000003802292

INSPECTION AFTER REMOVAL

Cylinder Head Bolts Outer Diameter

Cylinder head bolts are tightened by plastic zone tightening

method. Whenever the size difference between (C) and (B)

exceeds the limit, replace them with new one.

If reduction of outer diameter appears in a position other than (B),

use it as (B) point.

Cylinder Head Distortion

NOTE:

When performing this inspection, cylinder block distortion should be also checking. Refer to EM-143,

"CylinderBlock".

1. Using a scraper, wipe off oil, scale, gasket, sealant and carbon deposits from surface of cylinder head.

CAUTION:

Never allow gasket fragments to enter engine oil or engine coolant passages.

2. At each of several locations on bottom surface of cylinder head,

measure the distortion in six directions (A), (B), (C), (D), (E) and

(F).

If it exceeds the limit, replace cylinder head.

INSPECTION AFTER DISASSEMBLY

Valve Dimensions

Check the dimensions of each valve. For the dimensions, refer to EM-139, "CylinderHead".

If dimensions are out of the standard, replace valve and check valve seat contact. Refer to "Valve Seat Con-

tact".

Valve Guide Clearance

Valve Stem Diameter

B : High strength thread locking sealant application area

Standard press-fit height: 37.7 - 38.7 mm (1.484 - 1.524 in)

JPBIA0181ZZ

Limit [(C) - (B)] : 0.11 mm (0.0043 in)

A : Measuring point

d : 11 mm (0.43 in)

e : 48 mm (1.89 in)

JPBIA0173ZZ

Limit : Refer to EM-139, "CylinderHead".

JPBIA0176ZZ

Page 1980 of 5121

CYLINDER HEAD

EM-105

< DISASSEMBLY AND ASSEMBLY >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

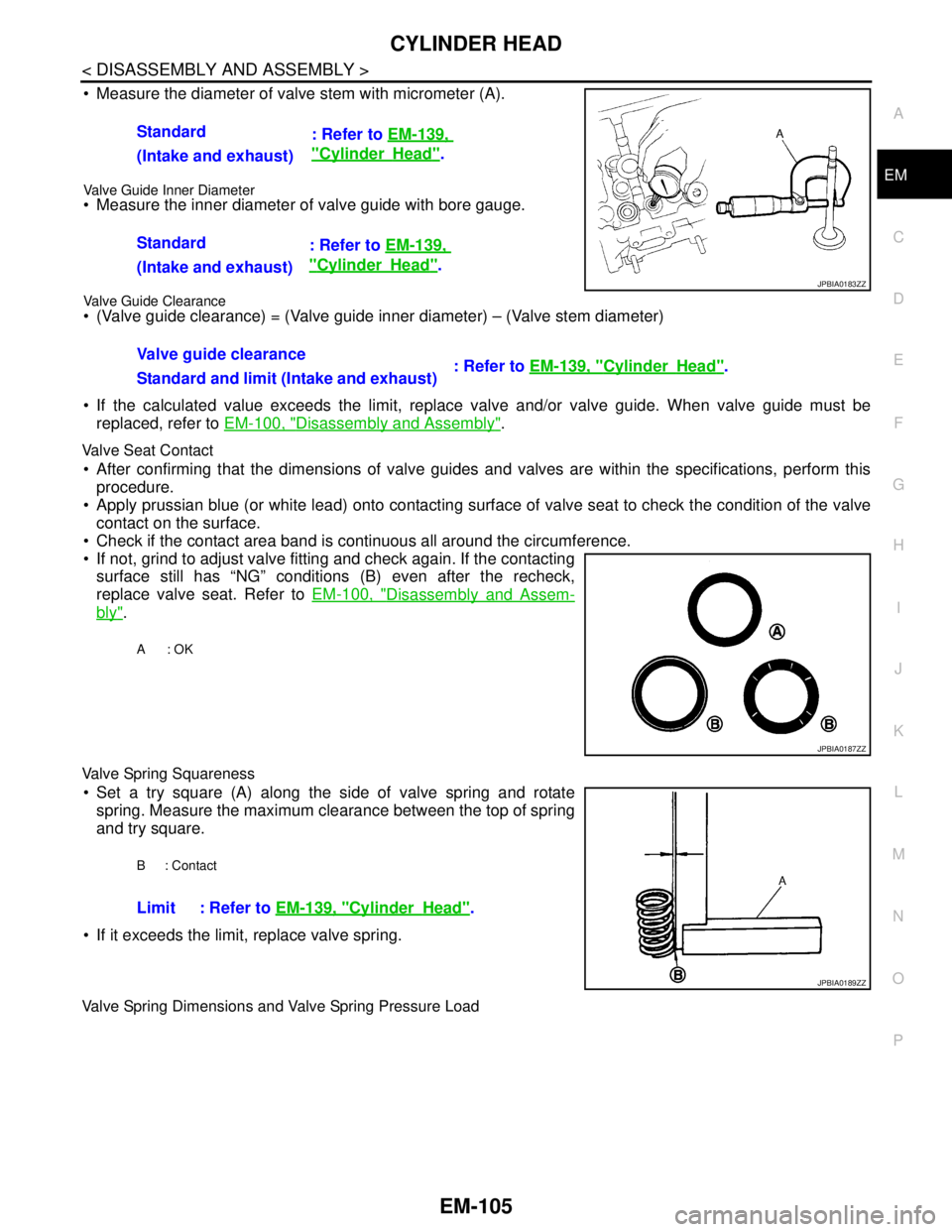

Measure the diameter of valve stem with micrometer (A).

Valve Guide Inner Diameter Measure the inner diameter of valve guide with bore gauge.

Valve Guide Clearance (Valve guide clearance) = (Valve guide inner diameter) – (Valve stem diameter)

If the calculated value exceeds the limit, replace valve and/or valve guide. When valve guide must be

replaced, refer to EM-100, "

Disassembly and Assembly".

Valve Seat Contact

After confirming that the dimensions of valve guides and valves are within the specifications, perform this

procedure.

Apply prussian blue (or white lead) onto contacting surface of valve seat to check the condition of the valve

contact on the surface.

Check if the contact area band is continuous all around the circumference.

If not, grind to adjust valve fitting and check again. If the contacting

surface still has “NG” conditions (B) even after the recheck,

replace valve seat. Refer to EM-100, "

Disassembly and Assem-

bly".

Valve Spring Squareness

Set a try square (A) along the side of valve spring and rotate

spring. Measure the maximum clearance between the top of spring

and try square.

If it exceeds the limit, replace valve spring.

Valve Spring Dimensions and Valve Spring Pressure Load

Standard

: Refer to EM-139,

"CylinderHead".

(Intake and exhaust)

Standard

: Refer to EM-139,

"CylinderHead".

(Intake and exhaust)

Valve guide clearance

: Refer to EM-139, "

CylinderHead".

Standard and limit (Intake and exhaust)

JPBIA0183ZZ

A: OK

JPBIA0187ZZ

B: Contact

Limit : Refer to EM-139, "CylinderHead".

JPBIA0189ZZ